If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Agronomist In Focus – Mark Dewes

Stones or Beatles? Oasis or Blur? Cereals or Groundswell?

It’s a lazy way to categorise farmers but I’m not the first person to compare and contrast the diversity of ideas showcased at the two leading events for arable farming. An even cruder test would be to ask if our farming problems will be solved by the wizardry of gene editing or by following the prophecy of a soil health guru?

In most previous winters I’ve been like most agronomists who sit through presentations on fungicide responses and resistance shifts. This winter Bill Clarke slipped off the top spot in the charts and there won’t be many agronomists who haven’t been engaging with webinars on soil microbiology and regen ag. Many of us are re-learning the empathy for soil and crops which had been demoted during a time when synthetic interventions have ruled. We’ve been busy putting names to things we thought we knew but couldn’t explain or quantify. Whether an understanding of concepts like the effects of arbuscular mycorrhizal fungus on soil aggregation will help us to achieve more resilient soils remains to be seen. The language may be new to some of us, but the practices have their origins in good farming, and what has been will be again. Amongst this excellent work is some material which I have found much more challenging. Having listened to John Kempf’s webinar on total immunity of healthy plants to pest and disease attack, I found myself trying to keep my mind open without letting my brain fall out.

We are on a more determined route to a more sustainable future now than at any time in my career, precisely because the systems which we have adopted are falling down more frequently. It’s easy to be hard on your younger self and I now look back with a wry smile to 1997 when I discovered that all I needed to do was get drilled up by the end of September and pick an appropriate programme of sprays to deal with any problems. In fairness to that arrogant youth I was right for a few years, but a system propped up on inputs has started to crumble very quickly, particularly when rainfall distribution has challenged the system further. It seems appropriate that the word humility is derived from the Latin humus for earth. Humility is perhaps something we should apply to our farming now to balance some of the hubris of recent decades.

The species diversity that is part of many farmers’ approach to more sustainable farming Is not the only diversity worth considering. I’ve been lucky to have the opportunity to look around at worldwide agronomy through a Nuffield Farming Scholarship study tour and taking influence from a diversity of sources has been a good experience. One that sticks in my mind was at the United Nations Committee on World Food Security where I heard a delegate from Rwanda describe farmers as priests in the marriage between food security and climate change. If I could live up to that description, it may be as close as I get to working in the clergy, but it reminded me that not all the answers will come from middle-aged white blokes in checked shirts like me.

Sustainability is defined for my purposes as those methods with which we can continue into the future, profitably and with acceptable external costs. Farmers had been adapting their systems for a long time before they discovered the need for an agronomist to navigate the complexity of crop protection choice. Agronomists play a part in the decision-making on farms but the principal role for which we originally trained and took instructions from our clients is diminishing; we need to continue to bring something to the table before our chair is removed. There is still a job to be done in organising a sensible crop protection programme, but as that programme becomes simpler and less effective, our skill set needs to evolve.

I was humbled last autumn as I realised that some of the most important decisions my customers were making were those which I’m not well qualified to help make. In two situations a few days apart, I contributed to the decision on whether or not to drill in poor conditions. In one case I said drill and the other I said don’t. As you might have predicted, both were drilled and, on reflection, I think I was wrong in both cases. It demonstrated to me that some of the things I need to do now are different from those I needed 20 years ago and I’m better qualified for the latter than the former.

So, an agronomist needs to adapt just like our customers do. This realisation seems to have hit home recently, and it’s been rewarding to see agronomists from the independent and trade sector alike raising their game regarding training and application to a rapidly evolving reality. Our customers want as much input from us on the way to integrate stewardship scheme options to their arable rotation as they do on herbicide regimes. Advising customers to build more resilient systems by growing fewer cash crops and more species rich pasture doesn’t come easily to all agronomists but alongside the adoption of new technologies and conventional chemistry it’s the blend between Cereals and Groundswell which will be increasingly important to get right.

At Agrii we have been developing an approach to this new normal, pulled together by our Green Horizons manifesto. It’s an umbrella which covers our commitments to sustainability, balancing the external costs of how we farm with the essential work of producing food. Of course, the answers aren’t simple or complete but in providing an over-arching direction for our work it will guide what we do. Examples include the commitment for 100% of research to be based on Integrated Pest Management principles, the introduction of Variety Sustainability Ratings based on genetic resilience and work to improve Nutrient Use Efficiency. All this is done with a continuing focus on productivity, as it is still the case that high yields usually maximise resource efficiency. Green Horizons is Agrii’s framework to address these issues and I expect to see more of the same from all sorts of agronomy businesses.

One element of this conversation which affects the whole industry is the unintended impact of agrochemical use. This elephant has been in the room for some time. We have been adopting Integrated Pest Management for many years but one of the indicators of success is the trend in agrochemical use. Results from the most recently published Pesticide Use Survey conducted by FERA don’t tell the story we would like. There is mounting pressure to reduce the unintended impact of plant protection products through legislation. The National Action Plan for the Sustainable Use of Pesticides and part two of the National Food Strategy are just two of the trains coming down those tracks. It’s time for us to grasp the nettle. Agrii have now made a commitment to measure and reduce the negative impacts caused by our use of PPPs. That might not be what was expected a few years ago and shows how far we have come and how quickly things are changing.

The blend of conventional, newer and re-discovered approaches will be what defines the future of the support that agronomists provide, and whether the technologies are showcased at Cereals or Groundswell, they will need to be considered in concert. I’m still only part way through my apprenticeship to this trade so I don’t want to pick a favourite just yet.

-

High Quality Food With A Positive Environmental Impact

Selling organic, ‘Pasture for Life’ food directly to consumers brings dividends for one farming family. Sara Gregson reports…

First generation farmers Chris and Denise Walton have, over the past 40 years built an award-winning sustainable farm and butchery business, operating close to the Berwickshire coast in the Scottish Borders.

“We always wanted to sell our beef, lamb and pork directly to consumers,” says Denise. “We strive to produce the highest quality food, whilst also having a positive environmental impact. We are organic and certified Pasture for Life (guaranteed 100% grass-fed with no grain ever fed), which we believe is the Gold Standard for land and animal welfare management and completely fits with our business ethos.”

Neither Denise or Chris come from farming backgrounds; Chris has accountancy qualifications and Denise trained in environmental and land management. Moving to Scotland and starting with a 20-acre smallholding in 1989, they increased their acreage to 250 acres by working in partnership with neighbour Amanda Cayley. In 1993, together they took the opportunity to buy the nearby arable unit of Peelham Farm, bringing the landholding up to 670 acres.

“The farm was pretty run-down, farmed for the short term, had no hedges and was ecologically poor. The land rises to 700ft and comprises some heathland and acidic grassland,” says Denise. “As new entrants, Chris had to work off the farm in the early days and making a profit has been central to what we do. But farming with nature was also a primary driver for the business from the very start.”

