If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Ag Tech Has a Problem

There is a common saying around the industry that “Farmers are slow to adopt technology.” It’s a long standing perception and it’s linked to my last article on step verses incremental change. Step change is difficult.

But I do think this is used by companies to explain away slow adoption of their products to their investors. Ag tech as a whole, needs to look intrinsically if it feels this is really what is holding your solution back or is your approach holding your solution back?

The Year Long Problem

The perception that farmers are slow to adopt technology, in my view, largely stems from the seasonal nature of agriculture. In an industrial or automotive setting, implementing a new solution provides almost immediate feedback on its impact. However, in farming, results take an entire harvest cycle to materialise. When it comes to digital agronomy tools, additional variables like weather conditions must also be considered. This means the evaluation process can take years before confidence in a technology is fully established—something that many outside the industry might not fully appreciate.

Now, let’s consider some ag tech solutions that have been widely adopted, such as GPS guidance systems and boom section control. These provide instant feedback—farmers see right away that they’re not steering the tractor manually or that they’re reducing seed and chemical use on irregularly shaped fields. On the other hand, digital agronomy tools, like those designed to optimise nitrogen application, require much more time to assess. Farmers must wait until harvest to analyse yield data, then determine whether the results were influenced by factors like weather or specific management practices. Did the technology perform well only because it was a wet year? Would it work just as effectively in drier conditions? Should nitrogen be applied differently to maximise the tool’s benefits? Answering these questions takes time—sometimes years and sometimes isn’t even possible.

Ultimately, this long evaluation process isn’t a sign of slow technology adoption in agriculture—it’s simply a reflection of how the industry operates. If your product does not offer an immediate response on a farm then it is going to take a lot more explaining to farmers and they will see it’s use as a lot more risky or complicated.

What is your approach as an Ag Tech Company?

Now for the tough part—the moment when ag tech companies need to take a serious look inward if they believe farmers are slow to adopt new technology. The first question to ask is: how much time are you actually spending with farmers? How many farmers really know about your products and how many of them really understand them? Have you taken farmers on a journey of development or have you simply presented a solution.

From what I’ve seen, many ag tech companies focus heavily on those at the forefront of innovation—the early adopters. But if you truly want to scale your solution and move beyond the frustration of “farmers are slow to adopt technology,” you need to step outside that bubble. You need to be taking a lot more farmers on a journey with you. If you really think a farmer will take 3 years to adopt your product then you needed to have started speaking with them 3 years ago. That doesn’t mean your product needed to be ready 3 years ago (they wouldn’t have bought it then anyway). But those farmers needed to be part of your journey then, to be adopters now.

There’s a wealth of insight to be gained from everyday farmers, the ones who aren’t always chasing the latest tech. Their feedback might not always be easy to hear, but it’s exactly what the industry needs. Its how you change over the period that means those initial farmers who weren’t ready to adopt, become your advocates of the future.

Engaging with them will reveal what it really takes to scale a product for the broader market. Are you solving a genuine problem farmers face, or are you pushing a solution in search of a problem? And even if your product does address a challenge, is the value it provides enough to justify the effort and potential headaches of implementation? Sometimes, the reality is that a farmer might find it easier to live with the problem than to adopt a complicated solution.

As with most things in life – communication is the key. It’s not easy – but every farmer I know like a chat. They are happy to hear from you as well.

-

Parsnip Pioneers: the world’s first autonomously grown parsnip crop

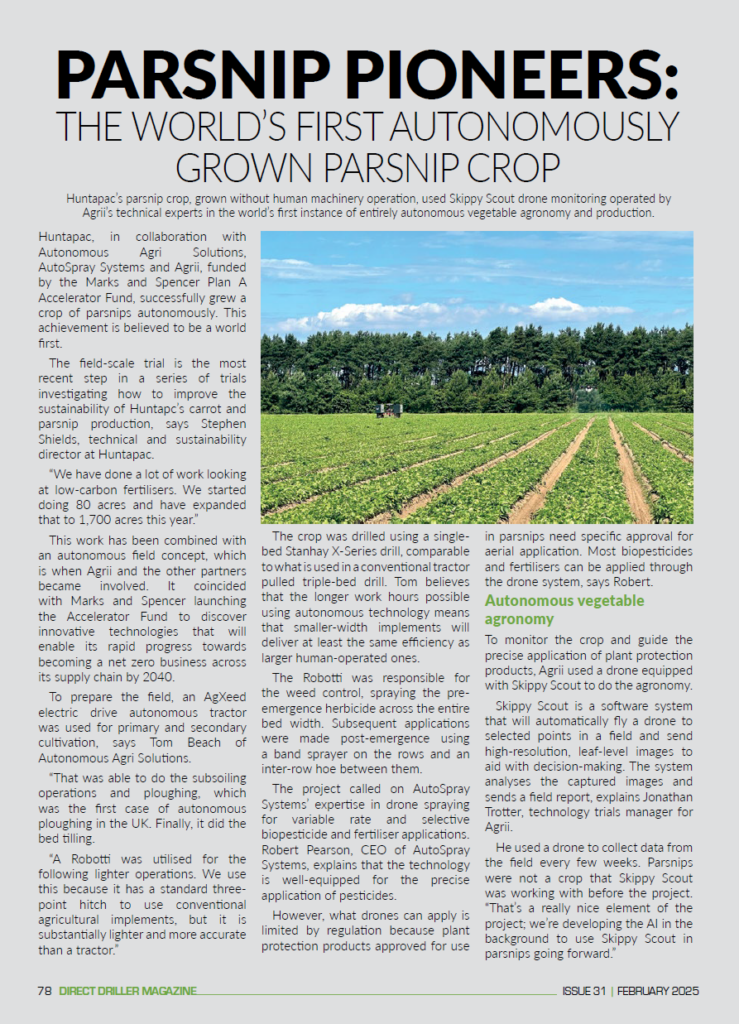

Huntapac’s parsnip crop, grown without human machinery operation, used Skippy Scout drone monitoring operated by Agrii’s technical experts in the world’s first instance of entirely autonomous vegetable agronomy and production.

Huntapac, in collaboration with Autonomous Agri Solutions, AutoSpray Systems and Agrii, funded by the Marks and Spencer Plan A Accelerator Fund, successfully grew a crop of parsnips autonomously. This achievement is believed to be a world first.

The field-scale trial is the most recent step in a series of trials investigating how to improve the sustainability of Huntapc’s carrot and parsnip production, says Stephen Shields, technical and sustainability director at Huntapac.

“We have done a lot of work looking at low-carbon fertilisers. We started doing 80 acres and have expanded that to 1,700 acres this year.”

This work has been combined with an autonomous field concept, which is when Agrii and the other partners became involved. It coincided with Marks and Spencer launching the Accelerator Fund to discover innovative technologies that will enable its rapid progress towards becoming a net zero business across its supply chain by 2040.

To prepare the field, an AgXeed electric drive autonomous tractor was used for primary and secondary cultivation, says Tom Beach of Autonomous Agri Solutions.

“That was able to do the subsoiling operations and ploughing, which was the first case of autonomous ploughing in the UK. Finally, it did the bed tilling.

“A Robotti was utilised for the following lighter operations. We use this because it has a standard three-point hitch to use conventional agricultural implements, but it is substantially lighter and more accurate than a tractor.”

The crop was drilled using a single-bed Stanhay X-Series drill, comparable to what is used in a conventional tractor pulled triple-bed drill. Tom believes that the longer work hours possible using autonomous technology means that smaller-width implements will deliver at least the same efficiency as larger human-operated ones.

The Robotti was responsible for the weed control, spraying the pre-emergence herbicide across the entire bed width. Subsequent applications were made post-emergence using a band sprayer on the rows and an inter-row hoe between them.

The project called on AutoSpray Systems’ expertise in drone spraying for variable rate and selective biopesticide and fertiliser applications. Robert Pearson, CEO of AutoSpray Systems, explains that the technology is well-equipped for the precise application of pesticides.

However, what drones can apply is limited by regulation because plant protection products approved for use in parsnips need specific approval for aerial application. Most biopesticides and fertilisers can be applied through the drone system, says Robert.

Autonomous vegetable agronomy

To monitor the crop and guide the precise application of plant protection products, Agrii used a drone equipped with Skippy Scout to do the agronomy.

Skippy Scout is a software system that will automatically fly a drone to selected points in a field and send high-resolution, leaf-level images to aid with decision-making. The system analyses the captured images and sends a field report, explains Jonathan Trotter, technology trials manager for Agrii.

He used a drone to collect data from the field every few weeks. Parsnips were not a crop that Skippy Scout was working with before the project. “That’s a really nice element of the project; we’re developing the AI in the background to use Skippy Scout in parsnips going forward.”

“We’ve reported back to the group every time we have surveyed the field. The idea is that we can then deploy the other technologies accordingly,” explains Jonathan.

“Skippy Scout helps identify the areas to be treated, which can be inputted into our app to treat those areas specifically,” says Robert. “We’ve been asked if our (spray) drones can do the same level of crop monitoring, and our response is absolutely not. That’s where Skippy Scout is a perfect solution.

“We believe this method will allow conventional chemistry to remain on the market for longer because you apply much less of it using our precise process. At the same time, it allows us to apply more novel products much more easily.”

Robert used the drone to apply bio-fungicides to the crop for disease prevention. This is a task a drone is especially well-suited to because the airflow from the propellers agitates the canopy, giving excellent leaf coverage for the bio-fungicide.

Scaling digital interoperability

The successful field-scale trial has demonstrated a 46% reduction in carbon emissions and significant labour and input savings. Naturally, thoughts move to how the system developed by the group can be rolled out on a larger scale.

Interoperability between the systems controlling the decision support tools and machinery is a crucial milestone. This is a challenge Agrii has already begun working on.

“We are integrating Skippy Scout with our digital platform, Contour,” says Jonathan. “This can then be linked to soil mapping through Rhiza, and further into the future, it could export treatment recommendations to the other technologies used within this very project.”

Tom Beach says the sprayer on the Robotti is already equipped and ready to do this. “It has the standard Topcon ISOBUS, giving us full variable rate capability. We can input field maps or shape files, whatever the source is.”

The data could originate from an agronomist or decision support system like Contour. As well as applying variable rates across the sprayer’s width, Robotti can be programmed only to treat specific areas and return ‘as-applied’ data through its Crop Eye camera.

More precise digital record-keeping will benefit Huntapac’s relationship with its suppliers, says Stephen Shields. “The request from our customers is to have full electronic traceability throughout the process. For some, that’s from 2025.”

