If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Another Extradordinary Year

Written by James Warne from Soil First Farming

What an extraordinary growing season we seem to have had. In a nutshell, very low rainfall, low temperatures until June and good levels of solar radiation (sunshine) resulting in generally good yields with good specific weight and moderate protein. Especially so as most crops senesced approximately 2 weeks earlier than normal.

All the more extraordinary is where we have, once again, been trialing reduced nitrogen rates on production we have seen very little difference in final yield between standard N rates and reduced N rates (until we reach a critical level, then yield drops significantly). Where we have found yield difference this comes from lower grain weight as opposed to reduced plant counts or tiller numbers. So what can we draw from this wealth of variables? Firstly, autumn 2021 was the kindest drilling season we have had for a couple of years suggesting that most crops went into good soil conditions backing up the adage ‘well sown-half grown’! the autumn and winter that followed was certainly dryer and in some areas was probably below average on the rainfall scale suggesting that crops rooted well.

Winter was also very mild with very few days of frost and certainly no prolonged periods of cold weather. Wheat tends to be growing at around 5’C and above and I believe that the crops were growing most of the winter, albeit very slowly probably contributing to root mass development as much as above ground vegetative growth.

Temperature

One of the greatest contributing factors in this year’s yield-fest has been the temperature, or rather lack of if we cast our minds back to the early spring and summer. For the majority of us the temperatures were in the comfortable mid to high teens (celcius) occasionally reaching the low 20’s but never exceeding this until mid-June.

Contrary to popular belief high-temperatures can be one of the greatest yield reducing factors for wheat as it can be sensitive to high temperatures throughout its growth cycle. It is, however, particularly to heat during the period from booting, through ear-emergence and flowering. This sensitivity then reduces after flowering trough grain-fill and maturity. Research shows temperature effects can start from the mid-late 20’s and become significant once into the 30’s. This is particularly so during the period of pollen formation and fertilisation.

Typically wheat is in flower around the second wheat in June (assuming the midlands of the UK). This occurred 7-10 days earlier this around, early June. The first really warm temperatures occurred around the 15th June onwards this year. By which time wheat had passed through the temperature critical period of pollen formation and flowering. From then on the temperatures typically remained in the low 20’s throughout June and into July when the skies cleared and we had prolonged periods if high 20’s-30’s and clear skies. This warmth and sun, combined with large soil moisture deficits, lead to rapid senescence and ripening. But the critical period of reproductive growth (stem extension and ear formation through to flowering) occurred during steady consistent conditions.

The high temperatures came too late to have any potential to reduce yield. Although those in the very dry east of the country probably found the lack of moisture contributed to a drop in yield.

Nitrogen

It is generally accepted that the crop only receives half its nitrogen requirement from that we apply. The other 50% comes from or via the soil. With the majority of the nitrogen being taken up in the nitrate form which is very water soluble it is assumed that the plant takes up most of its nitrogen as nitrate in the soil water.

With the bulk of the uptake happening from stem extension through to ear emergence. As I have already mentioned above a large chunk of the UK was very dry during this period of April & May with some areas receiving zero rainfall, yet crops were still able to access the nitrogen they required for canopy and ear development. Although it seems perhaps not enough to assimilate into protein but that may also be attributed to sulphur availability.

What is really interesting though is where we had reduced the soil applied N by half, combined with a small amount of foliar applied N this gave a very similar yield to wheat which had received a typical nitrogen dose. Where we had dropped the soil applied N further we did start to see a yield drop. I must stress these results were consistent on farms which have been practicing carbon building practices as in a Conservation Agriculture strategy, where we believe there to be a greater supply of N available for mineralization by the soil biology.

Although another question must surely be if the soil was moisture deficient the biology must surely have been dormant and therefore unable to mineralise the nitrogen! It’s also worth noting that while it developed into another low disease year we saw a marked increase in mildew develop in the high N plots compared to lower total N plots. Never forget that nitrogen can help drive disease levels within the crop. Finally, one of the most perplexing outcomes of this year is if the crop is able to produce the yields we have had when its growing cycle was at least two weeks shorter than average, why do we spend so much time and effort in trying to keep the canopy green? If there is one thing we have been shown this year it’s the lifespan of the crop has no direct influence on the final yield…..

-

Sometimes You Have To Disagree

Written by Tony Gent

A couple of articles caught my interest in the July additional of this Magazine, First What’s Your Colour written by James Warne and Farmer Focus by Andrew Ward. The theme of both is somewhat similar in questionable understanding the principle of how soil degradation works and putting in place appropriate practice to start a sequence of improving organic matter and resulting biology.

Since the evolvement of tillage mainly to establish a single species crop with reduce competition from other species – a weed, mass food production evolved highly successfully. What we now understand is that success was based on what some compared to mining products from the soil. The way soil evolved over millions of years to work before man’s intervention vegetation growth and subsequent die back were in balance I.E., organic carbon, fertility and nutrition release were at the same rate with no artificial soil movement taking place.

When soil fertility is naturally high soil movement results in robust crops due to the cultivation induced increased rate of nutrition release. This is particularly so as soil movement technology gets more and more aggressive particularly with development of inversion tillage such as the plough. What we now have as a result of cultivation causing instance of retention and release is soil which is out of balance with its biology resulting in degradation or as we say total mining of the soil-based resource.

The dilemma so many farmers are faced with, with soil in this situation is putting in place practices that turn the corner towards restoration of biology and protecting the short-term risk as they see it to the income stream from the farm. Also, judgement and assessment of what’s happening can become massively clouded and confusing with reduced soil movement reducing artificial soil structural correction, but which still compromises natural biological build up.

Particularly farmers with heavily degraded soil that has been vigorously attacked with more and more power and forced soil manipulating technology for timelier establishment and finer seed beds. The awareness of what other farmers have achieved in a No-Till position where they are growing very respectable cost-effective crops doing nothing. Their thought process is all too often that’s ok but I think there is an opportunity to do less, but if I continue to do something it’s got to be better than doing nothing. We have learned that again particularly with heavily degraded soil that logic is partly correct, but it must be applied from a different standpoint.

It doesn’t work if just removing some elements of what you are doing now and leave others in is “OK I’m doing less”. The problem is that what you were doing even with so-called min-till had an element of primary tillage or initial soil breaking in it, followed by seedbed preparation either prior to drilling or in conjunction with drilling. The problem as I have described is often a bad compromise first not achieving carrying soil along in its degraded state or doing a suitable operation to not compromise biology recovery and so just bumping along in the tough of doing neither of artificially doing natures job completely or treating the soil correctly to allow biology to recover and the soil and moving to a point of soil largely looking after itself as nature intended.

The first absolute rule in all this is do nothing if it is not needed and then only in suitable weather and rotational situations and opportunity. Also experience has shown us that grass related crops I,E, cereals have much stronger rooting than many break crops and usually tolerate heavily degraded soil with little or no loss of yield, so long as establishment is robust and there are no compaction or drainage issues. Break crops such as oil seed rape and beans though are weaker rooting and soon show their dislike to less than reasonable soil structure.

When you stop tillage of degraded soil so long as the previous crop and this is by far the best way to judge the structural state of a field was robust and suffered no signs of compaction or drainage problems and no severe damage was done to the soil removing the previous crop, then it’s completely rational to expect if its grown one successful robust crop why shouldn’t it grow another one, without any interference with the soil. With the first year or two of No-Till that’s usually the case.

But after that an element of weather luck and rotational circumstances creep in. The soil starts to forget the artificial structuring help you have been giving it and as I have said is yet to be at the stage to compensate for this. In practice and this is where weather luck starts to play a part usually with our maritime climate a wet sowing period compromises crop establishment and results in a less than ideal robust crop. Because soil recovery relies on the soil being active and full of roots and activity,

We have found the approach to the doing something to help for us has been low disturbance vertical tillage. With us there are two stages to this – repair and get soil going in the right direction and the much more laid-back simple rotation opportunistic rotational maintenance, of which as biology increases you need less and less. Very important you must not confuse soil hard or firmness with soil compaction – soil is naturally hard or firm, particularly in dryer conditions, but with the honeycomb built up as biology is restored firmness is not a problem. The big big misconception is trying replicate this structure with cultivation, it does not work like that. The more you cultivate the soil structural the weaker it becomes and wet and dry conditions and trafficking it just slumps together into one big hard lump or slush, and the cycle of obliterating it with cultivation must begin again. Also worms and microbes have no chance in this cycle of obliteration to slump.

