Farming in a greener way generally involves increasing efficiencies in pursuit of the goal for crops to produce more from less. Tech Farmer explores some novel technologies that use energy from the sun to enhance crop production.

Written by Lucy de la Pasture

About 93 million miles away the sun powers all of life on Earth, providing solar energy for plants to capture and turn to chemical energy through the process of photosynthesis. And it’s this solar energy that’s being harnessed to develop products that can help crops be more efficient in a surprising number of ways.

Photosynthesis is naturally an inefficient process, with plants only able to use about 1% of the solar energy available to them. That’s because plants evolved to harness the sun’s energy for the sole purpose of supporting growth sufficient to produce seeds, thus ensuring continued survival of the species. But humans ask much more of plants as they push the boundaries of food production, farming at scale, and despite the tremendous advances in crop production, a biological limit to yield remains because of a plant’s natural ability – or inability – to process light.

But what if the photosynthetic process could be more efficient, remove more carbon from the atmosphere and increase crop yields without using more fertiliser? This is exactly what ex-Bristol University researchers Dr David Benito and Dr Imke Sittel set out to achieve and they’ve been so successful in their quest that they founded Glaia in 2019 to commercialise a photosynthetic promoter.

The company is licensed to use the technology in biostimulant products to help increase crop yields in a sustainable way. The first product of this kind, Fragaria, has just been launched in the UK and Netherlands for use in strawberries, with availability in Spain and the US soon to follow.

“If we could increase the efficiency of photosynthesis to 2%, we could double the yield of crops. But we’re not there yet,” explains David.

Drawing inspiration from the carbon-based nanomaterials found in nature, the photosynthetic promoter uses a nanocarbon material derived from sugar. These sugar dots open up the photosynthetic process inside plant cells so they can take in more solar energy and convert it into more biomass. Essentially, it fine tunes nature’s engine, giving plants the potential to increase efficiency at a molecular level.

So how does this happen? David explains that plants capture energy from sunlight in the leaf, causing electrons in the chlorophyll to become ‘excited’. “It’s this energy stored in the chlorophyll that’s used to split water and generate oxygen. Additionally, electrons are transported down the photosynthetic chain and incorporated into high energy molecules that are then used with CO2 and nutrients to form carbohydrates.

“But the biological processes involved in transporting those electrons can’t cope with all the available energy, so the plant uses mechanisms to protect itself against light. What it does in very simplified terms is to stop photosynthesis when the light is very intense,” he explains.

A feedback loop switches the process back on when light intensity falls and it’s this ‘on/off’ switch that contributes to the inefficiency of photosynthesis, adds David.

“Our photosynthetic promoter allows plants to process more of that energy because it facilitates electron transport, enabling plants to capture more solar energy and transform it into chemical energy. And because less damaging, unused energy is left in the leaf, the plant doesn’t have to switch off photosynthesis for so long and there’s an overall improvement in photosynthetic efficiency.”

Although the technology hasn’t yet improved photosynthetic efficiency enough to double the yield of crops, trials are producing a very respectable 20% yield increase with no additional nitrogen inputs, effectively producing more food without increasing CO2 emissions, he says.

“We saw an opportunity for this technology to change the way we produce food in the sense that it can help reduce the climate impact of agriculture. Its mode of action improves the photosynthetic efficiency of plants by allowing them to utilise more sunlight, capture CO2 and increase yields sustainably because no extra nitrogen is required.

“By applying the Glaia technology, there’s an increase in yield and that’s because it improves nutrient use efficiency as well. It translates to an overall reduction in CO2 emissions per tonne of produce by at least 15%,” he claims.

The company aims to bring its biostimulant technology to all crops, with the biggest impact on CO2 emissions possible in arable crops, highlights David. Trials in winter wheat are underway and earlier work has already shown average yield increases of 18%, underlining its potential in broadacre crops.

“Because there’s a more limited opportunity to apply a photosynthetic promoter in wheat than in strawberries, we’re developing an application protocol that won’t involve an extra pass for growers,” he adds.

