If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Drill Manufacturers In Focus…

FOCUS TD OFFERS STRIP-TILL IN NEW 3M WORKING WIDTH

HORSCH has launched a 3m version of the proven Focus TD strip-till line to offer a solution for smaller operations to combine strip tillage and sowing. Following customer requests for a smaller machine, the 3m model has a steel hopper with 3500 litre capacity with a partition of 60:40. In addition, a MiniDrill with an additional 400 litre capacity is available.

MiniDrill increases productivity

The MiniDrill offers a third component in the application process and increases the productivity of the machine. In the case of OSR seeding, the rape seed can be metered with the MiniDrill and the two main hoppers can be used for fertiliser, increasing the seeding output of the Focus by 40%. If the MiniDrill is used as an addition to the PPF system, the seed outlets are located in the seed bar area and can be used to apply slug pellets, for example.

The Focus TD has been designed to be an uncompromising solution for strip and conventional drilling in one machine. The TerraGrip tine system creates a deep loosened area and fertiliser can be placed shallow, deep or 50/50. The tine cultivation frame can be replaced with the DiscSystem to create a compact rotary disc harrow.

Further options

As an additional choice to the wellproven TurboDisc double disc coulter, the new TurboEdge tine coulter can be specified. It is suited to row spacings that are larger than 25cm for rape and beans. Especially suited to heavy soils or those with a lot of residues on the surface, the seed tine offers exact placement of the seed. Even if there is limited cultivation work, the TurboEdge coulter shows its advantages. In other conditions, the TurboDisc coulter continues to be the best choice for optimum precise seed placement.

A crumbling unit, instead of the levelling discs, in front of the packer provides a fine earth in the seed strip and is particularly effective on medium and heavy soils. Due to its open design and small diameter, coarse soil is easily crushed and the self-cleaning effect on sticky damp soils is excellent.

-

The Buying Game

Written by Chris Fellows

Last month I got chatting to a driver delivering chemicals to the farm, and he got around to asking what I was doing that day. I was in fact working on a new service we are developing called Farm Compare, which is designed to help farmers buy more efficiently. I wasn’t sure how well this would go down, but his response was interesting. “Great” he said. “My next five deliveries are single drums of chemical to each farm. Maybe you’ll teach them to buy in more sensible quantities”. Farm deliveries are peculiarly wasteful. The delivery driver understands that dropping off a single drum is far from efficient; and the average housewife knows that buying a four pack of baked beans is more cost effective than buying singles as well. But despite this knowledge this driver was going to drive 45 minutes to get to the five different farms. That is not efficient, and the cost of that inefficiency is being paid for by farmers. In one way or another.

What is the issue?

The fault here doesn’t totally lie with farmers who like to get the goods they need when they need them. They don’t know that they are paying a premium price for getting single drums, because they don’t know the quantity discount. And the distributors pride themselves in their ability to deliver products as an when needed, one at a time if required. The scenario gets worse as the farmer only orders exactly what he needs for any job. In industry it is ‘Just-In-Time Procurement’. The supplier holds the stock and delivers little and often. It can be efficient for the farmer but is massively inefficient for the distributor. If so, why should the farmer be interested in making a change to this supply system? The reason is that every supplier has to load the distribution costs on to the price of the product. Everyone is a loser.

Enter Farm Compare

Here is a free price comparison and product lookup tool for farmers for crop protection products. It’s a simple idea which depends on the involvement of lots of farmers. If you contribute the prices which you have had to pay for product, you can then see the prices others have paid. It also shows the quantities in each order, revealing the quantity discount. There is no cost to use it.

The aim of Farm Compare is for you to see not just the price, but how was that price achieved. what quantities are ordered generally. Where was the delivery location? Remote or central? How many packs were ordered to achieve it? When was it? In high season to be used immediately or off-season? Was the product R&D, a generic or a parallel. There are lots of questions and Farm Compare gives you the answers. You can even compare prices from one equivalent product to another. That’s not to say they are exactly the same, just that they include the same chemistry.

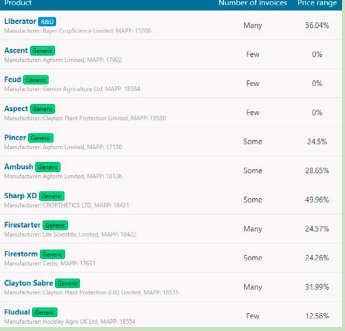

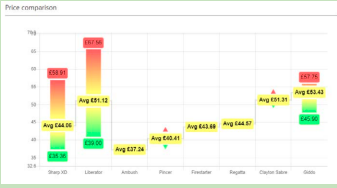

Knowing this information helps you buy better. Buying all your requirements product once and early in the year (by guessing your need) could have been the way to get the best price. But you also might have over-ordered and left with stock that could deteriorate. The buying risk is moving to the farmer, so the price paid should reflect that. For instance – most of us will use something like a Liberator. Did you know there have been 29 different products produced using the same chemistry in the last 18 months? That’s right, 29 equivalents for just one product. And the price difference on all of them are different. Here are just a few of them:

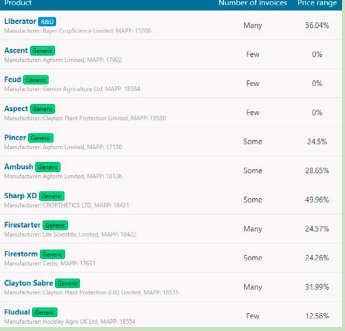

To see a price range is normal. You would expect there to be a difference between buying 1 pack and 50 packs. As the prices quoted also often include delivery, you might also expect a differential by location. For that reason, we have included filters for location. The above data is national, but you can also run a search for your region. This table is for the East Midlands:

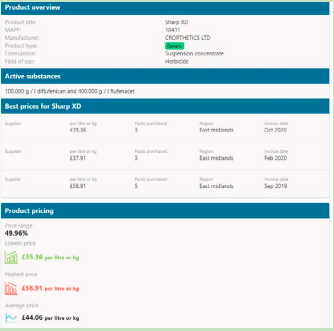

Obviously, the more filters you apply, the fewer number of overall prices there will be to compare with, but the more relevant those prices will be for you. By the way, everything you are seen so far is available to all, even if you don’t want to see more detailed information. If you just want to see what the equivalents are, then you can run those searches as often as you want. During the testing phase I’ve used it a lot myself, so we hope it will be a really simple but useful tool in every farmer’s pocket. If you have submitted prices then you can move to the next page, which gives you even more detail. This is what more detail looks like:

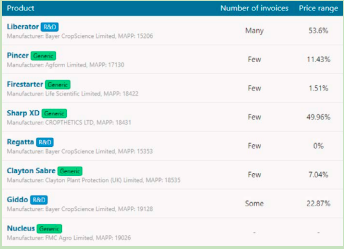

That however is just the prices for that product, and most of us are happy to use equivalents. The equivalent prices are also really useful. This is the graph Farm Compare produces to help you:

If you lived in the East Midlands, then the best prices were for Sharp XD, but there was also quite a range and that product. Pincer and Ambush gave the best average prices, with very little deviation from these prices. All prices are displayed per litre or Kg, this is so you can compare the prices where products are supplied in multiple pack sizes. Where you have bought that product or an equivalent, then your price also shows on this graph.

As a farmer you can run this same search for every product you bought last year if you want to do some benchmarking on farm performance. You can also run a search for every product you want to buy. Giving you a bit of market information to help you chose what products and where to buy them. Did you even know there was a product called Regatta? I didn’t before writing this and I feel I get to see a lot of crop protection products being involved in marketing them. Farm compare gives you all this information to help you with your buying decisions. It also helps you learn product names!

Price Transparency

The aim of this system of course is to create price transparency. This is the natural evolution of all markets. Let’s face it, if you were buying a TV you would be checking different sites, Google shopping for instance to see where the same product was for sale at different prices. You might not even buy the cheapest. You might buy the one that can deliver tomorrow. You might buy the one from the company how give you a line of credit. That’s normal in our lives. However, you can buy a 60 inch TV for the price of a couple of packs of Liberator, so why not take the same care when buying your crop protection products? Farm compare is a bit like Google Shopping for crop protection products, with a bit more information thrown in and just like all Google services it is all available for free. In fact, you can find quite a few crop protection products on Google Shopping already.

