If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Relentless rain creates significant challenges

This year’s numerous challenges continued into autumn on the Claydon family’s arable farm in Suffolk, writes Jeff Claydon, who invented the Opti-Till® direct strip seeding system.

Date: 27 November 2023.

What a difference a year makes! I started my last article for Direct Driller, written on 29 August, by suggesting that further agronomic, meteorological, political and economic headwinds would likely continue to test our resolve in the months ahead. They have certainly done that! Between New Year’s Day and when we finished harvest, a stop-go affair which promised much but was ultimately unexceptional, the total rainfall amounted to 436mm. The year-to-date figure has now reached 840mm!

What a contrast this autumn had been compared to last, when it was so dry post-harvest that getting weed seeds and volunteers to chit in the hard, parched soils was difficult. Because of this, and in common with many farms throughout the country regardless of the establishment system used, we saw more grassweeds in standing crops, requiring intensive stubble management.

Fortunately, meaningful rain after the combine had done its job created the ideal conditions for our Claydon Straw Harrow, an implement I often compare with a telescopic handler; you don’t see the need for one until you have one, then you wonder how you ever managed without it.

We went to work with the Straw Harrow immediately behind the combine and in the following weeks carried out five or six passes across the farm. That knocked the stuffing out of weeds and volunteers, as well as severely limiting the life of any slugs in the chopped straw. On 12 October glyphosate was applied to kill the remaining green material, but almost immediately the heavens opened, dropping 60mm of rain.

The first winter wheat went in on 15 October, albeit under slightly damp conditions, and over the next three days we established 75 per cent of the planned area using our 6m Claydon Evolution M6 drill. Particularly good progress was made until the door of opportunity was slammed rudely in our face by heavy rain on the night of 18 October. Over the next three days 93mm fell, followed by an average of 10mm every day for the remainder of the month. A further 60mm during the first three days of November simply compounded the problem. It just goes to show that however much you plan Mother Nature always has the last word.

So much rain falling in a short period made the application of post-emergence herbicides more difficult on our very heavy Hanslope series soils, but at least we were able to do it. The task was only possible because the firm, supportive soil structure left behind the Claydon drill allowed our self-propelled sprayer to travel virtually unhindered. However, it remains to be seen whether product efficacy has been impaired.

BUOYANT ATMOSPHERE AT AGRITECHNICA

The busy Claydon stand at Agritechnica 2023 Agritechnica 2023 in Hanover, Germany from 12 to 18 November was the first since 2019, the planned 2021 event having been cancelled due to ongoing Covid-19 restrictions. Attracting over 470,000 visitors, this mind-boggling display of agricultural technology has to be experienced to be believed.

Slug pellets were not used last autumn because the weather was extremely dry. That turned out to be a mistake, so this season Jeff applied them at drilling, with excellent results. There is significant cost involved in exhibiting at the world’s biggest agricultural show, from stand space, stand builders, catering, hotel, to travel and subsistence costs for all the Claydon team, but the investment is certainly worth it in terms of sales, contacts made and market awareness. With my eldest son Oliver at the wheel of his hybrid vehicle we headed to Hanover in an environmentally friendly fashion. Driving from Suffolk to the Channel Tunnel we couldn’t help but notice that the whole of southern England looked wet and drab, a theme which would continue in Europe.

Travelling through France, Belgium and Germany things didn’t get much better. Wherever we went 25 per cent of the land appeared to be waterlogged, the emerging crops barely visible above flooded land which resembled paddy fields. Those images left us thinking that this could have severe implications in terms of crop yields and prices in the months ahead. Feed wheat is currently circa £180 per tonne and oilseed rape £360/t, suggesting that no-one is seriously considering how much less farmers across much of Northern Europe might be harvesting in 2024.

Claydon was one of the few British companies exhibiting at Agritechnica and because, collectively, our staff speak many languages we were able to talk to most visitors in their native tongue. Amongst them were some from Bulgaria where, ironically, the weather had been remarkably dry.

The show was buzzing and over seven days the Claydon team welcomed happy customers from all corners of the world, many of whom have been using our Opti-Till® system for many years to successfully establish the widest range of crops quickly and efficiently in all types of terrain, soils and conditions.

Agritechnica 2023 featured a massive choice of equipment dedicated to the apparently simple task of establishing arable crops and it would be possible to spend a vast amount to do that. But why would you, especially at a time when combinable crops prices are significantly below where they should be to support a thriving farming industry?

Avoiding the complexity, excessive weight, high capital cost and substantial on-going running costs of many other methods, Opti-Till® delivers excellent results, very cost-effectively. Numerous customers to our stand at Agritechnica advised us that they are operating Claydon drills for €3 to €4/ha in wearing metal costs and that is much, much lower than many other systems.

The Claydon Straw Harrow again proved its worth this autumn as five or six passes eliminated most volunteers and weeds before glyphosate was applied two weeks before drilling. Given its proven benefits and low operating costs the Straw Harrow represents excellent value, and generally all that’s needed is to follow it with a Claydon drill, which also has extremely low running costs. The advantages of Opti-Till® obviously resonated with those wanting a simple, practical approach. We took hundreds of enquiries from farmers in 34 countries, many of whom are looking to change the way they establish their crops, for a host of reasons.

One of the key themes at Agritechnica was in-crop weeding, particularly inter-row hoeing. I recall being very sceptical when, a decade or so ago, my cousin David suggested that we should consider developing an inter-row hoe for use in strip seeded cereal crops. The reduction in herbicides availability and effectiveness are just two reasons behind the success of the Claydon Terra-Blade which we developed. A simple, low-cost implement, it is highly effective at removing weeds between the rows in cereal crops up to and including Growth Stage 31.

Weeds, such as blackgrass, are easily removed at the cotyledon stage using the Straw Harrow. I was amazed to see the range of equipment available in this sector but taken aback by the high price tags and complexity of some of it, largely reflecting customer demand for it to be self-steering. Claydon have developed and comprehensively evaluated self-steering inter-row hoes and we appreciate that they may have advantages in certain situations. However, we discounted any commercial development because their much greater complexity means that such products would be much more expensive, cost more to maintain and possibly be less reliable.

Claydon’s goal is to produce simple, effective, cost-efficient equipment which will reliably fulfil its intended purpose for many years. These attributes are becoming increasingly important as farming businesses look to keep machinery for longer to amortise the increasing capital cost over a longer period.

Having used a manually steered 6m Claydon TerraBlade to hoe thousands of hectares of cereals on our own farm over the years I can vouch for the fact that it does the job efficiently, effectively and reliably, with none of the drawbacks of far more costly and complex alternatives. However, there are some customers who would like to see guided self-steering hoes, so our engineers will be looking to offer this option going forward for those prepared to invest the extra cost.

EXPERIMENTING WITH DRILLING TIMINGS

On the return journey from Hanover to Suffolk the countryside was still as wet as it had been when we left. Therefore, it was with some trepidation that on my first day back home I drove around the farm to look at our crops.

As an experiment, some oilseed rape was drilled in mid-September to see whether it would avoid the flea beetle, but in mid-November some damage was evident and the crop significantly less advanced. Having been incredibly nervous about sowing oilseed rape immediately after harvest following painful experiences with cabbage stem flea beetle damage in recent years, I was pleased to see most of it looking extremely well; let’s hope it stays that way!

Cabbage stem flea beetle has caused a small amount of damage, but nothing excessive at present, so we will continue to monitor that situation closely. In the meantime, grassweeds have been taken out with Centurion Max and we await some dry weather to apply Kerb®. Hopefully, the crop will be much cleaner this season, although with oilseed rape currently £360/t it is not particularly viable from a financial standpoint. But what’s the alternative as there are no outstanding contenders out there at present?

Winter wheat being sown with the farm’s 6m Claydon Evolution drill just before heavy rain fell in mid-October. As an experiment we drilled an area of oilseed rape in mid-September hoping that it would avoid flea beetle attack, but the jury is still out on whether that approach will work. Some damage is evident, it is way behind that which was sown in August and looks very vulnerable.

Another interesting experiment we are trialling is in the Bio sector. There are so many companies experimenting with Bio products and many on offer, from some offering microbes to improve soil health, etc. We are currently using a natural product that encourages the biome in the soil, providing many health benefits, improving fertility, friability and the ability of the soil to withstand the weather events which we are experiencing. After our first-year trial in 2023 it looks promising, so we will continue to evaluate it in 2024.

The Claydon farm continues to experiment with strips of cover crops to assess whether they provide any benefits. This season, largely because wet weather curtailed autumn drilling, we will be growing more spring oats than ever before, but the crop is also significantly less risky than oilseed rape. In preparation we have Straw Harrowed stubbles up to six times to take out germinating volunteers and weeds at the cotyledon stage and any green material will be sprayed off before Christmas. This is important because over-wintering blackgrass seems to have a toxic effect on the soil and subsequently a detrimental effect on crop performance. The land will be left to rest over the winter, then another dose of glyphosate will go on in the spring just before drilling.

Catchy weather at harvest meant that field operations inevitably caused some surface compaction, although this was minimal by most standards due to the supportive nature of our direct drilled soils. Importantly, the leading tines on our 6m Claydon Evo drill remove this ahead of the seeding tines, so seed goes into ideal conditions and grows rapidly.

