If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Groundswell 2025: A Regenerative Festival That Goes Beyond the Soil

I know I’m biased as I was involved in the first Groundswell, but the event proved once again why it is the UK’s flagship event for regenerative agriculture. As always, held at Lannock Manor Farm in Hertfordshire, this year’s festival brought together farmers, scientists, environmentalists, entrepreneurs, and policymakers for a celebration of soil, food, sustainability and systems thinking. With over 200 sessions and 500 speakers, the event offered something for everyone, from hands-on workshops and field demos to deeply philosophical debates on food systems, land use and the future of farming.

I’m going to admit that I missed the sunrise bird walk and yoga sessions, I would imagine many farmers did, but this event is no longer just about farmers. Those passionate about food and what we eat as a nation were in attendance too.

Diverse Voices, Shared Vision

Groundswell 2025 showcased a global and multi-disciplinary view of conservation agriculture. Farmers from across Europe gathered for a panel titled Unity in Diversity, sharing stories of farmer-led action from Italy to Norway through the European Alliance for Regenerative Agriculture. The message was clear: systemic change is not just possible, it’s already happening. Highprofile keynote speakers like Prince

William, Gabe Brown and Tim Lang stirred the crowd with calls for radical change. Brown’s talk, What is All This Talk About Regenerative Agriculture? was a highlight (although some of us have heard a variant of it before), urging a shift away from input dependency and toward holistic land stewardship. Lang, meanwhile, painted a sobering picture of UK’s food system vulnerabilities and stressed the need for civil food resilience.From Soil to Supply Chains

This year, Groundswell expanded its lens beyond the field. Reshaping Supply Chains for a Regenerative Future drew a packed crowd eager to explore new economic models that prioritise fairness, transparency and ecological outcomes. The conversation wasn’t just about growing food, it was about how that food moves through the system and how farmers can retain more value. Discussions on AI in agriculture and

nature markets reflected the cuttingedge, even experimental spirit of Groundswell — open to technology, but never at the cost of ecology or

autonomy. We are still clearly missing the tools for AI to help farmers with their tasks or learning but it is on the horizon.Science in the Soil

One of the most striking elements of Groundswell 2025 was its focus on soil health as a living, breathing system. Attendees packed into sessions like Worming Your Way to Better Soil Health and Earthworms and Their Impact, which blended scientific rigour with real-world

farm case studies. Interactive features like Resonating Fields, an immersive installation capturing the bioacoustic sounds of soil life, offered a poetic reminder of the richness beneath our feet. This experimental blending of art and science caught the imagination of many and reinforced the idea that there is a heartbeat of regenerative farming.Trees and Livestock

Trees and livestock also featured heavily, with practical walk-and-talks on shelterbelts, silvopasture and integrating trees into vegetable production. The session Taking the Golden Hoof One Step Further offered real-world strategies for incorporating livestock into arable systems without compromising ecological integrity. The Dung Beetle Safari and Regenerative Rotation walk, helped bring theoretical principles to life. Farmers were able to get their hands dirty, ask detailed questions and walk away with practical insights.

Tackling the Big Questions

Panels like Can British Farming Be Saved? provided political context to the agronomic conversations. The mix of Defra officials, campaigners, and pragmatic land managers allowed for an honest airing of frustrations and a mapping of the pathways forward. It’s clear that more policy makers (and royals) attend Groundswell than Cereals. Thus, while they are in the room, it’s great to be able to talk to them about the problems that all farmers are facing, not just those embracing conservation agriculture.

A Festival

Perhaps the most unique aspect of Groundswell remains that it runs late into the evening (The nighttime music is certainly the closest I will get to a festival at my age). It’s also definitely a celebration of food. There is no doubt that farmers are outnumbered by food processors, supply chain workers, policy makers and investors, but I don’t see that as a bad thing. We are all in the same place and we want the same thing: healthier food on our plates and healthier returns for those who grow sustainable food. The bars and communal eating spaces buzzed with conversation all day and evening, underscoring the community ethos. Over a pint, you could talk to soil scientists, chefs, artists, smallholders and AI engineers.

It’s not just about methods; it’s about mindsets. It brings together a powerful coalition of the curious, the committed and the courageous. I can only thank everyone who took the time to speak to me about what they are doing and what they want our food system to be. I have, as always, come out of the event knowing a little bit more about many subjects. And that it the main reason I go and will continue to go every year. (That, and the fact they now have whisky stands.)

-

Why we need to talk about water and the land it runs through

Water is central to sustainable farming, but too often, it’s the part we leave out.

At Groundswell 2025, we set out to change that. As a water supplier working across some of the UK’s most environmentally sensitive landscapes, we were proud to join the event to share our work, listen to the farming community, and deepen our commitment to land and water stewardship.

Because water isn’t just something that arrives at the tap. It begins in the soil, runs through the land, and infiltrates into aquifers and carries the imprint of everything it touches.

What the land teaches us

One of our key messages at Groundswell was simple but powerful:

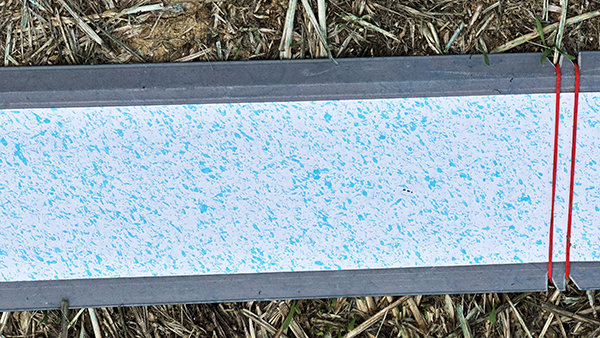

“Water quality starts with the land it moves through.”Through the rainfall simulator demo, we showed exactly what this means in practice. Visitors could see side-by-side comparisons of how different soil management techniques impact runoff, erosion, and water infiltration. The difference between compacted, depleted soil and living, healthy soil was striking, and undeniable.

Healthy soil doesn’t just support better crops, it leads to healthier water. It’s all connected.

From the ground up

Each year, we test over 200,000 water samples to ensure safety for both people and ecosystems. But the real work starts upstream, through our work with farmers to optimise inputs, improve soil structure to reduce losses, and support the transition to regenerative practices that benefit the whole system. Affinity Water’s catchment team have supported the drilling of over 11,000ha of cover and companion crops, a core regenerative farming principle, since 2020. These crops help fix nitrate and prevent leaching and reduce runoff of sediment and pesticides into watercourses.

At Groundswell, we had the chance to speak with dozens of farmers about our catchment schemes, innovation grants, and landscape-scale restoration programmes, including work to protect globally rare chalk streams and improve catchment resilience.

Danny Coffey, Catchment Manager at Affinity Water, explains:

“Water quality can reflect what is happening in the landscape. When we invest in better soil management and regenerative farming, we’re also investing in cleaner water, resilient rivers, and healthy soils. Groundswell gave us a vital opportunity to show how these pieces fit together and to work with farmers who share that vision and help us treat water, out in the catchment.”

We’re not just a water company

Affinity Water is evolving. We’re not just managing infrastructure; we’re building long-term partnerships with the landowners and farmers who care for their land.

We believe that supporting landowners and farmers is essential to protecting water at its source. That’s why we’re investing in practical solutions, from funding cover and companion crops, to river restoration schemes, and to demonstrating what works through tools like our rainfall simulator.

We are here not just as a water supplier, but as a partner in resilience, nature recovery, and sustainable food production.

Looking ahead

Groundswell was a powerful reminder of the innovation and passion driving change in British agriculture. And it reinforced why water needs to be a bigger part of the conversation.

As climate pressures grow and water becomes an increasingly precious resource, we’ll need to work together more than ever, across sectors, landscapes, and disciplines.

To protect water, we need to protect everything it touches.

Notes to editor:

- Affinity Water supplies drinking water to over 3.9 million people across parts of London, the Home Counties, and the East of England. We are the largest water-only supplier in the UK.

- Affinity Water is committed to protecting and enhancing the environment. We invest in river restoration, support regenerative agriculture, and work with land managers to improve water quality at source.

- The company plays a leading role in protecting the UK’s rare chalk streams, over 60% of the world’s chalk streams are in England, many of which run through Affinity Water’s supply region.

- At Groundswell 2025, Affinity Water showcased a rainfall simulator to demonstrate how different soil structures affect runoff, infiltration, and water quality. This hands-on demo highlighted the vital role of soil health in protecting water resources.

- Through its Catchment and Land Management programme, Affinity Water offers funding, soil health testing, and advice to help farmers transition to practices that benefit both their land and local watercourses.

-

Featured Farmer – Frederik Larsen

Writing this article (while the season is coming to a close in the midst of a 30C heatwave) is the perfect opportunity to reflect on yet another exciting year of arable farming. I’m usually idealistic on which directions to take my farm and arable clients, always striving towards ambitious goals. However, for each new season of arable cropping I experience, I seem to get more settled with the philosophy that farming is a journey towards an always-evolving target. It’s better to get used to the fact that no perfect season exists, no perfect crop can ever be harvested and there’s no perfect cropping system. Instead, it’s one big mess of trade-offs between the plan and reality. Then repeat.