Tom concludes by saying that regardless of the ag tech’s sophistication, external factors like the weather and soil conditions will still dictate how the crop is grown.

“As much as we can automate the sensing and recommendations, we are a long way from removing a human from the decision-making process.

“Robots will do whatever you tell them, but knowing what to tell them still requires a huge amount of skill.”

What is involved in growing a parsnip crop autonomously?

Autonomous tool Action AgXeed AgBot T2 Subsoiling Ploughing Bed tilling Agrointelli ROBOTTI Drilling and Nemguard (garlic extract) application Pre-emergence herbicide spraying Granular nitrogen placement Band spraying (herbicide, insecticide and trace elements) Inter-row hoeing Skippy Scout powered drone (Mavic 3 Multispectral) Crop monitoring, data analysis and decision support XAG P100 Pro Drone bio-fungicide application

-

New genomic technologies flex their potential

Billions are being invested in gene editing globally, but what innovations will that investment deliver? Tech Farmer visited the World AgriTech Innovation Summit to gain a global perspective on what it might deliver for UK farmers.

Written by Mike Abram

There’s been no shortage of global investment in gene editing, even if venture capital funding in the area has plateaued in recent years.

Since the first research paper demonstrating genome editing of plant genomes using CRISPR/Cas9 was published in 2013, somewhere between $4bn and $6bn has been ploughed into start-ups applying the technology in agriculture, while similar, if not higher amounts have been invested by seed companies of all sizes, according to Syngenta head of seeds research Gusui Wu.

“Significant investment or funding has also happened in the public sector in plant gene-editing research,” he told delegates at the World AgriTech Innovation Summit in San Francisco.

Progress has been made in turning that investment into commercialised products. The US Department of Agriculture (USDA), for example, has granted exemptions for (effectively approving) 53 gene-edited traits in 17 crops, as of January 2024.

“At the same time, we have not seen the kind of big impact, large scale commercialisation of gene-edited products in the market yet,” Gusui acknowledged.

That’s not totally surprising, he argued. It took over 10 years from the initial publication of research for the last disruptive technology in plant breeding, transgenic genetically modified traits, until the first blockbuster commercial trait in Roundup Ready soybeans.

And it wasn’t simply because of the regulatory process, although that played a part. It was as much that associated application technologies, such as methods to introducing traits into elite varieties, also needed to be developed alongside the plant transformation technique.

The same is true for gene editing, where enabling technologies are also required. “The good news is that in the past five years significant progress has been made,” Gusui said. “And we’re now approaching a turning point for gene-editing new breeding technology.”

Syngenta has developed a method of introgressing any trait into elite lines in just one generation, says Gusui Wu. Progress includes development of alternative CRISPR/Cas systems by companies like Inscripta, Pairwise and Syngenta to the CRISPR/Cas9 system originally used, which overcomes some of the Cas9 limitations, including its murky intellectual property path, Gusui suggested.

Syngenta has also developed a method of introgressing any trait into elite lines in just one generation, rather than six or seven generations it usually takes. “These types of technologies are very important for the success of gene editing in agriculture,” he said.

“Perhaps the largest opportunity is how we apply gene editing to complex traits,” he noted. “For those traits it is difficult to make simple edits. Instead, we will likely need multiple gene modifications and that is a step change that can be brought by CRISPR.”

Making multiple gene edits at the same time, including different types of edit such as turning genes on or off, or regulating gene expression up or down, will be crucial to making transformational changes, rather than just incremental improvements, according to Inari CEO Ponsi Trivisvavet.

“We are targeting 10-20% yield improvements in three key crops – corn, soybeans and wheat – without adding any resources,” Ponsi said. “In corn, we’re also targeting a 40% reduction in water use and 40% reduction in nitrogen by improving resource use efficiency.”

Inari is using two technology platforms to help achieve those goals. The first, artificial intelligence-powered predictive design help scientists understand what genes to target and express more effectively, she explained.

“For the second part, we use multiplex gene editing to not only turn genes on and off but also think about increasing or decreasing gene expression, like dimming a light switch or making it brighter.

Making multiple gene edits at the same time will be crucial to making transformational changes, says Ponsi Trivisvavet. “And we only use tools that work on natural genes, meaning when we edit wheat, for example, we only edit wheat genes.”

That approach has led to the development of a potentially higher yielding gene-edited wheat. “There is no simple answer for how to increase yield. Through predictive design we are working to build an understanding of the wheat genome’s complexity and create a blueprint for updating the plant’s architecture with our multiplex gene editing,” Ponsi said.

“In this project we’ve explored edits to address grain size, quantity and weight, as well as the number of tillers.”

The first trials of the gene-edited wheat will be in Australia, after Inari signed a collaboration with Australian breeding company InterGrain. “We delivered our gene-edited seeds into Australia, where they are currently in a quarantine greenhouse. Once released they will be further evaluated in local field conditions in field testing.”

Inari’s technology is transferable to other geographies and crops, she added.

Another example of a gene-edited wheat in development was given by Prof Eduardo Blumwald, professor of cell biology at University of California, Davis. His research is looking to address the challenge of reducing synthetic fertiliser use in crops, such as wheat, while maintaining production.

The starting point for his research was examining plant exudates from roots. “The plant communicates with the environment through chemicals,” he explained. “They extrude chemicals all the time through their roots, and with that they can talk with the environment.”

The reason why that is important is that in the soil are nitrogen-fixing bacteria – 80% of our air is nitrogen and only those bacteria can fix that nitrogen into ammonia which plants can use.

“The problem is only 10-15% of the bacteria in the soil can do that. But they don’t because in agriculture soils need oxygen, and oxygen inhibits the nitrogenase enzyme that can fix nitrogen.

“So we started analysing the plant exudates to see which one of those chemicals can induce the production of biofilms in soil. Why a biofilm? Because the biofilm is practically impermeable to oxygen.

“So although there is oxygen in the soil, bacteria surrounded by the biofilm start behaving like hippies by forming colonies and sharing resources,” he said.

Eduardo Blumwald’s research has examined how plants communicate with the environment through chemicals exudates from roots. While surrounded in the colony by biofilm the bacteria fix nitrogen and produce ammonium.

“They’re happy, the plants are happy, and the farmers are happy as they can reduce the amount of nitrogen applied.”

Finding exudates that induced biofilm production was not easy, Eduardo stressed. “We screened almost 3000 chemicals and only found a few candidates.”

The next step was to understand the complex metabolic pathway that produced the chemical in the plant. Instead of over expressing the pathway for the plant to produce more, Eduardo silenced the enzyme that uses the chemical in the plant, so it accumulates, and more is ultimately extruded.

“It sounds easy, but it’s not,” Eduardo said. “But we did it in rice and in wheat.”

The result are crops that need 50% less fertiliser to grow, albeit ones that currently come with a 25% loss in yield in wheat. That could be improved, Eduardo hopes, with further development in the hands of a major plant breeder.

“We think there could be some issues with the way the plants are assimilating the nitrogen, so we are working with the breeder to find better varieties. We believe that in very old cultivars there might be some great candidates.”

Biotechnology firm Switch Bioworks is also investigating the use of microbes to fix nitrogen to replace synthetic nitrogen fertiliser. Its initial research focused on corn, Elizabeth Ordeman, senior research associate at the firm, told Tech Farmer.

“We are isolating the best colonisers and nitrogen fixers that already live around corn roots, and then engineering them to share nitrogen with the plant.”

Typically, wild-type bacteria won’t share nitrogen because of the high energy intensity required for nitrogen fixation. “The resource is very precious for bacteria. What we do is add a genetic switch to microbes already great at fixing nitrogen that allows them to release ammonia that can be used by the plant.”

While the concept of engineering a microbial biofertiliser product isn’t unique to Switch Bioworks, the key differentiator for the company is the separation of the process of building the microbial population and producing fertiliser.

“If you engineer a microbe that always produces fertiliser, since it’s an energy intensive process, the microbe can never grow or compete well in the soil, and you don’t end up with that many bacteria producing fertiliser in the field,” Elizabeth explained.

Switch Bioworks is investigating the use of microbes to fix nitrogen to replace synthetic nitrogen fertiliser, says Elizabeth Ordeman. Switch Bioworks engineered bacteria incorporates a sensor that leads to the activation of ammonium release later in the season, once the population has built. “You get this period where the microbes grow and colonise the root, and then when they are at a high number and the plant needs nitrogen the most, you turn on the ammonium production.”

How exactly that happens is the firm’s intellectual property, but Elizabeth said there were a number of different options available that could serve as the trigger, such as changes in the soil, changes in the bacteria or something related to plant exudates to name just three.

But building the microbial population first was critical, she stressed.

“Every time the population doubles, it doubles the amount of fertiliser the bacteria can produce. It’s how we think one ounce of dried microbes will be able to inoculate an entire acre and replace up to a 100 lbs/acre (112 kg/ha) of nitrogen.”

US start-up Napigen is specialising in gene editing of mitochondrial DNA, using it to develop male sterile wheat plants that can be used in hybrid breeding of wheat.

Development of hybrid wheat has been held back commercially because of the difficulty in producing a viable hybrid seed production system in the crop, with one key challenge the development of male sterile parents, Dr Hajime Sakai told Tech Farmer.

“Currently there is no efficient, stable method of producing male sterile plants, but we hope our technology will enable that.”

Male sterility in rice, vegetables and wheat occurs naturally through genetic differences in the mitochondria, so Napigen is mimicking that through its gene-editing process.

The result, according to Hajime, will be a reliable male sterility trait in elite wheat lines in a much cleaner genetic background than anything currently available.

Once proven, he expects to partner with seed companies to develop hybrid wheat that could increase wheat yields by anything from 15% to even doubling current yields.

Napigen is also using its technology to develop other products, such as herbicide-resistant crops that will not cross-pollinate with weedy plants.

Gene-edited nematode resistant potatoes being developed

Israeli biotech start-up GeneNeer is developing gene-edited potato traits using its proprietary “Superlines” platform, including nematode and disease resistance.

Gene editing in potatoes has proven challenging, even with the newly developed gene-editing tools, CEO and co-founder Dr Kinneret Shefer says, partly because of the inability to completely remove the gene-editing machinery.

As long as foreign DNA is no longer present in the final gene-edited product, most regulatory bodies across the world do not regard the edited crop to fall under genetically modified regulations.

However, removing the DNA is difficult in potatoes due to vegetative clonal propagation from tubers rather than from true seeds. The complexity of the potato genome, particularly its tetraploidy – four copies of each gene – is another complicating factor, which makes generating new traits challenging.