What next?

While you can now find out the best places and times to buy every product, the optimum buying year cannot really be achieved. For a start, we may not have accounts with all the suppliers, then we probably don’t need products in the volume to get the optimum price. But we have a guide for every product. But what would be useful is to know more macro decisions, such as:

• How much in total am I buying above or below the group average?

• If I was to buy from one supplier, who would be the best supplier for me?

• If I was to select two suppliers, who should I buy from?

• If I am a supply customer paying £15/18/20 a hectare walking fee (insert your own figure), would I be better off as a serviced customer?

• If I am a serviced customer, what could I afford to pay per hectare as a walking fee and move to supply only and be better off?

Strategy questions like this, will help farmers guide their businesses. Dealing with one or two suppliers is practical, dealing with 10 isn’t. Not impossible, just not practical. Being serviced also gives you more guarantees than being supply only, so that carries a price, even if it’s more like an insurance policy. These are all decisions we need to make as farmers, all it requires is a transparent system like Farm Compare to allow us to make them. Within a year, the system will also be able to answer these questions for you. All you need to do, is make some time to use it.

-

Farmer Focus – Clive Bailye

Fake news?

Harvest 2020 was never going to be great, the perfect storm of a wet autumn and winter followed by a spring drought was always going to end in disappointment. When it came to yields any usual excitement and anticipation was replaced by simple desire to clear ground of such uninspiring crops and start again in the hope of a better season next year, an endless instinct of optimism that seems bred into all farmers. As combines started rolling our fears were confirmed and average yields were the lowest I have ever been responsible for. We consoled ourselves that weather had placed the outcome beyond our control and at least the right management decisions had been made to reduce spend in attempt to maintain margin. Prices are good but almost theoretical when you have so much less to sell, solace only found in a decision made to carry over harvest 2019 milling wheat taken during the spring drought once it became clear that yields were surely going to be lower and storage space un-stretched at harvest.

As a business that farms mostly land belonging to others under contract farming agreements there is always a day of reckoning post-harvest when the results are announced. We work closely with our landowning clients to keep them well informed about crop prospects and management decisions throughout the growing season, they were under no illusion as we entered harvest that this year those results would not be great. They had been consulted when we decided to cut back on input spend and agreed it was a wise strategy given the circumstance of the season, aspirations had been firmly aligned with likely reality…………… that is until they read the wider farming press and listen to the “pub yield” chatter of other farmers. Little regard is given to how such miracles have been achieved, their different locations, soil types, input use, irrigation, and dare I say even honesty, instead they are simply held up as evidence of failure of their own farm or contractor to perform.

It really isn’t helpful, in fact the lack of honesty or disclosure of all the facts is damaging not only to contractor / farmer relationships but also in the bigger picture of leading land agents, suppliers and even policy makers to conclude farmers can afford the ever inflating prices we are subjected to. In a year where I believe my management was better than it has ever been, and my team worked harder than ever to achieve their goals, it’s saddening that success is judged as failure because of a boastful few.

So, are farmers dishonest? Does agricultural media print fake news? I like to think not, it is more a case of selective reporting and agenda surely? In the case of a farmer maybe an genetic ability to “forget” after a few pints or a sloe gin too many about the 100ac of OSR that was ripped up and replaced with spring barley whilst boasting how they “averaged” 5t/ha of OSR this year ? or maybe recounting the cost of irrigating that 15t/ha wheat crop is best forgotten along with the myriad of snake oil products and top of the line fungicides his agronomist talked him into using to achieve that headline number seen momentarily as it flashed up on the uncalibrated yield monitor when the Lexion’s hydrostatic stick was jerked backwards? On occasion the reason for yield dishonesty can be a little more calculated however, in a competitive land rental and contract farming market would the land owner be better off if they farmed the estate for them and got them these better yield they boast of? Fake news, it seems, is not only reserved for American presidents with an agenda.

Sadly, I am a little more sceptical about just why these tales of success proliferate so much in farming media. Put simply, success sells, it attracts advertisers who flock to be associated with or highlighted in the aspirational success story, and they pay the bills. It runs much deeper than just “pub yield” stories however and over the last decade or so we have witnessed the death of any independence in farming media replaced by seemingly endless paid editorial, the value of which really is questionable to our industry. Rather ironically (as founder of www.thefarmingforum.co.uk) from me I blame the internet which has all but taken over as the primary source of information for most of us, squeezing those existing publishers harder to sell their souls and integrity. Maybe I should accept some personal blame here! It’s all harmless though, right ? No one really takes all this to seriously? Well it’s certainly does not feel that way when sat down with contact farming customers in year-end meetings that much is for sure.

It is not just yields that get exaggerated though and as regenerative agriculture gains in popularity it will inevitably attract its own fair share of fake news. As farmers move away from more conventional inputs, we can be sure that an array of “soil friendly” products and machinery will compete for the same cash. Products are increasingly discounted to “influencer” farmers in exchange for good reviews and recommendations, cheap and powerful marketing for those that know how to use it. Never has it been more important to have access to independent facts and value our integrity.

It now seems clear that DEFRA’s ELMs will accelerate uptake of conservation agriculture and this will be where the money is in the future. I have just listened to George Eustice’s speech that mostly seemed to announce that there would be a series of announcements to follow but did make reference and commitment to capital grants. I have never been a fan of grants, probably because I have never yet managed to meet any criteria to get one (I’m not bitter, honestly !). Mostly because they tend to penalise innovators, and encourage those that would not otherwise have adopted change to spend for no better reason than acquisition of something new and shiny at a discounted price. This fills me with fear in the context of conservation agriculture where those with experience understand that mechanisation changes are only really a small part of what is required in a successful system, I hope these proposed grants are smarter in their targeting used to invest in knowledge exchange and re-education and do not simply serve to further line the pockets of our suppliers.

As no-till farmers we must also be careful to not over exaggerate the benefits of it brings, we all know the cost savings and environmental advantages it can deliver, but we must remain conscious of conformation bias and look to back up what we do with good solid data wherever possible. We must be realistic about size of markets for some of the niches on the fringes. I love the idea of agroforestry and incorporating more tress into our farm and have looked at various ways to derive income from them, harvesting nuts and quince etc was suggested as a possible solution to me but seriously just how big is the UK market for quince? There are maybe niche opportunities out there, but the markets are small and would fail quickly if we all jump in at scale.

I hope that policy makers are not blinded by the impressive, extreme case examples of enviable success some have achieved on the fringes. Agroforestry, rewilding and clever value added direct marketing should not be seen as some kind of blueprint for ELMs; instead the creation of a scheme more achievable by the majority of us trying to produce commodities competitively for global markets alongside our management and regeneration of the countryside and environment will hopefully result. Over the years we have been farming under conservation agriculture principles, we have without doubt added benefit to wildlife, environment and climate, with cheap food the only output we sell though there has never been any direct reward or premium attached to the natural capital provided and I look forward to ELMs putting that right.

The relief of clearing the uninspiring crops of 2020 came with a hangover, later drilling and replacement of winter rape with spring linseed led to a later harvest which reduced opportunity for cover cropping and forced later drilling dates, but surely we would not get another wet autumn?

Ironically and without planning to do so our first fields of wheat were established on 22nd of September, the same date as they were a year previously, and then equally as coincidently it started raining again. A couple of weeks passed without a wheel turning and thoughts of 2021 becoming a repeat of the nightmare that was 2020 were hard to ignore. Unlike some parts of the country, however, luck was with us and in midOctober the rain stopped and gave us the 10 days we needed to get wheat, barley and rye drilled into reasonable conditions, the sense of relief was strong, the thought of another year like the last just too horrible to imagine for all involved.