Yet the 2025 season is one to remember. Our first-born baby boy arrived in April and so far it has been amazing. We are really settling into parenting and everything that it entails. I usually fly out of Denmark several times a month to consult on my clients’ farms in Europe, but I have been able to take a paternity break, thanks to my wonderful colleagues providing cover for me. I’ll miss Groundswell this year as well, with severe FOMO already developing.

The second big news for 2025 has been that I have taken over the family farm with full ownership. 250 hectares of prime arable crop land (among the top third of soil quality in Denmark), almost all of it is combinable.. I’m humbled to be given this opportunity and feel so thankful for the support I’ve received from my partner, Mathilde, and especially my younger brother and sister, who have been so encouraging and understanding throughout the whole process. Now I’m the sixth generation at Barløsegaard, and I look forward to doing my absolute best to take care of the family farm while it’s my responsibility. What has worked well for my family is that from the very beginning, my parents were strongminded and decisive on what they wanted: to pass the farm to one child on the best possible terms with a minor cash gift and no liability to siblings. Because our parents were settled on their goal from the start it has been easier for us siblings to accept the terms. Is this the best time in history to take over the farm? Most likely not, but there’s no such thing as ‘timing the market’ for a farm purchase. However, with a new property valuation tax reform on the horizon, we had another incentive. Farm succession in Denmark basically comes down to the following rules: 1) pass to family at 15% below full market value, 2) seller can keep promissory note on the estate (difference from market value to full mortgage), 3) if needed, pay 10% inheritance tax on cash/assets passed down, 4) seller will be capital gains taxed, but with an inflation adjustment.

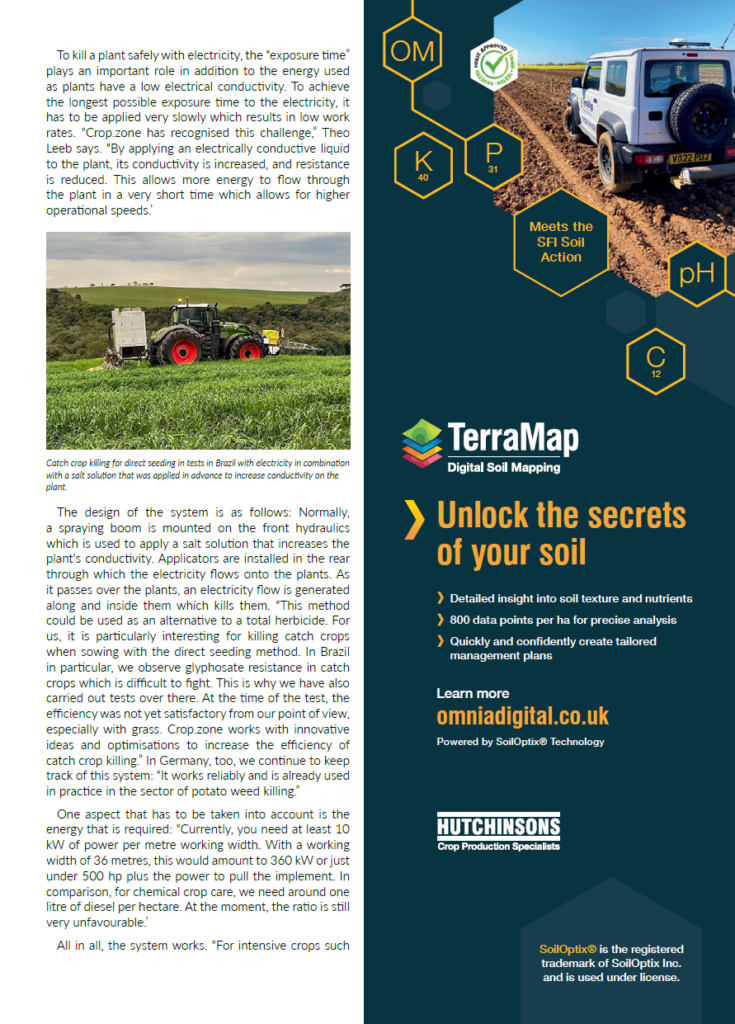

Above. Winter OSR undersown with living mulch mixture of 25 kg/ha (75% lucerne, 15% red clover, 10% white clover, weight based). The clear canopy effect of OSR has reduced the size of the undersown living mulch compared to no canopy to the right.

The current big threat/opportunity to farming conditions in Denmark is yet another push for even tighter environmental/nutrient legislation, which will force the profitability of arable farming even lower. This should have a negative farmland pricing but it’s looking like this is further exacerbating the huge gap between the earning potential of farmland and its market value, which seems to keep rising. Many nonfarming entities (government included) are heavily buying up farmland, which pushes the price even higher.

Barløsegaard has been no-ploughing for 25 years this season and with not illage crop establishment for the last 12 years. The majority of the land is what Brits would call boys land, with 1525% clay in a sandy loam clay mixture (almost no silt). The parent material is glacial tilth and our soils are very deep with no bedrock (I think it is at least 800 metres below). Our latitude is at 55.3, which corresponds to slightly north of Newcastle. We’re receiving around 700 mm of annual rainfall and 1800 hours of yearly sunshine.

We have been running our modified Primewest Cross Slot drill for nine seasons now and are really getting comfortable using it for most drilling options. It’s especially great for small seeds and grass/clover because of the advanced depth control and nonhairpinning from the hybrid disc/blade opener. Normally, we want to grow 50% of the farm with winter wheat, 25% with winter OSR and 25% with a spring break crop (faba beans, malting barley, oats). Sometimes we grow grass seed crops, but those are variable in acreage and contract depending. We keep a minor

but healthy population of Italian ryegrass, black grass and rats-tail fescue in some of our fields, so they play an important consideration on the crop management. Our core crop rotation is winter OSR followed by winter wheat, then spring break crop, then winter wheat, then repeat. Wheats are farm-saved feed variety blends of the three to four of the newest top performers selected on high disease tolerance (high untreated yield). OSR are hybrid variety blends of three top performers from distinct breeders with special attention to stem health including verticillium tolerance.

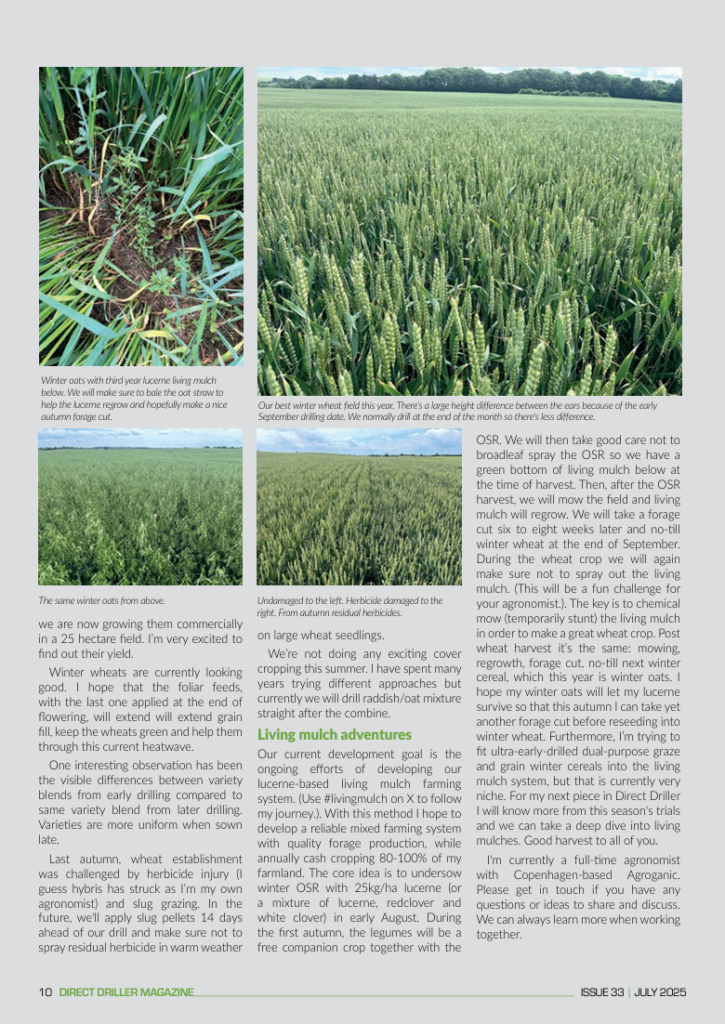

Winter oats with third year lucerne living mulch below. We will make sure to bale the oat straw to

help the lucerne regrow and hopefully make a nice autumn forage cut.

The same winter oats from above. I have recently finished a large soil sampling scheme. Because of our tillage approach, we have a clear nutrient/pH stratification with almost double the amount of phosphate and potassium in the top 10cm of our soils and 0.5 lower pH compared to the 10-20cm interval. We have not limed the soils for 25 years, but this autumn we will apply a baseline of 2 ton/ha of calcium lime with 2.5% magnesium. Afterwards, we will correct the odd sub areas where magnesium might become close to potassium levels. We can also conclude from this sampling that surface applied phosphorus and potassium are useless in our no-till system. Hence, we now apply a modest NPK fertiliser (50% of expected PK grain removal) seed bed placed in the autumn for winter wheat so we only have to apply N and S in the spring for winter wheat and OSR.