The few small areas of the Claydon farm where excessive moisture held crops back will benefit from additional drains in the spring. Winter wheat established in October before the onset of relentless rain looks good and is significantly more advanced than where we experimented with slightly deeper drilling to avoid the emerging crop potentially being affected by pre-emergence herbicides. Did we make the wrong decision in doing that and will we need to reconsider whether that approach was correct? Time will tell.

Most of our land is well drained, but I am pleased we took the opportunity presented by ideal weather in early October to mole 40 hectares where water had been slow to get away. That, combined with the effect of the Claydon drill’s leading tines, has been enormously beneficial in terms of allowing water to move from the surface down to the laterals. Exceptional rainfall since then has highlighted a few small areas elsewhere where excessive moisture is holding crops back, so we will attend to those next year and have already booked our drainage contractor for the spring.

In my next report I will let you know how our autumn-sown crops are faring following the winter and outline our plans for spring drilling.

The Claydon website (claydondrill.com) galleries contain numerous videos on soil health and resilience, as well as showing the Claydon Opti-Till® System being used to establish all types of crops, in all situations, both in the UK and overseas. You can also keep up with the latest posts, photographs, and videos from Claydon and its customers through the Claydon Facebook page www.facebook.com/Claydondrill

-

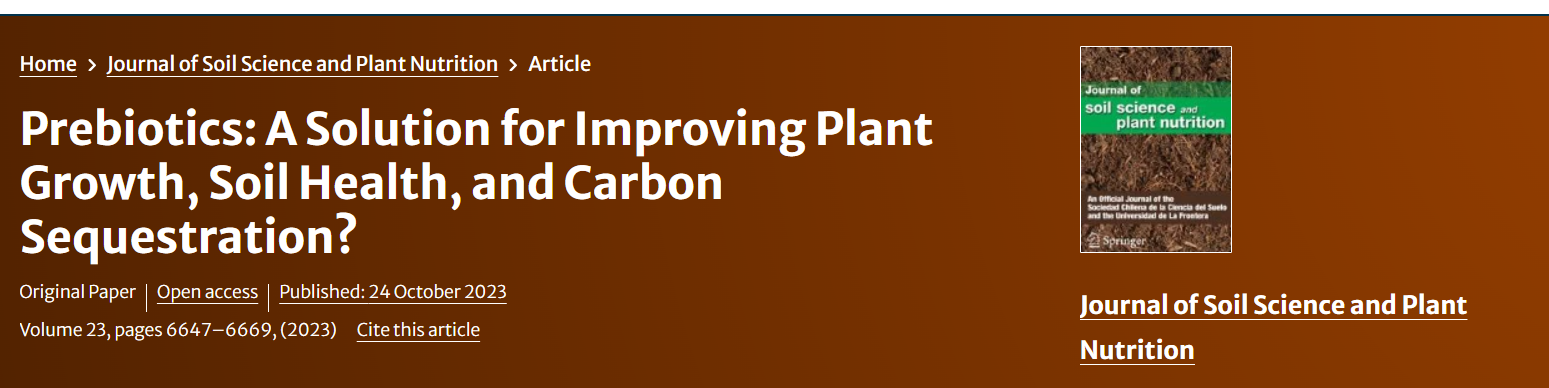

High-performance prebiotics

Nutrigeo L® and K1® at the heart of a scientific publication

Written by Mark Shaw from Gaiago

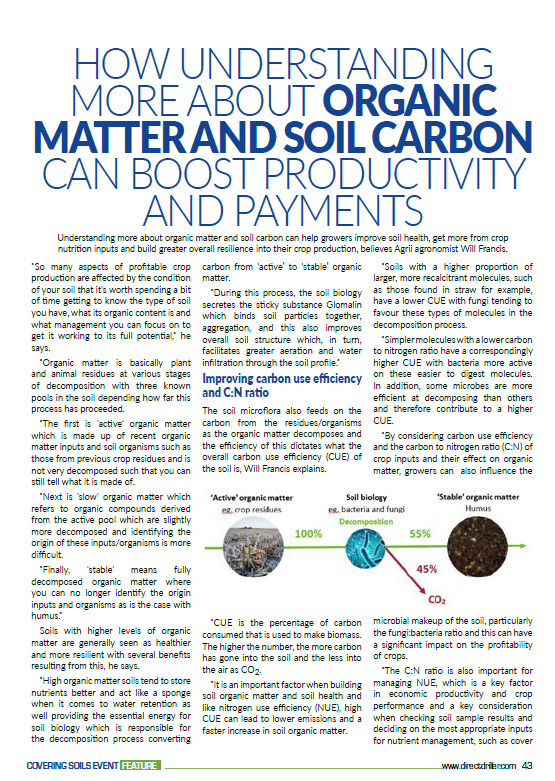

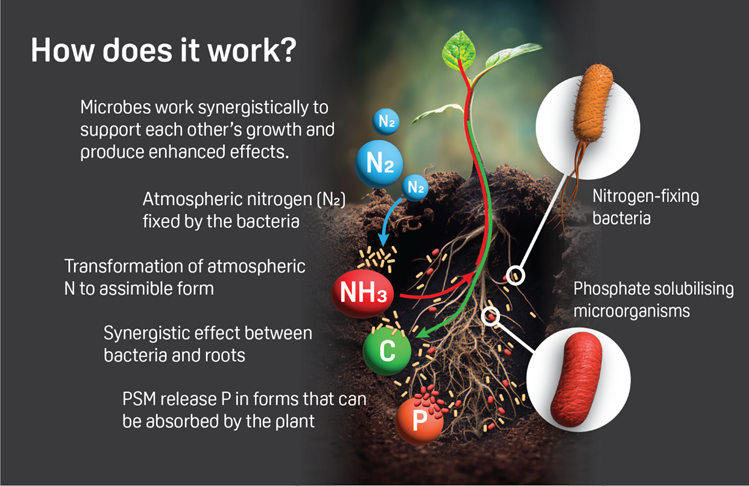

Nutrigeo L® and K1®, two soil biostimulants marketed by the company Gaïago, have shown, under controlled conditions, an agronomic interest for growing corn in loamy soil. The results of these trials are detailed in an article published on October 24, 2023 in the international scientific journal Journal of Soil Science and Plant Nutrition[1].

The BIOMES (Biomechanisms for Soil Life and Plant Nutrition) joint research and innovation chair between GAIAGO and UniLaSalle – which aims to deepen understanding of the interaction mechanisms of microorganisms, soils and plants – has published the first scientific article showing the effects of two soil biostimulants, Nutrigeo L® and K1®.

The article, entitled “Prebiotics: A Solution for Improving Plant Growth, Soil Health, and Carbon Sequestration?” and written by Dr. Abdel-Rahman ALAHMAD, was published on October 24, 2023.

An observation protocol for short- and medium-term effects on soil and plants

The two soil biostimulants, K1® and NUTRIGEO L®, were evaluated for their effects on loamy soil under controlled conditions on corn crops, in comparison with untreated soil. Analyses were carried out at two harvest dates: three weeks and ten weeks after product application and straw burial. Root growth and development of above-ground maize parts were monitored in this study. The variables studied in the soil samples included bacterial and fungal populations, as well as enzymatic activities in the carbon, nitrogen, sulfur and phosphorus cycles, changes in organic matter and mycorrhization of plant roots.

NUTRIGEO, a partner for fungi and soil organic carbon

Nutrigeo L® confirmed its positive effect on corn growth. In this modality, root weight increased by 30% and above-ground weight by 20%. In particular, Nutrigeo L® increased the abundance of “beneficial” soil microorganisms, including saprophytic and mycorrhizal fungi, which act to decompose organic matter and absorb nutrients.

In the NUTRIGEO L® modality, there was an observed increase in CEC, glomalin content and the quantity of carbon associated with fine soil particles at ten weeks (by 8.4% for organic carbon and 8.9% for total carbon). This experiment confirms the action of the NUTRIGEO L® prebiotic in initiating dynamics favorable to soil carbon storage at ten weeks.

K1, the universal decomposer of organic matter

For its part, K1® has also increased the abundance of fungi and bacteria considered beneficial, with action focused on the decomposition of organic molecules of varying complexity, illustrated by a greater metabolic diversity of the soil bacterial community and a higher level of enzymatic activity. This decomposition is coupled with an increase in electrical conductivity, CEC and certain nutrients such as assimilable phosphorus.

As with the NUTRIGEO L® modality, the K1® modality produced greater growth in the crops tested.

Continuation of the BIOMES Research and Innovation Chair’s work on soil fertility

This pioneering work is one of the first to establish the positive short- and medium-term effects of prebiotics on soil fertility, microbial communities, plant development and the initiation of dynamics and processes conducive to carbon storage.

The BIOMES Chair continues to deepen knowledge on these topics, with future publications in the pipeline.

A mode of action defined under controlled conditions with benefits already observed in the field

GEP – Good Experimental Practices – trials have also been carried out by independent technical centers in the field. These studies were carried out in different French and European regions, under different soil and climate conditions, and on different crops, in order to come up with recommendations for use and obtain approval as a soil conditioner with biostimulant effects on soil and plant.

