A change in circumstances meant Herefordshire-based mixed farmer, William Cawley, had to reassess his system to adapt to changes being made by his landlord. Leading to an overhaul of his current sheep enterprise, Mr Cawley now prides himself on a data-driven approach to on-farm decision-making.

Mr Cawley runs a successful mixed farm enterprise across Croft Castle and Berrington Hall National Trust estates near Leominster, in North Herefordshire.

Cawley Farms covers 550 acres of grazing, silage ground and maize, kept for the 500-head autumn-block calving dairy herd, while the sheep graze 540 acres divided across the two properties, plus a further 400 acres of combinable crops.

While Mr Cawley joined the farming partnership in 2014, his father ran around 600 Suffolk x North Country Mules for over 20 years before this.

He says: “We’d always lambed indoors, but in 2018 the National Trust wanted to take the lambing sheds back in hand as they were thought to be of historical importance.

“They were built in one of the only surviving walled gardens designed by Capability Brown in the UK and were looking to recreate it.

“With this change in mind, we had to consider what we could do to adapt without a big investment into new infrastructure.

“We saw this as an opportunity to really analyse what we were doing with the sheep – it’s easy to keep doing what you’ve always done, but the easy option isn’t necessarily the best option.”

With the upcoming changes on the horizon, Mr Cawley made the decision to switch to genetics that would meet the need to lamb outdoors.

“We were already running the dairy herd very efficiently on a low-cost low-input system, so naturally we wanted to reflect this with the sheep too,” he says.

Recognising flock genetics were key to ensuring the transition was a success, the farm looked to introduce EasyCare and Exlana ewes, known for being low-maintenance breeds with an ability to fatten well from grass and remain hardy throughout the winter.

Cawley Farms now puts approximately 1,000 ewes and 350 ewe lambs to the tup, lambing approximately 1,200 in the spring.

Mr Cawley explains: “We demand a lot from our sheep, we’re not able to grow the highest quality grass, largely down to the restrictions on the land in the tenancy agreement.

“We also can’t carry out any intensive grazing, not that the land would suit it anyway, as we’re mostly working with long-term pastures and permanent leys with multiple footpaths crossing them.

“This adds to the pressure of rearing high-efficiency animals, but in relative terms, efficiency will look different depending on the farm and individual circumstances.

“Our flock is also under a lot of worm pressure too due to the old, low-nutrient pastures.”

Data-driven performance

Key to his success in adopting new breeds, Mr Cawley places high importance on collecting data on-farm, which started with gathering data for the Signet Breeding Services database to generate estimated breeding values (EBVs).

He says: “This allows me to look at selecting the best ewes within the flock to breed from and for customers buying rams to select for the traits they’re interested in too.”

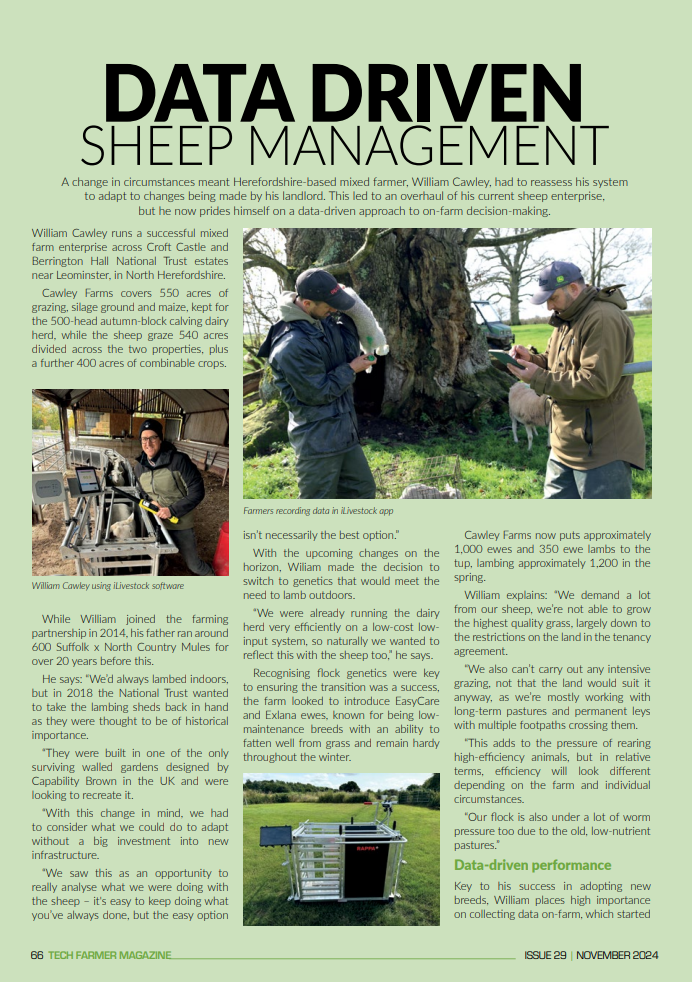

More recently, Mr Cawley adopted the iLivestock platform to improve the ease of data capture and recording.

