If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

OSR Monitoring Reaches New Heights

New software that uses a drone to image crops has been developed to help farmers walk crops more quickly and accurately. Skippy Scout has been developed by farming technology specialist Drone Ag to monitor a variety of broad acre crops. The latest developments in the software’s version 2.5 enables users to import field maps and track the crop from emergence to harvest. The data from each flight is recorded and reports generated that help to evaluate the crop throughout the growing season and collect data to compare growing trends and yields year on year.

Oilseed Rape (OSR) yields are affected by a variety of pests and environmental pressures, from cabbage stem flea beetle to rare late frosts. “Monitoring OSR more closely and regularly without the same time trappings of conventional crop walking can help to make vital decisions,” says Drone Ag founder Jack Wrangham. “Skippy Scout automates drone flight to view a field up to ten times faster than on foot,” he adds. By decreasing the amount of time needed to walk a field, and increasing the amount of data collected, Mr Wrangham believes that any farmer can see incremental yield improvements in crops like OSR.

Unlike some technology developers Mr Wrangham is a farmer. His brother Hugh works with his father John at the family’s 600-hectare arable farm in Northumberland. “At Harehope Farm, we have been using Skippy to monitor 15 fields over the season, each field had an average of nine key scout points, and each field was visited five times. To do this on foot would have taken 21 hours, with Skippy it took five and half,” he says. The scouting point locations are decided based on a combination of previous problem areas, satellite imagery showing areas of different biomass, and some additional points to balance data across a field.

Following variable rate sowing at Harehope the Wrangham’s use Skippy Scout to provide accurate post emergence plant counts. “This helps in any areas that have been missed and measures how effective variable rate drilling has been,” he says. Following early emergence, flea beetle is a concern for OSR. “It is crucial to find and identify flea beetle early, and with Skippy we can monitor fields faster and more regularly. Holes in the leaves are counted by the app and reports show the extent of any damage sustained. Areas with higher levels of damage are flagged to decide if spraying is necessary,” he adds. The effectiveness of subsequent crop treatments is also measured by further drone flights to image the OSR and track any further signs of damage increasing or decreasing.

Data collected has been used to make year on year adjustments to OSR. As the crop develops, an accurate green area index (GAI) can be taken at regular intervals to understand crop vigour, nutrition requirements, disease, and pest levels. “Using crop cover percentages and GAI we are able to adjust and learn from previous treatments to find and tackle problems earlier,” says Mr Wrangham. The damaged areas can be monitored throughout the crop cycle to minimise any losses in the current year and better understand what factors are making a positive or negative difference. “It’s all about having hard facts, statistical data, GAI and plant counts at the press of a button. It would not be realistic to walk the fields as many times as is possible with a drone, and the reports produced can be saved to help make decisions for future crops,” he adds.

Using the app has reduced the frequency and quantity of inputs needed at Harehope. “We also use the GAI readings for variable rate Nitrogen (N) applications. Satellite data is a useful tool, but it is often not enough because the weather prevents being able to see the crop regularly enough. We have also found that it provides inconsistent data because it does not differentiate weeds,” he says. The GAI readings provided by Skippy Scout are crop-only. This is because the drone flies close to the ground making its view of the crop more accurate. “When combined with satellite data, simple zoning is effective in reducing the amount of N needed to create a more even crop,” he says.

Despite the option to variably apply N to OSR, the Wrangham’s chose to apply at a flat rate per field this season because Skippy Scout was able to show that GAI was quite even across the crop. 234 kilograms per hectare was applied over two applications based on the average GAI recorded by scouts made with the drone on the day the application was made. “Using the reports from Skippy has allowed us to make better use of our inputs. We are more efficient and better informed to make applications,” explains Mr Wrangham.

This helped to develop one of the app’s new functions which helps users judge how to balance the use of inputs. “Crop evenness is a percentage value of crop variability. It identifies whether variable rate applications are needed and tracks how effective the decisions are through a season. One hundred percent is a completely even crop, and lower percentages reflect the impact of treatments and inputs on the crop,” he says.

The Wranghams have targeted a GAI of 3.5 at flowering onset as a key performance indicator for OSR. Regular drone flights that capture GAI show how the crop is developing through the growing season and enable adjustments to be made. “As the crop begins to flower, we are able to see how areas that are not meeting the target 3.5 GAI are going to affect the overall yield,” he says. This begins a process of careful monitoring to estimate yield in the run up to harvesting the crop. “Skippy has a flower fraction measurement that identifies the intensity of flowering. This, along with GAI measurements, helps to estimate yield and a later measurement of crop die-off helps to decide on desiccation and harvesting timing,” he says.

2020/21 has brought late frosts to OSR crops throughout the UK. “Skippy has highlighted that crops of highest early autumn vigour suffered, as they were well into stem extension when the cold weather hit in early spring. It is possible to establish this by using Skippy to count the pods on the stem of the plant,” says Mr Wrangham. This is also helping the farm to judge the timing and amount of fungicide. “Flowering has been prolonged in many crops this year. Skippy has been a good tool to identify fungicide timings for a second or third Sclerotinia flower spray in some places,” he adds.

Regular flights help the farm to gather data about flowering decline and crop die-off. “The reports generated from each flight provide an indication of green area duration and whether or not a late foliar N application would be worthwhile. When this is compared with other metrics through a season it is possible to estimate overall yield more accurately,” he says. This not only helps during a single growing season but is also creating a library of data that can help to predict how changes in the crop, or weather conditions, can improve future yields.

Tracking and logging the effect of the decisions made is the defining difference of using drone reports. Having a constant record of every flight and understanding the impact of choices based on that data is offering answers to common problems. “Often decisions can be made with relatively little data, but with Skippy it is possible to build up a database of specific points in each field and make incremental improvements with each crop,” says Mr Wrangham. This is applying a more scientific approach with an element of trial and error. “Skippy can help users develop techniques that produce healthier crops with higher yields more efficiently, by reducing costs and the use of chemicals,” he concludes.

-

Grazing Cropped Land – Part 4

The almost forgotten technique in the UK of grazing cereals is something being widely practiced across Australia in areas with widely varying rainfall levels. The Australian Grain Research and Development Council have produced a report titled Grain and Graze which sets out to evaluate the advantages and disadvantages of grazing a range of cash crops. We began serialising this report over forthcoming issues, exploring what is currently an untapped resource.

Originally Published by Grain and Graze in Australia in 2016 and continuing on from Issue 6 of Direct Driller MagazineStocking rate (intensity and duration of grazing)

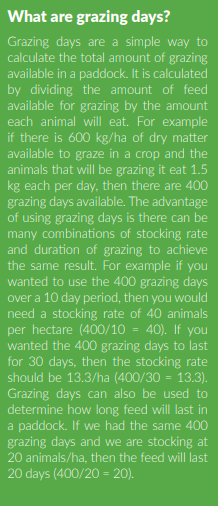

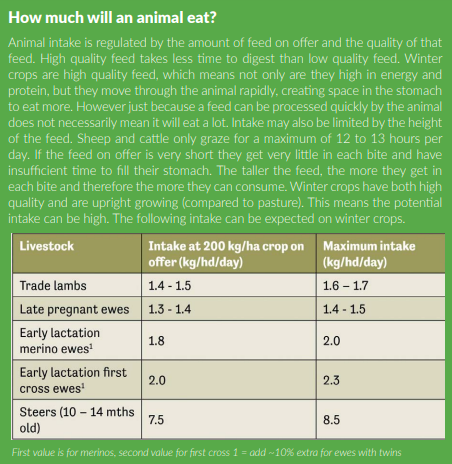

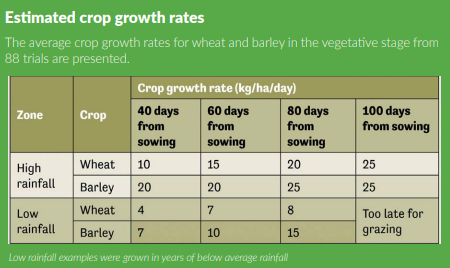

The three considerations of when grazing starts, the amount of crop to leave behind and when to stop grazing enables a calculation of the total number of grazing days available. Once this is known, the grazing intensity or stocking rate can be calculated if animal consumption is included. Where only a small grazing ‘window’ exists before GS 30 is reached, very high stocking rates are appropriate. This ensures even grazing of the crop and avoids the ‘lawn and rough’ effect that can occur when stock concentrate grazing on a small area. If the period of grazing can be increased through early sowing or very favourable growing conditions, then the approach to grazing can involve a lower stocking rate for a longer period of time. In this case crop growth should also be taken into account.

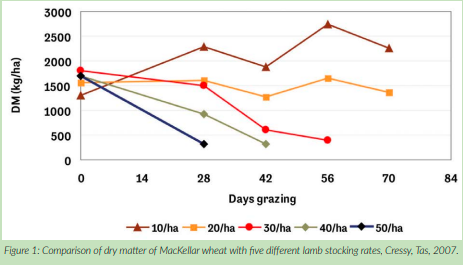

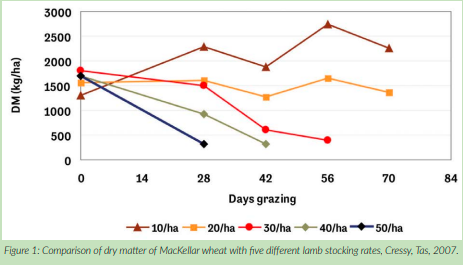

The effect of different stocking rates on crop dry matter is illustrated in figure 1 below. Grazing at 20 lambs per hectare roughly maintained crop cover. At higher stocking rates dry matter declined and at lower lamb numbers, crop growth during grazing was in excess of animal intake. This suggest crop growth was approximately 30 kg/ha/day (20 lambs eating 1.5 kg/hd/day).

