If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Why Agriculture Is A Practice And Not An Industry?

Jon Williams provides a fascinating insight into the development of chemical farming, the super-importance of calcium and magnesium, and the limitations of using PH as a guide to fertilising. He ends with a useful soil sampling suggestion

At the end of the second World War there was rationing in the UK and the Government edict to agriculture was to expand food production and farmers quite rightly responded to that call as they always do and particularly in times of crisis. This has been recently highlighted with the Covid Virus raging the country and the shut-down of most industries but agriculture remained resolute and carried on producing food for the nation.

However there is a major difference between agriculture and other industries and food production from our soils needs to be re-classified as “The Practice of Agriculture”.

Why is this so?

Firstly it is important to understand that companies such as ICI were very powerful at the end of the war as they had produced all the raw materials used for bomb making such as TNT (Nitrogen) and Potassium from their mined resource at Cleveland. The call for increased food production resulted in these bomb making ingredients being used for food production. The drive for more and cheaper food is the ethos we have followed ever since and has resulted in a more industrial approach to agriculture involving inputs and outputs and the margin of cost between these two regarded as success or failure of the farming methodology principals followed.

This approach to agriculture has resulted in ever tighter margins of production as the costs of the inputs have risen, and the yields have stagnated. This has been made worse as the hidden cost of the depletion of the natural assets of the soil such as Organic matter have not been accounted for. The result of this is soils used for cropping only, being depleted of organic matter to the extent that 70% of all arable land in the UK has now less than 3% organic matter remaining. This situation obviously cannot continue and if the UK was taken as one large farm it is out of balance with the intensive livestock areas having too much organic matter averaging 9.5% (the results of over 900 soil samples in Wales).

For good soil structure, nutrient holding capacity and good water retention the ideal levels need to be between 5 % and 7% and farmers are increasingly becoming aware that they need to rebuild this organic matter with the introduction of cover crops and re-introducing grassland as part of a rotation with livestock, as well as reduced tillage.

This rebuilding of soil organic matter levels includes the sequestration of carbon as it contains 55% Carbon and moisture retention levels improve, up-to 170,000 of extra water per hectare being held within the soil per 1% increase.

With the emphasis on public good along with food production this can be termed as “Regenerative agriculture” as we develop systems to rebuild soil as well as produce food it is likely farmers who have this intention will receive financial benefits alongside building a more resilient business.

The increasing supply of fertiliser was encouraged by ICI when they set up a company still operating today to carry-out basic soil analysis which was a guide for farmers as to which fertiliser to purchase and a PH reading for liming requirements to ensure a better response to that chosen applied fertiliser. Today it is important to understand that this was a tool to be used to purchase fertiliser only and it is now time to consider a more detailed look into soil analysis for building resilience in the food production process.

With the increasing awareness of impending climate change with rising temperatures and more unpredictable weather patterns it is imperative that we transform our agricultural practices quickly.

To achieve this transition as quickly as possible we need to follow the Albrecht Philosophy of soil analysis which is the result of 36 years of research into soil chemistry and along with soil texture can be used to amend the soil to improve soil structure and the aerobic nature of soil. This method of soil analysis results in a picture being formed of the effect of past management on the soil and can be used as a management tool to take the farm forward for improved crop performance and at the same time sequester carbon.

Having carried out nearly a 1000 of these tests there are several issues which are being highlighted and the first and possibly most important is the realisation that every field can be different according to its past cropping policy and this is why we need to consider agriculture as a practice and not an industry.

The realisation that the soil sampling method is holding back the development of this approach to food production is key to building a more resilient business and that the two nutrients required in greatest volume in soil – Calcium and Magnesium – need to be raised up to 80% on the clay colloid with the balance between the two dependent on soil texture. This incidentally raises the PH and so it is not PH that is the key indicator for successful crop performance but the level of these two major nutrients that governs the response of other elements and enhances crop performance.

pH can be at optimum for ever!

The choice of liming material can be done when a detailed soil sample is carried out and I suggest that all purchases of lime from a quarry need to come with a full analysis as the soil amendment needed may be for Calcium limestone or Dolomitic limestone depending on the existing levels with no more than two tonne being applied at any one time. For major shifts in the levels of Calcium and Magnesium the liming always need to be done in volume, however for small adjustments the liming can be achieved using the granular products now available such as Calci-fert or Mag-fert. The introduction of these relatively new products means that we need never allow the PH of soils to drop below the optimum for ever and the potential for improved crop performance is ensured.

Calcium is “KING” in the soil as it can be considered the trucker that takes most other elements into the plant and the other major nutrient Magnesium has a key role to play in “Nitrogen Use Efficiency” within the plant and so correcting both these nutrients and raising the levels to near to 80% on the clay colloid is a priority and not PH as such, which is essentially a measure of Hydrogen Ions.

More nutrient dense quality food

The adoption of this method of assessing soil quality is key to future proofing the resilience of the practice of agriculture and switches the emphasis away from the industrialisation of farming towards a more holistic approach to food production with the added benefit of producing more nutrient dense quality food. This is highlighted by the fact that 50% of the UK population is short of Magnesium and we ignore this method of analysis to the detriment of our soils, our crop performance and the health of the people we supply with our produce.

Maintaining these two major nutrients ensures that the locked-up Phosphorus in the soil and applied soluble fertiliser Phosphorus is made more available to the plant. The positively charged Calcium will attract the negatively charged Phosphorus reducing the potential for run-off and severe lock up when more Aluminium is present as a result of low Calcium levels.

Farmers need to be rewarded when they produce such quality food and ensuring a fair price is essential for the shift towards the practice of agriculture and away from the more industrialised approach.

Monitoring soil with detailed soil analysis as a management tool.