At the same time, in 2020, Gaïago, in partnership with over 80 French retailers, launched an operation called “La Terre Par Dessus Tout” (The Soil Above All). A total of 1,681 farms across France participated, representing 2003 plots and some 20,000 hectares of farmland. Different soil and climate conditions were incorporated into the demonstration. Observations, based on easy-to-implement, reliable and duplicable indicators of soil structure and organic matter decomposition, validated the effectiveness of NUTRIGEO L® in agricultural distribution, with visual benefits in almost 9 out of 10 cases.

The results obtained by the scientists of the BIOMES research chair have confirmed and illustrated the mode of action of NUTRIGEO L® under controlled conditions, and complemented the results already observed in plots through the national soil fertility operation.

In addition, this prebiotic is the main lever of the Gaïago Carbon program, which enables farmers to accelerate the revitalization of their soils thanks to the income generated by carbon credits. More than 26,000 hectares of 650 farmers in Europe are involved in this program.

[1] Journal with an impact factor of 3.9; ranked in the top quartile of scientific journals in terms of influence in its category.

-

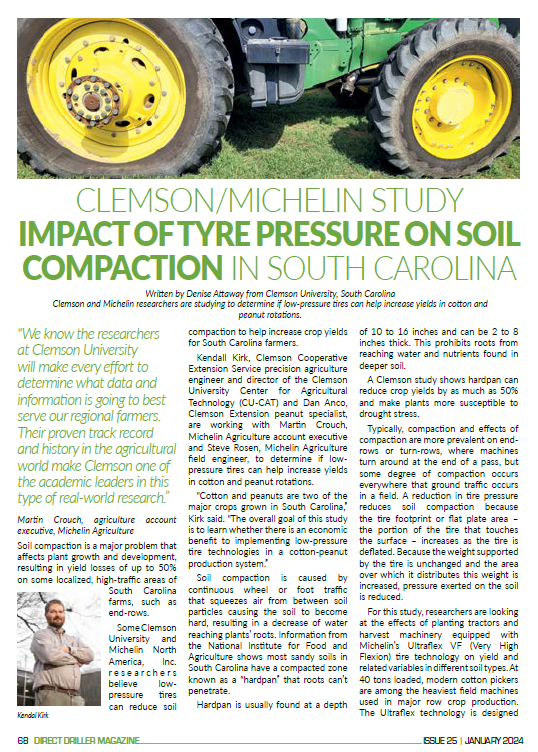

Clemson/Michelin study impact of tyre pressure on soil compaction in South Carolina

Written by Denise Attaway from Clemson University, South Carolina

Clemson and Michelin researchers are studying to determine if low-pressure tires can help increase yields in cotton and peanut rotations.

“We know the researchers at Clemson University will make every effort to determine what data and information is going to best serve our regional farmers. Their proven track record and history in the agricultural world make Clemson one of the academic leaders in this type of real-world research.”

Martin Crouch, agriculture account executive, Michelin Agriculture

Soil compaction is a major problem that affects plant growth and development, resulting in yield losses of up to 50% on some localized, high-traffic areas of South Carolina farms, such as end-rows.

Some Clemson University and Michelin North America, Inc. researchers believe low-pressure tires can reduce soil compaction to help increase crop yields for South Carolina farmers.

Kendall Kirk Kendall Kirk, Clemson Cooperative Extension Service precision agriculture engineer and director of the Clemson University Center for Agricultural Technology (CU-CAT) and Dan Anco, Clemson Extension peanut specialist, are working with Martin Crouch, Michelin Agriculture account executive and Steve Rosen, Michelin Agriculture field engineer, to determine if low-pressure tires can help increase yields in cotton and peanut rotations.

“Cotton and peanuts are two of the major crops grown in South Carolina,” Kirk said. “The overall goal of this study is to learn whether there is an economic benefit to implementing low-pressure tire technologies in a cotton-peanut production system.”

Soil compaction is caused by continuous wheel or foot traffic that squeezes air from between soil particles causing the soil to become hard, resulting in a decrease of water reaching plants’ roots. Information from the National Institute for Food and Agriculture shows most sandy soils in South Carolina have a compacted zone known as a “hardpan” that roots can’t penetrate.

Hardpan is usually found at a depth of 10 to 16 inches and can be 2 to 8 inches thick. This prohibits roots from reaching water and nutrients found in deeper soil.

A Clemson study shows hardpan can reduce crop yields by as much as 50% and make plants more susceptible to drought stress.

Typically, compaction and effects of compaction are more prevalent on end-rows or turn-rows, where machines turn around at the end of a pass, but some degree of compaction occurs everywhere that ground traffic occurs in a field. A reduction in tire pressure reduces soil compaction because the tire footprint or flat plate area – the portion of the tire that touches the surface – increases as the tire is deflated. Because the weight supported by the tire is unchanged and the area over which it distributes this weight is increased, pressure exerted on the soil is reduced.

For this study, researchers are looking at the effects of planting tractors and harvest machinery equipped with Michelin’s Ultraflex VF (Very High Flexion) tire technology on yield and related variables in different soil types. At 40 tons loaded, modern cotton pickers are among the heaviest field machines used in major row crop production. The Ultraflex technology is designed to operate at low pressures and adapt to changes in pressure without affecting tire structure.

Martin Crouch “Clemson is conducting these tests in South Carolina, which will provide region-specific information for farmers,” Crouch said. “We know Clemson researchers will determine what information is best for the region’s farmers. Their proven track record and history in the agricultural world make Clemson one of the academic leaders in this type of real-world research.

“If you want to learn from the leader in cellphone technology, you go to Apple and if you want to learn from the leader in agriculture you go to Clemson.”

A similar study was conducted on wheat by researchers at Harper Adams University in the United Kingdom. Researchers found a 4% increase in yields when machinery equipped with Michelin Ultraflex (IF/VF) radial tires was used, as compared to machinery using standard radial tires. A 2015 study by researchers at the University of Illinois at Urbana-Champaign on corn and soybeans found a 4.3% yield gain using Michelin Ultraflex radial tires versus standard radial tires.

“If similar yield benefits are found in South Carolina cotton and peanut crops, revenue benefits could be as much as $30 to $45 per acre,” Kirk said.

Michelin Ultraflex radial tires are designed to operate at lower air pressures as compared to standard radial tires. This technology also can be coupled with a Central Tire Inflation System, or CTIS, which equipment operators use to control tire pressure from the cab, such as when changing between field and road travel.

Steve Rosen “Operators can decrease tire pressure when they enter a field,” Rosen said. “Using lower tire pressure in fields increases the tire’s footprint to reduce ground pressures in the field, helping improve soil aeration, water infiltration and allowing for better root distribution.”

The CTIS is compatible with most agricultural machinery.

This first year of a three-year study is a “team effort,” Kirk said. In addition to Kirk and Anco, CU-CAT specialists, and the Michelin representatives, others helping with this research include trades specialists who work at the Edisto REC Tim Still and Kim Still, the South Carolina Peanut and Cotton boards and cooperating farmers.

“This project is unique in that it has buy-in and support from people in various sectors of agriculture,” Kirk said. “It is a model for the type of collaborations we seek to establish through Clemson’s Center for Agricultural Technology.”

Clemson University and Michelin researchers are working to determine the effects of low-pressure tires on soil compaction in South Carolina. Pictured are (from left): Steve Rosen and Martin Crouch from Michelin, and Kendall Kirk and Ben Fogle from Clemson. Harper Adams University research suggests running low pressure tyres can boost farmers’ yields

Published 27 April 2021

Photography credit: Jonathan Gill, Mechatronics and UAS Researcher at Harper Adams University. An in-depth international study into the impact of traffic and tillage on soil compaction has found agricultural machinery running low pressure tyres could boost farmers’ yields by four per cent.

The study by Harper Adams University academics used one site at its campus in Newport as well as another site in the USA in conjunction with the University of Illinois, working with tractors fitted with low pressure Michelin tyres.

Senior Lecturer in Soil and Water Management at Harper Adams University, Dr Paula Misiewicz, said: “Agricultural vehicles have got heavier and heavier over recent years and the impact that has on the soil can be severe. The aim of our investigation has been to find ways of alleviating compaction.”

The study in Illinois was conducted over three years, using 290 hp tractors with Michelin Ultraflex Technology low pressure tyres and standard pressure tyres running in two fields.

Dr Misiewicz added: “The results we saw in Illinois showed quite clearly that Michelin Ultraflex Technology tyres can help farmers to significantly reduce compaction and, in the process, boost their yields by 4 per cent in comparison to standard tyres.”

The study on the Harper Adams campus – which ran for nine years – also compared the two Michelin standard and Ultraflex tyre set ups combined with controlled traffic farming together with zero tillage, shallow tillage and deep tillage techniques.

“While there were some benefits of using low pressure Ultraflex Technology tyres in all three systems over the nine years, it was with the deep tillage techniques where it really stood out. Here again we recorded around a 4 per cent yield improvement in comparison to conventional farm tyres,” said Dr Misiewicz

Visiting Professor at Harper Adams University, Professor Richard Goodwin, added: “Whilst that improvement might seem small, when you think of it globally, it goes a very long way to help feed the world. Many people are worried about the sustainability of the human race, and if we could get these results for many different crops, it would make a huge impact in sustainability.

