Spring cropping provides one of the best opportunities for control of problem grassweeds, but with only a few of the selective herbicides used in the autumn authorised for application in the spring, growers need to plan carefully if they are to achieve the high-level control needed.

Spring weed control requires different tactics because there are fewer opportunities to stack, sequence and time the application of selective herbicides, explains Jodie Littleford, Agrii technical manager for combinable crop trials.

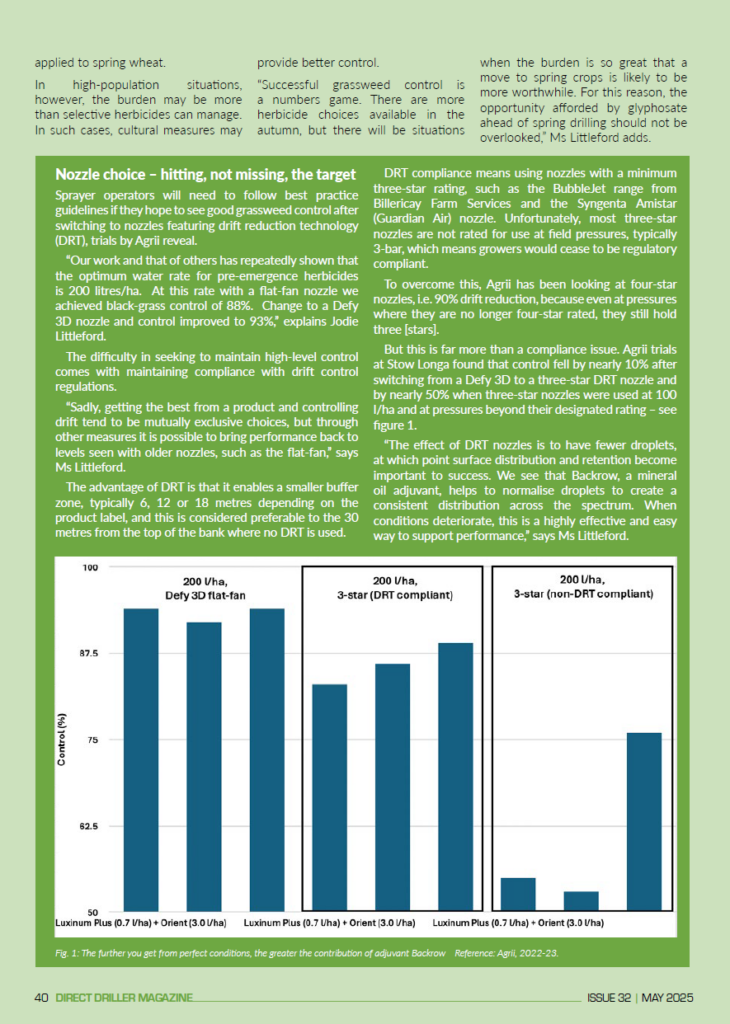

“Leaving seeds to germinate over the winter before spraying off with glyphosate ahead of drilling will do much to reduce weed populations. Our trials and other research over the past decade show quite clearly that cultural measures, which includes the use of glyphosate pre-drilling, can account for up to 95% of control. This is more than even the best selective herbicide can achieve,” says Ms Littleford.

Central to the effectiveness of cultural measures is achieving a high weed flush before drilling, as shown in figure 1.

“The bigger the flush, the better. Once the crop is sown, the means of control are far more restricted – and you have to battle the weather to apply them,” says Ms Littleford.

Fig 1: Cultural controls can account for up to 95% reduction in black-grass heads

Reference: Agrii, 2023

Agrii grassweed trials highlight the challenge when seeking to control of a range of grassweed species. The best combination of active substances for black-grass control, for instance, may perform equally strongly for brome species but is unlikely to be the best for rye-grass.

This is where is pays to identify your priorities, but there are some simple points that, if followed, will improve the chances of success, believes Ms Littleford.

- Use multiple active substances. Avoiding reliance on any one active substance or mode of action is essential to effective resistance management. Are your weeds ACCase or ALS resistant? Knowing the answer will determine your herbicide choices and potentially save you money. It is worth mapping field areas with a heavy weed burden so populations can be targeted.

- Mix modes of action. Different modes of action target different pathways. Mixing modes of action is essential to managing resistance.

- Stack and sequence active substances. Herbicides have different degradation rates. By stacking and sequencing products, it is possible to extend the period of activity and counter the atmospheric conditions, such as the above average temperatures experienced last autumn, which can enhance degradation rates and result in performance below expectations.

- Use the strongest herbicide products available. It’s a numbers game, so utilise everything available to you, including the best herbicides.

