Tillage is becoming increasingly interesting in some no-till regions. Michael Horsch talks about various systems all over the world that with regard to tillage focus on a simultaneous deep placement of fertiliser.

“While we observe an increased interest in direct seeding in intensive regions such as Europe, we also notice that tillage becomes more interesting again in traditional no-till regions,” Michael Horsch says. There are various reasons. Among them disturbing layers, dense layers and compaction in the soil. This is particularly the case on soils with a high sand content like we find in Australia or South America. These are sites that have been working very successfully with direct seeding for two decades or more. “Here we also see that farmers managed to increase yields by means of targeted tillage with longer intervals. The objective is to increase the root space and bring nutrients deep into the soil to optimally feed the plants for a longer time. And then to cultivate the fields again with direct seeding in the following year.”

The following article presents various systems that are used worldwide. A particular focus is on the simultaneous deep placement of fertiliser. The biggest difference between the methods presented is the intensity of the cultivation of the surface. It can be roughly classified as follows: the higher the precipitations and the hotter the peak temperatures can get, the less mixing is required on the surface. But read more about this yourself.

Michael Horsch

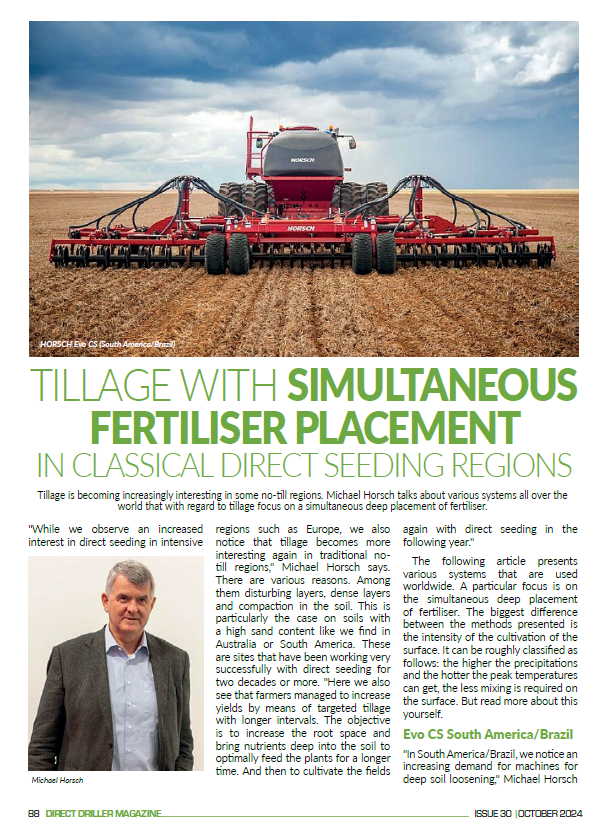

Evo CS South America/Brazil

“In South America/Brazil, we notice an increasing demand for machines for deep soil loosening,” Michael Horsch says. The objective is to loosen the soil deeply to break layers that have formed over several decades of direct seeding. These layers act like compactions and prevent further root penetration. In most cases, the reason is the washing in of fine soil particles from the surface and, on lighter sites, the dense compaction of sand. In regions with high rainfall and high biological activity, the objective is loosening without surface mixing. “These are the regions where we mainly sell the Evo CS and now also the Evo TL. The use of fertiliser is always possible and is also requested by the customers. In most cases, this is phosphorus, but we also notice more and more discussions about placing lime deeper in the soil.”

Fertiliser is placed across almost the full working depth. This allows for applying fresh nutrients, especially phosphorus and potash, to the soil in a targeted way. Fertiliser can be applied at two levels, with the option of changing and individually adapting the respective dose. In Brazil, the Evo CS is not used as a standard tool, but rather for the targeted improvement of fields where usually direct seeding is used. Equipped with a packer system, it leaves behind a closed surface.

Tiger MT with FertiProf Ukraine

In one single pass, the Tiger MT can mix in a lot of organic material and, in the Ukraine, is therefore mainly used after grain maize and sunflowers. The objective is to achieve a reasonable mixing ratio so that the straw can decompose during the vegetation period. In one pass, the Tiger MT manages to mix intensively, to loosen and level the soil as well as to consolidate it to achieve a horizon that is ready for seeding. The advantage of mixing is that the straw is in a more intensive contact with the soil and, thus, decomposes more reliably.

HORSCH Tiger MT with FertiProf (Ukraine)

In combination with the FertiProf attachment, fertiliser can be placed directly in the depot. The obvious advantage is that the fertiliser is applied in deeper layers where water is potentially available for a longer time, thus allowing for a longer uptake of nutrients as the soil dries off from above. This means that the water is available for a longer time for nutrient uptake. This effect plays a decisive role for phosphate in particular, but also for potassium in combination with heavy soils. Moreover, the plant specifically looks for phosphorus concentrations. This ensures that root penetration takes place. The third advantage of concentrating fertiliser is to create a small-scale saturation of the soil so that the nutrients are longer available to the plant. The black earth soils of the Ukraine are ideal for the concentrated placement of fertiliser, as nutrient supply is scarce, as they time and again are dry during the season and have a very high exchange capacity.