For many farmers a significant challenge is to find enough stock to graze the crop evenly within the grazing window. This is especially true if the cropping paddocks are large, sowing is early in the season or there are many crops that could be grazed all at the one time. Temporary fencing is one way of creating smaller paddocks so that the grazing intensity can be optimised.

Multiple Grazings

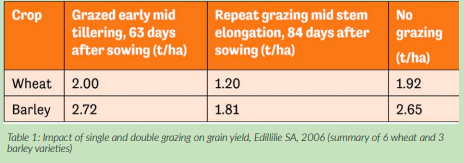

Multiple grazing can be undertaken which gives access to more dry matter, however, the second and subsequent grazing are likely to occur after GS 30 has occurred. This usually results in a loss of grain yield (table 1).

Grazing Cropped Land

There are other considerations that farmers need to appreciate when grazing winter crops. The information presented here seeks to quantify the magnitude of these risks under different situations. With this understanding, each farmer can make a decision on whether to accept the risk and graze the crop.

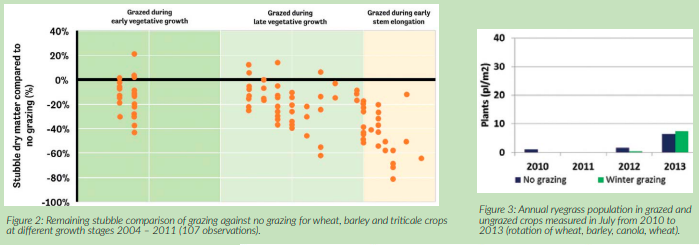

Stubble after grazing

In most cases grazing will reduce the amount of stubble left compared to no grazing. The average across all observations was 37%, although there is less effect the earlier the crop is grazed. The average reduction during early vegetative growth was 18%, 29% during tillering and 64% in early stem elongation. The smaller reduction when grazed early is probably because there is more time for the plants to recover before stem elongation commences (figure 2). The reduction in remaining stubble may be useful for farmers who have difficulty managing high stubble loads. However for those farmers who can bale and sell the straw, grazing will reduce stubble available. There is limited information on the effect on silage or hay production, although it would be reasonable to assume similar reductions to the dry matter available for baling when grazing occurs.

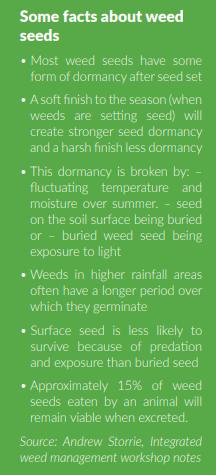

Weeds

Creating weed problems is a common concern expressed by farmers grazing winter crops. The fear is that grazing removes crop competition, encourages germination of weed seeds and increases tillering once the weeds are grazed. Weed populations are dynamic, which makes a simple answer to the question does grazing increase weeds impossible to answer. However information from 12 trials conducted throughout the Grain and Graze program is beginning to shed light on weed populations and to enable some general statements to be made.

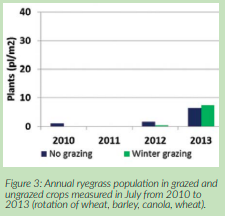

Weed free paddocks are the safest to graze When weed populations are already very low, grazing does not increase these populations, except with the possibility of opportunistic weeds such as toadrush (Juncus bufonius) which has an extremely long seed dormancy and only germinates when soil becomes saturated and pugged. An example is presented for annual ryegrass populations monitored for 4 years in South West Victoria (figure 3).

Crop competition is important in controlling weeds

Early crop competition will reduce weeds. This can be achieved through:

• Variety selection, using early vigorous types like oats and barley compared with winter wheat

• Higher sowing rates and narrow row spacing

• Earlier sowing, although this may compromise the timing of pre sowing herbicides

• Adequate fertility and soil conditions

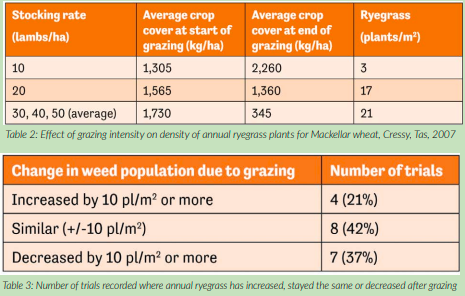

Grazing obviously removes plant competition and may change the subsequent weed populations. In a Tasmanian trial, the density of annual ryegrass plants was five to six times lower in ‘undergrazed’ plots with 10 lambs/ha compared with 20 lambs/ha or higher stocking rates of 30, 40 and 50 lambs/ ha (table 2). It was thought the extra leaf in the crop grazed with 10 lambs/ ha continued to shade the ryegrass, potentially reducing germination and vigour. In nil-grazed exclusion areas the density of ryegrass was comparable with the lowest stocking rate.

Grazing may increase or decrease weeds

The Grain and Graze data from 19 trials in Western Australia and Victoria (high rainfall) provides examples where weeds have increased, stayed the same or decreased after winter grazing (table 3).

Intensity of grazing is important

If both weeds and cereals are intensively grazed to the same level early in the growth of the crop, the actively growing cereal re-grows more rapidly than most weeds, thereby putting the weeds at a disadvantage. Lax grazing, where only the top part of the canopy is removed has a tendency to reduce shading of the weeds by the cereal, allowing the weed to intercept more sunlight. While there are examples of sheep actively seeking out some weeds in a cereal crop, it is unlikely that this can be assumed over a range of crops, population of weeds, varieties and growth stages. Also the variability in the response of different weeds to grazing adds to the confusion. So what does this mean for grazing crops? The basic principles of weed control in winter grazed crops are the same as the practices used in ungrazed winter crops. Maximizing leaf production through high plant density, adequate soil fertility and selection for rapid growing crops all suit weed control strategies and DM production for grazing.

Soil structure

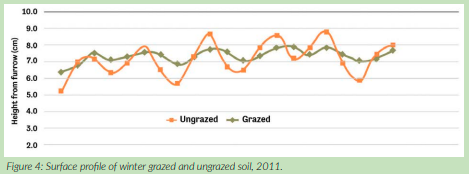

The impact of grazing on soil structure remains difficult to quantify. Trials in NSW and Victoria attempted to measure changes in soil structure after winter grazing which imposed extreme winter grazing conditions over multiple years. The main conclusions of this work were:

•Grazing resulted in visual changes to the soil surface (see picture) and reduced roughness in the soil surface (figure 4)

•There were no measurable changes to water infiltration or soil water storage as the result of grazing

•There was no difference in crop establishment in the year after grazing had occurred.

These findings are consistent with a review undertaken by the CSIRO that concluded grazing had no long term impact on soil structure and if there was any short term impact, the soil had an ability to ‘repair itself’, as long as the biological activity of the soil was adequate.

Animal health

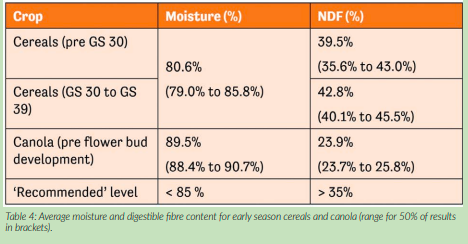

Farmers who have been grazing winter crops in the last few years have observed some animal health issues. In interviews conducted with 14 farmers in South West Victoria who were grazing winter crops, 40% believed there were slightly higher ewe mortalities and 30% reported increased scouring and dags. Crops grazed in winter tend to be lush and are characterised by high moisture content and lower amounts fibre compared to more mature feed. This can potentially create animal health issues that need to be appreciated. Fibre Fibre is required in a diet to maintain healthy rumen function. It slows down the flow of feed through the animal (but can also restrict intake) and helps stimulate contractions or mixing of the feed in the stomach. Neutral detergent fibre (NDF) is the common test for digestible fibre in feeds.

Currently there is no Australian standard for the amount of fibre to be fed to ruminants, however practical recommendations are that dairy cows require above 35% NDF to avoid reduction in milk fat.

Water Most water absorption in a ruminant occurs in the third stomach (the omasum) and the large intestine. The removal of water ‘hardens’ the excreted material. In diets with high moisture content, the animal is unable to absorb sufficient water to prevent loose faeces and appear to have ‘runny bums’. There is no benchmark for the maximum amount of water to prevent loose faeces although moisture contents above 85% are often observed to be threshold.

Winter crops in the early vegetative stage of growth are commonly low in fibre and high in moisture (table 4). Scouring may also be caused by a rapid change in diet, where the animal has not become accustomed to the different quality feed. The simplest way to minimise the potential scouring effect is to provide roughage just before entry to the crop and maintain access to this material during grazing. Late pregnant or lactating cows, or ewes, especially need good quality hay. Additional actions can include introducing stock to the type of feed over a three or four day period or only graze late in the afternoon for the first few days (to avoid potential nitrate poisoning). Always avoid turning hungry stock into a crop on an empty stomach.