I suggest farms are split into four areas for the purpose of soil analysis with a quarter of the farm being analysed every year and in year five the process is repeated. This needs to be the base from which to go forward before digital nutrient mapping and variable fertiliser rates can be employed successfully.

Min-Til

To ensure Min-Till is successful a good open structured soil needs to be established via this soil analysis method which when used to balance the major nutrients will produce and maintain a crumbly soil structure which is ideal for slotting in new seeds. So the need for traditional cultivation methods is eliminated and The Rodale Institute of America has been developing systems and machinery to introduce these methods for successful crop establishment on a wide scale including in organic agriculture systems. (therodaleinstitute .org)

-

Deeptill Radish The Living “Soil Drill”

Written by Christoph Felgentreu, Deutsche Saatveredelung AG · Bückwitz

Deeptill Radish (Raphanus sativus), also known as “melioration radish” is a plant breeding innovation. The focus was on a strong rooting performance to combat soil compaction during the crucifera selection process.

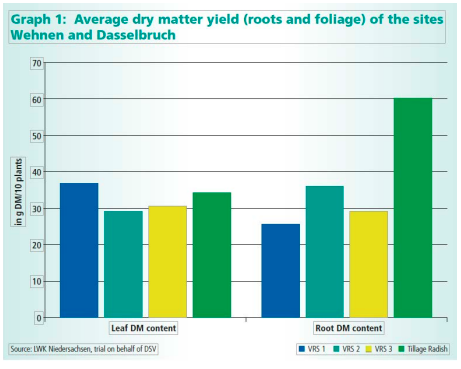

The aim of the breeding was to select a strong, aggressively downwards growing root. It should have properties similar to those of lupin roots: downwards vertical soil penetration, if possible even through compacted areas, such as tillage pans. This breeding goal has been achieved to a large extent (Figure 1). Today, Deeptill (DT) is also known to offer many other benefits such as a later generative phase, lower winter hardness compared with common oil radish varieties and faster soil warming in spring. The considerably many other benefits such as a later generative phase, lower winter hardness compared with common oil radish varieties and faster soil warming in spring. The considerably cover crop programme “TerraLife”, as its name suggests, places emphasis specifically on good rooting in the soil.

Warming the soil faster

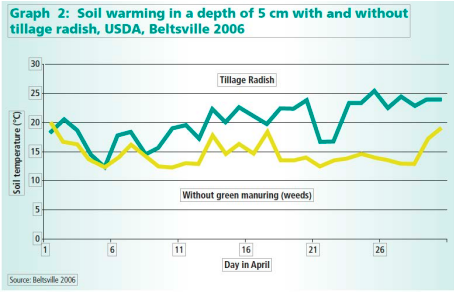

Another advatange of Deeptill radish is its ability to break up soil compaction and open up the soil, allowing the soil to warm up faster in the spring. Experiments by the U.S. Department of Agriculture (USDA) (Graph 2), were able to demonstrate the advantage of faster soil warming by Deeptill radish in spring. It allows the farmer for instance to sow maize earlier without deep cultivation. Deeptill radish will die quicker than other varieties of radishes (Fig. 3). Very shallow tilling or mulching in autumn can help to secure winter kill, particularly in a mild winter.

TerraLife DT

For the new cover crop season, DSV is offering mixes including Deeptill radish. These are marked with the abbreviation “DT”. These mixes are particularly well suited to limy sites, where lupins don’t grow well or possibly not at all, and combining the advantages of the other components in the mix with those of the radish.

The aim of the breeding was to select a strong, aggressively downwards growing root. It should have properties similar to those of lupin roots: downwards vertical soil penetration, if possible even through compacted areas, such as tillage pans. This breeding goal has been achieved to a large extent (Figure 1). Today, Deeptill (DT) is also known to offer many other benefits such as a later generative phase, lower winter hardness compared with common oil radish varieties and faster soil warming in spring. The considerably many other benefits such as a later generative phase, lower winter hardness compared with common oil radish varieties and faster soil warming in spring. The considerably cover crop programme “TerraLife”, as its name suggests, places emphasis specifically on good rooting in the soil.

Warming the soil faster

Another advatange of Deeptill radish is its ability to break up soil compaction and open up the soil, allowing the soil to warm up faster in the spring. Experiments by the U.S. Department of Agriculture (USDA) (Graph 2), were able to demonstrate the advantage of faster soil warming by Deeptill radish in spring. It allows the farmer for instance to sow maize earlier without deep cultivation.

Deeptill radish will die quicker than other varieties of radishes (Fig. 3). Very shallow tilling or mulching in autumn can help to secure winter kill, particularly in a mild winter.

-

Drill Manufacturers In Focus…

SOIL HEALTH BONUS FROM COST CUTTING SOLUTION

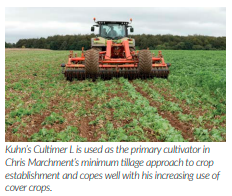

Cutting the cost of cultivations was the key driver for arable farmer Chris Marchment when he parked his plough for the final time 12 years ago.

Farming 80ha near Andover in Hampshire, just to the south of the North Wessex Downs, he faces the challenge working with clay-capped soils with flints. Under a conventional cultivation regime, the cost of wearing metal and excessive diesel use had become unsustainable, so he turned to a non-inversion minimum tillage system.

Initially building his own three metre machine, he then progressed to a four metre system where a single pass with a trailed shallow tine and disc cultivator precedes a min till drill. A decade or so on from his initial tentative steps, Chris is not only operating with substantially lower operating costs but is seeing a continual improvement in soil health.

“We’ve now reduced the cost of wearing metal down to around £5/ha and our diesel use for cultivations is in the region of £5 – £7/ha,” he says. “These cost reductions are vital, but its been just as beneficial to see the improvement in the overall workability of the land.”