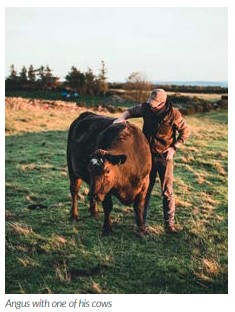

Twenty-seven years later, their son Angus and his wife Helen have joined the business and they have now started the third generation by having two young children. Amanda, now retired, is still very much involved in the life of the farm and the butchery. The couple started making charcuterie from their pork, mutton and beef in 2005 and then developed an on-farm butchery for their cattle, sheep and pigs in 2008. The aim was to become price-makers rather than just price-takers. They started attending farmers markets in local towns and cities such as Edinburgh and Glasgow and supplying independent retailers and restaurants.

“We talk to our consumers a lot and to local chefs to gain feedback about our products. We tell them how we aspire to excellence in land management, animal care and environmental stewardship. We are spreading messages of agroecological land regeneration and the production of healthy, grass-fed meat. It really fits in with consumer thinking at the moment – people want healthy, environmentally-sound food.”

Livestock

Peelham now has a herd of 150 Aberdeen Angus suckler cows. There are four Aberdeen Angus bulls, selected for breeding attributes of ease of calving, good depths of sirloin and high levels of intramuscular fat. Ninety per cent of the livestock is born and reared on the farm. The rest come from a small network of other organic and Pasture for Life farmers whom Denise and Chris work closely with in neighbouring counties, including 100% grass-fed dairies which supply rose veal from ‘unwanted’ male dairy calves.

Sheep numbers have fallen in the past couple of years and now comprise a rolling flock of 60 to 100 cull ewes and store lambs to supply the butchery with lamb, hogget and mutton.

“A few years ago we were trying to manage three breeding enterprises all at the same time,” Denise admits. “We were all exhausted at the end of calving and lambing. So we have reduced the number of Red Duroc x Tamworth sows down to 50 and Angus is now focussing on the cattle. We have moved away from setstocking and he is installing fencing and water supply to the fields to allow long-rotation grazing.”

Winters can be harsh with temperatures averaging around 1 degree centigrade for three to four months and average annual rainfall of 1,000mm. The cattle calve indoors in March and April and are out grazing by the end of April. There is good housing and the heavy soils have so far limited outwintering possibilities.

The cows are fed only grass silage. Calves stay with their mothers all summer and are weaned at housing. The poorer performing beef calves are kept back and reared and sold as ruby veal. All the calves are tagged with electronic tags and their growth rates are measured constantly. The beef calves finish at 24 months at 500 to 600kg liveweight on just silage and grazed grass.

Adding value

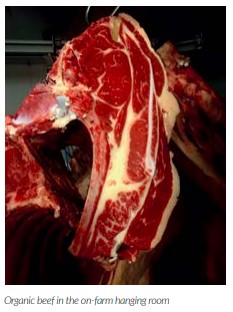

There are three full time butchers and a full time help with the charcuterie, making a wide range of air-dried and fermented meats including prosciutto ham, smoked juniper mutton, pancetta, salami, chorizo and smoked nduja.

“We try to add value to everything we produce and sell as much as every animal that we can, including liver, cheeks, trotters and marrow bones,”

says Denise. “We have just started selling Auld prime – native cow beef that has been hung for at least six weeks.

“Curing is a good way of adding value to an animal. For example, you can sell as ewe for £18 a head, or cure one of its legs and sell it sliced for £55/kg. “Having the butchery helps us see what effect any changes in management out in the fields is having. For example, we can see how much better native breeds are at converting grass into saleable meat compared to some continentals we once dabbled with. And we can see how the levels of intramuscular fat alter too.”

Coronavirus

The pandemic has had a significant impact on the business at Peelham Farm.

“Covid knocked us sideways for the first ten days of lockdown back in March, but since then demand has been five times what it normally is at the Christmas peak and interest has remained high,” says Denise.

“We are reaching many more customers online, website traffic has increased by 170%, and we have upped our game considerably on social media. We have engaged a brilliant photographer to take photos of us working and we do lots on twitter, Facebook and Instagram – telling potential and existing customers what it is we do and why we are doing it. “In essence, we are showing them how their purchasing decisions are affecting every stage of the production process – through the butchers, the farmers, the livestock, the grassland and the soils. They are an intrinsic part of an agroecological system which is bringing health and balance to every element of that chain.”

-

Farmer Focus – Andy Howard

As I write at the end of February it is finally starting to feel like spring. I have even managed to go out without wellies and a coat for the first time in months. Since my last article in September, we have had rain, lots of it! 650mm since 24th of September. Parts of the farm have flooded 4 times since Christmas but after all that, the majority of our crops look well. A couple exceptions of late drilled wheat on heavy clay have suffered but we are in a lot better position compared to last year.

Since my last article I have built 4 Johnson-Su bioreactors with the aim of applying compost extract next autumn with our drill. To be able to check the quality of the compost extract I have bought a microscope, so far, I have looked at a tick off our pet cat and my daughter’s blood with it. My aim is to add a wide diversity of biology into our soil to improve nutrient cycling and plant health.

How well it works only time will tell! Recently I purchased a second-hand Claydon Terrablade Inter Row Hoe. Our grass weed issues are mainly in patches or at low levels. Recently the efficacy of Spring SU herbicides has slid to almost useless with the price staying the same, so any leftover weeds have been hand rogued or spot sprayed. This is very time consuming and I feel if I can get 70% of the patches with the hoe it will make hand rogueing quicker and overall cheaper. This first year with the hoe is going to be a steep learning curve.

The last 6 months has also seen the start of a robotic development project (UKRI funded) where I am a collaborator https://n2visionai.wordpress.com/ . The aim of this project to use a robotic platform, with various cameras onboard, to capture image data of a crop of winter wheat and analysis how the crop reacts to different rates of nitrogen fertiliser and correlate this to soil data. This image data will be run through deep learning analytics at Manchester Met Uni. The long term aim of this project is to develop the software and hardware to measure at a plant scale the Nitrogen status and treat the plants with fertiliser individually, if fertiliser is needed. This will be real precision farming.

Robotics and AI seem to be a hot topic in agriculture at the moment. I believe it has a key role to play in solving challenges we face in agriculture. One concern that people seem to have with this technology is that it will mean a loss of jobs in agriculture, there is little evidence of this in past technology revolutions. Jobs change and are created in different areas; this I believe will happen in agriculture. One of my major concerns for the future is finding decent skilled labour and being able to pay them a decent wage. A question I ask is why would anyone want to work on a modern arable farm?

Why would you work for a relatively low wage, working very unsociable long hours at the time of year everyone else is on holiday or going to festivals and have to handle potentially toxic chemicals? Not a great job advert! There seems to be a badge of honour in farming for people to work longer and longer hours, if you don’t you aren’t a proper farmer. Personally, I do not mind working long hours, but I also want to spend time with my friends and family. I hope to be the last generation of my family that sits on a tractor for 100 hours a week just to get crops planted. If we want to encourage new young blood into the industry, we need to have jobs and wages to attract them. I believe Robotics and AI can help with this issue.

Good luck to all with the rest of the season, let us hope the taps have not been turned off completely again like last year!!

-

A Food Processor’s View…

REGENERATIVE AGRICULTURE – THE NEXT STEP FOR THE WHOLE SUPPLY CHAIN

Written by Rebecca Hesketh, Agriculture Manager for Fresh Produce at Waitrose & Partners

Many of us are asking whether this point in history is one we will look back on as when a ‘shift’ occurred in our system that changed the course of lives and the agricultural industry. There are many aspects of the agricultural world that may feel like they are on shifting sands at the moment, but the opportunity that presents itself through regenerative agriculture may just have some of the answers we need when facing the challenges ahead of this industry.

