If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Farmer Focus – Neil White

Berwickshire farmer Neil White calls for clarity and equity in their baseline carbon audit on his farm after six years of

No-till

Harvest 2021 was, in the end, better than expected. The crops came out of the wet cold spring looking respectable, but then continually improved to culminate in some top yields and good quality grain – not the case across the country, but in SE Scotland we had our turn at an easier and drier harvest this year.

I still run two systems to establish my barley crops, still ploughing a small percentage mostly due to remedial drainage work or the risk of wheat volunteers. I sowed the winter and spring barley crops with the Mzuri and comparisons with the plough/powerharrow combination drill were very interesting again this year. The Pearl winter barley sown with the Mzuri went into winter looking the better crop but in the wetter spring it stalled, and the conventional sown crop overtook it, maybe accessing available nitrogen quicker. The carrying capacity was noticeably different, the Mzuri ground carried the sprayer and spreader 6 or 7 days earlier without marks. This year the winter barley yield was admittedly better on the conventional by around 0.4t/Ha but still all above my historical average.

When I worked out the margin there was very little in it with the Mzuri sown crop just coming out on top. The biggest surprise was in the Diablo spring barley where the yield was reversed and the direct drilled came out on top despite it looking thinner. The higher yield and lower cost of establishment is always reassuring as I move towards 100% direct drilling. I have in the past noticed a bolder grain in the wider row, direct sown barley, maybe due to extra light inception on the upper leaves. But this year it was all very similar and all in spec for malting. This year I have the same two methods and conditions were perfect. I felt I still needed an earlier start in the direct drilled crop, so I went around 10 days earlier with the direct drill to aid establishment, so far everything looks great.

Like all winter crops in this area my cover crop went into perfect conditions, I don’t think Berwickshire has ever looked better going into December. Sown on Sep 3 the mixture of home saved spring beans, phacelia and buckwheat made up my relatively cheap cover crop. It was sown in one pass at two depths, beans at 2.5 inches down the front leg and at the coulter the phacelia and buckwheat 1 inch. It was sown at a faster than usual sowing speed, all at 12kph no spray or rolling and as the picture shows it has exceeded my expectations above ground. The first frost has killed off the buckwheat and I am hoping some hard frosts over new year may kill the beans leaving an open cover with only the phacelia to spray off ahead of hen muck and spring oats for Quaker. The concern I have about a strong cover over winter is if the ground fails to dry in the spring it may leave a wet seed bed prone to smearing, ideally 2/3 of this cover should be dying back or dead by New Year.

The companion cropping in the oilseed rape, while maybe doing unseen things, didn’t help gain yield or supress the pigeons, so I didn’t do it this year. It was inconvenient at sowing time and in the case of the clover, had very poor establishment. This year’s rape crops have covered the ground well, they are looking strong and go into winter looking well. I hope this will suppress the pigeons (for now). Slugs and pigeons are the main risk for rape here and while I vary my cereal seed rate, I would also like to move to variable rate on my slug pelleter. I have already mapped the heavier parts of my fields for the variable seed map, so I could also put a slightly higher rate of pellets on heavy areas while reducing rates on the lighter ground. This would give more targeted coverage without using more product. This is something to unlock or explore ready for next year’s rape.

I was asked to talk at a couple of events recently, the bigger one being the NFU’S autumn conference. I shared the real stage with ‘virtual’ Prof Jude Capper. Prof Capper had some excellent stats and made some fantastic points regarding sustainable British livestock production, worth looking up. The topic was Sustainable Farming, a very broad remit but I do firmly believe what I have done over the last 6 years has made my farm more resilient and sustainable in every way, it is now better placed to face the challenges ahead. There is an enormous desire for information and discussion around reduced tillage and direct drilling and magazines like this will play a part in that process. There is however still a fear in Scotland that we will be forced down this road by government and that will be a difficult route for many who haven’t considered trying it yet.

After an invite I sent the day she got the job, my son and I had an on-farm visit from Mairi Gougeon, Scotlands cabinet secretary for rural affairs and Islands. It’s always good to have politicians on the farm as they often openly admit there are gaps in their knowledge of modern farming practices. I think the political threat is one of the hardest to protect against or predict. We are still waiting for the Scottish governments new BPS which will take us from this limbo period into what looks like a ‘greener’, targeted, apply and fund, scheme led system. I conveyed my concerns regarding the combinable crop sector being overlooked when these schemes are devised and how nothing I have done in reducing tillage, companion and cover crops or machinery purchases tick a box or allow access to funding this side of the border. The main point I tried to address however is Scotland are going to have a baseline audit that gives a figure for your carbon footprint, eventually this will include biodiversity. I don’t have a problem with that as such, but every company I know which makes these calculations comes up with a very different number.

So, do I get the worst figure the first year and then save the favourable one until later, showing a good improvement or start with the best and hope I’m already ahead of the game? Who knows? We suggested that NFUS should have investigated this years ago when we asked them to and the company whom WE choose carried out the work. We are about to give away a huge amount of data and could be setting ourselves up for a tough time from environmentalists. If governments agreed an internationally recognised process to calculate these figures, then I’m sure it could help us sell our produce at home and all around the world. We must start with a level playing field that shows consumers what the actual consequences of their purchase are, good or bad! British agriculture should be shouting about the quality of our production methods and standards and not let others convince us we are the major polluters or destroyers of habitat, that is not British farming.

-

Michelin Tracks & Tyres European Tour

Written by Mark Hatton

I was recently, lucky enough, to be invited to attend the UK leg of the Michelin Tracks and Tyres European Tour in Cambridgeshire. The event was to showcase the features and benefits of their VF AXIOBIB 2 tyres, the latest track technology and the benefits of using the PTG Central Tyre inflation systems to vary tyre pressures to improve efficiencies, which we will focus on in this article, it turns out there’s much more to tyres than just being black and round!

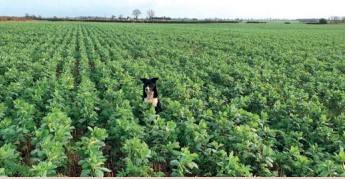

With tractors supplied by New Holland, a pair of identical T7.270, one fitted with Michelin’s Very high Flexion VF 710/60 R42 and VF 600/60 R30 Axiobib 2 tyres and the PTG Central Tyre inflation system, the other tractor fitted with 650/65 R42 and 540/65 R30 Multibib tyres. The event began with a demonstration to highlight the difference in tractive effort between different tyre pressures. To create the load a New Holland T8 SmartTrax was deployed to create resistance: lets call it the brake tractor method. This keeps the tractor at a constant speed, as it accelerates the wheels increase the tractive effort.