March, April and May have been very dry (although we luckily got 100mm of rain in late May), so again we can conclude that large nitrogen doses early on (in mid-March) are preferable to multiple modest split doses going into May. I’m a big believer in using the right type of nitrogen source. We try to avoid nitrate-N and instead prefer urea and ammonium sources. These N-types are safer to apply in large doses early without a leaching risk and they supply nitrogen for a extended period of time. The best part is that they are also the cheapest option. This approach works great together with foliar applied fertiliser (total nitrogen applied for winter wheat is around 180kg/ha with the target yield around 10 ton/ha. We’re still in the early Simplified choice Expertly selected Our expertise and rigorous assessment of both established and new seed varieties enable us to offer you a superior, short-listed selection. We simplify your seed decision process, giving you more t ime to focus on your farm. stages of getting used to foliar feeds at our farm, so we buy the expensive premium solutions from nearby Flex Fertilizer System. This season we have tried 3x 80 kg/ha of a NPKS 16-1-3-1 with 1Mg. (In Denmark we always list nutrient content in raw non-oxidised forms.). They work great together with our fungicide sprays but we have learned that evening and night applications are preferred in order to not burn leaves. Our wheat disease pressure is modest with an long-term average 100kg/ha yield benefit from fungicide control. I try and capture this as economically as possible by applying a T2 fungicide spray at 33%-50% label rate and a T3 at 2533% label rate.

Recently, we have had mixed experience with no-till and min-tilled spring malting barley and this season we have avoided growing spring barley. Instead, we have focused our attention on spring faba beans and winter milling oats.

Our best winter wheat field this year. There’s a large height difference between the ears because of the early September drilling date. We normally drill at the end of the month so there’s less difference Winter oats are not a common crop in Denmark. I have trialled them on a minor scale for two seasons and this third year we are now growing them commercially in a 25 hectare field. I’m very excited to f ind out their yield.

Winter wheats are currently looking good. I hope that the foliar feeds, with the last one applied at the end of f lowering, will extend will extend grain f ill, keep the wheats green and help them through this current heatwave. One interesting observation has been the visible differences between variety blends from early drilling compared to same variety blend from later drilling. Varieties are more uniform when sown late.

Last autumn, wheat establishment was challenged by herbicide injury (I guess hybris has struck as I’m my own agronomist) and slug grazing. In the future, we’ll apply slug pellets 14 days ahead of our drill and make sure not to spray residual herbicide in warm weather on large wheat seedlings. We’re not doing any exciting cover cropping this summer. I have spent many years trying different approaches but currently we will drill raddish/oat mixture straight after the combine.

Undamaged to the left. Herbicide damaged to the right. From autumn residual herbicides. Living mulch adventures

Our current development goal is the ongoing efforts of developing our lucerne-based living mulch farming system. (Use #livingmulch on X to follow my journey.). With this method I hope to develop a reliable mixed farming system with quality forage production, while annually cash cropping 80-100% of my farmland. The core idea is to undersow winter OSR with 25kg/ha lucerne (or a mixture of lucerne, redclover and white clover) in early August. During the first autumn, the legumes will be a free companion crop together with the OSR. We will then take good care not to broadleaf spray the OSR so we have a green bottom of living mulch below at the time of harvest. Then, after the OSR harvest, we will mow the field and living mulch will regrow. We will take a forage cut six to eight weeks later and no-till winter wheat at the end of September. During the wheat crop we will again make sure not to spray out the living mulch. (This will be a fun challenge for your agronomist.). The key is to chemical mow (temporarily stunt) the living mulch in order to make a great wheat crop. Post wheat harvest it’s the same: mowing, regrowth, forage cut, no-till next winter cereal, which this year is winter oats. I hope my winter oats will let my lucerne survive so that this autumn I can take yet another forage cut before reseeding into winter wheat. Furthermore, I’m trying to f it ultra-early-drilled dual-purpose graze and grain winter cereals into the living mulch system, but that is currently very niche. For my next piece in Direct Driller I will know more from this season’s trials and we can take a deep dive into living mulches.

Good harvest to all of you. I’m currently a full-time agronomist with Copenhagen-based Agroganic. Please get in touch if you have any questions or ideas to share and discuss. We can always learn more when working together.

-

Farmer Focus – John Pawsey

June 2025

I get asked a lot of questions about farming stuff, most of which I have no idea what the answer is. So I usually make something up that sounds right. However, I do suspect that there will always be an element of truth in whatever I say in those situations because after 40 harvests, I must have picked up some knowledge along the way. In any case, even if I come up with something which is quite obviously not true, who actually cares? We all know now that it’s not about literal truth in an empirical sense; it’s about lived experience and emotional authenticity. It is my truth, as people say today.

One of the most common questions I get — and you must all get this too, being readers of Direct Driller, challengers of the farming status quo — is where do you get your advice from? Usually, the question is centred around agronomic advice, and so for the purpose of this article, that is what I will focus on.

When we converted our first fields to organic production in the autumn of 1999, I still had my non-organic, independent agronomist. Alice will tell you that I spent more time with him than I did with her, which is probably true. He was my fixer. My dealer. Having made the organic pledge and not wanting the bromance to die, I persuaded him to come with me on my Magical Mystery Tour, hoping that he would accept the invitation to be my post-drug buddy and weather the painful cold turkey period as we weaned ourselves off chemicals. I’m sorry to say that he quickly relapsed and went back to the dark side, whereas I ventured boldly into the Post-Acute Withdrawal Syndrome phase.

To the rescue came the Organic Conversion Information Service or OCIS, which ran from 1996 until 2006 under the DEFRA Organic Farming Scheme. They offered me free unlimited telephone support, a visit from an accredited adviser to put a conservation plan in place on my farm as well as some guidance on soils, organic certification and other grant applicable schemes. Quite why DEFRA have not offered the same service for today’s farmers who are wanting to climb aboard the regenerative train is beyond me. It was an excellent service. We need to suggest an alternative service for the Sustainable Farming Incentive 2026 offer. As a first attempt, what do you think about the Transition Initiative for Tillage Sceptics? We may need to work on the acronym.

My accredited adviser introduced me to the Elm Farm Research Centre (ERFC), now the Organic Research Centre (ORC), (www.organicresearchcentre. com), as it was the ERFC that accredited those advisers in the first place. EFRC/ ORC was the greatest source of advice in my early days. Pretty much all of the stuff that gets re-researched today has already been done by the ORC and partners. Nothing is new. Some examples:

- Through the DIVERSify project, ORC trialled intercropping cereals with legumes (eg wheat with beans, linseed with oats), resulting in 7374% reductions in weed biomass and improved yields, thanks to resource synergy and weed suppression.

- They explored multi-species leguminous cover mixes, helping to improve nitrogen fixation, structure and soil biology. That work emphasised the use of cover crops for soil tilth, nutrient cycling, moisture regulation and erosion control, especially when aligned with reduced or no-till methods.

- ORC partnered in EU-wide trials (eg the Oper8 project) to test mechanical weeding tools, living mulches and alternative weed control, supporting f ield labs and events that promoted practical adoption. In projects like TILMAN-ORG, ORC evaluated reduced tillage in organic systems to understand its impact on weed communities, soil structure and resilience.

- Beyond trials, ORC championed participatory research, co-designing experiments with farmers to ensure real-world relevance. They also contributed to EU projects (COBRA, SOLIBAM, SUSVAR, CORE Organic II) and delivered farmer training, field labs, events and advisory services.

The list goes on. You should look into a few of those projects. They are easily found on the internet or your favourite AI wangle.

Then we have Agricology (www. agricology.co.uk), which is another excellent source of advice. A lot of ORC research and other brilliant stuff can be found on their platform. I am sure you know the site well.

There is also the wonderful BASE-UK (www.base-uk.co.uk).

In the year 2000, a group of French farmers from Brittany formed an organisation called Bretagne, Agriculture, Soil and Environment or ‘BASE’. It was and still is a network of farmers wanting to share information on ways of farming that not only produced food but improved soils and nature as well.

One of BASE’s leading lights, Frédéric Thomas, started to spread the word and in 2012 the good news arrived across the English Channel — or ‘la Manche’ as our Gallic neighbours insist — and BASE-UK was born. Helpfully, the French founders changed the name to Biodiversity, Agriculture, Sol and Environment to enable the organisation to travel better and all we had to do was to just insert an ‘i’ into ‘sol’ to make ‘soil’ and we were away. I don’t connect as much as I should with BASE. I need to do that more.