Tiger MT Australia

The approach pursued with the use of the Tiger MT in Australia aims to mix organic material into the partly sandy soils and deeply loosen the ground. Fine material on the surface is washed in by rainfall, forming compacted layers over the years. Initial experience shows that breaking these compacted layers has positive effects, while simultaneously leveling and re-compacting the soil with the Tiger MT helps prevent new compacted layers from forming. The primary goal is to maximize water absorption after rainfall and increase its availability for crops. In combination with a MiniDrill, the Tiger is also used to plant cover crops.

HORSCH Tiger MT (Australia)

Panther USA

Starting around 2007, the HORSCH Panther (then the HORSCH Anderson 60-15) started being used for autumn fertiliser operation in North Dakota and South Dakota. This system has grown in popularity since then and today is a common autumn fertiliser application system used by contractors and farmers alike in these regions. Compared to traditional strip till on 30” row spacing, the Panther system utilises its existing 15” shank spacing for fertiliser application. Narrow openers are installed for use with fertilizer sources of dry, liquid, or NH3 and even a combination of products at the same time. The overall concept of the Panther gives several agronomic advantages when being used for fall fertilizer applications.

The Panther has proven itself in the broadacre min-till/no-till type farming systems of the northern corn belt of North America. The opener system can place fertilizer 8 to 15 cm deep with minimum soil disturbance. A cutting coulter system is used in front of each shank to prevent plugging in heavy residue conditions. Surface level residue stays relatively intact. Usually, the Panther travels a slight angle to the direction of planting. This gives uniform coverage over the field, eliminates the need for RTK steering at planting, is independent of planter row spacing, plus provides an amount of soil loosening/mixing to break shallow soil compaction.

HORSCH Panther (USA)

Field conditioning is another agronomic topic with the Panther system. When applying fertilizer, the strips are closed and firmed, not leaving a ridge or berm. The disc levelling system and pneumatic tire packing system leave the field smooth for planting in the spring. This closing and firming action also aids in securing NH3, sealing the strip to prevent gas-off losses. The added benefit is with the soil movement and disc levers, small ruts from harvest get levelled. Some farmers will do a shallow pass of spring seedbed preparation, others will leave a stale seedbed.

With the Panther system there is large capacity for carrying dry fertilizer and also towing NH3 trailers. A very simple system, in the northern corn growing regions the results have been positive. Yield results in corn have been comparable to typical 30” strip till systems. Further north into western Canada the Panther is being used on a true 15” spacing of fall fertilizer strips then spring planting of canola and wheat. In addition, the Panther can be converted between seeding applications and fertilizer applications, adding to the versatility for farmers maximizing return on investment of the unit.

Phosphorus and potassium dynamics in the soil

The availability of phosphorus in the soil can roughly be divided into three parts. Stable phosphate is bound to calcium, iron, aluminium or in organic matter and is not available to the plant. Unstable phosphate is characterised by a more or less strong sorption to exchangers such as clay minerals, oxides or organic compounds. Dissolved phosphate is present in the soil solution as free and immediately plant-available HPO42-. The balance of these three fractions in the soil very quickly flows towards the stable phosphorus and also quickly and severely restricts the availability of fertilised phosphorus to the plant. This process is also referred to as phosphorus ageing and is very difficult to reverse. The concentration of dissolved phosphate is very low with an average of 1-2 mg/l and requires soil moisture, soil temperature, good basic phosphate supply and optimum soil reactions (pH value, microbial activity, root exudates) for sufficient replenishment. A high humus content increases the share of unstable phosphate and thus promotes the availability as well as a good root penetration by the crop.

Phosphorus is involved in all energy metabolic processes in the plant and is particularly important for root formation and the storage of starch in the grain.

Phosphate that is stored in a depot is sorbed as usual at the contact surfaces of the depot with the soil environment until the bonds are saturated. The majority of this soluble phosphate inside the depot thus remains fully available to the plant over a longer period of time.

The uptake of nutrients via the mass flow requires water. As only very small doses of phosphorus are present in the soil solution, the mass flow alone is not sufficient. The additional diffusion requires significantly more water. Thus, the uptake of phosphate suffers in dry conditions. Placing the depot in a deeper layer that is more likely to bear water increases the uptake reliability. As unstable and stable phosphate are not prone to wash out and as soluble phosphate is present in low concentrations, the risk of a displacement to even deeper layers is low. In rare cases, if it is extracted continuously from the subsoil without deeper, replenishing mixing, this immobility of phosphate can even be disadvantageous in dry periods.