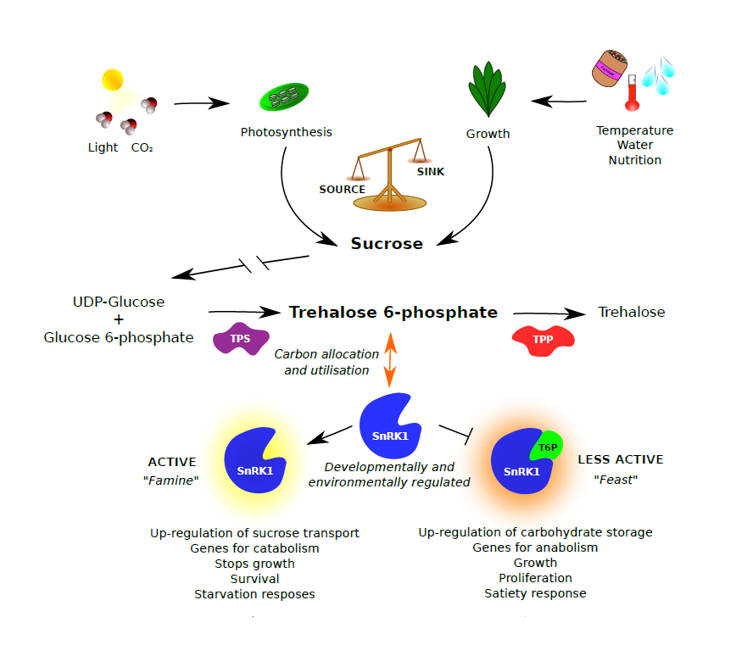

Another biostimulant technology with solar radiation at its heart is being developed by Hertfordshire-based SugaROx. The company was spun out of Rothamsted Research and Oxford University in 2021, bringing together the knowledge gained by researchers to improve sucrose allocation in crops, thereby increasing yield.

The technology is patented and licensed and will be the only authentic trehalose-6-phosphate (T6P) synthase technology available to growers, born out of the decade of research undertaken to develop it, explains Dr Cara Griffiths, co-founder and chief technology officer of SugaROx.

T6P is a signalling molecule and an intermediary of the trehalose biosynthesis pathway, in which endogenous levels are synthesised to match sucrose content. “You can think of T6P as a sucrose fuel gauge and it’s a mechanism that’s present in all plants to regulate sucrose use and allocation.”

It does this by interacting with an enzyme called SnRK1, explains Cara. “It’s a major sucrose utilisation enzyme, and it has two kinds of modes – feast and famine. This is where T6P comes in; it can switch the plant from famine into feast mode by telling the plant that there’s lots of sugar around so that it can transport it to where it’s needed and store more sucrose in its tissues.”

The discovery of the role of the signalling molecule highlighted the potential for manipulating the T6P mechanism for crop improvement purposes.

“Our aim was to find a way of increasing T6P and carbon allocation in a non-genetically modified way. To achieve this, we had to create a novel version of T6P,” she comments.

The products SugaROx is developing are a modified version of T6P, with a chemical group added to the molecule. “Essentially, it’s a caged T6P compound which acts as a T6P delivery system,” explains Cara.

This was needed as in unmodified form, T6P can’t be taken up by plants when applied as a foliar spray, she adds. “T6P itself is very polar, so once sprayed onto a leaf it will just sit on the leaf surface rather be taken up by the plant. The chemical addition that we’ve added changes the charge of the molecule, helping the uptake of T6P within the plant.”

And this is where solar energy has an important role. “Sunlight is needed to cleave this group off the modified T6P, which was added to aid its transport. The T6P is then released into the plant where it’s biologically active.”

The SugaROx technology is particularly suited for crops with a sink-based yield, such as wheat where Cara describes it as “a magnet for sugars and nutrients”. By applying during grain development, the applied T6P marries up with innate plant chemistry, causing T6P levels to spike and supercharging the grain fill process.

“It switches on the SnRK1 enzyme which pulls everything that supports good yield production into the ears of the plants, producing yield increases of up to 22% in the field,” she claims.

The interaction of T6P and SnRK1 affects a number of plant pathways, including sucrose use and allocation, starch conversion and storage, as well as a general nutrient uplift into the area, explains Cara.

“Essentially, T6P is signalling to the plant that there’s lots of nutrition around and it should turn on all of its processes to do with growth and resource allocation. We’re just enhancing processes the plant already uses itself.”

The use of solar energy isn’t limited to influencing photosynthesis and sugar metabolism, it can actually initiate a process that simultaneously removes pollutants and greenhouse gases from the air while also fertilising the crop.