This is the most reliable method for comparing traction efficiency, in the form of weight and resistance. This is done to measure the tractive effort at the drawbar. A sensor integrated into the drawbar linking the tractor to the convoy will measure this effort, which is a value in decanewtons (or kg). Linked to this sensor, a live display screen, allow us to see this value. The higher the value, the higher the tractive effort. In other words, the higher the tractor’s traction. Two runs were made with the T7.270, fitted with, Michelin’s Very high Flexion VF 710/60 R42 and VF 600/60 R30 Axiobib 2 tyres at different pressures, altered via the PTG Central Tyre inflation system. At a constant speed of 4.6 km/h, we can see an average of 6800 decanewtons or kg

The higher the value, the higher the tractive effort. In other words, the higher the tractor’s traction. By reducing the tyre pressures from 16 Psi to 10 Psi, we saw an increase of 17% tractive effort from of 6800 decanewtons to 8000 daN. This increase provides benefits in the way of reduced wheel slippage, less soil structure damage, increased fuel efficiency and overall improved machine productivity. The second test was a demonstration comparing tyre sizes, type of type (ULTRAFLEX and MULTIBIB) and tyre pressures. To achieve this, the New Holland T8.SmartTrax was again deployed to act as the resistance, by connecting both of the T7.270’s with a cable, which passes through a pulley attached to the T8.Smarttracx , Like for the previous tests, the tractors are set to travel at an identical speed. We will see over a given distance how many meters are gained with the more efficient configuration. The tyres pressure were again set on both machines, for the AXIOBIB 2 with CTIS is set as the previous test: rear 0.7b (10 Psi) and 0.6 b (9Psi)

The tractor fitted with the Multibib, a pressure of 23 Psi, was selected as the most used pressure by farmers in UK. As the tractors set off down the field, it was easy to see the difference between the two. The T7.270 fitted with the VF AXIOBIB tyres, set at a lower pressure quickly pulled ahead of the tractor fitted with the Multibib tyre. As with the previous test, the benefits of the different tyre technology between the AXIOBIB ULTRAFLEX and the Multibib, in combination with the lower tyre pressures, resulted in better traction and increased productivity.

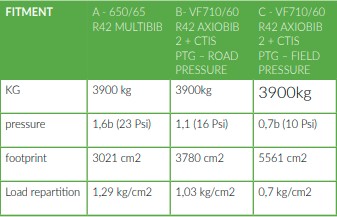

The impact of reduced tyre pressures on soil structure can be seen easily with the following experiments. The soil footprint sandboxes show the difference in tyre type and pressures, as shown in the table below:

• A: MULTIBIB 650/60 R42 MULTIBIB – Most used pressure by farmers in UK: 1,6b (23 PSI)

• B: VF710/60 R42 AXIOBIB 2 & CTIS PTG – ROAD PRESSURE → 1.1 bar (16 Psi)

• C: VF710/60 R42 AXIOBIB 2 & CTIS PTG FIELD PRESSURE → 0.7b (10 Psi)

The bigger the footprint, thanks to the reduced pressure, the higher the traction. In term of soil protection, bigger footprint reduced the kg by cm2 and spread the load on more surface. This ties in with the final test which calculates the weight transfer through the soil structure, compaction. By using probes inserted horizontally into the soil at around 20cm, When the vehicles go over the sensor, the probe is compressed, and the compression is measured every time a vehicle goes over the top. Even at tyre pressures of 23psi, there is less than 1 bar of pressure at 20cm depth (tested with the T7.270 on the MULTIBIB 650/60 R42

Around 10 years ago, Harper Adams University conducted a study on the effect of pressure on yield. This study, which was carried out using a wheat crop, involved growing plots side-by-side.

The same soil composition, the same seeds, the same crop protection products, the same tools, vehicles, crop growing techniques. Only one factor was different: for one plot, the vehicles were fitted with UltraFlex tyres (so low pressure), and in the other, standard technology tyres (higher pressure), like today. And this was throughout the growing cycle. As we offer ULTRAFLEX VF tyres for all farming vehicles: tractors: small, medium and high power, harvesters, sprayers, self-propelled spreaders, dump trucks and trailers, etc.

After harvesting, the university recorded an average 4% improvement in yield.

• 1 – Every year is different: the weather in particular, or the effect of previous crops, the choice of seeds, vehicles, etc.

• 2 – We need to have a complete vehicle fleet management approach. As we need to optimize tyres all year round for each task in the field and for all vehicles. It is not logical to have a tractor at 0.9 bar with tyre trailer at 4 bar.

The more the soil is protected, the more productive it is. The 4% average, also reported in US and Brazilian studies on soy and maize crops, represents a real return on investment.

Overall, Tyre choice and tyre pressures can directly affect not only soil structure and health, but play a huge part in increased productivity, machine efficiencies, primarily by increased traction, allowing larger implements to be operated and less wheel slippage damaging soil structure, overall not only better for the soil but better for your business as well.

-

A Sustainable South African Story

Justin Platt says “I was very fortunate to grow up on a farm in the beautiful Midlands of KwaZulu-Natal, South Africa. With no real agricultural experience to speak of, my father left the family printing business in the late 1950s and established us on 500 acres of farmland, a small fry by modern commercial standards but more than enough to build a diversified ‘mixed’ farming operation which included a diverse rotation of cash crops, pasture, sheep, beef and dairy cattle, and a small farm dairy. The KZN Midlands are blessed with excellent soils by Southern African standards, being predominantly dark and well-structured with a low PH, approximately 4% organic matter and high aluminium levels, that required the necessary calcium related remediation. My upbringing on these soils and in this environment laid the foundation for my later focus on improving soil health and regenerative agricultural practices as the keys to farm profitability and sustainability – although I didn’t quite know it at the time!”

After leaving university with a degree in botany and plant pathology, I spent my first five working years in the world of industrial agriculture corporations, where I was involved in testing and marketing new coded fungicides, herbicides and insecticides for well-known multinational chemical companies. The large skull and crossbones on each container were disturbing and the experience convinced me that there must be a better path. Unfortunately, my views were not shared by many at the time.

Conventional South African agriculture in the early 1990s, like most agricultural industries around the world, was firmly settled onto the treadmill of excessively high inorganic fertiliser applications coupled with a scary cocktail of chemical pesticides, fungicides and herbicides. We could see the harm this approach was causing to our soils, ecosystems and especially farm viability, so with the encouragement and backing of a small group of progressive and innovative growers, we set out to explore opportunities to develop alternative products and solutions with a focus on improved soil health as the foundation for successful and sustainable crop production.

A key turning point in our journey was a 2004 visit by Graeme Sait, a prominent advocate of ‘nutrition farming’ from Australia, who delivered a four-day conference on regenerative and nutrition farming to our audience of growers, researchers and industry members. The response was phenomenal! While this conference and subsequent editions that we ran over the next fifteen years played a crucial role in driving interest for these alternative methods and products we were advocating, our immediate challenge was addressing the lack of infrastructure, expertise and readily available local raw materials required to meet the demand here in South Africa.

Taking off from there, our ongoing focus over the past decade and a half has been on building the capacity and structures required to support the groundswell of growers both in South Africa and around the world who are making the transition to regenerative agriculture. Based on the demand created by a paradigm shift towards regenerating tired and damaged soils, we launched into relatively uncharted waters to develop organic raw materials locally, that would serve to manufacture “soil food’’ products. South Africa is blessed with abundant raw materials all of which require refining and value adding to create purpose-specific products. In many cases, the raw materials we source are natural waste and effluent byproducts from other industries (sugar processing and fish processing to name two), which work beautifully as microbe food. A win for all parties.

Whilst our range of raw materials and registered products form an integral part of a regenerative management program, there are no silver bullets. These, together with the balanced use of microbial products, cover crops, minimum tillage, an animal factor, and a good dose of common sense will contribute to farming profitably and restoring our natural environments in essentially any farming context around the world.

In the end, the success of any grower will be decided by their determination to make the transition! As Henry Ford said, “Whether you think you can, or you think you can’t – you’re right.”

A fundamental pillar of the Regenerative Agriculture community over the past few decades has been knowledge sharing and the free flow of support and ideas. After several years of effort in building our capacity and product range here in South Africa, coupled with a supremely favourable exchange rate, we are excited about the new opportunities presented to us by other agricultural regions, especially the UK. We welcome any advice and input as we undertake this challenge! We also plan to attend Groundswell in June 2022, where we hope to meet as many of you as possible.

