If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

A Revolution in Bio-Positive Agriculture

In today’s rapidly evolving landscape, farmers and agricultural professionals are always looking for innovative solutions that build better soil resilience and improve crop health whilst striving to lower their fertiliser inputs and their environmental impact. ActiV8-Bio, a unique biological product designed by SFS, is one solution that sparks curiosity and gains significant traction with a revolutionary approach to revitalising soil and boosting crop growth. But… before we get on to that, let’s delve deeper into what drives some of these decisions and promotes poorer growing conditions.

A ruler’s strength typically comes from the power of its subjects, so, if yield is king, yield is subject to this and subject to that.

Take a plant, for starters; as a seed, it gets thrust down into the soil’s hostile environment, fending for itself and scavenging for essential elements, all with one aim, to reach upwards and get its solar panels out of the ground quickly so that it can begin to make its food and support itself via photosynthesis. Sounds easy, right? After all, it’s a natural process; plants will do it anyway.

When you’re a young seed, the soil is not a nice place to be; everything down there wants to support itself first before lending its new neighbour a helping hand. Our new inhabitant has limited resources, so to bolster its dwindling reserves, it is keen to make new friends (quickly). Still, with all good relationships, things need to be mutually beneficial, which can be a bit of a sticking point for this fledgling seed; it ends up giving away some of its supplies to barter and attract the correct type of supportive partner, and unfortunately, the simple act of spending to survive, negatively impacts our seeds performance, but what choice does it have?

How about if there wasn’t such a panic to go upwards, and instead, the young seedling had the available resources to leisurely extend its rooting further, optimising its nutrient cycling capacity first, rather than desperately scrabbling for the surface? And what if the soil environment already contained billions of biological helpers supporting the seed and stimulating better soil health? Imagine building hardier growth with a plant that’s now less susceptible to stresses, insect and pathogen attacks.

Innovative biological starter products are more than fertilisers. They provide both soil and plant nutrition while reinforcing the soil microbial workforce. This departure from conventional fertilisers offers a more holistic and sustainable approach to agricultural production, inspiring a sense of responsibility and environmental commitment.

A blend of carefully selected ingredients that work synergistically to improve soil health and promote plant growth must be at their core. These elements should include humic and fulvic acids – crucial for enhancing soil structure and increasing aeration and water retention. These acids also play a vital role in chelating essential minerals, making them more accessible to plants.

In addition to humic and fulvic acids, ActiV8-Bio is enriched with a diverse range of beneficial micro-organisms, including

Phosphate fixers, Nitrogen fixers, plant protectors, and soil pathogen combatants. These micro-organisms work tirelessly to improve soil quality, enhance nutrient uptake, and safeguard plants from diseases and pests.Trace elements may only be needed in tiny amounts, but this doesn’t make them any less critical to crop productivity, which can suffer when many of these elements are deficient in soils. For example, Zinc, Boron, and Manganese are all vital for early growth and development, and by providing a readily available source of these elements, growers can effectively address nutrient deficiencies and optimise plant health.

It all sounds good, but how does it work? Well, by establishing a symbiotic relationship between the soil and the plants, micro-organisms can do what they do best, and that means that both parties are kept happy: The plant gets an available version of the element it needs, like calling in a food delivery driver – Our driver (microbe) gets paid in sugars from the plant exudates.

Still, it goes further…those microbes will defend their territory and meal ticket, leading to a healthier root zone with fewer pathogenic organisms where a plant can prosper better. An excellent biological product will contain billions of these helpful microbes. Still, an exceptional one will go that one step further and provide the biological army with food, so that it doesn’t need to rob soil resources and can get to work immediately.

Imagine you’ve planted your seeds, and they’re starting to grow; but you’re worried about pests and diseases that could harm your crops. But what can a biological product do to protect them? One way is to introduce beneficial micro-organisms to your soil. These tiny creatures can help your plants grow stronger and healthier.

One such beneficial micro-organism is Bacillus Amyloliquefaciens. I like to call this one the guard dog: This bacterium can recycle nutrients in the soil, making them more available for your plants to use. It can also create a protective layer around plant roots, shielding them from harmful pathogens. It produces substances that can kill harmful bacteria and fungi. By doing all these things, Bacillus Amyloliquefaciens can help your plants grow bigger and stronger and improve soil quality.

The opposing argument would suggest that using N, P, K, S, and Mg fertilisers as a starter will do the same job; the plants would grow, and the soil would be fine. I am not suggesting that fertiliser is not required, but available nutrition is, and many fertilisers are inefficient – with losses expected, not only wasting money but also increasing the risk of environmental contamination.

Biological starters such as ActiV8-Bio provide accessible nutrients in a form a plant can readily use without oversupplying or forcing feed, creating a more harmonious ecosystem.

Whether you adopt it now or sometime in the not-too-distant future, biological products that offer a sustainable and effective solution for modern agriculture are the way forward. By enhancing soil health, improving crop growth, and reducing the reliance on chemical inputs, growers can improve profitability and contribute to a more bio-positive, sustainable system. If you want to know more about biological products supporting today’s plant and tomorrow’s soil, contact us at SFS.

-

Living up to the SFI and its actions

The SFI offers financial payments to those who adopt variable rate applications, but demonstrating compliance is more than a tick-box exercise, explains Rhiza product manager Ben Foster

The Sustainable Farming Incentive (SFI) has much to offer growers from payments for environmental actions, to incentives that improve sustainability, productivity and, importantly, business resilience.

With 102 actions available across a multitude of activities, the SFI has something for every farm and with a defined payment schedule, participants can plan with confidence.

A core pillar of the SFI is the module on soils and the actions to help you ‘increase the long-term health, productivity and resilience of your soil’. Who could object to that?

The complementary nature of the three soil actions – SAM1, SAM2 and SAM3 – broadly support the same objective but offer different levels of participation depending on the interest of the land manager. The actions for nutrient management – NUM1, NUM2 and NUM3 – have similar objectives but with a specific focus on ‘increasing nutrient management knowledge, supporting more efficient use of nutrients and encouraging more effective use of organic sources of nutrition’. Again, who could object?

At its core, the SFI offers payment for actions that many consider good farming practice, such as maintaining desirable landscape features or demonstrating adherence to an Integrated Pest Management (IPM) plan. There are some that the land manager can complete themselves and there are others, such as the soil and nutrient management actions, which need to be demonstrated in the form of a plan produced by a suitably qualified person, such as FACTS registered adviser. Fortunately, Agrii’s team of FACTS-qualified crop input specialists and agronomists are trained in the finer details, so are well-placed to help.

Soil acidity

Central to both the soil and nutrient management actions is the requirement to maintain the long-term health of the soil and support the wider environment such as surface water and air quality. Although not a specific action, soil acidity (pH) and its role in supporting a functioning soil is widely recognised through these modules.

After a difficult season, many soils are likely to need some remedial action. Where soils experienced excessive water logging, compaction is likely to be the most obvious damage, with those transitioning to reduced tillage systems likely to be the most affected. Waterlogging can also adversely affect soil acidity. Addressing both compaction and soil pH is a key part of any soil remediation and should feature in a soil management plan.

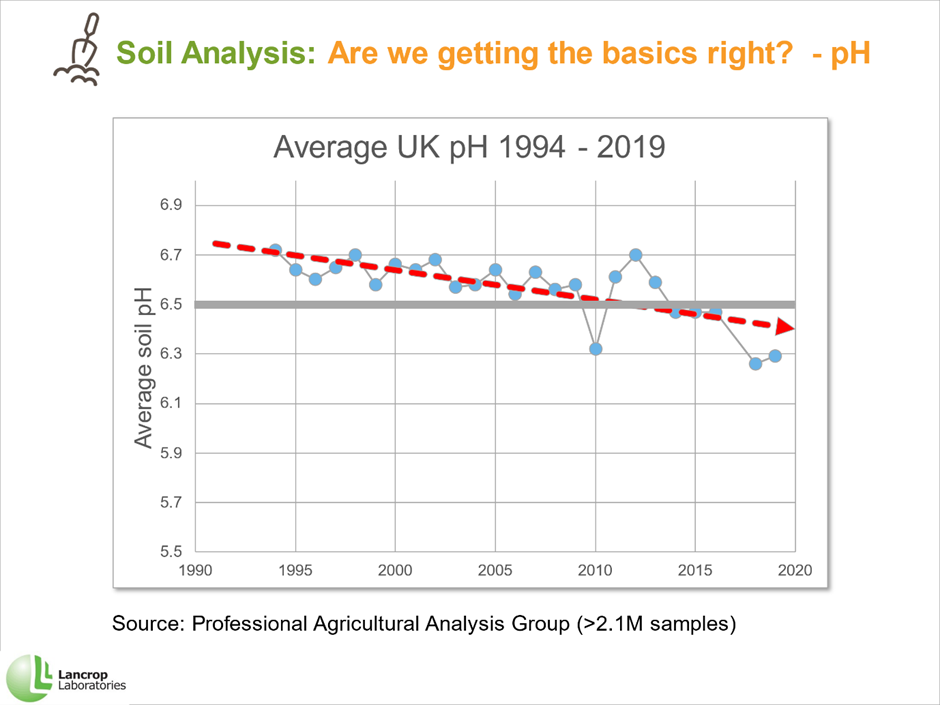

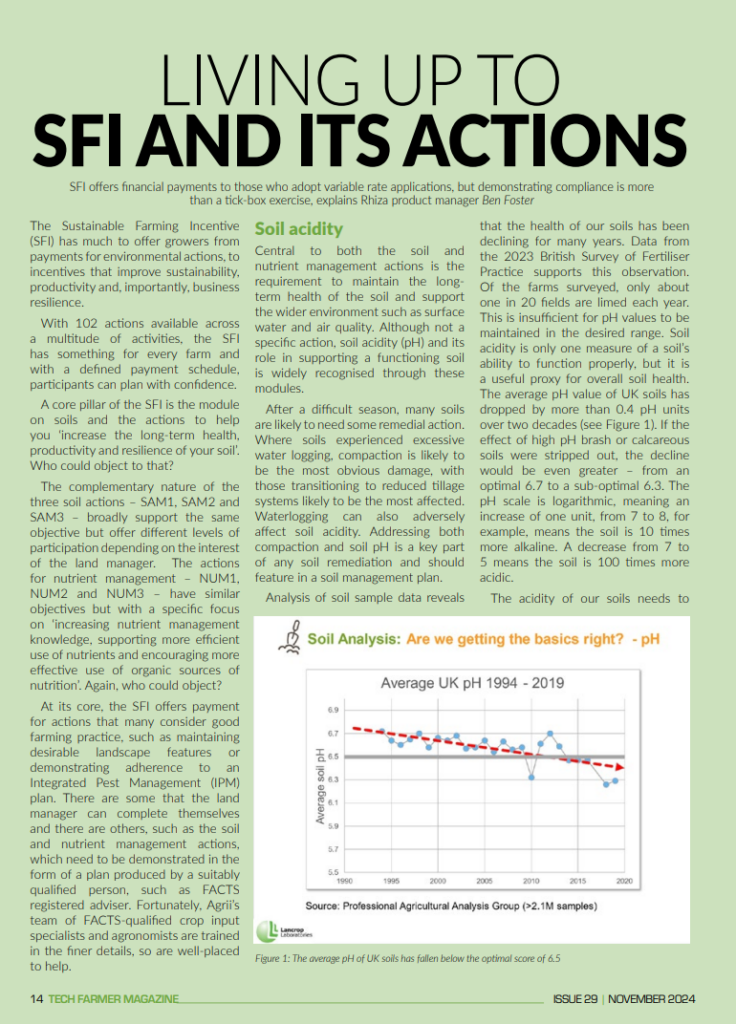

Analysis of soil sample data reveals that the health of our soils has been declining for many years. Data from the 2023 British Survey of Fertiliser Practice supports this observation. Of the farms surveyed, only about one in 20 fields are limed each year. This is insufficient for pH values to be maintained in the desired range. Soil acidity is only one measure of a soil’s ability to function properly, but it is a useful proxy for overall soil health. The average pH value of UK soils has dropped by more than 0.4 pH units over two decades (see Figure 1). If the effect of high pH brash or calcareous soils were stripped out, the decline would be even greater – from an optimal 6.7 to a sub-optimal 6.3. The pH scale is logarithmic, meaning an increase of one unit, from 7 to 8, for example, means the soil is 10 times more alkaline. A decrease from 7 to 5 means the soil is 100 times more acidic.