One of his biggest hurdles when converting to min till was finding the right cultivator for his system. This wasn’t due to any shortage of choice, but more to do with a lack of responsiveness from most machinery suppliers.

“It was difficult finding anyone willing to demonstrate a machine without some kind of guarantee of purchase or payment for delivery,” recalls Chris. “In the end, I saw the Kuhn Cultimer working at a tillage event and it seemed to offer most of what I was looking for. Within a week of seeing the machine in action Kuhn had arranged a demonstration on the farm and we then had a machine supplied by T.H Whites of Marlborough.

“I’m not aiming to move a lot of soil, so wanted a machine that would create a good tilth within the top four inches. I also wanted a trailed machine, to minimise the amount of weight on the tractor. The Cultimer is relatively light, being as much as two tonnes less than equivalent four metre machines, and yet it is still very strong and well built.

“Run behind a 170hp tractor, we’re able to operate with low tyre pressures of around 12psi, which – along with flotation tyres on other machinery – means we’re reducing the risks of compaction.

“Most important of all is the quality of the seedbed that’s created. When one of my neighbours saw the job the Cultimer was doing he immediately ordered his own six metre machine, it was that good.

The Cultimer has three rows of staggered tines, a row of levelling discs and a rear roller. It’s a versatile machine, offering a range of cultivation depths down to 35cm, but Chris opted for a specification with front depth control wheels and with wings on the tines, so the machine works within the top 10cm of the soil. With his flinty soils front of mind, he also specified tungsten tipped points on the tines and has certainly seen the benefits, as he has from the double spring loaded non-stop mechanical break-back system.

“It’s certainly been worthwhile investing the extra in tungsten tipped points because after close to 1,000ha of work we’re still on the original set,” says Chris. “The spring back safety system really protects the machine and is a particular advantage in our conditions. The system operates with 600kg of pressure at the points, so ground penetration is very good, but when there is an obstruction the leg retracts a good distance and springs back into work immediately. I can cultivate up to 30ha in a day and that’s certainly helped by the efficiency of the spring back system.”

The typical rotation at Foxcotte Farm is a first wheat (yielding close to 10 tonnes/ ha) followed by spring barley, grown for malting, with either winter or spring beans as a break crop. These are now all established with a minimum tillage drill, usually after one pass with the Cultimer, but a second pass is used where a cover crop has been grown.

Cover crops, along with the practice of incorporating all the straw, are another important factor in improving the soils.

“We’ve not baled any straw for ten years,” adds Chris, “and we’ve started growing mustard as a cover crop more recently, avoiding where possible any bare soil over winter. The mustard is soft stemmed, and we only allow it to grow to about one foot high, so the Cultimer copes with this perfectly well and allows the drill to follow without any problems.

“It’s all part of building fertility and improving the workability of the soil, and that’s helping to keep the cost of establishment down.”

-

The Evolution Of The £8000 Zerotill Drill

Back in issue one of direct driller Mike Donovan of Practical Farm Ideas wrote about our budget no-till drill in his article “How to start drilling for 8k”. The drill had been bought and modified at the time to run along our John Deere 750a, partly to increase capacity to cope with a seemingly ever expanding workload in constantly tightening weather windows and also to provide a low disturbance tine option, complementing the disc coulter of the John Deere machine,

by Clive Bailye – twitter.com/TWBFarmsThe question of tine vs disc on notill drills has been frequently debated amongst farmers. The disc can cope with extraordinary amounts of trash that would turn a tined drill into little more than a rake yet it some situations the disc can push straw residue into the slot, a process commonly referred to as “hair pinning” with undesirable agronomic consequences for the plant, whilst the tine avoids this by sweeping the seed zone clear of trash.

Coulter designs like the Cross Slot and Novag drills combine the trash handling ability of a disc drill with the slot clearing characteristics of a tine equipped machine but come at a cost both financially and in terms of power requirement, for the direct driller looking for a single drill this design of coulter possible best provides that solution.

Some disc drills are fitted with row cleaners that clear the trash ahead of the coulter, as our farmed area grew and we needed to use both the 750a and converted C06 in situations with hair pinning potential we did ultimately end up with a set of Aricks row cleaners imported from Australia fitted to our 750a, which although a good solution, not a cheap option or always one available to UK farms. The initial modifications carried out to the CO6 are covered back in issue 1 but other than a good service, fitting a 2nd small seed / slug pellet / avadex applicator and conversion to a low disturbance point it was still mostly as it had left the Horsch factory. Since then we have covered many acres with this machine and the modifications have evolved to become what I now think it’s the perfect tine drill solution.

Drawbar

We opted to buy a European spec Co as the seed carts ran a far superior single floatation tyre than the small double castored wheel more commonly specified in the UK. As well as the obvious ground pressure advantage this design was much more stable on the road, the drawback however was a lack of machine following on the road making traffic islands and access to tighter gateways off narrow lanes somewhat of a challenge. The solution was to add an articulation between seed cart and toolbar creating a drawbar with K80 style ball hitch, doing this also created the ability to disconnect the toolbar from the seed cart completely if required and use it in the front hoper configuration described later in this article.

Conversion points

The drill was originally converted to low disturbance using Metcalfe points, these 12mm points provided a very low disturbance solution, however on our higher stone content soils they often lost the tungsten tip leading to premature wear, the seed tube was too narrow to flow large seed like peas and beans without blockage so needed upgrade to their larger tube diameter which was prone to rapid wear. To try and address these issues we set about making our own version, slightly wider at 15mm and using Ferobide wear tiles rather than the tungsten of the Metcalfe, the logic being that the Ferobide could be replaced if it broke off using farm workshop Mig welder rather than specialist induction welding that is required to reattached tungsten. We also added a slide plate to these farm designed points to protect the seed tube all of which gave a significant improvement to reliability and wear but at the cost of much more soil disturbance.