Methods of establishment also plays a part in this with a fixed tine or disc approach. Tines range from the type that moves all or most of soil creating an affect that’s basically one pass cultivation and obviously compromises massively No-till and biology recovery to a very narrow low disturbance tine which is much better, but most still have some element of disruption and inversion effect on the soil. All tines have the disadvantage of blockage in residue, especially in cover crops. Discs generally have much lower surface disturbance and are much better at handling residue and as with tines there are various different approaches to design.

The main difference is that most create the opening by displacement of the soil sideways soil against soil, which results in compression soil damage and smear in wet conditions that is synonymous with most design limitations. An under-cut disc such as the Weaving GD is much kinder to the soil as there is little or no sideways movement and the opening is created with a natural sleight upwards action, resulting in minimal disturbance and pressure on the soil allowing the seed to be placed under the tilth. Soil friction is generally less than a tine because the disc rotates with the soil flow, resulting in less pressure needed to firm the soil around the seed leading to reduced shrinkage and slot opening, also the seed is predominantly placed to the side away from the primary cut therefore generally slightly away from any hair pinned residue.

Recently the theory of cover cops has come to the forefront, which is great, and no doubt could help with particularly the transition enormously, but the practicality has many challenges, particularly with the establishment window. As I write – ok its early and we have plenty of time and opportunity, but no moisture and as we have seen with small seed crops if you put them in the ground and they don’t immediately grow they lose vigour and often are a complete failure, even when it does eventually rain. Wet seasons often are cold and late also which compromises establishment before the autumn growing period tails of into winter. Also, with a later harvest workload becomes a compromise and cash crops must take precedence.

By all means embrace no-till, especially to address soil degradation and make sure your methods facilitate an improvement in soil biology. This is absolutely vital to allow the soil to recover, some appropriate help maybe needed to win in the long term, together with a little patience.

-

Be careful about doing nothing

Written by Tony Gent

It doesn’t work if just removing some elements of what you are doing now and leave others in is “OK I’m doing less”.

A couple of articles caught my interest in the July additional of this magazine, first What’s Your Colour written by James Warne and Farmer Focus by Andrew Ward. The theme of both is somewhat similar in questionable understanding the principle of how soil degradation works and putting in place appropriate practice to start a sequence of improving organic matter and resulting biology.

Since the evolvement of tillage mainly to establish a single species crop with reduce competition from other species – a weed, mass food production evolved highly successfully. What we now understand is that success was based on what some compared to mining products from the soil. The way soil evolved over millions of years to work before man’s intervention vegetation growth and subsequent die back were in balance so organic carbon, fertility and nutrition release were at the same rate with no artificial soil movement taking place.

When soil fertility is naturally high soil movement results in robust crops due to the cultivation induced increased rate of nutrition release. This is particularly so as soil movement technology gets more and more aggressive particularly with development of inversion tillage such as the plough. What we now have as a result of cultivation causing instance of retention and release is soil which is out of balance with its biology resulting in degradation or as we say total mining of the soil-based resource.

The dilemma so many farmers are faced with, with soil in this situation is putting in place practices that turn the corner towards restoration of biology and protecting the short-term risk as they see it to the income stream from the farm. Also, judgement and assessment of what’s happening can become massively clouded and confusing with reduced soil movement reducing artificial soil structural correction, but which still compromises natural biological build up.

Particularly farmers with heavily degraded soil that has been vigorously attacked with more and more power and forced soil manipulating technology for timelier establishment and finer seed beds. The awareness of what other farmers have achieved in a No-Till position where they are growing very respectable cost-effective crops doing nothing. Their thought process is all too often that’s ok but I think there is an opportunity to do less, but if I continue to do something it’s got to be better than doing nothing. We have learned that again particularly with heavily degraded soil that logic is partly correct, but it must be applied from a different standpoint. It doesn’t work if just removing some elements of what you are doing now and leave others in is “OK I’m doing less”. The problem is that what you were doing even with so-called min-till had an element of primary tillage or initial soil breaking in it, followed by seedbed preparation either prior to drilling or in conjunction with drilling. The problem as I have described is often a bad compromise first not achieving carrying soil along in its degraded state or doing a suitable operation to not compromise biology recovery and so just bumping along in the tough of doing neither of artificially doing natures job completely or treating the soil correctly to allow biology to recover and the soil and moving to a point of soil largely looking after itself as nature intended.

The first absolute rule in all this is do nothing if it is not needed and then only in suitable weather and rotational situations and opportunity. Also experience has shown us that grass related crops such as cereals have much stronger rooting than many break crops and usually tolerate heavily degraded soil with little or no loss of yield, so long as establishment is robust and there are no compaction or drainage issues. Break crops such as oil seed rape and beans though are weaker rooting and soon show their dislike to less than reasonable soil structure.

When you stop tillage of degraded soil so long as the previous crop and this is by far the best way to judge the structural state of a field was robust and suffered no signs of compaction or drainage problems and no severe damage was done to the soil removing the previous crop, then it’s completely rational to expect if its grown one successful robust crop why shouldn’t it grow another one, without any interference with the soil. With the first year or two of No-Till that’s usually the case. But after that an element of weather luck and rotational circumstances creep in. The soil starts to forget the artificial structuring help you have been giving it and as I have said is yet to be at the stage to compensate for this. In practice and this is where weather luck starts to play a part usually with our maritime climate a wet sowing period compromises crop establishment and results in a less than ideal robust crop. Because soil recovery relies on the soil being active and full of roots and activity,

We have found the approach to the doing something to help for us has been low disturbance vertical tillage. With us there are two stages to this – repair and get soil going in the right direction and the much more laid-back simple rotation opportunistic rotational maintenance, of which as biology increases you need less and less. Very important you must not confuse soil hard or firmness with soil compaction – soil is naturally hard or firm, particularly in dryer conditions, but with the honeycomb built up as biology is restored firmness is not a problem. The big big misconception is trying replicate this structure with cultivation, it does not work like that. The more you cultivate the soil structural the weaker it becomes and wet and dry conditions and trafficking it just slumps together into one big hard lump or slush, and the cycle of obliterating it with cultivation must begin again. Also worms and microbes have no chance in this cycle of obliteration to slump.

Methods of establishment also plays a part in this with a fixed tine or disc approach. Tines range from the type that moves all or most of soil creating an affect that’s basically one pass cultivation and obviously compromises massively No-till and biology recovery to a very narrow low disturbance tine which is much better, but most still have some element of disruption and inversion effect on the soil. All tines have the disadvantage of blockage in residue, especially in cover crops. Discs generally have much lower surface disturbance and are much better at handling residue and as with tines there are various different approaches to design. The main difference is that most create the opening by displacement of the soil sideways soil against soil, which results in compression soil damage and smear in wet conditions that is synonymous with most design limitations. An under-cut disc such as the Weaving GD is much kinder to the soil as there is little or no sideways movement and the opening is created with a natural sleight upwards action, resulting in minimal disturbance and pressure on the soil allowing the seed to be placed under the tilth. Soil friction is generally less than a tine because the disc rotates with the soil flow, resulting in less pressure needed to firm the soil around the seed leading to reduced shrinkage and slot opening, also the seed is predominantly placed to the side away from the primary cut therefore generally slightly away from any hair pinned residue.

Recently the theory of cover cops has come to the forefront, which is great, and no doubt could help with particularly the transition enormously, but the practicality has many challenges, particularly with the establishment window. As I write – ok its early and we have plenty of time and opportunity, but no moisture and as we have seen with small seed crops if you put them in the ground and they don’t immediately grow they lose vigour and often are a complete failure, even when it does eventually rain. Wet seasons often are cold and late also which compromises establishment before the autumn growing period tails of into winter. Also, with a later harvest workload becomes a compromise and cash crops must take precedence.