Whilst regenerative agriculture may feel familiar to many of the readers of Direct Driller Magazine whom I’m sure have long been farming with soil health in mind, we have found it helpful to further define what this means to us, drawing upon the number of definitions out there at the moment. To us, regenerative agriculture is a system of farming that increases biodiversity and enriches soils, therefore improving water quality, enhancing ecosystem services and capturing carbon in the soil. This definition allows us to bring this concept to life within our business and supply chains, to set ambitions and to build a plan to achieve them. There are many different ways we would look to work with our farmers to put this into practice on farm, but whatever we ask our farmers to do, it is important to us to ensure it’s meaningful and relevant to their farming business. There is no one size fits all! One area of focus will be building the health of our soils, which may be achieved through practices such as using cover crops and minimising soil disturbance. Importantly, through the practical application of regenerative agriculture through practices such as these, the benefits are seen not only in the improvement of our soil, but also in the quality of our water, the health of our surrounding ecosystems and just quite possibly the wider planet’s health too.

It is this that particularly draws us to regenerative agriculture, a movement that was built upon the foundations of conservation agriculture and has grown up from the grassroots movement started by the Rodale Institute and the revered Gabe Brown’s of this world. Through the lens of regenerative agriculture, healthy soil is seen as not a happy by-product in a supply chain, but as a core part of what farming achieves alongside the supply of food and a healthy ecosystem with thriving biodiversity. Seeing those vital parts of farming as just as important as what is produced to be sold. It can be best explained as a holistic framework through which to view farming and food supply in the future with the dual purpose of producing food that is both good for us and also the environment, doing more than just maintaining the current state of our planet, but enhancing it. Surely regeneration feels like the right path for us to be taking in a post-lockdown world with the looming challenges of the climate and biodiversity crises ahead.

These challenges require our system to evolve. The UN warns that we only have until the end of this decade to act against the climate crisis. The World Economic Forum warns that ‘biodiversity is declining globally, faster than at any other time in human history.’ Alongside this soil degradation is rightly causing concern to many, with recent studies finding that 16% of the conventionally managed soils looked at in the research had lifespans of less than a century. This gloomy picture has led influential thinkers within the business and agriculture communities to state that all businesses in the future will need to become regenerative. The key in this is ALL businesses – from the farmer to the retailer – we all need to be part of this progression towards becoming regenerative and to work as partners to make changes. This is why we want to start a conversation with our growers about the future of regenerative agriculture on our farms.

We at Waitrose have long worked closely with our suppliers and our growers to create finely tuned supply chains in order to make sure that food can arrive safely onto our customer’s plates. Over these past twelve months, we have seen an incredible amount of pressure applied to our carefully constructed supply chains. When you consider the possibility that the world may become yet more volatile and uncertain with the impact of environmental degradation and the increasing frequency of extreme weather events, it is difficult not to argue for an even stronger system of supply for the future.

This is one of the areas where regenerative agriculture offers potential for our food system. A healthy soil can be more resilient to environmental shocks, protecting this asset and its yield capacity for years to come, whilst thriving biodiversity on farm provides a wealth of ecosystem services. Underpinning our food supply with healthy, regenerating natural resources ensures a reliable base for food production for the future, benefitting a whole supply system on which it is based. Therefore we must work together to realise these benefits. Working in partnership with our farmers and the wider agriculture system is a key part of the way we work at Waitrose and Partners. T

he vast majority of our growers have been supplying Waitrose for multiple years and, through our suppliers, work in partnership with us to face the challenges ahead. Waitrose was founded over 100 years ago and in 100 years time we still want to be providing healthy food from flourishing farms. This is why as part of our Waitrose Agriculture Strategy we intend to embrace regenerative agriculture and play our part in regenerating the natural resources on which we rely. Through sequestering carbon into the soil and keeping it there, we are sure that regenerative agriculture will also play a key role in helping us to achieve our target of net zero across our UK farming base by 2035.

We recognise the important role that knowledge plays in bringing regenerative agriculture to life and this is why alongside these ambitions, we will aim to lead by example on our own farm, the Leckford Estate, innovating, learning and sharing new ways of farming. Alongside this we will continue to strengthen the partnerships we have built with organisations such as LEAF and Innovative Farmers. These partners work closely with us and our farmers to help us to farm with nature. They help us to ensure the right environmental approaches are in place on farm and bring agricultural research to life practically.

Customers are at the heart of every decision we make at Waitrose and the consideration of regenerative agriculture is no exception. The UK has seen an exponential growth in spending on ethically sourced goods over the past two decades, with figures showing spending by consumers on sustainable products reached £29.7bn in 2018, up from £3.1bn in 1999. It is arguable that the last year will have accelerated this trend. Alongside this, the presence of documentaries such as the inspirational Kiss the Ground on the popular streaming site Netflix demonstrates our customers’ interest in farming to regenerate. This is an opportunity to show farming can be a positive force in the action against environmental crises. Over in the US, regenerative agriculture has been taken up by household names, including Wallmart and General Mills, both of whom have made commitments to advance regenerative agriculture where they farm. Clearly these companies, their farmers and their customers see the benefits of a regenerative system.

Our customers make it clear to us that they want us to act in the face of the climate crisis and those crises facing the natural world. Regenerative agriculture could be the solution we need, offering a stronger system through which to supply food, whilst acting to mitigate climate change, biodiversity loss and soil degradation. As a business with customers at its heart and a mission to ‘do the right thing’, applying regenerative thinking to the way we work feels like the right path to take for a responsible business that cares about our planet. This is a path that requires the support of the whole supply chain to make it a success, from the farmer to the retailer and all the businesses both between and around them. To me it’s clear that this step is in all of our best interests to take and it might just be in our planet’s best interest too.

As a retailer that prides itself on working together with our suppliers, we welcome your thoughts on regenerative agriculture and would love for you to get in touch to share your views. You can contact me via LinkedIn.

-

Drill Manufacturers In Focus…

SUBMISSION TO FARM CONTRACTOR & LARGE SCALE FARMER

Customer-first philosophy sustains fifty years of growth

UK agriculture has seen considerable change in the past fifty years, with advances in farm machinery technology arguably one of the greatest examples of progress. Alongside massively increased working widths and capacities, the industry has seen innovation in techniques, significant automation, and new levels of precision application that would have been unimaginable half a century ago. Manufacturers have come and gone within this timeframe, but one that has endured and adapted – going from strength to strength – is KUHN Farm Machinery, which celebrates its 50th anniversary in the UK in 2020.

Founded by Dennis and Cath Hollins in 1970 as the UK subsidiary of the French company KUHN SA, based in Saverne, the business began as a modest operation with limited premises in Wellington, Shropshire. The initial offering to the UK market comprised a small range of grass machinery and some power tillers – a far cry from today’s extensive range that encompasses arable and livestock sectors and includes just about everything from primary cultivations through to crop protection.

The company’s longest standing employee is Peter Morris. He joined as parts manager in 1976 and has been integral to so much of KUHN UK’s progression over his 44 years, holding a variety of roles.