About the Author:

Justin Platt founded Zylem in 1990 and is the Managing Director of the business to this day. Based in KwaZulu-Natal, South Africa, Zylem is family-owned and operated. Justin’s wife (since 2005) and two sons (since 2021) have joined him in the running of the business. For more information or to get in touch, please see the details below:

W: www.zylemsa.co.za

E: justinp@zylemsa.co.za

L: www.linkedin.com/company/zylem-sa

-

Drill Manufacturers In Focus…

CHALLENGING AUTUMN WEATHER UNDERLINES THE NEED TO TAILOR CROP ESTABLISHMENT

APPROACH TO PREVAILING CONDITIONS

Despite a stop-start harvest and the very changeable weather which followed, Suffolk farmer Jeff Claydon was able to establish all the planned area of winter crops. But, he says, this autumn highlighted the necessity of having a flexible approach and the ability to utilise windows in the weather.

24 November 2021

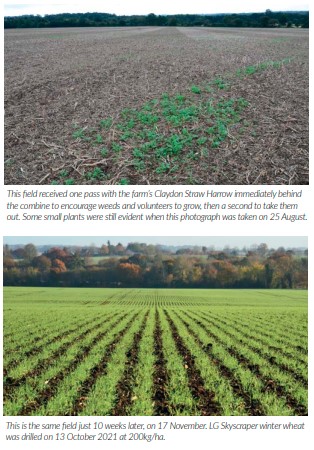

Harvest was a stop-start affair this year. After a marathon run with the combine early on, we were ahead of schedule until 15 August, but then had eight days with measurable rain. They say that every cloud has a silver lining and the interruption to harvesting allowed us to immediately start drilling DK Excited oilseed rape at just 2.7kg/ha directly into chopped straw and stubble with our new Claydon Evolution drill (to be launched at LAMMA 2022). We drilled all our oilseed rape in excellent conditions on 16 / 17 August, the first cotyledons appeared five days later and 4kg/ha of Ironmax® Pro (De Sangosse) slug pellets went on to sort out any slugs that were present because of the moist conditions.

The damp weather and slightly cooler temperatures resulted in excellent establishment and fortunately the dreaded cabbage stem flea beetle did not appear. Centurion® Max was applied to control annual grass weeds and we have been pleased with how the oilseed rape has grown away. As I write this the soil temperature is still 10.5°C, well above average for the time of year, and with the crop growing strongly conditions are too warm for the Kerb® to go on.

Conditions were not dry enough to fire up the combine again and begin harvesting the remaining area until the first week of September. In the interim, the prolonged spell of wet weather caused our spring oats to go flat so we were unable to accurately assess yields and draw firm conclusions from the various cover crop treatment plots on that area. However, a visual assessment suggested only minor differences between them.

Moist soil conditions provided ideal conditions for slugs, which will undoubtedly have been a problem on some farms this season, underlining the importance of a robust approach to stubble management. Dealing with slugs and slug eggs effectively is key to success, especially where winter wheat follows oilseed rape, so after harvest I regularly check fields when the soil is damp. Clearing away crop residues that have remained undisturbed for days will reveal slugs and slug eggs, allowing appropriate measures to be taken. In the early days of developing Claydon Opti-Till® we sometimes had problems with slugs where stubble management was not used, so it has been a cornerstone of post-harvest operations on the Claydon farm ever since. We do not want to rely on slug pellets, so the aim is to take out as many slugs and slug eggs as possible using cultural and mechanical methods, such as the Straw Harrow.

The late finish to harvest meant that we had only four weeks before starting to drill winter cereals, so a cover crop would not have had time to develop fully or justified the cost. We could have used this technique on land destined for spring oats but the glyphosate which went on at the end of October made such an excellent job of killing weeds and volunteers that there was little point. The more resilient seeds which germinate over the winter will be taken out with a second application of glyphosate before drilling the spring oats.

The performance of the winter wheat which followed oilseed rape confirms that our approach to stubble management works well: even the headlands are perfect! Everything was drilled by mid-October, helped by the fact that Claydon Opti-Till® enables us to establish crops in 20% of the time, at a fraction of the cost and using 10% of the fuel, less than 15 l/ha, than would be required with a conventional plough-based system. Such high productivity counts for a lot when the weather is catchy, the window of opportunity is limited, and the number of drilling days are far fewer than in a more protracted season.

This autumn was unusual and with rarely more than three or four consecutive dry days the soil was always moist. In October, for example, we had 48mm of rain in just two days. Although that was a great benefit in helping the preand post-emergence chemicals do their job, the moist soil stuck to the tractor’s tyres, and it was virtually impossible to Cambridge roll after drilling as we normally would. Instead, we ran our Claydon Straw Harrow at a diagonal to the direction of drilling and found that it did a much better job than rolling under poor conditions, which would have squeezed the air out of our heavy clay soils and created wheel marks in the crop. The Straw Harrow has delivered exceptional results and the crop has established better in the high-humidity seedbed than if it had been rolled.

Crops are looking good

I am pleased to report that we now have some exceptional crops, which were established on time, according to plan and with very few issues, despite the challenging weather. The variable conditions underlined the importance of responding to what nature throws at us and adapting the crop establishment techniques accordingly, rather than sticking rigidly to a set formula. Having developed Claydon Opti-Till® we know every nuance of how it should be used, but existing Claydon users or prospective owners who require any guidance should contact our team who will be pleased to offer advice.

Earlier, I mentioned headland establishment. The performance of these often-overlooked areas is fundamental to achieving high average yields because even on a relatively large arable farm they can easily account for 25%-30% of the total field area. It is easy to become complacent when the display on the combine’s yield meter shows 10t/ha-plus in the middle of the field, but rarely does that reflect the true field average.

On the Claydon farm the 2020 harvest underlined the importance of getting the headlands right, in terms of ensuring adequate drainage and eliminating wet spots, minimising compaction, ensuring good crop establishment, and reducing pest damage around field boundaries. For some, or all, of those reasons, in 2020 some of our headlands underperformed the main field areas by 30%- 40%, which had a significant detrimental impact on average yields. Even in that difficult season we still averaged 9t/ha of winter wheat, but what could it have been if all those areas had performed to their full potential? Having remedied any faults, we hope to have an answer to that question next harvest.

The combination of warmth and moisture in the weeks following harvest meant that the worm population went into overdrive, taking down almost all crop residues in a matter of weeks, helping to unlock valuable nutrients for the growing crops which will hopefully help to keep input costs under control given where nitrogen prices are currently.

Because of conditions this autumn some farms struggled to get crops in the ground, and they have been slower to develop. The spring will bring the dilemma of how much nitrogen to apply and whether to cut back on other inputs, because there is no point in throwing money at a crop with limited potential. However, crops that have established well are worth nurturing and developing their full potential will pay off. It is too early to calculate exactly final average yields from the 2021 harvest as all our spring oats and most of the wheat is still in our grain store. However, indications are that the wheat averaged 9t/ha and is selling for £170 – £250/t generating excellent returns, while the spring oats did 7t/ha. The oilseed rape came in at 3.3t/ha and all of it has left the farm at £500-£600/t.

My accountant has just informed me that the farming operation has made a profit again this year, even before taking support payments into account, so that is exceptionally good news. Higher prices for what we produce will partly offset much higher input prices, but it will be important to keep a close eye on the balance between the cost of inputs and their potential benefits.

The wall-to-wall coverage of the COP26 event in Glasgow over the last couple of weeks underlined that the focus on reducing emissions will only increase and as farmers we must find ways of reducing our carbon footprint. In conjunction with Yara, Claydon have been studying the relative efficiency of establishing crops using Claydon OptiTill® against conventional techniques. Early indications are that the Claydon System retains around 30% more carbon in the soil, so we are off to a good start, but we will be investigating this in more detail in the coming year.