Figure 1: The average pH of UK soils has fallen below the optimal score of 6.5

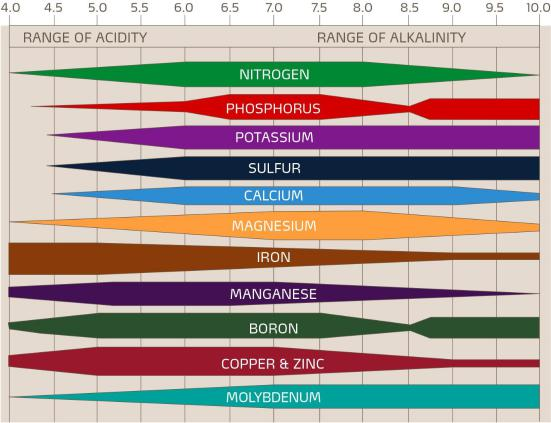

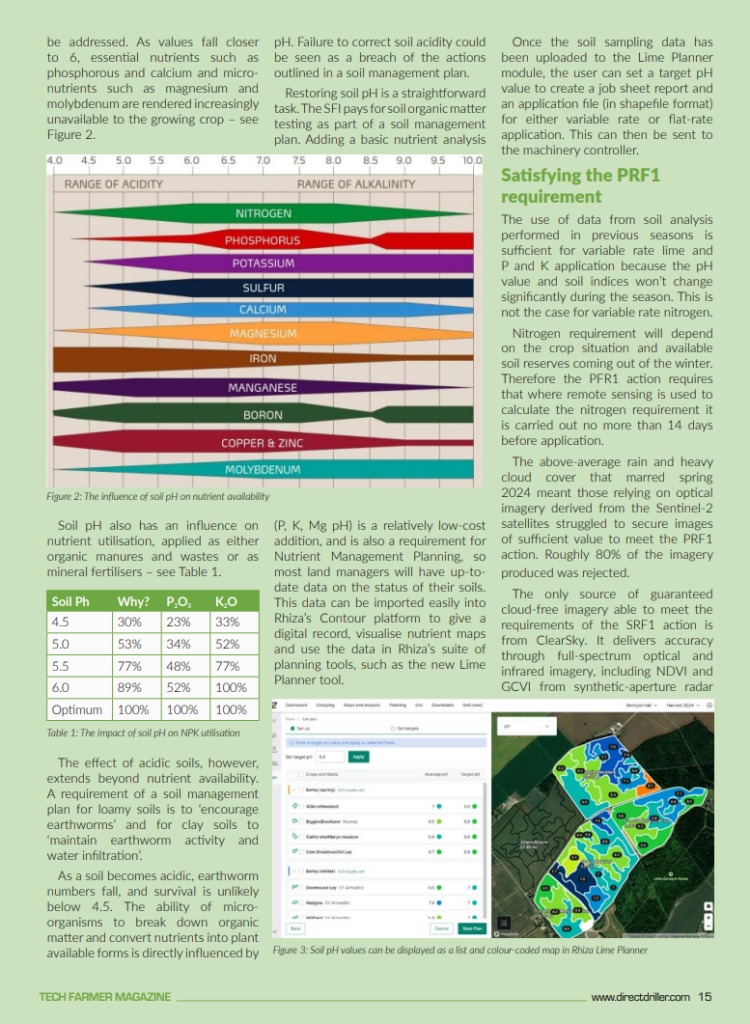

The acidity of our soils needs to be addressed. As values fall closer to 6, essential nutrients such as phosphorous and calcium and micro-nutrients such as magnesium and molybdenum are rendered increasingly unavailable to the growing crop – see Figure 2.

Figure 2: The influence of soil pH on nutrient availability

Soil pH also has an influence on nutrient utilisation, applied as either organic manures and wastes or as mineral fertilisers – see Table 1.

Table 1: The impact of soil pH on NPK utilisation

Soil pH N P2O5 K2O 4.5 30% 23% 33% 5.0 53% 34% 52% 5.5 77% 48% 77% 6.0 89% 52% 100% Optimum 100% 100% 100% The effect of acidic soils, however, extends beyond nutrient availability. A requirement of a soil management plan for loamy soils is to ‘encourage earthworms’ and for clay soils to ‘maintain earthworm activity and water infiltration’.

As a soil becomes acidic, earthworm numbers fall, and survival is unlikely below 4.5. The ability of micro-organisms to break down organic matter and convert nutrients into plant available forms is directly influenced by pH. Failure to correct soil acidity could be seen as a breach of the actions outlined in a soil management plan.

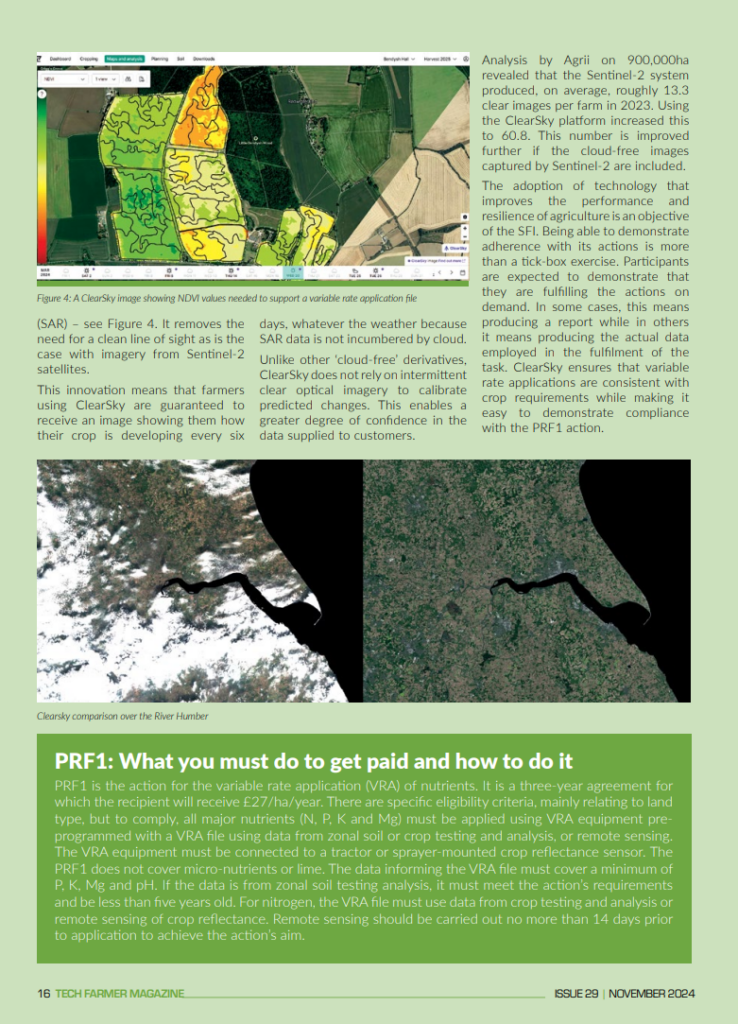

The Rhiza Lime Planner

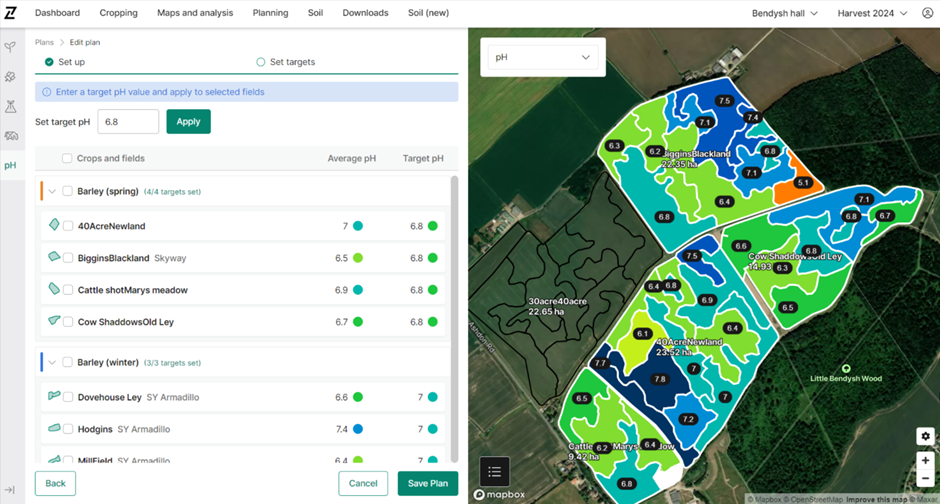

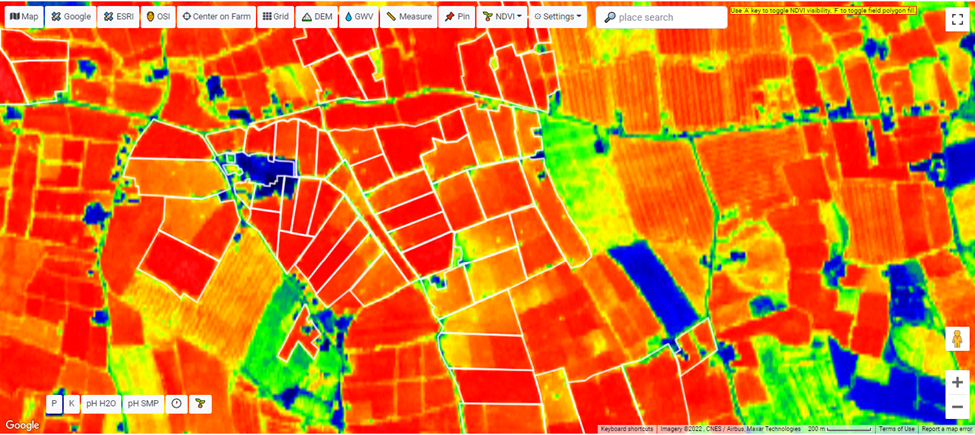

Restoring soil pH is a straightforward task. The SFI pays for soil organic matter testing as part of a soil management plan. Adding a basic nutrient analysis (P, K, Mg pH) is a relatively low-cost addition, and is also a requirement for Nutrient Management Planning, so most land managers will have up-to-date data on the status of their soils. This data can be imported easily into Rhiza’s Contour platform to give a digital record, visualise nutrient maps and use the data in Rhiza’s suite of planning tools, such as the new Lime Planner tool.

Figure 3: Soil pH values can be displayed as a list and colour-coded map in Rhiza Lime Planner

Once the soil sampling data has been uploaded to the Lime Planner module, the user can set a target pH value to create a job sheet report and an application file (in shapefile format) for either variable rate or flat-rate application. This can then be sent to the machinery controller.

Satisfying the PRF1 requirement

The use of data from soil analysis performed in previous seasons is sufficient for variable rate lime and P and K application because the pH value and soil indices won’t change significantly during the season. This is not the case for variable rate nitrogen.

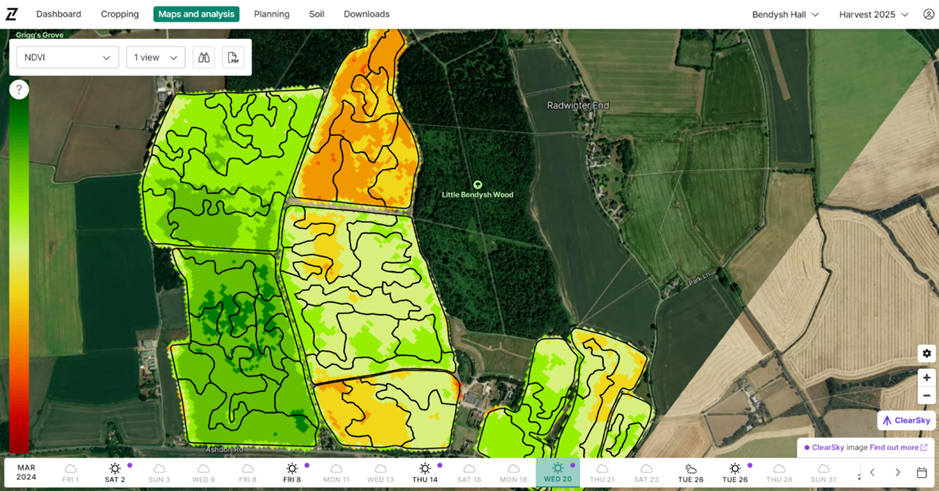

Nitrogen requirement will depend on the crop situation and available soil reserves coming out of the winter. Therefore the PFR1 action requires that where remote sensing is used to calculate the nitrogen requirement it is carried out no more than 14 days before application.

The above-average rain and heavy cloud cover that marred spring 2024 meant those relying on optical imagery derived from the Sentinel-2 satellites struggled to secure images of sufficient value to meet the PRF1 action. Roughly 80% of the imagery produced was rejected.