“Supplying spare parts always has been an essential element of the business and this has been transformed over the years,” says Peter. “In the early days, urgent orders would come in by phone to Mrs Hollins’ home, which was about a mile from the depot. We would travel to and from the Hollins’ house, twice a day, to pick up urgent parts orders and then despatch them through ‘weigh and pay’ at the railway station, or on Securicor. Less urgent parts orders came in by post and packages were sent out via the Post Office, using Data Post. As the business grew KUHN was at one point the biggest user of Data Post in Telford.”

Maintaining parts supply efficiency has always been a priority for KUHN, and the company pioneered online ordering in the UK in 2005 with its dealer network. During 2015 and 2016, the department underwent a major refurb, modernising its fully dedicated parts facility at its current seven-acre site in Telford. KUHN UK now has just over 6,500 parts lines in stock, despatching 70-100 orders on average per day to customers with an average annual pick rate of 97% being maintained.

“The system we have today, with the capability of next day and through the night delivery services for a huge range of components, is a long way from the six wooden racks and manually recorded system of the 1970s,” adds Peter. “Nevertheless, the philosophy of delivering what the customer needs, as fast as possible, has remained constant.” KUHN UK parts manager, Daniel Banks adds: “It is now possible for us to supply 95% of parts to KUHN dealerships across the country before 8am, offering dealers and farmers the best possible service.”

Being customer-led is a theme that perpetuates throughout KUHN UK’s history, with landmark developments such as the introduction of power harrows being a good example of how the company has responded to farmer demands. The company sold its first power harrows in 1980 and by 1996 was delivering over 1,000 units per year onto UK farms.

“Power harrows provided a major breakthrough for KUHN through the 1980s and 1990s,” says the company’s national sales manager Duncan McLeish, who joined as an area sales manager in 1985. “The KUHN machine has always been built to last and went a long way to establishing our reputation for strength and reliability.

“There was significant demand for four metre machines in the 1990s, and we developed a transport kit for these wider machines to allow UK farmers to have the working capacity they wanted whilst still being able to comply with road transport regulations. KUHN UK was also directly involved in the development of the first six metre folding power harrow, again being responsive to farmer demand.”

Sales of power harrows continue, with combination units incorporating the Venta pneumatic drill remaining a sector-leading implement, but KUHN has also embraced the move towards minimum tillage. The company now includes a range of minimum tillage cultivators and drills, alongside its more conventional soil preparation and crop establishment range.

Growth of the KUHN UK business over the fifty years has been a combination of organic development, partnerships and acquisitions. Fertiliser spreaders first came into the KUHN UK range in 1985 through the partnership with the German manufacturer Rauch, with this continuing to the present day with the highly successful MDS and Axis machines leading the market. 1987 saw the introduction of KUHN ploughs for the first time, following the acquisition of Huard, and the take-over of Audureau in 1990 further strengthened KUHN’s offering in the livestock sector with the introduction of bedding and feeding equipment. More recently, KUHN has entered the crop protection sector, with the acquisition of the sprayer company Blanchard in 2008. Balers and wrappers entered the range a year later when the company took over the baler division of Kverneland Group, complete with the factory at Geldrop in the Netherlands.

To support its expanding product range, KUHN UK has invested in a high level of support to its dealers and end customers. This took a significant step with the establishment of a technical and service department in 1984, and this has grown significantly in more recent years with the appointment of regionally based product support engineers, product specialists and a dedicated marketing department. Managing director Siân Pritchard instigated the expansion of the product support function around ten years ago as part of a wider recruitment drive that has in the past three years seen a 25% increase in the headcount for KUHN UK.

“We’re continuing with our commitment to deliver the very best technical support back-up to our customers,” she explains. “Our investment in people is consistent with our success in increasing sales and a continuing drive to grow market share in priority product areas.

“Having more people on the ground is being noticed by our dealer network and is becoming an important differentiator for the business. It’s a crucial factor in ensuring we achieve our goal to push UK sales figures to new heights and to provide a more complete, efficient and thorough service to our UK customers.”

Since its humble beginnings in 1970, KUHN UK has been part of a rapidly developing agricultural industry. The company has stayed relevant, and maintained growth, through innovation and continuing product development, and the aim is to continue the upward curve with an ever-improving offer.

“Strength and reliability have been core values for KUHN since the start, and these principles have led to strong relationships with dealers and end customers,” says Siân Pritchard. “Going forward, it’s essential that we maintain these principles and lead the way in electronics and precision agriculture. We also need to continue to offer the best in terms of servicing, warranty and finance, and ensure we maintain the very best customer communications. “I believe that with new initiatives like the MyKUHN customer portal, and innovations like our Click & Collect feature for ordering parts from the dealer, we are fit for the future and ready for the next phase of the agricultural revolution.”

-

Monitor Farming And Managing Reduced Cultivations

while listening to Radio 1)

John Aynsley, runs a 1,302ha mixed farm near Saltburn-by-the-Sea in the north east of England. Barn Farm with 566 ha of arable cropping in a predominantly cereals rotation has recently seen a system change to direct drilling. The transition has been followed and directed by the local AHDB Monitor Farm programme group. Read on to hear about this journey and John’s early conclusions…

Looking back through the mists of time to the 1970/80’s, when as a young man, ploughing was just what you did to start to prepare a seed bed to plant a crop. This was followed by double discing, harrowing, drilling and finally if it had not all got too wet, rolling. Radios were blaring out Radio 1 that you could not really hear above the noise of the tractor, while you were bouncing around in basic cabs. Happy days. The soils turned over beautifully, smelled wonderful and earthy, loads of worms and seagulls munching their way through them. Then power harrows appeared, WOW, one pass following the plough then drill and roll. Then we got really clever and put the drill on top of the power harrow, the combination was born. We thought we were really good then, more hp, more weight, better radios and CD`s and cab suspension. The halcyon days.

And it all worked well and still does for many businesses, drilling seeds/sq.m a lot more accurately, with more even crop emergence and establishment, and lower labour and fuel costs. It was only moving from energetic and naïve youthfulness into middle age, that I saw that the very soils that we once turned over so beautifully, that were so fibrous with organic matter and worms, had become depleted into poorer soils that with the first shower of rain became more difficult to work. How had this crept up behind me without really being aware of it? That was the light bulb moment when I knew we had to start to change.

Starting out on the journey to change

Our rotations had become too short and relied too much on OSR to be our saviour, there was no grass or livestock in the rotation. What would previous generations have made of this I wonder, probably already knowing the answer.

So, the journey to direct drilling had started, but like a lot of things in life it is never a straight or smooth road. It was certainly helped by attending a conference at Driffield in 2011 and listening to different people share their knowledge and experience of the move toward min till, direct drilling or regen agriculture, whatever you want to call it. It was at this point that I met Steve Townsend, who started to help us make that transition to better soils and different establishment methods. At first my agronomist David Coates and I had many discussions and brain storming sessions around the kitchen table, to try to understand exactly what Steve was advising us to look at and move towards.