By all means embrace no-till, especially to address soil degradation and make sure your methods facilitate an improvement in soil biology. This is absolutely vital to allow the soil to recover, some appropriate help maybe needed to win in the long term, together with a little patience.

-

Drill Manufacturers In Focus…

HORSCH AVATAR 12.25 SD UPDATED WITH NEW EQUIPMENT OPTIONS

The latest 12m HORSCH Avatar 12.25 SD, launched in early 2022, has been updated with new equipment options, including a new control concept. The intuitive handling system is based on ISOBUS and makes it easier for the farmer to adjust, operate and monitor the drill. The terminal interface can be adapted to the user’s requirements and, with the new hardware and software, HORSCH has created a platform which can supply an almost unlimited number of components when metering.

Thanks to the well-proven folding design the transport dimensions are very compact. With an outside width of 3 metres, it is also ideal for road transport. There are various tyre versions from 520 to 900 tyres and twin tyres.

The newly developed seed hopper platform has a capacity of 6500 litres and can be ordered as a double hopper with a 60:40 ratio. To increase the range further, especially for rape seed, a MiniDrill G&F is now available as an option. This additional hopper has a capacity of 400 litres and is often used for seed, granulates or slug pellets. Filling stops can be reduced and up to 3 components can be metered at the same time. The seed wagon layout increases the drilling window with the large tyre widths reducing compaction even in wet soil conditions. The double support wheels at the wings ensure low tracks and optimum adaption to the soil. With its 1-row design with SingleDisc coulters and a row spacing of 25cm, the Avatar 12.25 SD is ideal for mechanical population control, but also for the most different sowing methods, such as direct seed, mulch seed and into standing catch crops.

The new LED headlight system, WorkLight Pro, allows for driving at night and, like all HORSCH Avatar models, the HM skid as well as the newly developed HM Plus skid provide enormous stability and longevity of the seed coulter.

-

Horsch Avatar 12.25 SD updated with new equipment options

The latest 12m HORSCH Avatar 12.25 SD, launched in early 2022, has been updated with new equipment options, including a new control concept. The intuitive handling system is based on ISOBUS and makes it easier for the farmer to adjust, operate and monitor the drill. The terminal interface can be adapted to the user’s requirements and, with the new hardware and software, HORSCH has created a platform which can supply an almost unlimited number of components when metering.

Thanks to the well-proven folding design the transport dimensions are very compact. With an outside width of 3 metres, it is also ideal for road transport. There are various tyre versions from 520 to 900 tyres and twin tyres.

The newly developed seed hopper platform has a capacity of 6500 litres and can be ordered as a double hopper with a 60:40 ratio. To increase the range further, especially for rape seed, a MiniDrill G&F is now available as an option. This additional hopper has a capacity of 400 litres and is often used for seed, granulates or slug pellets. Filling stops can be reduced and up to 3 components can be metered at the same time.

The seed wagon layout increases the drilling window with the large tyre widths reducing compaction even in wet soil conditions. The double support wheels at the wings ensure low tracks and optimum adaption to the soil. With its 1-row design with SingleDisc coulters and a row spacing of 25cm, the Avatar 12.25 SD is ideal for mechanical population control, but also for the most different sowing methods, such as direct seed, mulch seed and into standing catch crops. The new LED headlight system, WorkLight Pro, allows for driving at night and, like all HORSCH Avatar models, the HM skid as well as the newly developed HM Plus skid provide enormous stability and longevity of the seed coulter.

-

Crop And Carbon: Optimising The Double Yield

Written by Thomas Gent, CEO Agreena UK

It’s no secret that employing regenerative farming techniques – minimal soil disturbance, the use of cover crops and organic manures, applying carbon-rich fertilisers – both reduce the amount of farm-generated greenhouse gas (GHG) emissions and add to the amount of carbon stored in the soil. These GHG reductions and carbon storage initiatives can then be quantified annually, depending on the practices carried out over the harvest year. This, in a nutshell, is what’s referred to as carbon farming.

The quantification of GHG reduction and carbon storage is measured in units called carbon certificates; one certificate represents one tonne of CO2-equivalent emissions (either removed or reduced). If you’re a typical farmer who’s practising carbon farming, you can expect to yield between one and two carbon certificates per hectare per year. But that’s just the beginning. The exciting bit comes when you’re able to optimise and garner a double yield, meaning both crop yield and carbon certificate yield. This is where I’d kindly like to ask you to pause for a moment, take a deep breath and reflect on this perspective:

A carbon certificate yield should be thought of as a crop

yield.Here’s why: Both yields take place once a year in line with the typical summer-tosummer crop cycles we’re all used to. This means you have the potential to harvest two crops from your field: one wheat crop and one carbon crop, for example. Once you’ve harvested your carbon certificates, you need to decide what to do with them. Much like a normal cash crop, they can be kept, used for your own purposes or sold to an end user. You can even work with a company to take them to market for you.

As a farmer myself, I’m constantly researching new and innovative ways to turn my farm into a battleground for combating climate change. Caring for the soil under my feet to sequester carbon from the atmosphere is a profitable and sustainable way to optimise my farm’s carbon negative position while at the same time producing a new asset in the form of a carbon certificate But it isn’t just me; I’ve spoken with many farmers in the area who have recently transitioned to carbon farming through the Agreena certification programme and are now yielding and earning from their carbon harvest.

They’re using Agreena to help them strategise how they can move further away from their established baseline to increase their yield of carbon certificates per hectare – moving more fields over to direct drilling, for instance. Still others have found that crops in the rotation with a high carbon yield, such as pulses and linseed, are inherently less profitable. The carbon payment they’ve received has topped up their profitability and improved their soil.

Other key takeaways from these conversations have been that the most ‘carbon yielding’ crops are those that have a cover crop before them. This has helped reduce the need for artificial fertiliser in the cash crop that follows, which can help save big considering the current high price of fertiliser. Planting an over-the-winter crop and following it with a spring cash crop can also generate a lot of carbon certificates and allow you to address problematic, annual winter weeds. This is a win-win for carbon yields and addressing long-standing weed problems.

The Agreena soil carbon platform, aptly named AgreenaCarbon, works to support you in the quantification and planning that’s necessary to begin earning carbon certificates after each annual harvest year. Employed by farmers in 14 countries, the internationally accredited soil carbon certification programme works with world-leading regenerative agriculture technology and external verification partners, so there should be no doubt for corporate buyers and farmers that the programme delivers high-quality carbon certificates. The programme is available to all farms of all sizes and types, and makes a transition to regenerative farming practices financially viable. Perhaps best of all, no matter where you are in your regenerative journey, you can enter the programme.

To learn more about AgreenaCarbon and how you can start optimising your double yield in the field, visit www.agreena.com

-

Crop and carbon: Optimising the double yield

Written by Thomas Gent

It’s no secret that employing regenerative farming techniques – minimal soil disturbance, the use of cover crops and organic manures, applying carbon-rich fertilisers – both reduce the amount of farm-generated greenhouse gas (GHG) emissions and add to the amount of carbon stored in the soil. These GHG reductions and carbon storage initiatives can then be quantified annually, depending on the practices carried out over the harvest year. This, in a nutshell, is what’s referred to as carbon farming.

The quantification of GHG reduction and carbon storage is measured in units called carbon certificates; one certificate represents one tonne of CO2-equivalent emissions (either removed or reduced). If you’re a typical farmer who’s practising carbon farming, you can expect to yield between one and two carbon certificates per hectare per year. But that’s just the beginning. The exciting bit comes when you’re able to optimise and garner a double yield, meaning both crop yield and carbon certificate yield. This is where I’d kindly like to ask you to pause for a moment, take a deep breath and reflect on this perspective:

A carbon certificate yield should be thought of as a crop yield.