Photocatalysts such as titanium dioxide have long been known for their powers of detoxification but can only absorb light in the ultraviolet spectrum. This would limit their efficiency as an application to UK crops.

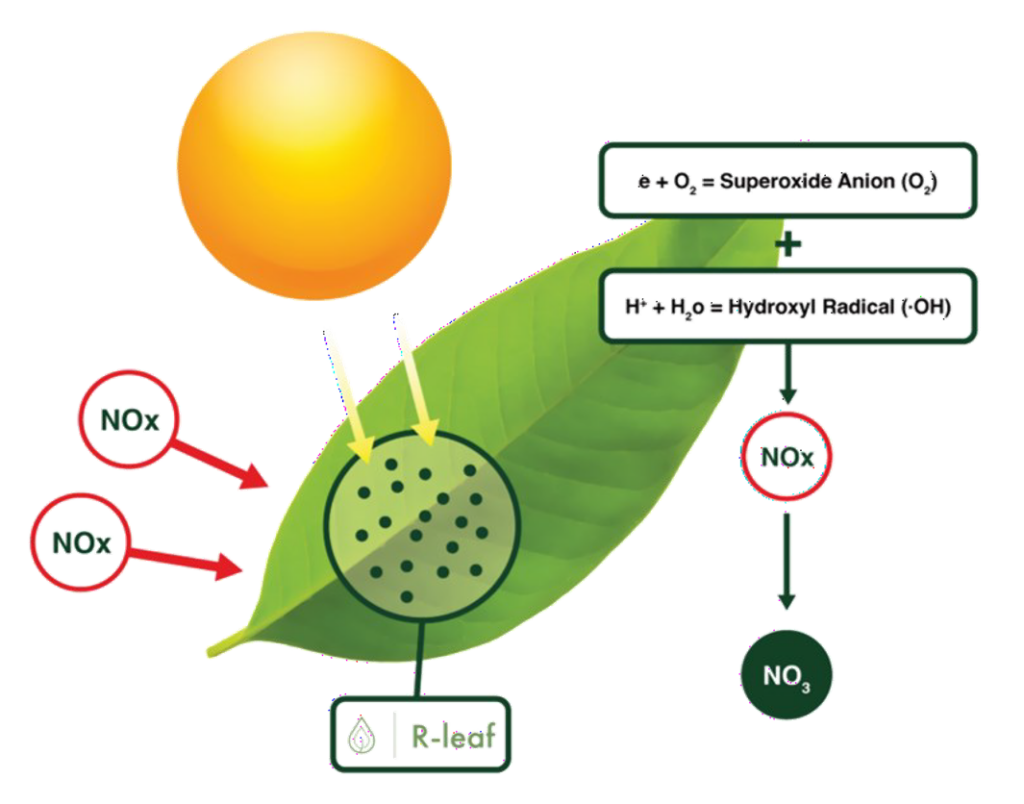

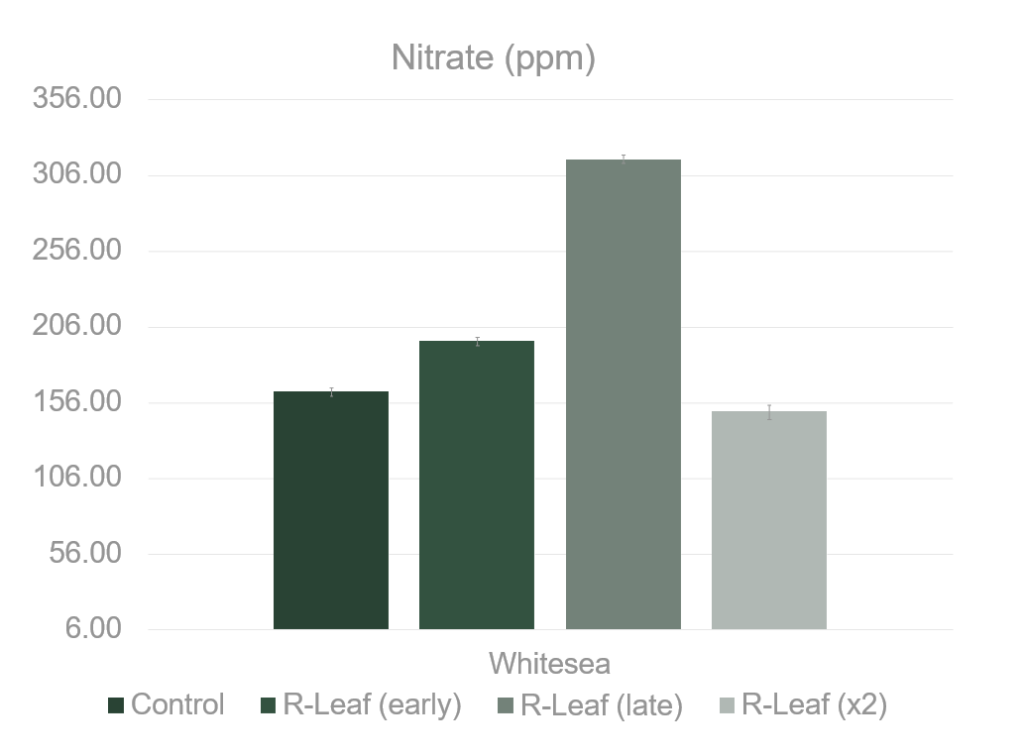

And it’s this problem that Crop Intellect has solved by processing titanium oxide in a way that makes it able to function as a photocatalyst under normal daylight conditions. The technology is available as R-Leaf, a sprayable suspension concentrate which acts as an alternative source of nitrogen and can replace 25% of the total nitrogen applied, according to the company’s trials data.

“This is the first time that photocatalysis has been used in agriculture as a way to generate nitrates, but the story does not stop there,” says Alvaro Montero Bockos, Crop Intellect’s chief operating officer and sustainability lead.