“Since using iLivestock, we’ve ultimately been able to improve our ability to rear better breeding stock, as it allows us to pinpoint issues early and act on them quickly.”

“Before we started using the software to record data, we were doing a lot of manual recording, and it was hard to keep track of individual ewes and their performance.

“Now everything’s right there at our fingertips. Each sheep’s data, including breeding history, health records, and lambing performance, is easily accessible on our phones.”

He explains this precise data helps identify ewes with desirable maternal traits, such as fertility, lambing ease, and mothering ability.

“The software tracks traits like fertility, how easily they lamb, and how well they raise their lambs. I can see which ewes are producing the best offspring and focus on breeding from them,” says Mr Cawley.

“It’s really helped manage our breeding programme, as we can use the data to produce animals focused on a shedding maternal sheep that’s highly efficient on a low input, low system.

Mr Cawley concludes: “But it’s not all about numbers; it’s about making informed decisions that lead to better performance year after year. With the tools we have now, we’re set up for long-term success, and it’s exciting to see how the flock continues to improve.”

Affordable data management

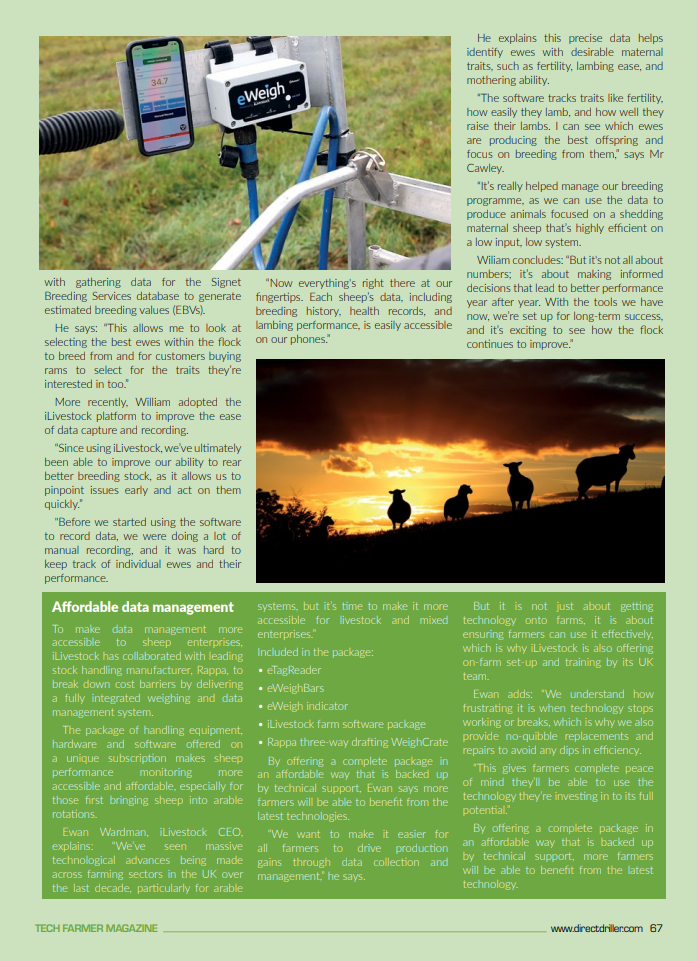

To make data management more accessible to sheep enterprises, iLivestock has collaborated with leading stock handling manufacturer, Rappa, to break down cost barriers by delivering a fully integrated weighing and data management system.

The package of handling equipment, hardware and software offered on a unique subscription makes sheep performance monitoring more accessible and affordable, especially for those first bringing sheep into arable rotations.

Ewan Wardman, iLivestock CEO, explains: “We’ve seen massive technological advances being made across farming sectors in the UK over the last decade, particularly for arable systems, but it’s time to make it more accessible for livestock and mixed enterprises.”

Included in the package:

- eTagReader

- eWeighBars

- eWeigh indicator

- iLivestock farm software package

- Rappa three-way drafting WeighCrate

By offering a complete package in an affordable way that is backed up by technical support, Mr Wardman says more farmers will be able to benefit from the latest technologies.

“We want to make it easier for all farmers to drive production gains through data collection and management,” he says.

But it is not just about getting technology onto farms, it is about ensuring farmers can use it effectively, which is why iLivestock is also offering on-farm set-up and training by its UK team.

Mr Wardman adds: “We understand how frustrating it is when technology stops working or breaks, which is why we also provide no-quibble replacements and repairs to avoid any dips in efficiency.

“This gives farmers complete peace of mind they’ll be able to use the technology they’re investing in to its full potential.”

By offering a complete package in an affordable way that is backed up by technical support, more farmers will be able to benefit from the latest technology.