YouTube. How many times has your partner rolled over in bed and asked incredulously, “What are you watching?” with an emphasis on the word ‘are’. In the Pawsey bedroom, this question is followed by Alice saying, “Can I put on the Archers now?” What’s happening here is that I have gone down a rabbit hole of being fed ingenious videos of farmers demonstrating pieces of homemade machinery for pulling out docks and creeping thistle. The best ones are from the subcontinent where protective guards are a no-no. The juxtaposition of successful weed control and a man potentially losing a limb is oddly captivating. Alice’s question is not actually a question. What she really means is, “Turn that screen off. I’m putting the Archers podcast on.”. It’s actually a wonderfully soporific show. All I get is, ‘Tum ti tum t i tum ti tum’, and the next thing I hear is my morning alarm. Brilliant! Anyway, that’s YouTube’s farming community, the motherlode of all agricultural knowledge.

Still on social media, I find Twitter (I refuse to call it X) useful , but you have to curate your experience. I make personal lists. My farming-related ones are: agricultural policy influencers, farmers I have met or know, strip and no-tillage agriculture and of course, organic farmers. Slot your relevant farming heroes into the relevant categories and you’ve got a concentrated feed on what is happening in the world of enlightened farming. All the nonsense is bypassed.

Then there is meeting actual people. I know, weird. They smell, some have accents I don’t understand, they puncture easily and sometimes they go on a bit, but meeting actual people is the best. Especially readers of publications like Direct Driller where we accept that we don’t have all the answers. We are on a never-ending journey of discovery and we understand that to learn, to take us to the next stage, we have to share knowledge with each other. After 25 years of giving farm tours at Shimpling Park, I’ve never had a group leave without someone solving one of my many agronomic problems.

So, having successfully survived rehab, did I ever replace my agronomist? No, but we possibly should. I say ‘we’ because the next generation of Pawseys are chomping at the bit to have a go. It’s not all about me. Although I do have stuff to pass on, so much has changed in the organic regenerative space over the last ten years, and that is for them to discover, to adopt and claim as theirs. Enlightened agronomy, it’s happening. If you don’t believe that it is, then you’ll just have to accept that it’s my truth.

-

Learning About AI in Farming

We’re constantly told that artificial intelligence (AI) is going to transform farming. There’s no shortage of tech companies, startups, and big ag players developing AI-powered solutions for farmers. But very few people have stopped to ask: what do farmers actually want or need from AI? More importantly, what tools already exist, and how can we make them work for us right now?

This article isn’t about future promises. It’s about equipping farmers with practical skills to start benefiting from AI today, using freely available or affordable tools that can make everyday jobs quicker, simpler, and perhaps even more profitable.

Farming Needs Farmer-Led AI

Much of the current AI buzz centres around data collection, analysis, and prediction, primarily designed to feed corporate dashboards rather than help you walk your fields more efficiently. These tools can be valuable, yes, but they’re rarely shaped by farmers themselves.

Our goal is different. We want to help farmers cultivate AI skills that give them control over how these technologies are used. We’re not developing tech in a lab; we’re starting in the field, asking real questions like:

- What AI tools are you already using (if any)?

- What kind of tasks would you like to automate or improve?

- How do we build confidence using AI without jargon or complexity?

Practical AI: Tips, Tricks, and Today’s Tools

While most headlines focus on flashy farm robots and complex imaging systems, some of the most powerful AI tools are already sitting in your pocket or on your laptop. Language models like ChatGPT, for example, can help:

- Write grant applications or stewardship paperwork

- Translate supplier emails or technical documents

- Draft health & safety protocols or job descriptions

- Summarise complex regulations or farming guidelines

- Create rotas or convert field notes into Excel spreadsheets

But it’s not just about ChatGPT. There’s a growing list of language models, each with different strengths.

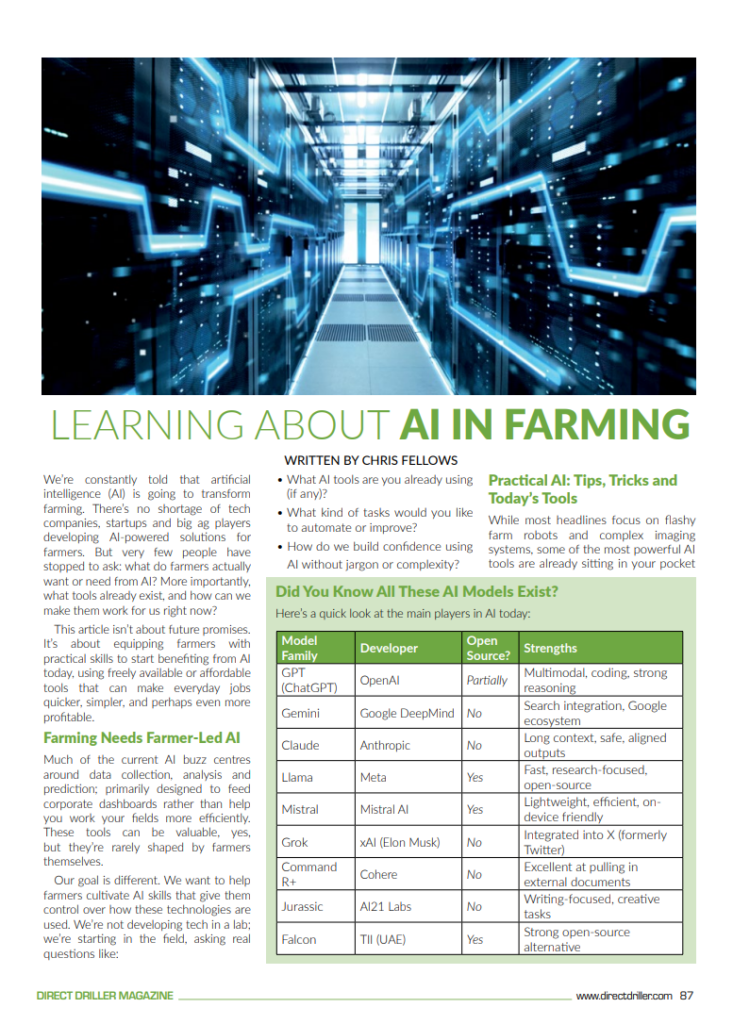

Did You Know All These AI Models Exist?

Here’s a quick look at the main players in AI today:

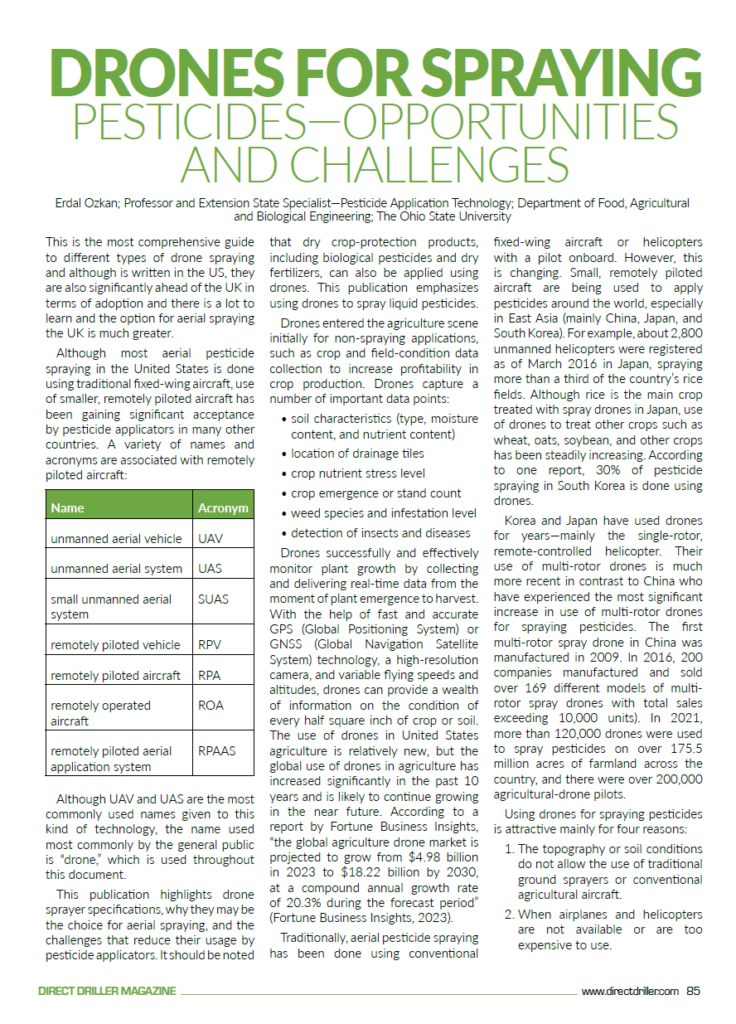

Model Family Developer Open Source? Strengths GPT (ChatGPT) OpenAI Partially Multimodal, coding, strong reasoning Gemini Google DeepMind No Search integration, Google ecosystem Claude Anthropic No Long context, safe, aligned outputs LLaMA Meta Yes Fast, research-focused, open-source Mistral Mistral AI Yes Lightweight, efficient, on-device friendly Grok xAI (Elon Musk) No Integrated into X (formerly Twitter) Command R+ Cohere No Excellent at pulling in external documents Jurassic AI21 Labs No Writing-focused, creative tasks Falcon TII (UAE) Yes Strong open-source alternative While most farmers will likely use GPT or Gemini for now, other models may better suit specific needs, especially when integrated into apps or farm software.

