If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Defra Answers your SFI 2024 Questions

Written by Chris Fellows

After the interruption of a General Election, Defra have been able to get back to answering farmers 2024. The delay, which has been frustrating for all, has now passed and on the 26th September Defra delivered a webinar in collaboration with the Farming Advice Service (FAS) and The Farming Forum (TFF).

The webinar was lead by Farming and Countryside Programme Director, Janet Hughes, joined by policy leads working on SFI, and colleagues from the Rural Payment Agency and Catchment Sensitive Farming.

As with previous webinars, questions could be asked in advance by farmers on TFF or submitted via Slido. Given the popularity of the SFI discussion section on TFF, there were a lot of questions. If you didn’t get a chance to attend, Defra have now loaded their answers to questions onto the TFF thread (read via QR Code) and the webinar is available on demand.

If following reading the thread and watching the webinar, you still have questions, please feel free to ask your own question ono TFF and see what the collective wisdom of all the farmers on TFF can come up with in terms of answers. We know Defra monitor this section closely, it’s likely they will see your question too.

Read the SFI section on TFF here.

-

Farmer Focus – Tim Parton

September 2024

How one’s life can change between articles! You never think anything is ever going to happen to you! I can honestly say that it has been the worst year of my life so far! As somebody that has always taken health and safety seriously, you just never know what is around the corner and I urge you all to never take life for granted.

Thanks must go out to everybody that was kind enough to contribute to my Go Fund Me page. I still feel very humbled by people’s generosity, and I cannot thank you enough. Special thanks must go to Micheal Kavanagh for organising the whole thing. I must also thank Nick Woodyatt and Micheal for looking after the farm for me in my absence. Farming from pictures and telephone calls is a whole new experience when lying in a hospital bed; currently, at the time of writing, I am still in rehab, which seems endless! My time is also taken up keeping my website updated, www.timpartonfarming.com and writing my book. The devil makes work for idle hands!

It has been a difficult farming year on many levels with the amount of rainfall being high on the list of things to contend with and why it’s so important to keep soils covered. Heavy rain will cause a lot of surface compaction, which is something I see time and time again when out consulting and can be rectified so easily with a low disturbance lifter! Nothing can grow without air and I often see people having poor yields and blaming the system, when in truth it is they that are letting the system down by not being the farmer and rectifying the problem. The worst thing that happens to a farmer’s brain when they start direct drilling is that any soil movement is bad and that they are direct drilling now, so they condemn all soil movement. Quite often their soil is not ready for direct drilling and soon goes even more anaerobic, causing reduced yield and loss of income, when in truth yields should be the same or better when things are done correctly! I often hear the term roots are better than steel, which is true as long as you have got a healthy soil, but if your soil is not quite there, then a little light lifting is perfect to get the cover crop going. Where the real benefits can be achieved and where everything moves forward is when the farmer becomes the observer.

OSR (canola) came in well for the year at 3.5T/ha. The crop had looked well all year and as usual no fungicides have been used, just nutrition and biology as nature intended. Disease and pests only ever attack a plant that is in poor health and unfunctional from a photosynthesis point of view, basically the whole production system is broken!

Wood vinegar has proven to be a very useful product and one that we have used as part of the programme this last season, with good control against sclerotinia, Rhizoctonia, phytophthora, septoria and yellow rust, but I cannot stress enough that it has to be used as part of a nutrition/ biological programme. Everything is always building on each other to increase immunity and strength of the plant in order to achieve a functioning immune system, but as with all applications the right amount is critical especially at drilling which improves rooting and germination.

It is the first harvest that I have not been involved in since being a small boy, where I spent many an hour sat on the foot plate of the combine with my swimming goggles on to keep the dust out of my eyes, under my father’s watchful eye, sat at the helm. Farming was all I ever wanted to do from the time of walking, with many pictures to prove it. I have found it most frustrating to be lying in hospital on bed rest at the time of cutting my wheat, receiving pictures of the action and wishing that I was there. I miss the smell of harvest and the adrenalin rush! It has always given me a buzz seeing the year’s work come home.

As Green Farm Collective we have been busy as ever with a fantastic conference back in May, hosted by Micheal Kavanagh, with numbers of attendees rising year on year, but also a sad day for me not being able to attend! We had a full programme of speakers, and I am told that there was a real positive vibe throughout the day. We have sold our first loads of regenerative wheat at 11.5 percent protein and on the day of movement we achieved a £88/ton premium over feed wheat, which is still pence on the end product. This is in recognition of the value of a regenerative wheat produced to our audited standards from FIA (food integrity assurance). This gives our customers the confidence to go on and sell our flour with the assurance that they are selling a genuine product for the health of the consumer. This has always been a vision of mine, to provide healthy food to the masses, otherwise it becomes a niche product for the upper middle classes, which in my mind will never have the desired effect on the planet or its inhabitants! Everyone needs to change the way they farm and consumers need educating on what they are eating and change their purchasing habits, something which we aim to facilitate within GFC. Together we begin to have a voice; as solos we go unheard! Join us and become part of the revolution within the history of the planet. Together we can make a difference!

-

Mycorrhiza manipulation: nature vs nurture

- Mycorrhiza can be added to systems physically via inoculation or encouraged from surrounding environments

- Inoculation strategies should be considered carefully given the ecosystem and climate in which they will be applied or they could act detrimentally or be wasted

- Future research is ongoing to validate inoculation tools for large-scale field use but more needs to be understood about the underlying molecular biology and genetics of mycorrhiza interaction before widespread application can be considered

Mycorrhiza and specifically ‘arbuscular mycorrhizal fungi’ (AMF) and Ectomycorrhiza (EcM) are important symbiotic fungi involved in the successful growth of the vast majority of plant species across the world. We have previously discussed their roles and strategies impacting their activities in an introductory article. The following article aims to expand on this by discussing the different strategies surrounding manipulating these species and the impacts of this on ecosystems, as mycorrhiza are well cited for their strong potential within sustainable food production.

Whilst it is agreed that there has been significant growth in the number of industries providing commercial mycorrhiza inocula for gardening, horticulture and agricultural amendment use, the effectiveness of these is subject to debate. Furthermore, additional approaches have been investigated for manipulating plant-mycorrhiza interactions which may be beneficial to consider for future strategies particularly given the outcome desires and funding support suggested in the ‘Sustainable Land Management’ (SLM) proposals.

Inoculations

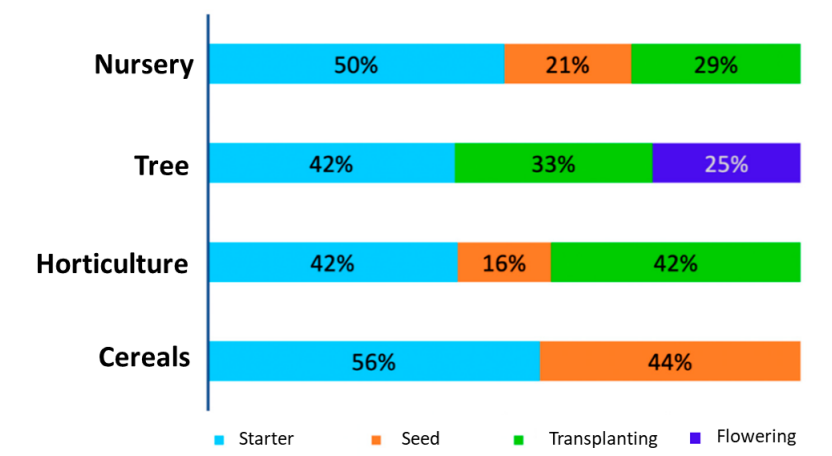

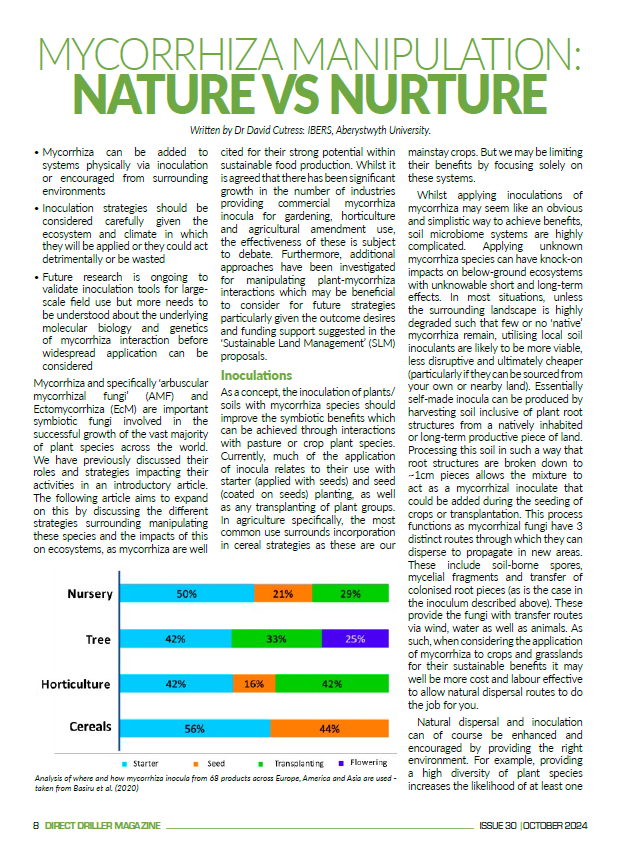

As a concept, the inoculation of plants/soils with mycorrhiza species should improve the symbiotic benefits which can be achieved through interactions with pasture or crop plant species. Currently, much of the application of inocula relates to their use with starter (applied with seeds) and seed (coated on seeds) planting, as well as any transplanting of plant groups. In agriculture specifically, the most common use surrounds incorporation in cereal strategies as these are our mainstay crops. But we may be limiting their benefits by focusing solely on these systems.