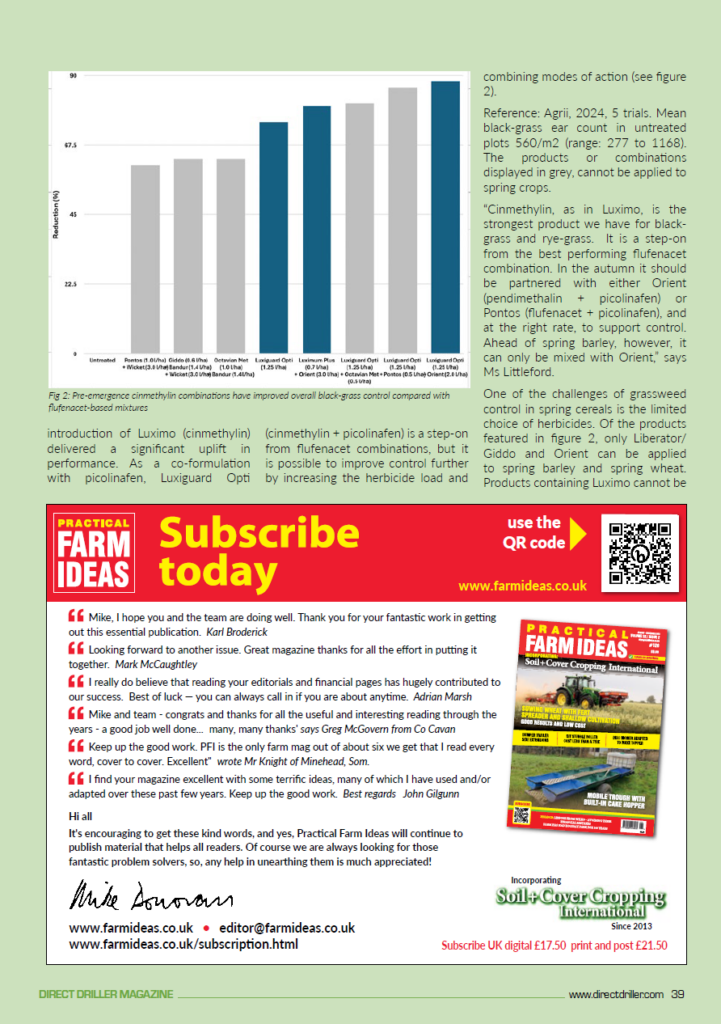

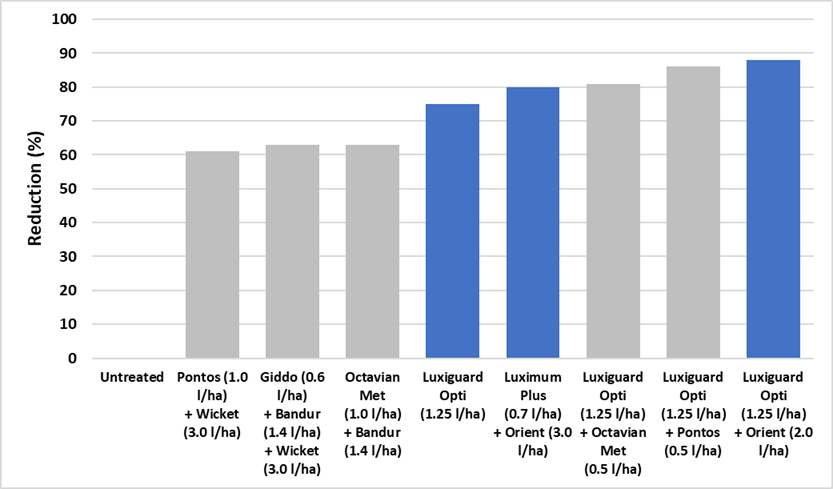

For black-grass control, flufenacet-based strategies such as those built around Liberator/Giddo (diflufenican + flufenacet), have been the basis of residual control for many years. The addition of Bandur (aclonifen) as a pre-emergence mixing partner improved overall control further, but the introduction of Luximo (cinmethylin) delivered a significant uplift in performance. As a co-formulation with picolinafen, Luxiguard Opti (cinmethylin + picolinafen) is a step-on from flufenacet combinations, but it is possible to improve control further by increasing the herbicide load and combining modes of action (see figure 2).

Fig 2: Pre-emergence cinmethylin combinations have improved overall black-grass control compared with flufenacet-based mixtures

Reference: Agrii, 2024, 5 trials. Mean black-grass ear count in untreated plots 560/m2 (range: 277 to 1168). The products or combinations displayed in grey, cannot be applied to spring crops.

“Cinmethylin, as in Luximo, is the strongest product we have for black-grass and rye-grass. It is a step-on from the best performing flufenacet combination. In the autumn it should be partnered with either Orient (pendimethalin + picolinafen) or Pontos (flufenacet + picolinafen), and at the right rate, to support control. Ahead of spring barley, however, it can only be mixed with Orient,” says Ms Littleford.

One of the challenges of grassweed control in spring cereals is the limited choice of herbicides. Of the products featured in figure 2, only Liberator/Giddo and Orient can be applied to spring barley and spring wheat. Products containing Luximo cannot be applied to spring wheat.

In high-population situations, however, the burden may be more than selective herbicides can manage. In such cases, cultural measures may provide better control.

“Successful grassweed control is a numbers game. There are more herbicide choices available in the autumn, but there will be situations when the burden is so great that a move to spring crops is likely to be more worthwhile. For this reason, the opportunity afforded by glyphosate ahead of spring drilling should not be overlooked,” Ms Littleford adds.