The Challenges: Not Built for Farmers (Yet)

If you’ve ever asked an AI model a farming question, you’ve probably noticed that the answer is often skewed towards American practices. That’s because the bulk of training data for many models is drawn from global sources, with a heavy U.S. bias. Regulations, terminology, and farming systems don’t always translate neatly to UK fields.

You can improve results by adding “UK only” or “according to UK law” into your prompts, but even then, the AI may struggle. That’s part of the reason we believe farmers need better training, not just in what AI is, but in how to talk to it.

Crafting good prompts is half the battle. It’s like asking a contractor to build a shed, you’ll get very different results depending on whether you hand them a sketch on a napkin or a proper plan. With AI, the more specific and detailed your prompt, the better your outcome.

Our Next Steps: Workshops and a Farmer-Led Survey

We want to understand where farmers are starting from. Whether you’ve never used AI in your life or you’re already tinkering with it to write a nutrient management plan, we want your input.

We’re launching two simple but important initiatives:

✅ A survey to understand:

- How farmers are currently using (or not using) AI

- What problems you’d most like AI to help solve

- What training formats work best (video, in-person, printed guides)

🧑🏫 A series of practical workshops:

Held at the Agri-Tech Centre at Harper Adams, these will offer:

- Live demos of tools like ChatGPT and Claude in a farming context

- Prompt writing exercises tailored to agricultural needs

- Examples of real-time use in farm management, record keeping, and even diversification projects

The workshops will focus on low-cost or free tools, not expensive enterprise software. You’ll walk away with hands-on skills and confidence, not buzzwords.

We Need You, No Experience Required

You don’t need to be a tech expert, or even comfortable with computers. In fact, the newer to AI you are, the better, we want to create training that meets people where they are, not where tech companies assume they are.

We’re particularly keen to involve farmers of all ages, backgrounds, and sectors, from mixed farms and hill sheep to arable and horticulture. Whether you’re using a notebook in the cab or a spreadsheet on your phone, your input will help shape something genuinely useful for farming. We aim to hold the workshops at the Agri-tech Centre at Harper Adams.

Final Thought

AI isn’t the solution to every farming challenge. But it is a powerful tool, if we know how to wield it. This is about giving farmers the skills and confidence to use AI on their own terms. To make their jobs easier, not harder. To use technology to serve the people who grow our food, not the other way around.

So if you’ve ever wondered what all the fuss is about, or if AI could save you time and stress, now’s your chance to find out, with people who speak your language.

📍 Take the survey by clicking the link below and optionally sign up for a workshop. Let’s build the future of AI in farming, from the ground up:

https://tinyurl.com/AINeedsAgriculture

-

On-farm trialists ‘lead the field’

The British On-Farm Innovation Network (BOFIN) encourages farmers to ‘lead the field’ in agricultural innovation by taking part in Defra-funded projects that are changing the shape of the industry. Here we catch up with the latest updates across its collaborative projects.

SLIMERS project advances in the battle against slugs

Farmers involved in a major slug project are planning to patch-treat against the pest this autumn, guided by novel risk-prediction maps. Working with scientists and innovators, they are gaining ground in their battle against the slimy pests.

SLIMERS – Strategies Leading to Improved Management and Enhanced Resilience against Slugs – is a three-year £2.6M research programme involving more than 100 farms and seven partners.

Funded by Defra’s Farming Innovation Programme, which is delivered by Innovate UK, the project is led by the British On-Farm Innovation Network (BOFIN). It combines expertise from partner organisations the UK Agri-Tech Centre, Harper Adams University, the John Innes Centre, Fotenix, Farmscan Ag and Agrivation. Together they are developing cost-effective forecasting and precision treatment tools, including Al-based autonomous slug monitoring and biological control and exploring ‘slug resistant’ wheat varieties.

Slug patch prediction

Now entering the third and final year of the project, researchers at Harper Adams University believe they have a reliable model to predict slug patch location. Created with data from farmers’ slug monitoring activities over the previous two years of the project, combined with extensive soil mapping and testing, the model predicts areas in their fields with a high likelihood of containing slugs.

The next step is for the team of Slug Sleuth farmer trialists to put the model to the test – using it for selective applications of slug pellets rather than blanket application. The data collected will also be used to further develop the model.

Professor Keith Walters, who leads the work at Harper Adams says: “We’ve known for some time that slugs gather in patches, but prior to SLIMERS we didn’t understand fully the specific factors that cause this and how the patches can be reliably located.

“Thanks to the data collected by the Slug Sleuths we now have that understanding and are using our predictive model to produce detailed risk maps for their fields. In 2025-6 we are asking them to treat only the predicted slug hotspots to fine-tune the models and bring the vision of precision pest management closer to reality.”

AI identification & precision control

The UK Agri-Tech Centre, Fotenix and Farmscan Ag are working on AI identification of slugs, and precision biological control in the form of nematodes.

Fotenix CEO Charles Veys says: “Our role is to build AI-powered slug detection, right there in the field. But first, we’ve got to train the AI, and that means putting slugs in the crosshairs.”

UK Agri-Tech Centre research associate Dr Kerry McDonald-Howard has been training and collecting data on Fotenix’s AI-based multi-spectral imaging cameras in a lab and in the field, before taking to Slug Sleuths’ farms for testing, helping pinpoint the exact spectral signature of the unwelcome visitors. As slugs don’t tend to surface until after dark this has meant heading out in the small hours to collect the training imagery data.

Dr McDonald-Howard says: “By harnessing AI and multi-spectral imaging, we are making significant progress towards in-field detection and identification of slugs. The next phase is to integrate this technology with precision application, enabling targeted biological control with nematodes for greater accuracy and efficiency.

Kerry McDonald-Howard “Through SLIMERS, we are translating advanced research into practical tools that have the potential to transform and future-proof slug management for UK farmers.”

The team at Farmscan Ag are working on a system with the smallest spray width possible which will be added to an existing autonomous farm vehicle.

“We are aiming for 25cm or less, which would mean four nozzles per metre,” explains director Callum Chalmers. “We are running the first trials at the end of 2025, then field trials will be in full swing in early 2026.”

Slug Sleuth

The data on slug activity collected by the 20 Slug Sleuth farmers has proven valuable not just for the project researchers – the farmers have gained from the increased insight too.

Adam Hayward farms at Bishop Burton in East Yorkshire. He says: “I don’t feel like we are ever on top of slugs and I couldn’t see a long-term solution. There must be a better way to control slugs, which is exactly what the project is looking to develop.”

Adam Hayward Like the other Slug Sleuths, Adam is paid for his time spent on the project monitoring slug traps weekly and recording data via a smartphone app.

“I soon learned which traps would have the most slugs. I didn’t know where they were before and found there was huge variation within just a few metres and between different days. It’s illustrated to me how spreading pellets across the whole field really isn’t the way to go.”

‘Slug resistant’ wheat

The final element of the project is exploring ‘slug resistant’ wheat varieties. Since discovering that one of the Watkins collection of landrace wheats at the John Innes Centre appeared to have slug resistant qualities, Dr Simon Griffiths and his team have been investigating further to identify the genes responsible for the apparent resistance trait and whether it could be introduced to commercial varieties. This work is supported by Dr Victor Soria-Carrasco and his team in the insectary who are continuing feeding trials with slugs on the unusual wheat line, Watkins 788.

In year two of SLIMERS Simon and Victor teamed up with Harper Adams University and six Slug Sleuths to trial a selection of Recombinant Inbred Lines – Watkins 788 crossed with Paragon – with additional monitoring to see if indeed these varieties are spurned by slugs.

Tom Allen-Stevens Tom Allen-Stevens, BOFIN managing director says: “This is research that would never have progressed if farmers hadn’t shown an interest. We now know from our field trials there is something in the genetics of this fascinating wheat that does indeed spurn slugs. The team at John Innes Centre have made progress on sifting through the massive wheat genome to pin down the genes responsible. We’ll be doing more field trials this autumn to help them in their quest.

“In the meantime, we will soon have a service that we can roll out as a tool that all UK farmers will come to rely on to reduce their reliance and expenditure on pellets to control arable farming’s biggest pest. With increasing pressure on chemical control, finding sustainable and environmental solutions has never been more important.”

Three years of pulse progress

The Nitrogen Climate Smart (NCS) project is now in its third year, and there’s plenty to celebrate, say the 17 project partners. The ambitious project aims to help UK farmers cut their carbon footprint by including more pulse crops in arable rotations – and livestock diets.

The NCS project is showing real promise as it heads into its final full year of field trials, says Roger Vickers, CEO of PGRO which leads the project. “We have now completed the second year of cropping trials so are beginning to have some interesting results which are confirming the enormous potential there is for pulses in UK agriculture.

“Together we are exploring all aspects of the production of peas and beans from agronomy to harvest through to processing and use in livestock feed.”

Project partners believe that if pulse production was increased to 20% of UK cropping, around 50% of the imported soya currently consumed by UK livestock could be replaced by homegrown peas and beans. This could lead to carbon savings of around 3.4Mt CO2 equivalent.