-

What is the Best Way to Measure Soil Carbon Stocks? A Guide to Choosing a Project Developer for Soil Carbon Revenues

By Dr. Harry Kamilaris

Introduction

Soil’s capacity to remove atmospheric CO2 and increase stored organic carbon is bringing new commercial opportunities for farmers. However, the market and regulatory landscape is still evolving and different Carbon Project Developers (CPDs) – companies who partner with farmers to create and sell carbon credits – have adopted a variety of different methodologies. The accurate measurement of soil carbon stocks is vital. For farmers, choosing to work with a CPD that will offer the best, long-term income is vital to making the most of this opportunity.

There are two main parts to the role of the CPD. First, they need to support farmers’ choice of farming practices to build soil carbon stocks. Second, they need to quantify and verify the increase in soil carbon stock – as reliably as possible. This second part is critical to securing carbon buyers – willing to pay for soil carbon removals – and for the agricultural sector to be recognised for delivering real and substantiated climate benefits.Success hinges on selecting the right CPD: one who not only understands your needs but who has also mastered the specialism of soil carbon MRV – Monitoring, Reporting, and Verification.

In this guide, we explain the essential components of reliable, transparent and future-proofed MRV, equipping farmers to ask the right questions and make informed decisions in their journey into monetising soil carbon restoration.What is Soil Carbon MRV?

Soil carbon MRV is the backbone of any credible carbon project. It involves robust measurement of the amount of organic carbon in farmed soils at the start of your contract, and then verifies the change in quantities of soil carbon stocks at the end. This is used to validate carbon credits that have been issued and paid for over the course of the project. It also provides a guide to the farming practices that are likely to yield the most carbon benefit. As you explore potential partnerships, it’s crucial to select a CPD who can demonstrate a fit-for-purpose and comprehensive MRV process that will stand the test of time. This ensures that your carbon credits will be respected and valued by the market as it evolves and offer the best income opportunities from buyers looking for high quality credits they can trust.

CarbonForce, Loch Tummel Key Considerations for Farmers

- Activity vs outcome-based payments: Some CPDs remunerate famers for making practice changes (e.g., use of cover-crops) while others make payments based on the soil carbon outcome. In both cases, the CPD still needs to provide robust evidence to validate the carbon benefit being sold to carbon buyers, for your income to be reliable.

- Scientific Rigor and Accuracy: Ensure the developer uses accepted science-based methods to measure soil carbon. This can be direct use of primary data or modelled estimates; both must be demonstrated to give reliable results when measuring change in carbon stocks over time.

- Protocol Alignment: CPDs should adhere to credible MRV protocols. Comprehensive MRV protocols are published by independent registries; to improve integrity, CPDs can align with these to ensure their work meets recognised carbon market standards.

- Transparency and Trust: Look for a developer who values transparency in their processes and communications, especially with carbon buyers. Clear, honest interaction helps you to understand your options and helps carbon buyers have confidence the credits they pay for from your land.

- Farmer-Friendly Approach: The ideal developer understands farming realities and tailors their approach accordingly. The service should be designed with practicality in mind, making the process accessible and manageable for farmers.

Activity vs outcome-based payments

Payments based on ‘farm activities’ are popular among Carbon Project Developers. It is often easier to validate implementation of farming practices (e.g., farm visits can check cover crops have been planted) than it is to measure the change in carbon in the soil (the outcome). In the near-term it may also be lower risk to farmers because payments do not require proof that a soil carbon benefit has been achieved. However, long-term this approach may be hard to maintain as carbon reporting and carbon markets become more structured and standards are established to avoid greenwashing. An approach that can clearly show measured change, or a well evidenced estimate, may be a safer option over the long term. Remember, once you have made a start with a chosen project developer, it may be hard to switch to a new scheme that requires a practice change to be introduced to qualify for credits.

Scientific Rigor and Accuracy in Measuring Soil Carbon Stocks

Measuring carbon stocks with rigor and accuracy requires expertise that often sits outside the CPD organisation. Using an independent service like Agricarbon, designed explicitly for the purpose of validating carbon credits, brings trust and value to the carbon buyer, and security of income to the farmer. The use of direct measurement (analysing actual soil samples) is fundamental, even where a modelled estimate is used to allocate carbon payments. ‘Ground-truth data’ from direct measurement is needed to set the start point and to calibrate models to give a realistic estimate. All credible MRV protocols, from independent carbon registries, require direct measurement at the start of a project and again at least every 5 years, to verify that benefits claimed and paid for are real.

The methodology should include a logical sampling design: the number of samples required and how they are allocated across the measured area. This should include a statistical assessment of whether the sample number will be sufficient to detect change in carbon stocks over the project timeframe and a valid approach to distributing samples to represent the whole measured area. For example, random allocation is a common and recognised approach, while more directed sampling (covering some areas and not others) is being developed by remote sensing companies and should be based on robust evidence (from ground truth data).

Sample collection and analysis should follow detailed standard operating procedures to ensure consistency and quality. Analysis should include measurement of Soil Organic Carbon (%) and Bulk Density (how much soil there is in each field) so that the carbon stock – total tonnes of carbon – can be calculated with confidence.

Agricarbon provides all aspects of the direct measurement process, from sampling design through sample collection, processing and analysis, and calculation of carbon stocks. By focusing exclusively on this vital part of the process, Agricarbon brings independence, deep expertise and consistency to measuring soil carbon to underpin trust in the credits issued and sold by Carbon Project Developers. This, in turn, assures farmers more reliable and higher value carbon farming projects.

Protocol AlignmentAll CPDs should be able to show you their MRV protocol (detailed instructions and requirements for robust Monitoring, Reporting, and Verification of carbon benefits). These can produced by the CPD, but reputable protocols are published by international registries such as VERRA (VM0042 protocol), CAR (Soil Enrichment Protocol) and Gold Standard. A developer aligned with these public protocols demonstrates their commitment to upholding standards in carbon credits and will ultimately have the widest access to carbon buyers. However, actual validation by these registries is costly so many smaller or newer CPDs will align, but not register, their projects. Agricarbon’s methods have been designed explicitly to comply with the main public protocols and allow CPDs to get ‘Measurement’ right for every project. As projects increase in size, formal registration will become increasingly important to ensure the integrity of credits and protect the income to farmers and the reputation of the agricultural sector.

Transparency and TrustTransparency in processes and communications is a cornerstone of the relationship between farmers and Carbon Project Developers. A developer who values transparency will keep you informed about the methodologies used, the progress of your project, and the carbon benefit of changes you implement on the ground. A developer using consistent methods of direct measurement across numerous projects will also build insights into farming practice impacts on soil carbon stocks and, in future, be able to guide your decisions about the environmental and commercial value of carbon farming approaches.

Farmer-Friendly ApproachCreating carbon credits is a complex and technical processes. Do not underestimate the work that a project developer must put into getting this right! They also need to translate this into something accessible and manageable for farmers. The breadth of knowledge within a good project developer spans agronomy, climate science, green finance, carbon reporting and carbon markets. Additionally, they must understand the farming context to ensure the project fits seamlessly into regular operations and doesn’t affect production. Agricarbon takes the Measurement part of that process and ensures the farmer has to do nothing more than open the farm gate. We usually integrate with the CPD’s process, and our data goes directly into their reporting.

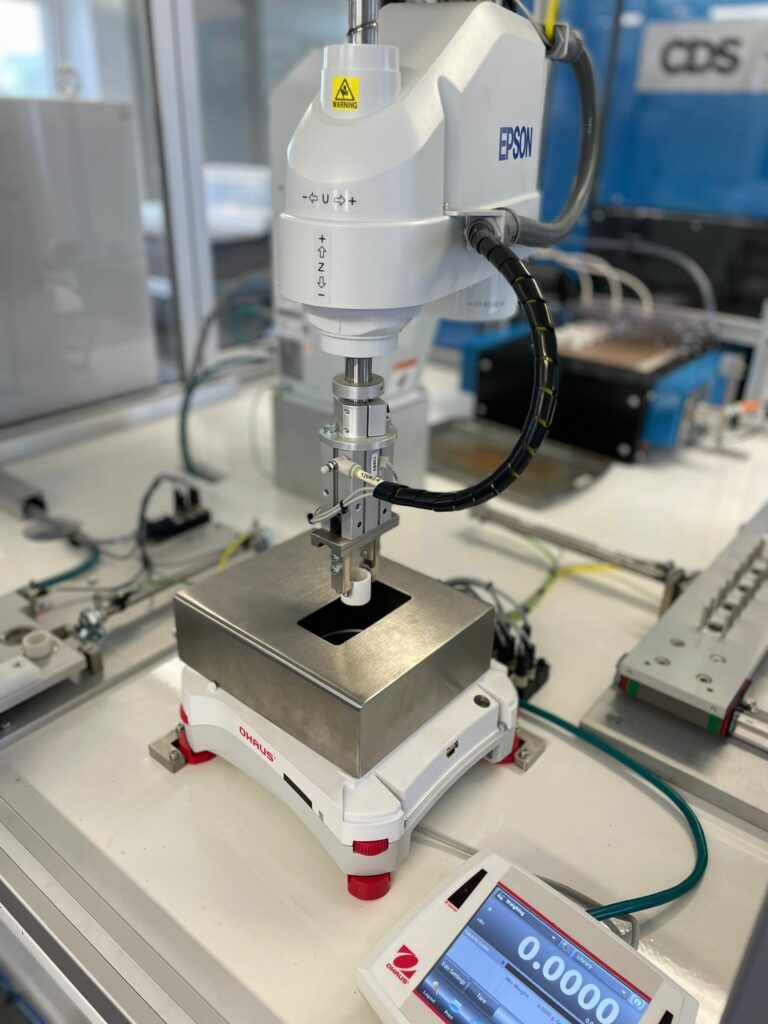

ASCA Machine Empowering Farmers with the Right Questions

When evaluating CPDs, farmers should feel empowered to ask specific questions to explore the expertise the CPD brings to each project. Questions could include:

- Who buys the carbon credits I generate and what validation do you give them?