I know our memories can sometimes be short and the last 12 months serve an extreme example, but it really does feel like the windows of opportunity to establish, treat, and harvest crops are getting tighter. Without the extra capacity gained moving from a 6 to a 12 m drill has bought us we would once again find ourselves missing targets and compromising cropping because of weather. If climate change is real, we as farmers are very much on the front line and will quickly become its first victims if significant steps to put things right are not taken.

I’m conscious this is an unusually negative article for me, but the last 12 months have been tough. No farmer that cares, likes to grow a crop they are not proud of, throw in a global pandemic and looming economic armageddon and positivity is a hard attribute to maintain. Yet again however my fantastic, committed team have turned things round and today we are back on track, set up well with a good-looking set of autumn crops ready to perform next harvest. I may even start talking pictures of them and positing on social media again ……… what was it I was saying about selective reporting and farmer honesty?

-

The Future Of Solid Urea Fertilisers Is On Trial.

James Warne from Soil First Farming defends urea and shows it may well be an easy scapegoat for the rise in atmospheric ammonia levels

It seems as though we are due to loose solid urea fertilisers very soon, or at least that is the conclusion I take from reading the current ‘Consultation on reducing ammonia emissions from solid urea fertilisers’. Out of the four options given, the stated preferred option is an outright ban on solid urea use. It appears the way forward has already been decided and this consultation is just an exercise. Does this meant that for those farmers using solid urea you will be forced to move to the only real alternative – ammonium nitrate (AN)? It seems to me that urea is being target not only as an easy victory but we are also chucking the baby out with the bath water. I suggest that urea brings some benefits over and above ammonium nitrate not only for the farmers but also in a wider environmental context over AN.

Ammonia emissions from agriculture fell by 21% between 1993 and 2013, but has risen subsequently by around 11%. Agriculture accounts for 87% of total ammonia emissions in the UK. Of this around 20% is attributable to inorganic fertilisers, the largest contributor of agricultural ammonia emissions are animal manures, particularly whilst in storage and spreading.

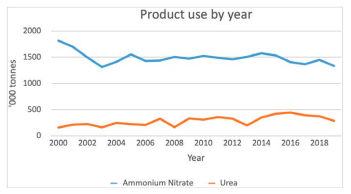

‘The British survey of fertiliser practice’ 2019 shows that total Nitrogen fertiliser use, averaged across grassland and cropping, is declining slowly and has been for several years. This seems to correlate to AIC data showing that fertiliser N consumption has been steady for the last decade at around 1030 kilotonnes (Kt) N per annum, which is well down on its peak of 1674 Kt N in 1987. While N use in cropping systems has remained steady, N fertiliser use on grassland has been slowly declining. If we analysis the data it is clear that since 2000 solid urea use in the UK has seen a significant rise (see the chart below) but has been dropping for the last few years. If urea were the cause of the increase in ammonia emissions within the last decade why were ammonia emissions decreasing in the first decade of the 21st century when there was a significant rise in urea use?

The UK has a legally binding commitment to reduce ammonia emissions to 8% below 2005 levels by 2020 and 16% below 2005 levels by 2030. Currently UK emissions stand just below the 2005 level, but projections indicate that the UK will overstep the 2020 target.

While there is little doubt that urea does contribute to net ammonia emissions its small fry compared to animal manures for instance, but it also brings some benefits too, not least where soil and plant health are considered. To understand this further let us take a closer look at the interaction of urea in the soil and plant.

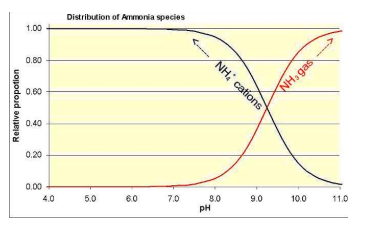

Once urea hits the soil if there is moisture and biological activity, hydrolysis (breakdown of urea into ammonium and carbonate), controlled by the urease enzyme, will begin. This is where the main loss of ammonia gas can come from. Ammonium and ammonia will sit in equilibrium with each other, dependent upon the pH of the solution. See the chart below.

The amount of nitrogen lost as ammonia volatilisation depends upon a range of other factors such as, soil & air temperature, air movement, soil CEC, crop canopy and a wetting or drying soil. The biggest opportunity for loss is likely to come from spreading urea onto a drying high pH soil. In order to minimise this loss urea should not be spread onto damp high pH (>pH 7.0) soils unless significant rainfall is predicted soon after spreading. Application to bare soil in direct sunlight without incorporation can increase volatilisation significantly. Similarly application into a crop with a good canopy followed by rainfall will mitigate losses considerably. So if we are applying solid urea to crops with a reasonable canopy typically from mid-Feb through to mid-April what is the likelihood of their being the conditions for significant ammonia loss through volatilisation?

The urease enzyme which activates hydrolysis is freely available in the soil, around 30% of the soil microbiome produces urease. When urea fertilisers are combined with a urease inhibitor it is this reaction that is controlled which can be seem as worthwhile when taken in isolation. If however your desire is to build a biologically active soil, there is some conjecture as to how much damage these urease inhibitors may do to the soil microbiome.

Ammonium within the soil is then nitrified to nitrite and nitrate principally by Nitrosommonas and Nitrobacter bacteria. This is an aerobic process that will slow down considerably in the absence of oxygen and/or low soil pH. This process happens very quickly in soils which have excess air in them, e.g. cultivated soils, but more recent work has shown that where the soil is less disturbed more ammonium tends to exist. Plants can take up and utilise nitrogen as nitrate or ammonium. Ammonium being a positively charged cation can be adsorbed onto the cation exchange sites and it therefore less vulnerable to leaching and the crop can take it up selectively and utilise it more efficiently than nitrate. Nitrate on the other hand being negatively charged is very prone to leaching and whilst soluble in the soil solution is taken up uncontrollably as the plant respires.

The crop therefore has little control over the amount of nitrogen is it taking up. This is evident in the differing growth habits of similar crops grown on cultivated and non-cultivated soils. Those grown on cultivated soils tend towards nitrate nutrition and consequently are much darker green (almost blue) and lush. This tends to make the straw weaker and more vulnerable to lodging; more susceptible to disease, particularly mildew. Whilst crops grown on no-till situations tend towards more ammonium nutrition which gives them a shorter more prostrate growth habit and gentler, more natural green. The plant it is able to assimilate ammonium into proteins and amino acids with relative ease, while it has to convert nitrate to ammonium before it can be utilised, this ‘costs’ the plant energy approximately 16% more energy than utilising ammonium.

So we believe that urea can be an effective fertiliser if applied correctly that can offer advantages over AN in terms of soil and plant health together with similar or better environmental attributes such as lower energy requirement for manufacturing per unit N, less bulk requiring less transport and lower spreading costs, easier storage for the farmer. To name but a few. It’s also clear that urea came contribute to lower nitrous oxide emissions from the soil compared to AN. Research published from five grassland trials sites across the UK in 2019 shows that nitrous oxide (a potent greenhouse gas) emissions from grassland (and presumably cropland too) are higher when using ammonium nitrate and CAN as opposed to urea. Nitrous oxide emissions from urea use were further reduced by using a stabilised urea with DCD.

So where could the increase ammonia emission come from? We know that animal manures contribute the largest percentage of agricultural emissions, but sheep numbers have been steady, while cattle numbers have been in slow decline for a few years now in the UK. So what else could be contributing to the increase in ammonia emissions? Could it be that green energy production is a significant contributing factor? In 2013 there were less than 100 AD plants operating in the UK, that figure now stands at around 600 producing around 300 MWe. AD plants produce digestate. Approximately 18,000 m3 of digestate per MWe per annum. Or 5.5 million cubic metres of digestate total per annum. The available nitrogen within digestate is predominantly in the ammonium form. Some recent digestate analysis from a crop fed digester showed it had ~ 2.5kg ammonium (readily available N) per cubic metre. The current RB209 suggest that ‘around 40% of the readily available nitrogen content of organic materials can be lost following surface application’ but this can be reduced by 30-70% depending upon timing and form of application.