John McArthur, of partner organisation McArthur BDC explains that this is equal to a 7% reduction in UK agriculture’s emissions. “This one intervention would make a huge difference to both the arable and livestock sectors and is something that with continued progress we believe can be achieved,” he says.

ohn McArthur, MD, McArthur BDC Part of the project led by McArthur BDC is exploring the effect of dehulling and thermal treatment on the nutritive value of beans to increase the soya substitution potential of faba beans, he explained. Other partner organisations are looking at the production side aiming to increase knowledge of pulse crops.

This includes trials by partner organisations and the Pulse Pioneer farmers which all look at optimising production. As the project progresses trials are looking at the legacy effects of pulses – comparing the effect of beans on subsequent crops as well as different treatments designed to optimise production. ADAS is also combining these findings with data from the Pulse Yield Enhancement Network (YEN).

BOFIN recruits and supports the farmer trialists in the project. Managing director Tom Allen-Stevens, who is also a Pulse Pioneer, explains that that more are needed for the 2025-26 trials.

“We currently have 23 farmer trialists on this project and need to increase that to 40 for the upcoming year,” he says. “We are looking for farmers who are at the top of their game and keen to know how they can grow beans better and share that knowledge with other farmers.

“Pulses promise huge opportunities for UK agriculture, and our Pulse Pioneers are driving that.”

New ADOPT fund empowers farmers to trial innovative ideas

Farmers have an exciting opportunity to put their own ideas to the test on their farms, thanks to the Accelerating Development of Practices and Technologies (ADOPT) Fund, which opened for applications in June.

Part of Defra’s Farming Innovation Programme and delivered by Innovate UK, the ADOPT Fund offers grants of £50,000 to £100,000. The aim is to support collaborative, farmer-led trials of the latest agricultural practices and technologies.

Projects are encouraged to tackle key challenges such as improving productivity, resilience, and sustainability. Importantly, these trials are designed to benefit both participating farms and the wider industry by sharing valuable knowledge and building confidence in new approaches.

BOFIN has been named an official ADOPT Project Facilitator, ready to help farmers develop strong proposals, build collaborations, and manage projects. This support allows farmers to focus on running meaningful trials while BOFIN handles the paperwork and partnership building.

Laura Beaumont, BOFIN’s Head of Projects, says: “We’re here to make it easier for farmers to bring their innovative ideas to life. By supporting them every step of the way, from application to delivery, we hope to help drive practical changes that benefit both individual farms and the whole sector.”

For more information about the ADOPT Fund and how BOFIN can help, visit www.bofin.org.uk/adopt

Growers needed to pioneer precision-bred crops

Farmers are invited to explore opportunities to be paid to trial novel crop traits on their farm with Defra-funded projects for 2025-26.

PROBITY is bringing precision-bred crops onto commercial farms for the first time in Europe. In 2025-26, this will involve growing varieties produced through TILLING (Targeting Induced Local Lesions in Genomes) to test traits also being introduced by gene editing.

Two of the three TILLING varieties demonstrate ‘enhanced gravitropism’, resulting in deeper rooting. The project team is particularly interested in hearing from growers in drought-prone areas to test these varieties.

‘PROBITY Pioneer’ trialists need to be committed to the project’s goals and able to demonstrate high standards of practice and professionalism, explains Andrew Newby, who drafted the grower guidelines for the trials.

“There are some important stipulations for our PROBITY Pioneers in order to retain integrity of the trials. This includes a requirement for separate storage for the PROBITY grain, the ability to clean down all farm equipment used in the trial after use, and rogue out off-types from their plots,” he says. “We will also need them to be meticulous with their record-keeping and be happy to share their experiences with other farmers.”

There is also the opportunity to join the NCS project as a ‘Pulse Pioneer’, which involves running a pulse trial. This is a pea or bean field in which an area is not growing a pulse crop (eg spring oats) that then comes back into the same crop as the rest of the field the following year. An additional product/practice should be trialled across at least two tramlines. Pulse Pioneers are also required to take samples throughout the project, a process managed through ADAS YEN, and to complete an annual carbon footprint through Farm Carbon Toolkit.

The SLIMERS project is also seeking additional ‘Slug Sleuths’ to join the team for the 2025-26 season. For 2025-6 this will involve patch-treating against the pest this autumn, guided by novel risk-prediction maps. Additionally, BOFIN is interested in hearing from farmers intending to grow spring wheat in 2026 who would like to join the TRUTH project as a ‘Root Ranger’, to explore soil and root health.

Tom Allen-Stevens, BOFIN managing director says: “The Root Rangers will get the opportunity to grow and monitor the only wheats in the world known to have the natural ability to control the rate at which nitrogen is processed in the soil – the exciting trait of biological nitrification inhibition.

“That’s just one of a number of opportunities we are offering to farmers to shape the future of farming. Farmers have the opportunity to lead the field – while getting paid for their time. Our on-farm trials are opening doors for forward-thinking growers to test cutting-edge innovations, influence research, and directly benefit from the results but also from collaboration with leading scientists.

“We welcome anyone with an interest in on-farm trials, and any of our projects, to find out more and register their interest with us.”

For more information and to register interest visit www.bofin.org.uk/LeadtheField

-

New Technology Lets Farms ‘Steam’-roll Weeds & Pests

Written by John Dobberstein and originally publish in No-Till Farmer USA

Plough it, spray it, crowd it, fry it – There are many ways to kill weeds, pests and diseases – and there’s a new technology emerging that allows farmers “dry clean” their fields, so to speak.

The Propane Education & Research Council (PERC) recently unveiled an eco-friendly solution for “soil disinfection” with the propane-powered soil steamer. PERC says the machine can, “address one of farmers’ biggest challenges in modern agriculture: how to effectively eliminate weeds, soilborne pathogens, and nematodes without relying on chemical pesticides.”

The machine’s banded steam design targets the top 1-2 inches of soil, the critical zone where weed seeds germinate, providing 80% weed control for both conventional and organic crops, says Mike Newland’s Mike Newland, PERC’s director of agriculture business development. The system can cut weeding labour costs in half, increases yields and reduces the dependency on harmful fumigants and herbicides, he says.

PERC cites studies showing the steamer manages 90-95% of annual weeds such as purslane and pigweed, and controls major soilborne diseases like fusarium, pythium and verticillium. When used for lettuce cultivation, it has been shown to increase yield by 25% in fields affected by lettuce drop.

The technology also provides an estimated 73% reduction in weeding time compared to traditional herbicides.

Years in the Making

Steaming has been used successfully before to disinfect soil but was too costly and time-consuming for large-scale operations. Steamer increases the size of crops such as lettuce and carrots and enables shorter crop rotation intervals, allowing for more frequent planting of high-value fruits and vegetables, Newland says.

At the current time the technology isn’t cost effective for production fields with thousands of acres. Newland says he can’t speculate if the steam would harm beneficial insects or soil organisms that many no-tillers work hard to protect.

Newland credited Dr. Steve Fennimore, a weed management specialist at the University of California-Davis research station in Salinas, Calif., for researching the technology here and in other parts of the world. PERC helped fund some early research. Newland says Fennimore spent much of his career, “trying to figure out exactly the appropriate temperature and appropriate duration of that temperature in soils to be the most beneficial.”

There’s been different iterations of field equipment with steam applications that Fennimore designed, and he also brought some equipment over from Europe to test, Newland says, but none of it was as effective enough. Fennimore approached PERC a couple of years ago to partner on a steam-related project, and Fennimore and his UC-Davis team developed the current machine from scratch.

When the buildout date arrived, the concept was taken to Valley Fabrication in Salinas, which makes custom field equipment for high-value crops in the region. “It does a great job of doing exactly what Steve and his team were hoping for. And the results are tremendous, so we’re excited about it,” Newland says.

“There’s steam units in other parts of the world. But this unit is very unique because it doesn’t move, stop and steam a block of ground, if you will. It’s constantly moving, and I think that very unique feature allows for Steve to control that temperature output and the duration of that temperature.”

Technology Promise

The original unit is mostly used in the lettuce industry in Yuma, Ariz., and testing is being done in carrot and strawberry crops. Valley Fabrication is preparing to build the second machine, which has already been spoken for. Newland declined to say who purchased it.

While the technology has a lot of promise, Newland says the machine is probably too expensive to run on row-crop fields with thousands of acres. He predicts most of the machines, for now, will be custom built because there is, “just enough variation in application or cropping techniques that nobody will want to pay for them to sit in a barn for most of the year.”

Newland isn’t ruling out the steam technology playing a future role controlling weeds and pests on production farms.

“If it moves to the Midwest,” he says, “it would probably be for the toughest conditions, just from a cost-per-acre standpoint. We hate to think we’d want to do every acre for herbicide-resistant weeds. But we may reach a point where different measures are needed to control those things.”

Innovative, propane-powered soil steam technology is a breakthrough method for eliminating soil pathogens and weed seeds, particularly beneficial for organic farmers or those looking to reduce the use of potentially harmful chemicals. This newest technology leverages the power of propane to create a more sustainable and effective solution for soil sanitization.

Researchers at the University of California Davis and University of Arizona began the project in 2020 with funding support from the Propane Education & Research Council (PERC). The banded applicator injects steam along the seed line before planting. Researchers say heating the soil to 150-160 degrees Fahrenheit for 15-20 minutes controls more than 90% of certain troublesome weeds.