- What MRV protocols will you follow and how do they align with internationally recognised standards for the wider carbon market (e.g. VERRA, CAR)?

- Who provides the measurement expertise to ensure robust carbon data underpins my project?

Opening the Gate to Agricarbon

As you consider venturing into soil carbon credits, remember that your choice of CPD will make all the difference. Choosing a developer who is working with Agricarbon means that they are dedicated to your success in the carbon market, grounding your project in the best practice most valued by carbon buyers.We also work directly with farmers and landowners who are empowering themselves by establishing a baseline of their soil carbon stocks today. An independently sourced baseline from Agricarbon can support a farm business’s own net zero ambitions or provide evidence of current soil carbon stocks before making a decision to enter any form of carbon market scheme.

If you’d like to know how to measure your soil carbon stocks. Contact Dr. Harry Kamilaris at hkamilaris@agricarbon.co.uk and begin your journey with Agricarbon.

-

Farmer Focus – David Aglen

Dec 2023

So it’s back down to earth with a bump this year. We have had a run of favourable summers that have helped us succeed with our direct drilling and progress with cover cropping across the farm. Essentially the harvests have been earlier and drier, allowing timely straw baling and cover crop establishment. However, we were back to our more usual harvest timings for 2023, this is more like the conditions we faced when we first ventured down the no-till route. Variable would be the best description of the outcomes then.

We have learnt a lot over the years and, with more appropriate technology and experience, we seem to have upped our game. I think our soil structure has improved to the extent that we can sow sooner after any wet weather, successfully. That said, 12 months ago we were looking at plenty of early sown winter cereals and cover crops with huge canopies being eaten by our newly resident sheep flock. This year we have very little early sown cereals, and the cover crops are not quite as large. Despite this we are still seeing big benefits. During the particularly wet October (I must confess we got off relatively lightly, compared to others further north, with only 250mm for the month). Yes, we did have plenty water running out of gateways, but the vast majority of this was running clear, still the odd bit after potatoes that left a lot to be desired, to remind us of what we are missing by not cultivating the whole place.

I briefly mentioned our livestock partners, Sheepleep, a livestock business run by Alex Johnston and Rosie Hetherington, a few months back. The deal is that we pay them an annual fee to manage our cattle and grazing in line with our requirements. The benefit to us is a dedicated livestock team and year round access to sheep, but more important is their mindset regarding mob grazing and building a ‘cheap to operate’ cattle enterprise. An example being that we now mostly walk the cattle around the farm instead of using a trailer and tractor. This has saved a lot of time and money in just 16 months. We even cross the dual carriageway with the much appreciated help from the police who close the road for us for a few minutes. It takes about 2 minutes for 150 cows and calves to cross, instead of a whole day to move them by trailer.

2022 no-till winter oat crop Sheepleep get access to 1200ha to graze and develop their sheep flock in return for a grazing fee. They benefit by having a portion of their income known for the year and having continuous access to a large block of land for their business to operate from. The opportunities for young people to build a business from nothing within agriculture seem to be slim, mostly related to land access issues and plenty established farmers willing to pay more to access what little does come available.

So currently we have 1100 ewes being tupped as they move rapidly across the cover crops in 2 separate mobs. The aim is to keep the ewes on as high a plain of nutrition as possible for the 19 days the tups are working. They are leaving about a third of the cover crop uneaten. Forcing the ewes to clean up more might reduce the lambing percentage, a risk not worth taking. The ewes will most likely go back over these crops later in the winter to clean up when they can be made to work harder for their feed. Benefits from an arable perspective include the retention of a living root system in the soil for a few more weeks of the year, as well as leaving some extra ground cover for a bit longer, after all we have most of the winter to come yet and with that, plenty precipitation I suspect.

We experimented with some hairy vetch in a few cover crops last winter. I was not convinced that this would survive the winter frosts. I need not have worried. We have added more into some covers this winter to aid diversity for both the soil and the grazing stock. Some of these crops will be cut for silage in May ahead of the kale crop establishment in the same fields. I am hoping the vetch will add something extra to the silage too.

2023 no-till Winter oat crop In the constant drive to increase diversity, it was decided we would graze sheep and cattle together this summer. The cows had other ideas. The grass was quite long when this started. The first problem was having to strim grass to get the 3 electric wires set up for the sheep. Then we discovered that the cows pay no attention to the orange electric wire, they are used to a white one, and proceeded to walk right through it. We ended up with sheep and cows all over the field along with the wire that was supposed to contain them. The experiment was given up after a couple days, back to the drawing board for this. Could technology help here with electric collars? Maybe, if they ever become cheap enough.

Despite the very wet October, the cattle made very little mess as they moved round the grazing platform. We had built up large covers that were able to carry the cows and hold them out of the soil on all but the wettest of days. Only a few of the paddocks were left looking a little dirty – they represent only a very small part of the grazing platform and will recover. Perhaps we will have to rest them longer through the spring next year for this. This is just one of the many benefits we are seeing as we adapt the rest periods of the grass to the growth rate. The longer rest period from July onwards allows a thatch to be built up, whilst still producing plenty grazing for the cows. I dread to think what the grazing fields would have looked like if we were still set stocking.

The cows moved onto the kale in November with calves still at foot. This is a little earlier than we would like. This decision was made to allow all the kale to be eaten up in good time giving us the option of timely establishment of the following spring cereals. Last spring, we held stock on the kale longer than ideal to eat it all up. This was to the considerable detriment to the spring oats that followed. We were too greedy with the cows. This is just one of the compromises we currently face in our system. Keeping livestock cheaply whilst not out staying their welcome on the arable part of the rotation. ‘Grow less kale’ some would say, and were I braver, I would agree. I feel anything gained over a year or two might well be wiped out several times over when we do get a winter where we need plenty extra feed. When this occurs, usually everyone is short, so buying in could prove costly in an emergency.

The humble spud or the dreaded spud – Potatoes previous crop 2023 Calves will not be weaned until mid-February. The cows will do the heavy lifting, greatly reducing the challenges on the outwintered calves. By weaning time, the days are longer, and the sun is starting to feel warm again. The stress from weaning shouldn’t be so great as the calves are a lot older than many wean. Calving is due to start on 10th April, and, for the first time will be outside, by design. We had better enjoy the quieter winter months now. With spring work hopefully getting going in February, calving, lambing, and turning fattening stock back onto grass in April, we will need to have our wits about us. February is less than 9 weeks away!

I was lucky enough to join the BASE UK trip to France in November. We spent 3 days visiting farms within a 3hr radius of Paris by car. A lot was learned, the knowledge they have of cover crop and extracting the most from them is huge. I can highly recommend this trip to all, as well as BASE UK membership, should the opportunity come around again. The knowledge transfer ability of peer-to-peer learning is huge. It was good to see livestock being seen as part of the cover crop recycling task over there too.

-

Drill Manufacturer – Mzuri

Introducing Mzuri’s Latest Innovation: The Pro-Til iGen Linkage Direct Drill, Making Mzuri Seeding Technology More Accessible than Ever

Mzuri, a renowned name in agricultural machinery, proudly introduces its latest innovation – the Pro-Til iGen linkage machine. This new model is strategically designed to provide a cost-effective alternative to the manufacturers premium range all while maintaining the high standards of Mzuri technology that users have come to trust.

Quality without Compromise

The Pro-Til iGen stands out with its commitment to quality, a hallmark of Mzuri products. The manufacturer is proud to present this latest range which demonstrates a wide range of innovative features, not usually associated with machines in this price range.

Impressive Features

One of the standout features of the Pro-Til iGen is its large 2,200-litre seed tank, pressurized for efficient metering and conveying of seed accurately, even at high forward speeds. This design ensures minimal downtime and an impressive overall output, providing farmers with a reliable and productive seeding solution.

The Pro-Til iGen 300 fitted with independent spring loaded coulters with individual depth wheels. Proven Mzuri Technology

Staying true to the Mzuri Technology blueprint for consistent crop establishment, the Pro-Til iGen features a leading tine, dual reconsolidation and independent coulters. Unique to this machine, the Pro-Til iGen features a full-width packer that ensures accurate depth control, producing a uniform, level seedbed reconsolidated against air pockets.

Seed Delivery Options

Seed is delivered into reconsolidated zones through two optional coulter configurations. Independent spring-loaded coulters, each equipped with its own depth wheel, offer precise seed placement and reconsolidation of the seeding zone. For a simpler format, users can configure the Pro-Til iGen with two rows of spring tines.

A double harrow bar follows to provide a uniform field finish ideally suited to pre-emergence chemistry application.