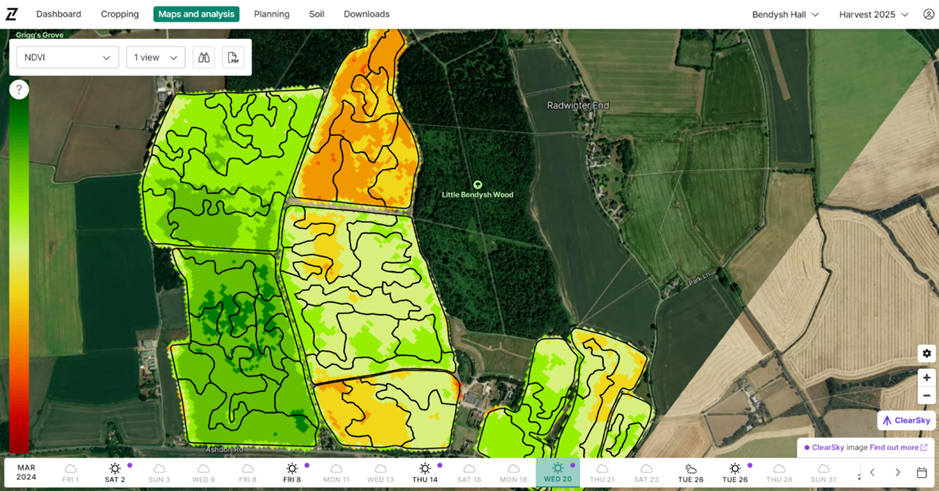

ClearSky

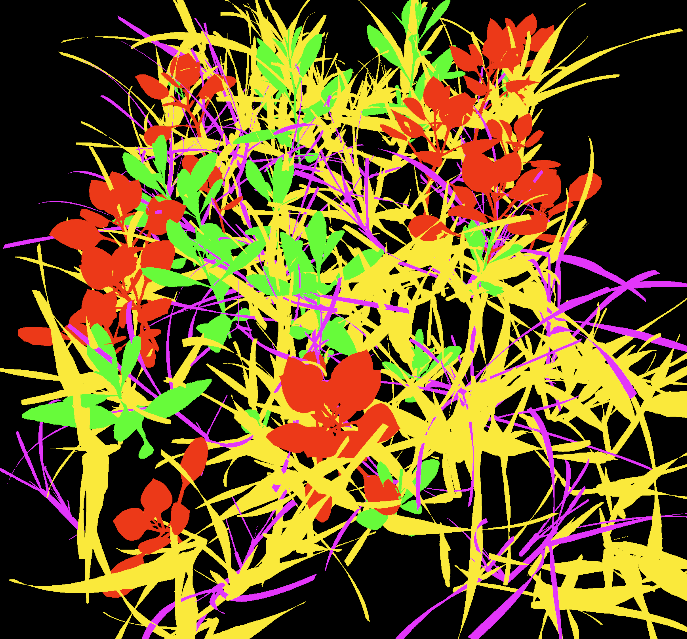

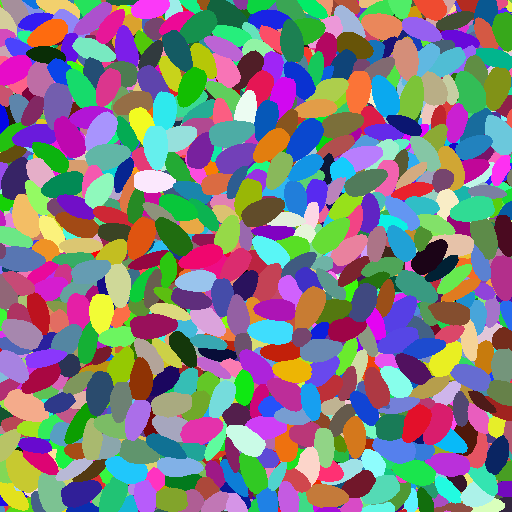

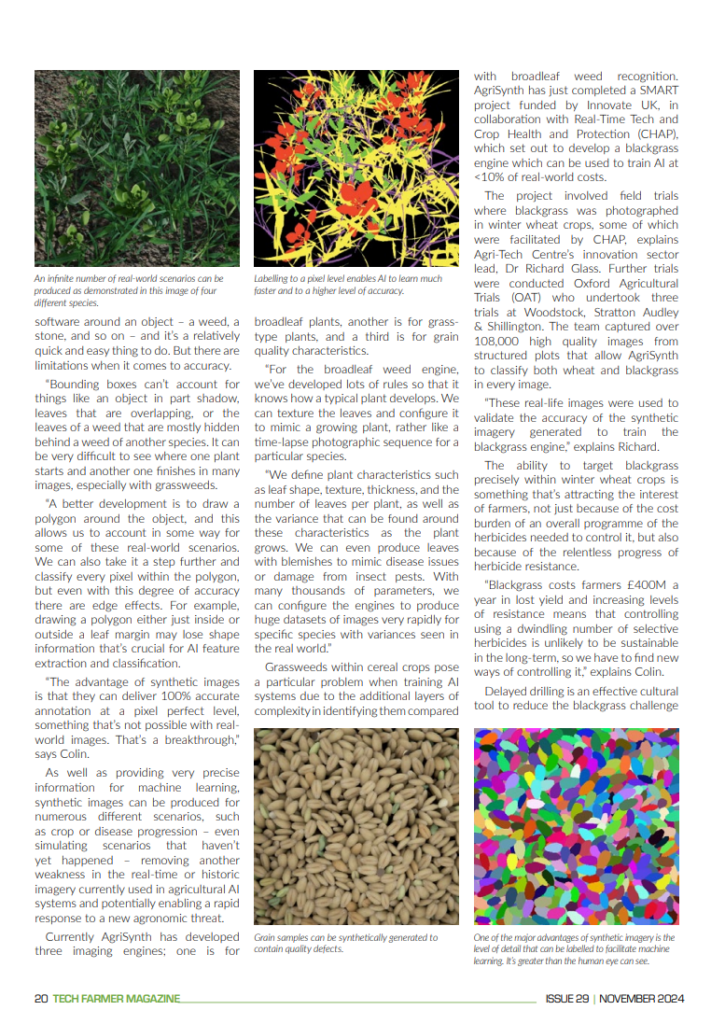

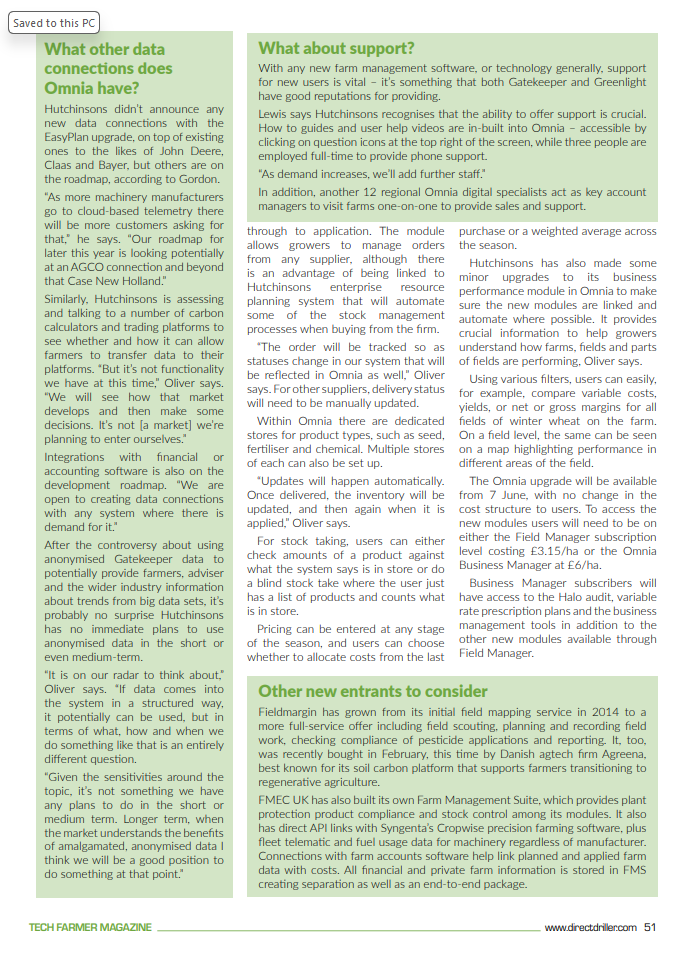

The only source of guaranteed cloud-free imagery able to meet the requirements of the SRF1 action is from ClearSky. It delivers accuracy through full-spectrum optical and infrared imagery, including NDVI and GCVI from synthetic-aperture radar (SAR) – see Figure 4. It removes the need for a clean line of sight as is the case with imagery from Sentinel-2 satellites.

Figure 4: A ClearSky image showing NDVI values needed to support a variable rate application file

This innovation means that farmers using ClearSky are guaranteed to receive an image showing them how their crop is developing every six days, whatever the weather because SAR data is not incumbered by cloud.

Unlike other ‘cloud-free’ derivatives, ClearSky does not rely on intermittent clear optical imagery to calibrate predicted changes. This enables a greater degree of confidence in the data supplied to customers.

Analysis by Agrii on 900,000ha revealed that the Sentinel-2 system produced, on average, roughly 13.3 clear images per farm in 2023. Using the ClearSky platform increased this to 60.8. This number is improved further if the cloud-free images captured by Sentinel-2 are included.

The adoption of technology that improves the performance and resilience of agriculture is an objective of the SFI. Being able to demonstrate adherence with its actions is more than a tick-box exercise. Participants are expected to demonstrate that they are fulfilling the actions on demand. In some cases, this means producing a report while in others it means producing the actual data employed in the fulfilment of the task. ClearSky ensures that variable rate applications are consistent with crop requirements while making it easy to demonstrate compliance with the PRF1 action.

PRF1: What you must do to get paid and how to do it

PRF1 is the action for the variable rate application (VRA) of nutrients. It is a three-year agreement for which the recipient will receive £27/ha/year. There are specific eligibility criteria, mainly relating to land type, but to comply, all major nutrients (N, P, K and Mg) must be applied using VRA equipment pre-programmed with a VRA file using data from zonal soil or crop testing and analysis, or remote sensing. The VRA equipment must be connected to a tractor or sprayer-mounted crop reflectance sensor. The PRF1 does not cover micro-nutrients or lime. The data informing the VRA file must cover a minimum of P, K, Mg and pH. If the data is from zonal soil testing analysis, it must meet the action’s requirements and be less than five years old. For nitrogen, the VRA file must use data from crop testing and analysis or remote sensing of crop reflectance. Remote sensing should be carried out no more than 14 days prior to application to achieve the action’s aim.

-

Using Farm Tech to Maximise and Manage the Sustainable Farming Incentive (SFI) Opportunity

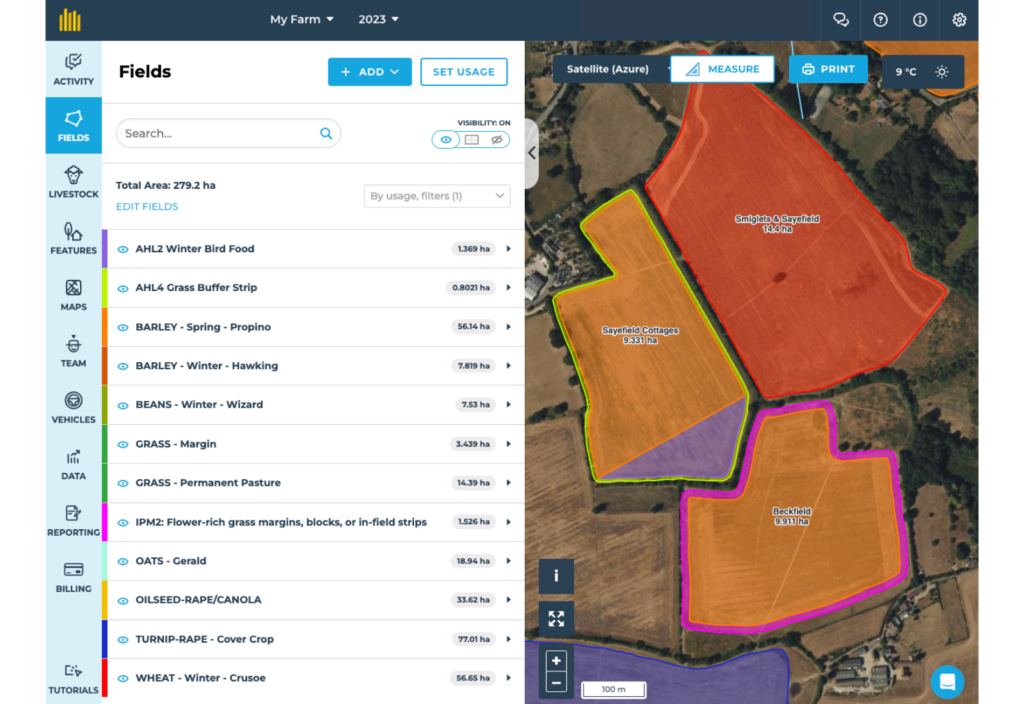

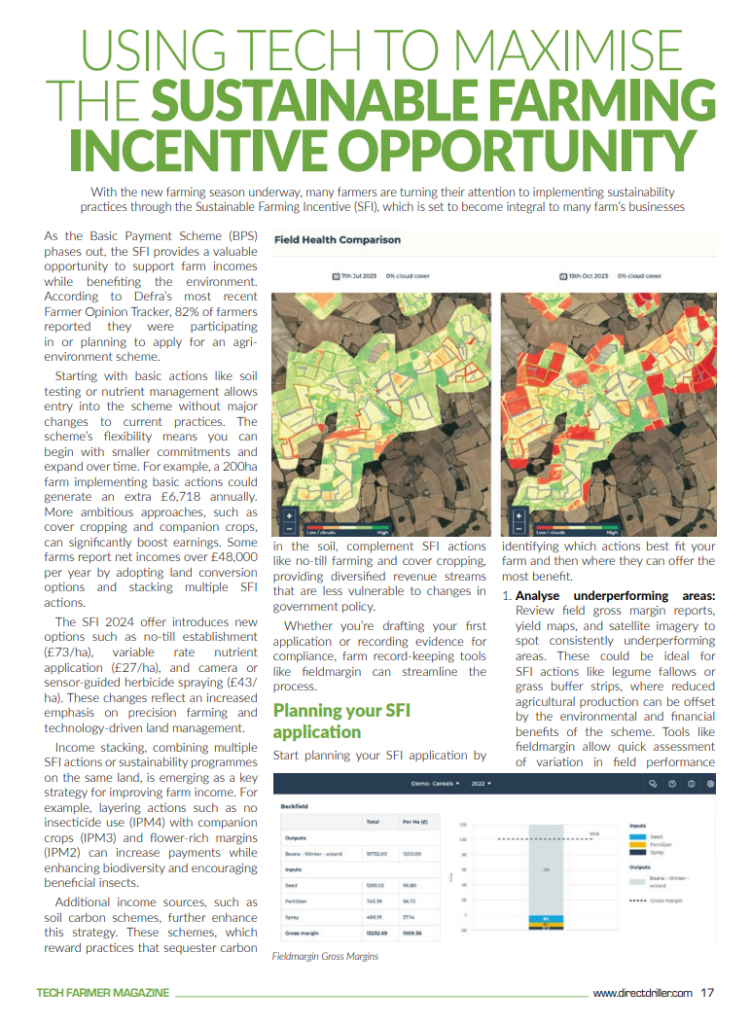

With harvest wrapping up and the new farming season underway, many farmers are turning their attention to implementing sustainability practices through the Sustainable Farming Incentive (SFI), which is set to become integral to many farm’s businesses. As the Basic Payment Scheme (BPS) phases out, the SFI provides a valuable opportunity to support farm incomes while benefiting the environment. According to Defra’s most recent Farmer Opinion Tracker, 82% of farmers reported they were participating in or planning to apply for an agri-environment scheme.

