What happens to the fertiliser which is sown on or near the surface of No-till fields? After a decent shower we see it has gone, presumably disappearing to the root area. But what happens then? How far does it get into the soil profile? Have you got the answer?

Marion Calmer from Illinois is a farmer, farming educator, innovator and maker of headers and other maize based machinery and in 2022 he decided to find out. Through ingenious soil sampling he discovered that most of the plant nutrients, which amounted to $1,000/ac over 14 years, were left in the top two inches. 42% of P was found in the top two inches, and just 16% in the bottom 6 – 8 ins slice.

Which meant the roots stayed close to the surface, so they stopped working in a dry spell. He could see and measure the quantity of this surplus fertiliser After 14 years No-till he got out his plough and cultivator after harvest, planted cover crops in the autumn and in the spring did a deep chisel to give the soil a thorough mixing. The result was a tremendous maize crop.

At the same time he divided the soil test into one inch thick layers extending to eight inches in depth. The test sites were done where the soil differed rather than in a grid, as he wanted to see if there was a difference in plant nutrients at various depths. He found that this was very much the case.

The financial difficulties of the 1980s forced Marion Calmer to find more efficient and profitable ways of farming. After a visit to then-world-record-holder Herman Warsaw’s farm in 1985, Marion became interested in narrow row maize due to the potential yield increase and input cost reduction.

In that same year he founded Calmer Agronomic Research Centre, an independent, self-funded enterprise with the goal of discovering ways to reduce input costs and increase profitability for himself and other farmers. This involved designing and building the world’s first header used to harvest maize planted at 15 inches in 1994. In 2013 he made the first 12-inch corn head. More recently he created the BT Chopper® Upgrade Kit which is a retrofit system that enables the heads on all the top brands of harvester to manage cornstalk residue more efficiently, saving farmers time and money.

Because of his research, Marion has:

- gone from conventional tillage to no-till

- adopted the use of biotechnology

- gone from growing maize and soybeans in 40-inch rows to growing both crops in 15-inch rows

- reduced his herbicide treatments down to one pass

Marion emphasises the independence of the research done in his name, and he won’t accept any outside money for research from commercial or government bodies. He knows the data is unbiased and can be used with confidence on his farm and on others.

What happens to residual No-till fertiliser?

Farming No-till for the past 30 years has provided him a huge amount of experience, multiplied many times by seeing the results of other farmers he visits. His interest turned to the way fertiliser travelled in the soil on his farm. He came up with a way of doing soil tests at different depths or strata which would measure the weight (using American lbs) in lbs per acre of available nutrient. He took a strata from ground level to a depth of 8 inches, and measured the contents of each sample for not only P and K but pH, Ca and even Organic Matter.

The samples were taken in early November, seven months since the last application which was at drilling time, so there was no newly sown fertiliser in the soil. The measurements showed the residual which was available for the cover crop and, potentially, for the crop following. The figures clearly illustrated how the nutrients linger in the top two inches and only a small quantity get to the 7 – 8 inch strata.

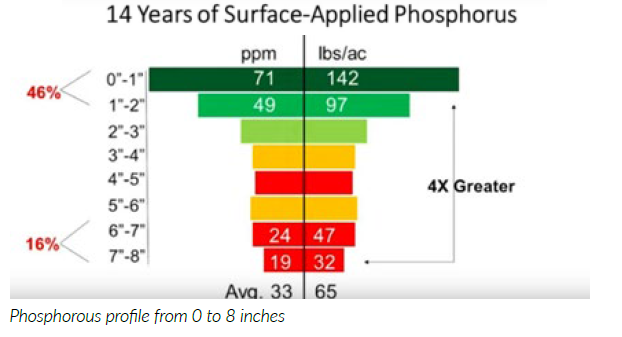

The phosphate goes from 37 lbs/ac at 7-8 inches to 142 lbs at 0-1 inch depth. Between 1 and 2 ins it has dropped to 97. The same applies to potash, the surface layer carrying 569 lbs and the 7-8 bottom section 177 lbs, an increase of 223%.

Many No-till farmers assume and are told that nutrients pass through the soil structure carried by winter rains and snow, but this test shows omething very different. The photos of Marion in the three different test areas are visual evidence of the differences in growth rate. The crop n field 1 was planted without fertiliser and had reached forearm height. It had leaves yellowing in the bottom. The crop in the second test area was healthier, taller and fewer leaves affected. The third field was cultivated to mix the soil in the 8 inch zone, and so was mouldboard ploughed, broken down with a cultivator, fertilised in the autumn and chisel ploughed before planting. This crop was stronger, taller by about a ft, and advanced over the other two.