Versatile Wearing Metal

The Pro-Til iGen’s leading point is compatible with a range of wings, providing flexibility for different degrees of soil disturbance based on field conditions. With a replaceable front point, the leading tine is fitted with a large tungsten carbide tip extending the wearing metal’s life expectancy.

Optional Extras for Enhanced Performance

Optional extras for the Pro-Til iGen include an additional tank for microfertiliser or chemistry application, marker arms, seed monitoring, and pre-emergence markers.

The Pro-Til iGen is a linkage direct drill built on proven Mzuri Technology Accessible Seeding Technology

With the Pro-Til iGen, Mzuri makes its cutting-edge seeding technology more accessible than ever, offering operators a cost effective mounted solution to achieving Mzuri’s trademark consistent and even germination.

-

An award-winning advisor’s path to no-till agronomy

Todd Jex won Arable Advisor of the Year at the Farmers Weekly Awards by being at the forefront of the latest regenerative and no-till farming practices. The award is the culmination of a journey he began almost a decade ago when his eyes were opened to a different way of farming following a visit to a pioneering farmer.

Based in Wiltshire but with clients across Dorset, Wiltshire, Hampshire and the Isle of Wight, Todd works for leading farm advice, technology and supply business Agrii. The proportion of his clients utilising no-till and regenerative practices has increased from the first farm approaching him in 2016 to almost 70% this season.

Although he did not grow up on a farm, Todd spent a lot of time with his grandfather, who managed a mixed arable and dairy farm on the Dorset – Wiltshire border. Today, his grandfather’s approach to farming would be called integrated crop management (ICM), but back then, it was considered just good crop and animal husbandry.

Todd Jex “Rotational ploughing, crop rotations and what he called ‘feeding the ground’ were essential parts of his philosophy,” says Todd. “He was my biggest influence until I went to Harper Adams to study agriculture, agronomy and crop science.

“I did a placement year working in R&D for another agronomy company and spent much of my time working on trials examining black-grass control. From this, I became fascinated by the cultural control options for black-grass management, like direct drilling or rotational ploughing, and followed it up with a dissertation on the subject.”

When Todd joined Agrii’s forerunner, Masstock, he helped with trial work alongside training to be an agronomist. Agrii supported his academic and practical training, with Todd completing his BASIS Diploma.

At the start of his career, most farms in the area were practising mill-till or rotational ploughing with no direct drilling. Ideas began to form in his mind about how different approaches to farming involving direct drilling might help farmers tackle black-grass.

Everything changed following an introduction to Paul and Oliver Harris. They had been doing some direct drilling with a Claydon machine but wanted to move to a true no-till system using a disc direct drill and were looking for an agronomist to support them with this change.

“The reason for the switch was for black-grass reasons and also improving soil health, which I had not encountered before. They arranged for me to visit Tony Reynolds, who had adopted no-till ten years earlier.

“Even as I was approaching the farm, I noticed how different it was because there was significantly less black-grass on his fields than others I had driven past to get there. Tony was fascinating, enthusiastic, and happy to share his knowledge and experiences.

“I was shown some research a university had been doing on his farm examining soil health and water infiltration rates compared to a neighbour’s mil-tilled farm. I couldn’t believe what I was watching; Tony’s land was absorbing the water as fast as they could pour it, and they stood waiting for the neighbour’s to drain.

“That day was a massive influence on me. Combined with my past experiences and the Agrii research I saw, especially at their Stow Longa site, I became increasingly interested in soil health. I began reading books, attending events, and listening to podcasts on the subject. By working with Paul and Oliver Harris on their farm, I could put much of what I learned into practice,” explains Todd.

The Harris family held an open day at their farm to show what they had been doing with Todd, which helped some of Todd’s other customers go in their direction a year later. This proportion has gradually built up to over two-thirds of his area.

In the future, Todd believes almost all the farmers he deals with will be utilising a direct drill system, and an agronomist’s role will become even more involved in all elements of farming. This increased involvement will be balanced by new A.I. and digital technology helping with existing tasks.

“Agronomy is already multi-faceted, but it will be even more so in the future. The agronomist will have to spend more time with farmers advising on aspects of crop production they do not currently do. Things like examining soils for compaction or advising on machinery will become the norm.

“I was delighted to have just made the Arable Advisor of the Year final, knowing that one of my customers had taken the time to nominate me. My colleague Neil Harper was also a finalist. I believe that is the first time any company has had two employees up for the award in the same year.

“I am incredibly proud to have won the award, and so are my family. It is always something I hoped to have a chance to win at some point in my career. I am a finalist for the Young Agronomist of the Year at the National Arable and Grassland Awards in February, which is another exciting opportunity.”

[panel] Case study: reaping the benefits of a different approach.

George Fraser of A&R Fraser has worked hand-in-hand with Todd to adopt a direct drill system, transforming their farming operation. Their journey began when George’s home farm was sown using a Weaving GD direct drill, and cover crops were integrated into the rotation.

A&R Fraser contract farms 3000ac across Wiltshire and Dorset. As well as contract farming, George’s brother Jonny runs a successful digestate contracting service for local farmers, and they have a herd of beef cattle. A rotation of winter wheat, spring barley, spring beans, and oilseed rape belies an astonishing performance highlighting what can be achieved through ICM and regenerative practices.

“We first started on our farm to test the system,” says George. “We then started suggesting the new approach to our customers because we could see the results. Our landowners were quick to get on board. Now, it has gone from us suggesting it to it being demanded. People say there is a big yield drop-off when you switch, but we have never seen this.”

“The main change we have made is to move away from cultivation to a focus on soil health to manage compaction and improve soil structure. We always start by measuring the soil when we bring new land into the system,” adds Todd.

The move from min-till and ploughing to direct drilling has drastically cut George’s fixed costs. He has calculated that they are 40% lower. George retains a low disturbance subsoiler for primary cultivation when needed, unlike some regenerative farmers who strictly adhere to a no-till system. He believes this can be necessary for up to five years on heavy soils to manage soil compaction.

It is not just fixed costs that have been reduced. The focus on soil health also means they are getting more yield from fewer inputs. Using slurry and digestate, combined with moving to liquid fertiliser and using inhibitors, has halved inorganic nitrogen use.

-

Farmer Focus – Phil Bradshaw

Dec 2023

We have had a very busy few months since my last article, with non-farming activities sometimes compromising the day job of farming.

The beans and mustard planted in the spring established well, and we also planted some home-made wild bird seed mix on the old stewardship plots. With a reduction in farmed area last year our Higher-Level Stewardship (HLS) agreement ended in January, but we kept some of the options such as Wild bird Seed plots going until we could start something new.

The mustard suffered from pigeon damage, and a ‘Biblical’ hailstorm, but recovered well. The beans always looked good, but I feel all crops suffered a little from the lower sunshine levels through Summer 2023 compared to the year before.

Harvest 2023 started with our Winter Barley trial plots which were reasonably good, but only a few hectares. We then moved into second wheat Skyfall which yielded well, at 9.2t/ha, but also had superb quality which has been good with milling premiums so strong.

The first wheat Zyatt was slightly better yielding, and the Extase grown mainly as a first wheat was better still, at just over 10t/ha, with good quality, and some has been sold already with a reasonable premium. The beans scraped 4t/ha which is slightly below average, and way below the 6t/ha we had in 2021.

The re drilled mustard was harvested fairly late in the season, but happily yielded 1.3t/ha which for a first-time grower, and a crop that had a huge run of bad luck, was fairly pleasing.

As usual everything was direct drilled, with just some land loosened where necessary with our old paraplow.

We did another low N trial, with some basic missed tramlines in some first wheat Extase following Oilseed Rape. While most of the field had a typical 120kg/ha of Nitrogen, mostly soil applied, the trial areas had just 6kg/ha of Nitrogen applied late as a foliar spray of Methylated Urea around the T3 timing, and reduced fungicides and growth regulators.

The results gave a fractionally lower yield but with slightly higher protein for the low N area. This is not a replicated professional trial, so it needs noting with caution, but it highlights the fact that here on this soil, we can cut Nitrogen rates and other inputs down by a significant amount, and hopefully maintain yield and quality.

We did some machinery upgrades this summer, including upgrading our 26-year-old combine harvester for a slightly larger 11-year-old machine, and our 1999 classic John Deere 6910 tractor was sold and replaced with a larger and newer, but still classic 2008 John Deere 7930 in good order which shares all tractor duties with our existing 16-year-old John Deere 7530. The strategy is to do all our farm operations in house, and quickly to allow time for other projects, but with machinery that is not depreciating where possible.