So if emissions from fertilisers only account for 20% of agricultural emissions, within that 20% urea only accounts for half, why is urea being targeted? Could it be that solid urea is the lowest hanging fruit?

-

Biology Up, Costs Down The Value Of Managing Soils

Let’s get straight to it and ask a simple question: ‘Is there a monetary return to be had from managing the biology of your soil?’

With every major agronomy company now having expanding soils programs and Government, post Brexit, replacing the common agricultural policy subsidises with payments in part based on environmental empathy, what is the strategy that underpins this? In the spirit of minimum tillage let us not dig too deeply into our current predicament in relation to soils. That said, it is worthy of reminding ourselves of some of the basic facts. Only a very small proportion of applied fertilisers is ever used by our crops. Our current farming practices in relation to rotation selection and chemical usage have acted to reduce the biodiversity of essential microbes in our soils; soil organic matter is reducing at an alarming rate; and we have a worryingly short period of time to reverse this trend.

Amidst the many scientific terms used to describe the complexity of soil science the one theme that is becoming ever more prominent is the concept of ‘plant efficiency’. Put simply it is a recognition that a plant, when it has an appropriate biological community of microbes at its roots, is better able to use both native and applied nutrition. This is a fundamental concept that once comprehended begins to lead our thinking about contemporary farming, for if a plant is more efficient it will be healthier, its systemic defence systems will be stronger, it will yield more and in relation to the soils, year on year things will get better.

All things considered and hopefully understood, what can we do as an industry to redress them? Well, the ‘long game’ in this story is being supported by the major soils programmes offered by agronomy companies that seek to offer to measure of current soil status on farms, and put plans in place to change practices and planting programmes to increase the biological function of soils.

So it could be argued, we have the terminology, we have direction, but what can we do this coming spring? Recent data from NIAB TAG research and other industrial sources on the use of biofertilisers shine light on the first real practical soil interventions for use by UK farmers. The UK has actually been working on the use of biofertilisers for many years. For the sake of clarity, we are not talking biostimulants, although they are often mentioned in the same breath, but rather biofertilisers comprised of living beneficial soil bacteria or fungi. Many companies are involved in this research and product development globally, leading this in the UK is PlantWorks Ltd, a spin out from a university some twenty years ago. Its science team have been refining soil bacteria and trialling them in UK soils for many years.

The company’s SMART ROTATIONS range includes both mycorrhizal fungi products and plant growth promoting rhizobacteria (PGPR) all produced at its production facilities at the Kent Science Park using controlled growing rooms and bioreactors. The company has spent years running laboratory trials to further understand the functioning of these beneficial organisms, both alone and in consortia, and have developed and tuned a number of products for use for crops grown in UK climate. Initially the company focussed on quantifying how its liquid bacteria products, sprayed to ground post emergence, could increase yield of crops by solubilising phosphorus, fixing and capturing nitrogen and making plants more efficient in up taking those nutrients. More recently, in collaboration with all major agronomy companies, and using its own monitor partner farms, it posed the question ‘with the biology of the soils increased how much applied nitrogen can be reduced in wheat production and what is the profit achieved?’.

For those not familiar with the SMART ROTATIONS SR3 products, they are a range of tuned consortia of beneficial soil bacteria selected and tested for their ability to fix nitrogen and solubilise phosphorous. PlantWorks supplies these bacteria in sterile infusion bags taking the bacteria directly from their controlled laboratory bioreactors. The company are at pains to point out that these are not compost ’teas’, but rather pure pharmaceutical grade bacteria grown in a very stringent conditions to an extremely high efficacy point, for those interested in such things the measure of potency is referred to as Colony Forming Units (CFUs). The products are supplied typically in 5 hectare units with 1 litre of biostimulant used as a feed source for the bacteria during establishment. SMART ROTATION SR3 liquid bacteria is applied to the crop post germination, for winter wheat planted in 2020 the ideal time to treat will be in early spring 2021 (GS25-GS31).

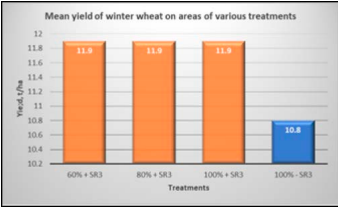

There has been a considerable body of work in the UK on the use of bacteria on wheat over recent years, both winter and spring, looking at the increment in yield alone without modulation of inputs. From a number of trials, across the UK using differing wheat varieties the average increase has been in the region of 6.0%, again attributed to improved plant efficiency. The results freshly in though are probably more resonant to a market where there is an increasing focus on farming for maximum profit, not yield and where there is an increasing sensitivity to the sympathetic management of the soil. These results are particularly interesting as the trends from three different sites are very similar. Studying the results on winter wheat KWS Zyatt the application of the beneficial bacteria shows an obvious direct effect on yield at the 100% nitrogen rate which is applied here at 260Kg/ha. Interestingly, as the nitrogen rate is reduced, the yield is actually maintained.

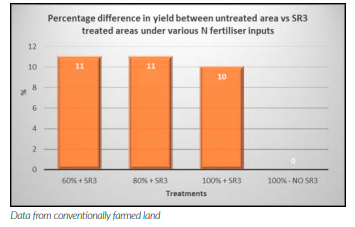

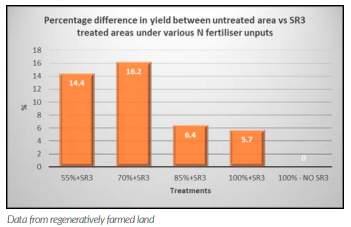

Comparing the percentage increase in yield to that the yield from the 100% nitrogen rate without bacteria application from two sites, one conventional and one regenerative, again, we see very strong correlation, which is statistically significant for those with a mathematical leaning.

Data taken directly from the combine on both farms show a consistent increase in yield when the biology in the ground has been enhanced. In the conventional system the results range from between 10-11% increase with greater variation in the regenerative system albeit the average increase is very similar.

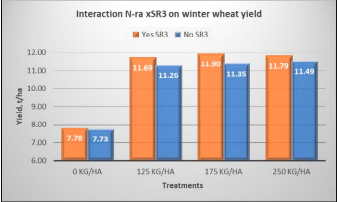

Taking into consideration the costs of the bacteria, typically at farm price of £20/ha and the extra spray run costs, reducing nitrogen inputs based on this data would achieve and incremental profit of £236/ha in the conventional system and £202/ha in the regenerative system, all whilst reducing the nitrogen loading on the soil. An independent trial undertaken by NIAB TAG designed by Dr Syed Shah, concurrently aimed to quantify the interaction of N-rate x SR3 (SMART ROTATIONS bacteria) on grain yield of winter wheat KWS Zyatt at its East Malling Kent facility.

Here a negative control is shown with wheat planted without any nitrogen input and not unsurprisingly the yields are considerably lower than those where nitrogen is applied. The data in relation to yield at different nitrogen rates is though fundamental and may cause many to reflect on their standard assumption when it comes to nitrogen best practise. Very little difference is shown in relation to yield, and indeed on wheat protein levels, when nitrogen is reduced from the standard 250kg/ha to 125Kg/ha. In all cases, where bacteria are applied, there is a clear uplift in yield, at approximately 5%.

Globally the market for bio fertilisers is reported to now exceed $1 billion a year. Not unsurprisingly industry is returning again to look at the natural biology in soils as a source of new products with the goal of enhancing ‘plant efficiency’.

-

Soil Cultivations: Ploughing, Non-Inversion Tillage And Soil Quality

Ploughing has received bad press in some organic farming circles due to the higher fuel requirements and the fact that it buries soil organisms and green material at too great a depth. The perennial questions are: should we plough and if so how deep?

Written by Mark Measures, Agricology Group Steering Member

Over many years I have remained a supporter of the plough but been actively involved in non-inversion tillage organic farming trials; the focus on minimising damage to soil life such as earthworms and mycorrhizae, avoiding disruption of the optimum stratification and depth of soil organisms, avoiding turning down manure, green manure, and the fertile topsoil too deep for maximising plant utilisation, all make shallow ploughing and / or minimal tillage a no-brainer. But it is not as straightforward as you might think! And don’t be taken in by the over-enthusiastic specialists who extrapolate successful practice in their own situation to universally applied dictates and dogma; site specific solutions are generally needed, even if we are working to common principles underlying a more sustainable farming.