Here’s why: Both yields take place once a year in line with the typical summer-to-summer crop cycles we’re all used to. This means you have the potential to harvest two crops from your field: one wheat crop and one carbon crop, for example. Once you’ve harvested your carbon certificates, you need to decide what to do with them. Much like a normal cash crop, they can be kept, used for your own purposes or sold to an end user. You can even work with a company to take them to market for you.

As a farmer myself, I’m constantly researching new and innovative ways to turn my farm into a battleground for combating climate change. Caring for the soil under my feet to sequester carbon from the atmosphere is a profitable and sustainable way to optimise my farm’s carbon negative position while at the same time producing a new asset in the form of a carbon certificate But it isn’t just me; I’ve spoken with many farmers in the area who have recently transitioned to carbon farming through the Agreena certification programme and are now yielding and earning from their carbon harvest.

They’re using Agreena to help them strategise how they can move further away from their established baseline to increase their yield of carbon certificates per hectare – moving more fields over to direct drilling, for instance. Still others have found that crops in the rotation with a high carbon yield, such as pulses and linseed, are inherently less profitable. The carbon payment they’ve received has topped up their profitability and improved their soil.

Other key takeaways from these conversations have been that the most ‘carbon yielding’ crops are those that have a cover crop before them. This has helped reduce the need for artificial fertiliser in the cash crop that follows, which can help save big considering the current high price of fertiliser. Planting an over-the-winter crop and following it with a spring cash crop can also generate a lot of carbon certificates and allow you to address problematic, annual winter weeds. This is a win-win for carbon yields and addressing long-standing weed problems.The Agreena soil carbon platform, aptly named AgreenaCarbon, works to support you in the quantification and planning that’s necessary to begin earning carbon certificates after each annual harvest year. Employed by farmers in 14 countries, the internationally accredited soil carbon certification programme works with world-leading regenerative agriculture technology and external verification partners, so there should be no doubt for corporate buyers and farmers that the programme delivers high-quality carbon certificates. The programme is available to all farms of all sizes and types, and makes a transition to regenerative farming practices financially viable. Perhaps best of all, no matter where you are in your regenerative journey, you can enter the programme.

To learn more about AgreenaCarbon and how you can start optimising your double yield in the field, visit www.agreena.com

-

Agronomist In Focus…

RICHARD HARDING

Always start with why…?

Four years ago, John Cherry and I were having an enlightened conversation while seated around his kitchen table discussing the future of agronomy. This was now several years since John and his brother Paul along with Paul’s son Alex, had founded the Groundswell Conference in Hertfordshire. Attending Groundswell, meeting Frederic Thomas, being a BASE member and the other people I have met along the way, have all been defining light bulb moments in my agronomy career. They allowed me to join the dots of mainly subconscious observations made throughout my career and some conscious ones too. I particularly remember one day as a harvest student getting out the tractor cab while waiting for the combine. I noticed the soil in the field under the stubble was loose and friable, it had a sweet smell and good worm activity – a perfect growing medium. Why then were we about to turn this soil upside down in an attempt to recreate the exact same result? That made no sense apart from that’s what everyone does, isn’t it? It felt like this conversation in John’s kitchen was another of these lightbulb moments. We were debating what should the agronomist of the future look like and indeed the type of service they should be offering in a regenerative system?

Fast forward to today and Groundswell Agronomy has enjoyed it’s second year successfully attending the Groundswell Conference 2022. During our conversation in John’s kitchen, I suggested what might appear to be a flawed business model and that was to make myself redundant in ten years. Not because I don’t immensely enjoy what I do, but if one of the overarching principles of the agronomist of the future is to make a regenerative farming system the solution, we have to do things differently. Rather than the current model of an in season, short term solution from a can focusing on margin over input costs. We know intuitively that we need to take a far more long-term view. Taking inspiration from organic systems or any system for that matter, where nutrition is considered rotationally rather than crop specifically.

Regenerative farming is nothing new, when you interrogate the principles of such a system, they are what good mixed farming has always been about albeit with a better understanding of the “why” something works. Our understanding of soil biology is just one example of an area that during my studies was barely mentioned. Today we are aware of its importance and seek to understand it in far more detail than ever before.

Over the last year we have seen huge volatility in input and energy prices which makes one of the key drivers behind my interest in a conservation or regenerative model so important, and that has always been to future proof the rural farm business (acknowledging most farm businesses are very diversified), maximise the return on investment and the management time employed. One challenge that a regenerative system currently faces and one that is having an increasing effect on the practical agronomy of these crops, is a consistency of core values. Regulation brings a degree of structure missing from regenerative agriculture at the moment. While I’m definitely not a fan of highly regulated industries having a framework to work within would bring credibility for the system and clarity to the consumer. There are fundamental principles that are well accepted within a regenerative system however these are interpreted slightly differently, depending on the individual’s interpretation of these principles and depending on their world view. Their attitude to risk, the time of the year and most definitely this year, changes in grain prices all derail the best of intentions.

Which means that communication between the grower and the agronomist becomes ever more important. I often joke about the need for farmers and agronomists to have couples therapy, but it is vital for everyone involved in growing the crop to have a clear understanding of the overall objectives, the businesses attitude to risk and the fundamental “why” behind the decision making. Why is such a powerful word and it’s not until we ask ourselves why at least four times can we rarely get to the reality of why we’re thinking and feeling a certain way. While we are skilled at crafting a rational justification for what we do. The reality can be sometimes quite different.

In trying to answer the question “is there another way” to farm. It has led me to question every decision we make as agronomists. As I researched further seeking to properly understand soils and how to manage them, I moved from thinking things were simple to very complex before realising what seemed complex was actually very simple. However, the key when working more closely with natural systems is to always have a plan B, C, D and E. Irrespective of farm size this is very possible, but it requires a very different way of thinking and being flexible and open to change. An example of this, and one that may seem extreme is that if we accept as farmers, we are ultimately trying to farm sunlight and if we’re to manage soils better, permanent soil cover is a fundamental goal of the system. Then when we plant something, we don’t necessarily know whether that crop will be a cash crop, a forage crop or a cover crop? We are used to controlling nature and I suggest we can learn more by taking inspiration from nature to create a truly efficient system.

All the while being aware as humans, we are very good at self-sabotage. We need to be aware of the cycle of SELF-SABOTAGE and be compassionate when we fall victim to this process particularly when we are trying to adopt a new system or approach. We favour doing what feels comfortable – we then decide to make a change – we take steps to change – the change feels good – this feels different – we feel uncomfortable – we question the changes made – our subconscious craves familiarity, and the cycle begins again. While it’s easy to explain a concept by going to extremes and to some a regenerative system can seem extreme, if it does nothing else but to make you stop and question your approach there is a value in that alone. There are always aspects of the system which can provide benefit and fit into a more conventional approach.

To find better ways of doing things to some extent ignoring labels can be helpful and shifting the focus on the value of each individual technique being deployed. One thing that is clear from other parts of the world is in order to make an alternative system work well it involves far more trusting and intimate relationships with the rest of the supply chain. Only by challenging convention throughout the supply chain will we achieve success. We need to reimagine everything from the soil up.

So, while having these grand aspirations is all very well, what does that look like day to day in the field and where could farmers trials, as well as more formalised trials start investigating? Here are a few conversation starters to have with your agronomist the next time you have your therapy session together!

1.Alongside trials, one starting point is to begin with knowledge exchange and financial benchmarking peer to peer, facilitated by the agronomist is essential first step. Many growers would be dismissive of the concept of no-till potatoes as unrealistic but such projects while extreme are a way to interrogate a different way of thinking. We need to ask what elements of this approach could have value whatever the system?

2.Where does your advice come from? Maybe growers should swap their agronomist every three years to maintain innovation? This was an idea suggested by Mark Dewes at a panel discussion at Groundswell in 2021. Mark had recently completed a Nuffield Scholarship into looking at different agronomy models around the world.