Analysis of where and how mycorrhiza inocula from 68 products across Europe, America and Asia are used – taken from

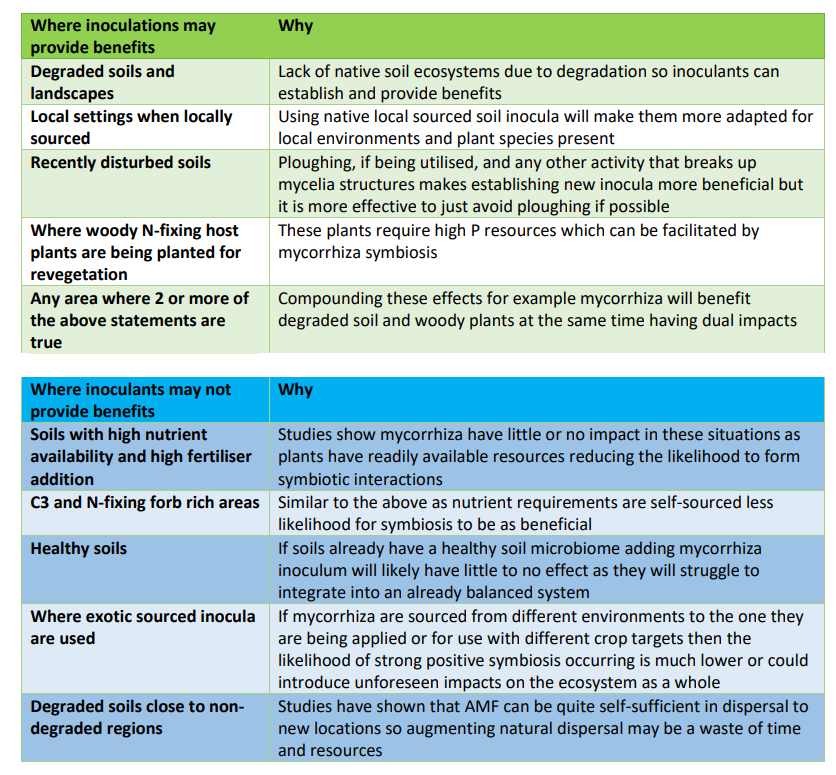

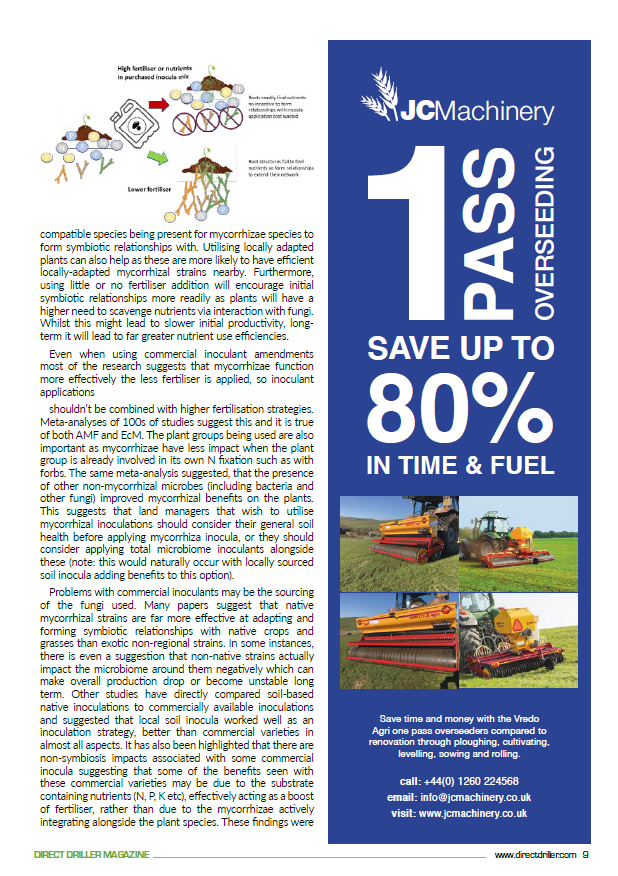

Basiru et al. (2020)Whilst applying inoculations of mycorrhiza may seem like an obvious and simplistic way to achieve benefits, soil microbiome systems are highly complicated. Applying unknown mycorrhiza species can have knock-on impacts on below-ground ecosystems with unknowable short and long-term effects. In most situations, unlessthe surrounding landscape is highly degraded such that few or no ‘native’ mycorrhiza remain, utilising localsoil inoculantsare likely to be more viable, less disruptive and ultimately cheaper (particularly if they can be sourced from your own or nearby land). Essentially self-made inocula can be produced byharvesting soil inclusive of plant root structures from a natively inhabited or long-term productive piece of land. Processing this soil in such a way that root structures are broken down to ~1cm pieces allows the mixture to act as a mycorrhizal inoculate that could be added during the seeding of crops or transplantation. This process functions as mycorrhizal fungi have 3 distinct routes through which they can disperse to propagate in new areas.

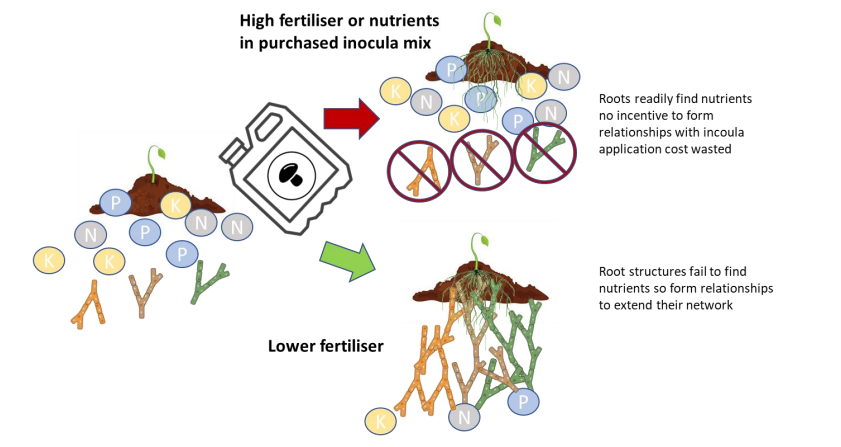

These include soil-borne spores, mycelial fragments and transfer of colonised root pieces (as is the case in the inoculum described above). These provide the fungi with transfer routes via wind, water as well as animals. As such, when considering the application of mycorrhiza to crops and grasslands for their sustainable benefits it may well be more cost and labour effective to allow natural dispersal routes to do the job for you.Natural dispersal and inoculation can of course be enhanced and encouraged by providing the right environment. For example, providing a high diversity of plant species increases the likelihood of at least one compatible species being present for mycorrhizae species to form symbiotic relationships with. Utilising locally adapted plants can also help as these are more likely to have efficient locally-adapted mycorrhizal strains nearby. Furthermore, using little or no fertiliser addition will encourage initial symbiotic relationships more readily as plants will have a higher need to scavenge nutrients via interaction with fungi. Whilst this might lead to slower initial productivity, long-term it will lead to far greater nutrient use efficiencies.

Even when using commercial inoculant amendments most of the research suggests that mycorrhizae function more effectively the less fertiliser is applied, so inoculant applications shouldn’t be combined with higher fertilisation strategies. Meta-analyses of 100s of studiessuggest this and it is true of both AMF and EcM. The plant groups being used are also important as mycorrhizae have less impact when the plant group is already involved in its own N fixation such as with forbs.

The same meta-analysis suggested, that the presence of other non-mycorrhizal microbes (including bacteria and other fungi) improved mycorrhizal benefits on the plants. This suggests that land managers that wish to utilise mycorrhizal inoculations should consider their general soil health before applying mycorrhiza inocula, orthey should consider applying total microbiome inoculants alongside these (note: this would naturally occur with locally sourced soil inocula adding benefits to this option).

Problems with commercial inoculants may be the sourcing of the fungi used. Many papers suggest that native mycorrhizal strains are far more effective at adapting and forming symbiotic relationships with native crops and grasses than exotic non-regional strains. In some instances, there is even a suggestion that non-native strains actually impact the microbiome around them negatively which can make overall production drop or become unstable long term.

Other studies have directly compared soil-based native inoculations to commercially available inoculations and suggested that local soil inocula worked well as an inoculation strategy, better than commercial varieties in almost all aspects. It has also beenhighlighted that there are non-symbiosis impacts associated with some commercial inocula suggesting that some of the benefits seen with these commercial varieties may be due to the substrate containing nutrients (N, P, K etc), effectively acting as a boost of fertiliser, rather than due to the mycorrhizae actively integrating alongside the plant species.

These findings were echoed across other meta-analyses with the same general trends found. Furthermore, it was highlighted that larger effects of mycorrhizal inoculation were found in studies where soils were already highly degraded and lacking in rich microbiome diversity. Similarly, it issuggested that soil inocula outperformed commercial/experimental inocula even whencommercial inoculations contained a higher diversity of mycorrhizal strains suggesting that buying a mycorrhizal mix isn’t a quick fix to these issues.

Delivery strategies

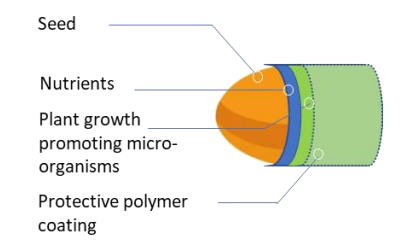

Some interesting future considerations in development for boosting the effectiveness of soil inoculations involve looking at the delivery mechanisms of the mycorrhizal fungi to the plants in soils. Alongside issues surrounding inoculations discussed above, there is also research suggesting poor survival rates of inocula in storage, transport and in soils due to environmental and other factors. One approach that could combat this is seed coating, whichis already a technique being used commercially to protect seeds, making them easier to plant (due to manipulating weight and size) and to incorporate growth promotion via combining with nutrients and microorganisms for example.

Seed coating can also reduce the inocula application dosages needed compared to solid and liquid amendments, as they are protected from environmental losses. To take this further some interesting experimentation surrounding nano-particle inclusion in seed coating strategies has shown the ability to reduce inoculant dosages by 97% whilst maintaining growth benefits and could make resource efficiency even better in the future. Overall, benefits have been shown in reviews for seedling establishment, germination and improving yields with lower nutrient fertilisers applied, but it is still noted that a better understanding of soil microbiome interactions is needed in many situations to ensure such strategies function in situ in fields.