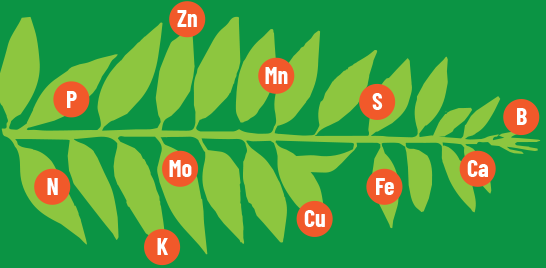

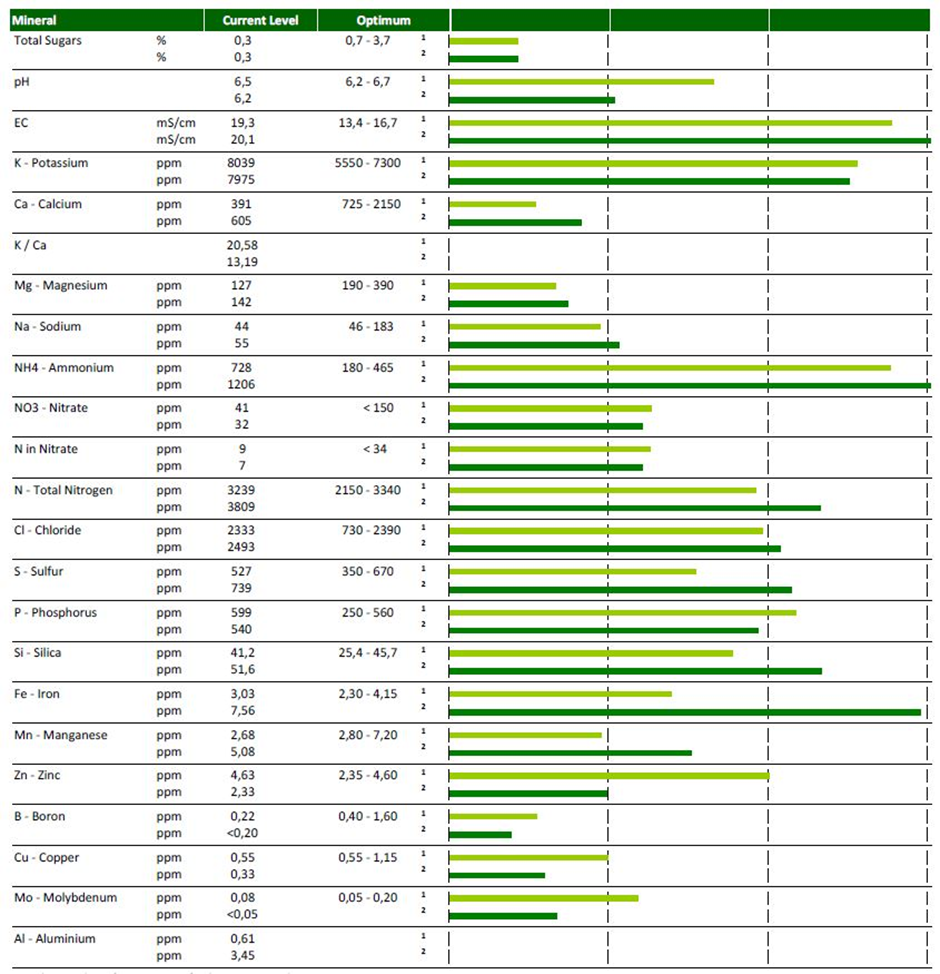

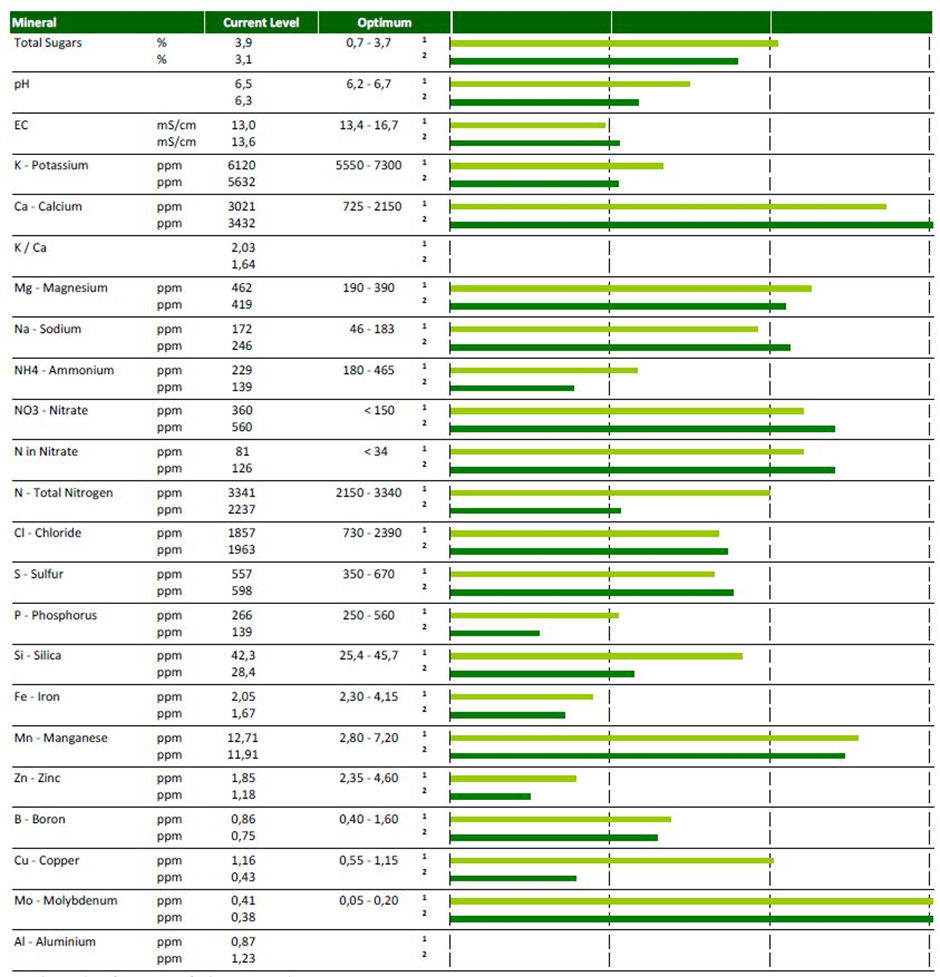

Minerals

Work conducted by Hugh Dove, former Chief Research Scientist with CSIRO Plant Industry in Canberra identified that low magnesium was present in wheat crops. Acute magnesium deficiencies result in grass tetany, however more marginal deficiencies present themselves as lower than expected growth rates. The cause of the magnesium deficiency is an imbalance of potassium and sodium in the cereal the animals are grazing. Excess potassium combined with low sodium reduces the absorption of magnesium in the rumen. This deficiency can be easily rectified with a simple mineral lick. Sheep only need 20g/d and cattle 150 g/day.

Metabolic disorders

Canola can pose a greater risk to animal health than cereals, but this usually occurs when animals are suddenly introduced to the crop, often combined with conditions that make the crop stressed such as a lack of moisture, frost or herbicide application. The potential animal health problems include pneumonia, gastroenteritis, hypocalcemia, polio, liver damage, photosensitisation and nitrate poisoning. Stock should be fully vaccinated against enterotoxaemia before grazing. The recommendation when grazing canola is to offer hay and observe the animals closely for at least the first two weeks of grazing.

Crop diseases

The anecdotal information on diseases in cereal crops is quite variable. Some farmers believe grazing reduces disease such as rust by removing the diseased leaves and therefore the source of ongoing infection, or by reducing the canopy which improves air circulation and creates a less favourable condition for disease build up.

There is limited information on the effect of grazing on disease incidence. Observations of stripe and leaf rust in two barley and four wheat varieties in South West Victoria revealed no significant difference in rust incidence in the grazed and ungrazed plots, although the observations were taken during a drought year where the rust incidence was extremely low. In contrast a trial in Western Australia on barley where powdery mildew was about threshold control levels early in the season showed a substantial reduction in disease incidence until later in the season.

-

Introduction – Issue 19 – October 2022

Written by Mike Donovan

I have some sympathy for the new Defra Secretary Ranil Jayawardena. He got the job on Sept 6 and before the month was out was facing questions over ELMS – the greatest change in UK farming since the 1947 Agriculture Act. Ranil’s knowledge of farming is scant and he was surely hoping for time to bone up on the huge industry he now heads. Farming, environment, water and nature do not feature in his CV!

The growing financial crisis of the new government makes a re-think of ELMS look increasingly probable, and Minister Jayawardena will be lobbied from all sides. Government will question the benefits of farm subsidy. The NFU is not happy with present arrangements. Minette Batters wants the scheme delayed, saying “We called for a delay … because we believe that the SFI [part of ELMS] needed to have more detail and it needs to be profitable. We have always been calling for a better policy, one that does deliver for food production and for the environment.” Pro-ecology NFU members threaten to leave while Batters supporters want area payments to continue.

On Sept 26 a Defra spokeswoman explained that, while environmental land management remained important, the department was reviewing its plans “given the pressures on farmers, and the government’s aims of boosting food security and economic growth”. With the economy haemorrhaging as it is she could easily be referring to the UK economy rather than farmers.

She added: “In the light of the current global economic situation, we know that the cost of inputs has gone up, which might make it more difficult for farmers to both improve the natural environment and underpin food production, so we will continue our engagement with the sector to make sure the outcomes that the British people want to see are delivered.”

Given the current dismal national financial scene it looks very much as if ELMS will be on the back burner for some time with a distinct possibility of a cut in overall farm payments.