Nozzle choice – hitting, not missing, the target

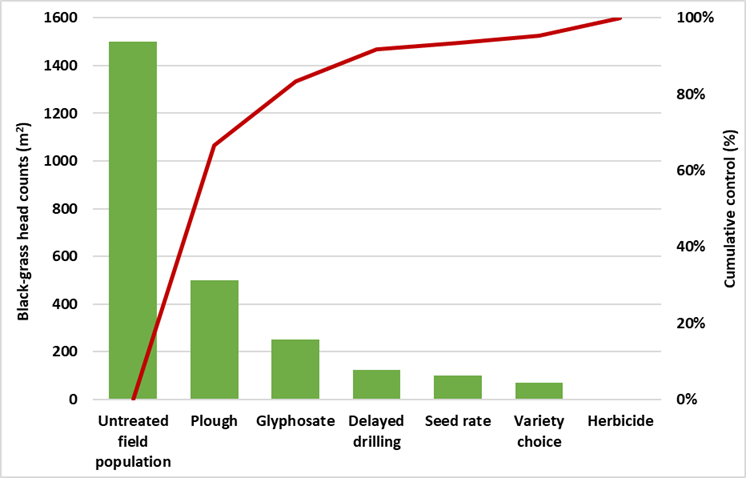

Sprayer operators will need to follow best practice guidelines if they hope to see good grassweed control after switching to nozzles featuring drift reduction technology (DRT), trials by Agrii reveal.

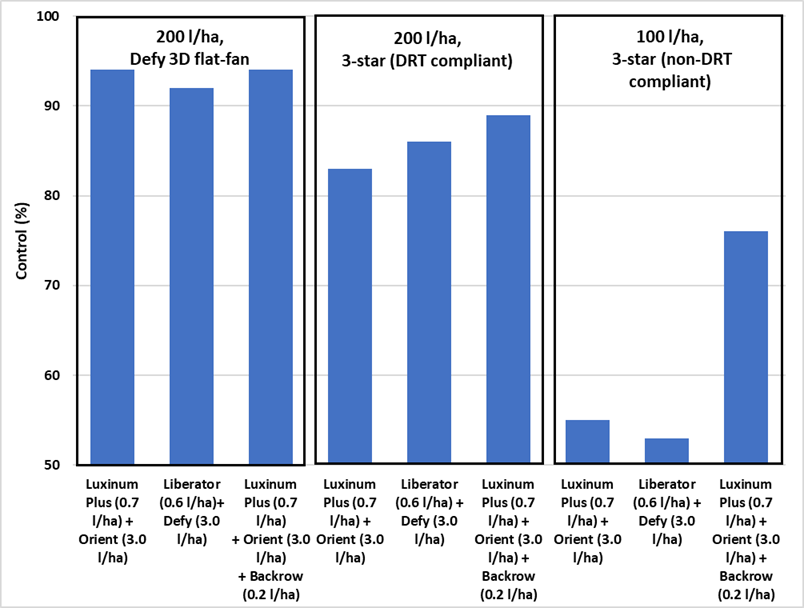

“Our work and that of others has repeatedly shown that the optimum water rate for pre-emergence herbicides is 200 litres/ha. At this rate with a flat-fan nozzle we achieved black-grass control of 88%. Change to a Defy 3D nozzle and control improved to 93%,” explains Jodie Littleford.

The difficulty in seeking to maintain high-level control comes with maintaining compliance with drift control regulations.

“Sadly, getting the best from a product and controlling drift tend to be mutually exclusive choices, but through other measures it is possible to bring performance back to levels seen with older nozzles, such as the flat-fan,” says Ms Littleford.

The advantage of DRT is that it enables a smaller buffer zone, typically 6, 12 or 18 metres depending on the product label, and this is considered preferable to the 30 metres from the top of the bank where no DRT is used.

DRT compliance means using nozzles with a minimum three-star rating, such as the BubbleJet range from Billericay Farm Services and the Syngenta Amistar (Guardian Air) nozzle. Unfortunately, most three-star nozzles are not rated for use at field pressures, typically 3-bar, which means growers would cease to be regulatory compliant.

To overcome this, Agrii has been looking at four-star nozzles, i.e. 90% drift reduction, because even at pressures where they are no longer four-star rated, they still hold three [stars].

But this is far more than a compliance issue. Agrii trials at Stow Longa found that control fell by nearly 10% after switching from a Defy 3D to a three-star DRT nozzle and by nearly 50% when three-star nozzles were used at 100 l/ha and at pressures beyond their designated rating – see figure 1.

Fig. 1: The further you get from perfect conditions, the greater the contribution of adjuvant Backrow

Reference: Agrii, 2022-23.

“The effect of DRT nozzles is to have fewer droplets, at which point surface distribution and retention become important to success. We see that Backrow, a mineral oil adjuvant, helps to normalise droplets to create a consistent distribution across the spectrum. When conditions deteriorate, this is a highly effective and easy way to support performance,” says Ms Littleford.