Summary

Mycorrhiza manipulation and considerations are likely to become increasingly important when considering future sustainable agricultural production practices. Whilst there are currently a large number of gaps in our knowledge with regards to specific interactions dependent on factors such as plant species, mycorrhiza species, abiotic factors and biotic factors. There is a wealth of research suggesting some general trends of functionality which are useful to understand. Local inoculants or allowing native nearby mycorrhizal systems to propagate naturally currently seems more viable than commercial inoculants in all but the most extreme scenarios. A summary of the considerations surrounding the use of mycorrhiza inoculation is as follows;

-

Restoring farmland biodiversity: The Allerton Project

The Allerton Project, as a research and demonstration farm, has been in operation since 1992. We are, however, a part of the wider Game and Wildlife Conservation Trust (GWCT), a membership organisation who have been conducting conservation science to enhance the British countryside for over 90 years. Today, the GWCT’s Farmland Ecology Unit carries out some of the most important research into nature friendly farming that is undertaken in this country, and is of international significance.

One of the jewels of GWCT research is the ‘Sussex Study’, the longest running monitoring project in the world that measures the impact of changes in farming on the fauna and flora of arable land. Since 1968, it has been conducted annually across 3200ha of land owned by the Duke of Norfolk on the Sussex Downs, between Arundel and Worthing. The starting point of the study was to determine the causes for the decline of the grey partridge, the iconic bird which forms the logo of the GWCT. Sadly, the British Trust for Ornithology recorded a drop in numbers of 91% between 1967 and 2010, a trend which has seen little national improvement in the past decade.

It was determined by the GWCT that the main reason for their decline was a reduction of chick-food insects in cereal crops caused by the disappearance of arable weeds such as the prickly poppy, cornflower and narrow-fruited knotgrass, given that such insects are the sole food source of recently fledged partridge chicks, which hatch in early-mid June. (In order to keep the dataset consistent, at least 100 sites (always arable fields) are monitored in the third week of June by hoovering up the invertebrates present with a ‘D-vac’). Ultimately, a lack of insect food was leading to the starvation of many hatched chicks, with the loss of arable weeds via agricultural intensification leading to the loss of both a habitat and a food source for those vital farmland invertebrates, the prime species of which are:

- Caterpillars (lepidoptera)

- Hoppers (homoptera)

- Bugs (heteroptera)

- Click beetles (elateridae)

- Sawfly larvae (symphyta)

- Leaf beetles (chrysomelidae)

- Weevils (Curculionidae)

- Ground beetles (carabidae)

The figures collected on the decline of these populations is stark; overall invertebrate abundance decreased by 37% across all taxa (a group of one or more populations of an organism or organisms) with 47% of taxa in decline (and 16% increasing). Yet beneath those headline figures, the study shows that insect predator species declined by 67% on average, while crop pests increased by an average of 26% (if aphids are excluded, which actually recorded a 90% reduction in population size). Happily, in this study at least, pollinator populations remained broadly stable.

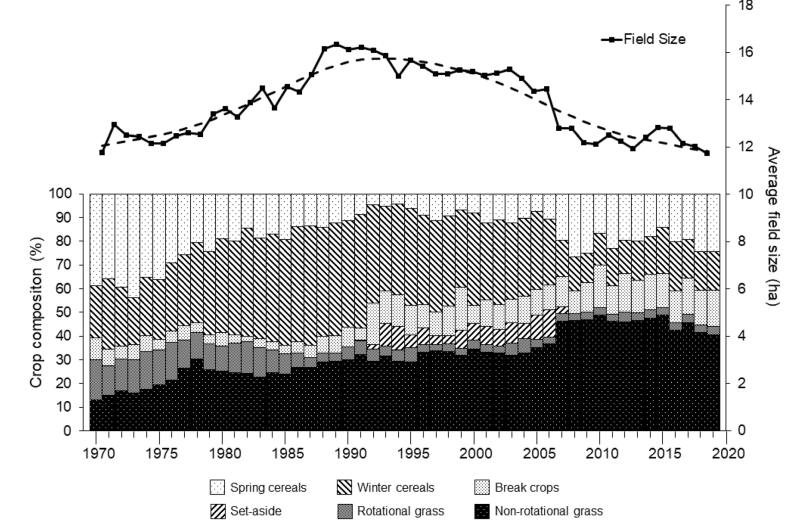

The data of the Sussex Study indicates that the majority of the invertebrate population decline occurred in the early decades of the work, and particularly in the 1970s, before stabilising (though still on a generally downward trajectory). This reflects the rapid and generalised intensification of agricultural land use in this period, much of which was captured by the GWCT in the form of field application records and land use. In the study area, as across much of the country, there was a marked decline of broader, more traditional rotations from 1970 as the area put down to spring crops and rotational grass declined, and the area of winter cereals increased along with average field size. There was also a general increase in the intensity of pesticide usage across the decades, largely in line with national trends. Although herbicide and fungicide use are currently at historically high levels across the study area, insecticide use peaked in the late 1980s, again in the mid-2000s, but has decreased significantly to the present day.

The GWCT has developed a metric called the ‘Chick Food Index’ (CFI) to determine the health of a population of farmland invertebrates to support a range of farmland birds. Different bird species will have a different CFI, but for grey partridge the figure is 0.7 – i.e. we need to see an invertebrate population of 0.7 to enable a grey partridge colony to maintain its current size. Worryingly, in a recent GWCT survey of ten farms nationwide between 2018-2020 across hundreds of grass, arable and horticultural fields, in no situation did the CFI rise anywhere near 0.7. Perhaps even more concerningly, where the same process was repeated in a range of agri-environment margins, the same result was obtained. In short, we do seem to be facing a generalised decline in our insect populations, with all the implications that has for farmland ecosystems. This is a trend which we know is also being experienced globally, with a 1-2% reduction in invertebrate numbers being reported annually.

I would be the first to say that agriculture is not the sole cause of the decline of invertebrate biodiversity – and that even where it is largely to blame, farmers are only reacting to the pressures of a society which demands ever-cheaper food, but dislikes asking questions of it. However, with agriculture covering some 70% of the UK landscape, and the implications of the historic intensification of agricultural practices for all manner of farm wildlife being well established, it’s clear that we do have our part to play in reversing this downward trend. And here too GWCT research has something to say.

Although grey partridge numbers nationally have continued to fall since the 1960s (including in some parts of the Sussex Study area), in parts of the estate where extensive measures have been put in place to recover their populations we have seen a significant increase in numbers since the mid-2000s – alongside other species such as skylark, lapwing and linnet. Such measures include the creation of beetle banks and hedgerows to break up larger arable fields and encourage the development of invertebrate populations within them, the establishment of grass strips and unharvested, low-input conservation headlands around field edges, and the provision of supplementary feeding for farmland birds through the winter. It also includes establishment of bespoke wildflower mixes, such as the GWCT Advanced Wildflower PARTRIDGE Mix which has been extensively trialled and developed to deliver the best outcomes for farmland birds and invertebrates throughout the year. It contains more than 20 species, both annuals and perennials (and primarily native), and has the potential to last for a full decade if managed correctly. Insect abundance in this mix peaks after around six years.

Other GWCT research also points the way toward healthier invertebrate populations on farm, for example indicating higher populations of pollinators on farms which have adopted ‘regenerative’ farming practices – primarily wider, more diverse rotations and the establishment of pollen and nectar margins and legume-rich rotational options, as well as more sympathetically managed hedgerows with a greater profusion of flowers. At the Allerton Project itself, we are part of the Rothamsted moth monitoring network, and for the past thirty years we can demonstrate an increase of around 35% in our macromoth populations, while at the national scale there has been a decline of around 35% in the same time period. This we have managed at the same time as retaining our core identity as a productive, ‘conventional’ and primarily arable farm. It’s also well established that many invertebrates – such as carabid beetles, which can play an importance role as crop pest predators – live part of their lifecycle in the soil, and therefore reduced tillage can play an important part in enhancing such populations.

The new options available to support Integrated Pest Management (IPM) via the Sustainable Farm Incentive (SFI) will do much to help many farmers think more carefully about farm invertebrate populations, but it must also be recognised that insecticide and herbicide use is only one part of the picture, and that the broader scope of SFI and other potential income streams must be utilised to build up the ‘green infrastructure’ needed across a farm to start to build beneficial insect populations. Simply going ‘cold turkey’ on inputs is likely to lead to decreased yields and disillusionment. That’s why the Allerton Project has put together a practical guide for farmers – ‘A guide to insect-rich farmland habitats’ – which is available online, and we are always open to groups of visitors to come and see some of the work which we have undertaken in our living lab landscape over the past 32 years.

-

Stow Longa delivers vital insights into carbon and nitrogen efficiency

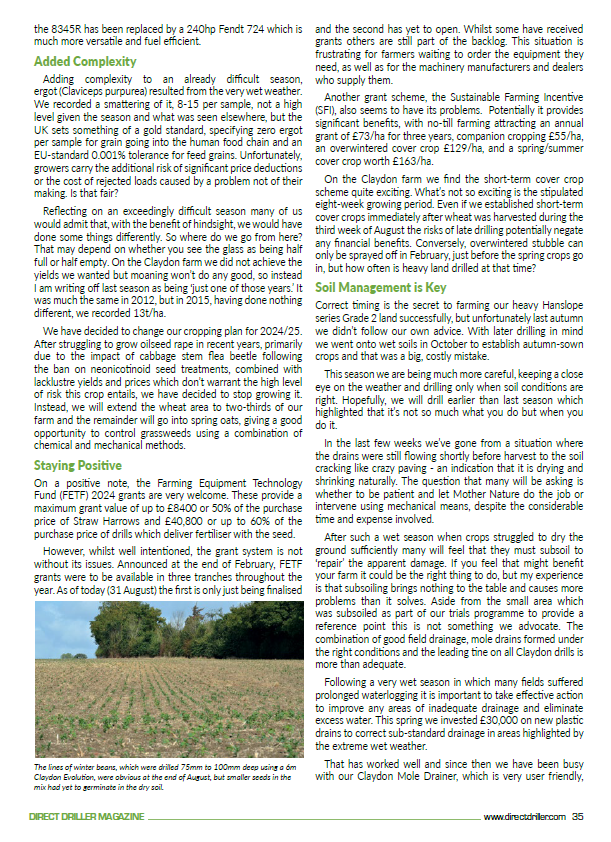

With its current trials programme now entering its tenth year, Agrii’s Stow Longa site, near Huntingdon, continues to provide new crop production insights with some of the latest being the carbon footprint implications of different cultivation methods and just how much blackgrass can reduce the efficiency of nitrogen applications.