GeneNeer is overcoming these challenges through its Superlines platform, which simplifies the gene-editing process by creating tissue cultures of leading varieties that serve as innovation platforms for researchers to modify genes and create improved traits.

This eliminates the need for crossing or single cell assays to remove the gene-editing machinery as well as reducing the time to produce improved traits.

One of the first traits arising from GeneNeer’s platform is a gene-edited potato with nematode resistance.

“We can use our technology to silence genes in a tissue-specific manner,” Kinneret explains. “Our manipulation occurs in the root tissues, where we silence some specific genes which prevent the nematode from proliferating. Even if a nematode attacks the potato, it cannot complete its lifecycle, cannot lay eggs and use the potato as a host.”

Initial work is being done in three varieties – Russet, Atlantic and Desirée – against both potato cyst and root knot nematodes.

The second development is aiming to solve what Kinneret suggests is a growing problem in potato production in North America – verticillium wilt.

“The reason why it is a growing problem is the push in Canada for faster maturation of the potato crop is genetically linked to greater susceptibility to the fungus causing wilt, Verticillium dahliae.

“It is very hard to target with chemicals, and because of the genetic link, it is difficult to solve with traditional breeding. However, with gene editing we can break that link,” she says.

What is gene editing?

Gene editing, also known as genome editing, at its most basic changes a DNA sequence in a living cell. It’s only been practically possible since 2012, when Nobel laureates Jennifer Doudma and Emmanelle Charpentier discovered the CRISPR-Cas9 method for precisely editing genomes.

Using such a tool allows breeders and plant scientists to “cut” a specific DNA sequence and rely of cells’ natural DNA repair mechanisms to introduce changes at that site. Think of it like a word processor used to edit documents – adding, deleting and replacing letters in the cell’s natural genetic code.

Editing just a single gene can have important effects. Most gene editing to date in food and agriculture are the result of simple edits like turning off, of “knocking out” genes. Examples include improved soybean oil with reduced saturated fatty acids, GABA-enriched tomatoes with higher levels of amino acids to lower blood pressure and browning-resistant mushrooms to prolong shelf life.

But simple edits may not be sufficient to tackle some challenges. The size and complicated nature of many plant genomes increases complexity, while some functions, such as water use efficiency or increased yield, can be driven by multiple genes working together rather than a single native gene.

Enhancements might also require different types of edit, where one gene might need to be knocked out, while other genes’ expressions need to be amplified or suppressed.

That’s where multiplex gene editing can help. It involves making a variety of edits and edit types to multiple genes at the same time. Coupled with the latest advances in genomics and artificial intelligence it provides the opportunity to address biological complexity resulting in accelerated crop improvements.

-

New technology connecting the lab to the field

Drone technology is unlocking the potential of traditional crop trials and helping to bridge the gap between detailed laboratory studies and field trials.

Drones were used to assess an oilseed rape trial this spring at a site in Yorkshire, gathering data that hasn’t been possible before.

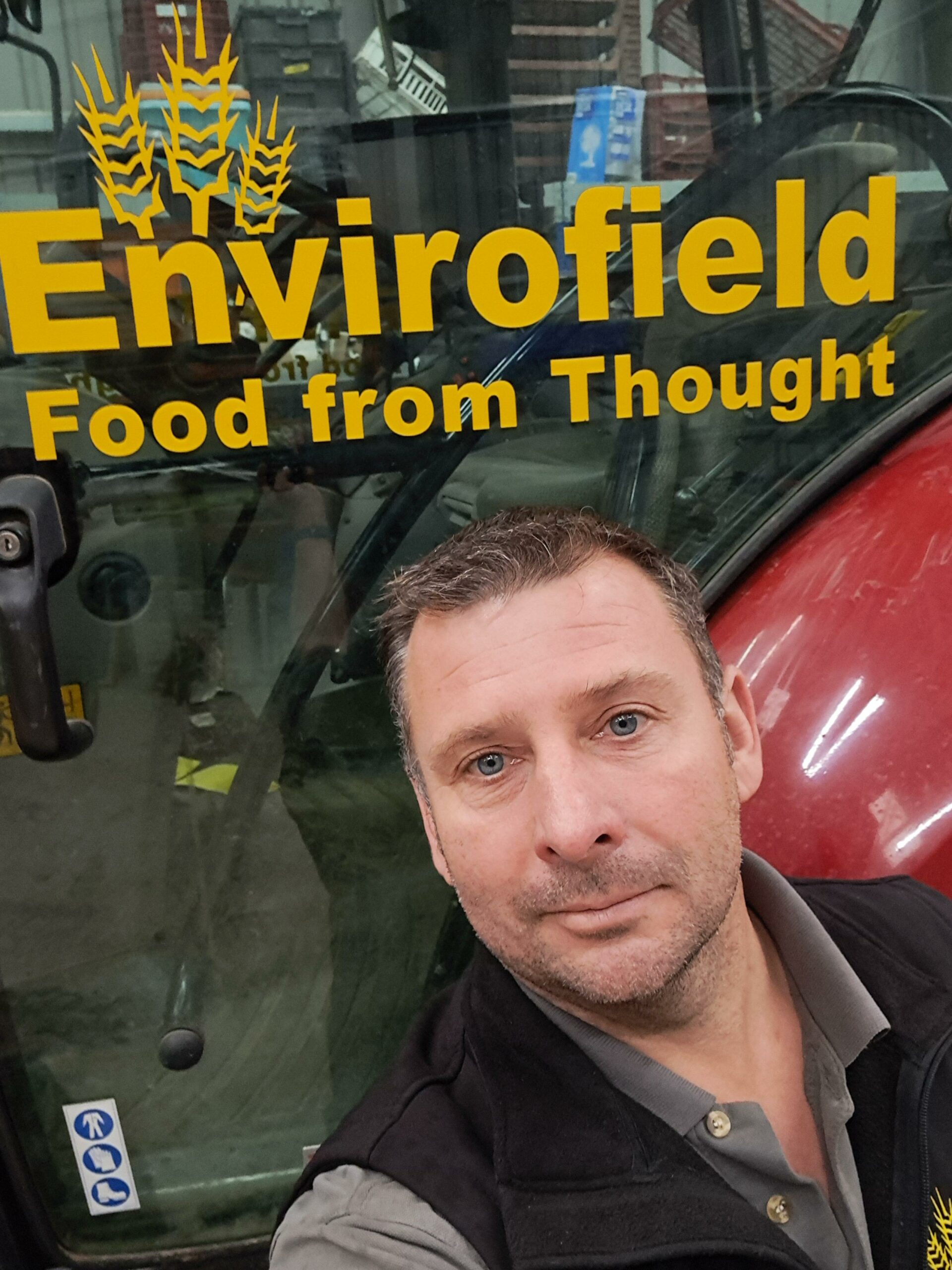

The trial is a collaboration between Envirofield, Agrii and Yara. Envirofield is a crop research organisation that conducts independent trials. In 2022 it was acquired by Origin Enterprises, Agrii’s parent company.

Will Baldwin, director of Envirofield, says the business has maintained its independent status in the Origin group, but also benefits from being part of a bigger organisation. Most recently, this has included access to higher level technology via Agrii’s research and development drone technology to enhance trial assessments.

Will says: “Envirofield acquired a drone five years ago, but we didn’t have the capability to conduct assessments. It just gave us a nice visual perspective of a trial, with only the obvious differences showing.”

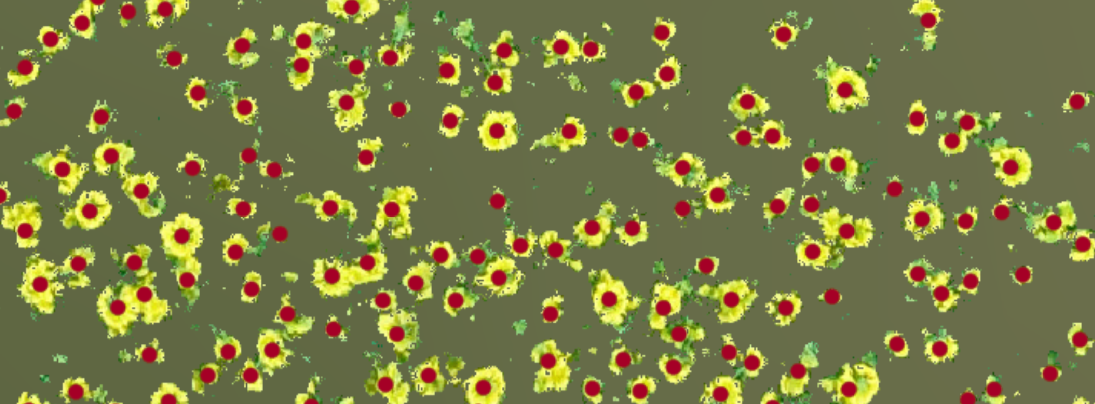

Jonathan Trotter, technology trials manager for Agrii has been operating the drone to assess the trial. He uses photogrammetry, a method in which the drone maps the trial with hundreds or thousands of high-resolution images stitched together for analysis.

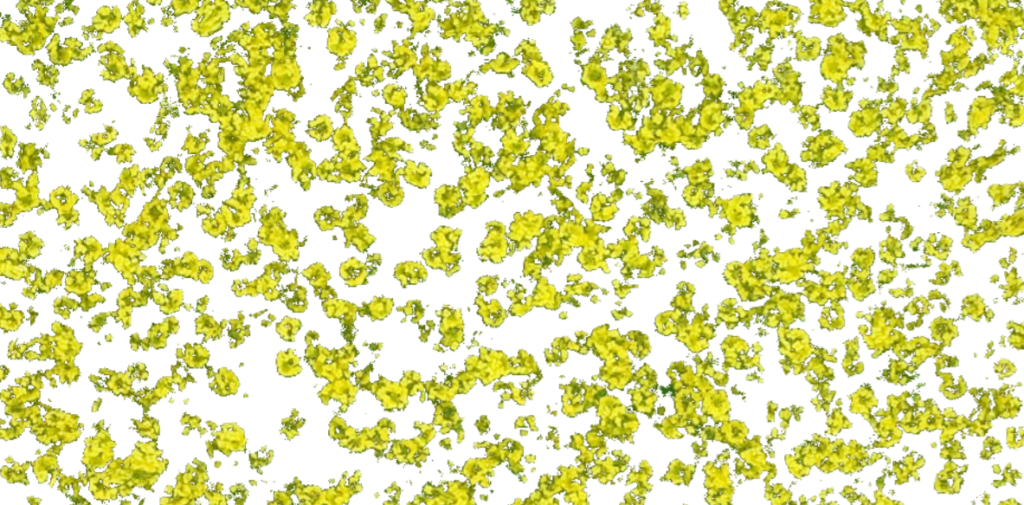

He explains: “The brief from Envirofield was that Yara was interested in counting oilseed rape flowers and understanding how flowering is impacted by the products being tested. The exact details of the trial don’t concern me, my role is to help facilitate their work with the drone.