-

UK Carbon – Code Of Conduct

Written by Doug Wanstall from Re-generation Earth

We are in a climate emergency, it is down to everyone to make a difference and with that in mind a group of land managers, tech and finance experts have come together to ensure that farmers and land managers benefit from the burgeoning carbon market whilst ensuring a robust system of project approval, measure, reporting and verification (MRV) protocols is created.

The idea was borne in 2015 when one of the founders of the system, Doug Wanstall completed a Nuffield study looking at building financial resilience in farm businesses. It happened to coincide with the Paris Climate talks at which there was a lot of chatter about a project called ‘4 per mille’ A group of French scientists had calculated that if all the worlds’ soils increased their organic matter by 0.4% per year they could sequester all anthropological CO2. A massive undertaking but it was the lightbulb moment when Doug realised that land management and more importantly change in land management would play a significant role in the reversal of climate change and biodiversity collapse.

After an exhaustive 5 further years, gathering information, reading reports and putting together a dynamic group the UK Carbon Code of Conduct and its associated block chain enabled carbon tracking, registry and market place is ready to be launched in Q1 2022.

It was important to the group to ensure that the system was robust and capable of being scrutinised by investors, press and those that may wish to accuse carbon credits of being no more than a way that big companies can ‘greenwash’ their operations.

The code and associated immutable information system have been developed to ensure that the carbon credits issued from UKCCC approved projects are fully fungible, investment grade offsets, capable of assuring any customer of their validity. UKCCC approved projects have to uphold the 4 pillars of the code, Assured Permanence, Assured Additionality, Avoidance of Leakage and the Avoidance of negative outcomes. It is of vital importance when developing projects that issue carbon credits that the projects go through a thorough process of approval, otherwise a land manager may run the risk of having to pay back money paid for credits that turn out to be less than robust.

Sequestered carbon needs to be additional and occurred due to the change in practice that is being rewarded. Projects are long term, usually 25 years and reward a trend in actual, measured sequestration into soils, timber, biomass and biodiversity habitats. Tenants can partake in the process as long as they have a minimum 5-year term. They have to actively engage with their landlord who should give approval to enter a long term agreement. If a tenancy ends then soil tests are taken and the outgoing tenant will be issued the credits accrued to date. The same soil tests then become the baseline for the incoming tenant and the whole project is assigned. So far landlords seem to have been receptive to this approach.

Why write a new code? The answer Doug responds is simple. Globally there are a range of carbon codes with the Clean Development mechanism being amongst the originals and the Gold Standard and Verra following on as the main global leaders. Discussions with all 3 led the team to realise that none of them were going to work in the UK as they were simply too costly and complex, meaning much of the benefit of offset investments was lost in the cost of administering the scheme. In addition, the team, having spoken to a carbon exchange based in Geneva realised that they were buying Gold Standard credits from third world countries for less than $10 per tonne and selling them to their European clients for over $30 dollars per tonne, again delivering little or no benefit to the ones on the ground doing the work IE the land managers.

Back home in the UK there was the Woodland Carbon Code and Peatland carbon codes, both very sector specific. There is talk of a soil carbon code and groups developing grassland, hedgerow, wetland and salt marsh codes, the team decided a single code that could encompass all of these elements was most likely to work and be accepted by the majority of landowners. The UKCCC is a single set of standards that each project has to adhere to, then depending on the elements adopted by the project there are a range of MRV protocols to follow that measure, report and verify the outcomes of the project. This means that whole landholdings and even landscapes can become a single project and benefit from carbon sales. New woodland, wetland creation, a move to regenerative agriculture, carbon cropping, biochar production and use, agroforestry and biodiversity habitat creation can all be approved under a single project.

The aim is that the UKCCC is nimble and that it adapts to new and innovative ways to remove atmospheric greenhouse gases. The UKCCC will look at all nature-based solutions that can deliver additionality and permanence as long as a suitable MRV protocol have been developed. The code actively responds to the latest UK Climate Change Committee reports and other scientific and research papers, the aim to ensure best practice at all times and to respond to latest climate thinking. The code has a technical committee that works on the version cycle and in the early days new versions will be released as the consultation process continues.

The approval process is simple but robust. The first stage is to appoint a UKCCC approved project developer with whom the project host will develop the project and help the host move through the approval process. The project developer will help identify the opportunities on any farm and will have an in-depth knowledge of regenerative agriculture as well as the UKCCC approval process. The next two steps are vital, firstly to establish the project hosts current net CO2 position and secondly establish the baseline.

No project host can sell carbon without first being carbon neutral. Currently the UKCCC does not insist on any particular carbon calculator use but this is likely to change as the UKCCC looks to build uniformity in the system. Either way, it’s important to be honest with the information that gets logged, the project developer will challenge many of the report findings. Baseline soil tests are one of the most important elements and should be taken as soon as possible, regardless of how, if or when a land manager might be planning to sell excess carbon. One of the main pillars of the UKCCC is additionality and nothing counts before a baseline has been taken. Historic tests can be used but a higher discount factor may be applied depending on the type of test and how many samples were taken.

Once these two elements have been established the project design process can begin. The project developer will walk the landholding with the host and discuss the options, the aim will always be to help maximise the opportunity. They will look at whether the host has a desire to move to more regenerative practices and help the host along that journey, look at how nutrient use can be optimised, where opportunities may exist to convert some land to biodiversity projects, if agroforestry is a desirable option or growing carbon crops that sequester large amounts of CO2.

Once the project detail has been discussed a project plan template is completed along with the associated documentation and an annual monitoring plan completed. Once all this is done the project is forwarded to the UKCCC for final approval or comment. The UKCCC undertakes to approve or make suggestions for amendments within 28 days. Once approved, credits are issued on an annual basis less a discount factor dependant on the risks associated with the project. The discounted credits are held on the registry but in a buffer until successful 5-year verification that measures the actual outcomes of the project. Exceed the planned outcome and more credits are issued, not meet the planned outcome and the required number of credits are deducted from those held in the buffer.

Every year the project developer conducts a light touch audit with the project host to ensure all is on track, update any best practice learnt in the interim and to complete the annual monitoring report. The UKCCC system may seem onerous but it is amongst a small number of carbon credit issuance schemes that will stand up to extreme scrutiny and ensure that neither the project host nor the customer for the credits can be accused of green washing. More often than not reducing carbon emissions makes good business sense in the first instance, the lower a landholdings carbon footprint the greater the opportunity to sell excess carbon.

The recent announcement of further detail of DEFRAs much vaunted Sustainable Farming Initiative contained no surprises and is actually a big help to those wishing to start the journey of regenerative agriculture. Those entering the scheme will have to test for soil organic matter, something that will help to establish the baseline required to enable carbon sales. A soil health management plan will form part of the UKCCC project design process and will help satisfy the requirements of the SFI.

The UKCCC is onboarding project developers now and these can be individuals, companies, land agents etc. Project developers need to have an in-depth knowledge of regenerative agriculture and have a keen interest in working with the code to continually improve the system. The aim of the UKCCC is that it becomes part of a wider eco system of people, land managers, businesses that all have the shared goals of reversing climate change and biodiversity collapse.

Expressions of interest are being taken now to join the scheme to enable project hosts to start the process in early 2022. In the first instance interested parties, both land managers acting as project hosts and potential project developers should send a short email to info@ ukcarboncode.org to register their interest.