With the need to use inputs as effectively as possible in modern crop production, the impact of cultivation choice and blackgrass control method can have a major effect not just on the profitability of a farming business, but also its carbon footprint.

“Over the years at Stow Longa, we’ve learned a huge amount about rotations, crop establishment and blackgrass control, with the sustainability agenda increasingly effecting the way we look at our cropping,” says Agrii seed technical manager John Miles.

“But one thing it is impossible to get away from is the importance of yield in the equation and this is very much the case when looking at nitrogen use efficiency (NUE) and carbon.

“While it’s often assumed reduced cultivations will result in less fuel consumed and a correspondingly lower carbon footprint than plough-based approach, making a direct drill system work effectively means this is not always the case.

“They can be much closer than many think and this was certainly the case on Stow Longa’s heavy soils when several passes of a straw rake, combined with a low-disturbance sub soiler, were factored in.

“Using information supplied by equipment manufacturers, diesel use estimates were 25litres/ha for ploughing and 17 litres/ha for direct drilling using an LD leg and straw rake, with fuel for drilling on top of this.

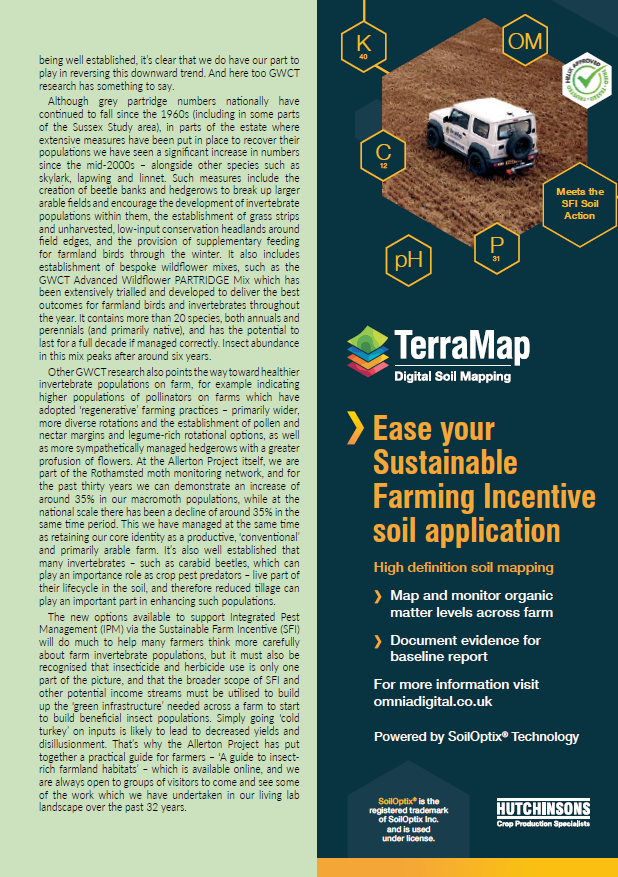

Spring oats have outyielded spring barley in sub-optimal seedbeds at Stow Longa, but not in better ones. Importance of yield

The results become more interesting when looking at yields and CO2e per tonne of production, he points out.

“We used greenhouse gas figures from ADAS Yen Zero, which pitches the ploughing option as the worst in terms of greenhouse gases/ha at around 1350 kg/ha compared to direct drilling at 372 kg/ha – which is a big difference.

“But with a spring barley yield of 9t/ha for ploughing, for example, the carbon is 155 kg/t whilst it is 176 kg/t for the direct drilling approach with its lower yield of 6.5t/ha – much closer and much more relevant when it comes to grain marketing options.

“Early results from 2024, however, suggest use of the low disturbance subsoiler, used in good conditions, with a stubble rake and a more successful cover crop, have reduced the yield difference between ploughing and direct drill approaches to around 0.4t/ha.

Stow Longa results suggest every 100 ears/sq m of blackgrass results in a yield loss of 1t/ha. “So, it will be interesting to see how this affects the carbon footprints – we’ve closed the yield gap but we’ve used more diesel, too.”

There are many lessons still to be learned from Stow Longa and it remains an invaluable tool in the company’s R&D armoury for the future, John Miles believes.

“With nitrogen being such a large component of both the cost and carbon footprint of crop production, Stow Longa’s findings of the effects of blackgrass on NUE, for example, are extremely compelling.

“We know every 100 ears/sq m of blackgrass results in a yield loss of 1t/ha, so it’s a double whammy to realise your costly nitrogen applications are feeding this, too.

“In spring barley crops with little blackgrass we’ve seen yields at Stow Longa of 9t/ha from about 120kg N/ha which equates to an NUE of over 90%.

“Others with higher blackgrass levels, but the same level of nitrogen application, have produced a yield of 6t/ha resulting in an NUE of little over 60%.

“So, the bottom line is whether it is optimising profitability, carbon footprint or NUE, achieving high yields is still an incredibly important objective.”

-

Farmer Focus – John Pawsey

September 2024

Alice and my pre harvest holiday was with Wild With Consent whose website promises ‘This is wild camping, but not as you know it’. I have always asked for Alice’s consent before going wild otherwise she would have me arrested. What the website actually meant that we could camp in a remote place on somebody’s farm without the landowner showering us with some animal’s excrement. It is that kind of consent.

If was also a fact-finding mission. We have just placed a pitch on our own farm on the Wild With Consent website and so we wanted to check what other farmers were offering to make sure that our Shimpling pitch was up to scratch.

The deal is that once booked you get a What Three Words reference giving you the exact pitch location, personally checked by the Company’s owner to be wild enough, and all you have to do is make sure that you leave no trace of human presence when you vacate your allotted spot.

Not being a natural camper I immediately took to the World Wide Web to find a huge fridge to cool alcoholic beverages and bacon, a mattress that would self-inflate before I had reached the top of our roof top tent’s stairs and a power input to ensure that communication with humanity could be accessed at all times. Because Alice had said that it was illegal for me to dig a hole to naturally fertilise the periphery of our remote home, I spent an inordinate amount of time researching a natural portable loo, as being of the organic persuasion it is against my principles to sit astride the chemical version. Huge success in that department. All I can tell you is that it involved a tripod, a biodegradable plastic bag and copious amounts of sawdust. It was a triumph.

Alice did say that with all the money I had spent on “stuff” it would have been cheaper to stay in a five-star hotel. “But this will be fun” I said. I can’t remember exactly what she replied but I’m pretty sure it involved a sharp implement and me tackling a piece of gymnasium equipment.

Our destination was the Lake District but also to cram in as many locations as possible over the six days we were away to fulfil the research element of the holiday.

Dreadful planning on my part meant that night one (Leicestershire) was the evening of the World Cup final. Fortuitously during my spending spree in the quest for camping comfort I had purchased a dongle with unlimited data. With the roof tent erected, awning splayed, chairs and tables positioned, iPad streaming that fated game and with views over the verdant Cottesmore Country, Alice began to warm to the situation. However, my pièce de résistance was producing some fizzy wine, chilled by the aforementioned fridge, which seemed to cheer her up no end.

I’m not going to lie, the first two nights were a little grizzly as we acclimatised to a sheet of canvas between us and the outside world, negotiating the roof top tent’s ladder at 3am in the morning to answer the call of nature without falling out of said tent like a sack of potatoes and the fact that because most of the locations were so wild that there was no phone signal. But by the third night we got into a routine and went slightly native on the whole camping thing. With all devices severed from the outside world we also discovered the art of speech and found out that even after nearly thirty years of marriage we still actually quite liked each other. Oh, and books made out of paper, you should try one, the battery life is amazing.

Following Leicestershire, we had three nights in Cumbria and on the way home a night in Yorkshire. We ended up by loving the whole experience. Wild With Consent, you have to try them and suggest a pitch on your own farm so that we can come and see you too.

You are probably wondering where all this is going. He hasn’t mentioned a direct drill yet which I fully intend to but first I do want to tell you about two things that happened in the Lake District.

Firstly, Alice and I spend a day’s walking up to Angle Tarn and experienced the most amount of weather I have ever been exposed to in my life. Being north of Suffolk I assumed that no sun cream would be necessary on my bald head during the trek, but I was wrong. I don’t care what the boffins tell you, they do have that fiery ball north of Preston so much so that I had to bathe my bald head in the tarn to cool my third-degree burns. Then in a flash the weather gods threw hail stones at us like cricket balls, we were lucky to get away with mild concussion. Quite what farmers up there know what to put on in the morning is a mystery to me. Flat cap or a hard hat? String vest or Sou’wester? Tricky. I’ll never complain about our Suffolk weather again. Also the Cumbrian landscape goes up and down a lot which meant that our under-developed East Anglian calves screamed in pain on the way up and then on the way down we discovered that we had no actual muscles around our knees. Our biggest climb in Shimpling is upstairs to bed.

The second thing I want to tell you about while lakeside is a conversation I had with the famous organic Cumbrian farming influencer, James Robinson or as we Twitter (X) fans know him @JRfromStrickley.

James and I have bumped into each other at various organic and regenerative events over the years, but I felt that I had never really sat down and chewed the cud with him, and since we were in the area it seemed rude not to meet up.

Having just been to Groundswell and then the National Organic Crops event I was curious to know what Jame’s take was on the rise of regenerative agriculture and he said a really interesting thing. In the context of organic verses regenerative farming he said, “I think that the ambition of regenerative farming is limitless”. I was sort of taken aback as to me his statement suggested complacency in the organic sector.

The main thrust of James’s point was that organic certification took us to a certain point in terms of it’s standards but once you had achieved those standards that was it. Job done. Sure, there are lots of practices in those standards that align and go further than regenerative farming principles but the ambition stops once they are met.

I began to think about my recent organic inspection. Part of the annual routine is a drive around the farm checking that I have done what I have said I have done. Does it look like we have been spraying any pesticides? Have we got sufficient physical barriers between us and our neighbours to reduce the risk of spray drift? Samples are taken of forage, grain and soil and sent off for analysis to check if we are lying. The inspection feels like a test. It should be a celebration.