“I timed how long it took me to conduct an assessment using the drone. From opening my car door, doing the flight, packing the equipment away and finally closing the car door, it took 17 minutes!

“The drone flies across the plots at about 12 metres high. There are 40 plots, about 0.2ha, and the drone captures almost 400 images across the trial.

“Once the images are processed, every pixel equals 0.31cm of resolution,” explains Jonathan.

Agrii uses Solvi to analyse its drone images. Jonathan uploads the data to the platform, which takes about one hour to process.

Using a new tool that Solvi introduced, alongside Agrii’s experience with reflectance, Jonathan used the triangular greenness index (TGI) measurement. He explains that TGI filters out different wavelengths to remove specific colours, such as green and brown, leaving just yellow.

“TGI is perfect for only measuring flowering, which you can record as a percentage cover per plot, giving individual treatment results to monitor throughout the flowering period.

“This couldn’t have been done without a drone,” says Jonathan.

Chris Harrold, YaraVita product manager for Yara UK, says the company is investigating a range of pipeline products based on a mix of nutrients and biostimulants. Their global R&D team has found benefits in using them on flowering crops to improve flowering and pod set.

“We have been working on how we can develop these products in the UK on oilseed rape, peas and beans,” explains Chris.

“When our R&D team placed the trials with Envirofield, they requested a detailed flowering score assessment. Will Baldwin couldn’t imagine how they could accurately deliver this before drone technology was suggested.

“I saw the appeal of that, as did the R&D team. There’s a cost involved, but it’s only a fraction of the cost if we had tried to do it manually.”

The cold spring weather extended the trial’s flowering period longer than expected. Fortunately, since the drone assessments are relatively quick to conduct, Jonathan has been able to add additional assessments to cover all of the flowering.

Meanwhile the R&D team have been speaking to colleagues in Canada who expressed an interest in the work. They want to know if the methodology can be replicated in their country and if it works on other crops.

Chris continues: “Yara has been on board with the work from the outset. The results at the end of the year will reveal the benefits of the products we are testing. Regardless, I believe in the approach and can see its value in different crops and scenarios.”

He hopes to repeat the work next year to gather further data on Yara’s new products and expects the drone assessments to be an important part of the research.

Drone data enhances confidence in trials

Collecting data using drones allows Envirofield to have an archive of evidence showing how it produces its datasets from trials. Will Baldwin believes it gives companies placing trials with them confidence in their work.

He says: “We report what we find in the field at the time of assessment. The digital images taken by the drone can be revisited anytime to see exactly how the dataset was made. With traditional visual assessments, we rely on the eye of the assessor. If another party wants to look at the images, they can if they have permission.”

Will sees potential for drones to fill gaps in our understanding of new products as they go from being tested in glasshouses to small plot and tramline trials.

“What is possible in a glasshouse is not achievable in a field. If there are only one or two plants growing in a pot in a glasshouse, you can measure any physiological or pathological aspect you want in detail,” says Will.

Jonathan Trotter, technology trials manager for Agrii “Once you scale that up to in-field measurement, assessment becomes more subjective due to the large area you must cover to include variability across each plot. We could use two trial agronomists to conduct an assessment depending on what is required. This helps to alleviate any unconscious bias in the data, but that doesn’t always eliminate it.”

In the short term, Will says drones will enable trial contractors to conduct assessments in the field that could previously only be done in a controlled environment. Looking further ahead, he believes they will make it possible to capture even minor differences and account for spatial variation across much larger-scale (tramline) trials and more frequent assessments possible.

He concludes: “Our job in R&D is to give growers the confidence that the data we are collecting is done in conditions that reflect growers’ actual practices.”

Drone in a box to allow autonomous operation

Although the drone assessments only took 17 minutes, Jonathan Trotter had a three-hour round trip to get to the site. Authorisation by the Civil Aviation Authority (CAA) of the ‘drone in a box’ (DiaB) concept for trial use could eliminate the travel time and allow Agrii to assess the trials remotely and more frequently.

Jonathan explains: “Fully autonomous flight would allow us to capture the data daily to see exactly when the plots started flowering, and monitor that through the whole period to count how long each plot is flowering for and how extensive it was.”

In May, Agrii installed one of the first DiaB systems to be used for trial plot data collection and analysis in the UK at one of their sites in Yorkshire. The team is collaborating with DroneAg via Skippy Scout on this project.

“For now, we must use it with a person monitoring the drone as it flies autonomously. We have to be there with a visual line of sight and be able to take control if necessary,” says Jonathan.

“This is part of the process for us to prove autonomous drone flights are safe and possible to receive authorisation for fully autonomous flights.”

He expects Agrii to receive approval in 2025. The process is complex, with authorisations granted on a company-by-company basis. The CAA assesses each case on its merits, creating a high bar for the investment required.

-

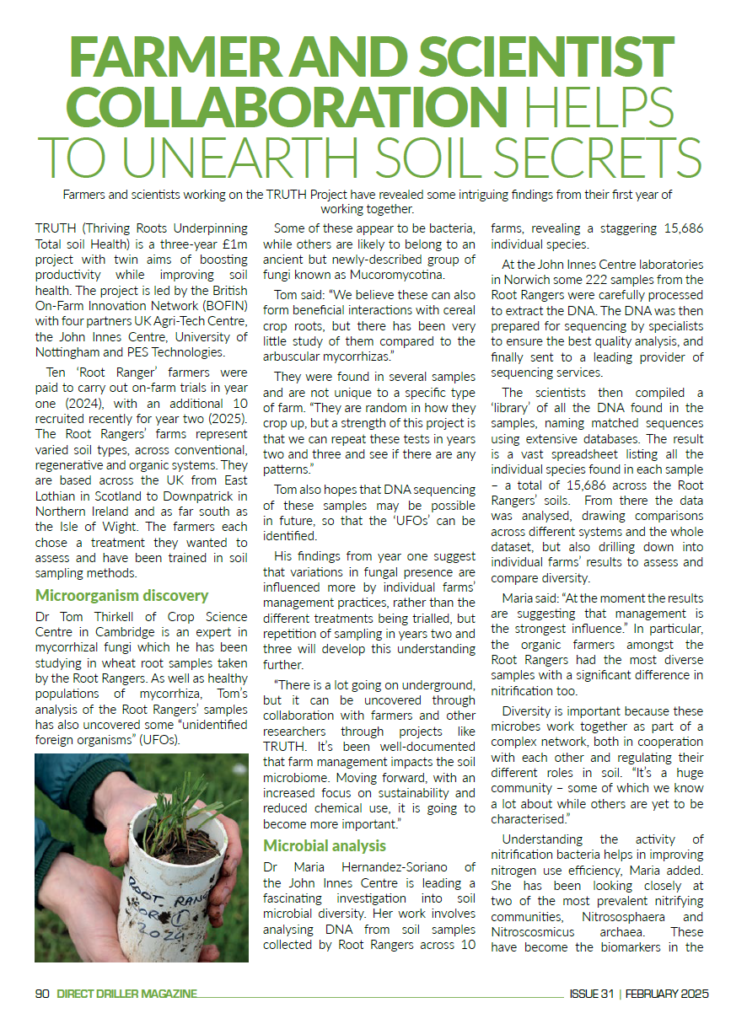

Farmer and scientist collaboration helps to unearth soil secrets

Farmers and scientists working on the TRUTH Project have revealed some intriguing findings from their first year of working together.

TRUTH (Thriving Roots Underpinning Total soil Health) is a three-year £1m project with twin aims of boosting productivity while improving soil health. The project is led by the British On-Farm Innovation Network (BOFIN) with four partners UK Agri-Tech Centre, the John Innes Centre, University of Nottingham and PES Technologies.

Ten ‘Root Ranger’ farmers were paid to carry out on-farm trials in year one (2024), with an additional 10 recruited recently for year two (2025). The Root Rangers’ farms represent varied soil types, across conventional, regenerative and organic systems. They are based across the UK from East Lothian in Scotland to Downpatrick in Northern Ireland and as far south as the Isle of Wight. The farmers each chose a treatment they wanted to assess and have been trained in soil sampling methods.

Microorganism discovery

Dr Tom Thirkell of Crop Science Centre in Cambridge is an expert in mycorrhizal fungi which he has been studying in wheat root samples taken by the Root Rangers. As well as healthy populations of mycorrhiza, Tom’s analysis of the Root Rangers’ samples has also uncovered some “unidentified foreign organisms” (UFOs).

Some of these appear to be bacteria, while others are likely to belong to an ancient but newly-described group of fungi known as Mucoromycotina.

Tom said: “We believe these can also form beneficial interactions with cereal crop roots, but there has been very little study of them compared to the arbuscular mycorrhizas.”

They were found in several samples and are not unique to a specific type of farm. “They are random in how they crop up, but a strength of this project is that we can repeat these tests in years two and three and see if there are any patterns.”

Tom also hopes that DNA sequencing of these samples may be possible in future, so that the ‘UFOs’ can be identified.

His findings from year one suggest that variations in fungal presence are influenced more by individual farms’ management practices, rather than the different treatments being trialled, but repetition of sampling in years two and three will develop this understanding further.

“There is a lot going on underground, but it can be uncovered through collaboration with farmers and other researchers through projects like TRUTH. It’s been well-documented that farm management impacts the soil microbiome. Moving forward, with an increased focus on sustainability and reduced chemical use, it is going to become more important.”

Microbial analysis

Dr Maria Hernandez-Soriano of the John Innes Centre is leading a fascinating investigation into soil microbial diversity. Her work involves analysing DNA from soil samples collected by Root Rangers across 10 farms, revealing a staggering 15,686 individual species.

At the John Innes Centre laboratories in Norwich some 222 samples from the Root Rangers were carefully processed to extract the DNA. The DNA was then prepared for sequencing by specialists to ensure the best quality analysis, and finally sent to a leading provider of sequencing services.