The other commonly used conversions for these drills are the Dutch Industries coulter and the Bourgault VOS (Versatile opener system) both offer a similar cast point with seed (and in some versions fertiliser) delivery run internally through the casting. Having run a test of both brands the Boulgault seem the better option, no only did it seem to wear better on our soil types but it offered more options for both solid and liquid fertiliser placement and a range of seed banding widths.

Possibilities with this coulter seem endless and open opportunity for companion cropping, seed and fertiliser banding and biological liquid placement separately or in the same slots. We started off using the 75mm twin band point which was very successful but in the terrible wet conditions and late drilling of autumn 2019 we moved to the single row 19mm point. I doubt we would have had half the area planted if we hadn’t used it. This point seems to be the sweet spot for us and I like the 250mm row widths which are the same as our Avatar disc drill. For farms with more challenging grassweed issues than we have I can see the wider twin row versions of this point would be a excellent solution. As well as the performance the wear rates seem low so I do not think we will look any further in the future than the VOS opener.

Packers

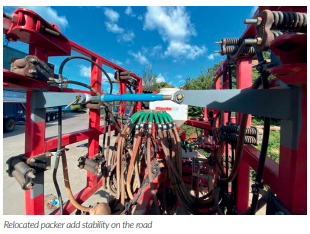

Our CO6 had clearly been loved by its previous Polish owner who had made several upgrades. Not only had they converted the rear packer to the later, more reliable sprinter style bearings but they had fitted a front packer to the toolbar. Such a front packer would have been ideal when the drill was used on cultivated land providing some consolidation ahead of the seeding. But in a none disturbed no tillage situation it was somewhat redundant. However when the drawbar conversion was done it served a new role in providing depth control at the front of the machine so was retained.

The tyres were a small diameter which in wet conditions could struggle to keep turning, they were also quite worn, punctures and a few tyres with damaged sidewalls ultimately made it more economic to replace its depth control role with 4 larger diameter wheels, we used the same size wheel and tyre as fitted to our 12.25 Horsch Avatar giving us a universal fitting spare.

The rear packer ran the standard CO car pattern tyres that were again getting quite worn and were less than ideal in wet conditions so these have now also been replaced with a similar size BTK tyre with a self-cleaning tread pattern again helping with wet condition performance.

Safety and stability

With the addition of the drawbar the stability of the machine when folded was reduced, the high centre of gravity less anchored by a fixed linkage. The solution was to remove the first packer axle from each of the vertical wings and reattach it to the centre section, giving a wider, more stable wheelbase but still within the 2.95m road legal transport widths. Another small addition has been the addition of a fixed top link locking bar to hold everything securely on the road and not rely on hydraulics or straps.

Front Hopper

The move to having drawbar connection between seed cart and toolbar offered the possibilities of running the drill with a front hopper rather than the large seed cart. This offered the advantage of a much-simplified machine with far better visibility of the toolbar for the operator along with enhanced weight distribution and 2 less tyres on the ground. This created a drill that’s wet weather performance is truly exceptional and was able to complete 100% of our 2019/2020 workload through record wet conditions. The combination of undisturbed soil, optimal weight distribution over as few weight carrying tyres as possible and the low disturbance coulter allowing the rear packer to run clean without soil contact. All worked together to establish crops successfully through a very difficult season.

The hopper we chose was the Horsch Partner, this fully ISO hopper uses the same control software as our Avatar and incorporates the same blockage monitoring system so is familiar to operators. Like the Avatar it’s a very simple one man operation to calibrate and has metering and fan capacity to cope with a 12 m toolbar giving us options to use it with the Avatar (giving ability to drill up to 6 products, meaning less pre missing of cover crops ) or with other 12m wide seeders in the future fitting in with the 12/36m control traffic farming system we operate. The hopper can be split into 2 products giving seed / fert or companion cropping options which with the versatility of the Boulgault openers creates a new word of possibilities!

Costs and Conclusions

Of course, over the years of development the cost has now moved on from the original £8000 spent buying and converting the drill, approximately an additional £6000 was spend on drawbar, opener, and packer conversion. The seed cart has been sold offsetting some of the cost of the front hopper the cost of which can be anything from £1000 for a well-used Accord unit at a farm sale to £20,000 plus for a fully specified ISO 2 product unit with blockage monitors

It’s taken us 4 seasons to fully develop this machine to where it is today, even after the additional spend it offers a relatively cheap and versatile no till tine drill that agronomically complements our Avatar disc drill, gives us additional capacity and offers a degree of insurance against wet conditions. It shows you don’t always need to spend huge amount on a new machine to direct drill. All it needs now (this winter’s project) is a sandblasting and a coat of shiny paint to smarten up all than “development mule” primer !

-

Feeling Tired?

If you are serious about reducing soil movement to reduce costs in fuel and labour without reducing yield through compaction what are your options, and how do you ‘dip your toe’ without financial commitment? “Just looking thanks” is the phrase while on a manufactures show stand whilst trying to form your own opinion. How do you do a bit of non-bias research on system change on your farm? AHDB’s Monitor Farm meetings are one way, either on-line or in the future back to face to face meetings. But again how do you build a system for your farm, based on your soil type, your area to be covered and time available to you?

To gain an idea of the size and width of a direct drill whatever design you choose you can look up the AHDB Machinery Calculator and mess with the width, forward speed and field efficiency (time spent actually drilling rather than turning and filling) and come up with a drill width to suit you. If the numbers don’t stack up, up the speed or more hours per day, eventually you will come up with a consensus of what you need.