High magnesium contents favour the uptake of phosphorus. Iron and zinc mobility within the plant is restricted if the phosphorus content is high. A high nitrate supply also restricts the uptake of phosphorus.

In contrast to phosphorus, potassium is much more mobile in the soil. The three fractions are also found in potassium. However, the potassium content in the soil of up to over 100,000 kg per hectare in the top 30 cm of the topsoil are enormous. The strength of the bond to clay particles, organic matter and to minerals and salts varies and ensures a constant supply and, due to the high solubility of potassium, an easy washing out on light soils. The availability is limited by the K saturation at the exchanger (correct ratio of calcium, magnesium and potassium), the soil structure and the depth as well as by antagonisms among others with ammonium. The higher the content of potassium-fixing clay particles, the stronger the bond and the lower the risk of washing out. After many years of extraction, clayey soils with mainly expandable clay minerals (smectite or the transformation to illite) tend to fix potassium immediately after fertilisation.

The fertilised potassium is stored in the intermediate layers of the clay minerals and is no longer available until these layers are replenished. As the ion diameters of K+ and NH4+ are similar, ammonium is sometimes also incorporated in these empty layers. “Fresh potassium” can displace ammonium and ensure that nitrogen is replenished.

Potassium influences the regulation of water uptake via the roots which also influences the supply of nutrients and their distribution within the plant parts. In dry conditions, it is responsible for the proper closing of the stomata and thus prevents further drying out. Barley and sugar beet react much more sensitively to the lack of potassium than for example wheat.

Due to its high mobility and the good solubility, the short-term top fertilisation of potassium also makes sense. Well-supplied soils with a high clay content react somewhat slowlier to top fertilisation than sandy soils. In the case of poorly supplied clayey soils, recognisable by the low soluble potassium content even after fertilisation, top fertilisation is not practicable. In this case, the plant has to be supplied via a concentrated fertiliser band. The resulting “micelle” saturates the adjacent clay minerals and remains available to the plant in the core.

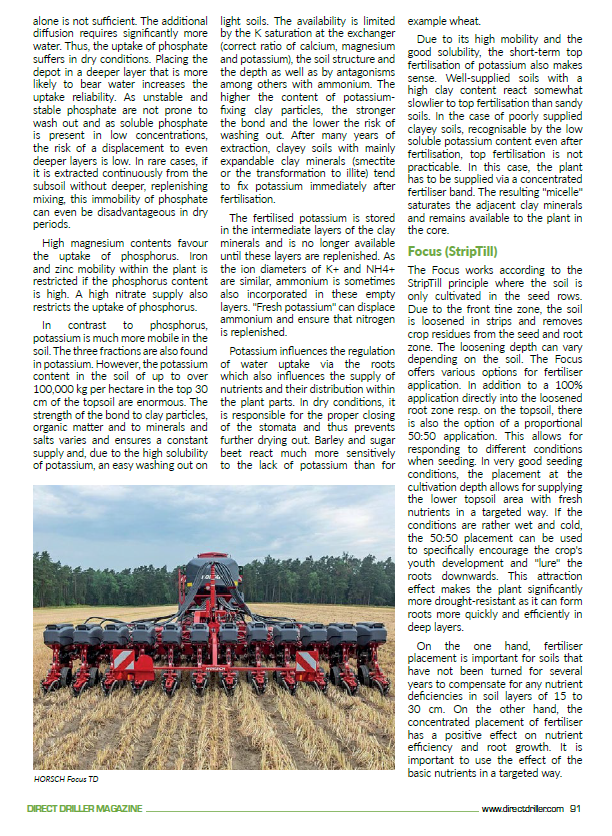

Focus (StripTill)

The Focus works according to the StripTill principle where the soil is only cultivated in the seed rows. Due to the front tine zone, the soil is loosened in strips and removes crop residues from the seed and root zone. The loosening depth can vary depending on the soil. The Focus offers various options for fertiliser application. In addition to a 100% application directly into the loosened root zone resp. on the topsoil, there is also the option of a proportional 50:50 application. This allows for responding to different conditions when seeding. In very good seeding conditions, the placement at the cultivation depth allows for supplying the lower topsoil area with fresh nutrients in a targeted way. If the conditions are rather wet and cold, the 50:50 placement can be used to specifically encourage the crop’s youth development and “lure” the roots downwards. This attraction effect makes the plant significantly more drought-resistant as it can form roots more quickly and efficiently in deep layers.

HORSCH Focus TD

On the one hand, fertiliser placement is important for soils that have not been turned for several years to compensate for any nutrient deficiencies in soil layers of 15 to 30 cm. On the other hand, the concentrated placement of fertiliser has a positive effect on nutrient efficiency and root growth. It is important to use the effect of the basic nutrients in a targeted way.