Many farmers have discovered that they can do without the plough; experiences are reported in the IOTA Technical Leaflet Non Inversion Tillage in Organic Arable Cropping. This review features Richard Gantlett who has shown that with a combination of tined and duck foot cultivators, generally used in multiple passes it is practicable to operate a non-inversion tillage system on the well drained, relatively easily worked, calcareous clay loam soils of Wiltshire. This avoids inversion but still involves working at 15 – 25 cms.

More radical is the work of Friedrich Wenz of southern Germany who has developed a stockless farming system based on a unique machine, the EcoDyn. This fixed tine tool bar allows very shallow cultivations and weed control by repeated skimming of annual and perennial weeds. While in some circumstances good results have been achieved, weed control has not been as good as with a plough and where multiple passes have been made in order to get better weed control crop yields have been substantially reduced due to poorer soil structure and aeration in winter crops on heavier clay loam soils in Gloucestershire. The results from our work at The Organic Research Centre are interesting. Perhaps Wenz also found that the fixed tine, tool bar technique does not always work as well as he claimed as I see that he is now also using powered cultivators.

Direct drilling cereals into a crimped green manure is currently much in vogue, enthusiastically advocated by the Rodale Institute in Pennsylvania. They make great claims for carbon sequestration using this technique; in my experience they are unlikely to be achieved in all soil and environmental conditions. Unfortunately the research is not fully written up. The technique has not proved consistently effective in the maritime climate of the UK or in the Argentine Pampas, where I am involved. It remains one of those good ideas which has a long way to go before commercial application in the UK.

I have been motivated to put these notes together by the very recent publication of results from the long term DOC trial at FiBL in Switzerland, which includes a 15-year comparison of ploughing with reduced tillage. Read the report for the full details but among key conclusions they found: “Clay loam in temperate Switzerland: reduced tillage vs. ploughing, solid vs. liquid manures and biodynamic preparations. A synthesis of 15 years reveals an increase in topsoil organic carbon (SOC, +25%), microbial biomass (+32%) and activity (+34%) and a shift in microbial communities with conversion from ploughing to reduced tillage. Soils under reduced tillage are more stratified in SOC and nutrients……………Both higher and lower yields were harvested in the reduced tillage system in relation to ploughing. The main yield determinants were N supply and higher weed infestation under reduced tillage. Continuously reduced tillage in organic farming has been proven to enhance soil quality at this site, while also presenting more challenges in management.”

In this trial there are some clear advantages for the reduced tillage system over ploughing, which are in part due to shallower cultivations (5 cm – with occasional loosening to 15 cm – compared to ploughing to 25 cm) avoidance of inversion, and less soil disturbance at depth. This trial shows some very significant advantages for many beneficial soil organisms including earthworms and fungi. Not surprisingly the trial found soil carbon was higher in the top 10 cm layer with reduced tillage. However, unlike many other cultivation trials results, which show lower soil carbon below 10 cm, in this trial soil carbon was similar in both systems, probably due to the soil type.

Lessons learnt

Ploughing is not all bad and it remains the most effective means of weed control, it is usually essential for crops such as potatoes and it is a predictable method of seed bed creation, particularly in difficult weather conditions. So ploughing is likely to remain an option for many if not most organic farmers, just ensure that you have the right plough bodies to allow you to plough as shallow as possible.

Look at all the relevant research, observe and learn from other farmers and advisers, and develop a system and practices that are appropriate to the soil and environmental conditions in which you are working.

-

Drill Manufacturers In Focus…

STRIP TILLAGE BEST PRACTICE

What a year it has been.

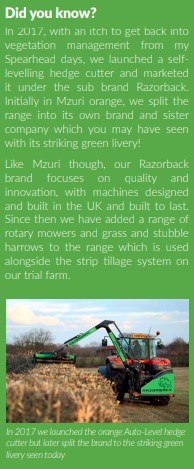

Now that we are nearing the end of this unforgettable year it is a good chance to look back and reflect on what a year it has been and just how encouraging it has been for us growing the Virkar Brand in the UK. The Virkar brand is rapidly growing here in the UK and coming off the back off a highly successful autumn demonstrations programme where we had to deal with some particularly challenging autumn weather. 2021 looks to be even better. With more drills working on farms across the country, new Virkar products being launched, and the continued growth of Virkar in the UK. Next year looks to be very encouraging for us.

2021 Changes to the Virkar Dynamic DC

Having our own test farms allows us to constantly evaluate the drills performance and strive to always develop it further. Having our own farms means we can relate to our customers and understand exactly what they need in a machine. Knowing our product like we do and using it on our own farms gives our customers confidence in the machines and peace of mind that we will always be there to offer support.

One of the changes has been the cooperation along with JJ Metcalfe to now be able to run their low disturbance seeding point on the Virkar Dynamic DC drill. Having run and evaluated this point on our demo drill this autumn it has performed incredibly well and moving forward it will now be an option to choose between the standard Virkar point or the JJ Metcalfe point.

Other changes to the Dynamic DC for 2021 is a new inhouse built Virkar ECU for the drills electronic control of all major function, which has greatly reduced the amount of cabling on the machine. Combined with other updates that include the main hydraulic lines being upgraded to improve the machines longevity and general performance. The ethos of the Virkar Dynamic DC is to maximise performance and crop establishment, combined with low operational costs. Having machines including our own carrying out operations on some very stoney clay capped ground has allowed us to really get a sense of true running cost in terms of wearing parts.

Something else we are working on is the ability to use the drill as an inter row hoe. The factory is currently evaluating several point options and we are hoping to carry out field trials in the Spring. We are seeing a big increase in interest for inter row hoes as farmers are looking for ways to reduce their reliance on herbicides. With the way the Virkar Dynamic DC works and the coulter design with contour following and on the move pressure control as well as the steering rear axle which ensures the machine is always running true behind the tractor, makes the drill a good starting point to try inter row hoeing in a direct drilling system. If testing goes well in the Spring then this feature enhances the drill even further to set it apart from the competition.

Wider Dynamic DC Drills coming 2021

Virkar have been working on and will be out testing in early 2021 a nine meter model of the Dynamic DC. The plan is that this new range of wider drills will be on a completely different chassis design and eventually they will be able to offer widths from 9-13.5 meters in this configuration. Like everything Virkar do their philosophy is to build the highest quality machines. Virkar wishes to listen to farmers and at the same time provide a modern and technological outlook, thanks to its multidisciplinary team, to create high quality and reliable machines whilst keeping them easy to operate with a high degree of innovation.

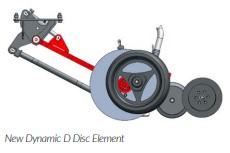

New for 2021 is the direct disc coulter version of the drill. The Dynamic D has been thoroughly tested in tough Spanish conditions for 2 years. The coulter design means it can mount into the same frame as the Dynamic DC drill meaning you keep the modular design with all the benefits this provides, widths from 4.5-7 meters will be available with 19 or 25cm row spacings.

The coulter arms are maintenance free, they have sealed bearings and bushed everywhere there is a pin. The coulter design means you get 35cm of travel for contour following, with on the move coulter pressure adjustment, and only one manual adjustment per coulter leading to quick set up time in the field. Again, the drill can be specified with 3 hoppers and various other options.

We already have a lot of interest in the Dynamic D mainly due to its contour following capabilities, and the simplicity and ease of use. This machine now allows us to offer both methods for direct drills, which Is only going to help us moving forward into 2021 growing the Virkar brand further. The plan for us is to have one on show at the Groundswell event in June as well as running a demonstration unit in the Spring to run alongside our demonstration Virkar Dynamic DC. This December marks two years since we first came across the Virkar brand. Who knew from watching a video of the drill online we would now have numerous drills running across the country, a demonstration book already nearly full for the Spring and that is before we have got our hands on the new Dynamic D drill to showcase to farmers/contractors.