Direct Driller readers know conventional cultivation methods are from the Steam Age and farming is moving quickly to a period of biology and working with nature. Yet the lobbying power of ‘old ag’ remains considerable and Mr Jayawardene will need rapid education into the costs, benefits and needs of the new biological farmer. First among this is trials and advice, which is where Direct Driller (and Practical Farm Ideas) can play a part. Read this issue of Direct Driller and you will find a dozen and more vital areas of research, many being tackled by individual farmers.

Finally, I sincerely thank all who have contributed, and invite others to do the same.

-

Reading more

Written by Chris Fellows

We have recently taken part in an Innovate UK competition to try and encourage farmers to read from formal material. Trial results, papers, research, on-farm projects and so forth. The assumption being that farmers who are better informed, make better decisions and thus become more profitable or sustainable (or both hopefully). This same aim being the reason behind this magazine and Groundswell starting at the same time. We wanted to give farmers a view on farming knowledge that wasn’t available through conventional sources. This concept was also peer reviewed in a paper by Sumane et al (2018). Farmers who read more information from more sources are more resilient.

Has been an interesting exercise. Some great ideas, like how to integrate video content into this knowledge exchange process, which we already do in Resources on The Farming Forum. It is hard to link contextually without a transcript of the video. This really makes you think about the overall KE landscape when faced with a problem.

As part of the process, we built TFF Resources to test how we could put formal and informal content on the same site and test ways to present and promote it. The first think to note is that TFF Resources now contains over 1200 pieces of knowledge. We have included many around the regen and conversation ag topics. Its has also in the last 4 months generated over 150,000 reads of this content organically. We intend to increase this to over 10,000 knowledge pieces over the next few years and create a library of information. But the real challenge is how you help farmers navigate that information and “suggest” what to read next. That is, the content that they will find most interesting and relevant. We don’t have all the answers right now, but a solution will help farming as a whole and balance some of the commercial bias that sits behind so much of the knowledge we currently read.

Have a look at the TFF Resources sections and see what you can find of interest: https://thefarmingforum.co.uk/index.php?resources/

-

Featured Farmer – John Farrington

Farm Facts

245 Ha plus 40 Ha Woodland

Arable, Sheep and Diversification

Crops: Wheat OSR Oats Maize Spring Beans Miscanthus

Rainfall: 850-900mm average. Last 3 years 1200mm.

Soils: Sandy Loam, “Hungry” Soil, Low CEC and Low OM

In the time I have been a reader of Direct Driller Magazine, I have learnt a lot from the magazine’s content. While at the fantastic Groundswell event, Chris Fellows persuaded me to write a contribution to the magazine, which I am more than happy to do to give something back, so here is my roller coaster ride so far. I farm in partnership with my brother, Charlie, based in West Somerset. My father had got out of beef in 1999, contractors had been doing the majority of the arable work, and the grassland was rented out to neighbouring livestock farmers while he concentrated his efforts on old farm building renovations.

When I came back to the farm I gradually took operations back in hand and set about trying to improve the farming system. No disrespect to my father, but the soils had been overworked and under loved. The plough was used up until 2000, then a “min till” approach was taken with a tine and disc machine. Stubble was worked soon after harvest to get a chit and again before a contractors Vaderstad Rapid did the drilling, by the time it had been rolled it was like a sandy beach. At the time It all looked lovely and a perfect seed bed, but often the weather that followed was the down fall of the system. The autumn rain came and capped the surface, and the wheelings of the drill were there to be seen all year on the headlands.

We had to change something.

Not having any FYM on the farm, I used sewage sludge from Wessex water for a number of years, but I stopped using it 3 years ago, concerned about the long-term effects of the chemical based cleaning products that go down the kitchen / bathroom waste pipes. I did use green waste compost for a few years, a combination of haulage costs and plastic in the compost put a stop to this. I decided to chop all straw to help put some goodness back into the soil.

Being blackgrass free, I was concerned about balers bringing it onto the farm, it can be found locally. But chopping straw has had a knock-on effect when establishing cover crops and OSR in a direct drill scenario. To help the process I wanted to grow cover crops and go down the direct drilling route. I found a 2nd hand 4m Horsch Sprinter that our 150hp copes with on our hills. The Horsch duetts were removed and 4” Bourgault coulters fitted and ran them for 3/4 years. I now also have a set of 2” Bourgault. The 4” generally do cover crops and forage crops for sheep and the 2” do everything else.

I have been really pleased with both sets of points and their low disturbance. Now all crops are direct drilled. We have also done some targeted subsoiling. Crops are certainly looking a lot more even across the field and right out to the edge of the field since we have reduced cultivations. Cover crops have been grown for a number of years, usually consisting of phacelia, vetch, radish, berseem clover, bought as straights and mixed on farm. Costing around £25/Ha. These were grazed during the winter by a neighbour but now we have more control as our sheep graze the covers.

Catch crops are grown when timing allows. Another trigger for my change in thinking, was taking part in AHDB benchmarking and seeing my chemical costs £40/ Ha higher that the group average, being a lower yielding farm than the group this was a concern (wheat average 8.6T/Ha). I was wanting to implement some changes (that we have now done) but I was not getting the support from my agronomist, so I made the change to an Independent who was on the same line of thought as myself, and this has been a breath of fresh air.

Insecticides have not been used on the farm for about 4 years, we are trying to build up natural predators within and around the field. BYDV has not been anymore of a problem than it used to be when using insecticides, other than one field which had a spring/summer cover crop mix which included oats, the wheat was drilled into this on the green and we had a problem with “green bridge” carryover. I have stopped using all seed dressings and the home saved seed is tested for disease.

In Autumn 2019 we had 2 part fields of OSR and Wheat which we wrote off and used the failure as an opportunity in the spring to put in some small leaved white clover as an understorey in the following wheat crop. This was grazed twice over the summer. Our Sprinter drill wouldn’t cope with drilling into the clover so Horizon Agriculture came with their DSX drilling wheat into 4” tall wet clover after 16mm of rain overnight. This was an impressive machine, did a fantastic job, and the wheat looked the best on the farm right up until late May. Nutrition was used instead of fungicides, no pgr and only 125kg N.

It combined easily leaving a clover understorey for the sheep to graze a few weeks after harvest. The yield was disappointing at 6.2T/Ha, after how good the crop looked. This was mainly due to the low rate of N. We had hoped the clover would nodulate and provide some N to the growing crop but this did not happen due to the cold spring and the clover using the artificial N rather than producing its own. The winter oats following the wheat/clover looked greener all season where the clover had been and yielded higher than the rest of the field, but the clover ended up being sprayed out with a communication error from myself.

The other part field of clover was going into its 2nd year with 2nd wheat, we had to spray the clover off as too many grass weeds were present even after glyphosate and hard grazing before drilling. I see clover being used somewhere in the rotation but it is a challenge to keep grass weeds out with just glyphosate between crops. I need to try it again. I wish I could justify the Horizon DSX as it was a fantastic product, instead I fitted a set of front cutting discs to run in line with each leg onto my Sprinter. This has been great for cutting through trash and reducing soil disturbance from the coulter.

We always used to be a 4 spray fungicide programme whatever the weather, we now react to the crop/season and try to use more nutrition and less fungicides. Nitrogen has always been 220kg for wheat and we have started to reduce this over the last few years. This year we were at 170kg, Last year we tried to reduce N too quickly and by too much in a few fields and it did show up. I feel it needs to be reduced in small increments each year. We moved to liquid fertiliser 2 seasons ago, to help with the accuracy around the headlands on our small fields (average 10 acre), a carbon source of fulvic and humic acids are added to the liquid fertiliser.

In September 2021 we bought our own flock of 500 Exlana breeding ewes onto the farm, forage based, lambing outdoors. Sheep was totally new to us, but it hasn’t been a disaster in our 1st season !! This was to make better use of the grassland that had been rented out and have better control of the sheep when grazing cover crops and winter cereals and to bring livestock and some muck back onto the farm. I get reminded that I said “ I would never be a livestock farmer.” We have survived year one… As a trail – A cover crop was planted in August 2021 after oats, volunteer oats sprayed out, but no glyphosate, Wheat was direct drilled into this in October, with sheep grazing for a week after drilling. Wheat and cover crop continued to grow together with sheep grazing it again in Jan/Feb.

The cover crop was then sprayed out in early March. The wheat yield was a little lower, but this is also the lightest field on the farm so the drought may have contributed. More trials needed. I have always been against renting ground out for maize/ p o t a t o e s and undoing all the soil improvements. But this year I planted strip till maize into cover crop. I am taking the financial risk and growing it for a neighbour so I chose the establishment technique. Currently looking good despite the drought, yet no plough/powerharrow was involved. Fingers crossed for a dry weather when the forager arrives.

I have waffled on for long enough now so In summary… We are learning all the time, got a long way to go, made mistakes and its certainly not all perfect. But we will continue down this route and keep learning. I think my neighbours probably think I’m a bit mad, but you can’t worry what they think, and hopefully I am one step ahead of where we may have to be in the future. My advice would be to get the right people around you to help you with the direction you want to go, if they don’t want to change then replace them. Try things out on a small scale, don’t feel you need to be spending lots of £££ on new DD drills or expensive cover crops mixes. There is no quick fix and there are many parts involved to get it right – It takes time and don’t expect things to change in one season. And finally a lot of it is certainly in the mind – if the mind won’t change it won’t work. Hope you all have a safe and successful harvest and autumn drilling campaign

-

Featured Farmer – John Farrington

Farm Facts

245 Ha plus 40 Ha Woodland Arable, Sheep and Diversification Crops: Wheat OSR Oats Maize Spring Beans Miscanthus Rainfall: 850-900mm average. Last 3 years 1200mm. Soils: Sandy Loam, “Hungry” Soil, Low CEC and Low OM

In the time I have been a reader of Direct Driller Magazine, I have learnt a lot from the magazine’s content. While at the fantastic Groundswell event, Chris Fellows persuaded me to write a contribution to the magazine, which I am more than happy to do to give something back, so here is my roller coaster ride so far. I farm in partnership with my brother, Charlie, based in West Somerset. My father had got out of beef in 1999, contractors had been doing the majority of the arable work, and the grassland was rented out to neighbouring livestock farmers while he concentrated his efforts on old farm building renovations.