3.Our cover crop knowledge is very much in its infancy, and everyone is trying to achieve different things. The starting point is to know the value of the benefit you are getting from that particular cover crop. Aiming to ideally make every cover crop a cash crop. Relay cover cropping and blurring the line overlapping a cash and a cover crop can be a more nuanced way of getting the best return on investment from that cover crop. Quantifying the true value cover crops bring to improving nutrient use efficiency would give more confidence in using cover crops more widely.

4.Maintain a balance; as farmers we love the production element of growing but maintaining a balance accepting for a regenerative system to work our attention needs to be focused, 50% on marketing and 50% on growing in that order and irrespective of whether the product leaves the farm as a 29ton bulk lorry or a single branded 500g bag. The best example of farmers making the system work around the world is through diversity of crop and market. It may be a contentious question, but why exactly in a more normalised year are we growing so much wheat, while historically farm profitability has been declining for some?

5. Is our idea of efficiency flawed – a question for another day but something to ponder?

Lastly, an interesting question. Why is it that Microsoft is reportedly the second-largest employer of anthropologists in the world? In essence it can be summed up by the fact that in order to know where were going we must first know where we have come from. There is nothing new in farming or farming regeneratively just the way we think and join the dots. richard@groundswellag.com

-

Agronomist in Focus – Richard Harding

Always start with why…?

Four years ago, John Cherry and I were having an enlightened conversation while seated around his kitchen table discussing the future of agronomy. This was several years after John and his brother Paul along with Paul’s son Alex, had founded the Groundswell Conference in Hertfordshire.

Attending Groundswell, meeting Frederic Thomas, being a BASE member and the people I have met along the way, have all been defining light bulb moments in my agronomy career. They allowed me to join the dots of mainly subconscious observations made throughout my career and some conscious ones too. I particularly remember one day as a harvest student getting out the tractor cab while waiting for the combine. I noticed the soil in the field under the stubble was loose and friable, it had a sweet smell and good worm activity – a perfect growing medium. Why then were we about to turn this soil upside down in an attempt to recreate the exact same result? That made no sense apart from that’s what everyone does, isn’t it? It felt like this conversation in John’s kitchen was another of these lightbulb moments. We were debating what should the agronomist of the future should look like and importantly, what type of service they should be offering in a regenerative farming system?

Inspiration from organic systems

Fast forward to today and Groundswell Agronomy has enjoyed it’s second year successfully attending the Groundswell Conference 2022. During our conversation in John’s kitchen, I suggested what might appear to be a flawed business model and that was to make myself redundant in ten years. Not because I don’t immensely enjoy what I do, but if one of the overarching principles of the agronomist of the future is to make a regenerative farming system the solution, we have to do things differently, Rather than the current model of an in season, short term solution from a can focusing on margin over input costs. We know intuitively that we need to take a far more long-term view. Taking inspiration from organic systems or any system for that matter, where nutrition is considered rotationally rather than crop specifically.

Regenerative farming is nothing new, when you interrogate the principles of such a system, they are what good mixed farming has always been about albeit with a better understanding of the “why” something works. Our understanding of soil biology is just one example of an area that during my studies was barely mentioned. Today we are aware of its importance and seek to understand it in far more detail than ever before.

Over the last year we have seen huge volatility in input and energy prices which makes one of the key drivers behind my interest in a conservation or regenerative model so important, and that has always been to future proof the rural farm business (acknowledging most farm businesses are very diversified), maximise the return on investment and the management time employed. One challenge that a regenerative system currently faces and one that is having an increasing effect on the practical agronomy of these crops, is a consistency of core values. Regulation brings a degree of structure missing from regenerative agriculture at the moment. While I’m definitely not a fan of highly regulated industries having a framework to work within would bring credibility for the system and clarity to the consumer. There are fundamental principles that are well accepted within a regenerative system however these are interpreted slightly differently, depending on the individual’s interpretation of these principles and depending on their world view. Their attitude to risk, the time of the year and most definitely this year, changes in grain prices all derail the best of intentions.

The key to working closely with natural systems

Which means that communication between the grower and the agronomist becomes ever more important. I often joke about the need for farmers and agronomists to have couples therapy, but it is vital for everyone involved in growing the crop to have a clear understanding of the overall objectives, the businesses attitude to risk and the fundamental “why” behind the decision making. Why is such a powerful word and it’s not until we ask ourselves why at least four times can we rarely get to the reality of why we’re thinking and feeling a certain way. While we are skilled at crafting a rational justification for what we do. The reality can be sometimes quite different.

In trying to answer the question “is there another way” to farm. It has led me to question every decision we make as agronomists. As I researched further seeking to properly understand soils and how to manage them, I moved from thinking things were simple to very complex before realising what seemed complex was actually very simple. However, the key when working more closely with natural systems is to always have a plan B, C, D and E. Irrespective of farm size this is very possible, but it requires a very different way of thinking and being flexible and open to change. An example of this, and one that may seem extreme, is that if we accept that, as farmers, we are ultimately trying to farm sunlight and so if we’re to manage soils better, permanent soil cover is a fundamental goal of the system. Then when we plant something, we don’t necessarily know whether that crop will be a cash crop, a forage crop or a cover crop? We are used to controlling nature and I suggest we can learn more by taking inspiration from nature to create a truly efficient system.

Question your approach to farm management

All the while being aware as humans, we are very good at self-sabotage. We need to be aware of the cycle of SELF-SABOTAGE and be compassionate when we fall victim to this process particularly when we are trying to adopt a new system or approach. We favour doing what feels comfortable – we then decide to make a change – we take steps to change – the change feels good – this feels different – we feel uncomfortable – we question the changes made – our subconscious craves familiarity, and the cycle begins again.

While it’s easy to explain a concept by going to extremes and to some a regenerative system can seem extreme, if it does nothing else but to make you stop and question your approach there is a value in that alone. There are always aspects of the system which can provide benefit and fit into a more conventional approach.

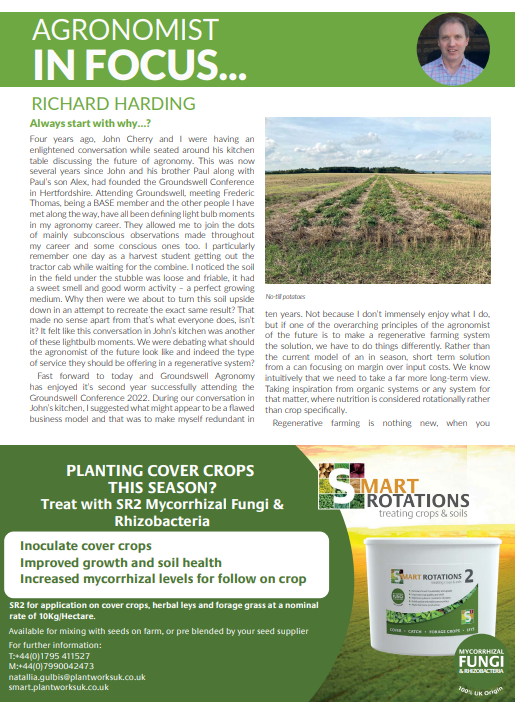

No-till potatoes To find better ways of doing things to some extent ignoring labels can be helpful and shifting the focus on the value of each individual technique being deployed. One thing that is clear from other parts of the world is in order to make an alternative system work well it involves far more trusting and intimate relationships with the rest of the supply chain. Only by challenging convention throughout the supply chain will we achieve success. We need to re-imagine everything from the soil up.

So, while having these grand aspirations is all very well, what does that look like day to day in the field and where could farmers trials, as well as more formalised trials start investigating? Here are a few conversation starters to have with your agronomist the next time you have your therapy session together!

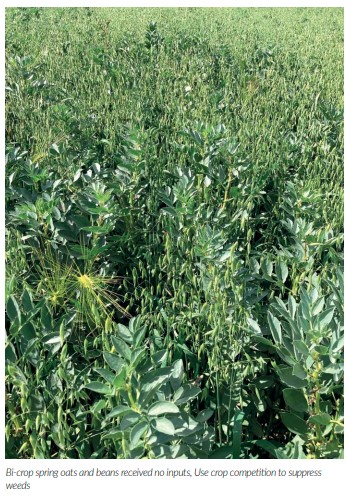

• Alongside trials, one starting point is to begin with knowledge exchange and financial benchmarking peer to peer, facilitated by the agronomist is essential first step. Many growers would be dismissive of the concept of no-till potatoes as unrealistic but such projects while extreme are a way to interrogate a different way of thinking. We need to ask what elements of this approach could have value whatever the system?