“While the conversion of NOx air pollutants into nitrates produces an input to support crop growth and reduce fertiliser usage, R-Leaf brings a key difference to traditional fertilisers through its capacity to remove N2O greenhouse gas at the same time.”

The effectiveness of the photocatalyst used in R-Leaf has also been verified by researchers at Manchester Metropolitan University. Their work has shown the R-Leaf material is 10 times more effective in photocatalysis, both under UV light and normal daylight, compared with the unprocessed material. The results confirm that under daylight the product works close to that of the performance of titanium dioxide under UV light.

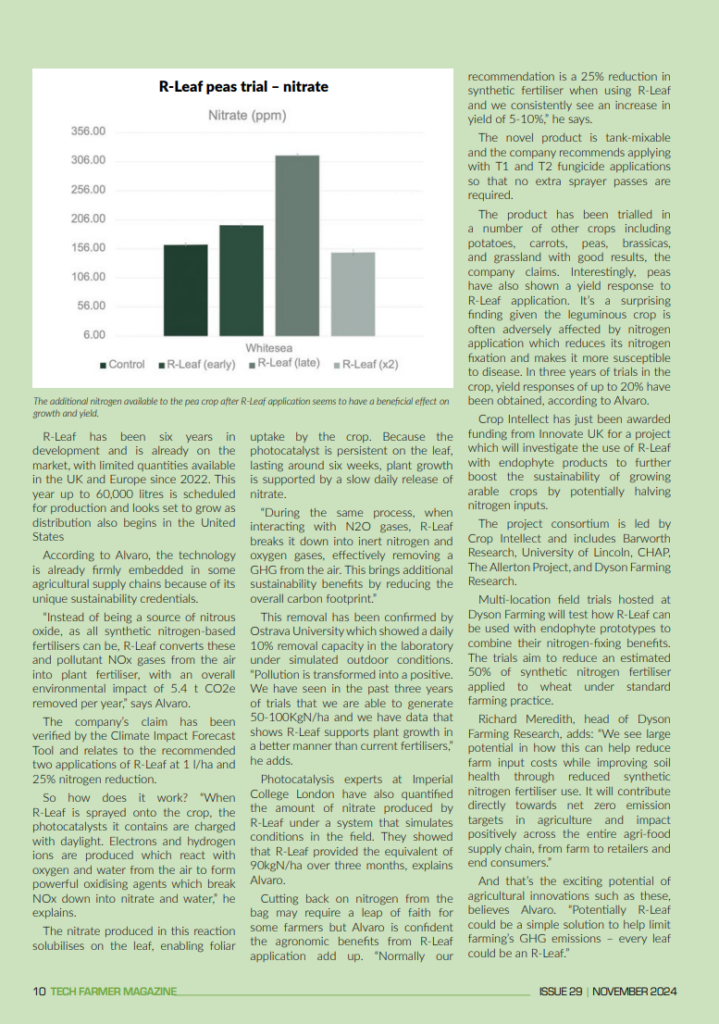

R-Leaf has been six years in development and is already on the market, with limited quantities available in the UK and Europe since 2022. This year up to 60,000 litres is scheduled for production and looks set to grow as distribution also begins in the United States