Soil is checked traces of pesticide and not soil health or any increase of organic matter. Tillage methods go unquestioned. A sustainable rotation has to be demonstrated but it’s requirement is pretty basic. Bi-cropping or any multi-species cropping is not a thing. No mention of the use of cover crops or to keep the soil covered. Other than complying with the rules there is no expectation of agroecological progression. No ambition. And it’s possibly why you do come across some organic farms that don’t look very “organic”.

Well reader, you will be happy to know we are doing all of the above at Shimpling Park Farm even though our inspection doesn’t document it and that takes me to the final point that James made. “We have to go beyond organic”. I’ve been to James’s farm and he certainly does.

I want our inspection day to be one of celebration. Smelling healthy soils rather than packaging samples for testing. Walking in our crops to witness food and nature in the same place rather than focusing on segregation. Recording innovation within our rotation rather than ticking a box to demonstrate adherence to basic agronomy.

In my previous December submission, I argued the validity of organic standards verses regenerative principles, but we do have to be honest about where just achieving the organic standard is limiting best practice.

We need our farms to feel organic rather that a farm that doesn’t use any pesticides. Equally, our farms must feel genuinely regenerative rather than just a farm with a direct drill.

There, told you I’d mention a direct drill.

-

Glyphosate or tillage: which is worse for soils?

Which is the lesser of two evils – glyphosate or tillage? That’s what Rothamsted Research’s Prof Andy Neal has been trying to find out

Written By Mike Abram

Glyphosate or tillage – which will do more damage to soil health? It’s a question that has exercised both regenerative farmers and the organic sector from different sides of the same coin.

It also provoked some practical weed control concerns for zero-tillage growers looking to grow crops for Wildfarmed, particularly when a three-year agreement term for a field was being proposed.

While Wildfarmed has rowed back on that proposal, and now effectively allows the use of glyphosate to terminate cover crops, for example, before a Wildfarmed crop is sown – its terms say no pesticides can be used in the growing crop – the debate about which is least damaging led to some research involving Rothamsted Research’s Prof Andy Neal.

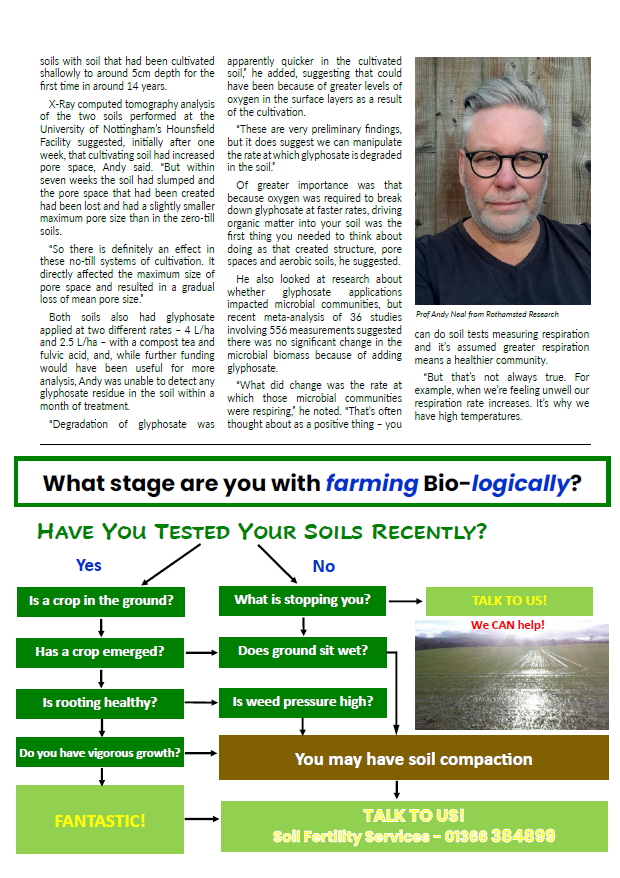

“We were particularly interested in understanding whether it is possible to use glyphosate sensibly and responsibly while still looking after soils,” he told delegates at the Green Farm Collective’s annual regenerative farming conference in May.

That research is still ongoing, with further funding being sought to deliver more insights, but through Andy’s understanding of how soils work, he’s already starting to think about what glyphosate and cultivations are likely to do to soils, as well as look to other research.

Evaluating the risks from glyphosate, he explained glyphosate was broken down microbiologically. “We know this can occur aerobically or anaerobically.

“But in the absence of oxygen it occurs much more slowly. So, when we think about applying glyphosate to soil, ideally that soil would be full of pore spaces and oxygen because under those circumstances we can guarantee it would be broken down as rapidly as possible,” he said.

That suggested there were certain circumstances growers should be considering whether their soil was in a fit state to degrade glyphosate rapidly, and whether growers should address soils in a poor state first, he said.

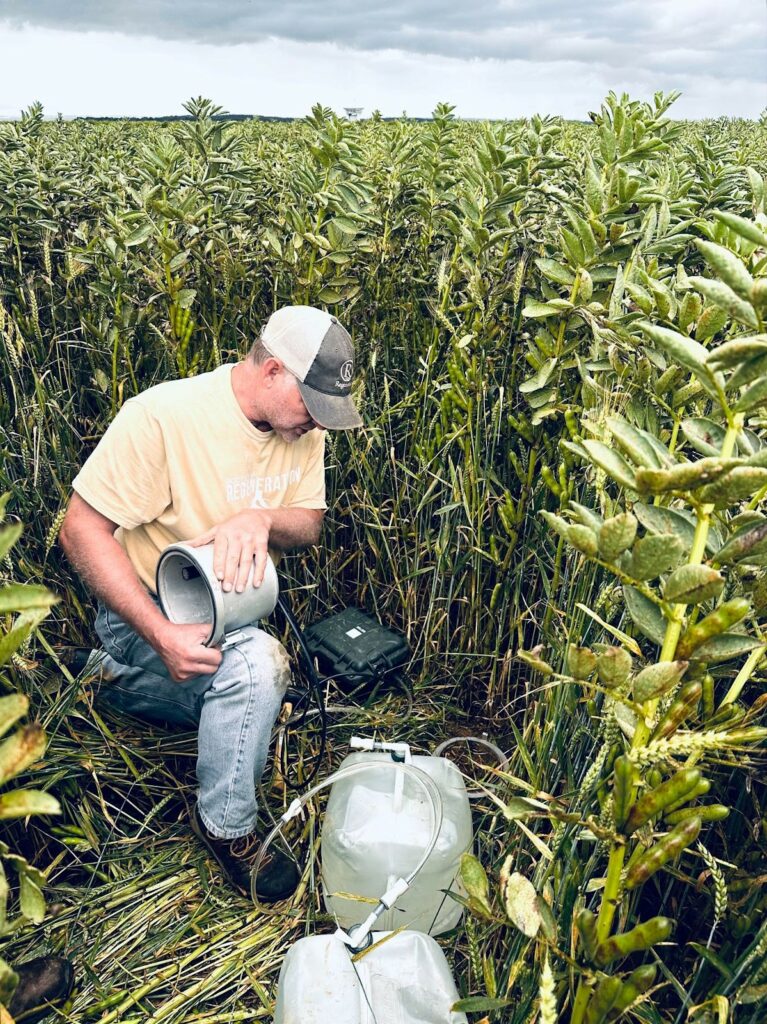

There were interesting impacts on pore space in the trials Andy conducted in conjunction with Green Farm Collective co-founder Tim Parton last year. These compared long term zero-till soils with soil that had been cultivated shallowly to around 5cm depth for the first time in around 14 years.

X-Ray computed tomography analysis of the two soils performed at the University of Nottingham’s Hounsfield Facility suggested, initially after one week, that cultivating soil had increased pore space, Andy said. “But within seven weeks the soil had slumped and the pore space that had been created had been lost and had a slightly smaller maximum pore size than in the zero-till soils.

“So there is definitely an effect in these no-till systems of cultivation. It directly affected the maximum size of pore space and resulted in a gradual loss of mean pore size.”

Both soils also had glyphosate applied at two different rates – 4 L/ha and 2.5 L/ha – with a compost tea and fulvic acid, and, while further funding would have been useful for more analysis, Andy was unable to detect any glyphosate residue in the soil within a month of treatment.

“Degradation of glyphosate was apparently quicker in the cultivated soil,” he added, suggesting that could have been because of greater levels of oxygen in the surface layers as a result of the cultivation.

“These are very preliminary findings, but it does suggest we can manipulate the rate at which glyphosate is degraded in the soil.”

Of greater importance was that because oxygen was required to break down glyphosate at faster rates, driving organic matter into your soil was the first thing you needed to think about doing as that created structure, pore spaces and aerobic soils, he suggested.

He also looked at research about whether glyphosate applications impacted microbial communities, but recent meta-analysis of 36 studies involving 556 measurements suggested there was no significant change in the microbial biomass because of adding glyphosate.

“What did change was the rate at which those microbial communities were respiring,” he noted. “That’s often thought about as a positive thing – you can do soil tests measuring respiration and it’s assumed greater respiration means a healthier community.

“But that’s not always true. For example, when we’re feeling unwell our respiration rate increases. It’s why we have high temperatures.

“So it would be easy to assume this is a positive influence of glyphosate, but what I think we are seeing is a measure of the stress imposed upon communities as a result of adding glyphosate. It doesn’t mean it is a lethal effect, but means the communities are working harder to break down that glyphosate or to overcome some other effect.”

A second set of studies compared soils where glyphosate had been applied regularly for a long period against organic farms in Maryland, Mississippi and Washington states in the US, with the aim of identifying any changes in microbial community as a result of applying glyphosate.

But what the studies found was that other factors, such as annual variation or how the soil was managed, had a much greater influence on the microbial communities in the different soils than the application of glyphosate.

What those experiments didn’t consider was what those microbial communities were doing, he pointed out. “That’s what we’ve been trying to understand with the Wildfarmed trials on Tim’s farm. We know microbial species change happens, but what’s important is understanding the way microbial function changes as a consequence. That’s what we’re looking to achieve in the next few years,” he said.

So what about the impact of cultivations on soil health? Evidence from Rothamsted’s North Wyke site in Devon suggested that just one year of ploughing reduced organic matter from 6% to 3% when converting fields that had been in long term pasture into an arable system.