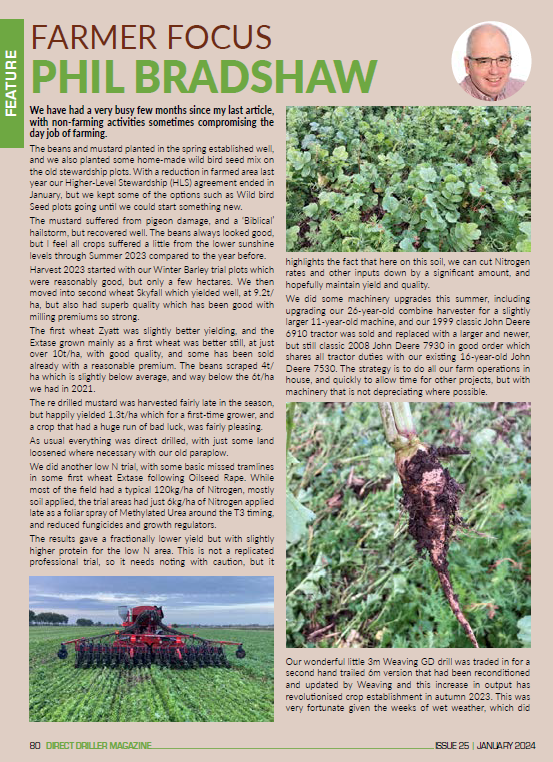

Our wonderful little 3m Weaving GD drill was traded in for a second hand trailed 6m version that had been reconditioned and updated by Weaving and this increase in output has revolutionised crop establishment in autumn 2023. This was very fortunate given the weeks of wet weather, which did give some challenges, but it was great to quickly cover the land when conditions allowed.

We still have a smaller Sabre tine drill, but the GD is generally our first choice, and I spent some time setting it up with SK Sprayers liquid delivery components, utilising the tank and primary plumbing already on the drill.

This autumn has also seen a slightly refreshed direction for strategy and cropping. With our Landlords deciding not to proceed with the planned new grain store build here, and our Farm Business Tenancy racing towards its end in 5 years, we have taken a view to simplify and reduce our cropping, with a new live Sustainable Farming Incentive (SFI) agreement enabling more ‘Countryside Stewardship’ style options than our old HLS agreement had, and also some whole field options rotationally replacing some of our unreliable break crops such as beans.

This means that we can concentrate on a larger percentage of first wheat crops and some Mustard as cash crops, and have less storage challenges, while also freeing up more time for our other projects. We also find ourselves conscious that our FBT here is due to end soon, and our sons have pursued non farming careers, so we are making plans and provisions for impending retirement.

This is amazing, as it seems like yesterday that we started farming on our own account in 1989 with a David Brown 62 hp tractor, 2 furrow Ransomes reversible plough, MF 30 drill and a MF 525 combine bought for £1500 that did 6 harvests for us. While I look back fondly on those days, life and profitability is so much better for us without a plough!

-

The scorecard that unearths a soil’s secrets

A full picture of soil health can be captured by a new ‘scorecard’. AHDB technical content manager Jason Pole investigates.

Not everything that matters can be measured. Not everything that can be measured matters. Wise words. Nobody would dispute that soil health matters. Now it can be measured.

The soil health scorecard is the product of a levy-funded partnership that tackled soil biology and soil health. It provides a simple way to measure the physical, chemical and biological condition of soil.

To develop the approach, the partnership identified core soil health assessment indicators that slot in with farm practice, along with the typical benchmark range(s) for each indicator to help reveal if a soil is healthy, getting sick or poorly.

Physical indicator

Visual evaluation of soil structure (VESS): For VESS, a spade-sized block of soil (about 30 cm deep) is levered out, leaving a side undisturbed to show topsoil structure. Assessments involve allocating a soil quality score by following the guidance in AHDB’s new ‘How to assess soil structure’ factsheet (which is laminated for use in the field). Where horizontal layers are identified, the worst-performing (limiting) layer is assessed.

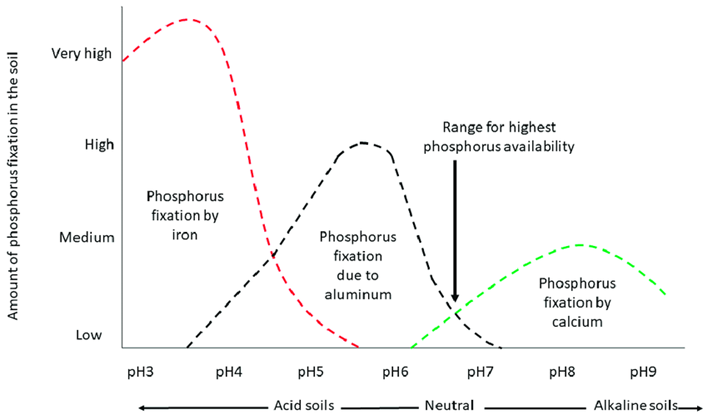

Chemical indicators

pH: A soil’s pH affects its chemical (e.g. nutrient availability), biological (e.g. microbial activity) and physical (e.g. clay mineral aggregation) properties. It is easily revealed by an indicator test or laboratory analysis, with pH 6.5 to 7.49 the ideal range. Higher pHs may result in nutrient interaction issues or trace element deficiencies. Lower pHs, especially under 5.5, require immediate investigation and liming plans adjusted.

Extractable nutrients: A laboratory analysis of a representative soil sample can reveal phosphorus, potassium, and magnesium levels. Compared to England and Wales, Scotland has a different approach to nutrient analyses, which is accounted for in the benchmarks.

Biological indicators

Earthworms: Impacted by pH, waterlogging, compaction, tillage, rotation and organic matter, earthworms are an excellent soil health indicator. A spade-sized soil block is used for earthworm counts. In cropped land, 9 or more earthworms is good and 3 or fewer is bad. The AHDB website includes information on how to count earthworms, including ecological groups, and adults and juveniles.

Soil organic matter (SOM): SOM levels depend on many factors, including soil texture, use of organic materials, farming system and environmental factors, such as soil moisture and temperature. This complexity is reflected in the benchmarks, with different values for England and Wales, and Scotland. They also account for soil texture and rainfall region. For organic matter, measuring it periodically (using the same laboratory and method) to determine trends is as important as the absolute value.

Soil assessment tips

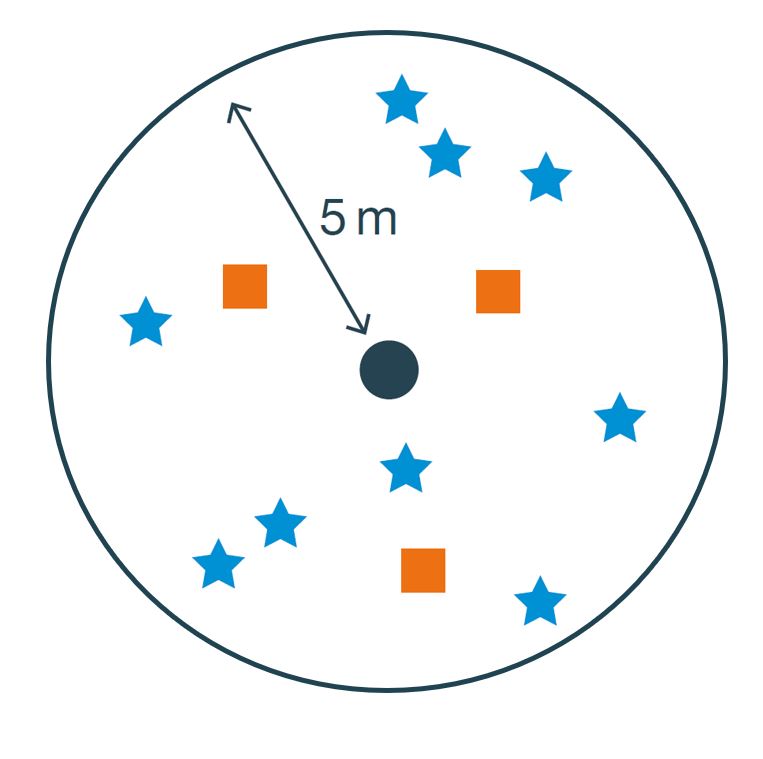

Ideally, gather information (observations and samples) for the indicators from representative field zones:

- Every three to five years (at the same point in a crop rotation)

- At the same time of year (warm moist soils in the autumn are often best)

- At least a month after soil disturbance and/or organic material applications

Simply record a centre point for the assessment area and take samples up to 5m away from it at random points. For VESS and earthworms, take three samples (illustrated by the orange squares). For other indicators, take several samples (illustrated by the blue stars).

Soil health scorecard

Indicator results (values) can be entered into an Excel-based version of the scorecard on the AHDB website. This automatically assigns a soil status for each indicator: continue monitoring (‘CM’ green), review (‘R’ amber) and investigate (‘I’ red).

In addition to the indicator values, the scorecard also uses three site characteristics – UK region, land use and topsoil characteristics – and features ‘management notes’ for each core indicator and soil status.