• Where does your advice come from? Maybe growers should swap their agronomist every three years to maintain innovation? This was an idea suggested by Mark Dewes at a panel discussion at Groundswell in 2021. Mark had recently completed a Nuffield Scholarship into looking at different agronomy models around the world.

• Our cover crop knowledge is very much in its infancy, and everyone is trying to achieve different things. The starting point is to know the value of the benefit you are getting from that particular cover crop. Aiming to ideally make every cover crop a cash crop. Relay cover cropping and blurring the line overlapping a cash and a cover crop can be a more nuanced way of getting the best return on investment from that cover crop. Quantifying the true value cover crops bring to improving nutrient use efficiency would give more confidence in using cover crops more widely.

• Maintain a balance; as farmers we love the production element of growing but maintaining a balance accepting for a regenerative system to work our attention needs to be focused, 50% on marketing and 50% on growing in that order and irrespective of whether the product leaves the farm as a 29ton bulk lorry or a single branded 500g bag. The best example of farmers making the system work around the world is through diversity of crop and market. It may be a contentious question, buy why exactly in a more normalised year are we growing so much wheat, while historically farm profitability has been declining for some?

• Is our idea of efficiency flawed – a question for another day but something to ponder?

Lastly, an interesting question. Why is it that Microsoft is reportedly the second-largest employer of anthropologists in the world? In essence it can be summed up by the fact that in order to know where were going we must first know where we have come from. There is nothing new in farming or farming regeneratively just the way we think and join the dots.

richard@groundswellag.com

-

Drill Manufacturers In Focus…

EXCELLENT RESULTS FROM THE 2022 HARVEST, BUT WHAT NEXT?

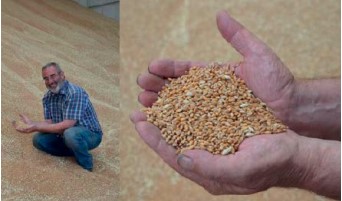

With the harvest safely gathered in Jeff Claydon, Suffolk arable farmer and inventor of the Opti-Till® direct strip seeding system, discusses the results and looks ahead to next season.

18 August 2022

It has been a very strange year for weather in most parts of the UK. Here in Suffolk, where annual rainfall is just 600mm making it one of the driest regions, the exceptional conditions brought back memories of 1976. That year, almost no rain fell between March and September and during a visit to the county then Minister of Agriculture, the late Fred Peart, described the drought as a tragedy, urging the public not to panic. Sounds familiar! Between New Year’s day and the end of May this year our farm weather station recorded 196.8mm of rain, well below the long-term average. April brought only 18.6mm and in May 41.6mm fell, followed by 34.4mm in June and a miniscule 10.4mm in July, contributing to a total of just 244mm for the year to date. Much of that came in the form of short, localised showers, so the water evaporated very quickly and produced little benefit.

One positive of the exceptionally dry conditions was our earliest-ever harvest. The 12m Claas Lexion 600 Terra-Trac had an uninterrupted run from the time we cut the first oilseed rape in mid-July until the last spring oats which were combined during the first week of August. With daytime temperatures consistently in the mid-to-high 30s and little in the way of overnight dew we were able keep going for as long as we were physical able to do so. It was a very tiring couple of weeks, but with help from my sons, Oliver and Spencer, harvest was completed in record time and with wheat coming into store at 11-12% there were no drying costs.

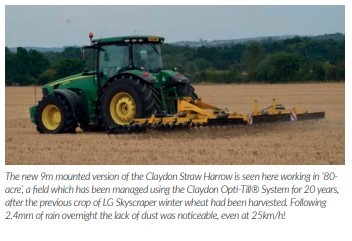

Too dry to drill

The downside of the prolonged dry weather is that currently the land is too dry to drill oilseed rape. Normally, the crop would have been in the ground a week or two ago but, with no moisture to start the germination process, drilling it then would have been a mistake. Patience is the key as we await some meaningful rain! The ground is so dry and cracked that undertaking any form of conventional cultivations would be very expensive in fuel, excess wear on machinery and ground-engaging metal. Breaking down the large clods created by that approach would also be very time-consuming and expensive but driving around the area those drawbacks have not stopped some from trying. On our own heavy clay land, the Claydon Straw Harrow has been successfully deployed across the whole farm, the main limitation being keeping dust to a minimum by restricting forward speed when operating close to houses in the village, especially if they have washing on the line!

With our rotation having changed from wheat and oilseed rape to include more spring-sown and break crops, the aim is to use land destined for spring drilling to help reduce the weed burden and seed bank using Opti-Till® stubble management techniques which move no more than 2cm of topsoil. This enables us to control weed seeds and volunteers without herbicides, other than one full-rate application of glyphosate just prior to drilling. Effective stubble management has become particularly important following the loss of neonicotinoid seed treatments and some products to control grassweeds due to the inherent fear that the aphid vectors of Barley Yellow Dwarf Virus (BYDV) will increase significantly. However, BYVD can be reduced considerably by using the Opti-Till® system to manage stubbles and eliminate the ‘green bridge’ effect. It also enables drilling to be delayed, but to do that with any degree of certainty you must be able to get the crop in the ground quickly, which means not having too many operations before sowing.

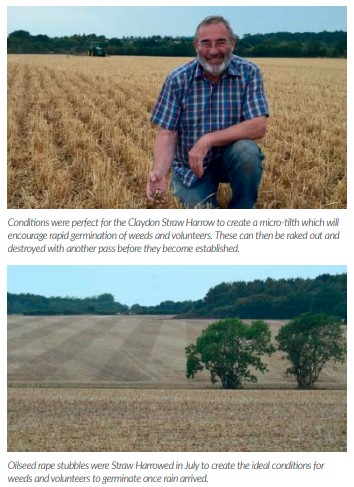

Last night’s 2.4mm of rain was just enough to make conditions perfect for the Claydon Straw Harrow, a simple, robust, fast, and very effective stubble management tool with many uses. Operating at 15 – 25km/h, it is equipped with sprung steel tines which vibrate rapidly to break up straw and expose chopped crop residues. They also create a ‘boiling’ action which uproots weeds and volunteers, as well as destroying slugs and slug eggs. An additional upside of the hot, dry conditions has been that slugs have had a very tough time and have been unable to breed, so we will not have to worry about them this season.

The Straw Harrow creates a fine micro-tilth in the top 20- 30mm of soil, providing ideal conditions for rapid germination of weeds and volunteers, which can then be raked out and destroyed with another pass before they become established. When glyphosate is eventually applied, it is as a single, full strength dose prior to drilling, which maximises its effectiveness and reduces the risk of weed resistance Even during a prolonged dry spell and high summer temperatures the difference between harrowed and unharrowed soil is clear. Unharrowed soil is hard and baked with shrinkage cracks; soil that has been harrowed has a crumbly, fine tilth and crop residues have been broken into small pieces.

20-Year Anniversary

This harvest marked 20 years of establishing all crops on the farm using only Claydon Opti-Till® products. These consist of the Straw Harrow, occasionally the TerraStar® light rotary cultivator where slightly more soil movement is required, together with the Claydon direct strip seeding drill, followed by the TerraBlade inter-row hoe. My last article for Direct Driller mentioned that our crops were showing exciting potential, and they certainly lived up to expectations. That was a pleasant surprise given the lack of rain and the fact that we backed off on the nitrogen due to concerns that it would not be fully utilised in the dry conditions. This was a good decision, made easier because we only grow feed wheats. Winter wheats received 190kgN/ha, 50 – 60kgN/ ha less than our normal 240-250kgN/ha, and oilseed rape a similar amount, again less than normal.