“From the trials it suggests it takes roughly seven or eight years to recoup the carbon that was lost under a pasture, as long as no further tillage takes place,” he added.

A second series of trials he highlighted were at FarmEd in the Cotswolds, where the farm incorporates grazed herbal leys into a cereal rotation. Andy has been investigating the impact of multi-species herbal leys on soil structure and the consequences of moving from herbal leys into arable in the rotation.

“We looked at several different treatments on the farm, including a permanent pasture. The four-year herbal ley had the largest amount of pores of any treatment – it had developed a nice structure, which would drain well and hold an awful lot of water.

“But we were shocked that after ploughing shallowly to 10cm, plus two power harrow passes, rolling and drilling reduced the amount of pore space significantly. We would predict this soil will now drain poorly because it will be difficult for water penetrate, and for it to hold onto what water does penetrate because of the lack of pore space.”

Connected pore spacing was crucial for optimal soil function, he explained. “And there is a clear connection between the amount of organic matter that goes into your soil and pore spaces.”

That connection was much stronger in soils with significant clay and / or silt content, and less so in sandy soils, but in those soils with the right texture higher organic matter equalled high porosity leading to a high flux of nutrients and oxygen through the system.

“That will give you a high nutrient use efficiency. Anaerobic space [caused by poor soil structure and lack of connected pores] causes the selection of microbes that use nitrates rather than oxygen to respire, resulting in the production of nitrous oxide, low nutrient use efficiency and high greenhouse gas emissions.”

The implication of making the connection between organic matter, connectivity between pores and soil structure was in how growers might manage how they use organic matter on farm, he suggested.

“If you want to make the biggest impact with small amounts of organic matter you might invest them in clay soils you know to be low in organic matter because that’s where you’re going to see the maximum benefit in improving water holding capacity and improving lots of other metabolic issues associated with anaerobic respiration with microbes,” he concluded.

-

Farmer Focus – Andrew Jackson

September 2024

Another year has passed and although I am without doubt a bit older, hopefully I am a little wiser from all the errors that I have made. We have tried to devise a rotation based around predominantly first wheats, interrupted with break crops of grass seed (down for two and a half years and grazed in the winter periods), OSR and this year for the first time, spring beans and BOATS (spring oats sown alongside spring beans). Although we were confronted with a wet autumn, we have a low grass weed burden which enabled us to press on with the autumn drilling, we used our own seed, a ten-way soft wheat blend and took it straight out of the shed (rightly or wrongly). Our six metre Horizon drill, operated by my daughter Anna went well and although I would have liked to have tried to place some liquid biologicals alongside the seed, last autumn did not allow the time to be trialling.

We successfully sowed all our seed before the heavens really opened. Throughout the wet winter period, I was asked whether, because we had direct drilled and not cultivated to take out any compaction, then surely our fields must be full of puddles, the answer was ,there were no puddles apart from one or two parts of historically compacted tramlines on better bodied soils. This free draining soil, represented the results of four years drilling and levelling the fields with a Sumo DTS, followed by four years using a direct drill, no cultivations, just putting faith in the system.

Anna and to a lesser extent myself, appear in the film Six Inches of Soil. This had been three years in the making and we attended the first viewing in December in Cambridge.

We attended the first public viewing at the Oxford Real Farming Conference. Prior to the viewing we enjoyed a beer with Tim Parton, this was shortly before his horrific accident. I am sure that you will all join me in wishing Tim a speedy recovery in his adjustment back to his farming life.

We also had a film viewing in our play barn at the Pink Pig Farm. This was for me particularly nerve racking because my farm and its system was being judged by many of my farming friends on the big screen. I sat at the back and knowing that I would be answering questions on a panel after the film, I filled myself with Dutch courage maybe excessively! Needless to say, I have not been asked to sit on a post film panel since. Anna and I have attended other viewings at York and John Pawsey’s farm in Suffolk, all the viewings were well received and followed up by a plethora of questions for the panel.

We finally completed the foliar nitrogen plant. Within the plant we have a twenty-five thousand litre tank which can be filled with rainwater to the required level and then urea and sulphur are added to a specified recipe, the contents of the tank are agitated for twelve to twenty-four hours, depending on the ambient temperature, then the finished product can be pumped into one of three twenty thousand litre storage tanks.

I have an eighty thousand litre rainwater tank sited outside the building to capture rainwater and since the recipe specifies soft water, I was particularly concerned that the collection from the gutters would not supply enough. I need not have worried, after that wet winter, I have even had to fill one of my fertiliser storage tanks with the precious, soft rainwater. I should add that we had to bund the whole building and simultaneously we relocated our chemical store to enable the whole mixing and storage operation to take place under cover. We would like to thank Anglian Water for a grant which contributed to the cost.

On the day of foliar fertiliser application, we then add in biologicals such as Fish hydrolysate, molasses and Hutchinson’s Humagro, all is applied at one hundred litres per hectare which means that we can cover some ground quickly. No scorch was apparent; however, we did endeavour to apply early in the mornings. The theory of applying foliar nitrogen as opposed to soil applied nitrogen is that it is up to four times more efficient, therefore allowing for a reduction in application rates accompanied by financial savings of home mixing and using less product. Amendments, such as magnesium and manganese can be added when sap tests dictate. The wheats crops were also treated with Sycon as a fungicide replacement, eventually the disease pressure was so high that we had to apply a normal fungicide in the latter growth stages.

The spring beans had always been planned and were grown on contract for seed for Limagrain, for many farmers spring beans were sown because of the wet autumn and winter. We also tried BOATS, apart from one trace element application, they received no fertiliser, herbicide, or fungicide products and may be suitable for a premium market outlet. Following a three-year break of two years of grass and one year of OSR or Beans, we were able to grow a crop of Basic Typhoon seed for Limagrain, but we requested no seed dressing, this action also allowed us to spread our risk of growing 100% home saved seed.

I attended Groundswell with the aim of investigating three topics: adding value to my grain, robotic camera guided hoes and Exlana sheep. I came away having decided that I would try Wildfarmed wheat, if its happening on Clarkson’s farm ,then it probably should happen on mine. Although the SFI pay reasonable rewards for interrow hoeing and there are grants to buy the hoe, two things are holding me back, firstly if I could achieve an understory of clover or indeed lucerne, then it may not be easy or desirable to inter row hoe and secondly, I cannot believe the price of the hoes. Have they pumped up the price on the back of the government incentives? Every year our sheep enterprise is confronted with fly strike, shearing costs and bags of wool with very low value. At Groundswell I visited the Exlana stand and concluded that going forward we should run wool shedding sheep , such as Exlanas, I just must convince my daughter.

By completing two Carbon Calculators, I have come out just about carbon neutral and consequently I have been approached to become a Climate demonstration farm, I attended a webinar in relation to this which was presenting thoughts and theories from lecturers from a selection of European Universities. What they said could have been straight out of a presentation from thirty years ago. It’s so concerning that the educational institutions do not appear to have moved with the times.

More encouraging was an excellent conference at Downing College Cambridge, it was organised by a group of trusts, being predominantly driven by members of the Sainsbury family, who are themselves farming regeneratively. The conference had the aim of creating more collaboration between the scientists (educational institutes), the farmers and the city institutions who might fund research on our behalf. Once again, the scientific community only like to measure one or two variables in a single trial. I stood up and explained the multitude of changes which have taken place on my farm in a relatively short period of time, I fear that I am acting on hope and blind faith, using and adapting research from other countries around the world, in the absence of any meaningful research in the UK. One very positive presentation came from Ruth Wade who, in conjunction with a cluster of Yorkshire farmers is carrying out some more relative trials work at Leeds University, albeit she is about to run out of funding.

After years of growing Birds Eye peas in a six-year rotation, our farm has become pea sick with foot rot, regrettably the system was not as sustainable as we thought, or was it the decades of ploughing?. We now rent land for peas and this year, due to the weather conditions and the fact that I refused to plough, (instead I had Sumo trio ’ed the field, leaving some surface trash), I was asked to direct drill the peas, this went reasonably well considering that direct drills do not really like cultivated soils. However, my field was hit by every pigeon in the territory and given that margins are quite tight on rented land, after forty years of being a Birds Eye pea grower, I have given notice to quit growing peas. I also had poor OSR yields, part of this might have been seasonal, however I do believe that OSR is quite a weak rooter, and I have struggled to get outstanding OSR crops from direct drilling, so out of the window goes the OSR also.

For years I have operated Gatekeeper, and I guess that I have learnt to live with its clunkiness, Anna will not work with Gatekeeper, she said that it is back in the ark, so we are changing to the Hutchinson crop recording package Omnia, and she will be in the driving seat for that product.

We have tried various actions with our direct drilling to establish an herbal ley into existing grassland, all have failed, so this year we have had to hire/borrow a plough and two of my children were taught the acquired skill of how to plough. The herbal ley seed was then sown into the blacked over soil and we eagerly await emergence.

I have been in the SFI pilot which is coming to an end soon and so I have been reviewing the options of the 2024 SFI Scheme. It may come as no surprise that being a regenerative farmer, I will be able to tick so many more boxes than my conventional neighbours. It seems likely that the Wildfarmed area may be eligible for the low input cereal option, on those grounds BOATS could also qualify, therefore enabling BOATS to become a viable break crop, which may replace OSR in the rotation.

Our wedding barn diversification has gone well for two summer seasons, which is just as well because both of my daughters have announced their engagements this summer. Carl and Anna announced their engagement in May, on the weekend of the engagement, it had been suggested by Claire Mackenzie that Anna might want to go to London to promote the Six Inches of Soil book at a book signing. The event would take place alongside Gabe Brown, who would be in the UK, not only to promote his book, but on other business. I explained to Claire that I had prior knowledge of Anna’s forthcoming engagement, and that Anna would not be available to go to London. A plan was then hatched (not by me), to drive Gabe straight from Heathrow to Scunthorpe, with the intention of giving Anna a second surprise for that weekend. This cunning plan was implemented and we hosted Gabe and his colleagues to a brief farm walk and a Barbeque, on which turned out to be, one of the most idyllic of May days that you could possibly imagine, Gabe might have been a bit jet lagged, but wow, who would have told me back in 2016, when I read Dirt to Soil, that I would be entertaining its author in my garden, eight years later?