But as the power needed increases so does the weight of tractor need to pull the drill. Can you assess the level of compaction going in below where your chosen drill is working? Based on the weight on the tyres, soil type and soil moisture, yes you can.

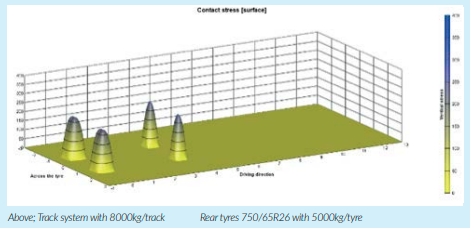

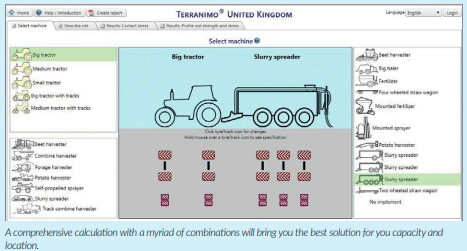

Terranimo is a website where you can select the tractor/implement combination or crop sprayer, combine harvester, beet harvester, Potato harvester, forage harvester for that matter. Select the tyres, calculate the weight on each tyre, select the soil type and soil moisture and calculate the depth of compaction based on the data you have entered. Hey presto you can generate a detailed report on your chosen set up. And, like the machinery calculator, if you don’t like what you see, change the numbers and try again. Nothing ventured and all that.

For the lucky living in Scotland the soils data is already entered, just pick your county and the soil data at 10cm steps to 150cm depth is available. Choose between dry, moist, and wet for your soil water content and choose if you plough and cultivator or not. For those not living in Scotland work is on going to bring England into the fold, but for now your soil type can be entered manually.

Of course, those reading these pages will be keen to remind of increased soil organic matter and higher magnesium content in clay soils would help too. But for now, lets keep it simple.

In choosing tyres there are over 800 tyre sizes, brands and designs to go at. Twin track and four track tractors are in there too. But I’m not pretending every brand and combination is achievable and the very latest tyre on the market may not be present. The website is the work of Aarhus University in Demark and the AHDB have been funding its availability in the UK.

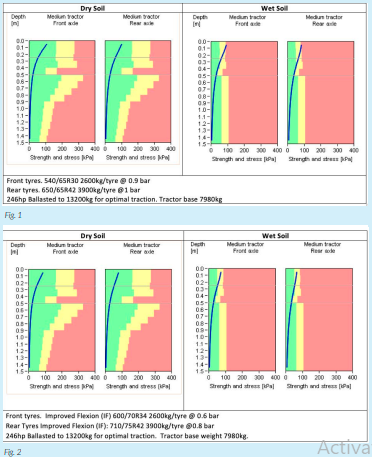

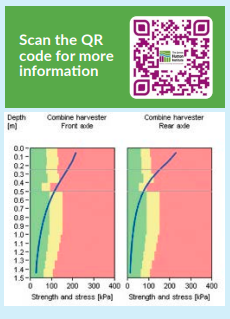

So, looking at a typical 246hp drill tractor (Fig.1), if it is ballasted to achieve full traction then the graphs below represent the soils ability to carry the weight of the tractor on the tyres selected. The blue line represents the tractors front and rear axles and the boundary between green and yellow corresponds to 75% of the calculated soil strength, and the boundary between yellow and red shows 125% the soil strength. In the wet soil condition graph both front and rear axles reach 125% to a depth of 10cm and compaction is still ‘going in’ at 50cm. In the dry condition graph, the soil is able to support the tractor without undue compaction.

If the same tractor is fitted with wider IF (Increased Flexion) tyres, (Fig.2), then things improve. But it must be stressed that the tractor is fully ballasted for full traction, so its unlikely in the real world to need this level of ballast for drilling.

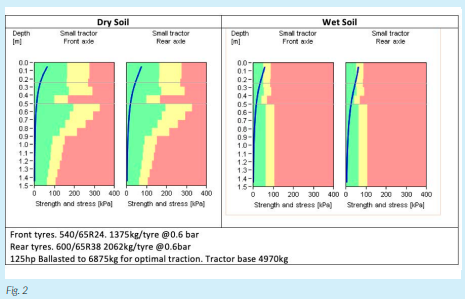

Looking at a 125hp tractor fitted with the optional wider tyres (Fig. 3) shows similar characteristics to the 246hp tractor on IF tyres and of course this is fully ballasted, worst case scenario. Removing the ballast, sheds almost 30% off the tractors weight.

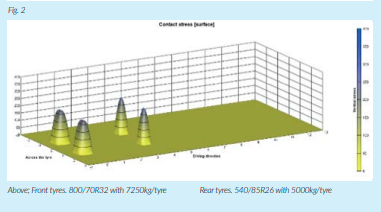

Choosing whether to go with tracks or a wheeled machine for your next combine? The Contact Stress function can point out the peak pressures from wheeled or tracked combines. Below is a typical large wheeled combine with 9-metre header fitted. With both grain tank and fuel tank full the front axle comes to 14500kg with 10000kg on the rear axle. Note the rear axle in this case is exerting more stress on the soil the front axle.

The same combine with the track option fitted show a marked improvement in soil stress, the front and rear rollers with two centre idlers exerting the peak pressures. This combine is also fitted with much larger rear tyres but still exert more stress than the track unit. Both combine calculations here used Dry Soil. But of course, this is not always available. Just as an illustration we have sent our fully leaden wheeled combine into wet, clay soil conditions. As you can see below the front axle did not find soil able to support its weight until at 50cm depth and the rear axle is little better. Yes, the combine is stuck. And if this where real, que the social media fest.