To start with we did more soil sampling looking at a wider analysis, and in our case, it was showing an imbalance between the magnesium and calcium ratios. Once we started to correct this imbalance our soils have become easier to work with, had a bit more tilth in the top few inches and didn’t revert to a plasticine consistency when things get a bit wet. It will always be work in progress, but you have to start somewhere. The transition to min till is fairly easy and straightforward once you figure out which cultivator and drill suits the farm and system you want to adopt. The next stage however is a bit trickier, this is when the mindset and focus are really challenged.

Monitor Farm programme opportunity

I was given the opportunity to become a monitor farmer as part of the AHDB programme. This gave me the chance to move from min till to direct drilling on 260 acres as part of a 3-year project. Once I had committed to that there was no going back, we would find out whether we could make it work or not. As part of the project, I had to form a Steering Group and we agreed our aims would be to include winter beans and cover crops in the rotation, try to control sterile brome which is our biggest grass weed problem, direct drill all beans and cereals, to see whether the effect of these changes starts to improve the soil and ask whether it can all be profitable.

We bought a second hand Horsch CO6 drill to do the direct drilling for £10,500. This has proved to be more than adequate for the job, it only needs 150hp on the front travelling at 7/8kph. One of the things that I have learned since we started min tilling and direct drilling is that the earlier we get the crops in the ground with a higher than normal seed rate the better they are. The one discipline that we try very hard to stick to is if the soil starts sticking to the tractor tyres get out of the field as it is too wet, and we will be doing more damage than good, hence the need to get on early.

We have been benchmarking the whole arable area through AHDB for several years now, so it is interesting to compare the different costs/income from min till and direct drilling. The 3-year Monitor Farm project is not really long enough to come to any firm conclusions about whether we have managed to achieve all our objectives, but we will continue to monitor the changes over the years ahead.

Early conclusions

What I can say with some certainty however is that direct drilling does work, it uses a lot less labour and fuel. First wheat and bean yields are equally as good as min till. The inclusion of winter beans into a wider rotation is helping improve the soil structure, where we have severe brome the use of cover crops and glyphoshate followed by minimal soil disturbance drilling is certainly working. As to the profitability, I think the weather still has probably the biggest influence over both systems. We are doing more direct drilling year on year and I am fairly sure that we are seeing the benefits of this through better tilth, increased worm numbers and soil smelling a lot better, although as it took some time for the soils to become depleted, it will take time for them to repair. We will have to allow mother nature to do her bit unimpeded by poor practice and hopefully this will help accelerate the process.

Moving to direct drilling I feel that we now have a better understanding of our soils and of what we should and should not do to them, but it is and always will be, work in progress. It does require more attention to detail and it certainly does not look as good to the eye until it gets above the stubble, but as long as it delivers profitability then the soils will improve and we will be able to lower our input costs.

-

How To Count Earthworms

Importance

Earthworms improve plant productivity, are principally responsible for engineering the soil environment and are an important food source for native birds such as the song thrush. There are up to 10 common earthworm species in agricultural soils and these can be grouped into three ecological types: epigeic, endogeic and anecic earthworms – each group having a unique and important function. Earthworms are an indicator of soil health, being impacted by pH, waterlogging, compaction, tillage, rotation and organic matter management.

How to identify earthworms

Epigeic (litter-dwelling earthworms)

• Dark red-headed worms

• Small (<8cm) in size, typically about the length of a matchstick

• Often fast-moving (most likely to escape from the worm pot!)

Sensitive to: Tillage (detrimental) and organic matter management such as manure applications (beneficial)

Roles: Carbon cycling and prey for native birds

Endogeic (topsoil earthworms)

• Pale-coloured and green worms (not red)

• Small to medium size

• Often curl up when handled, and green worms may emit a yellow fluid

• The most common earthworm group found in arable fields

Sensitive to: Organic matter management (beneficial)

Roles: Soil aggregation and nutrient mobilisation for plants

Anecic (deep burrowing earthworms)

• Dark red or black-headed worms

• Large size (>8cm), typically similar size to a pencil

• Make deep vertical tunnels, up to 2m

• Often found below surface earthworm casts or midden residue piles

• Feed at night, foraging the soil surface around their burrow for litter

• Commonly found in grassland but often absent from ploughed fields and where there is no surface litter

Sensitive to: Tillage (detrimental) and organic matter management such as manure applications and straw return (beneficial)

Roles: Deep burrows that improve aeration, water infiltration and root development

Identifying adults and juveniles

Adult earthworms have a clearly developed saddle (reproductive ring) and juveniles do not. You may need to rinse worms with water to determine if a saddle is present. Size is not a good indicator of maturity as adult earthworms typically range in size from 2cm to 15cm, depending on species.

When is it best to count earthworms?

Spring and autumn are the best times to carry out earthworm assessments. Timing the sampling after warm, wet conditions often provides the best earthworm population estimates.

How to assess the earthworm populations

Tools: Spade, pot, bottle of water, mat and a record sheet

Procedure:

1. Dig out a soil pit (20cm x 20cm x 20cm) and place soil on mat

2. Hand-sort the soil (aiming to spend 5 minutes sorting), placing each whole earthworm into the pot

3. Count and record the total number of earthworms

4. Separate earthworms into adults and juveniles (see above)

5. Return juveniles to the soil pit 6. Count and record the number of each type of adult earthworm (see overleaf)

6. Count and record the number of each type of adult earthworm (see overleaf)

7. Repeat steps 1–7, until 10 soil pits per field have been assessed following a standard W-shape field-sampling pattern.

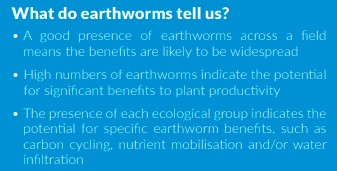

What does this mean?

• RED = If 3 or fewer of the ten pits have 16 or more worms, this suggests suboptimal earthworm populations, which can indicate problems with the soil’s physical or chemical properties

• YELLOW = If 16 or more worms are found in 4 to 6 pits, this suggests a patchy presence of earthworms. With this number, you could make improvements in the parts of the field where earthworms are not currently present

• GREEN = If you have 7-10 pits containing 16 or more earthworms (of any type). The most significant benefits to plant productivity are more likely in fields where you find high numbers of earthworms

• If you are unlikely to find epigeic, endogeic or anecic earthworms, you are unlikely to be benefiting from their specific actions

-

Hampshire Farmer Reaps Regen Rewards

Last autumn, the annual Agri-TechE REAP conference was held virtually, sharing technological ideas from people and companies innovating at the frontier of agriculture. The keynote speaker, supported by AHDB, at the event was David R. Montgomery, whose remit was to discuss how soil linked into the conference theme of “From micro-scape to landscape – innovating at the frontier”. David’s talk showcased how, when thinking about soils, we need to be looking at both of these scales.

An author and professor of geomorphology at the University of Washington, David has travelled the world to hear how farmers have reversed the fortunes of their soils. Numerous conversations later, he now believes soil-health nirvana can be achieved through the adoption of three general principles of conservation agriculture:

1. No or minimal soil disturbance to help soil life flourish

2. Growing ground cover to lock in nutrients and protect the land

3. Using a diverse rotation (three or more crops) to promote life and avoid nutrient over-extraction

The approach, alongside integrated pest management (IPM), provides an opportunity for farmers. However, as David concluded: “There is no ‘easy button’, when it comes to implementing regenerative farming”. Those who use their independence, intelligence and ingenuity to learn from their own experiences and those of others are most likely to thrive. One such farmer, David Miller of the Wheatsheaf Farming Company near Basingstoke, has worked with the three regenerative agricultural principles for decades – long before the term gained traction. A recent AHDB podcast featured machinery expert Harry Henderson, who discussed these principles with David and unearthed the secrets of the company’s success.