When I came back to the farm I gradually took operations back in hand and set about trying to improve the farming system. No disrespect to my father, but the soils had been overworked and under loved. The plough was used up until 2000, then a “min till” approach was taken with a tine and disc machine. Stubble was worked soon after harvest to get a chit and again before a contractors Vaderstad Rapid did the drilling, by the time it had been rolled it was like a sandy beach. At the time It all looked lovely and a perfect seed bed, but often the weather that followed was the down fall of the system. The autumn rain came and capped the surface, and the wheelings of the drill were there to be seen all year on the headlands.

We had to change something.

Not having any FYM on the farm, I used sewage sludge from Wessex water for a number of years, but I stopped using it 3 years ago, concerned about the long-term effects of the chemical based cleaning products that go down the kitchen / bathroom waste pipes. I did use green waste compost for a few years, a combination of haulage costs and plastic in the compost put a stop to this. I decided to chop all straw to help put some goodness back into the soil. Being blackgrass free, I was concerned about balers bringing it onto the farm, it can be found locally. But chopping straw has had a knock-on effect when establishing cover crops and OSR in a direct drill scenario.

To help the process I wanted to grow cover crops and go down the direct drilling route. I found a 2nd hand 4m Horsch Sprinter that our 150hp copes with on our hills. The Horsch duetts were removed and 4” Bourgault coulters fitted and ran them for 3/4 years. I now also have a set of 2” Bourgault. The 4” generally do cover crops and forage crops for sheep and the 2” do everything else. I have been really pleased with both sets of points and their low disturbance. Now all crops are direct drilled. We have also done some targeted subsoiling. Crops are certainly looking a lot more even across the field and right out to the edge of the field since we have reduced cultivations. Cover crops have been grown for a number of years, usually consisting of phacelia, vetch, radish, berseem clover, bought as straights and mixed on farm. Costing around £25/Ha. These were grazed during the winter by a neighbour but now we have more control as our sheep graze the covers. Catch crops are grown when timing allows.

Another trigger for my change in thinking, was taking part in AHDB benchmarking and seeing my chemical costs £40/ Ha higher that the group average, being a lower yielding farm than the group this was a concern (wheat average 8.6T/Ha). I was wanting to implement some changes (that we have now done) but I was not getting the support from my agronomist, so I made the change to an Independent who was on the same line of thought as myself, and this has been a breath of fresh air.

I n s e c t i c i d e s have not been used on the farm for about 4 years, we are trying to build up natural predators within and around the field. BYDV has not been anymore of a problem than it used to be when using insecticides, other than one field which had a spring/summer cover crop mix which included oats, the wheat was drilled into this on the green and we had a problem with “green bridge” carryover. I have stopped using all seed dressings and the home saved seed is tested for disease.

In Autumn 2019 we had 2 part fields of OSR and Wheat which we wrote off and used the failure as an opportunity in the spring to put in some small leaved white clover as an understorey in the following wheat crop. This was grazed twice over the summer. Our Sprinter drill wouldn’t cope with drilling into the clover so Horizon Agriculture came with their DSX drilling wheat into 4” tall wet clover after 16mm of rain overnight. This was an impressive machine, did a fantastic job, and the wheat looked the best on the farm right up until late May. Nutrition was used instead of fungicides, no pgr and only 125kg N. It combined easily leaving a clover understorey for the sheep to graze a few weeks after harvest. The yield was disappointing at 6.2T/Ha, after how good the crop looked.

This was mainly due to the low rate of N. We had hoped the clover would nodulate and provide some N to the growing crop but this did not happen due to the cold spring and the clover using the artificial N rather than producing its own. The winter oats following the wheat/clover looked greener all season where the clover had been and yielded higher than the rest of the field, but the clover ended up being sprayed out with a communication error from myself. The other part field of clover was going into its 2nd year with 2nd wheat, we had to spray the clover off as too many grass weeds were present even after glyphosate and hard grazing before drilling. I see clover being used somewhere in the rotation but it is a challenge to keep grass weeds out with just glyphosate between crops. I need to try it again.

I wish I could justify the Horizon DSX as it was a fantastic product, instead I fitted a set of front cutting discs to run in line with each leg onto my Sprinter. This has been great for cutting through trash and reducing soil disturbance from the coulter. We always used to be a 4 spray fungicide programme whatever the weather, we now react to the crop/season and try to use more nutrition and less fungicides. Nitrogen has always been 220kg for wheat and we have started to reduce this over the last few years. This year we were at 170kg, Last year we tried to reduce N too quickly and by too much in a few fields and it did show up. I feel it needs to be reduced in small increments each year. We moved to liquid fertiliser 2 seasons ago, to help with the accuracy around the headlands on our small fields (average 10 acre), a carbon source of fulvic and humic acids are added to the liquid fertiliser.

In September 2021 we bought our own flock of 500 Exlana breeding ewes onto the farm, forage based, lambing outdoors. Sheep was totally new to us, but it hasn’t been a disaster in our 1st season !! This was to make better use of the grassland that had been rented out and have better control of the sheep when grazing cover crops and winter cereals and to bring livestock and some muck back onto the farm. I get reminded that I said “ I would never be a livestock farmer.” We have survived year one…

As a trail – A cover crop was planted in August 2021 after oats, volunteer oats sprayed out, but no glyphosate, Wheat was direct drilled into this in October, with sheep grazing for a week after drilling. Wheat and cover crop continued to grow together with sheep grazing it again in Jan/Feb. The cover crop was then sprayed out in early March. The wheat yield was a little lower, but this is also the lightest field on the farm so the drought may have contributed. More trials needed. I have always been against renting ground out for maize/ p o t a t o e s and undoing all the soil improvements. But this year I planted strip till maize into cover crop. I am taking the financial risk and growing it for a neighbour so I chose the establishment technique. Currently looking good despite the drought, yet no plough/powerharrow was involved. Fingers crossed for a dry weather when the forager arrives.

I have waffled on for long enough now so In summary… We are learning all the time, got a long way to go, made mistakes and its certainly not all perfect. But we will continue down this route and keep learning. I think my neighbours probably think I’m a bit mad, but you can’t worry what they think, and hopefully I am one step ahead of where we may have to be in the future.

My advice would be to get the right people around you to help you with the direction you want to go, if they don’t want to change then replace them. Try things out on a small scale, don’t feel you need to be spending lots of £££ on new DD drills or expensive cover crops mixes. There is no quick fix and there are many parts involved to get it right – It takes time and don’t expect things to change in one season. And finally a lot of it is certainly in the mind – if the mind won’t change it won’t work. Hope you all have a safe and successful harvest and autumn drilling campaign.

-

No-Till Innovation Come in Leaps and Bounds

By Brian O’Connor originally published by No-Till Farming

Wisconsin no-till dairyman Chris Conley thwarts heavy rain and hills with no-till, covers and planting green.

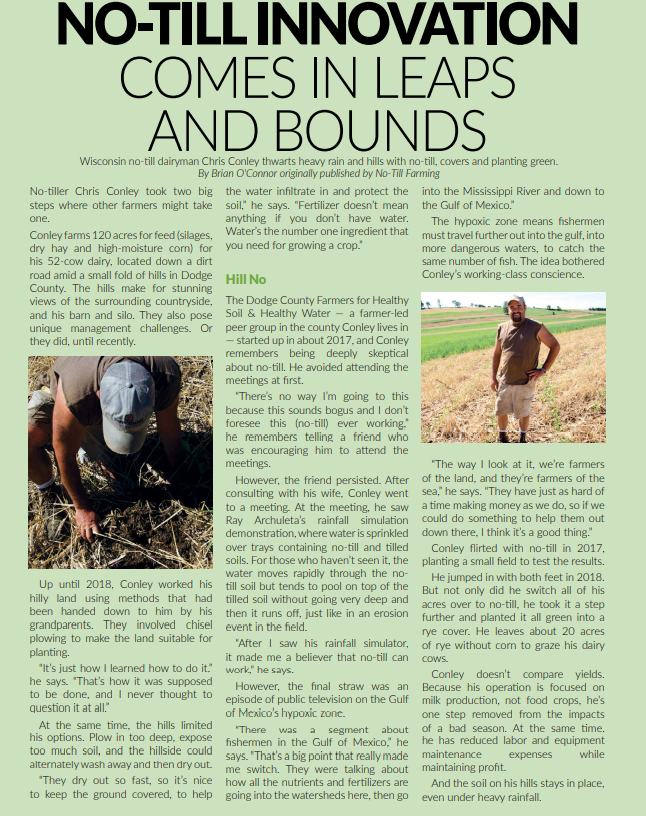

No-tiller Chris Conley took two big steps where other farmers might take one.

Conley farms 120 acres for feed (silages, dry hay and high-moisture corn) for his 52-cow dairy, located down a dirt road amid a small fold of hills in Dodge County. The hills make for stunning views of the surrounding countryside, and his barn and silo. They also pose unique management challenges. Or they did, until recently.