Obviously, the examples I have shown here, while real, are not likely to be what you need. So, get the kettle on, forget Strictly goes Dancing and have a go at calculating the right tyres, power, indeed farming system for your future.

-

Will It Work For Us?

Andrew and Sam Melton, new to the AHDB Monitor Farm programme this year, are looking at how to make cover cropping and direct drilling work on their soils at Wisbech, Cambridgeshire.

Farming silty clay loam soils and with a keen interest in farming sustainably, whilst improving yields and productivity, Andrew and Sam Melton have kept a keen eye on the developments in cover cropping and direct drilling over the last few years. Seeing how other farms have made the successful transition to using cover crops and shallow tillage, Andrew and Sam, the father and son team, invested in a new direct drill (John Deere 750A) last season and are now interested in how to get optimum output from the drill, soil and the crop itself for their business.

The Melton’s farm 1,400 hectares of silty clay loam soils near Wisbech, Cambridgeshire. Their rotation includes wheat, barley, winter linseed, beans and sugar beet. The farm currently operates shallow tillage and full inversion cultivation systems, but have been looking at reducing soil tillage.

Joining the Monitor Farm programme in June 2020, one of the areas that Andrew and Sam are keen to focus on is incorporating cover cropping and reduced tillage into the rotation. To start on this journey, this autumn, the Melton’s are doing a try-out and testing three different cultivation methods:

1. Plough with a 7F Gregoire Besson

2. Shallow tillage using a Vaderstad Carrier with cross-cutter discs

3. Direct drilling with the John Deere 750A

The three systems have all been trialled alongside each other in a field, which was winter wheat last season. Following the combine, a catch crop (buckwheat, millet and sorghum) was established on some of the tramline plots but not where ploughed.

In addition, the shallow tillage area has a section with and without straw. Andrew is interested to test which of the systems works better for managing straw residue, something that he is keen to get right for optimum establishment.

In this way, one part has been chopped and the second section baled and removed. Measurements will be taken across the try-out areas through the season, including a look at soil (soil analysis, resistance, infiltration and structure), residue (levels left on the surface after drilling) and plant measurements (emergence, canopy cover, plant, tiller and ear counts, NDVI and yield).

The farm business also actively uses technology throughout all operations and to effectively manage fields and areas. As part of this try-out, fuel use and machinery telematics will be analysed to look at the impact of the different cultivation methods, alongside an analysis of the costs of using the different establishment systems. Building on previous farmer experiences, existing industry research on cover crops and now having the opportunity to try this on-farm, it is hoped that this will start to build a picture of how the Melton’s can best employ this system effectively for their business in the future.

Results will be shared in a future issue.

-

Arbuscular Mycorrhizae All Greek To Me!

In this article, Jason Pole explores the crop-friendly fungi focus of one of our crop PhD studentship projects, funded by AHDB Cereals & Oilseeds

If your crop roots are in good nick, there’s a decent chance they’ve cuddled up with some potentially powerful soil allies: arbuscular mycorrhizal fungi (AMF). The word ‘mycorrhiza’ stems from two Greek words: mykos and rhiza, which mean ‘fungus’ and ‘root’, respectively. Unlike fungal pathogens, which infect and damage plants, AMF form symbiotic relationships with roots – in a healthy game of give and take

AHDB PhD student George Crane has developed a fascination for AMF, which are ubiquitous in nature. AMF colonise root cells, undergo intense branching and form ‘arbuscules’ – sites for fungus–plant metabolite exchange and nutrient accumulation.

Based at NIAB, George leads on a series of field-scale trials and glasshouse experiments that aim to tap into the potential of AMF for crop production.

As part of a UK soil assessment programme, the effect of common farm practices on AMF diversity and abundance has already been examined. For example, deep cultivations influenced AMF species composition, with disrupted soils potentially hosting fewer beneficial species.

Cover crops, which deliver various benefits to farming systems, can also promote AMF. This aspect is under investigation in two fully replicated trials in Norfolk (Bawburgh and Morley). Various cover crop species are being tested – sometimes with a helping hand in the form of commercially produced AMF inoculum (five species).

The study has also linked with Innovative Farmers (IF) too, to apply these findings at the farm scale. The research is providing a steer for onfarm trials at six sites that use cover crops and anaerobic digestate (AD) to influence AMF. So far, all trials have delivered mixed results. However, longterm use of cover crops is most likely to deliver a positive effect on AMF communities.

The work has also refined the use of targeted primers that amplify specific AMF DNA. Such molecular approaches can help detect the presence of fungal species in soil samples. For example, George’s work has confirmed the presence of 87 AMF taxa in the UK soil assessment samples, which will now be further investigated.

With UK farming under increasing pressure to demonstrate its sustainability, AMF provides another great opportunity to harness and work with nature. The PhD, which receives part funding through the AgriFood Charities Partnership (AFCP), is due to conclude next year.

For more information:

-

Drill Manufacturers In Focus…

ESTABLISHMENT COSTS V RETURN

For once weather conditions were similar around the country, poor conditions in the backend of 2019 leading to a lot of ground remaining undrilled or those that had been, failing due to water logging. A late start in spring thanks to prolonged rain on heavy land delayed drilling until well into April, then it stopped and didn’t start again until most crops looked as though they had just about expired. The plants then decided that with a bonanza of water they would “wake up” and put their new found energy to great effect and a late surge of secondary growth led to crops looking much improved but meaning a late harvest and very uneven ripening.