According to Alvaro, the technology is already firmly embedded in some agricultural supply chains because of its unique sustainability credentials.

“Instead of being a source of nitrous oxide, as all synthetic nitrogen-based fertilisers can be, R-Leaf converts these and pollutant NOx gases from the air into plant fertiliser, with an overall environmental impact of 5.4 t CO2e removed per year,” says Alvaro.

The company’s claim has been verified by the Climate Impact Forecast Tool and relates to the recommended two applications of R-Leaf at 1 l/ha and 25% nitrogen reduction.

So how does it work? “When R-Leaf is sprayed onto the crop, the photocatalysts it contains are charged with daylight. Electrons and hydrogen ions are produced which react with oxygen and water from the air to form powerful oxidising agents which break NOx down into nitrate and water,” he explains.

The nitrate produced in this reaction solubilises on the leaf, enabling foliar uptake by the crop. Because the photocatalyst is persistent on the leaf, lasting around six weeks, plant growth is supported by a slow daily release of nitrate.

“During the same process, when interacting with N2O gases, R-Leaf breaks it down into inert nitrogen and oxygen gases, effectively removing a GHG from the air. This brings additional sustainability benefits by reducing the overall carbon footprint.”

This removal has been confirmed by Ostrava University which showed a daily 10% removal capacity in the laboratory under simulated outdoor conditions. “Pollution is transformed into a positive. We have seen in the past three years of trials that we are able to generate 50-100KgN/ha and we have data that shows R-Leaf supports plant growth in a better manner than current fertilisers,” he adds.

Photocatalysis experts at Imperial College London have also quantified the amount of nitrate produced by R-Leaf under a system that simulates conditions in the field. They showed that R-Leaf provided the equivalent of 90kgN/ha over three months, explains Alvaro.

Cutting back on nitrogen from the bag may require a leap of faith for some farmers but Alvaro is confident the agronomic benefits from R-Leaf application add up. “Normally our recommendation is a 25% reduction in synthetic fertiliser when using R-Leaf and we consistently see an increase in yield of 5-10%,” he says.

The novel product is tank-mixable and the company recommends applying with T1 and T2 fungicide applications so that no extra sprayer passes are required.

The product has been trialled in a number of other crops including potatoes, carrots, peas, brassicas, and grassland with good results, the company claims. Interestingly, peas have also shown a yield response to R-Leaf application. It’s a surprising finding given the leguminous crop is often adversely affected by nitrogen application which reduces its nitrogen fixation and makes it more susceptible to disease. In three years of trials in the crop, yield responses of up to 20% have been obtained, according to Alvaro.

Crop Intellect has just been awarded funding from Innovate UK for a project which will investigate the use of R-Leaf with endophyte products to further boost the sustainability of growing arable crops by potentially halving nitrogen inputs.

The project consortium is led by Crop Intellect and includes Barworth Research, University of Lincoln, CHAP, The Allerton Project, and Dyson Farming Research.

Multi-location field trials hosted at Dyson Farming will test how R-Leaf can be used with endophyte prototypes to combine their nitrogen-fixing benefits. The trials aim to reduce an estimated 50% of synthetic nitrogen fertiliser applied to wheat under standard farming practice.

Richard Meredith, head of Dyson Farming Research, adds: “We see large potential in how this can help reduce farm input costs while improving soil health through reduced synthetic nitrogen fertiliser use. It will contribute directly towards net zero emission targets in agriculture and impact positively across the entire agri-food supply chain, from farm to retailers and end consumers.”

And that’s the exciting potential of agricultural innovations such as these, believes Alvaro. “Potentially R-Leaf could be a simple solution to help limit farming’s GHG emissions – every leaf could be an R-Leaf.”