The scientists then compiled a ‘library’ of all the DNA found in the samples, naming matched sequences using extensive databases. The result is a vast spreadsheet listing all the individual species found in each sample – a total of 15,686 across the Root Rangers’ soils. From there the data was analysed, drawing comparisons across different systems and the whole dataset, but also drilling down into individual farms’ results to assess and compare diversity.

Maria said: “At the moment the results are suggesting that management is the strongest influence.” In particular, the organic farmers amongst the Root Rangers had the most diverse samples with a significant difference in nitrification too.

Diversity is important because these microbes work together as part of a complex network, both in cooperation with each other and regulating their different roles in soil. “It’s a huge community – some of which we know a lot about while others are yet to be characterised.”

Understanding the activity of nitrification bacteria helps in improving nitrogen use efficiency, Maria added. She has been looking closely at two of the most prevalent nitrifying communities, Nitrososphaera and Nitroscosmicus archaea. These have become the biomarkers in the rhizosphere of modern cultivars following N-fertiliser application, to the detriment of other communities, she explained.

“The abundance of these microbes in soil dramatically increases when you apply ammonium-based fertilisers, rapidly turning ammonium into nitrate, which is highly soluble and easily lost to the environment through leaching or gas emission as nitrous oxide.”

Year two of the project will focus more on the rhizosphere and now with 20 Root Rangers on board the sampling will produce an even stronger dataset.

“Working on the TRUTH project is a dream,” says Maria. “The farmers have been brilliant, and have sent us quality samples meaning that scientists like me can focus on what we do best. Through our work together we can deliver information that is of real value to the farmers.”

A 360 view of soil health

The Root Rangers have also been given a unique view of their soil structure and root systems through X-ray Computed Tomography (CT) scanning.

Dr Craig Sturrock of the University of Nottingham explained that CT scans were used to compare soil ‘cores’ from the different farms. The farmers took samples from their chosen fields of first winter wheat using sections of plastic pipe (15 cm x 8 cm). These were hammered into the ground before being carefully excavated to preserve the structure of the soil and roots inside. Each of the Root Rangers took 10 samples in a typical w-formation, five samples from the treated area under scrutiny in their trials and five from the untreated area.

Craig explained: “It’s been a really exciting first year of the project, using the imaging technology to visualise the structure of soils across the UK, completely non-destructively, which is usually really difficult to see.

“We’ve found some nice differences between the soils. There’s variation between geographical location, soil texture, treatments, and differences in the root structure.”

The research highlighted the impact of management practices, such as ploughing and grazing. The results were not always as expected, with ploughed soil showing minimal differences to min or no-till. This may have been related to the time of sample collection being relatively late in the growth season (May 2024), where the soil has had time to settle after cultivation the previous autumn. “This year we plan to sample in March so tillage differences between sites may be more apparent.”

In year two the Root Rangers will repeat the sampling process, but this time with five soil cores just from untreated areas.

Craig concluded: “I’m really looking forward to year two of the project, seeing how the results will look and what more we can learn from repeating the sampling.”

Root Ranger feedback

Anna Pearce is an organic farmer and seed producer from Northumberland. She joined the TRUTH project as she was keen to work with scientists to learn more about the health of the soil on her farm.

She said: “As farmers we don’t often get the opportunity to interact with scientists and this is a huge opportunity to be able to put our heads together.” Anna was particularly interested to find out how her soil compared to other farms and to see the soil core CT scans.

“It is fascinating to see pictures of what is under the ground,” she said. “It was reassuring to learn that my soil copes well with being lightly ploughed and that there is enough life in it to repair any changes to structure.”

Hertfordshire farm manager Ted Allen-Stevens also welcomed the opportunity to take part in the project, particularly as it validated the introduction of regenerative practices on the farm.

He said: “When I saw our results from the TRUTH project I felt that I had some real evidence that soil health had improved since we brought in regenerative practices here.

“It’s only when you drill down into the detail of your own farm that you can get that substance and reassurance of what you’re actually achieving.”

Next steps

The second year of the project will build on the successes so far, with the soil/root testing tools under further scrutiny by the farmers and scientists. An innovative soil health sensor, developed by PES Technologies, will also be circulated amongst the Root Rangers who will put it through their paces. The sensor is designed to measure microbial diversity and fungal:bacterial ratio.

Also, in year two novel wheat varieties are being multiplied ready for trialling on Root Rangers’ farms in the final year of the project. These include a ‘remarkable’ variety that can moderate its own nitrogen supply. Originating from Iran, this particular wheat landrace is part of the historic Watkins collection at JIC.

Maria Hernandez-Soriano explained: “What is interesting about this particular wheat, is that it has demonstrated capacity to decrease the transformation of ammonium into nitrate in the soil. This is believed to be an adaptive trait.”

It means much less nitrogen from fertilisers potentially being lost to the environment and more being taken up and used by the wheat plant itself, because it is controlling the transformation in soil and optimising the uptake.

“We haven’t observed that same capability or trait in any commercial wheat cultivars yet, so that is remarkable.”

Tom Allen-Stevens, managing director of the British On-Farm Innovation Network (BOFIN) which leads the project said: “The quality of samples and resulting data has proven again the value of on-farm trials and what can be gained when farmers and scientists work together.

“There is a huge appetite amongst farmers to learn more about soil health. This project is paving the way for discoveries about how we can improve the long-term productivity of our farms through improved understanding and management of our most precious resource.”

TRUTH is funded by the Farming Futures R&D fund, part of Defra’s Farming Innovation Programme. Defra is working in partnership with Innovate UK, the UK’s innovation agency, who are delivering the programme. TRUTH is led by BOFIN alongside PES Technologies, UK Agri-Tech Centre (which is responsible for project management), John Innes Centre and University of Nottingham.

-

A ‘big revolution’ in nitrogen management

Written by Clemmie Gleeson from BOFIN

Could hyperspectral imaging revolutionise nitrogen management in agriculture? Clemmie Gleeson spoke to George Marangos-Gilks, CEO of agritech startup Messium to find out.

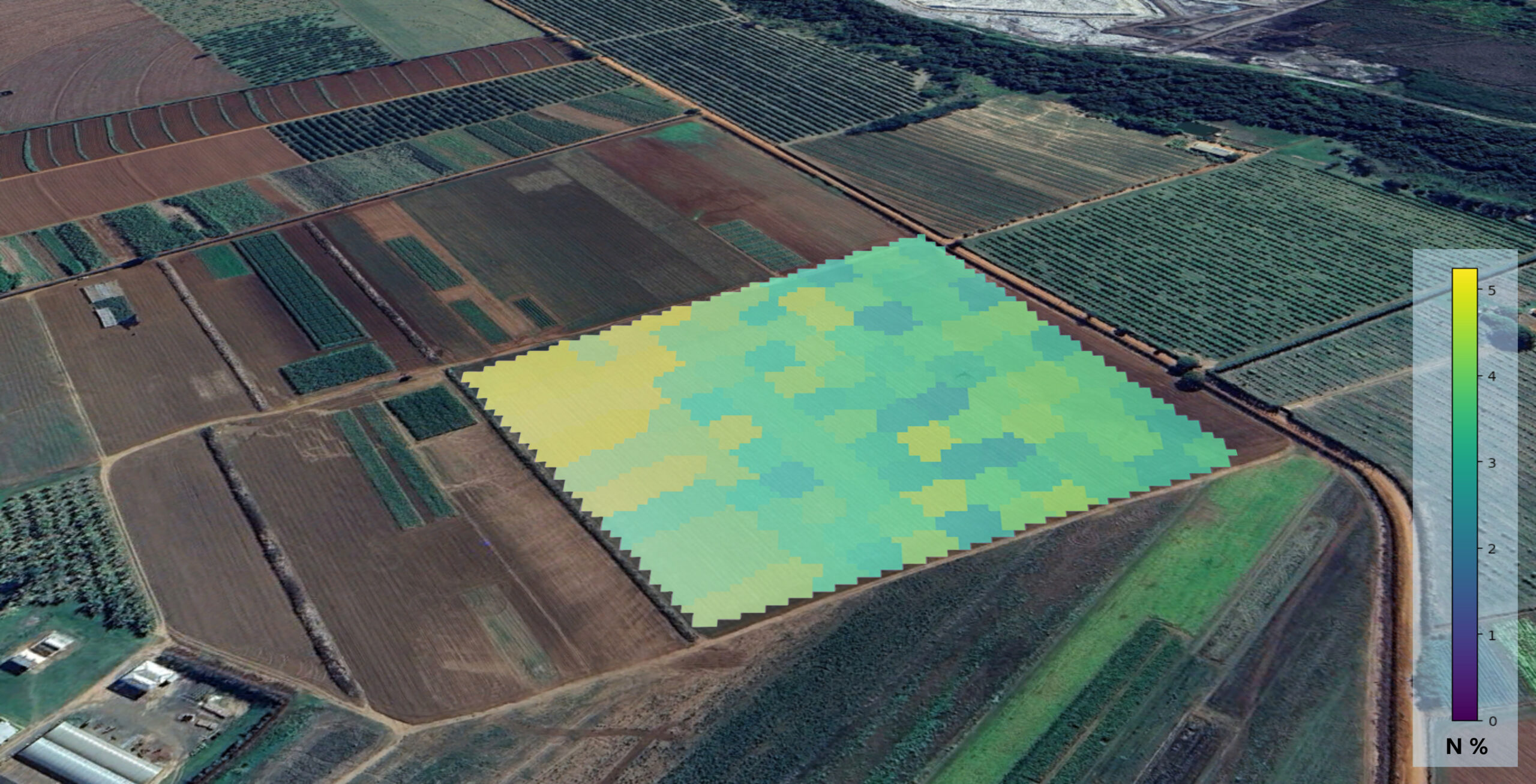

Hyperspectral imagery can overcome the limitations of existing nitrogen assessment methods, equipping farmers with high level insights that could optimise fertiliser applications according to George Marangos-Gilks.

Conventional approaches like lab tests are accurate, but often impractical due to high costs and time constraints, he says. Handheld sensors, though more accessible, struggle with farm-level practicality. And current satellite technologies using NDVI (Normalised Difference Vegetation Index) offer valuable biomass insights but fall short in directly quantifying crop nitrogen levels.

Hyperspectral satellites however are changing the game by capturing hundreds of wavebands, including the invisible infrared spectrum, far surpassing the capabilities of traditional multispectral imaging.

Initially introduced by NASA over two decades ago, early hyperspectral satellites were prohibitively expensive and data-intensive. However, 2024 marked a turning point with the launch of the first commercial constellations creating the possibility of cheaper and more powerful satellites. Indeed, the number of hyperspectral satellites is increasing at a rapid rate and Messium has secured priority supply deals with the major players.