Starting with basic actions like soil testing or nutrient management allows entry into the scheme without major changes to current practices. The scheme’s flexibility means you can begin with smaller commitments and expand over time. For example, a 200ha farm implementing basic actions could generate an extra £6,718 annually. More ambitious approaches, such as cover cropping and companion crops, can significantly boost earnings.

Some farms report net incomes over £48,000 per year by adopting land conversion options and stacking multiple SFI actions. You can layer actions, such as no insecticide use (IPM4) with companion crops (IPM3) and flower-rich margins (IPM2), to increase payments while enhancing biodiversity and encouraging beneficial insects.

The SFI 2024 offer introduces new options such as no-till establishment (£73 per hectare), variable rate nutrient application (£27 per hectare), and camera or sensor-guided herbicide spraying (£43 per hectare). These changes reflect an increased emphasis on precision farming and technology-driven land management.

Additional income sources, such as soil carbon schemes, further enhance this strategy. These schemes, which reward practices that sequester carbon in the soil, complement SFI actions like no-till farming and cover cropping, providing diversified revenue streams that are less vulnerable to changes in government policy.

Whether you’re drafting your first application or recording evidence for compliance, farm record-keeping tools like fieldmargin can streamline the entire process.

Planning Your SFI Application

Start planning your SFI application by identifying which actions best fit your farm and then where they can offer the most benefit.

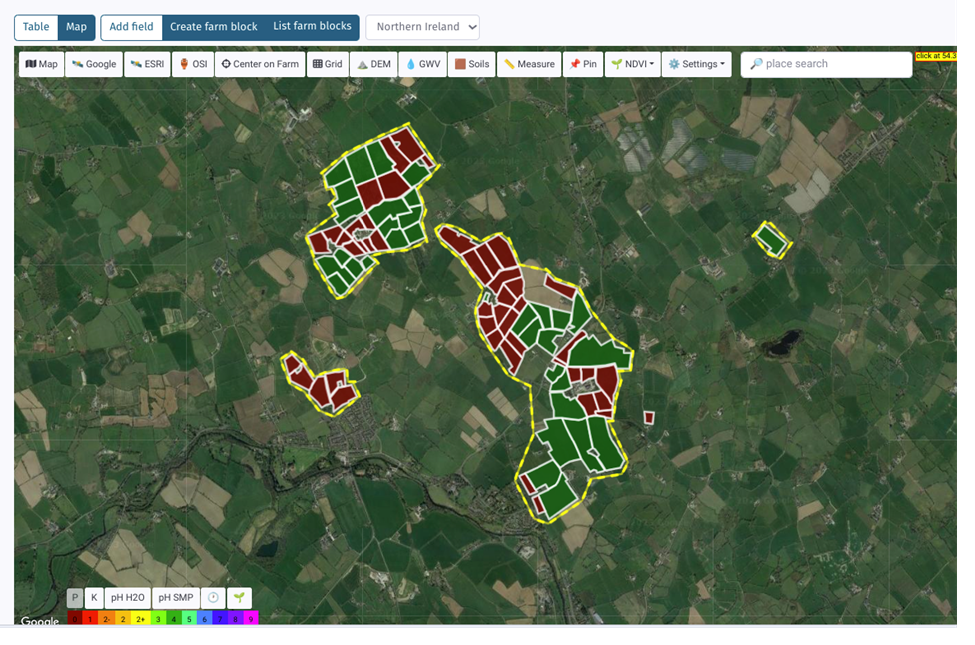

- Analyse underperforming areas: Review field gross margin reports, yield maps, and satellite imagery to spot consistently underperforming areas. These could be ideal for SFI actions like legume fallows or grass buffer strips, where reduced agricultural production can be offset by the environmental and financial benefits of the scheme. Tools like fieldmargin allow quick assessment of variation in field performance using NDVI analysis from satellite imagery, helping you make data-driven decisions.

- Review historic field data: Notes on past issues like erosion, runoff, or pests, can help inform which SFI options might be most effective. Targeting areas with recurring challenges can help address these problems while fulfilling SFI requirements.

- Consider your farm strategy: If you’re planning a transition to regenerative practices, look for SFI options that align with these changes. Explore opportunities to enhance public funding with private schemes, like carbon credits.

Mapping and Managing SFI Implementation

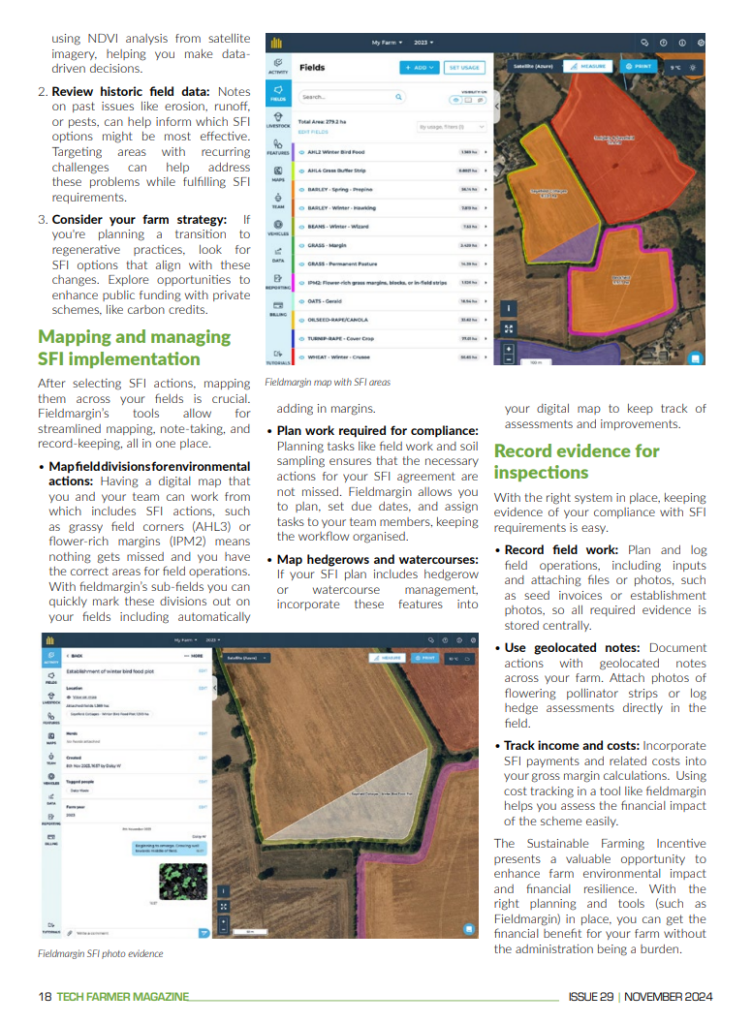

After selecting SFI actions, mapping them across your fields is crucial. Fieldmargin’s tools allow for streamlined mapping, note-taking, and record-keeping, all in one place.

- Map field divisions for environmental actions: Having a digital map that you and your team can work from which includes SFI actions, such as grassy field corners (AHL3) or flower-rich margins (IPM2) means nothing gets missed and you have the correct areas for field operations. With fieldmargin’s sub-fields you can quickly mark these divisions out on your fields including automatically adding in margins.

- Plan work required for compliance: Planning tasks like field work and soil sampling ensures that the necessary actions for your SFI agreement are not missed. Fieldmargin allows you to plan, set due dates, and assign tasks to your team members, keeping the workflow organised.

- Map hedgerows and watercourses: If your SFI plan includes hedgerow or watercourse management, incorporate these features into your digital map to keep track of assessments and improvements.

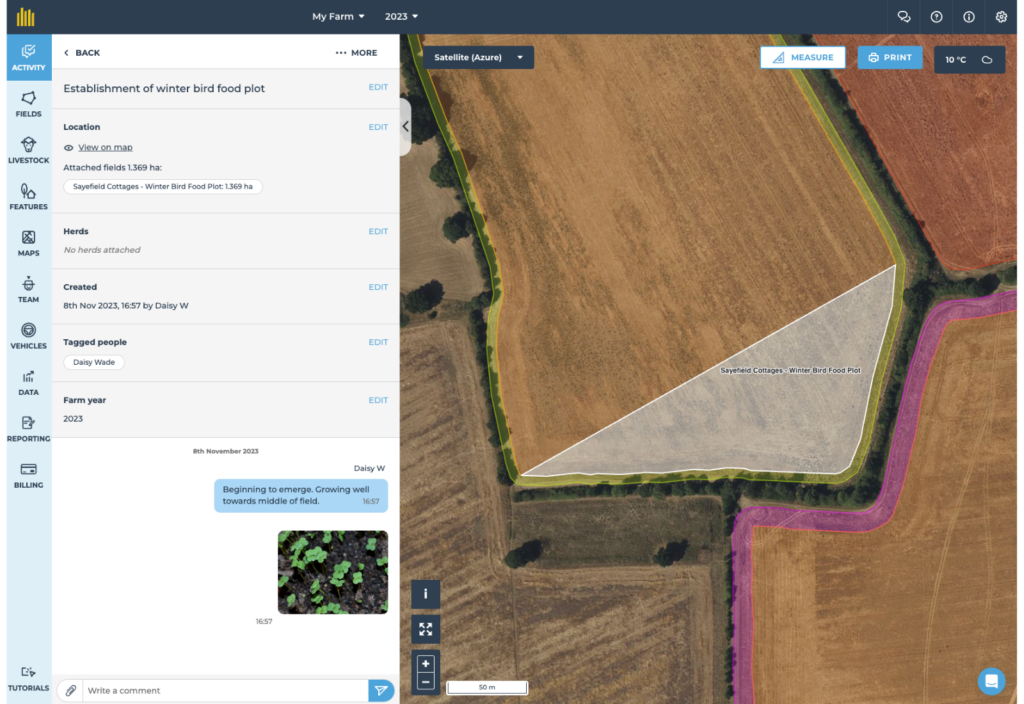

Record Evidence for inspections

With the right system in place, keeping evidence of your compliance with SFI requirements is easy.

- Record field work: Plan and log field operations, including inputs and attaching files or photos, such as seed invoices or establishment photos, so all required evidence is stored centrally.

- Use Geolocated Notes: Document actions with geolocated notes across your farm. Attach photos of flowering pollinator strips or log hedge assessments directly in the field.

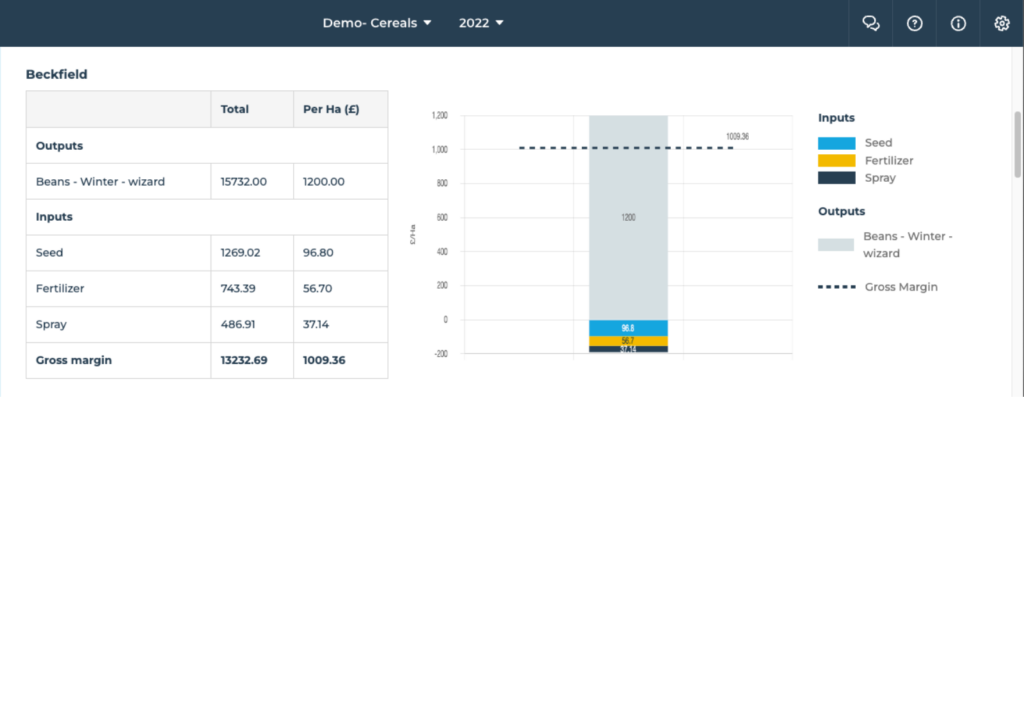

- Track Income and Costs: Incorporate SFI payments and related costs into your gross margin calculations. Using cost tracking in a tool like fieldmargin helps you assess the financial impact of the scheme easily.

The Sustainable Farming Incentive presents a valuable opportunity to enhance farm environmental impact and financial resilience. With the right planning and tools (such as fieldmargin) in place, you can get the financial benefit for your farm without the administration being a burden.

-

Agronomist in Focus – Simon Francis

New ‘boots-on-the-ground’ precision farming service

A new service makes the benefits of precision farming accessible without growers having to master all its complexities, says ProCam’s UK Technical and Services Manager, Simon Francis.

Using satellite mapping of soil and crop variability across fields, the new FieldSense service derives tailored variable rate input applications to improve economic crop output across the field and bring environmental gains.

However, what makes FieldSense particularly appealing is that the system is based on a collaborative approach between the agronomist and grower.