In a couple of small areas where nitrogen was missed when applying it through our 36m self-propelled sprayer, for which I can only blame myself, the yield plummeted, highlighting the importance of this major nutrient. Without fertiliser and agchems yields would quickly regress to 1970s levels, around 30cwt for barley and 2 tons per acre in ‘old money’ terms, or 3.7t/ha and 5t/ha respective in modern parlance. The key difference between the 1970s and now is that there are more mouths to feed. According to the Office of National Statistics the UK population was 56,226,000 in 1975, it rose to 65,110,000 in 2015 and is projected to hit 69,444,000 by 2025. Should we therefore be concerned about the dramatic curbs on nitrogen use currently being proposed by the governments of The Netherlands and Canada?

Fungicide programmes were maintained at normal levels because these products more than cover their cost through increased yield. Past experience has shown that if yellow rust or other foliar diseases take hold significant yield potential has already been lost by the time the signs become visible, far outweighing the cost of an effective treatment programme..

Good drainage increases yields

Drainage is very important to get the best from our heavy clay soils and in a couple of areas where the old tile system had broken down a significant reduction in yield was apparent. One 12ha area produced 7.78t/ha, compared with over 9.5t/ha in the adjacent field, an overall loss across that small area of around 25 tonnes, so correcting the problem was a priority. Dry weather allowed local drainage contractor W. R. Suckling & Sons to install new plastic pipes 1m deep across a total of 40ha in various fields. Some was done in the spring, some through rape stubble, and we will mole drain across these areas when conditions allow. Land is far too valuable to have it underperform, and this investment should maximise its potential by increasing yields.

The dry spring and summer, combined with the use of a Claydon TerraBlade inter-row hoe meant that our crops were the cleanest I have ever known, with no spring-germinated blackgrass. I am delighted with the results of the 2022 harvest, high yields underlining the benefits of establishing deep rooting structures which enabled crops to make best use of available moisture. Having recently invested in a new weighbridge we know that the yield information is precise and have posted it on the Claydon website (claydondrill.com). Those of you who have visited the Claydon factory will know the 16ha field to the right of the access road. The winter wheat there yielded just over 10t/ha, while the average across our whole IACA registered area was 9.54t/ha, with higher-thanaverage hectolitre weights. Given the lack of rain and 25% reduction in nitrogen use those are both excellent figures.

Hybrid oilseed rape provided a similarly pleasing result. DK Excited, which was drilled at just 2.7kg/ha using a preproduction version of our new Claydon Evolution drill, averaged 3.84t/ha, with one field producing 4.2t/ha. Given that the crop had to contend with very dry weather, some pigeon damage, and small areas where cabbage stem flea beetle had attacked, these yields are exceptional. With very low establishment costs, a low level of fungicide use, and just 190kgN/ha the margin will be very attractive. Spring oats put in a surprising performance and are destined for use in a range of gluten-free products such as breakfast cereals and oat milk. We drilled the new Elsoms variety Lion directly into stubble which had been Straw Harrowed using a seed rate of just 100kg/ha and the crop subsequently received a total of 100kgN/ha in two equal splits.

A Claydon TerraBlade inter-row hoe took out any grassweeds growing between the band-sown rows before they had a chance to develop and compete with the spring oats, so the crop looked clean throughout. Given the season’s challenges I was very pleased that it averaged 6.11t/ha, which was slightly below the 7t/ha from last year’s crop of WPB Elyann (KWS) but that had much more favourable growing conditions. We will be drilling Lion again in 2023, as 25% of the farm will be into spring oats, 25% oilseed rape and 50% winter wheat, all first wheats.

Current conditions are the polar opposite of those last year, when there was plenty of moisture in the ground during August, but September was quite dry. With the ground currently bone dry we are waiting for significant rainfall to provide some moisture, so everything is currently in a state of limbo. The soil temperature is much higher than at the same time last year, so I am not too concerned that oilseed rape has not been drilled; it is much better to wait and sow into moisture than have the seed sit there doing nothing. Our own land is showing none of the deep cracking which is evident on some nearby farms where conventional cultivations and establishment protocols are used, nor do we have deep tramlines which will take time and money to put right. In contrast, our, fields are level with a layer of fine tilth and crop residues on the surface which will protect and insulate the soil, providing perfect conditions for drilling when we do get some rain.

With Claydon customers saving up to £250/ha on establishment costs by using the Opti-Till® System demand for our products from farmers throughout the world is at record levels, so I am delighted that our new 36m x 36m clear-span building is almost finished. We have managed the build project in-house but, due to difficulties in getting contractors, progress has been slower than anticipated. The concern now is finding enough additional staff to fill the numerous vacancies that we have to offer so if you know of anyone who might be interested in a role please ask them to contact us! When complete the new facility will double our production capacity.

Just before harvest, accredited master thatcher Harry Roberts of Harry Roberts Thatching Services finished replacing the roof at Gaines Hall, our Grade II listed 16th Century farmhouse. After 44 years’ service it was rethatched using wheat straw grown by Harry using the heritage wheat variety Maris Widgeon, drilled using a Claydon drill. We are delighted with the results.

-

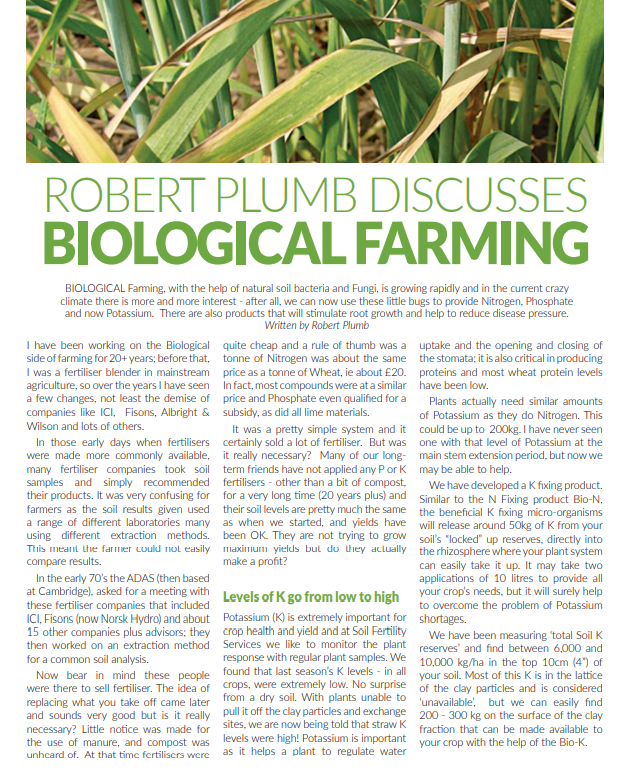

Robert Plumb Discusses Biological Farming

BIOLOGICAL Farming, with the help of natural soil bacteria and Fungi, is growing rapidly and in the current crazy

climate there is more and more interest – after all, we can now use these little bugs to provide Nitrogen, Phosphate

and now Potassium. There are also products that will stimulate root growth and help to reduce disease pressure.

Written by Robert Plumb

I have been working on the Biological side of farming for 20+ years; before that, I was a fertiliser blender in mainstream agriculture, so over the years I have seen a few changes, not least the demise of companies like ICI, Fisons, Albright &Wilson and lots of others. In those early days when fertilisers were made more commonly available, many fertiliser companies took soil samples and simply recommended their products. It was very confusing for farmers as the soil results given used a range of different laboratories many using different extraction methods, this meant the farmer could not easily compare results.

In the early 70’s the ADAS (then based at Cambridge), asked for a meeting with these fertiliser companies that included ICI, Fisons (now Norsk Hydro) and about15 other companies plus advisors; they then worked on an extraction method for a common soil analysis.