What Is Soil Steam Technology?

Propane soil steam technology involves using steam to sanitize the soil, killing pathogens, pests, and weed seeds. Soil steam equipment uses propane to heat water and create steam, which is then injected into the soil. This method is environmentally friendly, reducing the need for chemical pesticides or herbicides, making it an ideal solution for organic farmers and beyond.Why Propane?

Environmental Sustainability: Unlike chemical herbicides, which can contaminate soil and water and harm non-target organisms, soil steam technology relies solely on heat while remaining extremely effective. Propane produces fewer emissions, reducing the environmental impact of farming operations, and produces minimal emissions compared to gasoline or diesel, making it a greener choice for pest and weed control.Effective Pathogen and Weed Control: Propane-powered soil steam units effectively eliminate a wide range of soil pathogens and weed seeds. The high temperatures achieved by these units ensure thorough sanitization for healthier crop growth.

Improved Soil Health: Soil steaming technology reduces the need for chemical treatments, for optimal soil health and minimal ecosystem interruptions. Healthy soil supports better crop growth for higher yields and better-quality produce.

Organic Farming Compliance: Propane-powered soil steam units align with sustainable farming principles and practices. Farmers using soil steam technology can easily meet organic certification requirements.

Real-World Experiences

Recent field testing showed the soil steaming process reduced weeding times by 73% compared to standard herbicide, and increased lettuce yields by 25% where lettuce drop was present. Propane also presents significant fuel cost savings compared to diesel models.Steve Fennimore, professor of Cooperative Extension at the University of California-Davis, has been conducting a research and extension program focused on weed management since 1997 and is currently focusing on the development of field-scale steam applicators to reduce the need for chemical fumigation.

“An incredible benefit to this technique is that we don’t have to treat the entire field and are instead able to target exactly where the disinfestation is needed,” said Fennimore. “Not only does soil steam technology allow producers to get into the field almost immediately after using it, the effects last weeks to months because it takes a while for the pest to reinvade what is now clean.”

By integrating new propane-powered soil steam technology into weed and pest management efforts, farmers can enhance crop quality, boost yields, and contribute to a more sustainable future in agriculture.

Case Study

Steam: Sustainable management for weeds, soil pests

Based on article from by Trina Kleist, UCDavis

Steam treatment of soil offers growers a viable alternative to chemicals and a money-saver for organic farmers. She is assessing the impacts on weeds, soil-borne disease and the soil biome of steam treatments used to disinfest lettuce and spinach fields in the Salinas Valley.

She works with Steve Fennimore, a professor of Cooperative Extension in the UC Davis Department of Plant Sciences, and she presented her research during the poster session at the recent Automated Technology Field Day here.

Steam injected into the ground is hot enough to kill most weed seeds in the soil after cultivation, making it a sustainable alternative to both chemical herbicides and hand-weeding, Escalona said. With temperature above 160 degrees Fahrenheit for 10 to 20 minutes, steam also kills pathogens such as Fusarium, Pythium and Sclerotinia — all fungi that grow in the soil. They can cause plants to rot from the roots and die, causing farmers to lose production.

“It’s a balance,” Escalona said. The steam can’t be too hot, or it could kill things living in the soil that help the plants. “At 70 degrees Celsius, we’re finding good recovery of the soil microbiome after 30 days, including the beneficial organisms.”

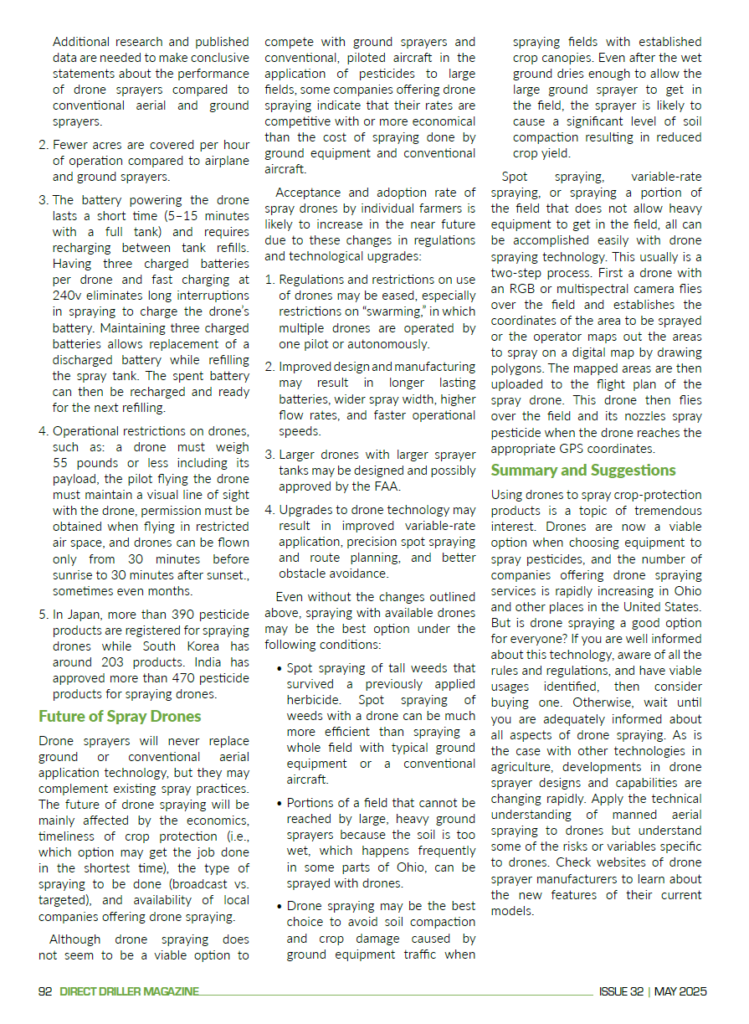

Erika Escalona is a graduate student working with Steve Fennimore, in the UC Davis Department of Plant Sciences. The machine shown here is a custom-built steam applicator, used to tackle pests in the soil before planting. (Trina Kleist/UC Davis)

Steam treatment was used as early as the 1880s, mostly in greenhouses but also in fields, to battle weeds and disease, Escalona said. It fell out of favor when chemical pesticides became more prevalent in the 20th century.

Previous studies have shown steam treatments reduced weeds and boosted lettuce yields. In addition, steaming appears to reduce the fungus Fusarium; and the tiny balls, or microsclerotia, that allow fungus to survive in the soil, according to Fennimore’s research.

“It also offers a tool for organic farming to deal with pests, because right now they don’t have a lot of options,” Escalona said.

-

New Standard for On-Farm Autonomy and Laser Weeding

As farms across the UK grapple with mounting labour shortages, rising input costs, and tighter sustainability expectations, automation is becoming less of a novelty and more of a necessity. Leading the charge is US-based agri-tech firm Carbon Robotics, whose latest developments in autonomous tractor control and laser-based weeding solutions are rapidly redefining how arable operations are managed.

Their newest offerings—Carbon AutoTractor and the next-generation LaserWeeder G2—present a compelling vision for scalable, dependable automation in the field, particularly for vegetable, broadacre, and organic growers looking to improve precision, cut labour costs, and maintain production round the clock.

AutoTractor: Real-Time Autonomy with a Human Touch

The Carbon AutoTractor system is a retrofit autonomy kit designed for John Deere 6R and 8R Series tractors, enabling full autonomous operation without permanent modification. Installation is completed in under 24 hours, and tractors can still be operated manually if required—offering a flexible entry point into autonomous farming.

But what sets Carbon’s solution apart isn’t just the kit—it’s the Remote Operations Control Centre (ROCC), where trained Carbon Robotics staff remotely monitor every autonomous machine in real time. Whether it’s navigating past an irrigation pipe, detecting unexpected wildlife, or avoiding debris, human oversight ensures reliable, uninterrupted fieldwork with minimal downtime.

“In agriculture, autonomy has too often been oversold and underdelivered,” says Paul Mikesell, founder and CEO of Carbon Robotics. “Our approach is built around real-world farming challenges. We don’t just sell the kit—we stay with it.”

Tasks such as cultivating, ploughing, disking, mulching, mowing and other ground prep operations can all be handled autonomously. Safety is a clear priority too: with RTK-GPS, 360° camera vision, radar-based sensors, and physical plus remote emergency stops, operators can trust that operations are carried out safely, even when no one is in the cab.

And for those already using Carbon’s LaserWeeder? The AutoTractor works in tandem, intelligently adjusting speed to optimise weeding performance based on weed type and density—delivering up to 20% greater coverage compared to conventional tractor operation.

LaserWeeder G2: Next-Level Precision Weed Control

Originally launched to great acclaim, Carbon’s LaserWeeder now enters its second generation with a range of upgrades designed to improve flexibility, speed, and performance. The LaserWeeder G2 boasts a new modular design, reduced weight, and significantly increased processing power, opening up laser weeding to a broader range of farm sizes and crop types.