It will be the ProCam agronomist who makes sense of the field data, drawing on their boots-on-the-ground experience of the field and ground-truthing any anomalies that the data might reveal. This can be combined with the farmer’s own knowledge of the field as necessary. Once the data has been interpreted, the agronomist will produce variable rate files for downloading directly to the tractor that is controlling the drill or fertiliser applicator. It is precision agronomy through partnership.

Growers can also cherry pick only those parts of the package relevant to their farm and machinery and can begin by trying FieldSense over just a few hectares.

This first phase launch will focus on four key areas for combinable cropping: grid-based soil sampling; variable rate seeding; variable rate nitrogen, phosphate, potash and lime applications; and yield mapping input.

The process starts by mapping fields into various sized grids – for example one hectare squares for soil sampling, 24 metres squared grids for variable rate fertiliser spreading, and 6 metres squared grids for variable rate drilling, or the most appropriate grid size tailored for the width of machine.

The variable rate drilling package in FieldSense uses historical field performance maps to show the variations in crop biomass that have occurred in that field over multiple years. From these, the agronomist will create a variable seed rate plan – to drill proportionally more seed in historically lower biomass grid squares and less seed where needed – with the aim of achieving a uniform, optimum tiller density over the whole field.

In one test, we’ve found that almost double the seed rate was needed in poorer areas of a field to bring tiller numbers back up towards the better areas. Without this knowledge, poorer areas would have been drilled at sub-optimal density, risking sub-optimal yield.

Variable rate seed drilling and fertiliser application are just two of the packages available in ProCam’s new FieldSense service For soil sampling, the location of where samples were taken from in each hectare is captured by GPS and shared back to the FieldSense platform. Samples can be analysed using ProCam’s SoilSense service, with the resulting gridded nutrient maps used by the agronomist to create variable rate spreading files to correct phosphate and potash deficiencies, and for liming if required.

Variable rate nitrogen application, on the other hand, uses satellite NDVI measurements of the growing crop. These are taken every five to seven days on a 10m x 10m grid or every three to five days on a 3m x 3m grid. Here, the aim is to use variable rate nitrogen to produce the optimum green area index (GAI) over the whole field. Farm-testing in oilseed rape where GAI in March was found to vary from a near optimum of 3.0 to just 1.0, showed that by varying nitrogen between 60 and 90 kg/ha, crop uniformity was corrected by early June.

In fields where yield mapping is carried out on the combine harvester, yield data can also be uploaded into FieldSense to guide future agronomic decisions.

Simon Francis explains that it will be the ProCam agronomist who makes sense of the satellite images, drawing on their boots-on-the-ground experience, rather than growers having to do everything themselves The launch of FieldSense is the latest in a sequence of technical introductions from ProCam, following on from the launch of the soil testing and nutrient planning service, SoilSense, last year.

Growers face increasingly heavy workloads and pressures from legislation and environmental scrutiny, while at the same time, farm profits are volatile and under pressure.

FieldSense provides a way for ProCam agronomists to take some of the complexity out of precision farming for growers, while bringing greater accuracy to agronomic decisions. In the case of variable rate application of nutrients, there are also potential SFI payments available of £27/ha.

In essence, FieldSense offers focused use of key inputs for optimum crop output through partnership, technology and boots-on-the-ground collaboration. Satellite image field maps are one element of precision farming, but they are just the start. They need underpinning with solid field experience to interpret and make sense of them.

-

We can benefit from innovation

Our production systems must become more resilient in order to combine productivity, climate protection and biodiversity. How can this be achieved, what role does digitalisation play, and where are the new opportunities? We pose these and other questions to Hubertus Paetow, President of DLG in Germany.

The advancing climate change, increasing loss of biodiversity, the growing population and the associated global demand for resources will shape future arable farming. How can these challenges be met?

I believe we need to become much more open to everything that can be roughly categorised as innovation in the direction of greater sustainability. The theme of the field days “Out of the box” shows this. We naturally find it difficult to understand progress in terms of questioning the familiar and looking for something new. Especially when the familiar works quite well in the short term.

In the entire toolbox of innovations, we must never exclude anything from the start because the problem determines the solution, and not the other way around. Neither 100% organic farming, 100% smart farming nor 100% genetic engineering will help us, but it will probably be a mixture of everything.

DLG President Hubertus Paetow manages an arable farm in Mecklenburg-Western Pomerania. Photo credit: DLG

Are there only conflicting interests between production and ecology. Which innovations benefit both goals equally?

Admittedly, some conflicts of interest cannot be resolved even with the best formulations, nor can they be resolved with technical progress. The trivial wisdom that where there is a dense crop of wheat, there will not be enough flowers for pollinating insects is a fact. And the fact that we need this wheat population for land productivity is not something we can change much with innovations.

It is much more a question of achieving a better balance. The concept of productivity plays a role here. We are used to measuring productivity in tonnes per hectare, but that is only half the truth. Of course, the breeding pairs of skylarks per hectare are just as much a part of ecological productivity. Or the avoidance of nitrate input into the groundwater, and so on. As always, when we have such conflicts, it’s best if we measure and balance them somehow.

Are innovations a Unique Selling Point?

Absolutely, and in Germany, we have to make sure that it stays that way. After all, we don’t have the lowest land costs or the lowest labour costs – we can only be competitive through efficiency and that depends on innovation. Any political measure that limits the scope for innovation really needs to be very well justified. We can still score points through innovation, we just have to make sure that we handle the delicate plant carefully.

If sustainability can be evaluated objectively, does it matter whether our systems are organic, conventional or regenerative?

It is not a given that an organic farm will perform better in the overall sustainability assessment than a well-managed conventional farm. In this respect, this system of indicators is dependent on agreement being reached at some point. That is the biggest problem, because the indicators are described, as is the methodology for recording and evaluating them.

Let’s take farm-to-fork as an example. Indicators were wildly plucked out of the air for this. Is a 50% reduction in pesticides really a useful indicator for biodiversity conservation? I say no, because it can develop just as well if I don’t reduce crop protection so much, but instead establish a wider crop rotation, for example.

The use of chemical crop protection will become more challenging in the future. How can production and environmental interests be balanced here?

It is always extremely damaging to think in rigid categories about improving sustainability. If you publicly announce that you want to reduce the use of pesticides and see this as an end in itself, then no company will develop new active ingredients because they know they can’t sell them, even if this active ingredient is ‘biodiversity friendly’. That is the great disadvantage of losing sight of the actual goal – namely biodiversity conservation – when creating political instruments.

The world won’t get any better just because we only spray half as much. It may well be that we can achieve this target in a different way, which may be better than with a rigid reduction or territorial framework.

Many see ‘digitalisation’ as the key to the future. Where is the problem and what promises success?

It always becomes difficult when several components have to work together and data cannot overcome certain restrictions between different systems. There is still a lot of catching up to do. Let’s take the example of combined chemical-mechanical weed control in sugar beet, i.e. band spraying and hoeing. Here you always have different machine and equipment manufacturers involved and no one can offer you a system ‘out of the box’. As the DLG, we are trying to make progress in this area with a platform like FarmRobotix.

I see the greatest potential in AI-supported decision-making systems. Is the pest below the damage threshold? Can I do without treatment? Many farm managers still find it difficult to make this decision and take the risk. If they had greater certainty through the use of AI, it would be easier. And of course, the most biodiversity-friendly measure is the one I don’t take at all.

-

First look: Innovations that might be on your farm

Around 2,500 delegates attended the World AgriTech Innovation Summit in San Francisco in March. Mike Abram went along to hear about some new exciting innovations.

If you’re the CEO or founder of an agritech start-up, or looking to find such companies, it’s the place to be. If you’re the global head of sustainability or digital agriculture for a global food brand, retailer, machinery or ag input manufacturer it’s also a more-than-useful event to be seen and perhaps heard.

If you’re a farmer, it’s probably not even on your radar, at least based on attendance lists, although any farmer interested in new tech will find a huge amount to be interested in. The price of entry might put you off though.

The place is San Francisco in March, where the largest of five World AgriTech Innovation Summits around the world takes place.

Around 2,500 attendees meet for an event that is a mix of conference – panel sessions discussing topics such as regenerative agriculture, artificial intelligence, new breeding techniques and future of agtech funding – and exhibition both for established agtech companies and start-ups looking to tell the world about their big idea and hopefully encourage new investment to help make it a reality.

Among those firms was Crop Diagnostix, which is attempting to bring crop intelligence to a new level by analysing hole punch size leaf samples to understand plant health.

But unlike more traditional plant health tests, which rely on visual symptoms for diagnosis or tissue tests that could give inconsistent results, Crop Diagnostix analyses the plant leaf’s RNA to reveal the plant’s gene expression, CEO Brandon Chi explained.

“We help plants communicate with farmers and agronomists,” he said. “The power of gene expression is that genes within the plant are turning on and off in response to environment constantly.

“A plant can look green and healthy but be feeling some signs of nutrient deficiency or starvation. Through gene expression we can look at all facets of plant health at the earliest possible stage and because we don’t need visual symptoms to make a diagnosis, we can see that at a much earlier stage,” he said.

For example, in corn, growers could start to understand plant health from the V2 to V3 stage rather than V5 or later. “This gives the farmer weeks of actionability in advance compared with other technologies.”

Once the leaf RNA is analysed, Crop Diagnostix uses machine learning to mine through gene expression data to understand which genes are switched on or off to figure out what’s happening in the plant.

That could help answer questions around nutrient stress or even whether a plant was able to reach maximum yield potential based on the current gene expression, Brandon suggested.

With an infinite number of possibilities for the technology, Crop Diagnostix is initially concentrating on helping growers with nitrogen applications and other nutrient deficiencies in corn, after the initial research by co-founder Joseph Swift for his PhD found biomarkers that could predict yield and nutrient stress based on genetic expression in rice.

“We hope to launch a commercial product in 2025, and then rapidly scale up for 2026,” Brandon said. Samples will cost around $20 (£16)compared with $30-60 for a spectroscopy sample, with the added benefit that it is non-destructive and it doesn’t matter which leaf is sampled.

Other areas of trials include club root in oilseed rape and fusarium in onion where the company is involved in trials in the UK.

“These are high pain point pathogens with long asymptomatic periods that growers aren’t able to detect early on.”

Another company providing crop intelligence to farmers is Taranis, which uses drones to capture crop imagery at submillimetre resolution to monitor fields through the entire season, complemented with data from satellite imagery.

Already a commercial offer covering millions of acres of corn, soybeans and cotton in the USA and Brazil, the company had more recently started providing a service to sugar beet and potato growers in Germany, with France likely to follow soon, CEO Opher Flohr told Tech Farmer.

“Our biggest differentiator, which I’m not aware of anyone else doing, is offering very high leaf level resolution at 0.3 mm/pixel.

“To give a little perspective we would be able to read your business card from the sky or see the spots on a ladybird. There’s no difference between that and a human being standing over a weed and looking with their own eyes.”

The same kind of resolution is possible using the firm’s proprietary imaging pod on a plane which has patented technology to fix the image in the same position even while the plane is flying at full speed.

“It uses mirrors, gyros and different lasers to take the same, perhaps even slightly better imaging than we can with off-the-shelf drones,” Opher said.

Once a grower has signed up for the service, which in the US costs around $13/ac (£26/ha) through an ag retailer, and provided field location, crop and planting date, Taranis automatically schedules all the drone or plane flights.

“We operate all the pilots,” Opher said. “Making sure the pilots arrive at the field at the right crop stage to deliver insight and value to the farmer, while building the right software and tools to optimise flight plans and image quality is a huge task, which is probably why we haven’t seen anyone else provide a service like this.”

As well as weed identification, Taranis also offers accurate, AI-powered insights into plant stands – extremely useful to help provide precise information about replanting decisions that can provide a large return on investment – and disease, pest and nutrition insights.

Soils are, not surprisingly, a big growth area for investment in agtech with new ideas at the event aiming to potentially help farmers improve soil health or understanding and management of their key asset.

Mexican/American biotech start-up Solena is using its AI-driven Prometheus platform to analyse and compare the functions of microbes from two different performing areas of a field or farm, for example the highest and lowest yielding parts.

“All farmers know what the best or worst performing areas on a farm are,” chief financial officer Gerardo Guerrero told Tech Farmer. “So if the seed is the same, the climate, the irrigation system, the difference is in the microbiome.”

That information can then be used to recommend how to improve the poorer performing areas with customised inputs, including dose and timing, based on the soil microbiome.

Initial use cases have concentrated on finding differences in pathogens to help target biological or chemical input use to boost crop performance, or, in the case of a potato project with PepsiCo in north Mexico to help growers identify when they don’t need to apply pesticides.

“We were able to reduce chemical applications by 30% compared with the previous season, while maintaining yields,” Gerardo said.

That kind of in-season analysis would help PepsiCo to drive regenerative agriculture adoption without losing productivity, he noted.

Californian-based Biome Makers is on a similar path with its soil microbiome analysis. Over the past 10 years the firm has analysed soils from six continents, 56 countries and over 200 crops to build a database of over 24m microorganisms, making it, according to Biome Makers, the largest database of soil data.

“What we do is decode soil biology to optimise farming practices and improve soil health,” explained Sarah Basiri, global head of marketing. “We extract microbial DNA from the soil, analyse it, and then using our BeCrop Technology, we analyse the functions of microorganisms to understand what is happening below ground.”

Ralph Weir Zayndu credit Zayndu The results provide key agronomic insights, such as early disease detection, identification of beneficial microbes with positive impacts on pests or diseases, or ones that mobilise a whole range of nutrients, including nitrogen, phosphorus and potassium, as well as micronutrients.

It also helps farmers understand whether there are microbes present that are linked to withstanding stress conditions or promoting or regulating crop growth, such as auxins, cytokinins and gibberellins.