Regenerative agriculture in Hampshire

In the early 2000s, the company’s land was plagued with plateauing yields and rising costs. In 2010, the mission was to regain control of the soil and help it look after itself with minimum inputs. By working closer with nature, David wanted to bring back the feel-good element of farming. The 700 farmed hectares is situated mainly on grade 3 land, with drainage occurring naturally through the dominant chalky, stony and flinty soils.

Use of cover

They experimented with cover crops, starting with a single species (crimson clover), followed by a trial-and-error approach that now sees fairly diverse mixtures deployed. The mix is tailored to the situation (e.g. larger seed mixes used toward the end of autumn) with brassica species avoided – due to their bridging potential for slugs and diseases. They use species that succumb to frost, so the standing cover is not too thick and sucking up all the nutrition. They roll after any frost to tackle the remaining cover, although glyphosate is still needed for complete kill. By around 2014, all spring cereal crops followed an over-winter cover..

Minimal soil disturbance

The on-farm default for cultivation and establishment is minimal disturbance methods. However, the use of more disruptive forms of cultivation are used, when the situation demands it. For establishment, a cross-slot drill was purchased in 2015. Since then, the land has become easier to work – and the heavier cross-slot has gone, replaced by a more nimble disc-drill system. It is important to get the drill right at the start, David says. In the last five years, the choice and experience has exploded in the UK. It is important to explore the options and make the right choice for your system. Most straw on the farm is chopped at harvest and raked to even the distribution. As the soils are fairly resilient to compaction, self-restructuring, and all effort is made to avoid working the soil in suboptimal conditions, there is never the need to mechanically restructure them.

David has found that weeds now only tend to come up where the soil has been disturbed and what’s on the surface lose viability or are eaten by birds. However, the weed population has changed. Now there is less black-grass and more brome.

Rotational diversity

In addition to the use of cover crops, the cash crops in the rotation add diversity and flexibility, with a third of the land down to spring crops (barley and wheat). The winter crops include wheat, barley, oilseed rape, rye and, crucially, beans. Livestock are not a part of the system. Although they bring many benefits, they also bring risks, such as compaction in a bad winter.

Yielding success

With no blueprint available for regenerative agriculture in the UK, the sharing of locally relevant experiences is essential – and this is where our AHDB Monitor Farm and Strategic Farm networks come in. We are delighted to announce that David has been selected as AHDB’s fourth Strategic Cereal Farm, with the official launch in June 2021. The Strategic Farms promote the uptake of knowledge and provide a platform for farmers to explore new ideas that can have an impact on their business. David will represent the South, with Strategic Cereal Farms already established in Scotland, East and West.

David’s aim for the programme is to find a responsible pathway to reduce inputs. He said: “We are very pleased to have been chosen as the 4th AHDB Strategic Farm. Our vision for the next 6 years is to trial and prove various scenarios to ease the journey into regenerative agriculture. We aim to look at ways of quantifying the results of our actions in growing crops in a more biological way with less reliance on chemicals and inorganic fertilisers. The end result will, hopefully, give a reliable path of principles for others to follow.

-

Agri-Environment Subsidies Provide More Stable Farm Incomes Than Direct Payments

Full Paper published by Caroline Harkness, Francisco J. Areal. Mikhail A. Semeno, Nimai Senapati, Ian F. Shield, Jacob Bishop

Subsidies paid to farmers for protecting the environment lead to more stable incomes compared with payments based purely on the number of hectares being farmed, according to a new study of farms in England and Wales. The findings are of great relevance as, post-Brexit, the UK moves to the new Environmental Land Management subsidy system. The research, from Rothamsted Research, the University of Reading and Newcastle University, also shows that farmers shouldn’t put all their eggs in one basket, as those diversifying into a wider variety of crops or livestock receive more consistent year-to-year incomes – as do those who reduce their use of fertiliser and pesticides.

Lead author and PhD student, Caroline Harkness said: “Farmers are facing increasing pressures due to changes in climate, government policy and prices. Instability in farm income can be a real challenge. It was interesting, and encouraging, to find that farms adopting environmentally friendly practices also had more stable incomes.

“Farmers may be benefiting financially from their environmental management, while in contrast an increase in direct payments per hectare was associated with less stable farm income. “Environmentally friendly farming practices including engaging in agrienvironment schemes, diversifying outputs, and reducing the use of chemical inputs such as fertiliser and pesticides, are associated with ecological and environmental benefits and importantly could also increase the stability of farm income.”

The researchers examined data from the Farm Business Survey for 2333 farms in England and Wales, between 2007-2015, for a range of different farm types. Using statistical models, the team examined the effect of farming practices and subsidies on the stability of farm income, and their relative importance over the nine-year period.

An increase in direct subsidies paid to farmers based on the area farmed was associated with less stable farm income, across most farm types. In contrast, dairy, general cropping and mixed farms that received more agri-environmental payments had more stable incomes in the short and medium-term. However, farms in the so called Less Favoured Areas – predominantly upland farms who graze sheep or cattle, do not see the same stability benefits from agrienvironmental payments. Ms Harkness said: “Farms in the uplands are already operating in challenging environments and many of the options in agri-environment schemes may not be available or well suited to deliver ecosystem service benefits in these landscapes.”

The results also showed that greater diversity in crop and livestock activities increased the stability of farm income, in dairy, general cropping, cereal and mixed farms – but this was not an important factor for farms that primarily graze livestock. “Increasing diversity of outputs could make farm businesses more resilient to economic shocks or price fluctuations,” says Ms Harkness. Reducing the input intensity also seems to be an important factor increasing the stability of income for all farm types, she added.

“With rising input prices, a concern of many farmers is to control the use of expensive inputs. Whilst farms with higher input costs are more likely to have higher outputs this does not always translate to a higher farm business income, and these farms also saw larger fluctuations in income.”

Dr Jake Bishop, Lecturer in Crop Science and Production from the University of Reading’s School of Agriculture, Policy & Development said: “Our latest research is interesting as it shows that farms that were adopting environmental management actually benefitted financially from their stewardship. This is encouraging news for farmers as the UK moves to the Environmental Land Management scheme.

“Diversifying outputs and more efficient use of agrochemicals is also associated with environmental and ecological benefits, including for soils and pollinators, these benefits may have translated into more stable farm incomes over the nine years we examined.”

-

Drill Manufacturers In Focus…

ANOTHER EXCEPTIONALLY WET WINTER HIGHLIGHTS THE BENEFITS OF GOOD SOIL STRUCTURE AND DRAINAGE.

Following another extremely wet winter Jeff Claydon, a Suffolk farmer and inventor of the Opti-Till® direct strip seeding system, talks about the importance of good soil structure and drainage. He also discusses the initial results of stubble management and cover crop trials on E. T. Claydon & Sons’ arable enterprise.