Up until 2018, Conley worked his hilly land using methods that had been handed down to him by his grandparents. They involved chisel plowing to make the land suitable for planting.

“It’s just how I learned how to do it,” he says. “That’s how it was supposed to be done, and I never thought to question it at all.”

At the same time, the hills limited his options. Plow in too deep, expose too much soil, and the hillside could alternately wash away and then dry out.

“They dry out so fast, so it’s nice to keep the ground covered, to help the water infiltrate in and protect the soil,” he says. “Fertilizer doesn’t mean anything if you don’t have water. Water’s the number one ingredient that you need for growing a crop.”

He couldn’t see No-till would work

The Dodge County Farmers for Healthy Soil & Healthy Water — a farmer-led peer group in the county Conley lives in — started up in about 2017, and Conley remembers being deeply skeptical about no-till. He avoided attending the meetings at first.

“There’s no way I’m going to this because this sounds bogus and I don’t foresee this (no-till) ever working,” he remembers telling a friend who was encouraging him to attend the meetings.

However, the friend persisted. After consulting with his wife, Conley went to a meeting. At the meeting, he saw Ray Archuleta’s rainfall simulation demonstration, where water is sprinkled over trays containing no-till and tilled soils. For those who haven’t seen it, the water moves rapidly through the no-till soil but tends to pool on top of the tilled soil without going very deep and then it runs off, just like in an erosion event in the field.

“After I saw his rainfall simulator, it made me a believer that no-till can work,” he says.

However, the final straw was an episode of public television on the Gulf of Mexico’s hypoxic zone.

“There was a segment about fishermen in the Gulf of Mexico,” he says. “That’s a big point that really made me switch. They were talking about how all the nutrients and fertilizers are going into the watersheds here, then go into the Mississippi River and down to the Gulf of Mexico.”

Farm watercourse pollution was the deciding factor

The hypoxic zone means fishermen must travel further out into the gulf, into more dangerous waters, to catch the same number of fish. The idea bothered Conley’s working-class conscience.

“The way I look at it, we’re farmers of the land, and they’re farmers of the sea,” he says. “They have just as hard of a time making money as we do, so if we could do something to help them out down there, I think it’s a good thing.”

Conley flirted with no-till in 2017, planting a small field to test the results.

He jumped in with both feet in 2018. But not only did he switch all of his acres over to no-till, he took it a step further and planted it all green into a rye cover. He leaves about 20 acres of rye without corn to graze his dairy cows.

Conley doesn’t compare yields. Because his operation is focused on milk production, not food crops, he’s one step removed from the impacts of a bad season. At the same time, he has reduced labor and equipment maintenance expenses while maintaining profit.

And the soil on his hills stays in place, even under heavy rainfall.

The Atari Planter

Conley’s first concern was whether he could no-till without forking over a hefty sum for a new planter. However, when he began his research online, he found numerous examples of farmers using older equipment, and the originators and proponents of no-till using their contemporary equipment to accomplish the same ends.

“They started out with John Deere planters, the same as what I have,” he says. “So I’m like ‘Well, if they started out with it, there’s no reason why I can’t use what I have.’”

More research turned up the fundamental similarities between today’s equipment and past equipment.

“The concept of putting a seed from the box to the ground is basically the same,” he says. “It’s just newer planters can go faster.

“If I can go slow and plant my crop with an old planter, I’m still money ahead because I’m not spending all that time in another tractor tilling and all that.”

Ultimately, Conley decided to go with his older planter, which he says resembles an Atari game console in its sophistication, but was good enough for his needs.

“My corn planter is a John Deere 7000 from the early 1980s,” he says. “The only thing on it is a light that tells if you’re planting or not planting.”

Conley added May Wes spiked closing wheels, Keeton seed firmers and Dawn row cleaners to his 4-row planter, which is on 36-inch spacing. He puts 50-pound sandbags in each of the planter’s insecticide boxes to increase the down force.

He went with second-hand modifications for economy’s sake.

Despite the modifications and added weight, he says he would be comfortable pulling the planter with a 50-horsepower tractor, though he uses an 80-horsepower tractor for the work.

The next consideration was herbicides. Conley has his custom applied by the local co-op, which uses a blend of Roundup, Halex, atrazine and Dominance herbicides.

“I don’t know much about chemicals, and I trust their judgment on what there is for weeds and what you need for a burndown,” he says.

He’s looking into the possibility of eliminating herbicide as much as possible, and potentially using roller-crimping to terminate cover crops.

Planting green

“I’m not saying that I want to be organic,” he says. “I want to be able to keep the tool in the toolbox using herbicide.”

Conley had previously stopped using phosphorous (P) based on soil testing results. In 2022, he’s following a nutrient management plan, and testing showed he didn’t need any potassium (K), either.

Currently Conley uses 100 pounds of urea and 50 pounds of AMS with his planter. The starter nutrients are placed 4 inches away from the seed trench because he doesn’t have no-till fertilizer coulters. He broadcasts an additional 100 pounds of urea at the V5 growth stage, and continuously applies manure from his cows throughout the season.

For his planting green plans, in the third week of May he typically plants corn at a rate of 34,500 seeds per acre into a stand of living rye that had been seeded at a rate of 60 pounds per acre in October (though he has planted as late as Christmas Eve). He bumped the rate up to 100 pounds per acre in 2022.

He terminates his rye cover after planting.

While he’s used to the practices now, Conley admits no-till and planting green caused nerves as he launched his new methods.

“When I started this, there were a lot of sleepless nights. I thought ‘This is totally not supposed to be working,’” he says. “It was so weird. It was one of the most uncomfortable things I think I’ve ever done farming. But now I do it, I’m like ‘Oh, whatever.’ It’s normal.”

Observations

The Sand County Foundation installed two solar-powered soil probes in his rye field as part of a wider look at soil conditions in various tillage methods. When fall rolled around, Sand County officials reached out to get the probes removed, and Conley asked that they stay in place.

“I had talked to them and finally got them to keep them in because I felt that they were missing a crucial time of the year, over wintertime into spring, of seeing what the water cycle is,” he says.

That data will become especially important as winters become warmer.

The results of the study haven’t yet been released. Conley says he’s seen some data that validates his management decisions, such as more beneficial soil temperatures under cover crops.

“I’ve taken temperatures between two different types of soil — covered and uncovered — this spring, when the air temperature was 95 degrees,” he says. “The uncovered soil was 90 degrees and my soil underneath the manure and cover crop rye was 70 degrees.”

Those 20 degrees can be the difference between heat-sterilized biologically dead soil and biologically active soil in the summer months, Conley says and water infiltration has also improved.

Rain Man

Another data point came in torrents.

Heavy rains swept through southern Wisconsin on the afternoon of June 16, 2022, forcing motorists to temporarily shelter on the sides of Interstate highways. Flash flood warnings were issued for large parts of Dodge County, and other nearby counties.

At the hilly, scenic Conley farm, the rain gauge recorded more than 6.5 inches of rain. Nearby Hartford recorded 3 inches of rain that day, according to National Weather Service Records.

After the rain stopped, Conley and his daughter Mckayla went out to check whether the heavy rains had moved his crops. He saw some movement, but not from his plants.

“The other night, when we got that heavy rain, after we were done in the barn, me and Mckayla were looking out in the field,” he says. “There were millions of earthworms out there. When you took the flashlight, you could see the ground move.”

On a walking tour the next day, corn plants nestled in among heavy straw from his rye covers. On the small paths and headlands, where patches of some soil were visible, heavy rains had carved inch-deep canyons into exposed mud. The soil under the straw — and under a layer of manure below that — was damp but hadn’t moved.

“It’s looking good, I think,” he says, digging through residue. “How much better can you have soil covered than this?”

-

No-Till Innovation Comes In Leaps And Bounds

Wisconsin no-till dairyman Chris Conley thwarts heavy rain and hills with no-till, covers and planting green.

By Brian O’Connor originally published by No-Till FarmingNo-tiller Chris Conley took two big steps where other farmers might take one. Conley farms 120 acres for feed (silages, dry hay and high-moisture corn) for his 52-cow dairy, located down a dirt road amid a small fold of hills in Dodge County. The hills make for stunning views of the surrounding countryside, and his barn and silo. They also pose unique management challenges. Or they did, until recently.

Up until 2018, Conley worked his hilly land using methods that had been handed down to him by his grandparents. They involved chisel plowing to make the land suitable for planting. “It’s just how I learned how to do it,” he says. “That’s how it was supposed to be done, and I never thought to question it at all.” At the same time, the hills limited his options. Plow in too deep, expose too much soil, and the hillside could alternately wash away and then dry out.

“They dry out so fast, so it’s nice to keep the ground covered, to help the water infiltrate in and protect the soil,” he says. “Fertilizer doesn’t mean anything if you don’t have water. Water’s the number one ingredient that you need for growing a crop.”

Hill No

The Dodge County Farmers for Healthy Soil & Healthy Water — a farmer-led peer group in the county Conley lives in — started up in about 2017, and Conley remembers being deeply skeptical about no-till. He avoided attending the meetings at first. “There’s no way I’m going to this because this sounds bogus and I don’t foresee this (no-till) ever working,” he remembers telling a friend who was encouraging him to attend the meetings.

However, the friend persisted. After consulting with his wife, Conley went to a meeting. At the meeting, he saw Ray Archuleta’s rainfall simulation demonstration, where water is sprinkled over trays containing no-till and tilled soils. For those who haven’t seen it, the water moves rapidly through the notill soil but tends to pool on top of the tilled soil without going very deep and then it runs off, just like in an erosion event in the field.