“Farmers and advisers can use these results to understand how management practices and ag inputs impact the soil microbiome,” Sarah said. “And we can also help advisers provide tailored recommendations and place the correct product based on these biological insights.”

A single introductory test cost $199 (£159), although buying the service through an ag retailer in the US brought the cost down to $3-9/acre (£6-18/ha), Sarah said.

Pluton Biosciences is also trying into tap into the world of microbes, but this time in pursuit of consortia of microbes that will solve particular challenges. “Why try to rediscover the wheel when you can search for microbes that are already doing what you’re looking for,” suggested Adam Blaszczak, Pluton Bioscience’s vice-president of R&D.

One of the first development products emerging from the micro-mining process undertaken by the firm was a microbial consortium that will capture carbon from the atmosphere, Adam told Tech Farmer.

The concept, which started as a collaboration with Bayer, is based on the observation that soil microbe pioneers in the desert can live off carbon and nitrogen from the atmosphere, forming a film of crust on the soil surface.

Pluton’s proof of concept research predicts the right grouping of microbes, applied in a spray at planting and harvest can scrub 1t/acre/year of CO₂e from the atmosphere to help address climate change while replenishing nutrients in the soil, potentially earning farmers carbon credits.

“The idea is they could be an alternative to cover crops, while also helping to reduce soil erosion and fertiliser requirements in following crops,” Adam said.

Field testing of the first generation was due this spring, while next generation development was already underway with the potential to add microbes that secreted a molecule that looked like coal to store carbon more permanently in the soil, he added.

Could next generation seed priming improve crop performance?

Both biostimulants and elicitors have had their fair share of challenges in gaining the trust of farmers, mostly because the performance of both has been inconsistent at best.

But two start-up companies at the World AgriTech Innovation Summit were suggesting that they had developed products that would change that perception.

UK-based start-up Zayndu uses cold plasma – a kind of ionised gas – to activate the air around seeds, explained CEO Ralph Weir.

“That improves seed health in a number of ways. Firstly, it kills off any pathogens that might be on the seed surface.

“It also removes the waxy layer that seeds are coated in, which is there to waterproof the seed. That’s counterintuitive when you think seeds need water to germinate.”

Ralph Weir Zayndu credit Zayndu The plasma creates micro fissures on the seed surface which helps moisture get into seeds, with the combined effect of enabling the seed to germinate more quickly.

“Activating the air also re-arranges the nitrogen into nitrates and nitrites, which are noted for being fertilisers, and by also creating these little fissures, it enables the fertiliser to get close to the embryo,” Ralph said.

“Now the seeds have quick and easy access to water and fertiliser just as we are about to plant them.

“We also tweak the hormone balance in the seed a little bit, effectively saying it is your time to germinate – it removes any conservatism in the seed. A lot of seeds hold back energy when germinating in case of drought or other stress, but our technology is mostly designed for greenhouses or other controlled environments so you don’t need to worry about those things.

“The end result is quicker germination, and bigger, stronger seedlings and roots. And it turns out if you do that in the wild and there is a drought, it’s actually in a better place because of the stronger roots. We typically see something like 20% uplift in yields, or it allows a grower to hit spec size or weight more quickly – say in 20 days rather than 23 days in a greenhouse , which means you can do more cycles in a year.”

Zero Gravity Solutions, meanwhile, is using a plant priming platform originally developed for NASA to grow robust, nutrient-dense plants in hostile environments.

“We offer a next generation biostimulant technology,” CEO John McLean claimed. “It’s a product that allows plants to protect themselves.

“The way our product works is we developed a set of chemical elicitors that the plant perceives as a stress signal,” he explained.

That signal causes the plant to grow faster to get to the next generation by producing seed more quickly, and in some cases, depending on the nature of the stress signal, encourages the plant to produce antioxidant molecules which resist disease, he said.

“As climate becomes more variable in terms of temperature and water availability, it’s helpful for plants to be able to activate its natural defences. The plant can react to diseases and stresses but pre-priming acts like a vaccine, and allows the plant to respond quickly and aggressively to these kinds of stresses and challenges.”

Elicitors in the past had struggled with the natural conflict between energy used to produce defence mechanisms and the energy needed to produce yield, he said. “We’ve addressed both of those issues.

“Our elicitors are designed to activate a number of pathways simultaneously inside the plant, so you get a broader set of protections against disease. Secondly, we have been able to understand the mode of action sufficiently to optimise the balance between improving yield and fighting disease.”

While the main focus for the product is high value fruit and vegetable crops, the firm has also investigated row crops, such as soybeans and wheat. “We’ve exciting data on soybean rust showing we can reverse infections and recover yields, while in wheat trials in India that showed yield increases of 30% when using the elicitor in combination with fertiliser over fertiliser treated wheat alone.”

-

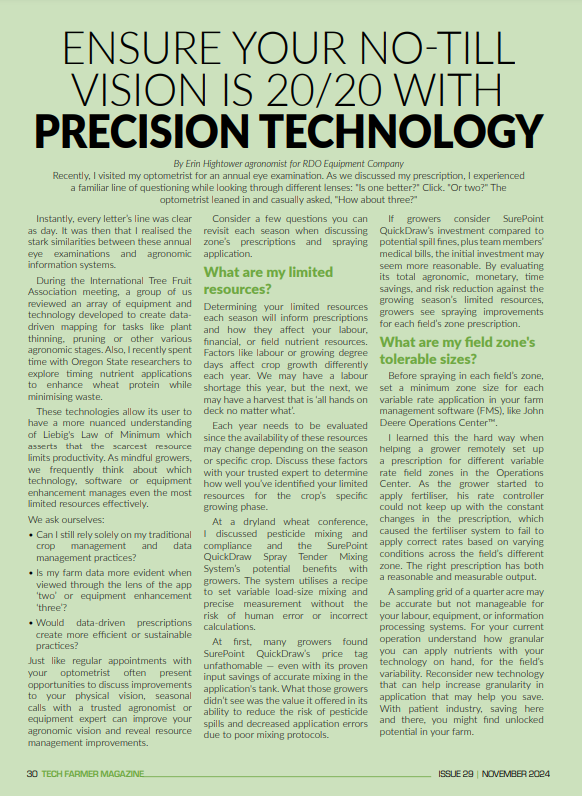

Ensure Your No-Till Vision is 20/20 with Precision Technology

By Erin Hightower agronomist for RDO Equipment Company

Recently, I visited my optometrist for an annual eye examination. As we discussed my prescription, I experienced a familiar line of questioning while looking through different lenses: “Is one better?” Click. “Or two?” The optometrist leaned in and casually asked, “How about three?”

Instantly, every letter’s line was clear as day. It was then that I realised the stark similarities between these annual eye examinations and agronomic information systems.

During the International Tree Fruit Association meeting, a group of us reviewed an array of equipment and technology developed to create data-driven mapping for tasks like plant thinning, pruning or other various agronomic stages. Also, I recently spent time with Oregon State researchers to explore timing nutrient applications to enhance wheat protein while minimising waste.

These technologies allow its user to have a more nuanced understanding of Liebig’s Law of Minimum which asserts that the scarcest resource limits productivity. As mindful growers, we frequently think about which technology, software or equipment enhancement manages even the most limited resources effectively.

We ask ourselves:

- Can I still rely solely on my traditional crop management and data management practices?

- Is my farm data more evident when viewed through the lens of the app ‘two’ or equipment enhancement ‘three’?

- Would data-driven prescriptions create more efficient or sustainable practices?

Just like regular appointments with your optometrist often present opportunities to discuss improvements to your physical vision, seasonal calls with a trusted agronomist or equipment expert can improve your agronomic vision and reveal resource management improvements.

Consider a few questions you can revisit each season when discussing zone’s prescriptions and spraying application.

What are my limited resources?

Determining your limited resources each season will inform prescriptions and how they affect your labour, financial, or field nutrient resources. Factors like labour or growing degree days affect crop growth differently each year. We may have a labour shortage this year, but the next, we may have a harvest that is ‘all hands on deck no matter what’.

Each year needs to be evaluated since the availability of these resources may change depending on the season or specific crop. Discuss these factors with your trusted expert to determine how well you’ve identified your limited resources for the crop’s specific growing phase.

At a dryland wheat conference, I discussed pesticide mixing and compliance and the SurePoint QuickDraw Spray Tender Mixing System’s potential benefits with growers. The system utilises a recipe to set variable load-size mixing and precise measurement without the risk of human error or incorrect calculations.

At first, many growers found SurePoint QuickDraw’s price tag unfathomable — even with its proven input savings of accurate mixing in the application’s tank. What those growers didn’t see was the value it offered in its ability to reduce the risk of pesticide spills and decreased application errors due to poor mixing protocols.

If growers consider SurePoint QuickDraw’s investment compared to potential spill fines, plus team members’ medical bills, the initial investment may seem more reasonable. By evaluating its total agronomic, monetary, time savings, and risk reduction against the growing season’s limited resources, growers see spraying improvements for each field’s zone prescription.

What are my field zone’s tolerable sizes?

Before spraying in each field’s zone, set a minimum zone size for each variable rate application in your farm management software (FMS), like John Deere Operations Center™.

I learned this the hard way when helping a grower remotely set up a prescription for different variable rate field zones in the Operations Center. As the grower started to apply fertiliser, his rate controller could not keep up with the constant changes in the prescription, which caused the fertiliser system to fail to apply correct rates based on varying conditions across the field’s different zone. The right prescription has both a reasonable and measurable output.

A sampling grid of a quarter acre may be accurate but not manageable for your labour, equipment, or information processing systems. For your current operation understand how granular you can apply nutrients with your technology on hand, for the field’s variability. Reconsider new technology that can help increase granularity in application that may help you save. With patient industry, saving here and there, you might find unlocked potential in your farm.

Can existing equipment automatically read data?

We are experiencing a technological renaissance that would have seemed like science fiction just 30 years ago when it comes to data in the field. However, these impressive field mapping systems may have one potential setback: How do they translate technology mapping back into actionable input and decision-making?

For example, I conducted a side-by-side study to map fields using unmanned aerial vehicles (UAVs) with several different mapping systems in the same field. One aerial field map produced intricate wine grape maps that resembled artwork. (I still want to frame them on my wall.) Yet, the practical vineyard owner asked these questions after every flight:

- Can I automatically integrate this data into my machinery? (Which it could not for their application systems)

- Can the machinery use this data so I can test soil or check irrigation lines in zones created from these maps? (It couldn’t since the mapping was too granular to make actionable sections.)

We would need to spend hours of time with maps to synthesise the information to help discern irrigation rates. Numerous technologies in the agricultural industry focus on reading crop quality, quantity, and thinning targets. I feel most of these technologies have a rich future. However, only a small handful of known technologies can effectively apply insights from field inputs, and many are expensive. While data and equipment technology has exponentially improved the applications of spraying prescriptions, we should still be aware of our current limitations in automating equipment based on data integration.

Ask questions, adjust and future-proof operations

At times, we track ag data sets for documentation to provide evidence for future decisions. For years, as an example, we ‘spoon-fed’ the most fickle of agronomy systems: the potato.

We field-scouted and sampled small grids for soil levels. During the past 10 years, these data sets have informed field maps to improve zone prescriptions when applying fertiliser.

Recently during harvest, these data collections were validated when we started to receive updated yield data, signalling that mindful resource management — informed by data — delivered measurable results.

There is hope that these years’ worth of data will uncover new action steps. In the case of our potato fields, years of grid sampling, followed by the use of Greentronics systems with the Gen 4 and G5 John Deere displays, was the combination of corrections we needed to see clearly. We do have hope for the potential of useful information, but we need to ask the right questions, collect data in faith, and build the right adjustments once it becomes affordable and practical for your farm.

Just like when your glasses prescription slightly adjusts and you discover newfound clarity, collecting field zone data and making even seemingly minor adjustments can have long-lasting effects for your agronomic and financial future.

-

New technology connecting the lab to the field

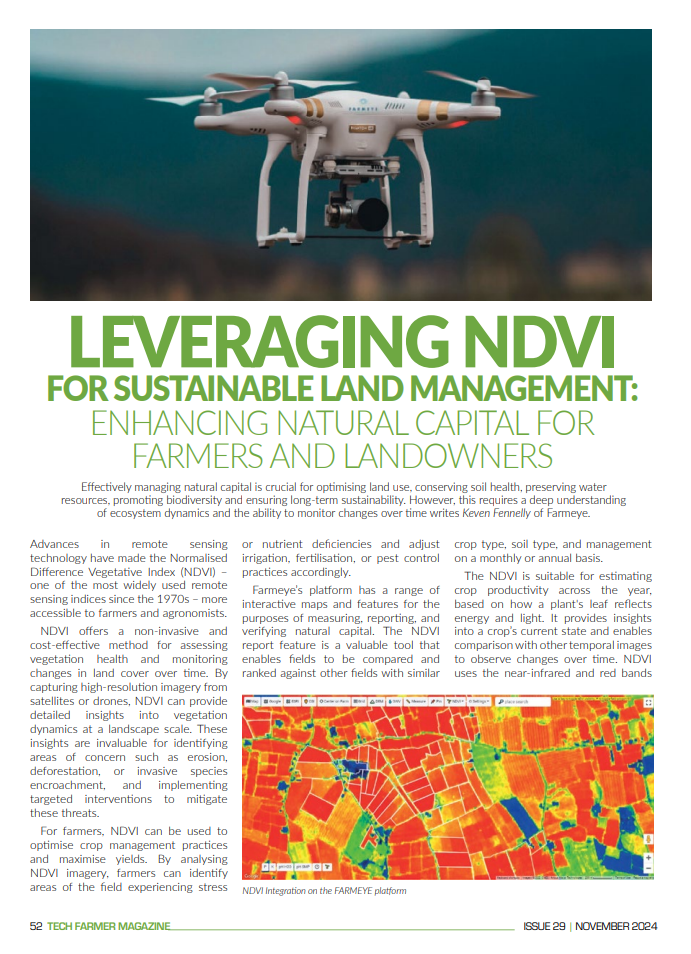

Drone technology is unlocking the potential of traditional crop trials and helping to bridge the gap between detailed laboratory studies and field trials.