The scorecard approach has already been embraced by many AHDB monitor and strategic cereal farmers to:

- Facilitate a routine soil health check

- Identify production constraints

- Evaluate changes to practices

Limavady Monitor Farm

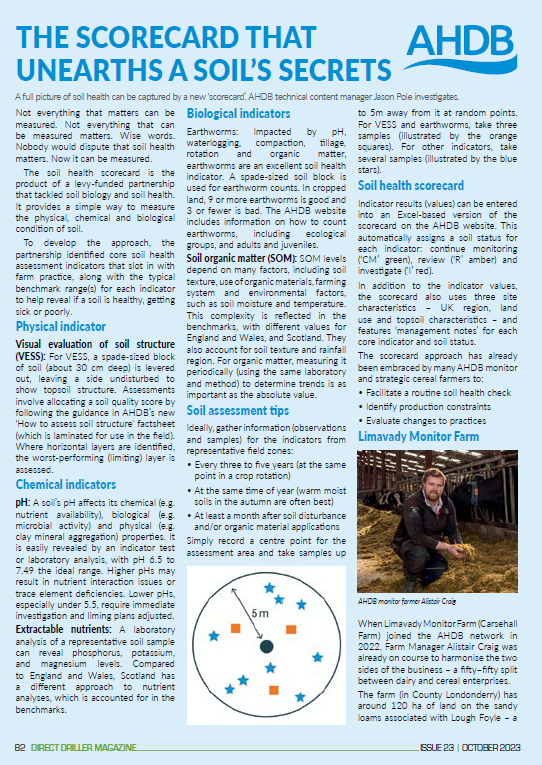

AHDB monitor farmer Alistair Craig

AHDB monitor farmer Alistair Craig When Limavady Monitor Farm (Carsehall Farm) joined the AHDB network in 2022, Farm Manager Alistair Craig was already on course to harmonise the two sides of the business – a fifty–fifty split between dairy and cereal enterprises.

The farm (in County Londonderry) has around 120 ha of land on the sandy loams associated with Lough Foyle – a large tract of land reclaimed from the sea – and a further 80 ha on clay loam soils.

Alistair already put the farm’s manure to good use, reducing the fertiliser requirements for his arable crops and boosting SOM levels. It was a good start, but he wanted to go further and pinpoint the causes of poor crop performance in some fields.

In mid-November 2022, soil assessments were done at six sites, with scorecards used to help analyse the results. Alistair found VESS particularly informative. No soils were in a poor condition, which was a surprise. For example, sample site 1 was in a field previously used to grow potatoes, which was assumed to be in poor condition.

During the VESS, the field had Alistair’s first crop of winter oilseed rape companion cropped with a mixture of spring beans, sunflowers, vetch and buckwheat. The average (across three samples) VESS score was 3, which put the field in ‘moderate’ condition. It was not as bad as expected, and rooting was far more extensive than feared. The cropping diversity had already started to perform its magic on the hard-worked land.

Rooting at sample site 1 The field also performed relatively well for other indicators, including the highest earthworm number recorded across the six sampling sites. Most (68%) of these earthworms were young (juvenile), which may indicate that the population was bouncing back from previous cultivations.

When Alistair saw the extent of the rooting, the high number of earthworms and the positive results from the laboratory analysis, he decided to sow the companion crop mix on a third of the farm in the 2022/23 growing season.

Encouraged by the soil structure assessments, Alistair used VESS on other fields. One was in poor structural condition, with very few pores and roots, after growing potatoes for two years. The field was planted with cereals in autumn 2022, which performed poorly. Alistair said: “Looking at the soil profile, it was not hard to see why the crop struggled to grow in this field.”

It was a cry for help, so Alistair reviewed the rotation to help the field recover. He took the field out of cereals and grew an eight-species cover crop mix, followed by a cash crop in the spring.

Other issues

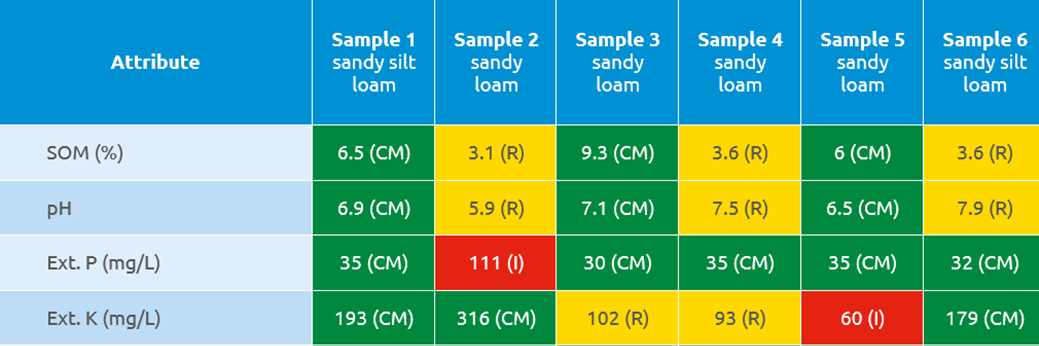

The scorecard highlighted many areas that required attention (see the table, below), including some indicators that warranted immediate investigation (I) in some fields. For example, some of these red flags were associated with low earthworm numbers and nutrient levels far beyond the optimum for the soil.

Soil assessment results at Limavady Monitor Farm in soil health scorecards. All combinable crops, except sample 3 (permanent pasture). Scorecards also show results for indicators of microbial activity.

Alistair will continue to routinely review soil health, which will help monitor the impact of the boosted companion crop area. A full soil health scorecard review will also be done in the Monitor Farm’s final year.

Use the scorecard

The scorecard, which was funded by AHDB and BBRO, can be used for UK’s main cropping and lowland grassland systems. To access the scorecard and instructions, visit ahdb.org.uk/scorecard

-

Farmer Focus – John Pawsey

Dec 2023

To Certify or Not to Certify, that is the Question

I was fascinated by Helen Browning’s reply to the leading question in a session at this year’s Groundswell entitled, “Is it time to certify regenerative farming?” Given Helen’s position as Chief Executive of the Soil Association and her role as a board member of Soil Association Certification, I was surprised at her answer which was, “No”.

Coming from the Queen of all things organic and me being a loyal subject, I was surprised at her reply given our similar organically certified shackles. To qualify her answer she added that regenerative farmers were still, “Feeling their way”, that they had, “Fire in their bellies” and that certification might “Stifle innovation”.

I brooded on Helen’s leniency.

Organic standards have been preserved in aspic over the time we have been farming under the big ‘O’, so not moving with the times could I suppose lay their rigour bare to the accusation that they do stifle innovation. Over the last few years I have felt that at organic events, my no-pesticide chums have something more akin to a flickering ember in their stomachs rather than a blossoming man’s red flower. Nobody wants to be part of a movement that doesn’t have new thinking at its core, and an excitement for change in the marrow of it’s bones, at least I don’t. I am sure that Helen doesn’t either.

If I had a penny for every farmer who said when contemplating exiting organic farming, “If I stopped organic farming I wouldn’t go back to my old conventional ways, I’d take the best of what I’ve learnt from organics and use it alongside the best of non-organic methods”, I’d have about fifteen pence. But Helen’s take on the excitement at that Groundswell session did get me thinking about the possibility throwing my hat into the ring with part of my own farm to try a bit of organic-lite, or regenerative agriculture. Everyone wants to be in with the in-crowd. I know, I’m so shallow.

There is much debate about what regenerative agriculture actually means and everyone seems to be interpreting it differently, so it is difficult to know how to approach it when thinking about what I might be aiming for. So to help me with the conundrum I consulted the oracle, ChatGPT.

default I posed the question, “What are the principles of regenerative agriculture?” I used the word ‘principles’ rather than ‘standards’ as I tried principles first and got the reply, “Regenerative agriculture does not have universally standardised criteria like organic farming”, but we will discuss the pros and cons of ‘standardised criteria’ later.

The generated reply said this, “Regenerative agriculture principles focus on improving soil health, biodiversity, and overall ecosystem resilience. Key principles include minimising soil disturbance, maximising plant diversity, keeping living roots in the soil, integrating livestock, and prioritising organic matter. These practices aim to enhance soil structure, water retention, and nutrient cycling while promoting sustainable and resilient farming systems.”

It all sounded pretty organic. An ‘aim’ sounded workable too. We didn’t quite get there, but we tried kind of thing.

Most of the principles are already fully adopted at Shimpling Park Farm. We have lots of plant diversity with green manures, herbal leys, varietal mixing and multispecies-cropping. There are very few times of the year when there are no living roots in our soil, as in practice we never manage to get rid of 100% of our unintended plants even with cultivations. Post harvest there is always a mat of rare arable weeds (I keep telling myself that they are rare to make me feel better) that always do well in the pre-harvest light of a senescing crop. Sheep were re-installed on the farm in 2014 ticking the livestock box. By default all of the above has resulted in the prioritising of organic matter which has increased on the farm twofold over the last twenty years.

Transitioning from an organic system to my mind would only be enhanced as far as regeneration principles were concerned by less soil disturbance. Having said that, with only appropriate soil movement, I feel that my current system is improving soil health, biodiversity and ecosystem resilience, all three focuses of regenerative principles. My only reason for wanting to move less soil is because of the enormous cost of doing so in terms of power, machinery and labour. It is an ever increasing input.

But I have a dilemma. Less soil disturbance does equal more weeds and not having used any herbicides on the farm since we converted our last field to organic, I couldn’t possibly bring myself to use them again. Killing the diversity that we have built up in our fields in terms of plants (you say weeds), the insects that they host and the food chain they in turn support, is not going to be a thing for me. I especially couldn’t use glyphosate. It is the ultimate weapon if you are wanting to eliminate living roots in the soil. There is nothing regenerative about a systemic weed killer.

So, that sticks me right back into the organic camp, their rigorous standards and having deal with stifled innovation and a dwindling fire.

But do standards stifle innovation? Is my fire really dwindling?

Actually, it’s quite the opposite.

Standards, especially ones governed by a legal framework, force you to innovate. They are the mother of invention.