20 February 2021

Following the extremes of weather and associated challenges which most farmers had to deal with during 2019/20, one might have hoped that the law of averages would mean that this season was easier. So far at least, that has not been the case. With such extremes becoming increasingly frequent, clearly, we must position ourselves to deal with them by ensuring that our soils are in optimum condition and that we use an establishment system which significantly reduces our exposure to weather risk.

Statistically, Suffolk is one of the driest counties in the UK, but even here, after a scorching summer when temperatures peaked at 36°C, we still ended 2020 with 700mm of rain. Of that, over 400mm fell between harvest and the end of December, which has been a challenge on our very heavy Hanslope series chalky boulder clay soils that are notoriously difficult to manage. When wet, they can become impossibly sticky, unfriendly, and slow to drain, but when dry set like concrete. At either extreme they are impossible to work, so all field operations must be carried out within a very narrow time window and when conditions are exactly right.

Until mid-October, our soils remained dry enough to absorb the persistent and often heavy rainfall, but the wet weather continued throughout the autumn and winter. Our weather station next to the Claydon offices recorded another 146mm during January and 46mm in the first two weeks of February, making this one of the wettest winters on record. Driving around the area over the last few weeks I have passed many fields that are in poor condition after being over-worked, or where inappropriate machinery was used at the wrong time. Some were waterlogged, slumped, and capped, worm activity was minimal, crops which had been drilled were stressed and even weeds refused to grow in some areas. Elsewhere, topsoil had been washed off fields, causing crop loss and polluting water courses.

As I write this during the third week of February, we have experienced two weeks of extremely cold weather. The plume of Arctic air that the media dubbed ‘The Beast From The East’ caused temperatures to plummet to a low of -15°C with the windchill factor. The cold snap may have passed, but the wet weather shows no signs of abating and our crops are at their most depressed point in the growing cycle. However, unlike many, they are all set to flourish once the mercury starts to rise.

Every week I talk to existing and prospective Claydon customers throughout the UK and overseas, so I know that many of you also operate in extremely challenging situations and need a robust establishment system. Because of the Claydon Opti-Till® System’s ability to establish any seed that can be air-sown, in all soils and conditions, using around 16l/ha of diesel even on our heavy clay soils – about 10% of that required for a plough-based system – it is now being adopted not just by arable producers but increasingly those in the dairy sector for crops like grass, maize and stubble turnips. With the current talks of reducing CO2 to much lower levels and increasing carbon capture, we are ahead in this field.

When you next have a few minutes to spare you might like to watch ‘The first year of Claydon direct drilling on a UK dairy farm’, an excellent video which Charlie Eaton, Claydon’s Territory Manager for the South and West of England, made over several months on a farm in the Cotswolds. Visit the Wiltshire section of the UK video gallery on our website www.claydondrill.com – it’s well worth a look. Our website video galleries also have numerous videos on soil health and resilience, as well as of the Claydon OptiTill® System being used to establish all types of crops, in all situations, both in the UK and overseas. You can also keep up with the latest posts, photographs, and videos from Claydon and our customers through the Claydon Facebook page (www.facebook.com/Claydondrill). It’s also a great place to share, discuss and question what you are seeing on your farm with other like-minded individuals.

Time to check soils

Extremes of weather such as we have experienced during the last two seasons highlight the importance of having resilient soils with excellent structure, supported by an effective drainage system to take water away. Spring is the ideal time to take stock of your soils, test how good they are, look for signs of compaction, and check that the drainage system is operating correctly. This can be done easily and cheaply using nothing more complicated than a fork, penetrometer, water infiltration tray and a couple of jam jars if you really feel like pushing the boat out to do a Slake Test! With this information you can then plan to correct any deficiencies.

When assessing soil condition, the first thing I do is to carry out several penetrometer tests across the field to check there are no soil pans, as these will severely limit drainage and root development. If they are present, the probe becomes much more difficult to push into the ground and the indicator needle swings into the red. Pans are not caused solely by compaction from heavy machinery or working when conditions are unfavourable but can result from the sedimentation of soils that have been over-cultivated and ‘settled out’ over the winter.

This is clearly demonstrated with the Slake Test, which provides an excellent indication of a soil’s resilience and health, is easy to do and costs nothing. Briefly, it assesses the stability of soil aggregates when exposed to rapid wetting, as in the case of heavy or prolonged rainfall. The slower the soil breaks up the better as this indicates that it contains a high degree of organic matter which helps to bind it together. You can see this simple yet important test being carried out on the Claydon farm by Dick Neale, Technical Manager for Hutchinsons, in a short video on the ‘Soil’ page of our website.

Good drainage is essential

One cannot talk about soil health and resilience without discussing drainage, an area of soil management that is fundamental to good soil structure but often neglected. You don’t need me to tell you that well-drained soils go hand in hand with healthy soils and high yields. The key is to ensure that drains are adequate to cope with the highest flows and well maintained so they don’t become blocked or have their capacity reduced and become overwhelmed during periods of heavy, prolonged rain.

Since land drainage grants finished in the 1970s many farms have been unwilling or unable to invest in new schemes. Four decades on, many existing ones have become obsolete and ineffective, which is a major blow because effective drainage helps soils to dry out and improves timeliness. It also makes them easier to manage, enables fertilisers and ag-chems to work most efficiently and minimises leaching, not forgetting that it also typically leads to yield improvements of 25%-30%. Recent studies have confirmed that new land drainage systems on average can start to pay for themselves after eight years.

If, after heavy rainfall, the water flowing from field drains is dirty this indicates that it is full of sediment, so your valuable soils are literally going down the drain, increasing the risks of soil erosion and flooding. This sediment will also block worm holes and capillaries, killing worms, starving the crop’s roots of essential air and nutrients, reducing yield potential, and ultimately increasing the cost-pertonne of production. Most of the Claydon farm is drained and after two decades of using OptiTill® our soils are very well structured, so water permeates freely. Nevertheless, the drainage system has been pushed to its limits this season. In January, for example, we had one day when over 35mm of rain fell, which overburdened the field drains and water coming out of the pipes ran cloudy. A small amount of overnight surface ponding was also evident in a couple of areas, so I will want to address this in the months ahead by installing additional laterals.

Some have the fear that well drained land increases the flow rates, which to a point it does, but they do not consider the sponge effect of well drained land, where the water is gently filtered through the soil and released steadily, unlike waterlogged soil which washes off the top at a time when we need to achieve clean water to drain and a healthy environment. Healthy soil copes better with these extremes due to the increased presence of soil biota, and our high organic scores on the farm have certainly proved their worth in recent weeks. Driving past some fields where conventional full cultivations and mintill systems have been used, you can see the results of overworked soil which has had its structure destroyed and worm populations adversely affected. It can easily be seen in the last two years where the wrong equipment has been used in wet, adverse conditions. Degrading the soil in this way also reduces its ability to drain water away during extended periods of wet weather and increases capillary action moisture losses in dry conditions.

Given increasing public interest in countryside and environmental issues, including soil erosion, Defra would do well to reinstate drainage grants and fund attenuation ponds to catch sedimentation, as well as to control the release/flow of water. This could be a base for future management strategies considering the weather patterns of the last couple of years. Their work should also address both the capacity and condition of river systems, the need for adequate maintenance of ditches, and give more recognition to the role of correctly structured and managed farmland in holding water and releasing it gradually to prevent water courses from being overwhelmed, leading to flooding.