-

Farmer Focus – Steve Lear

What a different a year makes…

Steven Lear fine tunes his arable cropping, and looks to

Aberdeen Angus to produce some low cost beefAfter the soul destroying previous two autumns when we managed to drill very little winter grain, this year has been rather refreshing. After cutting all of our spring crops in half decent conditions we have been able to establish all of our winter cropping with relative ease this year. I was planning to drill a little earlier this year and make a start in the last week of September, but a bit of moisture came through which delayed us into October. I’m very thankful for that as it has meant delayed drilling will have helped somewhat with blackgrass control. On some of the worst blackgrass fields control from pre-ems has suffered a little from the lack of rainfall through November, I’m hoping the next week or so we will have a little rain to get them to knock the grass weeds back before the cold really sets in.

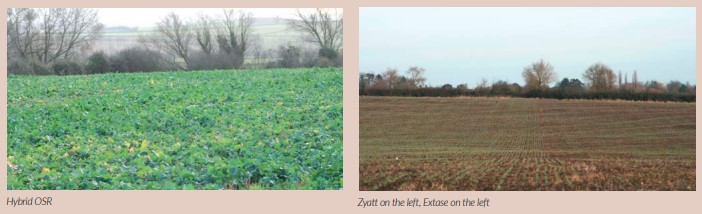

Both the Crossslot and the Simtech drill have been out this autumn and, in a few cases, we have run them in the same field to get a comparison. The Simtech crops seem to get going a little faster which is probably due to some mineralised nitrogen from slightly more disturbance but also chits a little more blackgrass (this has probably been made worse due to not being able to roll some areas). It will be interesting to see any differences throughout the season and on the yield mapping at harvest time. We drilled a few fields of OSR this year which is a crop we have stayed away from for the past 7 seasons. We have seen a big difference between the hybrid varieties which seem to have got up and away and the conventional varieties which didn’t really get going and consequently ended up with a huge amount of flea beetle damage. The conventional was also drilled on heavier soil and I wonder if that has been a factor in their demise. I wasn’t prepared to use an insecticide on the osr so as a result I have redrilled 60 acres of brassica with some group1 milling wheat, given the prices at present it may not have been so bad after all.

On the wheat side we have drilled Zyatt, Extase and Nelson on the farm this year, all group 1’s. Extase is new to us, but first impressions is that its very fast out of the blocks. The Extase and Nelson are both being grown due to their fantastic disease profile, maybe going forward I’ll have a go at a group 1 blend if the markets I sell into will accept it. The Zyatt went in late and is probably a variety that we won’t grow on again as it’s become fairly susceptible to fungal disease. Soil conditions at drilling on the heavy clay have been some of the best we have ever seen. Zero till has certainly changed how our soil is behaving. What used to be a smeary mess now has crumb structure and it’s a real joy to see. We still however notice a big difference where we have mole ploughed so that is going to be something we do slightly more of compared to our old tillage regime. When direct drilling clay soils I believe good drainage is key, especially in the first few years.

The big question we have going into this season is how much fertilizer to use. With urea prices well over £700 last time I looked it is just the push we needed to bring nitrogen use down and develop techniques to drive efficiency of the nitrogen we do use. As our soils have historically had a large amount of manure, cover crops, legumes and composts we should be mineralising a fairly chunk of our nitrogen requirement through natural processes. With this in mind we have come up with a bit of a plan.

How we plan to increase nitrogen efficiency and use less

nitrogen.• Use a little and often approach. Smaller doses of N at more regular intervals will hopefully increase NUE.

• A lean towards more foliar applications. Foliar N has a much better NUE than soil applied so we need less of it. (It is however a lot more expensive).

• Back loading our N. We plan to delay applications of N to allow the natural soil nitrogen supply to provide for the crops earlier in the season. This may also reduce our need for fungicides as we won’t have large green biomass crops early on in the spring.

• Our poorer land which tends to need higher nitrogen applications has been allocated to spring beans this year.

• Our spring whole crops will have an application of fym before drilling and will be undersown with a red clover ley. I’m hoping to grow these without any synthetic nitrogen at all (maybe some foliar if needed).

• All nitrogen applications will once again go on with a carbon source.

I’ll let you know if our plan pays off or is a dismal failure after

harvest.On the livestock side we have seen some very good prices in the trade for beef. But at the same time the costs for feeding and looking after cattle have gone through the roof. I’d hate to be having to buy in large amounts of concentrate at current prices. As I write this (in December) the majority of our Limousin herd is still out at pasture which is fairly unheard of on our soils. Grass growth has continued, all be it at a slow pace, through November and the animals look happy and healthy for it. Going forward we will be trying to develop techniques to grow more low input forage crops for our cattle by using more legumes and diversity within the swards. On top of this we have also started a small (but growing fast) Aberdeen Angus herd along side our Limousins. It will be interesting to see what the native breed brings to the farm in terms of fattening on pasture and using less concentrates

I’m very much looking forward to events happening again this year around the country and can’t wait to have a catch up with some of you to discuss what your doing on farm. Keep safe and look after yourselves. It been a tough few years, and I know many farmers who have felt isolated through the pandemic. Please reach out and get help if your struggling. ‘Depression is an illness not a weakness’ yanahelp.org are there to help, give them a call.

-

Autonomous Agricultural Machinery, Precision Technologies And Controlled Row Farming

At Amazone, the topic of autonomous agricultural machinery has been at the forefront ever since the BoniRob project was launched together with Osnabrück University of Applied Sciences and Robert Bosch GmbH in 2008. The BoniRob field robot was a milestone in robotics and way ahead of its time. Many technological and legal questions still had to be clarified and a market was not yet ready. The BoniRob is still in use today in various research projects at the Osnabrück University of Applied Sciences. This includes the Agro Nordwest trial site at the BMEL.

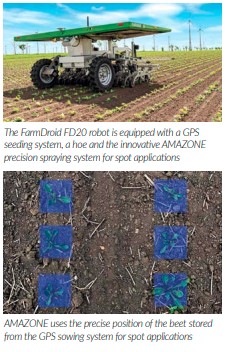

FarmDroid, the Danish robot

start-upThe FarmDroid FD20 was developed by Kristian and Jens Warming and has become one of the most successful field robots in Europe in just a few years. This success is based on highprecision sowing followed by hoeing between and especially in the rows. The FarmDroid FD20 leads to clear economic advantages in organic sugar beet establishment and vegetable cropping by greatly reducing the costs of the many workers required for manual hoeing. The aim is to be able to reduce the use of herbicides (and insecticides) to a minimum in future by using the highly automated, solar-powered FD20 sowing and hoeing robot along with a special spot spraying method. Initial trials are currently underway on a trial site field at Südzucker’s experimental farm in Kirschgartshausen near Mannheim, Germany.

AMAZONE has further developed the FarmDroid FD20 into a high-precision, spot spraying device. It was shown in the trial project with the partner company Südzucker AG that sugar beet can be grown with a 90 percent reduction in herbicide usage. For AMAZONE, this project was another step towards the further development of automated technologies and to broadening its understanding of the market potential in field robots.

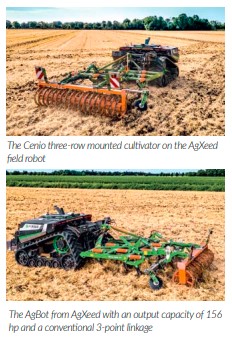

AgXeed and the establishment of autonomous processes

In addition to BoniRob and FarmDroid FD20, the automating of typical work in the field is an interesting topic for the future. In this respect, the autonomy of connected implements and the work required from these implements is the key development issue for Amazone. In contrast, the autonomous tractor is better left in the hands of the tractor manufacturers or specialised start-ups. As of this year, Amazone has been cooperating with AgXeed, a start-up from the Netherlands. In Amazon’s view, AgXeed’s experienced team of developers has chosen the right technological and systemic approaches. The key issue for AgXeed is the commitment to create standardised interfaces both in the mechanical coupling of machines and in communication via ISOBUS. Ultimately, the customer should have the freedom of choice for the best implement on the best tractor unit, which is normally the case today and produces the greatest innovative power. This should be the same for robotics too.