“There is a new age coming with much richer data,” says George.

George Marangos-Gilks, CEO of agritech startup Messium Hyperspectral’s application for assessing nitrogen in crops is based around the fact that every chemical on earth absorbs and reflects a wavelength and has a spectral signature and research has shown that there are key nitrogen wavelengths.

“We can take these wavelengths and use that to develop a very good understanding of the amount and intensity of the nitrogen in the crop.

“Hyperspectral satellites are the first satellites that can accurately detect nitrogen,” he stresses.

Previous generation satellites such as NDVI are adept at understanding biomass – different levels of green density in the crop and where the biomass is larger or smaller – but they can’t tell if that biomass has high or low nitrogen.

“This is the big revolution. We are linking biomass and nitrogen insights together to then apply the science.”

Messium has collected more than 16,000 samples to date – each sample being a 50cm row of crop which is connected to a GPS location and sent to a laboratory where it is analysed for nitrogen concentration and biomass.

George continued: “We take this data and match it to the satellite images that were acquired at the same time. The more we link this data together the more powerful our predictive AI model becomes.

“We are confident that we’re on track to achieve a 90% accuracy level compared to a lab test in the next year.”

Handheld and tractor sensors are also accurate, but they are time consuming and impractical, he adds. Tractor sensors in particular only assess the crop as it is driven over.

“You could be two weeks too early or too late to hit that optimum nitrogen level. The obvious solution therefore is satellites. With satellites you can image an entire farm, but NVDI simply doesn’t do nitrogen.

“You could have high biomass and low nitrogen in the crop or high biomass and high nitrogen. It doesn’t tell you whether you’re above or below that nitrogen nutrition index, the critical nitrogen curve which is the key to utilising the science effectively.”

Cloud cover presents less of an issue for hyperspectral satellites than NDVI satellites, as they operate in networked constellations to increase the frequency of flyovers. Whereas legacy satellites have historically provided imaging opportunities every five days or more, hyperspectral constellations are moving towards daily, and eventually multiple times per day.

“There is basically a satellite overhead every single day, so the chance of having a cloud-free day in a two-week period in the UK is about 96%. With the number of satellites set to double in 2026, cloud is less of a blocker.”

In 2024 Messium collected over 1,000 samples from 47 farms across Europe.

“The results showed that 51% of fields were over-fertilised, they were 40% above the critical nitrogen curve. Then 39% of fields were under-fertilised, by an average of 28%. That’s a big error either side.

“But it makes sense – it is very difficult to understand the nitrogen concentration of a crop mid-season.”

Worldwide Messium has run 47 recommendation trials and plans to release results from its Australia and New Zealand harvest soon. From its trials in the UK 10 out of the 14 farmers involved saw a significant financial benefit in terms of cost saving from reducing nitrogen application and/or yield gained from increased application.

Three were helped with reduced nitrogen for the second or third application, says George. “For four farmers, who were actively trying to reduce nitrogen use, we could demonstrate how applying a bit more would boost yields.

“Then for three farmers, we noticed that nitrogen was not the limiting factor. Plenty of nitrogen had been applied, the crop was not responding, and it wasn’t increasing in biomass. This indicates, potentially a P, K, manganese or calcium issue instead.”

From left Vishal Soomaney Vijaykumar (Messium CTO and co-founder), Nick Wilson (farmer) and Violet Hill (Lead Crop Growth Modeller, Messium) Farmer experience

Mid Suffolk arable farmer Tom Jewers has been trying to reduce nitrogen applications to increase efficiency and has a keen interest in technology that could potentially help, but satellite imagery had previously been a source of ‘endless frustration’.

Speaking at a webinar co-hosted by Messium and the British On-Farm Innovation Network (BOFIN) he said: “We started using NDVI imagery in about 2011, but realised that if we couldn’t get even establishment, it was pointless.

“We then used a variable seed rate to try and get a level playing field, and then varied the nitrogen. When we were purely looking at biomass the advice was always to chuck more on the low bits, and invariably they don’t catch up, so you then put less on afterwards.

“It seemed to me that was the wrong advice.

“We’re now measuring the nitrogen in the crop. Here in the east of England we can suffer with very dry springs, so we’ve tended to start applying more and more N earlier.

“If we’re above the critical N curve, then it’s not going to take that nitrogen up as efficiently, because it’s already got too much, so our use efficiency will go down.

“The really interesting thing to me from working with Messium is the delay in application.”

Mid Suffolk arable farmer Tom Jewers Tom had eight trial strips – some managed under his usual regime, others with higher rates of nitrogen and another in accordance with Messium’s findings. The Messium strip received 227kg of Nitrogen and the strip next to it received 225kg however Messium strip yielded 0.6t/ha more. This was due to the timing of that application.

“Seeing that yield response from a place in the field where there isn’t historic variation was really interesting,” concluded Tom. “We don’t often see that sort of response from a trial so I’m quite excited by this.”

Oxfordshire farmer and managing director of the BOFIN Tom Allen-Stevens said: “It’s essential that farmers can make best use of the latest technology if they are to increase productivity and sustainability in 2025 and beyond.

“Satellite technology has become part of the toolkit for UK farmers seeking precision application, so hyperspectral imaging is of huge interest to those wanting to take their production to the next level.” “My advice to farmers is that to give it a go in trials as Tom has, to find out what difference you can achieve on your farm with your soils.”

-

Nuffield Recommendations for ‘AgTech’ entrepreneurship and development

Yorkshire entrepreneur Hannah Senior NSch has published her Nuffield Farming report ‘Innovating AgTech Entrepreneurship’, sponsored by the Elizabeth Creak Charitable Trust.

The full report is now published and available on the Nuffield Farming report library. A recording of Hannah presenting at the Nuffield Farming Conference watch via the QR Code.

During her Scholarship, Hannah travelled to New Zealand, Australia and the United States, in addition to conducting a number of visits in a further 11 countries via video call due to travel restrictions during the COVID-19 pandemic.

Hannah wanted to learn how to create a more vibrant ecosystem for AgTech entrepreneurs in the UK, understand beneficial support around entrepreneurship and how interactions between start-ups and farmers should operate.

In her report Hannah found that it was inappropriate to model AgTech entrepreneurship ecosystems on those found in Silicon Valley.

“Farming is a very different ‘problem space’ to computing or software,” she says. “AgTech innovation influences the food system, ecosystem and economic system, all of which are influenced by a complex set of interactions and feedback loops. This makes the impact of a new technology hard to predict.”

She identified a pattern which she named the ‘Chain of Extraction’ that happens at macro-level between the environment, agriculture, entrepreneurs and investors. “Despite both the two-way nature of the transactions and the many exceptions, overall benefits tend to accrue more in one direction than the other and this erodes one party’s ability to sustainably create value.

“Improving AgTech innovation requires greater awareness of this dynamic. It also needs creative approaches to align interests and address imbalances, paying attention to how risk, value creation and trust are created and shared.”

In her report, Hannah shares several suggestions, including involving farmers earlier in technology development, diversifying how early-stage investments are made and equipping people in AgTech with ‘Systems Thinking’ skills.

“Technology is only a partial answer to our problems. Changing less obvious things like how we solve problems, invest our capital and measure success will also be essential,” she concludes.

Study objectives

- Investigate how to better align interests between the environment, farmers, entrepreneurs and investors.

- Learn how to create a more vibrant ecosystem for AgTech entrepreneurs in the UK.

Key messages

- A lot of emphasis is put on technology to address agriculture’s major challenges. Technology matters, but it’s equally crucial to address other issues, e.g. how we solve problems, invest capital and measure success.

- Many entities are involved in agriculture and agricultural innovation, including governments, the environment, farmers, entrepreneurs and investors. Naturally all these parties want to benefit, but currently imbalances in the relationships undermine long-term value creation.

- Important differences exist between AgTech and the Silicon Valley innovation template that often informs entrepreneurial ecosystems. To align interests and make a more vibrant AgTech ecosystem these differences need to be considered.

- Equipping the agricultural sector to understand the complicated relationships and unpredictable effects of change requires a new ‘tool set’ – more skill in Systems Thinking will help.

- Farmers, growers and their representative organisations must be more involved in entrepreneurial innovation as idea progresses from its conception, to commercialisation, to a change in farming practice. We must also diversify who invests in AgTech start-ups and how investments are made.

- All this requires a greater emphasis on collaboration, which involves finding methods to build trust, share risk, and equitably distribute value that’s created.

Executive Summary – From Full Report

Written by Hannah Senior NSch

The potential for entrepreneurs to bring new technology to agriculture (“AgTech”) has created a recent focus for start-up activity ($19Bn invested in “on-farm” innovations in 2021). Most AgTech innovations promise to tackle agriculture’s most pressing concerns: environmental impact, labour issues and farm profitability.

This study set out to explore how to create a vibrant AgTech entrepreneurial community, and investigated questions such as what support around entrepreneurship is beneficial, and how interactions between start-ups farmers should operate. However, it also asked much wider questions such as whether AgTech entrepreneurship can really influence farming, the environment and the food industry in the way founders and investors often hope. I questioned the appropriateness of modelling AgTech entrepreneurship ecosystems too closely on what worked well in Silicon Valley. Farming is a very different ‘problem space’ to computing or software. AgTech innovation influences the food system, ecosystem, and economic system, all of which are influenced by a complex set of interactions and feedback loops. This makes the impact of a new technology hard to predict – what is a good idea in one respect (e.g. artificial fertiliser) can bring unforseen negative consequences (e.g. climate change impact, water pollution). I began to recognise a pattern that I came to call a “Chain of Extraction” that happens, at a macro-level, between the environment, agriculture, entrepreneurs and investors. • Agriculture extracts from the environment (e.g. biodiversity, carbon, water) • Entrepreneurs extract from farmers (e.g. time, insight, risk) • Investors extract from entrepreneurs (e.g. financial returns, mental health, lifetime earnings) • Everyone is extracting from the public purse (e.g. tax breaks, subsidies, publicly funded research) Despite both the two-way nature of the transactions and the many exceptions, overall benefits tend to accrue more in one direction than the other and this erodes one party’s ability to sustainably create value. The chain arises despite most people trying to do the right thing most of the time. It that emerges from the way social, economic and environmental systems operate. Improving AgTech innovation requires greater awareness of this dynamic. It also needs creative approaches to align interests and address imbalances, paying attention to how risk, value creation and trust are created and shared. Examples include: • Involving farmers earlier and more substantially in new technology development. Tennessee AgTech business accelerator AgLaunch does this well, working with farmers to select and trial entrepreneurs’ innovations while ensuring the farmers’ contributions are reflected when financial returns are distributed. • Diversifying how early-stage investments are made. Novel ways to structure startup investment (“innovative finance”) exist but are not widely used although there is emerging evidence that investors can achieve strong financial returns even with agriculture-like characteristics (e.g. ii longer adoption timeframes). Greater efforts to diversify who invests would also be beneficial. • Equipping people in the AgTech ecosystem with “Systems Thinking” skills (e.g. being better equipped to identify how/where to make change in complex systems, and understand how influences can deflect us from our stated goals) alongside an openness to collaboration. New Zealand’s Te Hono movement aims to build a more holistic mindset among leaders of their Primary Industries, and build “collaborative advantage” The study concluded that technology is only a partial answer to our problems. Changing less obvious things like how we solve problems, invest our capital and measure success will also be essential.