It is clear to see that the Virkar brand will go from strength to strength in the coming years, and 2021 is very much looking to be busy, but we would not have it any other way.

-

It’s In Our Nature…

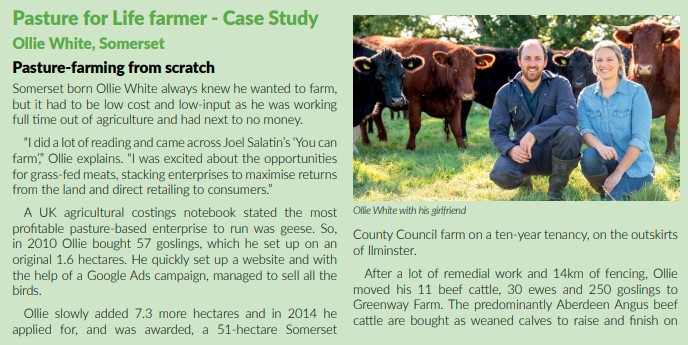

James Warne from Soil First Farming defends urea and shows it may well be an easy scapegoat for the rise in

atmospheric ammonia levelsWhen I have something on my mind I tend to reach for a cup of tea and a biscuit. Those who have seen me will be able to verify this happens often. This is exactly where I had gravitated to one wet Saturday morning two years ago after paying another round of chemical and contracting bills and it was apparent there was going to be very little margin even if we did have a good year. I sat at the table and opened the country section of certain Yorkshire paper. There was the article penned by Angus Gowthorpe in which he spoke of his farming method “conservation agriculture” and his association to BASEUK. That article has led to a great many things for me.

I originated from a small livestock farm near York and have found myself on an Arable farm in East Yorkshire. I have no previous experience of Arable land management, cultivation or cropping. A recipe for disaster if there ever was one. Possibly it is a blessing as I have no preconception of how things should be done, and ignorance is bliss. The ethos of what Angus had written resonated with me, so I applied for my BASE membership and embarked on my voyage of discovery.

A few farm visits ensued to people who were practicing regenerative agriculture methods, and these were a real insight into what they were encountering. How the principle adopted translated into the practical. Mostly I loitered at the back hoping not to trip myself up by saying something stupid but absorbing as much information as possible. Everyone was very welcoming, and I felt confident to attend my first BASE AGM.

Two days of guest speakers. I will admit it was with some trepidation that I took my seat on the first morning not knowing anyone or what to expect. Those two days were like a light bulb moment! I learnt about soil, soil health, physical, chemical, and biological indicators. Financial costings, worm science and so much more. The whole event was recorded for members who could not attend to access later. I returned to the farm with enthusiasm. Previously the only time I might have got close to making holes in the ground or sniffing soil was if I had fallen off a horse. Now here I was with my shovel counting worms, really looking at the soil, what the structure was like, getting soil samples, doing filtration tests. I had begun to ask questions and look for the answers. The photograph above shows our first attempt at direct drilling…. Spring Malting Barley.

It was very clean all year although drilled nearly 3 weeks later than the more conventionally established only yielded slightly less. The lower chemical and cultivation cost made up for any yield deficit.

The first time I asked my contractor to put a molasses like substance through his expensive sprayer with the liquid fertiliser there was a raised eyebrow. To his credit he went along with it. I am not completely sure who was the most relieved when it all went without a hitch. I may not know a lot but have been incredibly blessed to have a fantastic agronomist and great contractors supporting me throughout. From the AGM I learnt about Groundswell and that is where I headed next. BASE has opened the door to a great many things. Recommended reading lists have provided a wealth of information, Farming Forum, Agroecology, and pod casts.

This year’s AGM was held at York pre pandemic. Speakers included Dr Sam Cook from Rothamsted Research, Dr Lea Harold from the PGRO, Edward Dickin on plant breeding, BASE-UK Member farmers, and scientists but for me Dr Anna Krzywoszynska was a standout. She spoke of “geosmin”; a chemical released from dead microbes in soil and how the human body can detect this smell in minuscule quantities, an evolutionary hangover that has the ability to lowers the heart rate – amazing! We need to trust our instinct. She spoke of the communities of practice, how we learn, seeking information, motivation, experimenting and how psychologically hard it is to make a change on your own. BASE has given me that community of support.

Especially welcome through the COVID-19 pandemic BASE has held webinar meetings, again, all recorded with BASIS and NRoSo points available. The quality of speakers throughout has been inspiring, diverse and educational. From mob grazing systems to the Lamport research trials to Fredric Thomas to name a few. BASE manages to cater for the novice like me to the very experienced.

The photograph above is of some of the expanding sheep flock as we start to get some livestock incorporated into the arable system.

The pandemic has highlighted how important conversation and a sense of belonging are. Normally I would play badminton, go swimming, attend a competition with the horse or head off to the livestock market and all that social interaction has gone or is seriously restricted. The Zoom meetings have been fab and best of all, if I look a bit of a mess, I can keep my camera off.

I have had many a night in the last two years laid awake worrying about if I could manage the task ahead of me. Was I making the right decisions? Will the cost of cover cropping be worth it? The intake of breath through gritted teeth from people who have farmed this type of land when they hear of my next step. It does really make you doubt if this moral path is right, after all “the road to hell is paved with good intentions” they say. No doubt there will be some failures along the way. From John Wooden the quote, “Failure is not fatal but failure to change might be”.

Male, female, young or old, the demographic is irrelevant. If you have an enquiring mind, then BASE-UK membership has something to offer you even if it is just to have a support network of likeminded people working towards a common goal to make agriculture more sustainable for future generations.

-

Farmer Focus – Neil White

Harvest now seems like a distant memory; thank goodness you say! We seemed to get away reasonably light here in S.E. Scotland compared to many others around the UK. I still run two systems on some crops, and I can compare the results rather than wonder what if?

It started with the poorest crop this year, winter barley. The direct drilled and plough/ combi drilled crops were equally poor, at best 2/3 of an average crop but easy to cut and dry. I have struggled to get my strip tilled winter barley to match my plough/combi yield and although close this year it was again below. It was obviously much cheaper to establish but I think the fact my winter barley is at the end of my rotation may be causing a delay in the improvements shown by the other crops.

My Mzuri sown Diablo spring barley matched my plough combi drilled yield this year and that was all above my 5-year average. The TGW of the barley was greater on the Mzuri sown ground, which was as I had hoped, the wider rows allowing light inception and a fuller grain. The Mzuri sown Canyon spring oats, for Quaker out yielded my plough/Combi drilled oats by over 1t/Ha and cost 1/4 of the establishment cost. The oats sown after the plough struggled in the dry spring (as I show on YouTube) and never caught up. The wheat was all sown with the Mzuri and like most in the area was very bold but mostly below average. The spring beans sown directly into overwintered stubble were the highlight at the end of my harvest, they yielded well above average and were a first-class sample. The beans went in well and the lack of soil disturbance retained the moisture, that gave them the great start shown on YouTube and Instagram as I love walking in them.

I continue to look for answers regarding the winter barley and there is a lot of advice out there. As well as reading this magazine, I follow lots people and businesses on Instagram and online. The Soil_doctor is one which provides lots of information which stimulates thought, although not always easy to apply in my situation. They recently had a periodic table of cover crops which was very cleverly laid out and worth a look. My version of cover cropping this year also incorporates my favourite form of muck spreading, it is on around half my spring oat stubble which will be over-wintered, spread with calcium lime and then drilled with Diablo spring barley. The stubble had a good cover of volunteer oats growing in it and a small flush of weeds which developed late due to the dry spring.

I called a neighbour whose sheep graze my TGRS, he provided another batch which have now had a month on the stubble tidying it up and adding some manure without the compaction. The benefit of the grazing and muck may be minimal, but the lack of traffic involved can only be a good thing for my soils.