From automation to autonomation

Automation and monitoring must be perfected, in order to be able to use implements without human supervision. Amazone has been pursuing the automation of processes in the machine for many years. Examples of this include the ComfortPack plus automatic cleaning system in the sprayers, monitoring of the spreading quality with ArgusTwin or the AutoPoint system for the precise switching of seed drills at the headland. It is not yet clear which machines will be the first to take the step from automation to autonomation. Apart from the technical and legal challenges, the primary question concerns the customer segment in which an economic advantage will become apparent.

Autonomy in the Controlled Row Farming system

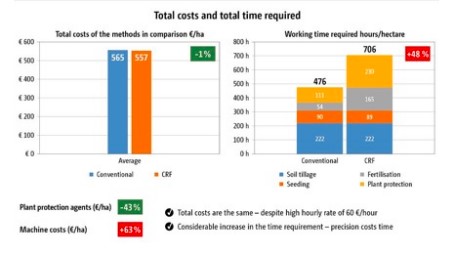

In 2020, Amazone started new longterm field trials together with its subsidiary Schmotzer Hacktechnik and its partner Agravis. The Controlled Row Farming (CRF) trials at the new test centre in Wambergen, close to the production site and main plant in Hasbergen-Gaste, will contribute important findings to new crop production methods in the coming years. With a fixed row width of 50 cm in all crops, the sensitive inputs of fertiliser and plant protection are reduced through precise placement. An additional goal is to increase biodiversity in the field and to keep the economic success of the farm at least constant. The first harvest results confirm a constant yield, also in cereals in a double row with a spacing of 50 cm. The results can also be found at www.controlled-row-farming.de.

In an illustrative economic analysis of the CRF system for a farm with 300 ha, it becomes clear that the reduced costs for the inputs are offset by the increased costs for labour. Apart from the purely economic consideration, the additional work time required in the main season is a critical point: 476 hours/annum are required for fertilisation and plant protection in conventional arable farming compared with 706 hours/annum (+ 48 %) in the CRF system. In times of a shortage of skilled labour, this factor is critical in the short term. Autonomous agricultural machinery in the CRF system could undertake the labour-intensive tasks for the farmer in the medium to long term. The clear structure in the track guidance and cultivation system suits the robotic systems in any case.

Today, the CRF system is operated with conventional RTK-guided tractors, intelligent connected implements and an attentive driver. It is easy to imagine the use of autonomous field robots for this in the future. Every step of the process would be closely monitored. Slower speeds with smaller working widths and completion of the tasks with even more precision are then also conceivable. Ultimately, the farm manager will have to spend less time monitoring standardised work processes and be able concentrate on other tasks.

-

Drill Manufacturers In Focus…

Horizon CEO George Sly writes “What a year it’s been! We have continued to grow and develop quickly during

extremely challenging times for the manufacturing sector.

We have made some big strides in 2021 and have a lot of exciting things happening in the next 12-24 months! When we launched Horizon, we had an extremely tough decision to make, with Brexit looming – do we manufacture in the UK or in Europe? Our decision to stay in the UK is something we are very pleased with, despite some inevitable challenges along the way.

We are proud to fly the ‘Made in Britain’ flag and to employ local people in South Lincolnshire. Approximately 78% of our components are also sourced in the UK, so when you buy Horizon you really are buying British!

What’s on the Horizon?

Plans for a new 11 hectare site, featuring a manufacturing facility and R&D centre are in the final stages. This will be the largest seeder / planter manufacturing site in the UK in terms of output and will operate a linear production system incorporating LEAN manufacturing principals. Production will sit alongside our R&D centre, which will also house our engineering team. The site will be unique in that crop trials, R&D and production will all take place on the same site. As part of the new production facility move, we will be launching a range of 9-12 metre machines in 2022 to begin production for 2023. Further details will be revealed in the 2nd quarter of 2022.

UK Dealers announced!

We were very happy to welcome our new Sales Manager – Charlie Eaton to our team earlier this year. Charlie has been busy building our UK sales network, with 3 key dealers joining us to date – Smallridge Brothers in the Cornwall, Devon and South Somerset, Redlynch Tractors in North Somerset, Wiltshire and Dorset and RES Tractors in Leicestershire.

Automation

Whilst we are extremely proud of our 40 strong workforce, like any other business, it’s imperative that we look to evolve and to identify opportunities to increase efficiency. As we strive to be the leading European manufacturer of premium planting / seeding machines and tools for regenerative agriculture, we are investing heavily in our future, in order to compete with the larger European OEM’s.

Welding: We are about to take delivery of ABB Robot cells to automate around 65% of our welded components, this ensures repeatable accuracy, quality and efficiency. Parts Storage: As we all know downtime is something no farmers want. For this reason and to improve our internal efficiency we invested in two automatic storage systems. These systems can store a total of 90,000KG of parts or up to 35,000 lines, all of which are accessible within 8 seconds. The systems allow us to process a parts order in less than 4 minutes from order to packing. They are linked to our ERP software allowing us to send orders to be picked remotely

Introducing: The 3 C’s – Clearing, Cutting, Closing

All our row units have to perform 3 tasks:

• Clearing resude ahead of a disc opener or tine

• Cutting the soil evenly and to uniform depth to place the seed

• Closing the furrow assuring optimum seed to soil contact for even germination

As we delve depeer into the technology in our products and release more information on how each component gives you a return on investment you will see much more of the 3 C’s in the future! We hope you like it as much as we do!

-

High Fertiliser Prices Focus Attention On N Input Efficiency And Soil Health.

Written by David Newton – Technical Manager, Timac Agro UK

The current fertiliser production and supply issues are leading to producers examining their inputs and expenditure, looking at the returns on their investment and the opportunity to enhance the effi-ciency and return from every kilo of input.

One way to help the soil regain balance is by using a soil conditioner. These are often based on the addition of calcium to soils, sometimes mistaken for liming, along with other trace elements and biological stimulants to help the soil heal itself. Liming is the addition of Calcium Carbonate to mop-up excess hydrogen ions-acidity, whereas soil conditioning, while buffering pH on a local level, also aims to improve soil structure, air and water flow, soil biological activity and, through this, nutrient availa-bility.

Two such products are Physiolith and Humistart, both based on a marine calcium base “Calcimer”; a highly reactive source of soluble calcium carbonate rich in essential trace elements that rapidly buff-ers any surface acidity, binds clay and humus to strengthen structure and regulate water flow, pro-vides a safe haven for soil microbes and can counter excess Mg & potash effects. Add into this a sea-weed-based rooting cytokinin and you have Physiolith; a great stimulator to improve crop establish-ment and rooting. The biostimulant in Physiolith also opens up nutrient uptake pathways generating more vigorous growth and healthier plants to strengthen establishment and return value for money.

In more established crops, or situations with potential for utilising OM, (min/no till, manure/compost additions, long-term grassland) Humistart may be more applicable. In this product the biostimulant is aimed at feeding soil life and stimulating fungal growth. The Minactiv biostimulant, again seaweed derived, targets the mineralisation of organic nutrition, especially where any tough, lignified material is involved. So breaking down cover crop, straw-based manure, wood-chip or high C-N ratio compost at temperatures down to 2oC to release “free” nutrition.

“In these times when we are examining every input, a soil conditioner can complement a lower input regime to reduce compaction, stimulate soil health, buffer pH and generate good returns” says David. “But I have a calcareous soil! Why would I add more Ca when it is locking up nutrition?”