With models ranging from 6.6 feet to a staggering 60 feet in width, there’s now a version to suit everything from small-scale vegetable growers to large organic cereal operations. The lighter weight means G2 models can be paired with more economical tractors and used earlier in the season, helping to reduce compaction and improve soil health.

Each LaserWeeder G2 is powered by Carbon AI, a deep-learning system trained on over 40 million plants from around the world. The platform enables ultra-precise identification and elimination of individual weeds using high-energy lasers—eliminating the need for herbicides or mechanical cultivation.

Fitted with NVIDIA-powered image processors, high-resolution cameras, and 240-watt lasers, the G2 system can operate day or night, in all weather conditions. The 100% liquid-cooled design ensures consistent performance, and all data syncs in real time via Starlink internet, allowing for fast software updates and secure uploads of field images.

Farmers can manage and monitor operations via an iPad app or the Carbon Ops Centre, giving access to field-level performance data, weed detection stats, and even individual crop health metrics. For growers looking to boost yields while maintaining sustainability credentials, it’s an appealing combination.

Broadacre Expansion and Affordability

While initially developed for high-value vegetable crops, the G2 range now includes models specifically designed for organic broadacre crops like maize and soybeans. The 40-foot and 60-foot configurations are particularly suited to larger-scale, 60-foot implement farming systems and promise to be the first laser weeding solutions capable of handling such operations without disturbing the soil or crops.

With a pay-per-hour pricing model, Carbon Robotics has made this high-tech system surprisingly accessible—even for farms not looking to make a huge upfront investment.

A Practical Leap, Not a Gimmick

Farmers trialling the systems in the US report transformational gains in efficiency and reliability.

“Carbon Robotics showed us they could deliver with the original LaserWeeder,” says Brandon Munn of Columbia Basin Onion LLC. “Now, with our tractors running autonomously and LaserWeeders working through the night, we’ve extended our working hours and improved safety—all without adding staff.”

UK growers may still face logistical and import hurdles in bringing this tech across the Atlantic, but it’s clear that a new standard is being set in autonomous and laser-powered fieldwork. For farms struggling to manage labour and scale output sustainably, solutions like the AutoTractor and LaserWeeder G2 may soon prove as essential as the sprayer itself.

-

Introduction – Issue 32

How full was your grain store this harvest and how have your planting plans changed between 2021/2 and 2024/5? My guess is your 2024 harvest is 10 per cent below a 2022 baseline average and you’ll be planting as much as 10 per cent fewer acres for the next. The area planted will largely depend on SFI initiatives. The betting is this time next year the grain store will be even emptier.

Maintaining income from your cereals in the next year will need the farm gate price to rise 15 to 20 per cent which will probably mean the family loaf rising from £1.30 to £1.60 — a significantly smaller rise than the nurses’ award (around 30 per cent), or many others in the public sector. Grain imports will balance the supply and demand equation. World grain prices might reach record levels if global weather doesn’t play ball; if the Russians are still barred from western markets and so dependent on their grain going to China and neighbouring countries; or if a major grain area is negatively hit. Given the disaster will be well away from Britain, it may turn out not so bad after all.

Global grain shortages always hit the poorest populations, and those with the smallest reserves. Countries with major political problems such as Sudan, which, along with Zimbabwe were considered to be the bread-basket of Africa in the 1970s, may experience difficult shortages as the smaller harvest is shared out by the wealthier players. President Trump’s action may play a part in the markets, as he diverts America’s exportable surplus to those countries he favours.

Farmers frequently compare today’s harvest figures with those of 20 years ago. In the 80s corn made £140/t, fertiliser was £100, and red diesel around 25p. Today the corn price is roughly the same £140, but fertiliser is £350 and diesel 75p. The corn price has been left behind while the erosion of state support which used to provide 50 per cent of the profits is a further blow.

Direct drilling is an important solution, and the purpose of your Direct Driller magazine is to come up with solutions, provide advice and information. Early adopters will have a head start but those still hesitating certainly haven’t missed the bus. In consolation there’s a mountain of info now, far more than when we started the magazine.

-

Critical Role of Water in Regenerative Agriculture

Written by Chris Fellows

I was reading a paper on water usage (QR code at the end if you want to read the whole thing) and realised we don’t talk enough about water in this magazine. Water is the lifeblood of agriculture, but in regenerative agriculture, its role is especially critical and multifaceted. While much attention in has focused on soil health and carbon sequestration, understanding and managing water is equally essential to unlocking the full promise of regenerative systems.

At the heart of this water-soil relationship are two key properties: readily available moisture (RAM) and soil infiltration rate (SIR). RAM refers to the portion of water in the soil that crops can easily access for transpiration, while SIR determines how efficiently rain or irrigation can enter the soil. Together, these properties govern how resilient a farming system is to drought, erosion, and runoff.

Healthy, regenerated soils can store more water and absorb rainfall more effectively, leading to improved crop growth, reduced need for irrigation, and greater resilience during dry spells. Moreover, better infiltration means less surface runoff and erosion, allowing more water to recharge groundwater systems. This not only supports farm productivity but benefits the broader ecosystem.

However, the paper I read, by Lankford and Orr warns against oversimplifying these benefits. It’s easy to fall into the trap of thinking that regenerative systems are automatically “net water positive.” But achieving such outcomes requires careful management, especially in semi-arid regions where water resources are already stretched thin.

There’s also a risk in generalising regen as universally water-efficient. In some cases, regenerated soils may use more water because crops grow more vigorously and transpire more. Context matters. The success of regen practices depends on local soils, rainfall patterns, crop choices, and water availability.

Ultimately, integrating water more explicitly into the regenerative narrative is vital. It means quantifying water inputs and outcomes, designing policies with local context in mind, and listening to farmers who know their land best. It would definitely be nice to near more from the water companies themselves about this.

Regenerative agriculture holds great potential, but only by acknowledging water’s central, complex role can we build truly resilient, sustainable farming systems.

-

Apply Now: New ADOPT Fund Backs Farmer-Led Regenerative Innovation

Written by Chris Fellows

Farmers are at the frontline of meeting environmental challenges while keeping their businesses resilient and productive. Innovation—especially farmer-led innovation—is key to moving regenerative practices forward. The ADOPT Fund is now open and aims to do exactly that.

With up to £20.6 million available in 2025/26, the Accelerating Development of Practices and Technologies (ADOPT) Fund is designed to support the on-farm trialling and demonstration of practical innovations that improve productivity, resilience, and environmental sustainability.

What You Can Apply For

There are two key funding opportunities available:

- Full ADOPT Grant

For farmer-led trials and demos that help spread new regenerative techniques or tools across the sector.- Funding per project: £50,000–£100,000

- Must be collaborative, practical, and designed for long-term change—not just short-term experiments.

- ADOPT Facilitator Support Grant

A £2,500 grant for farmers, growers or foresters in England to bring in a Project Facilitator to help prepare and submit their application for the full grant.

The fund is being delivered by Innovate UK, with application support available via webinars and an online hub.

What the Fund Is For

ADOPT is aimed at speeding up the adoption of innovations that:

- Boost productivity and profitability

- Increase resilience to climate and market shocks

- Help reduce emissions and improve environmental outcomes

Projects must show how they’ll make a lasting difference—ideally with results that others can adopt and adapt.

Regenerative Farming-Focused Examples

If you’re practicing or transitioning to regenerative farming, here are the kinds of projects ADOPT could support:

- Multi-species cover crop trials: Testing species combinations for soil structure, nutrient cycling, and weed suppression under different rotations and conditions.

- Low-disturbance direct drilling innovations: Demonstrating machinery or methods that reduce soil disturbance and maintain surface cover while improving establishment.

- On-farm composting systems: Trialling aerobic composting or vermicomposting setups to convert local waste into high-quality amendments and reduce reliance on synthetic inputs.

- Integrating agroforestry: Testing silvopasture or alley-cropping layouts to improve water retention, boost biodiversity, and provide additional income streams.

- Biological inputs in regenerative rotations: Evaluating the role of bio-stimulants, mycorrhizal fungi, or microbial inoculants in enhancing crop health and reducing inputs.

- Mob grazing and pasture monitoring tech: Trialling decision-support tools or satellite imagery to improve grass recovery, stock health, and carbon outcomes.

Next Steps

If you’ve been experimenting with regenerative practices or have an idea that could benefit others in the community, now’s the time to take it further.

The fund is open for applications, and support is available to help shape your project. Whether you’re focused on soil health, biodiversity, or low-input systems, ADOPT is a chance to turn ideas into action—and share the benefits with others and have the support of up to £100,000 of funding.

Do you need a collaborator?

Support from Direct Driller Magazine

If you have an idea, but need support from a Project Partner, then why not pick Direct Driller to support your project. We have been part of projects before, so can offer project management, survey support, farmer communication, market identification and most importantly – you can write about your project in the magazine to help other farmers to understand your project and how they could adopt the idea as well.

After all – that is the real aim of this, the aim Direct Driller has had since it started. Helping farmers benefit from the experience of other farmers. This collaborative approach aims to help farmers learn from each other’s experience, pick up insights and get more out of their projects.

Please email me on chris@agriwebmedia.co.uk and we can have a conversation about your project and how to get started.

Webinar