-

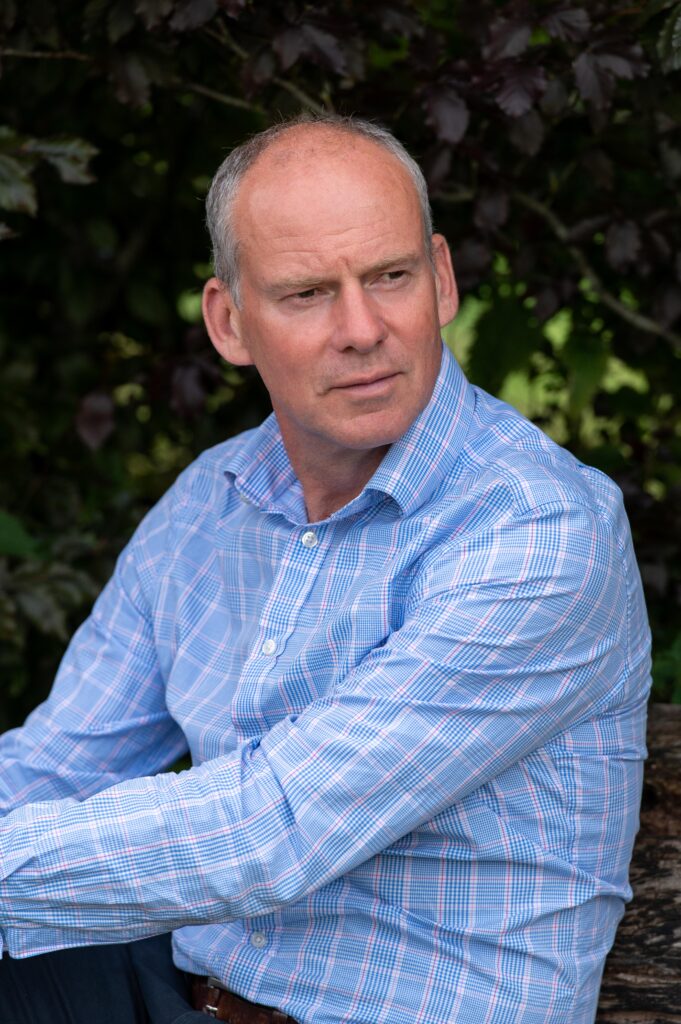

Getting emissions down in a measured way

Written by Rob Nightingale from Frontier

“Yield is king!” This was a tag line in farming throughout my career as a farm manager and agronomist. Interestingly, now as a technical sustainability specialist, it’s a phrase finding resurgence again.

At times in our history it has probably been more pertinent than others, for example during the second World War when the UK was cut off from imports and the onus on domestic production and supply was significant. Since then, however, conversations about yield have typically centred around profitability.

Being profitable has often meant producing as much yield as possible from a piece of land, ideally with minimal investment to ensure the best returns. However, in the last 30 years, UK wheat yields have plateaued and rather than reaching for the highest, the focus shifted to aiming for the optimum.

Rob Nightingale This was the case when I started as a farm manager and continued as an agronomist – matching inputs to outputs and keeping the cost of production per tonne in mind. Since moving to my technical sustainability role, yield is indeed still king, but the narrative around what that looks like in today’s agricultural landscape has shifted again.

But, why? To put it simply, in the UK we have some of the best yielding land in the world. The global winter wheat average for the last five years was 3.53t/ha, whereas the UK average for the same period was 8.05t/ha. If we consider that comparatively, you could say that every hectare in the UK yields 2.2 times more than the global standard.

Of course, this doesn’t mean we should farm the entirety of the UK. We have incredible flora and fauna here and, importantly, we rely on that biodiversity to sustain and enhance the farmed environment we depend on. Instead, where crops are being grown, the priority now is to optimise those areas to deliver the highest yield with the lowest environmental impact, ensuring sustainable, resilient farming systems that delivers for the long term.

With the benefit of hindsight (it is 20:20 after all), the ‘optimum yield’ can seem clear, but basing the experience of one season on the next is never a guarantee. Instead, it’s about ongoing monitoring to understand what the yield potential truly is, using those insights to better understand what the picture could look like next time.

Reviewing crop input strategies is an important part of this and we’re continually investigating solutions that support growers to adopt approaches based on applying the right amount in the right place; matching crop need.

If we look at nitrogen requirements in wheat for example, calculating optimum applications might seem a relatively straightforward exercise on paper. A crop of wheat’s offtake is the amount of nitrogen removed from the field, otherwise expressed as yield (dry matter) x grain nitrogen (%). For example:

8t/ha yield x 11% grain protein = 6800kg/ha x 1.93% nitrogen = 131kg grain nitrogen offtake.

Once we have this figure we then need to account for the nitrogen taken up by the crop to produce roots, stems and leaves that doesn’t get transferred into the grain by harvest.

The proportion of nitrogen in grain is typically around 68%, so we divide the grain nitrogen offtake by 68% to get the total nitrogen uptake. For example:

131kg grain nitrogen offtake ÷ 68% = 193kg/ha total nitrogen uptake.

If we think back to the five-year UK average of just over 8t/ha at 11% protein, based on the above calculations we therefore need the crop to take up 193kgN/ha from all sources. Simple, right? Not quite. How we get enough nitrogen there in the first place is key.

To maintain or even improve the yields we see in the UK, it’s important to create conditions where adequate nitrogen can be taken up by the plant to support grain production. The challenge our industry has is how to achieve these optimum levels.

Today, agriculture relies on mineral fertilisers as its predominant nitrogen source; with nitrogen produced by the Haber-Bosch process estimated to support food production for nearly half the world’s population.

However, with a growing focus on the sustainability credentials and carbon footprint of food production, exploration into ‘greener’ fertilisers is growing. Of course, moving away from the ‘norm’ isn’t a process that can happen overnight without there being wider impacts on crop production.

It’s therefore important to look at how to make the most of current practices too. For example, setting rotations up to get the maximum from soil nitrogen supply for those crops with a higher nitrogen demand. This could be along the lines of using grain legumes i.e. incorporating peas and beans, or even approaches such as undersowing with clover to help retain and increase nutrients for future crops.

Measuring the amount of available nitrogen in the soil provides a better understanding of how much additional nitrogen is needed to supply the crop too. Assessing biomass through precision services such as SOYL provides insight into nutrient levels across the farm and individual fields, supporting more targeted, variable applications with nitrogen doses subsequently adjusted higher or lower to suit demand.

At the end of the season, the results from in-field grain analysis and harvest sampling provide the equivalent of a ‘report card’, detailing how well a crop’s needs were met and therefore what worked and what needs reviewing. This data combined with the amount of applied nitrogen can help calculate a nitrogen use efficiency (NUE) score – a great measure for understanding how and where inputs may need adapting.

This calculation can provide a lot of insight into where nitrogen has been used and the yield potential of a field. For example, feed wheat’s optimum yield is seen when grain protein is at 10.8% protein. Using that as a benchmark, it can help in identifying whether nitrogen has been over or under-applied, if there is an issue with crop uptake or if the yield is lower than the potential of the field in question. If we look again at the UK vs. global average, any ‘lost’ yield potential is therefore a waste.

In my current role looking at the sustainability of farming systems, I spend a lot of time discussing production data and how to interpret the insights gathered during the process of growing a crop. This includes fertiliser product use, tillage type and yield principally, but reporting can be broadened to encompass much more, such as grain quality for example.

By collating this information, powerful data sets can be constructed and the insights gathered can support all parties of a supply chain, from farmer to grain processer, to continually advance the future of food production and make the right moves towards a more sustainable future. I always stress too that it isn’t the data in and of itself that is ‘valuable’, it’s the story it tells, the understandings it can generate at scale and the time and effort taken to do that.

Truly, I believe that UK farming is some of the best in the world, and it is intrinsic to supporting future improvements to our environment. There are a lot of positives to share about our industry and the ever-evolving science, innovation and forward-thinking approaches so many adopt and explore. Recording more of this better equips us to share this work even more widely, including to those buying the products derived from this work.

Yield is king when we’re talking about sustainability. Getting more from less in the right ways drives all of us to be more efficient. This is not just a discussion around land sparing vs. land sharing, it’s about striking the right balance between food production and the environment, doing the right things in the right places and for the right reasons. The story of how and why we do it is one we can all help to capture – not only can we all learn from it, but we can share that knowledge (and pride) with so many others too.

-

The Time is Now: Why It’s the Perfect Moment to Get Behind Regenerative Agriculture

Written by Angus Chalmers, Managing Director of RDP Comms

The World Economic Forum defines regenerative agriculture as ‘a way of farming that focuses on soil health.’ This is its key premise, using nature’s recipe, soil, to achieve productivity goals rather than relying on ever more complex manmade interventions. The last agricultural revolution was transformational for the wellbeing of the world’s population, but now we understand more about the impact of conventional farming, there is a growing realisation that we need to work more closely with mother nature’s natural processes.

Regenerative agriculture allows us to do this. As a more holistic approach to farming, it encompasses the whole eco system, enables us to work with and enhance what nature can deliver, and has the potential to provide a balanced and more efficient way of producing food. However, let us not forget that data, knowledge, and precision agriculture will be just as important in a regen world as it has always been. We will just be doing it as part of a more sustainable food system.

Industry events we have attended so far this year have demonstrated just how much momentum there is behind the regenerative movement. At Groundswell, Cereals, and a visit to an AHDB monitor farm, there has been a focus on different regenerative techniques and approaches. This illustrated just how broad a church regenerative agriculture is and therein lies its beauty. The reason it’s become such a strong movement is that it does not try to force farmers to follow a blueprint. It is inclusive, farmers can enter at multiple levels, starting simply by making a few minor changes or adopting wholescale system change. Ironically many farmers already practice some form of regenerative agriculture, but just do not recognise it as such.

The strong message of the regenerative ‘brand’

If we consider the regenerative ‘brand’ as a representation of UK agriculture, we need to be careful about how it is developed. How can we nurture the brand to cut through misinformation, particularly given that it is not perfect science and consumer understanding is lacking?