According to a recent BBC news article England uses only 0.41% of its environmental monitoring budget monitoring soils! This seems mind blowing considering we know how important a healthy soil is and as farmers we have been testing soils for a considerable time now realising what we do has a big influence on them.

Scoring your soil using VESS scoring system is something SAC promote and while I am not necessarily using this system I do frequently walk, dig and examine the soil as this is a simple guide to its condition. Trust your eyes and nose, I read recently that we have in our DNA the ability to recognise healthy soil by its smell, this check is cost free. In September, having held off last year due to the wet conditions, I spread the ash from my biomass boiler on some of the less favourable heavy clay patches in some fields. While this is a very blunt instrument this has helped soil condition and achieve more tilth and a more even crop emergence.

I am using Solvita burst soil testing and while the results were relatively good to start with, I have noticed a great improvement in my soils in the relatively short time I have been direct drilling/strip tilling. The structure of the soil has visually improved in this time and I am now beginning to re-test some of the fields direct drilled from the start in 2015, they have been ploughed 1 or less times since then. I know that true direct drillers would maybe say my approach, still using a plough in rotation, is a bit like claiming your a vegan and having meat once a month but I can’t yet remove the plough completely from my rotation. The shame of it!!

Some of the soil damage is being caused by harvest machinery. I have written before about trying to look at cause rather than mechanical cure. This has been a costly exercise for me, my combine was overdue a change so putting my money when my mouth is I ticked the track and the power spreader options, two things I feel can play a big part in improving my soils. The tracks will reduce the compaction caused in the less than ideal conditions we, in Scotland, are often forced to cut in. This will allow me to raise the leading leg on my drill, and the spreader is a must as a good spread of chopped straw is essential for my system.

Establishment of winter crops this year has been good with challenges similar, but much less extreme, compared to last years. Early sown crops have fared the best with record high rainfall in October compromising some later crops and calling an end to some farmers autumn campaign. Where we are in SE Scotland once the weather and soils turn wet, they can often stay wet until spring. I drilled wheat for a neighbour in October this year. A 5-year grass ley, sprayed off, then wheat sown directly with the single coulter. This was the first time I had done this and despite the front leg running around 6 inches deep the single coulter left a narrow almost minimum disturbance finish, and the crop has emerged well.

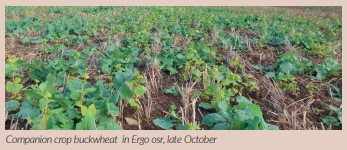

I have tried some companion cropping this year in my OSR. We do not have the severity of flea beetle problems experienced farther south but like a few farmers in this area I thought I would try some companion crops so I had experience of what may work up here. I have tried a block of Buckwheat and a block of Berseem clover in my OSR, each mixed with the slug pellets and spread out the pelleter on the drill at sowing. I was putting fertiliser down the leading leg on the drill, OSR seed at the coulter then pellets and companion crop down at the harrow rather than mixing the companion with the seed in case it settled in the hopper. The buckwheat has established well whereas the clover has not.

The suspicion is that the preem which was deemed ok for clover may have found its way to the seed and killed it off. My conclusion from the trial so far is, if your growing Buckwheat put in a sacrificial crop of OSR as buckwheat seems to grow well but the predator here is more often slugs which still prefer to eat OSR. It is good to know the buckwheat established well with this method and now the frost has killed it off maybe it will leave some fixed nitrogen, providing a benefit and an option for the future. Maybe something which slugs prefer to OSR would be a better companion!? I will have another go next year. I have mixed wheat varieties again this year in some fields, mixing seed in the drill, then treating the whole field as the lower input variety. I find this works well.

I know I am not as brave as many other contributors to this magazine, I do have very low establishment costs and I am beginning to reduce fungicides and insecticides on my farm, and as my soils improve I hope I can go further each year.

-

Sharing The Strategic Farm Results

Teresa Meadows, AHDB Knowledge Exchange Manager, East Anglia, takes a look through the season and findings from the Strategic Cereal Farm East and West demonstrations for harvest 2020.

As we come into the autumn time, it gives an opportunity to look back on the last harvest – yields, costs, margins and wider improvements to soils or biodiversity achieved over the previous year. Whilst harvest 2020 will be a year to forget in so many ways, there are always lessons that can be learnt along the way. Reflecting on the last season of results from our AHDB Strategic Cereal Farms in the East and the West, this is certainly the case for them too.

The difficult conditions in autumn 2019 and spring 2020 meant that establishing a crop was a real challenge for Rob Fox, Strategic Farm West host in Warwickshire. With much of the OSR area needing to be re-drilled and wheat not able to be drilled at all, alternative solutions were sought to take advantage of the situation. This included the establishment of a summer catch crop area to look at the advantage of having cover in place vs the stubble for the following crop establishment, nutrient uptake and more.

Over in the East, Brian Barker, the farm host in Suffolk had patchy establishment in some areas, challenges to spray off cover crops with enough time to drill the following crop and making decisions on what to do with the opportunity to lower inputs in what resulted in a largely low disease pressure year.

The results from the findings of these trials and demonstrations and other longer running demonstrations on-farm, can be found summarised below. Full details including the reports, graphs and costs are available to download from the links at: https://ahdb.org.uk/sfweekwinter-2020.

STRATEGIC CEREAL FARM EAST

How to manage lowering fungicide, trace element and biostimulant inputs and harnessing varietal resistance

This trial has been looking at how to use varietal resistance as a way of reducing fungicide inputs. Five varieties were assessed (Siskin, Crispin, Santiago, Graham and Shabras) and four programmes of increasing cost were overlaid (untreated, low, medium and high). As harvest 2020 was a low disease pressure season, the results showed that growing more resistant varieties with a low input regime gave the best net margin in this year.

There was a minimal yield response to increasing fungicide spend on the resistant varieties with the low inputs, showing the best net margins. In this year, the highest percentage of septoria was seen on the most susceptible variety, Santiago. The more resistant varieties (i.e. Graham and Siskin) tended to hold onto green leaf area for longer. Varying programmes according to the season, looking at, knowing and harnessing the varietal resistance can certainly work in this kind of season.

Boosting early crop biomass

This demonstration has been looking at whether using a starter fertiliser, either placed or broadcast, is effective at boosting biomass in the autumn. Establishing crops later in the autumn, due to black-grass and BYDV pressure is balanced with the knowledge that crops that yield well have good biomass from the autumn. This demonstration was looking at if it was possible to boost this further with later-drilled autumn crops. The results from this year showed that there may be yield benefits from broadcasting kieserite and possibly TSP at planting where soil nutrient indices are low. However, established plant populations in both fields were fairly low and crop development was slow over winter, due to the season.

On one of the fields, broadcast kieserite and TSP appeared to increase yield by up to 0.4t\ha, whilst polysulphate showed no yield benefit compared to standard farm practice. The results from this work haven’t drawn large conclusions in terms of final yield results, but will be something to bear in mind as we go forward about using this option at drilling.

Cover crops and water quality

Cover crops are well known to have a positive effect on water quality and soil structure. The results from this trial have reinforced those conclusions, demonstrating that a well-established cover crop is effective at improving water quality by bringing nitrate concentrations in drainage water below 50 mg/l. Four different methods have been looked at this year, the second site that we have used the same principles – an area that was ploughed; an area that was ploughed and then a cover crop (rye, buckwheat, phacelia, oil radish, sunflowers) established; an area that was overwinter stubble and then an area of over-winter stubble with a cover crop drilled using a strip till drill at 33cm row spacings.

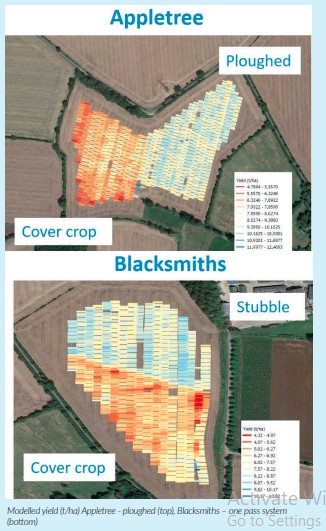

Soil structural assessments (completed on 14.02.20) using Visual Evaluation of Soil Structure (VESS) scores also indicated that the soil on the ploughed field, Appletree, was classed as being ‘firm’ with some angular non-porous aggregates (i.e. clods) present; whereas in the one-pass system on Blacksmiths, the soil structure was better (i.e. friable/intact) containing more porous aggregates and no clods. Bulk density within the cover crop-ploughed area was marginally higher at 1.57 g/cm3 compared to no cover crop-plough suggesting the soil was more compact which could have impeded root growth.