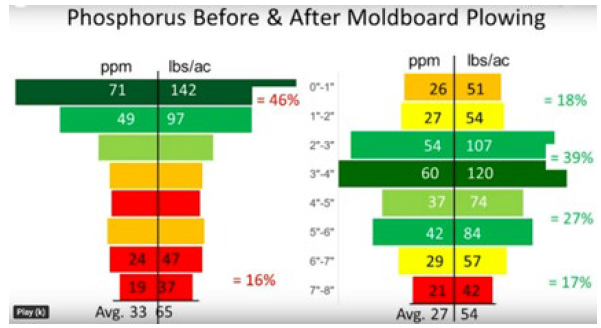

The soil sample from the ploughed land showed how the nutrients were distributed evenly with the 0-1 inch profile reading 51 lbs P/ac, followed by 54 lbs in 1-2in; 107 in 2-3; 120 in 3-4; 74 in 4-5; 84 in 5-6; 57 in 6-7 and 42 in 7-8ins depth. The plough had inverted the surface burying the nutrient into the moisture zone, putting the nutrient where it does the most good. The soil samples of each three fields were taken so to find the level of nutrients in each of the eight layers. To do this he cut them into one inch slices which were sent off for analysis. Samples were taken from the best, the median and the poorest parts of each plot in a field that has a uniform soil structure.

The maize grown without fertiliser was showing stress from the 10 week drought. The outside of the bottom leaves was yellow, indicating a deficiency in potassium. Marion points out in the video that if the yellowing occurred up the spine of the leaf the problem would be N.

The results are maybe what we might expect, but not necessarily want to see. After 14 years of fertilising on the surface, 42% of the P was found in the top two inches. In the 6-8 inch slice the figure was 16%. The available P was hanging around on the surface while the plant could use the nutrients in the root zone. The figures were the same for potash where the top inch had five times as much as the soil between 7 and 8 inches.

Stratified soil tests reveal nutrients at the top

Soil tests show that applying phosphorous to the soil surface for 14 years results in 142 lbs/ac in the top inch and 97 in the 1 – 2 in strata. The top two accounted for 47% of the total P. The lower 6 – 7 ins strata (47 lbs) and 7 – 8 ins 32 lbs accounted for just 16% of the total. The figures for potash showed similar results, with 569 lbs/ac in the top inch and 177 in layer 7 to 8 ins. Figures for the stratified samples of elements which were not added show no major variation through the profile. Soil pH averaged 5.7 and was 5.8 in the 0 – 1 in strata and 5.5 in the deepest. Ca was 4,515 in 0 – 1 in and 4,751 at 7 – 8 in; Mg 908 and 822Lbs. Base saturation was again evenly distributed for Ca and Mg, but in K was 3.5% in the top strata and 1.0 in the bottom.

Soil tests for P after ploughing and soil mixing show a lbs/ac score of 51 and 54 in then first and second inch strata, rising to 107 lbs (2 – 3 in) and 120 lbs in 3 – 4 ins. The quantity then falls to 57 lbs in 6 – 7 ins and 42 lbs at 7 – 8 ins. Soil tests for K show a similar pattern, starting with 221 lbs in layer 1, rising to 376 lbs at 3 – 4 ins and remaining at 300+ until the deepest 7 – 8 ins strata at 177 lbs. The %age saturation remains even

throughout the strata, with an average 55% for Ca; 17% for Mg; 1.6% for K. It seems that it stays on top. Ploughing, cultivating and subsoiling the highly fertile surface which had been under No-till for so many years may seem like sacrilege.

It’s not the experience which everyone has, but soils are hugely different. Over ten years of No-till is a long time for soils to lose porosity. Resisting changing the No-till system would produce the same results as in previous years Incorporating the residue fertiliser with tillage has had outstanding results for this first year, while increasing costs.

Conclusion

and assessed. Not knowing where the fertility is placed means possible waste. American experience shows that stratification encourages surface rooting so making low rainfall periods stressful for the growing crop. Fertiliser and nutrient in the top two inches are not being used

efficiently. Mechanical mixing makes the nutrients available at depths of 8 ins or more. Cover cropping utilises free N and other nutrients to build soil quality.

Stratification needs measuring more widely in the UK. There may be major differences in the soil type between here and the USA with the soils working in an entirely different way, but maybe the differences are not so great. Maybe long term No-tillers have highly fertile soil surfaces and poorer soils at depth.

Maize remains a relatively niche crop in Britain, and perhaps the stratification of soils when used to grow cereals is less significant as the root zone is shallower. Improving lower level fertility may be achieved with surface work using aerators and spiked rollers which crack hard soils.

No-till crop establishment has won the approval from the government’s Sustainable Farming Incentive, and there seem few known disadvantages.

No-till, alongside the use of cover crops over the winter, improves soil condition, involves far less work and leads to better yields. Like any technique it needs understanding, and this involves getting advice which is specific to the land in question. The nutrient stratification needs to be considered, especially before clearing out the ploughs, power harrows and other conventional equipment. They may be needed!