It is all down to reactivity and roots! The highly reactive Ca in Calcimer works to produce stable aggre-gates even in calcareous soils, improving structure and reducing salt build-up. “at Timac we have done research into the effect of root density on local pH” says David: “Root exudates are mildly acidic, so it follows that if you increase root density you increase the concentration of exudates reducing the pH of the rhizosphere, this can be up to 1 pH point, so releasing locked up nutrition such as phosphate, so stimulating root growth not only finds more nutrition, it releases more from the soil”

“Soils have taken a battering, much like the agricultural industry for many years now, it isn’t the farmer’s fault, they have just been following the best advice of the time” says David, “however awareness of soil biology and interactions has improved so we need to farm differently now, the fertiliser price increases have forced growers to look at their input and consider their practices, hence the growth of regenerative farming, min/notill practices and soil conditioning”

What is the current situation?

The commonly used fertiliser materials that, in recent years, have been in plentiful supply and relatively cheap: Ammonium Nitrate, DAP, TSP, MOP work on a principle akin to the “carpet bombing” approach of the 1940s, 50s, 60s and 70s warfare; i.e. throw enough nutrient into the system and some of it will hit the target species. Unfortunately, as with Carpet bombing there is “collateral damage” of soil health, plant health, weed growth and reduced fertility that have led to a dependency on further chemical solutions. To mix metaphors, nitrate fertiliser is the “gateway drug” to dependence on the fungicides, herbicides and growth regulators that have been profitable for the Agronomy industry over the last 40 years. The focus on sustainable productivity, Carbon footprint reduction and the rise in input prices lead us to question this approach and look at ways to a more “precision strike” method of nutrition.

Is it time to try something different?

Fertiliser formulation has moved on from the simple commodities to include extra technology to en-hance nutrient uptake efficiency, plant physiology, the delivery of the nutrients involved and enhance soil health to add sustainability into the nutrition system. For the last 40 years Timac Agro have been at the forefront of this enhanced fertiliser offering, developing soil conditioning phosphate and nitro-gen solutions that protect and improve (rather than disrupt) soil health with their soil conditioners, Physalg, N-process and a totally new phosphate, Top-phos ranges. These products utilise natural seaweed and humate technology to package nutrition in ways that pro-tect it from pH lock-up, leaching and volatilisation, working with the natural nutrient uptake processes of roots to deliver nutrition to plants in ways that promote both plant and soil health.

By including marine Calcium (from seashells), Sulphur and magnesium, elements demonstrated to have a synergy with nitrogen uptake, bound with the N-sources at a molecular level in their N-process molecule, Ti-mac nitrogens provide an ideal early-season application in all commercial crops to get the season off to a healthy start. The company is unusual in that it recommends rival products such as CAN for subse-quent applications due to the (usually) high price point of their inputs. This year is the exception as explained by James Hay, Deputy Manager of Timac Agro UK:

“Due to the nature of our manufacture process we are less subject to the fluctuations of the com-modity market and, although we have also experienced price pressure, our rises are considerably less than those experienced by the commodities such as Urea and AN, bringing us into line with and in-deed cheaper than some of the prices being circulated currently”

David Newton, Timac Agro UK product manager explains how they can help with the current price storm:

“by including soil conditioning technology in your fertiliser program this year and in years to come you will increase overall efficiency in nutrient uptake, a healthy soil, balanced for pH, will respond in a far superior way to all inputs, be they from manure or chemical sources, the future of nutrition must listen to the needs of the plant and soil to give sustainable, intensive agriculture. For example, one of our customers, utilising soil conditioning and N-pro in their program, have brought the N-input down from 250kg/ha to 180kg/ha over the course of three years with now yield penalty. With the current fertiliser market you can’t afford to ignore these opportunities”

“We have been talking soil health and input efficiency for many years now, the current changes to payments, fertiliser market and emphasis on soil health and productivity means that our message is more relevant than ever”

Another approach to getting the best from your soils is to make sure they are in peak condition. Nu-trient availability drops off considerably in adverse conditions, readers of Direct Driller are all too aware of the issues caused by:

• Low or High pH

• Compaction

• Low OM

• Poor water flow (too fast/slow)

• Imbalance of elements, excesses of one nutrient can severely affect the availability of others.

• Over tillage

All of these conditions above will affect the chemistry and biology of your soils, and, for optimal plant growth the soil needs to be balanced to allow the science to work. “At Timac we work with farmers to examine their particular situation, dig and test soils, look at crop-ping and establishment to see if there is anything inhibiting optimal growth. We focus on long term improvements, not just instant, short-term fixes to deliver sustainable growth in so many ways”

-

Methane And Carbon What Should UK Farmers Do?

The standout pledge at COP26 for farmers was the target to reduce methane emissions by 30% by 2030. Eyes, as usual, turned to ruminant production. We know that agriculture is responsible for around 40% of total UK methane emissions, with most of those associated with ruminant livestock and livestock manures.

But the picture is more complicated than simply eradicating ruminant production – and I believe we need to bring arable farmers into the picture when we look at reducing emissions from livestock farming. We need to look at the level of meat and dairy consumption that is appropriate for our health, what production systems we should transition to, and make sure that we consider the potential benefits of some productions systems for nature restoration.

At the Soil Association we call for a less but better approach – we should eat less meat overall, and what we do eat should be of a higher quality. For this, we need more mixed farming, bringing more livestock into arable rotations. This leads us to the “Ten Years for Agroecology in the UK” agricultural model, which defines a clear pathway towards an agroecological farming system for the UK. It recognises that the UK has a production advantage in ruminant product production, in terms of weather and appropriate agricultural land. Adoption of such a farming system across the UK would see us able to reduce overall emissions by around 40% (before any additional sequestration activity through for instance tree planting). This model includes key assumptions around future diets, future use of artificial inputs, and that much more mixed model of farming.

Manures from animals would help us to reduce nitrogen fertiliser, which we must do if we are to reach net zero. At the moment some 43% of total emissions from every loaf of bread we eat comes from the artificial fertilisers used to grow wheat, so we can’t ignore this problem. We also need to find ways to bring legumes into crop rotations in a way which makes them profitable to grow – including peas and beans more in livestock concentrate feeds as well as eating more of them ourselves. If this were possible then farmers could routinely adopt legumes as break crops and fertility building crops.

Alongside such changes, it will be essential to revisit how we select crop varieties in future, and this begs the question about the place of yield as a key trait for selection in future. Increasingly we might wish to move to maximum sustainable output for any given land area under any given crop. This would identify the optimum output possible without reducing the area’s natural capital (over a rotation length). Such a change would greatly change the traits required and internalise those externalities of production which are currently picked up by society, or by consumers who choose to purchase products from farmers who have internalised those costs, such as organic farmers.

Alongside these changing imperatives for farm businesses to reduce greenhouse gas (GHG) emissions there is also the new voluntary market for soil carbon to consider.

The new voluntary market for carbon

Although the voluntary carbon market has been around for more than 20 years, there is currently huge interest in the sale and purchase of landbased carbon credits as offsets. This interest is because the net zero policy agenda has ramped up significantly over the last 18 months, with many organisations and companies making net zero emission commitments and needing to deliver on them. Almost all these net-zero strategies plan for continued carbon emissions, that need to be offset by compensatory carbon credits (offsets), to achieve the stated net zero target. There is increasing debate around this, as it is becoming clear that emissions reduction is the key requirement rather than paying a third party to sequester carbon whilst continuing to emit at the same level. As a consequence of this, the focus on supply chain emissions is coming to the fore, with retailers committing to support reductions in emissions from their supply chains. The latest of these being one multiple retailer supporting chicken farmers to produce insect protein from food waste to replace imported soya in poultry diets, thus reducing the potential for deforestation, one of the largest sources of worldwide GHG emissions.