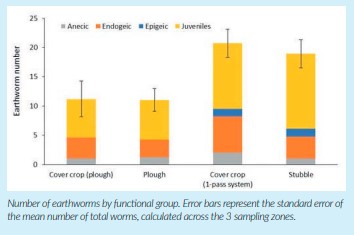

A good number of earthworms were also recorded across both of the trial fields (i.e. more than 8 per pit), mainly comprising juvenile and adult endogeic (topsoil) earthworms. Overall number of earthworms were greater on Blacksmiths, which was cultivated using a strip-tillage one-pass system (mean = 20) compared to Appletree which was ploughed (mean = 11), with no difference between areas with or without cover crops. Epigeic, (i.e. surface/ litter dwelling) earthworms were recorded on Blacksmiths but not Appletree fields; this corresponded to there being more surface trash following the one-pass system, compared to ploughed. The overall greater number of earthworms and presence of epigeic earthworms on Blacksmiths compared to Appletree, indicates that ploughing maybe having a detrimental impact on both overall earthworm numbers and community structure by reducing the availability of surface trash and disturbing burrows.

On both fields, the mean yield measured within the cover crop area was c.1.7 – 2 t/ha lower (95% confidence interval = ± 0.24 t/ha) than the ploughed treatment at 8.1 – 8.3 t/ha. Drilling the cover crop after autumn ploughing, caused some surface soil compaction and Brian Barker noted that it was harder to drill the spring crop; the slots did not close and pigeons ate the seed. The cover crop area on the one pass system also led to wetter soil conditions at spring crop drilling, with more slug damage. Throughout the season, on the cover crop treatment the spring crop was consistently ‘behind’ compared to the overwinter stubble treatment.

This final result was different to the result from harvest 2019, which showed a positive yield effect after the cover cropped area. This variation in yield (both positive and negative effects) has also been noted in the AHDB MaxiCover Crop research and wider research. It is learning this balance between the original aims for using cover cropping on-farm, which species to use, how to manage their establishment and destruction and release of the nutrients through the following crop that are questions to still be discussed and shared.

Conclusions from this work do continue to show the many benefits of cover cropping to water quality and soils. Furthermore, in the spring if wet soil conditions are likely, allow soils to dry out by leaving a large enough ‘window’ between cover crop destruction and spring crop drilling.

Very low inputs – how low can you go?

A 3.1ha field was also used at the Strategic Farm East this year, where Brian went as low as he felt that he could go with inputs through the season. During the harvest 2020 season, this resulted in a total fungicide spend of £12/ha, a yield of 9.43t/ha and a cost of production of £67/t. Given the low disease pressure season of harvest 2020, these results suggest that there is little benefit in increasing fungicide spend to improve gross margins. Do we have the evidence, in-season monitoring and forecasting and information available to do this at scale going forwards?

STRATEGIC CEREAL FARM WEST

The impact of cultivation depth on soil properties, rooting and yield

The aim of this trial is to determine any differences in soil quality and health, crop rooting properties, yield and cost of production between cultivation systems. Starting in 2018, with three cultivation depths at 5, 15 and 30 cm depths before the addition of direct drilling in 2019, this trial will continue for the duration of the Strategic Cereal Farm West programme. OSR was established in this trial field for harvest 2020 and the results showed the importance of moisture at drilling for OSR. Minimal cultivations and direct drilling can both help to maintain moisture levels for better OSR establishment. Crops that are establishing slowly are at risk from CSFB attack.

As a result, poor plant establishment and fewer plants were found in the deeper cultivation treatments (15 and 30cm) than the shallow cultivation (5 cm) and direct drill treatments. In general, more CSFB adult feeding damage (as % leaf loss area) was found in the treatments with deeper cultivations (15 and 30cm cultivations) than the 5 cm cultivation of direct drill treatment. Additionally, fewer larvae were found on the deeper cultivation treatments (15 and 30cm) compared to the shallow cultivation (5cm) and direct drill treatments, in both November and January (P<0.05).

The average measured yield for harvest 2020 for the 30cm treatment was 2.22 t/ha with yield differences for the treatments showing: 15cm: -0.09 ± 0.51 t/ha 5cm: -0.70 ± 0.50 t/ha Direct drill: -0.53 ± 0.58 t/ha.

The impact of summer catch crops on soil physical properties and performance of the following crop

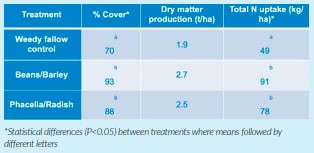

This demonstration, which started in 2020, is looking at the effect of a summer catch crop on soil nitrogen supply, soil structure and the performance of the following crop in the rotation. In this trial we are comparing the impact of comparing summer catch crop mixes to leaving the land fallow. Three treatments were established in May 2020; a control where the field has been left in stubble, a phacelia and oil radish mix, and farm saved seed and barley. The catch crop was assessed in July 2020 and the results showed:

The topsoil was also noted to be slightly drier where the catch crop treatments had been grown and the soil N supply higher where catch crops were grown. Soil and crop characteristics across these three treatments will now be assessed through to harvest 2022.

So, lots of questions asked, assessments taken place and conclusions that can be drawn across some areas…and always more questions to ask as a result! As with much of what we do in farming, the best place to learn and find what suits your system is to try this out on-farm. The aspiration is that the demonstrations on the Strategic Farms put into practice the findings from the research and then the resources are created for you to be able to take this forward for your farm or business. This can be from counting plants at establishment, disease scoring your crops through the season, looking at earthworm levels or calculating the costs. The links to all of these resources are all available from: h t t p s : // a h d b . org.uk/sfweekwinter-2020.

Many of these results were also discussed through webinars held on these topics, along with wider areas such as weed management and boosting beneficials through the use of flowering strips, through the Strategic Farm Week held on 16-20 November. Recordings of these, along with other videos can be found via the same link above or on the AHDB Cereals and Oilseeds channel on YouTube. As we turn now to harvest 2021, some of the themes of cover cropping, weed management, cultivations, pest and natural enemy assessments are being taken forward, along with new areas of work. We look forward to sharing these results as we go through the season.

As ever if you have questions, comments, suggestions or would like more information, please feel free to get in touch.

-

Bring Back The Cow!

Written by Tom Chapman – Mob Grazing Specialist at EnviRumen Ltd

The value that grazing ruminants bring to soil is, once again, starting to be appreciated by farmers. The combination of their dung, urine, saliva and hoof action, plus the effect of the forage plants, all help to bring dramatic and welcome improvements in soil health.

The true benefits of cattle were highlighted to me when I visited Jay Fuhrer at Menoken Farms in North Dakota several years ago. He spelled out the five key practices for soil health. The first four were: Keep the soil covered; keep a living root in the ground at all times; do not disrupt the soil, chemically or physically; and have lots of diversity, avoiding monocultures. When he came to the fifth, his eyes lit up: Bring cattle into the rotation. He became excited, animated as he spoke. He grabbed his spade and started digging into the strange, grey-coloured sand at Menoken. He grabbed two sods from different patches, triumphantly pointing out that one was much darker, much more enriched with carbon, than the other. “Three years!”, he exclaimed, “Only three years and we can already see a marked difference”

It was true, the cattle had been moved onto the arable fields only three years earlier, as part of a changed rotation and the differences were both stark and encouraging. It gives hope that we can restore our soils in a relatively short time, through careful and considered management practices which include all of those five principles Jay outlined to me back then.

Ways to get livestock on arable farms