Now bear in mind these people were there to sell fertiliser. The idea of replacing what you take off came later and sounds very good but is it really necessary? Little notice was made for the use of manure, and compost was unheard of. At that time fertilisers were quite cheap and a rule of thumb was a tonne of Nitrogen was about the same price as a tonne of Wheat, ie about £20.In fact, most compounds were at a similar price and Phosphate even qualified for a subsidy, as did all lime materials. It was a pretty simple system and it certainly sold a lot of fertiliser. But was it really necessary? Many of our long term friends have not applied any P or K fertilisers – other than a bit of compost, for a very long time (20 years plus) and their soil levels are pretty much the same as when we started, and yields have been OK. They are not trying to grow maximum yields but do they actually make a profit?

Levels of K go from low to high

Potassium (K) is extremely important for crop health and yield and at Soil Fertility Services we like to monitor the plant response with regular plant samples. We found that last season’s K levels – in all crops, were extremely low. No surprise from a dry soil. With plants unable to pull it off the clay particles and exchange sites, we are now being told that straw K levels were high! Potassium is important as it helps a plant to regulate water uptake and the opening and closing of the stomata; it is also critical in producing proteins and most wheat protein levels have been low.

Plants actually need similar amounts of Potassium as they do Nitrogen. This could be up to 200kg. I have never seen one with that level of Potassium at the main stem extension period, but now we may be able to help. We have developed a K fixing product. Similar to the N Fixing product Bio-N, the beneficial K fixing micro-organisms will release around 50kg of K from your soil’s “locked” up reserves, directly into the rhizosphere where your plant system can easily take it up. It may take two applications of 10 litres to provide all your crop’s needs, but it will surely help to overcome the problem of Potassium shortages.

We have been measuring ‘total Soil K reserves’ and find between 6,000 and10,000 kg/ha in the top 10cm (4”) of your soil. Most of this K is in the lattice of the clay particles and is considered ‘unavailable’, but we can easily find200 – 300 kg on the surface of the clay fraction that can be made available to your crop with the help of the Bio-K.

-

Robert Plumb Discusses Biological Farming

BIOLOGICAL Farming, with the help of natural soil bacteria and Fungi, is growing rapidly and in the current crazy climate there is more and more interest – after all, we can now use these little bugs to provide Nitrogen, Phosphate and now Potassium. There are also products that will stimulate root growth and help to reduce disease pressure.

I have been working on the Biological side of farming for 20+ years; before that, I was a fertiliser blender in mainstream agriculture, so over the years I have seen a few changes, not least the Demise of companies like ICI, Fisons, Albright & Wilson and lots of others.

In those early days when fertilisers were made more commonly available, many fertiliser companies took soil samples and simply recommended their products. It was very confusing for farmers as the soil results given used a range of different laboratories many using different extraction methods. This meant the farmer could not easily compare results.

In the early 70’s the ADAS (then based at Cambridge), asked for a meeting with these fertiliser companies that included ICI, Fisons (now Norsk Hydro) and about 15 other companies plus advisors; they then worked on an extraction method for a common soil analysis.

Now bear in mind these people were there to sell fertiliser. The idea of replacing what you take off came later and sounds very good but is it really necessary? Little notice was made for the use of manure, and compost was unheard of. At that time fertilisers were quite cheap and a rule of thumb was a tonne of Nitrogen was about the same price as a tonne of Wheat, ie about £20. In fact, most compounds were at a similar price and Phosphate even qualified for a subsidy, as did all lime materials.

It was a pretty simple system and it certainly sold a lot of fertiliser. But was it really necessary? Many of our long-term friends have not applied any P or K fertilisers – other than a bit of compost, for a very long time (20 years plus) and their soil levels are pretty much the same as when we started, and yields have been OK. They are not trying to grow maximum yields but do they actually make a profit?

Potassium (K) is extremely important for crop health and yield and at Soil Fertility Services we like to monitor the plant response with regular plant samples. We found that last season’s K levels – in all crops, were extremely low. No surprise from a dry soil. With plants unable to pull it off the clay particles and exchange sites, we are now being told that straw K levels were high! Potassium is important as it helps a plant to regulate water uptake and the opening and closing of the stomata; it is also critical in producing proteins and most wheat protein levels have been low.

Plants actually need similar amounts of Potassium as they do Nitrogen. This could be up to 200kg. I have never seen one with that level of Potassium at the main stem extension period, but now we may be able to help.

We have developed a K fixing product. Similar to the N Fixing product Bio-N, the beneficial K fixing micro-organisms will release around 50kg of K from your soil’s “locked” up reserves, directly into the rhizosphere where your plant system can easily take it up.

It may take two applications of 10 litres to provide all your crop’s needs, but it will surely help to overcome the problem of Potassium shortages.W e have been measuring ‘total Soil K reserves’ and find between 6,000 and 10,000 kg/ha in the top 10cm (4”) of your soil. Most of this K is in the lattice of the clay particles and is considered ‘unavailable’, but we can easily find 200 – 300 kg on the surface of the clay fraction that can be made available to your crop with the help of the Bio-K.

-

Groundswell 2022

Farmers and growers flocked to the sixth annual Groundswell, the UK’s largest regenerative agricultural show in late

June this year. It was another sell-out event with 5,500 attendees who travelled to North Hertfordshire for two days of

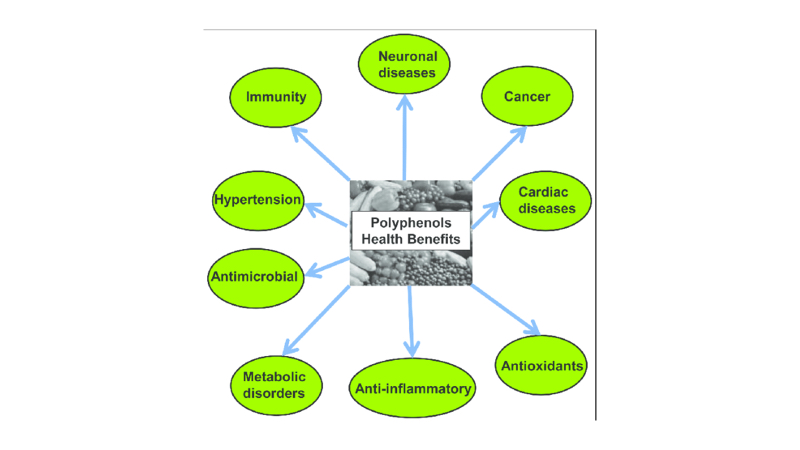

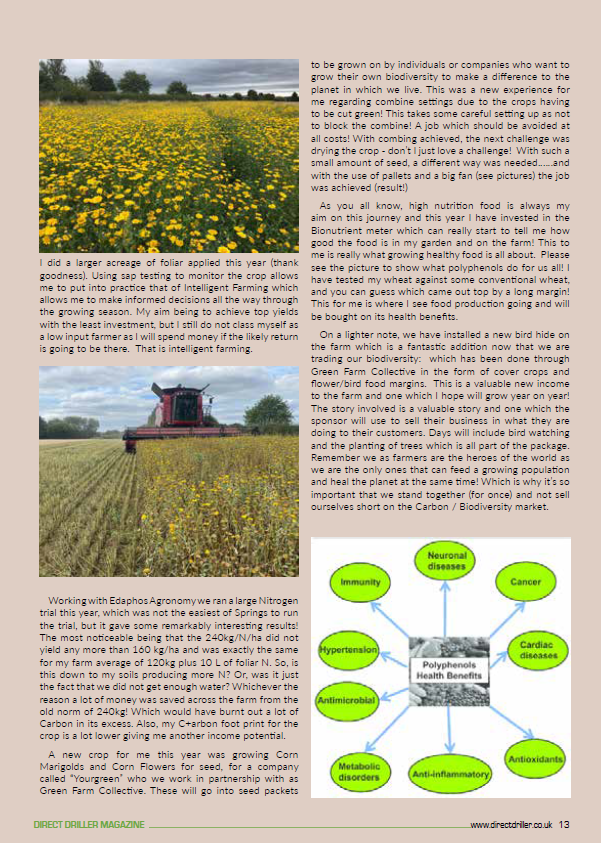

information exchange, inspiration and a bit of liquid refreshment during the worst drought since 1976.Written by Alex Cherry