Read the full report here: https://www.nuffieldscholar.org/sites/default/files/2025-02/Hannah%20Senior%20final%20report%20pdf.pdf

-

Artificial intelligence is speeding up the development of the next generation of Biostimulants

Written by Syngenta

- Syngenta Crop Protection and TraitSeq announce a pioneering collaboration which could help farmers transition to more sustainable practices.

Syngenta and the pioneering artificial intelligence (AI) company TraitSeq are combining forces to use the full power of AI for the development of innovative, high-performance biostimulants.

Syngenta, a world leader in developing the next generation of biologicals products for agricultural use, will use its extensive knowledge of crop biology to complement TraitSeq’s proprietary AI methods to identify highly specific indicators of a plant’s cellular state called biomarkers. When activated, these biomarkers can indicate how well a plant is responding to efforts to boost its health or to block the effects of external, abiotic stressors.

Biostimulants are products applied to plants, seeds or the root environment that enhance natural plant processes, leading to an improved nutrient use efficiency, increased tolerance to abiotic stress or better crop quality. Biostimulants are a vital and growing component of sustainable agriculture, yet their performance can vary depending on environmental factors such as temperature and local climate.

Syngenta has extensive data across different branches of science – such as genomics, proteomics, metabolomics, and phenomics. Using TraitSeq’s sophisticated proprietary platform, scientists from both teams hope to leverage AI to analyze complex biological big data, to uncover the intricate molecular interactions that impact a crop’s ability to utilize available nutrients in the soil. Once specific biomarkers can be identified, scientists hope to be able to quickly and accurately assess the efficacy of a new biostimulant in enhancing plant health.

The development of such biostimulants also fits in Syngenta’s efforts to support farmers transition to regenerative practices and its commitment to sustainability. Syngenta’s recently launched Portfolio Sustainability Framework (PSF) rates Syngenta’s products for sustainability and stakeholder alignments into 3 tiers. New products are also included with the aim to shift the portfolio towards the top tier.

Camilla Corsi, Head Crop Protection Research & Development, said: “At Syngenta, we are accelerating the pace at which we innovate, to deliver solutions farmers urgently need. Technologies such as TraitSeq’s AI-driven platform enable us to revolutionize our research, attain important data-driven insights, so that we can develop the next-generation of sustainable solutions faster – while further strengthening our pipeline of innovative agricultural technologies.”

Dr. Joshua Colmer, CEO of TraitSeq, said: “This partnership highlights how TraitSeq’s versatile platform can transform agricultural input development by uncovering predictive biomarkers that directly link molecular insights to biostimulant performance. By equipping Syngenta’s innovation pipeline with these capabilities, we aim to optimise and accelerate the development of new biological solutions, which will support farmers in adopting more sustainable agricultural practices.”

Biostimulants offer an important solution to farmers seeking to improve the sustainability of their farming operations while addressing challenges arising from an increasingly constrained toolbox of available agricultural technologies and evolving consumer demands.

About TraitSeq Ltd

TraitSeq Ltd is an agri-biotechnology company specialising in applying proprietary machine learning approaches to omics data analysis for agriculture. A spin-out from the Earlham Institute, TraitSeq’s platform combines omics data with other data types to predict complex phenotypic traits. This provides agritech companies with actionable insights to accelerate and optimise chemical and biological crop input development, plant gene editing, and complex trait development in agricultural crops and animals.

-

New sequenced genome sheds light on weed resistance

Written by the Earlham Institute

Genomic advances reveal how similar weeds can dominate wheat fields that are geographically separated by over 5,000 miles.

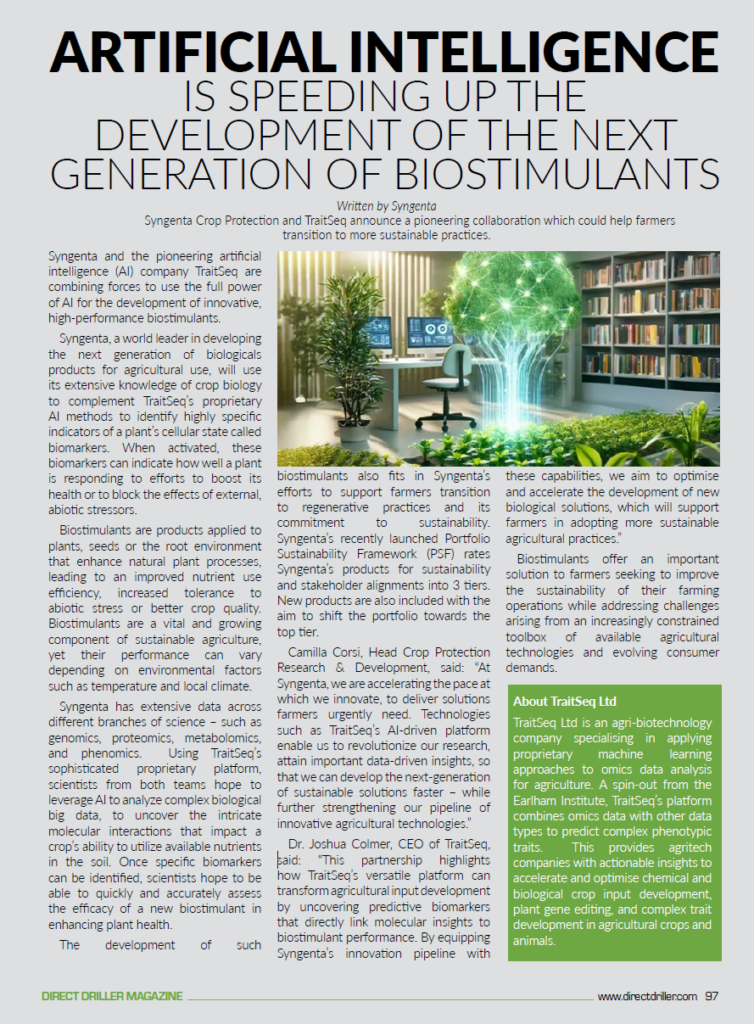

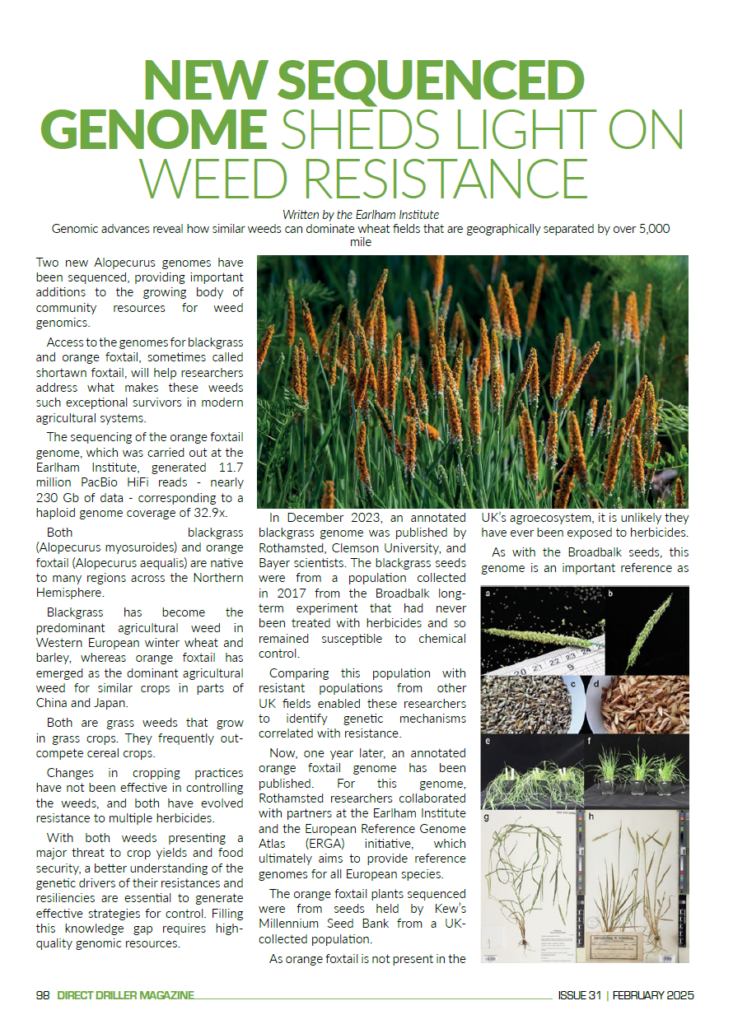

Two new Alopecurus genomes have been sequenced, providing important additions to the growing body of community resources for weed genomics.

Access to the genomes for blackgrass and orange foxtail, sometimes called shortawn foxtail, will help researchers address what makes these weeds such exceptional survivors in modern agricultural systems.