Interestingly we had a trial field of Spring Oat, drilling 5 acres with the farms conventional system of power harrow followed by a Vaddy, to the other 5 acres drilled direct onto last backend sumoed ground which had been successfully treated with roundup. All drilled the same day, unfortunately due to operator error a 4.8 metre strip was missed the length of the field in the direct drilled plot (more on this later). The two crops emerged at the same time, thanks to the Vaddys narrow row spacing and even colour of the freshly cultivated soil the crop appeared to have a much better coverage/emergence than the direct drilled crop. But as the crop grew in the dry conditions whilst the direct drilled crop remained a healthy dark green virtually until the rains finally came, the cultivated crop look thoroughly sick, yellow and with every wheeling of the previous operations evident.

Certainly next doors conventionally worked and drilled field (inset) doesn’t look any different to Ma/Ag direct drilled the same day with double the horsepower per metre!!!

We just now need a bit of warmth to get things moving

In order to widen the appeal of the Ma/Ag drill and offer a much more price competitive units for smaller farmers and contactors wishing to start down the direct route, we have launched ready for Spring (when it arrives !!!) a 3 metre mounted version of the Ma/Ag drill. Utilising the same fully floating coulter unit with its twin disc design, including scalloped straight disc and angled plain disc with a rear rubber press wheel.

If you want to carry tools, fuel or perhaps some cover crop seed, maybe you should treat yourselves to a WorkBox ideal for anyone who needs to have a workshop in the field?

The lid is waterproof and dust proof so every angle is covered, although dust seems a way off at the moment !

More details on drills or Workboxes

contact Ryetec on 01944 728186 -

Tyres In Focus…

COMPLETE TYRE PRESSURE SOLUTIONS

Written by Chris Dolman from Michelin UKMichelin is introducing its latest agricultural tyre technology into the UK with the launch of Zen@Terra for high-powered tractors – enabling farmers to easily adjust tyre pressures for heavy road and field work.

Designed specifically for fitment in combination with a central tyre inflation system (CTIS) and Michelin’s Ultraflex tyre range – although it can be used with any Michelin agricultural tyre – Zen@Terra connects directly into the tractor’s ISOBUS system. Once installed, it allows farmers to switch between low pressures, for maximum soil protection, and higher pressures, to maximise performance on the road. The process takes a matter of minutes and can be operated via an easy-touse, integrated in-cab touch-screen display.

Pre-programmed settings allow the user to tailor pressures depending on the implement attached and vehicle usage. Pressures can be adjusted for empty, half or full loads, as well as slope work. A ‘boost’ function sets extreme low pressure for three minutes, when extra grip is needed.

Compatible with most modern tractors, it is the result of years of research and development by Michelin’s team of expert engineers and, following successful trials across Europe, Zen@ Terra is now being rolled out to farmers and contractors across the UK.

Mark White, Michelin’s National Sales Manager – Agriculture & Construction, says: “Michelin is determined to keep helping farmers get the absolute maximum performance from their machinery

“Zen@Terra is a complete solution, managing all aspects of tyres and their interaction with the ground, both in the field and on the road. “Using an in-built CTIS and our Ultraflex technology tyres, the customer can quickly change tyre pressures to best suit the ground they are working on. This helps to optimise the performance of their vehicles, increases tyre life, improves productivity and yields, while reducing fuel costs and protecting the soil – all of which supports Michelin’s core value of sustainable mobility.”

The system has been developed following direct feedback from farmers and contractors, with Michelin focused on developing a solution offering maximum quality and reliability. The in-built CTIS was designed in conjunction with PTG – industry leaders in tyre pressure control systems – which Michelin acquired in 2017. Zen@Terra can be used with any Michelin Ultraflex agricultural tyres; including Michelin’s AxioBib, AxioBib 2, EvoBib and XeoBib fitments. It will be fitted exclusively in the UK by approved supplier TractAir – a family-owned company which designs, manufactures, supplies and fits air brake systems, air compressors and tyre inflation systems for agricultural applications.

-

Drill Manufacturers In Focus…

This year has been an incredibly busy year for us. We sent our first DSX seeder to our customer in February 2020 and have now manufactured over 20 which has been a huge effort from our team.

We now have DSX seed drills in the UK, Tasmania, New Zealand, Germany, Denmark and France. We also build planter frames, planters and soon strip-till units. We have faced a global pandemic that has not been seen before in recent history. Supply issues have been there to be dealt with – and that has not been helped by one of the wettest autumns on record which led to earlier demand for sold seeders. We are a UK company based near Spalding in Lincolnshire. We firmly believe in employing local people and as such we are a significant employer in our local area.

We invested over £500,000 in a semi-automatic blast and paint line, we did this to ensure a high end premium finish that the major OEM’s are using. This preparation and paint process forms part of our whole business model, to produce premium, long lasting machines that are upgradeable over time. We believe this is the future in machine manufacture to allow the entire agricultural industry to become more sustainable and to counter the ever-increasing operation costs.

Our assembly hall works on a bay principle. We aim to have all the parts arriving in the bay for each machine just as the assembly team want to assemble them onto the seeder. This requires a lot of coordination with our purchasing department as the only thing that is the same about every seeder we build is that each customer has a different specification.

Once the machine is assembled, we then spend a day inspecting it. The machine is connected to a hydraulic test rig and every function is checked to ensure leak free operation. The machines controller is programmed ready for delivery – with all electronic functions also being checked.

We are passionate about the entire manufacturing process from design to PDI and although it has not been easy to setup so quickly, we have a great team and are proud to be where we are today. There is a great ambition I feel pre and post Brexit for the UK manufacturing industry to thrive and it has been great to see British farmers choosing British made products. The DSX has been designed to be modular.

This means that should your needs change you can add or remove parts to the machine. It could be that you need to go up a size and make your 4m machine a 6m machine. We can sell you the parts accordingly so that you do not need to purchase a new seeder. Same goes for liquid, row cleaners and automatic downforce. When we did this we realized that we would need to make the seeder long lasting and robust. It’s been designed with high quality bearings, bushes and parts as possible to ensure a good longevity.