“After I saw his rainfall simulator, it made me a believer that no-till can work,” he says.

However, the final straw was an episode of public television on the Gulf of Mexico’s hypoxic zone. “There was a segment about fishermen in the Gulf of Mexico,” he says. “That’s a big point that really made me switch. They were talking about how all the nutrients and fertilizers are going into the watersheds here, then go into the Mississippi River and down to the Gulf of Mexico.” The hypoxic zone means fishermen must travel further out into the gulf, into more dangerous waters, to catch the same number of fish. The idea bothered Conley’s working-class conscience.

“The way I look at it, we’re farmers of the land, and they’re farmers of the sea,” he says. “They have just as hard of a time making money as we do, so if we could do something to help them out down there, I think it’s a good thing.”

Conley flirted with no-till in 2017, planting a small field to test the results. He jumped in with both feet in 2018. But not only did he switch all of his acres over to no-till, he took it a step further and planted it all green into a rye cover. He leaves about 20 acres of rye without corn to graze his dairy cows. Conley doesn’t compare yields. Because his operation is focused on milk production, not food crops, he’s one step removed from the impacts of a bad season. At the same time, he has reduced labor and equipment maintenance expenses while maintaining profit.

And the soil on his hills stays in place, even under heavy rainfall.

The Atari Planter

Conley’s first concern was whether he could no-till without forking over a hefty sum for a new planter. However, when he began his research online, he found numerous examples of farmers using older equipment, and the originators and proponents of no-till using their contemporary equipment to accomplish the same ends. “They started out with John Deere planters, the same as what I have,” he says. “So I’m like ‘Well, if they started out with it, there’s no reason why I can’t use what I have.’” More research turned up the fundamental similarities between today’s equipment and past equipment. “The concept of putting a seed from the box to the ground is basically the same,” he says. “It’s just newer planters can go faster.

“If I can go slow and plant my crop with an old planter, I’m still money ahead because I’m not spending all that time in another tractor tilling and all that.”

Ultimately, Conley decided to go with his older planter, which he says resembles an Atari game console in its sophistication, but was good enough for his needs. “My corn planter is a John Deere 7000 from the early 1980s,” he says. “The only thing on it is a light that tells if you’re planting or not planting.” Conley added May Wes spiked closing wheels, Keeton seed firmers and Dawn row cleaners to his 4-row planter, which is on 36-inch spacing. He puts 50-pound sandbags in each of the planter’s insecticide boxes to increase the down force.

He went with second-hand modifications for economy’s sake. Despite the modifications and added weight, he says he would be comfortable pulling the planter with a 50-horsepower tractor, though he uses an 80-horsepower tractor for the work. The next consideration was herbicides. Conley has his custom applied by the local co-op, which uses a blend of Roundup, Halex, atrazine and Dominance herbicides.

“I don’t know much about chemicals, and I trust their judgment on what there is for weeds and what you need for a burndown,” he says. He’s looking into the possibility of eliminating herbicide as much as possible, and potentially using rollercrimping to terminate cover crops. “I’m not saying that I want to be organic,” he says. “I want to be able to keep the tool in the toolbox using herbicide.”

Conley had previously stopped using phosphorous (P) based on soil testing results. In 2022, he’s following a nutrient management plan, and testing showed he didn’t need any potassium (K), either. Currently Conley uses 100 pounds of urea and 50 pounds of AMS with his planter. The starter nutrients are placed 4 inches away from the seed trench because he doesn’t have no-till fertilizer coulters. He broadcasts an additional 100 pounds of urea at the V5 growth stage, and continuously applies manure from his cows throughout the season.

For his planting green plans, in the third week of May he typically plants corn at a rate of 34,500 seeds per acre into a stand of living rye that had been seeded at a rate of 60 pounds per acre in October (though he has planted as late as Christmas Eve). He bumped the rate up to 100 pounds per acre in 2022. He terminates his rye cover after planting. While he’s used to the practices now, Conley admits no-till and planting green caused nerves as he launched his new methods.

“When I started this, there were a lot of sleepless nights. I thought ‘This is totally not supposed to be working,’” he says. “It was so weird. It was one of the most uncomfortable things I think I’ve ever done farming. But now I do it, I’m like ‘Oh, whatever.’ It’s normal.”

Observations

The Sand County Foundation installed two solar-powered soil probes in his rye field as part of a wider look at soil conditions in various tillage methods. When fall rolled around, Sand County officials reached out to get the probes removed, and Conley asked that they stay in place.

“I had talked to them and finally got them to keep them in because I felt that they were missing a crucial time of the year, over wintertime into spring, of seeing what the water cycle is,” he says. That data will become especially important as winters become warmer. The results of the study haven’t yet been released. Conley says he’s seen some data that validates his management decisions, such as more beneficial soil temperatures under cover crops. “I’ve taken temperatures between two different types of soil — covered and uncovered — this spring, when the air temperature was 95 degrees,” he says. “The uncovered soil was 90 degrees and my soil underneath the manure and cover crop rye was 70 degrees.”

Those 20 degrees can be the difference between heat-sterilized biologically dead soil and biologically active soil in the summer months, Conley says. Water infiltration has also improved, Conley says.

Rain Man

Another data point came in torrents. Heavy rains swept through southern Wisconsin on the afternoon of June 16, 2022, forcing motorists to temporarily shelter on the sides of Interstate highways. Flash flood warnings were issued for large parts of Dodge County, and other nearby counties. At the hilly, scenic Conley farm, the rain gauge recorded more than 6.5 inches of rain. Nearby Hartford recorded 3 inches of rain that day, according to National Weather Service Records. After the rain stopped, Conley and his daughter Mckayla went out to check whether the heavy rains had moved his crops. He saw some movement, but not from his plants.

“The other night, when we got that heavy rain, after we were done in the barn, me and Mckayla were looking out in the field,” he says. “There were millions of earthworms out there. When you took the flashlight, you could see the ground move.”

On a walking tour the next day, corn plants nestled in among heavy straw from his rye covers. On the small paths and headlands, where patches of some soil were visible, heavy rains had carved inch-deep canyons into exposed mud. The soil under the straw — and under a layer of manure below that — was damp but hadn’t moved.

“It’s looking good, I think,” he says, digging through residue. “How much better can you have soil covered than this?”

-

Kuhn’s Performer offers four levels of cultivation

The KUHN Performer is a deep cultivator, available in working widths from 3 to 7 metres, designed to prepare the soil for minimum tillage drilling. The Performer fulfils four cultivation tasks in one, by chopping, mixing, loosening, and levelling the soil in just one pass.

At the front of the machine there are two rows of hydraulically adjustable, 510mm cutting discs. The discs are capable of cutting through crop residues and root systems and can be used independently for stubble cultivation at depths of 10 centimetres, even at higher speeds.

The discs are followed by hydraulically pressured tines with options for 80mm standard points, 50mm carbide points with deflectors, or 80mm and 50mm carbide points. The carbide coating provides strength and durability, making the tine longer lasting. The tines can be adjusted to operate at depths of 5 to 35 centimetres, depending on the point chosen, to cover a wide variety of soil types.

Behind the running wheels, are four rows of tines set at equal widths that perform an in-depth mix, incorporating any residues and straw into the soil. Also available as standard on the Performer are 350mm carbide wings.

In addition, a single row of star shaped levelling discs provide a fine tilth. At the rear of the Performer is a double U-shaped packer or the option of an HD liner roller to roll the soil and leave an even finish.

All of the Performer’s functions are adjustable from within the cab using KUHN’s KTH 105 selector terminal which only requires one double acting valve for the axle and a single acting valve for the safety legs. The discs can be operated independently for stubble cultivation and the roller can be lifted and carried above the soil when not required.

The Performer range is designed for tractors with outputs of between 180 horsepower for the 3 metre machine and 420 horsepower for the 7 metre model. It also folds to less than 3 metres, making it ideal for tight gates and narrow lanes.

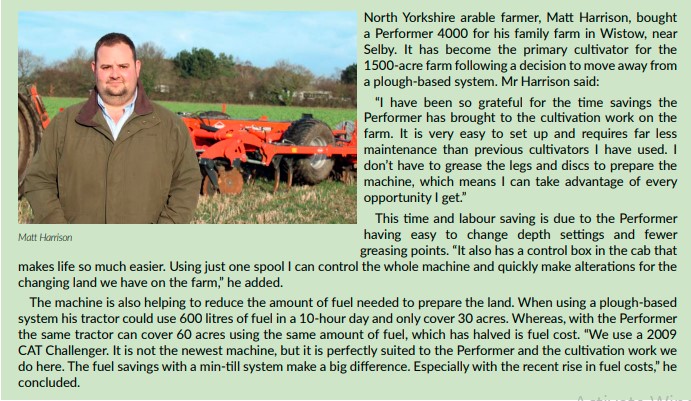

North Yorkshire arable farmer, Matt Harrison, bought a Performer 4000 for his family farm in Wistow, near Selby. It has become the primary cultivator for the 1500-acre farm following a decision to move away from a plough-based system. Mr Harrison said:

“I have been so grateful for the time savings the Performer has brought to the cultivation work on the farm. It is very easy to set up and requires far less maintenance than previous cultivators I have used. I don’t have to grease the legs and discs to prepare the machine, which means I can take advantage of every opportunity I get.”

This time and labour saving is due to the Performer having easy to change depth settings and fewer greasing points. “It also has a control box in the cab that makes life so much easier. Using just one spool I can control the whole machine and quickly make alterations for the changing land we have on the farm,” he added.