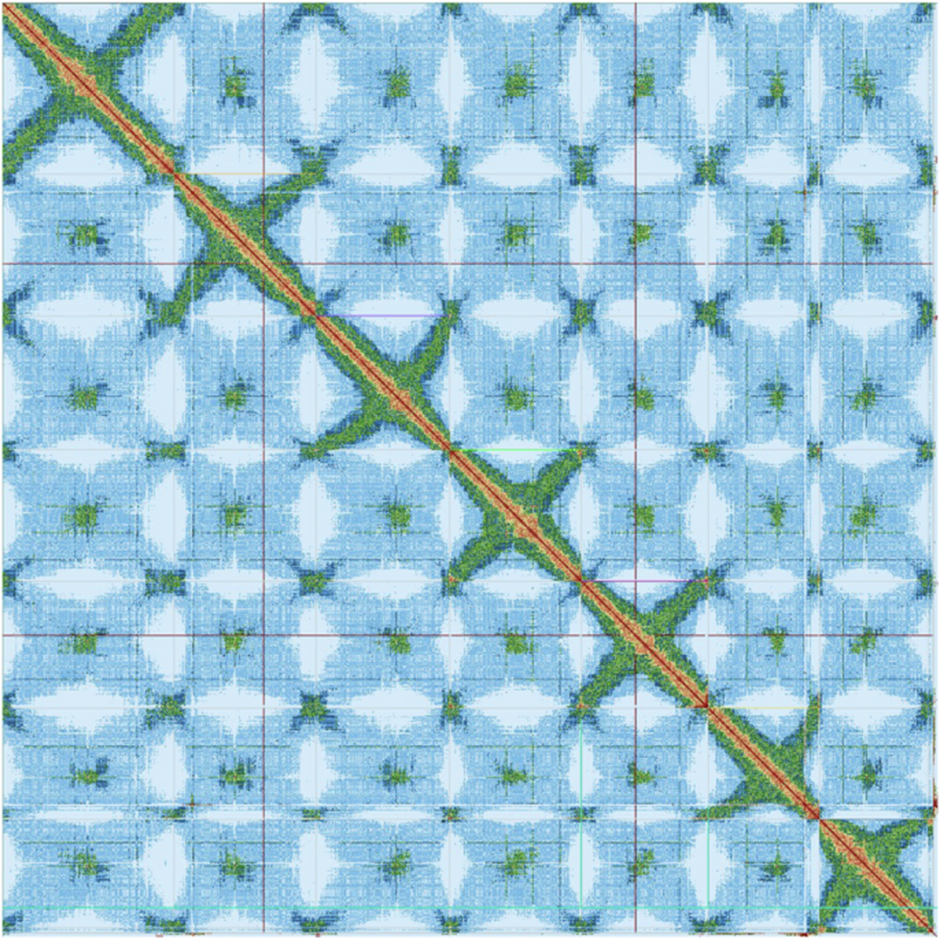

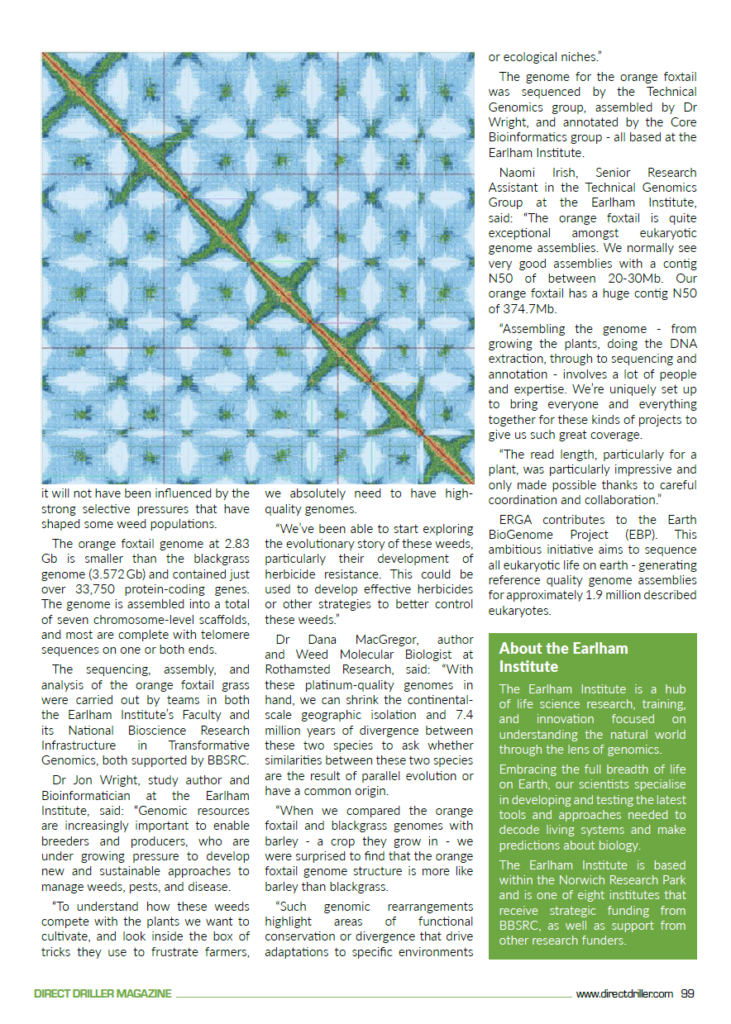

The sequencing of the orange foxtail genome, which was carried out at the Earlham Institute, generated 11.7 million PacBio HiFi reads – nearly 230 Gb of data – corresponding to a haploid genome coverage of 32.9x.

Both blackgrass (Alopecurus myosuroides) and orange foxtail (Alopecurus aequalis) are native to many regions across the Northern Hemisphere.

Blackgrass has become the predominant agricultural weed in Western European winter wheat and barley, whereas orange foxtail has emerged as the dominant agricultural weed for similar crops in parts of China and Japan.

Both are grass weeds that grow in grass crops. They frequently out-compete cereal crops.

Changes in cropping practices have not been effective in controlling the weeds, and both have evolved resistance to multiple herbicides.

With both weeds presenting a major threat to crop yields and food security, a better understanding of the genetic drivers of their resistances and resiliencies are essential to generate effective strategies for control. Filling this knowledge gap requires high-quality genomic resources.

In December 2023, an annotated blackgrass genome was published by Rothamsted, Clemson University, and Bayer scientists. The blackgrass seeds were from a population collected in 2017 from the Broadbalk long-term experiment that had never been treated with herbicides and so remained susceptible to chemical control.

Comparing this population with resistant populations from other UK fields enabled these researchers to identify genetic mechanisms correlated with resistance.

Now, one year later, an annotated orange foxtail genome has been published. For this genome, Rothamsted researchers collaborated with partners at the Earlham Institute and the European Reference Genome Atlas (ERGA) initiative, which ultimately aims to provide reference genomes for all European species.

The orange foxtail plants sequenced were from seeds held by Kew’s Millennium Seed Bank from a UK-collected population.

As orange foxtail is not present in the UK’s agroecosystem, it is unlikely they have ever been exposed to herbicides.

As with the Broadbalk seeds, this genome is an important reference as it will not have been influenced by the strong selective pressures that have shaped some weed populations.

The orange foxtail genome at 2.83 Gb is smaller than the blackgrass genome (3.572 Gb) and contained just over 33,750 protein-coding genes. The genome is assembled into a total of seven chromosome-level scaffolds, and most are complete with telomere sequences on one or both ends.

The sequencing, assembly, and analysis of the orange foxtail grass were carried out by teams in both the Earlham Institute’s Faculty and its National Bioscience Research Infrastructure in Transformative Genomics, both supported by BBSRC.

Dr Jon Wright, study author and Bioinformatician at the Earlham Institute, said: “Genomic resources are increasingly important to enable breeders and producers, who are under growing pressure to develop new and sustainable approaches to manage weeds, pests, and disease.

“To understand how these weeds compete with the plants we want to cultivate, and look inside the box of tricks they use to frustrate farmers, we absolutely need to have high-quality genomes.

“We’ve been able to start exploring the evolutionary story of these weeds, particularly their development of herbicide resistance. This could be used to develop effective herbicides or other strategies to better control these weeds.”

Dr Dana MacGregor, author and Weed Molecular Biologist at Rothamsted Research, said: “With these platinum-quality genomes in hand, we can shrink the continental-scale geographic isolation and 7.4 million years of divergence between these two species to ask whether similarities between these two species are the result of parallel evolution or have a common origin.

“When we compared the orange foxtail and blackgrass genomes with barley – a crop they grow in – we were surprised to find that the orange foxtail genome structure is more like barley than blackgrass.

“Such genomic rearrangements highlight areas of functional conservation or divergence that drive adaptations to specific environments or ecological niches.”

The genome for the orange foxtail was sequenced by the Technical Genomics group, assembled by Dr Wright, and annotated by the Core Bioinformatics group – all based at the Earlham Institute.

Naomi Irish, Senior Research Assistant in the Technical Genomics Group at the Earlham Institute, said: “The orange foxtail is quite exceptional amongst eukaryotic genome assemblies. We normally see very good assemblies with a contig N50 of between 20-30Mb. Our orange foxtail has a huge contig N50 of 374.7Mb.

“Assembling the genome – from growing the plants, doing the DNA extraction, through to sequencing and annotation – involves a lot of people and expertise. We’re uniquely set up to bring everyone and everything together for these kinds of projects to give us such great coverage.

“The read length, particularly for a plant, was particularly impressive and only made possible thanks to careful coordination and collaboration.”

ERGA contributes to the Earth BioGenome Project (EBP). This ambitious initiative aims to sequence all eukaryotic life on earth – generating reference quality genome assemblies for approximately 1.9 million described eukaryotes.

About the Earlham Institute

The Earlham Institute is a hub of life science research, training, and innovation focused on understanding the natural world through the lens of genomics.

Embracing the full breadth of life on Earth, our scientists specialise in developing and testing the latest tools and approaches needed to decode living systems and make predictions about biology.

The Earlham Institute is based within the Norwich Research Park and is one of eight institutes that receive strategic funding from BBSRC, as well as support from other research funders.

-

What the public think of farming?

I had already written this into based on the IHT announcement and the subsequent farming protests and events organised around the country. But having listened to the brilliant Tom Martin talking on stage at the BASE conference I gave it a little update – as his ideas on communication are spot on and really show us to how to connect more with consumers (our ultimate customers).

But protests don’t necessarily endear you to the public – the train drivers strikes being an example of where this damaged their public support. As an someone involved in the organisation of some of the events, you need to consider what the public think of farming overall.

Public Awareness and Support

The widespread protests have undeniably brought significant attention to the challenges faced by the farming community. Media coverage has been extensive, with major outlets highlighting the concerns and struggles of farmers (possible with the exception of the BBC where coverage has not been extensive). I think, based on looking at our socials, this heightened visibility has fostered a sense of empathy among the public, many of whom were previously unaware of the intricacies of agricultural operations and the financial burdens associated with them.

A public poll conducted shortly after the protests indicated substantial support for farmers, with a majority believing that agricultural estates should be exempt from the proposed inheritance tax changes. I think this sentiment stems from a recognition of the essential role farmers play in ensuring food security and maintaining the rural economy. The public’s growing awareness has translated into a broader appreciation for the hard work and dedication inherent in farming. But does this mean they are more likely to buy UK grown products?

Perception of the Inheritance Tax Reforms