Recent research from EIT Food (European Institute for Innovation and Technology) looked at consumer perceptions of regenerative agriculture. It found that consumers do not think much about the different agricultural methods used to produce their food, but they are concerned about chemical use and food quality. They also perceive that food grown in a regenerative system is healthier, nutritious, and tastes better mainly because fewer chemicals and pesticides are used in production. There is also a wider recognition that regenerative agriculture is aligned to a sustainable food future in a greater way than conventional farming.

For both consumers and farmers, the regenerative agriculture brand has a strong message. It delivers nutritious food, and whether tastier or not is subjective, but it enhances soil health. Ultimately this delivers healthier crops requiring less intervention to help them grow and ward off pests and disease as they are extracting much of what they need from the soil. Mother nature’s recipe, when healthy and in good heart is more effective and has the potential to deliver greater returns to farmers.

A wider opportunity for society

The time is right for us as agriculturalists to back the regenerative movement, but in my mind the far bigger prize is the opportunity this represents for UK agriculture to engage with the rest of society and rally behind a brand which is already seen as positive. Rather than occupying different camps, demonising conventional farming for being too industrial, or organic farming for being expensive and low output, we need to embrace the regenerative movement, in all its guises. Encourage its uptake and development and invest in its future.

We need to recognise that this brand has the opportunity to penetrate right through to the consumer. Let us ask ourselves the question; how do we grow this positive position? What we must not do is confuse and divide, ‘my regenerative method is better than yours.’ Our great industry tends to shoot itself in the foot when our eyes are too firmly faced inwards, let us look outwards at our industry’s reputation in the eyes of the end consumer, we have a remarkable story to tell. By all means, if a certain approach provides a unique selling point, then make the most of it, enhance your brand and marketing approach but let us not damage the industry’s wider reputation.

In this age of instant communication and social media, it does not take long to spread messaging that is wildly incorrect, and that people take as gospel. There is no right way to adopt regenerative agriculture, we still have so much to learn, so we must not be too possessive, but be embracing for the good of UK agriculture.

I am under no illusion, however that there is a challenge in developing the regenerative brand, as it currently possesses so many definitions. A tighter definition would reduce the chances of damaging misinterpretation and enable faster growth and wider acceptance. However, the existence of this wide definition is exactly the reason regenerative agriculture has demonstrated such dramatic momentum. Is there is a place for an umbrella brand that remains a broad church, with more nuanced and focussed approaches developing their unique positions in support of the wider movement?

The regenerative movement is gaining momentum, in all its many guises, and combined with innovative technology and precision agriculture will increase the chance we have of delivering the food we need whilst enhancing soil health, biodiversity and nature reconstruction. Regenerative agriculture might not be perfect, but it speaks to many of the challenges we are facing and above all provides cut through to our most important judge, the consumer, so let us build on this opportunity.

-

Beyond the barrel: the unique process behind the added fulvic acid in L-CBF BOOST

By David Maxwell, sales director, QLF Agronomy

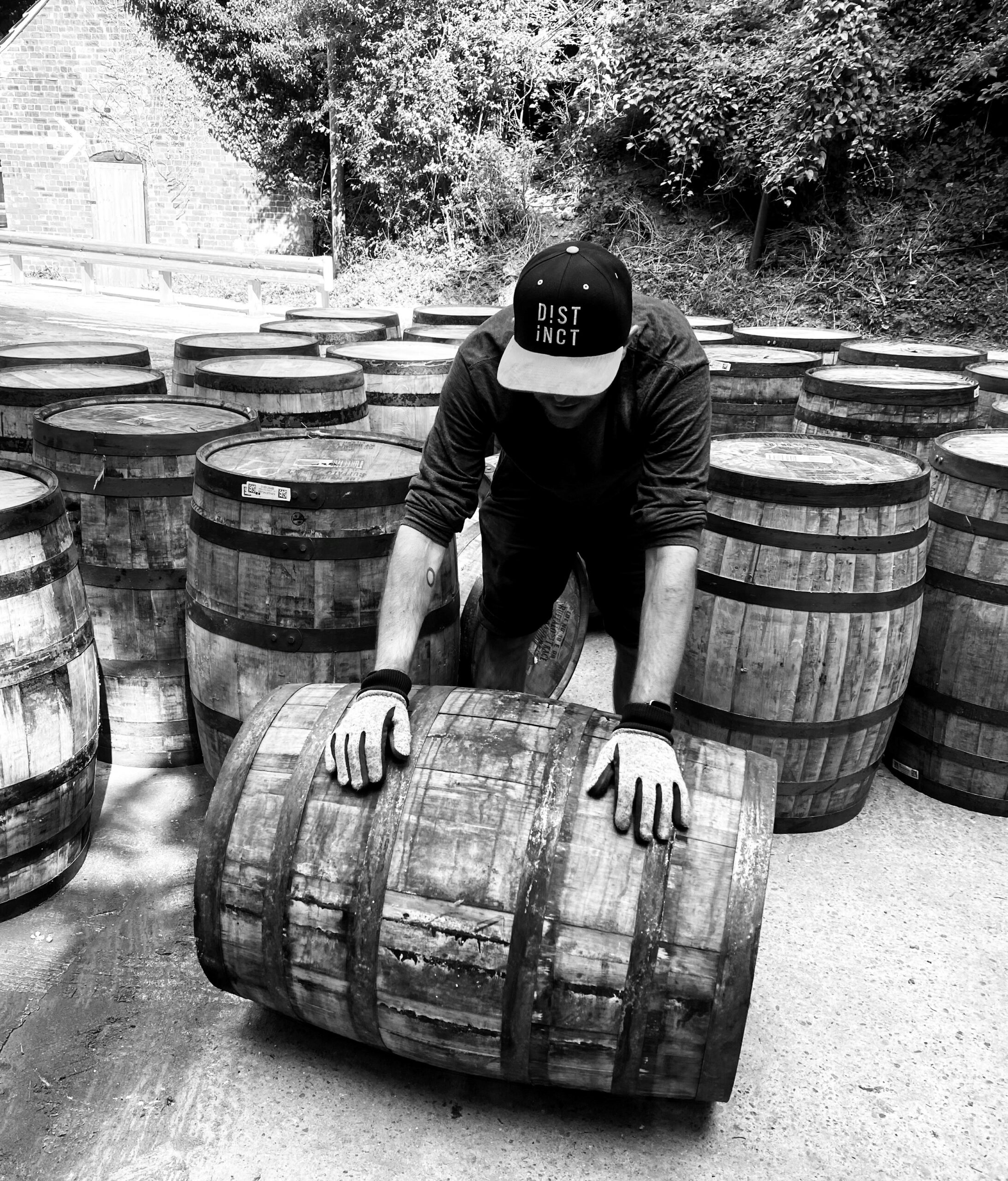

The welcome addition of a family-owned distillery at the site where QLF Agronomy products are manufactured not only gave us a healthy supply of rum, but we have also been able to ‘boost’ our BOOST with added fulvic acid as a byproduct from the distilling process.

Distinct Distillers is co-located with the Landowner, Quality Liquid Feeds and QLF Agronomy manufacturing site. It currently produces several white and dark rums using the same raw material that goes into our QLF Agronomy products – molasses.

The fermentation of molasses creates a lot of nutrients alongside the alcohol, and the distillation kills off any live yeast. What’s left at the end of the process is a distillate that goes to the other side of our manufacturing site for us to utilise in our QLF Agronomy products. This distillate has a high concentration of fulvic acid, which is ideal for adding to our L-CBF BOOST, TL17, TL30 and Amino 15 products.

It’s a win-win. The distillery has a willing customer for what would otherwise be waste, and farmers using QLF Agronomy products benefit from additional fulvic acid for their crops. This is on top of the existing fulvic acid in our molasses-based fertilisers.

With a 1,000L IBC of straight fulvic acid costing around £3,000, what we include from the distillery byproduct adds considerable value to a farmer.

Fulvic acid is a natural organic substance that improves soil health in many ways. Its importance to plant health comes from its open carbon structure and low molecular weight. It is an excellent chelating agent, meaning it can bind to nutrients and make them more available to the plant.

Fulvic acid enhances nutrient uptake by increasing the permeability of plant cell membranes. This results in improved nutrient absorption and utilisation by plants.

Alongside nutrient uptake, the other benefit of including fulvic acid with nitrogen is how it aids the conversion of urea into amino acids by providing a carbon source.

If a farmer applies foliar urea, it will also help uptake into the plant by neutralising the charge on the leaf surface. This stops urea, a positively charged cation, from binding to the surface and not being absorbed.

The molasses that form the basis of our products has similar benefits to plant health, but fulvic acid works in a complementary way.

Fulvic acid’s sister compound is humic acid, which is also becoming an increasingly popular input. It tends to go on the soil rather than the leaf. However, there’s evidence on grassland that humic acid is a more effective foliar feed than fulvic acid.

We don’t get any humic acid from the distillate. L-CBF BOOST already contains humates, the solid form of humic acid. This makes it an exceptionally rounded foliar feed.

Distinct Distillers is about to increase production, giving us access to even more fulvic acid. We are considering if we can use this to introduce a range of specific foliar fertilisers with higher concentrations of fulvic acid. For the moment, farmers can benefit from the flexibility that a product like L-CBF BOOST gives them when they apply it to the soil or leaf.

QLF Agronomy issues a guide to carbon fertilisers

A new technical guide aimed at helping growers understand the benefits of incorporating carbon-based fertiliser in their nutrition programmes has been created by QLF agronomy.

With so much focus in the last 50 years on nitrogen and the nitrogen cycle, the importance of carbon and the carbon cycle has been neglected. The guide explains how maintaining a healthy carbon-to-nitrogen balance helps soil microbes thrive, improves nutrient use efficiency and increases yields.

Contained within is trial data, recommendations for L-CBF BOOST, grower case studies and frequently asked questions. Farmers and advisors who download and read it are entitled to 2 BASIS and 2 NRoSO points.

Distinct Distillers: the drinks company improving soil health

Following a successful career in the drinks industry, Distinct Distillers founder Hannah Boon decided to set out on her own. She set up Distinct Distillers as a separate business from her family’s Landowner Group but linked through the same infrastructure.

They produce dark and light rums and plan to begin producing whiskey soon. The spirits are cask-conditioned underground using an old World War Two aviation fuel bunker. This provides a consistent temperature and humidity, which are ideal conditions for conditioning spirits.