Stubble management and cover crops

In the last issue of Direct Driller, I outlined the trials we are conducting to evaluate different approaches to stubble management and cover crops, in the same field, under the same conditions. Even at this early stage they have provided plenty of food for thought. The field next to the Claydon factory which we allocated for this is part of 55ha destined for sowing with WPB Elyann (KWS) spring oats, a crop which is easy and relatively inexpensive to grow but often produces a margin on a par with winter wheat. Some of the area was straw harrowed up to four times then left, while on 10ha we drilled a cover crop using different methods to see if, and by how much, it improves the yield and overall margin from following crops. The yield from each area will be measured so we can assess the agronomic and financial impact.

Cover crops are still relatively new in the UK, with most farmers and agronomists still learning about what does and does not work. The trials have been very revealing, but as the lockdowns, sadly, have greatly restricted travel and prevented us all from holding public events you can watch a video of Dick Neale, Technical Manager for Hutchinsons, discussing our cover crops on the video gallery of the Claydon website at www.claydondrill.com

We used Hutchinsons MaxiCover, a general-purpose over-winter cover crop mix containing linseed, buckwheat, phacelia, daikon radish, fodder radish, brown mustard, hairy vetch, and crimson clover. Costing £35/ha, it was drilled at 12.5kg/ha on 9 August using three seeding options on our 3m Claydon Hybrid test drill. With a few simple, quick, low-cost modifications any new or existing Hybrid drill can be used for conventional sowing, lower disturbance establishment and zero-till seeding, with or without fertiliser placement between or in the seeded rows, directly into stubbles, chopped straw, cover crops and grassland. This makes it a versatile, costeffective solution.

In one area we used the standard Claydon Opti-Till® set-up comprising the leading tine which relieves compaction and aerates the soil, followed by a seeding tine with a 20cm A-share. In another we used the leading tine followed by our twin-tine kit. The third was drilled with the new lower-disturbance ‘LD’ twin-tine kit preceded by double front cutting discs which reduce power requirement and minimise soil disturbance. In all cases the cover crop produced a mass of roots. The diversity of species in these mixes means that, regardless of weather, soil conditions, field aspect and establishment methods, it produces a viable cover crop, because even if a couple of species do not thrive because conditions are not right for them in that situation others will grow. Having various plant canopy profiles provides good soil armour and weather protection which has a positive effect in terms of controlling grassweeds, as well as further improving soil condition.

The heavy calcareous clay soil on the Claydon farm has a high calcium base which attracts phosphate and locks it up, so crop roots can have difficulty in accessing this vital nutrient. Buckwheat, one of the species in the MaxiCover mix, produces acids which help to release phosphate and so it plays a valuable role in achieving a correct soil nutrient balance. Ideally, we want the cover crop to be in the ground long enough to gain maximum advantage from the rooting structures, but not so long so that it generates excessive stick-like biomass. The original idea was that cover crops would be sprayed off at the end of November and those areas left until spring, when we will drill spring oats directly as soon as conditions allow. However, we decided instead to graze some off with a neighbour’s small flock of sheep and then rolled the cover crop area with our 12m Cambridge rolls around Christmas on a small frost.

The cold weather of recent weeks has broken down almost all the top biomass, so we will have no issues with it shielding grass weeds from an application of glyphosate applied before drilling. Neither will we have any problems sowing spring oats into the heavy soil, which can be very wet and cold with too much green cover, and this should allow a perfect seedbed environment. The cover rooting has been retained with high levels of worms, so it will be interesting to see how the different areas behave in the following crop.

Obvious differences

With our rotation having changed from wheat and oilseed rape to include more spring-sown and break crops, the aim is to use land destined for spring drilling to help reduce the weed burden and seed bank using Opti-Till® stubble management techniques which move no more than 2cm of topsoil. This will enable us to control weed seeds and volunteers without herbicides, other than one fullrate application of glyphosate just prior to drilling. Effective stubble management has become particularly important following the loss of neonicotinoid seed treatments and some products to control grassweeds as there is a fear that the aphid vectors of Barley Yellow Dwarf Virus (BYDV) will increase significantly. This can be reduced considerably by using Opti-Till® to manage stubbles and eliminate the green bridge effect. It also enables drilling to be delayed, but to do that with any degree of certainty you must be able to get the crop in the ground quickly, which means not having too many operations before sowing.

It has been fascinating to compare the effects of two, three and four passes with the Straw Harrow, a fast, low-cost operation, under identical conditions. This has highlighted the effectiveness of this technique and the significant benefit of using more passes. The differences are as clear as day, as can be seen from the accompanying photographs. We also have numerous videos about stubble management on the Claydon website.

In the next issue of Direct Driller, I will look at how each of the trial areas drilled in the spring and talk through any differences that were apparent at that time.

-

Farmer Focus – Clive Bailye

A global pandemic has few positives, but if I were asked for any I would say the rise of the webinar. As soon as the first lockdown was imposed physical farm events were ended. Participation and involvement in farm shows, auctions and meetings could only be done by farmers and others using software applications such as Zoom, Teams and other programs they had never used before. Over the time they have become so familiar even grandparents are using them to keep in touch with friends and family. While it may be a poor substitute for face-to-face human contact provides, online has become remarkably popular.

Lockdown was as if someone had pressed ‘fast forward’ on the internet. Websites like The Farming Forum, Farm Marketplace and Farm Classifieds with which I’m involved suddenly saw a big increase in traffic. Farmers and others who previously were not interested in digital coms were forced to try – and liked the experience. Meeting online has its problems – broadband connections which let users down at a critical moment; people talking over one another; or that funny moment when a meeting participant speaks up… with microphone still on mute! But these downsides are heavily outweighed by the accessibility that the almost limitless geography of the internet offers.

Attending a meeting or event prior to Covid Lockdown often involved a full day, travelling (with environmental impact of course), small talk before and after, lunch and multiple coffee breaks. All reduce the efficient uptake of the information you had really come to digest. In contrast an online event allows you to turn up just moments before proceedings start. There’s no travel time and cost. But most importantly the internet allows an infinitely wide range of both speakers and participants. As a BASE UK committee member, I have been involved in helping organise speakers for the group over several years, and our choices have often been limited by both the speaker’s diary and more often geography.

Flying in speakers from New Zealand, Australia or the Americas is simply just too expensive, yet these are some of the most knowledgeable soil and No-till people in the world and ones which BASE members want to learn from. Online meetings have made such speakers accessible. In a year when BASE and others might be expected to struggle to do its work, it has in fact done more than ever and membership has grown to new highs as a result. Hopefully we will not abandon Zoom when lockdown and travel restrictions become distant memory.

Farming and carbon trading

Some of the most exciting meetings I have attended have been based around carbon sequestration and storage, and how farmers will be able to sell this and other ecosystem capital benefits in the future. While DEFRA’s ELMS scheme (now known as the Sustainable Farming Incentive “SFI”) has bold vision to pivot production-based subsidies to natural capital and public goods payments, the complexities of creating trading systems for Carbon seems now to be a step too far for them to get involved in. This has created an opportunity for the private sector to provide certification and trading of this farming asset.