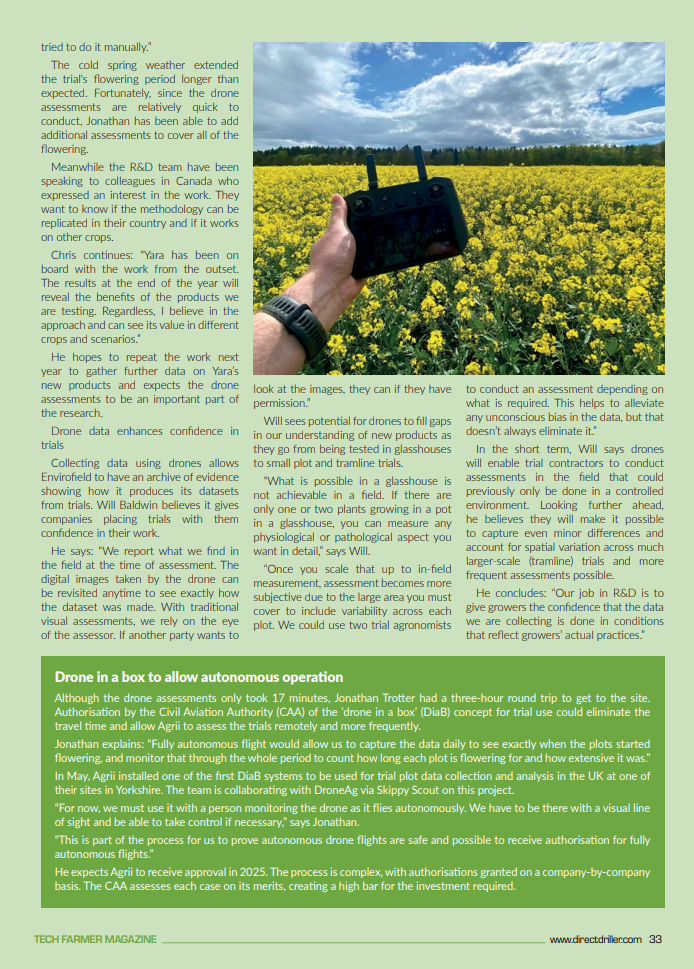

Drones were used to assess an oilseed rape trial this spring at a site in Yorkshire, gathering data that hasn’t been possible before.

The trial is a collaboration between Envirofield, Agrii and Yara. Envirofield is a crop research organisation that conducts independent trials. In 2022 it was acquired by Origin Enterprises, Agrii’s parent company.

Will Baldwin, director of Envirofield, says the business has maintained its independent status in the Origin group, but also benefits from being part of a bigger organisation. Most recently, this has included access to higher level technology via Agrii’s research and development drone technology to enhance trial assessments.

Will says: “Envirofield acquired a drone five years ago, but we didn’t have the capability to conduct assessments. It just gave us a nice visual perspective of a trial, with only the obvious differences showing.”

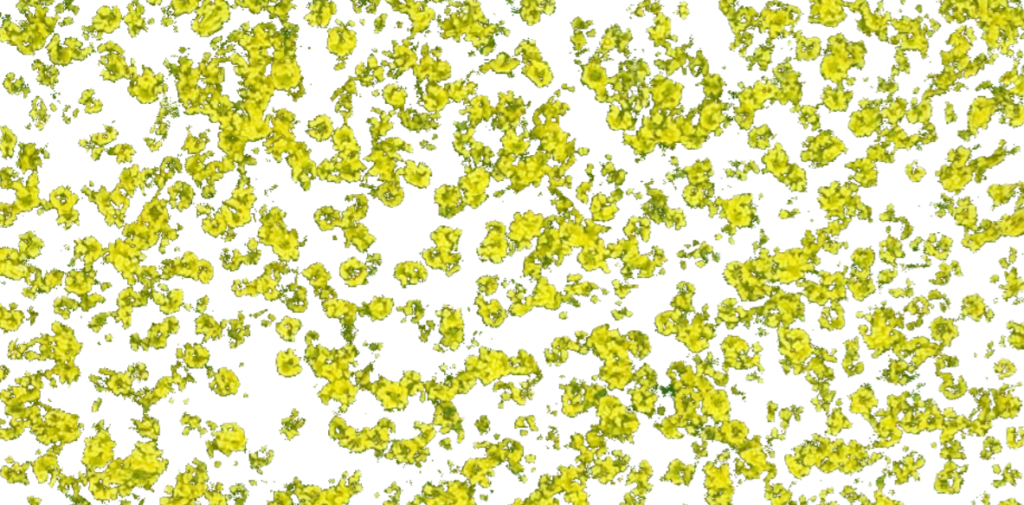

Jonathan Trotter, technology trials manager for Agrii has been operating the drone to assess the trial. He uses photogrammetry, a method in which the drone maps the trial with hundreds or thousands of high-resolution images stitched together for analysis.

He explains: “The brief from Envirofield was that Yara was interested in counting oilseed rape flowers and understanding how flowering is impacted by the products being tested. The exact details of the trial don’t concern me, my role is to help facilitate their work with the drone.

“I timed how long it took me to conduct an assessment using the drone. From opening my car door, doing the flight, packing the equipment away and finally closing the car door, it took 17 minutes!

“The drone flies across the plots at about 12 metres high. There are 40 plots, about 0.2ha, and the drone captures almost 400 images across the trial.

“Once the images are processed, every pixel equals 0.31cm of resolution,” explains Jonathan.

Agrii uses Solvi to analyse its drone images. Jonathan uploads the data to the platform, which takes about one hour to process.

Using a new tool that Solvi introduced, alongside Agrii’s experience with reflectance, Jonathan used the triangular greenness index (TGI) measurement. He explains that TGI filters out different wavelengths to remove specific colours, such as green and brown, leaving just yellow.

“TGI is perfect for only measuring flowering, which you can record as a percentage cover per plot, giving individual treatment results to monitor throughout the flowering period.

“This couldn’t have been done without a drone,” says Jonathan.

Chris Harrold, YaraVita product manager for Yara UK, says the company is investigating a range of pipeline products based on a mix of nutrients and biostimulants. Their global R&D team has found benefits in using them on flowering crops to improve flowering and pod set.

“We have been working on how we can develop these products in the UK on oilseed rape, peas and beans,” explains Chris.

“When our R&D team placed the trials with Envirofield, they requested a detailed flowering score assessment. Will Baldwin couldn’t imagine how they could accurately deliver this before drone technology was suggested.

“I saw the appeal of that, as did the R&D team. There’s a cost involved, but it’s only a fraction of the cost if we had tried to do it manually.”

The cold spring weather extended the trial’s flowering period longer than expected. Fortunately, since the drone assessments are relatively quick to conduct, Jonathan has been able to add additional assessments to cover all of the flowering.

Meanwhile the R&D team have been speaking to colleagues in Canada who expressed an interest in the work. They want to know if the methodology can be replicated in their country and if it works on other crops.

Chris continues: “Yara has been on board with the work from the outset. The results at the end of the year will reveal the benefits of the products we are testing. Regardless, I believe in the approach and can see its value in different crops and scenarios.”

He hopes to repeat the work next year to gather further data on Yara’s new products and expects the drone assessments to be an important part of the research.

Drone data enhances confidence in trials

Collecting data using drones allows Envirofield to have an archive of evidence showing how it produces its datasets from trials. Will Baldwin believes it gives companies placing trials with them confidence in their work.

He says: “We report what we find in the field at the time of assessment. The digital images taken by the drone can be revisited anytime to see exactly how the dataset was made. With traditional visual assessments, we rely on the eye of the assessor. If another party wants to look at the images, they can if they have permission.”

Will sees potential for drones to fill gaps in our understanding of new products as they go from being tested in glasshouses to small plot and tramline trials.

“What is possible in a glasshouse is not achievable in a field. If there are only one or two plants growing in a pot in a glasshouse, you can measure any physiological or pathological aspect you want in detail,” says Will.

“Once you scale that up to in-field measurement, assessment becomes more subjective due to the large area you must cover to include variability across each plot. We could use two trial agronomists to conduct an assessment depending on what is required. This helps to alleviate any unconscious bias in the data, but that doesn’t always eliminate it.”

In the short term, Will says drones will enable trial contractors to conduct assessments in the field that could previously only be done in a controlled environment. Looking further ahead, he believes they will make it possible to capture even minor differences and account for spatial variation across much larger-scale (tramline) trials and more frequent assessments possible.

He concludes: “Our job in R&D is to give growers the confidence that the data we are collecting is done in conditions that reflect growers’ actual practices.”

Drone in a box to allow autonomous operation

Although the drone assessments only took 17 minutes, Jonathan Trotter had a three-hour round trip to get to the site. Authorisation by the Civil Aviation Authority (CAA) of the ‘drone in a box’ (DiaB) concept for trial use could eliminate the travel time and allow Agrii to assess the trials remotely and more frequently.

Jonathan explains: “Fully autonomous flight would allow us to capture the data daily to see exactly when the plots started flowering, and monitor that through the whole period to count how long each plot is flowering for and how extensive it was.”

In May, Agrii installed one of the first DiaB systems to be used for trial plot data collection and analysis in the UK at one of their sites in Yorkshire. The team is collaborating with DroneAg via Skippy Scout on this project.

“For now, we must use it with a person monitoring the drone as it flies autonomously. We have to be there with a visual line of sight and be able to take control if necessary,” says Jonathan.

“This is part of the process for us to prove autonomous drone flights are safe and possible to receive authorisation for fully autonomous flights.”

He expects Agrii to receive approval in 2025. The process is complex, with authorisations granted on a company-by-company basis. The CAA assesses each case on its merits, creating a high bar for the investment required.

-

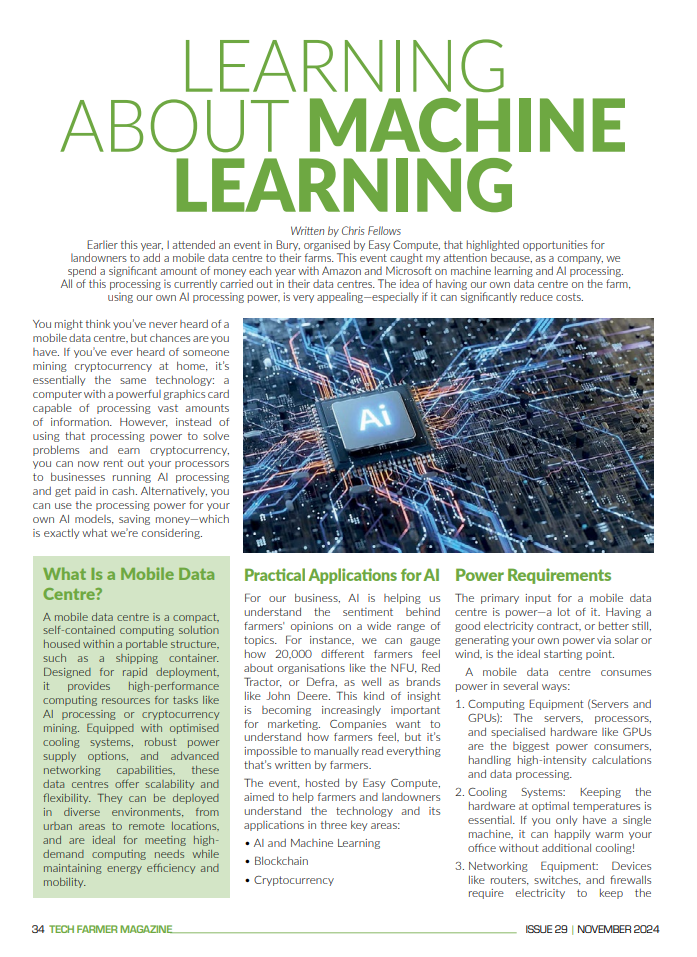

Learning about machine learning

Written by Chris Fellows

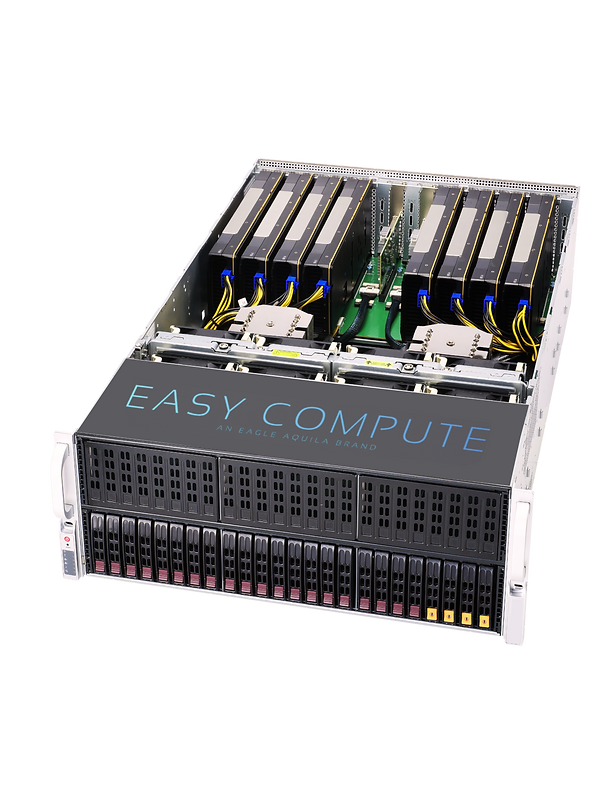

Earlier this year, I attended an event in Bury, put on by Easy Compute, that highlighted opportunities for landowners to add a mobile data centre to their farms. This event caught my attention because, as a company, we spend a significant amount of money each year with Amazon and Microsoft on machine learning and AI processing. All of this processing is currently carried out in their data centres. The idea of having our own data centre on the farm, using our own AI processing power, is very appealing—especially if it can significantly reduce costs.