At the moment in the UK, the majority of voluntary carbon offset projects are provided by afforestation via the Woodland Carbon Code, followed by peatland restoration via the Peatland Code. These voluntary standards were established to provide guidance to project developers to deliver high integrity carbon benefits and assurances to voluntary carbon buyers that the climate benefits they purchase are real, quantifiable, additional and permanent. Standards are now being developed in the UK, funded by the Environment Agency’s Natural Environment Investment Readiness Fund, including the creation of a proposed UK Farm Soil Carbon Code to reward farmers for the carbon sequestration benefits of more regenerative practices. At the moment there is no common UK agreed code, leaving scheme developers to develop their own, resulting in a range of different opportunities for farmers. Most, if not all, schemes are focussing on arable farmers with opportunities to sequester carbon through increasing below ground productivity and reducing removals of above ground biomass; adding external sources of carbon (soil amendments); reducing soil disturbance; maintaining high water tables and minimising soil erosion. Schemes for grassland farmers are less common, mainly due to the need for additionality over current farming practice.

The practice which has the greatest capability for sequestering carbon s directly increasing the amount of biomass in the system through, for instance, adding hedgerows or trees. Again, the key tests are real, quantifiable, additional and permanent. These terms and their precise meaning are causing much debate. Take for example permanence: In the ideal offset project, reversals of carbon emissions are physically impossible or extremely unlikely. Standard convention in offset markets has been to guarantee that carbon is kept out of the atmosphere for 100 years. Yet, this is not practical for soil carbon, which is considered as “shortlived” storage carrying a higher risk of reversal. In the USA, Nori manages permanence by offering short-term credits that expire after 10 years. In Europe, Soil Capital has a 5-year crediting period, in which farmers can earn and generate credits, followed by a 10-year retention period. Carbon Farmers of Australia must choose between 25- and 100-year permanence guarantee. Without an agreed UK farmland soil carbon code, different definitions and offers are being developed in the UK and farmers should be aware of what they are signing up to before committing.

As retailers start to move to make good on their commitments to net zero, inevitably farmers will need to be able to demonstrate their credentials in terms of net zero. Farmers who have developed their own on farm mechanisms to reach net zero will need to be able to evidence these robustly, but it will potentially make them more attractive suppliers. However, if such a farm chose to sell carbon offsets, the carbon sold is removed from their balance sheet to appear on that of the purchaser. This could render the farmer a high emissions producer and hence less attractive to product customers. This needs to be considered when entering into any carbon offset agreements.

The quality of schemes also relies on the accuracy of soil data. Some schemes rely on regional data whilst others require field soil samples down to 50cm of more. The more granular the data the more accurate the picture on soil carbon levels should be. Taking soil samples requires attention to a number of features including timing, field selection, within field sampling, number of samples per field, depth of sampling and frequency of sampling. These features need to be standardised to provide consistency of results, which is necessary for entry to carbon markets.

The final question is to ask how best to test for carbon in soil. The three most common ways are loss on ignition (LOI), dry combustion (DUMAS) and potassium permanganate oxidation. LOI is the most common due to its traditional usage in evaluating the organic matter content. DUMAS is the most accurate and direct measure. Potassium permanganate oxidation (sometimes; permanganate oxidisable carbon (POXC)) is another way of characterising organic matter. It is less common and indicates “active carbon”. Although this is an informative quantity, if only one method is to be used, we want to measure all organic carbon that is built up and stable for the long-term. Each method has its own advantages and disadvantages for different soil types, budgets and uses.

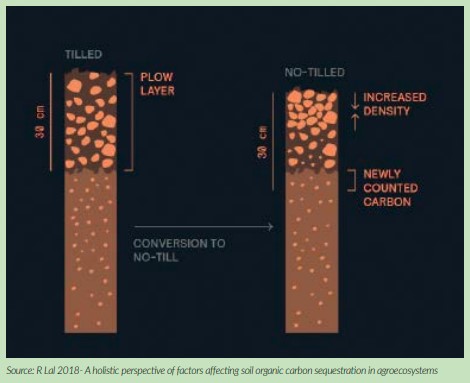

The density change effect

The volume of soil carbon in any given area of soil depends on both the soil carbon content and the soil density. Changes in soil density can affect estimates of carbon storage, even without a change in the amount of carbon stored in the landscape. Shifts between conventional tillage and no-till are a classic example of this accounting problem.

Soil density leads to a depth-related effect on net carbon storage alongside the redistribution which occurs when tillage is practiced. This can lead to overestimation of carbon storage under no-till relative to conventional tillage. This potential source of bias is easy to correct for with the right sampling approach, though few soil carbon protocols currently account for it.

Tillage breaks up the soil structure, essentially “fluffing up” the soil and reducing its density. Conversion to no-till allows the soil particles to settle into a denser structure. As a result, the plough layer of no-till soils is on average roughly 2-3% denser than the plough layer of tilled soils. The difference in soil density under no-till versus conventional tillage can affect carbon stock estimates. The table below illustrates this. On the left, a field is sampled to a fixed depth of 30 cm and carbon stocks are calculated at that depth. After conversion to no-till, the density of the plough layer increases, shifting the soil surface downwards slightly. If soil is then collected to the same depth, soil particles that would have been left out before are now included, leading to a larger carbon stock estimate. This larger carbon stock estimate would be entirely due to changing the frame of reference for sampling.

This emphasises the need for a detailed protocol which all farmers can follow when taking soil samples. The Farm Carbon Toolkit Soil Monotiring Guide recommends it includes protocols for the following areas:

• Timing: Spring or autumn are more suitable for field access and sampling ease; the most important factor is consistent sampling the same time each year

• Field selection: Choose fields which best represent current and historical land use and try and represent all soil textures across the farm

• Within field sampling: Make the sample as representative of the field as possible i.e. the main cropping area. Across this area sampling can be carried out in a straight line, W shape or grid pattern. If accuracy and precision are important and the sampling is to be repeated in future years, it is important to GPS log the sample points across the field

• Characteristics of the samples taken: A minimum of 5 sample points per field are recommended, but preferably 15 sample points will increase accuracy. Sampling is recommended to 30cm deep. This allows the assessment of the carbon that is held at depth and is therefore less likely to be released. It is recommended to carry out analysis every 3-5 years

The UK Farmland soil carbon code seeks to address the current lack of clarity for farmers in this new, evolving, voluntary carbon marketplace, including soil sampling testing and analysis protocols, and it cannot come soon enough. For now, though, the watchword for farmers has to be to look very carefully before entering into any agreements to sell carbon offsets.

Ask yourself – If I enter this agreement, what claims will I be able to make about my farm carbon footprint in the future? does the scheme have a transparent, robust methodology on permanence, additionality, measurement and verification? and am I happy to be doing business with the credit buyer?

-

Farmer Focus – Andy Howard

Every year you learn something new and the last two years have been tough, and we have learnt a lot! This shows in our machinery purchases over this period. We have bought a mole plough, a drain jetter, a set of rolls with paddles and a Tech Neat Outcast catch crop spreader. These are all linked as I hope they will all allow us to cope better with increasingly wet autumns.

Our heavy clay soils are always the fields that cause us the most issues in No Till. We have managed to improve the soil structure over the years, but a slow permeable clay soil will be a slow permeable clay soil, no matter how good the soil structure on the top is. We needed a method to get the water away from the surface faster, with low disturbance and benefits which last longer than 2 months, unlike subsoiling. This led us to purchase a mole plough in February 2020 and it seems to have been very successful this autumn. Mole ploughing is not that common in Kent, in this sense we are behind our neighbours in Essex, I will give them that one thing!!