The machine is also helping to reduce the amount of fuel needed to prepare the land. When using a plough-based system his tractor could use 600 litres of fuel in a 10-hour day and only cover 30 acres. Whereas, with the Performer the same tractor can cover 60 acres using the same amount of fuel, which has halved is fuel cost. “We use a 2009 CAT Challenger. It is not the newest machine, but it is perfectly suited to the Performer and the cultivation work we do here. The fuel savings with a min-till system make a big difference. Especially with the recent rise in fuel costs,” he concluded.

-

Another Extraordinary Year

What an extraordinary growing season we seem to have had. In a nutshell, very low rainfall, low temperatures until

June and good levels of solar radiation (sunshine) resulting in generally good yields with good specific weight and

moderate protein. Especially so as most crops senesced approximately 2 weeks earlier than normal.

Written by James Warne from Soil First Farming

All the more extraordinary is where we have, once again, been trialing reduced nitrogen rates on production we have seen very little difference in final yield between standard N rates and reduced N rates (until we reach a critical level, then yield drops significantly). Where we have found yield difference this comes from lower grain weight as opposed to reduced plant counts or tiller numbers.

So what can we draw from this wealth of variables? Firstly, autumn 2021 was the kindest drilling season we have had for a couple of years suggesting that most crops went into good soil conditions backing up the adage ‘well sown-half grown’! the autumn and winter that followed was certainly dryer and in some areas was probably below average on the rainfall scale suggesting that crops rooted well. Winter was also very mild with very few days of frost and certainly no prolonged periods of cold weather. Wheat tends to be growing at around 5’C and above and I believe that the crops were growing most of the winter, albeit very slowly probably contributing to root mass development as much as above ground vegetative growth.

Temperature

One of the greatest contributing factors in this year’s yield-fest has been the temperature, or rather lack of if we cast our minds back to the early spring and summer. For the majority of us the temperatures were in the comfortable mid to high teens (celcius) occasionally reaching the low 20’s but never exceeding this until mid-June. Contrary to popular belief high-temperatures can be one of the greatest yield reducing factors for wheat as it can be sensitive to high temperatures throughout its growth cycle. It is, however, particularly to heat during the period from booting, through ear-emergence and flowering. This sensitivity then reduces after flowering trough grain-fill and maturity. Research shows temperature effects can start from the mid-late 20’s and become significant once into the 30’s. This is particularly so during the period of pollen formation and fertilisation.

Typically wheat is in flower around the second wheat in June (assuming the midlands of the UK). This occurred 7-10 days earlier this around, early June. The first really warm temperatures occurred around the 15th June onwards this year. By which time wheat had passed through the temperature critical period of pollen formation and flowering. From then on the temperatures typically remained in the low 20’s throughout June and into July when the skies cleared and we had prolonged periods if high 20’s-30’s and clear skies. This warmth and sun, combined with large soil moisture deficits, lead to rapid senescence and ripening. But the critical period of reproductive growth (stem extension and ear formation through to flowering) occurred during steady consistent conditions. The high temperatures came too late to have any potential to reduce yield. Although those in the very dry east of the country probably found the lack of moisture contributed to a drop in yield.

Nitrogen

It is generally accepted that the crop only receives half its nitrogen requirement from that we apply. The other 50% comes from or via the soil. With the majority of the nitrogen being taken up in the nitrate form which is very water soluble it is assumed that the plant takes up most of its nitrogen as nitrate in the soil water.

With the bulk of the uptake happening from stem extension through to ear emergence. As I have already mentioned above a large chunk of the UK was very dry during this period of April & May with some areas receiving zero rainfall, yet crops were still able to access the nitrogen they required for canopy and ear development. Although it seems perhaps not enough to assimilate into protein but that may also be attributed to sulphur availability. What is really interesting though is where we had reduced the soil applied N by half, combined with a small amount of foliar applied N this gave a very similar yield to wheat which had received a typical nitrogen dose.

Where we had dropped the soil applied N further we did start to see a yield drop. I must stress these results were consistent on farms which have been practicing carbonbuilding practices as in a Conservation Agriculture strategy, where we believe there to be a greater supply of N available for mineralization by the soil biology. Although another question must surely be if the soil was moisture deficient the biology must surely have been dormant and therefore unable to mineralise the nitrogen! It’s also worth noting that while it developed into another low disease year we saw a marked increase in mildew develop in the high N plots compared to lower total N plots. Never forget that nitrogen can help drive disease levels within the crop.

Finally, one of the most perplexing outcomes of this year is if the crop is able to produce the yields we have had when its growing cycle was at least two weeks shorter than average, why do we spend so much time and effort in trying to keep the canopy green? If there is one thing we have been shown this year it’s the lifespan of the crop has no direct influence on the final yield…..

-

Drill Manufacturers In Focus…

KUHN’S PERFORMER OFFERS FOUR LEVELS OF CULTIVATION

The KUHN Performer is a deep cultivator, available in working widths from 3 to 7 metres, designed to prepare the soil for minimum tillage drilling. The Performer fulfils four cultivation tasks in one, by chopping, mixing, loosening, and levelling the soil in just one pass.

At the front of the machine there are two rows of hydraulically adjustable, 510mm cutting discs. The discs are capable of cutting through crop residues and root systems and can be used independently for stubble cultivation at depths of 10 centimetres, even at higher speeds. The discs are followed by hydraulically pressured tines with options for 80mm standard points, 50mm carbide points with deflectors, or 80mm and 50mm carbide points. The carbide coating provides strength and durability, making the tine longer lasting. The tines can be adjusted to operate at depths of 5 to 35 centimetres, depending on the point chosen, to cover a wide variety of soil types.

Behind the running wheels, are four rows of tines set at equal widths that perform an in-depth mix, incorporating any residues and straw into the soil. Also available as standard on the Performer are 350mm carbide wings.

In addition, a single row of star shaped levelling discs provide a fine tilth. At the rear of the Performer is a double U-shaped packer or the option of an HD liner roller to roll the soil and leave an even finish.

All of the Performer’s functions are adjustable from within the cab using KUHN’s KTH 105 selector terminal which only requires one double acting valve for the axle and a single acting valve for the safety legs. The discs can be operated independently for stubble cultivation and the roller can be lifted and carried above the soil when not required.

The Performer range is designed for tractors with outputs of between 180 horsepower for the 3 metre machine and 420 horsepower for the 7 metre model. It also folds to less than 3 metres, making it ideal for tight gates and narrow lanes.

-

Wye oh Wye…?

Wye oh Wye…?

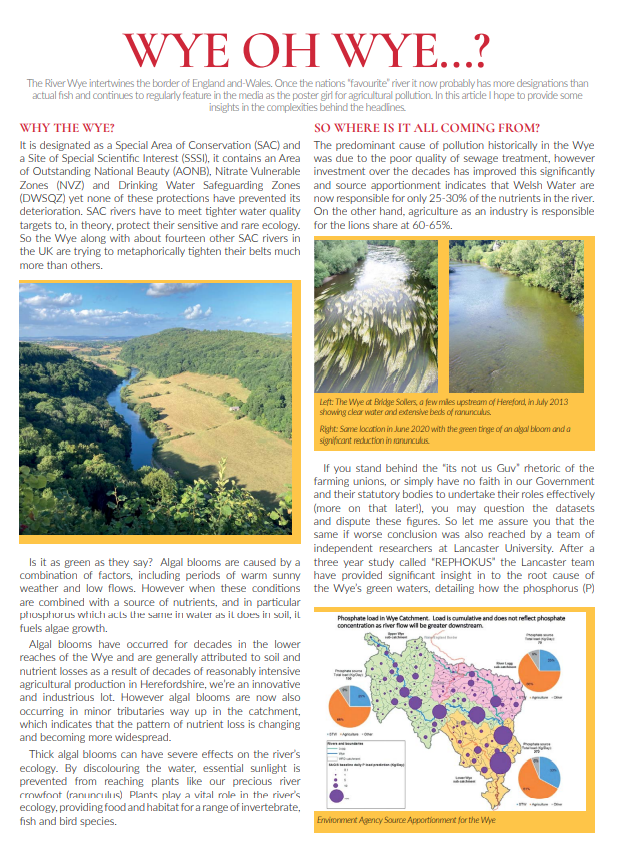

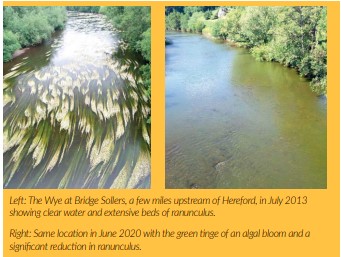

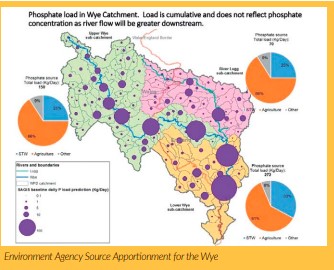

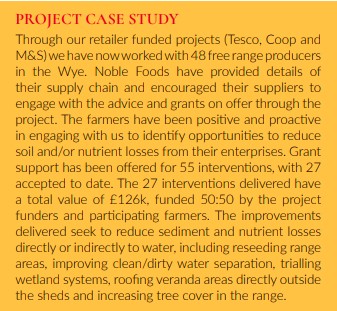

The River Wye intertwines the border of England and-Wales. Once the nations “favourite” river it now probably has more designations than actual fish and continues to regularly feature in the media as the poster girl for agricultural pollution. In this article I hope to provide some insights in the complexities behind the headlines.