You might think you’ve never heard of a mobile data centre, but chances are you have. If you’ve ever heard of someone mining cryptocurrency at home, it’s essentially the same technology: a computer with a powerful graphics card capable of processing vast amounts of information. However, instead of using that processing power to solve problems and earn cryptocurrency, you can now rent out your processors to businesses running AI processing and get paid in cash. Alternatively, you can use the processing power for your own AI models, saving money—which is exactly what we’re considering.

What Is a Mobile Data Centre?

A mobile data centre is a compact, self-contained computing solution housed within a portable structure, such as a shipping container. Designed for rapid deployment, it provides high-performance computing resources for tasks like AI processing or cryptocurrency mining. Equipped with optimised cooling systems, robust power supply options, and advanced networking capabilities, these data centres offer scalability and flexibility. They can be deployed in diverse environments, from urban areas to remote locations, and are ideal for meeting high-demand computing needs while maintaining energy efficiency and mobility.

Practical Applications for AI

For our business, AI is helping us understand the sentiment behind farmers’ opinions on a wide range of topics. For instance, we can gauge how 20,000 different farmers feel about organisations like the NFU, Red Tractor, or Defra, as well as brands like John Deere. This kind of insight is becoming increasingly important for marketing. Companies want to understand how farmers feel, but it’s impossible to manually read everything that’s written by farmers.

The event, hosted by Easy Compute, aimed to help farmers and landowners understand the technology and its applications in three key areas:

- AI and Machine Learning

- Blockchain

- Cryptocurrency

Power Requirements

The primary input for a mobile data centre is power—a lot of it. Having a good electricity contract, or better still, generating your own power via solar or wind, is the ideal starting point.

A mobile data centre consumes power in several ways:

- Computing Equipment (Servers and GPUs): The servers, processors, and specialised hardware like GPUs are the biggest power consumers, handling high-intensity calculations and data processing.

- Cooling Systems: Keeping the hardware at optimal temperatures is essential. If you only have a single machine, it can happily warm your office without additional cooling!

- Networking Equipment: Devices like routers, switches, and firewalls require electricity to keep the servers connected to the internet.

- Lighting and Security Systems: Though a smaller expense, lighting, surveillance cameras, and other security measures still require some power, particularly for 24/7 operations.

Depending on your setup, profitability is still achievable even with electricity costs of 35p per kWh. However, costs drop significantly if you have a better contract or generate your own renewable energy, such as solar or wind power, where rates can be as low as 7p per kWh. For farms already selling power to the grid, using it to operate a data centre could be far more lucrative.

Making Use of Heat

The primary “waste” output from a data centre is heat—but that’s only waste if you can’t use it. A single computer in your office generates the equivalent heat of a 2kW heater. Twenty rigs in a container will produce a considerable amount of heat, which farms can repurpose:

- Drying or Maintaining Grain: Heat from the data centre can be used to dry grain over time, reducing the need for traditional grain dryers.

- Heating Sheds or Greenhouses: Chicken sheds, grow houses, or other heated spaces can utilise this waste heat.

- Slurry and Methane Capture: Combining a data centre with systems like the Bennamann methane capture system is highly efficient. Heating the slurry generates even more methane, which can then be used to feed the generator that powers the data centre itself. This means operating a data centre would be basically free, using the methane reduces a farms carbon footprint as well. However, I’m not sure most people think of dairy farms as the “perfect” place to have a data centre! But I think they just might be.

Diversification

We all know that multiple revenue streams for farming businesses reduces overall risk. Whether that be different crops, agri-tourism, AD or renewable energy. Mobile data centres represent a low-maintenance diversification option. Unlike holiday lets, you don’t need extra staff, cleaning services, or marketing efforts. This solution works particularly well alongside renewable energy.

While this technology has been used extensively in crypto currency mining historically, this would not be the main focus for me. Crypto mining relies heavily on the price of the currencies at any given time. It builds in more risk (although prices just keep going up). Some people also have ethical issues with using power from the grid to produce a crypto currency, but there are plenty of companies that have made significant sums from coins like Bitcoin.

I remember stating proudly in 2013 that buying bitcoin was madness, at $8 a coin. Which clears up that I have made some bad decisions when it comes to crypto in the past. A £1000 investment in 2013 would now be worth £11 million today and you would be missing out on my writing skills.

A Mobile Data Centre is like an Airbnb

During the event I quite liked this analogy. It’s something many farmers are familiar with, having properties, tents or caravans to rent on their farms. If you have a machine with 5 processors in it. You effectively have 5 properties to let. You can let them short term for a higher daily price or long term to a cheaper daily rate. But you aim is always to keep you occupancy as high a possible to get most reward from your property. Having a data centre on your farm is just the same. You want to keep it rented out as much as possible.

And in the same way Cottages for You will rent out your holiday cottages for you, there are websites lie Vast.ai and RunPod that help you rent out your processors for. Companies like Easy Compute can help you with this process.

Also, when your processors aren’t being rented out for AI, you could use the spare time to generate some crypto currency. If you are happy with the risk, you could still choose to do this. With the reward you receive being variable based on the price of the coin. Some people are suggesting the price of bitcoin to rise to $250,000 while others are saying it will be worthless. While the total value of bitcoin in circulation, is worth more than the total value of the silver market, would you feel more comfortable owning bitcoin or silver?

Bitcoin price for last 3 years in USD

Artificial intelligence and ChatGPT

You may have heard of ChatGPT, which is OpenAI’s version of AI. To “teach” their AI they have processed information from across the internet using graphics cards in data centres around the world. Based on this, ChatGPT can now answer questions – and every question asked requires more processor usage. Subscriber numbers are growing the tech is being used more and more.

But the more people that use the like of ChatGPT, the more computers and graphics cards are needed to process these requests. Some of this infrastructure is owned by the companies, like Microsoft. Some of it is rented from others. And this AI needs powerful computers and these computers use GPUs. Meta (Facebook) on its own will have 350,000 GPUs in its data centre by the end of the year.

Typical computer rig with graphics cards The Costs

With any diversification, it is all about the costs. Investment versus reward. Is the waste heat worth anything to you? What does you electricity cost? When considering a bigger mobile data centre or even a single rig with 4 processors, you need to consider it within the context of your farm, your power costs and your heating needs.

A single rig uses about 1000 units of electric a month. If your electric cost 12p per unit, a 4-processor rig will cost around £120 a month in electric. This figure needs to be adjusted then for exactly what you pay, be this the price you pay or the price you export at. This could be as high a £240 a month or as low as £50 a month.

You set an hourly rate per processor to rent it. A typical rate is £0.40 GBP per hour. Ideally you then want to rent out 70-90% of the time. This generates between £800 – £950 a month in income. But like renting property, the more effort you put in, the better rental fee’s you can receive. Consider these figures a baseline.

In this example you would generate between of £560 – £880 a month. Quite a big difference. But if you can also use the heat, that might save you some money somewhere else, so there may be other factors to consider.

The Hardware

If you have been thinking, “this sounds amazing, what’s the catch” well we also need to discuss the cost of the hardware in the first place and the ongoing support to maintain the system. A single 4 processor system on a fully maintained basis (which is important if you are new to the sector) will cost circa £25,000. The good news is that is fully tax deductible, so can be offset against any tax bill.

Also based on the figures above, a system over 10 years would conservatively generate AI processing revenues between £67,200 and £105,600. There would of course be economies of scale on bigger data centres and the value of the heat has not been factored in.

The Future

Demand for AI processing is rapidly increasing and is projected to grow over the next decade. If you’re looking for a forward-thinking diversification strategy, a mobile data centre could be the perfect addition to your farm.

-

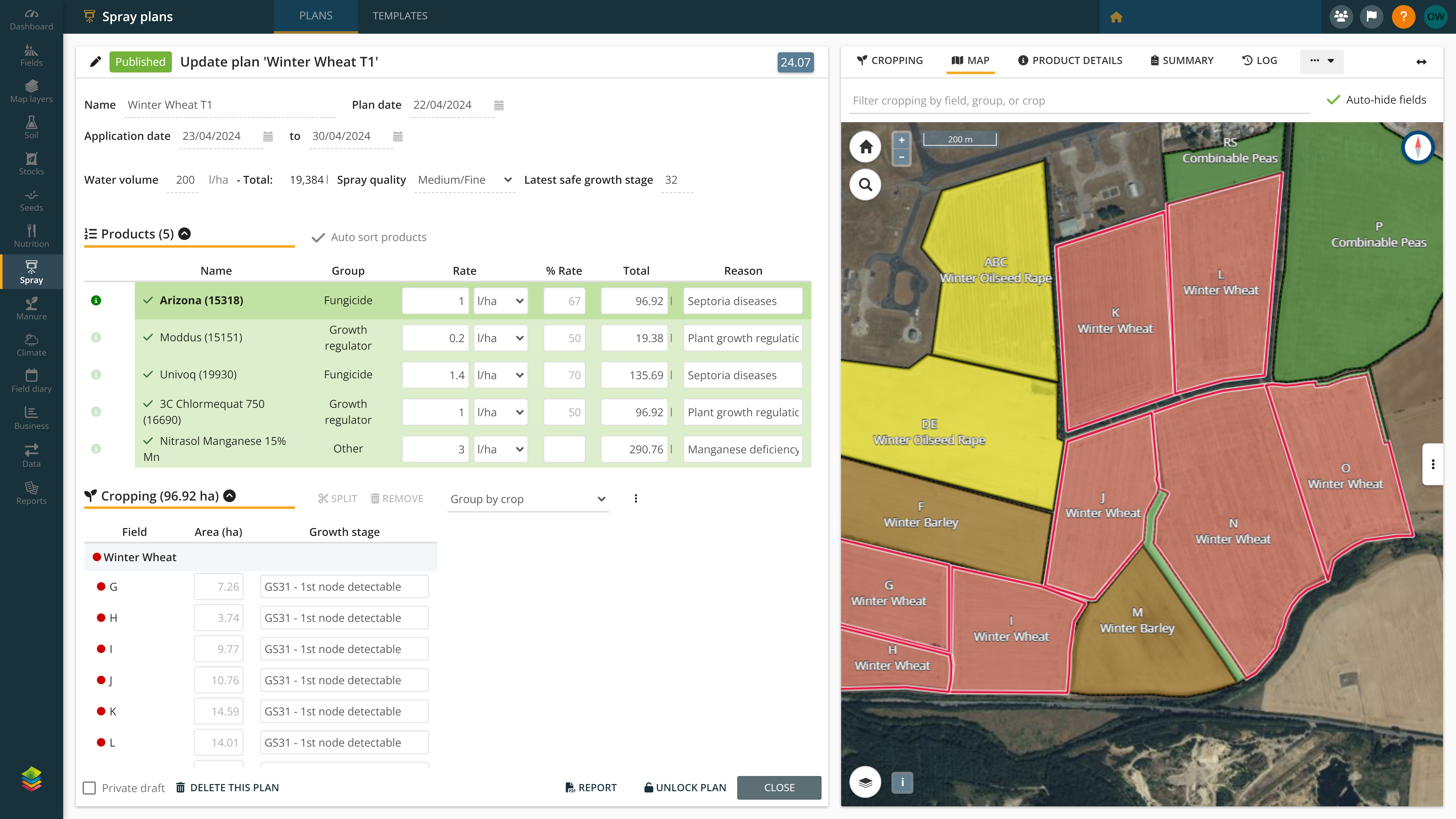

Farm management software gets an EasyPlan

New solutions are seeking to disrupt what was a stable farm management software market. Tech Farmer gets the lowdown on a major new entrant – an upgrade to Hutchinsons’ Omnia platform

Written by Mike Abram

Arable farm management software was probably due an upgrade. For years, Gatekeeper has been the dominant player in the market, with Muddy Boots – now Greenlight Farm Management – the main competitor, while Landmark with Geofolia had a loyal following.

But times are changing. Both Greenlight and more latterly Gatekeeper in March have been bought by Canadian telecommunications firm Telus Agriculture and Consumer Goods. Quite what that means for the future of either software is currently unknown.

That uncertainty plus a recognition of gaps in delivering what growers would ideally want from a system has encouraged new entrants into the arena, the latest of which is agriculture advice and input supplier Hutchinsons. It is launching its EasyPlan upgrade to further develop its digital offering, Omnia, which has over 4000 users, covering 1.5m ha of land.

Hutchinsons managing director Gordon McKechnie claims it is the most advanced, easy to use farm management system for UK growers.

Gordon McKechnie claims EasyPlan is the most advanced, easy to use farm management system for UK growers. “The updates will move Omnia from a precision farming system into a new style of farm management software. It leverages the latest digital technologies, data analytics and agronomic expertise, and provides farmers with a comprehensive suite of services.

“These services are designed to optimise crop production, enhance resource efficiency and maximise profitability,” he says.

Omnia began life in 2016 as a precision farming nutrient management tool, explains Hutchinsons head of Omnia Oliver Wood.

“Since its launch the platform has evolved into a broader digital farming system offering a range of user-friendly business modules, such as cost of production, yield mapping, rotational planning and carbon mapping tools.”