We back all of our machines with a two year manufacturer’s warranty. We carry a good inventory of stock ensuring that most crucial parts can be supplied on a next day basis. We have invested heavily in our people and have a dedicated service and parts team.

It is very important to prove and demonstrate the agronomic advantages of our opener and options. We have to give the user a return on their investment and as time goes on we will run studies and detail results on our website which will be independently verified. We also hope to welcome people back to our farm for open days when restrictions lift. We wish everyone the best for this autumn drilling campaign!

If you would like any further information about our products please get in touch with us. Our contact details are as follows:

Sales + technical advice:

Tom Carnell (UK)

Tom.carnell@horizonagriculture.com

Mobile: 07487 387265Service:

Jon Gray

Jon.Gray@horizonagriculture.com

Mobile: 07551 908595Spare Parts:Lee Graves

Lee.graves@horizonagriculture.com

Office: 01945 440999

Mobile: 07368 237149 -

Methane And Microbes

Written by Sally Morgan who edits Organic Farming magazine smorgan@soilassociation.org

With ruminants getting bad press at the moment over their methane-filled belches, Sally Morgan looks at the science and the critical role of methane-eating microbes

Are ruminants really to blame for the rapid increase in methane levels over the last decade?

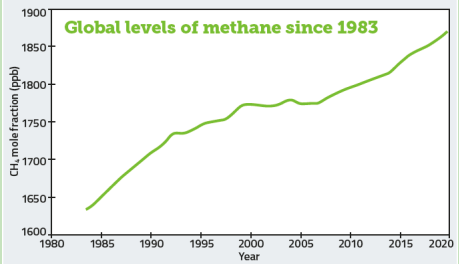

There is no denying methane is a significant contributor to climate change. Its global warming potential is said to be as much as 28 times that of carbon dioxide, but it has a much shorter life of around 12 years. The concern about methane is the sudden surge in levels since 2008. It came out of nowhere and scientists are still unsure of the cause. Current levels are just under 1,900 parts per billion, contributing an estimated 20 per cent of total atmospheric warming to date.

Commentators have been quick to put the blame on ruminants, a blame game that started back in 2006 when the UN Food and Agriculture Organisation published a study entitled Livestock’s Long Shadow. The study claimed that livestock production was responsible for 18 per cent of all greenhouse gas emissions (a figure which has since been revised down considerably). Since then, many organisations have called for a reduction in meat consumption and a switch away from extensive systems to intensive ones, in which animals are raised quickly on grain and soyabased diets that generate less methane. However, it’s becoming increasingly apparent that the methane story is far from clear cut.

Methane sources

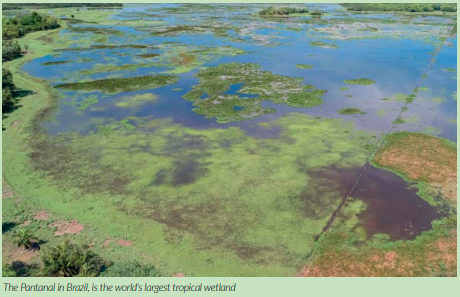

There are various sources of methane, both natural and anthropogenic, with the latter being responsible for about 60 per cent of global methane emissions. Methane is released by microbes called methanogens during microbial decomposition of organic matter, especially that which takes place under water in anaerobic conditions as found in wetlands and paddy fields. It’s also released by microbes living in the gut, in particular, the rumen of ruminant mammals and the gut of insects, such as termites.

Methane is released during the decomposition of natural gas, the so-called geological methane, which is stored in underground reservoirs and reaches the surface via seepage, geothermal and hydrothermal activity etc, along with climate-active ethane and propane. Other sources include fossil fuel extraction, fracking, mining, landfill, waste management and the manufacture of nitrogen fertiliser (see Organic Farming 131, Summer 2019).

Interestingly, atmospheric methane levels did not rise between 1999 and 2006 despite a 70 per cent increase in livestock numbers and looking further back to times when vast herds of ruminants were grazing grasslands across the world, methane levels ranged between 350 and 750 ppb. So what’s caused the dramatic rise over the last 12 years? There’s much finger-pointing. Some put the blame on leaks from gas fields, while recent research from Cornell University puts the blame on the boom in the US shale gas and oil industry. Discovering that the chemical fingerprint of methane from fracking differs from that released by traditional fossil fuels and livestock, researchers were able to track the source. They claim that as much as a third of recent methane emissions may come from shale gas development. However, others suggest that tropical wetlands are the only source large enough to explain the sudden rise.

Methanotrophs

It’s not just methane sources that are important; we need to know how much methane is oxidised to carbon oxide and water. This happens naturally in the lower atmosphere but there’s another methane sink of interest, a group of microorganisms called methanotrophs. These are single-celled organisms, such as bacteria, that consume methane as their source of carbon. They can be aerobic or anaerobic and are usually obligate, which means that methane is their only carbon source, so they are particularly common in places where methane is produced. Without them levels of methane would be much higher. In fact, half the methane released by wetlands may be taken up by methanotrophs and oxidised (Dunfield, 2007).

Boosting methanotrophs

Little is known about the soil-living methanotrophs. We know they are found in a range of soils and survive on low levels of methane and that soil management affects their numbers. In conventionally managed soil, the continued application of inorganic nitrogen fertiliser reduces the capacity of soil to oxidise methane and this is linked to reduced numbers of methanotrophs, whereas organic sources of nitrogen, such as manure, enhance the ability of soil to oxidise methane (Brady, 2002). Tillage and other soil disturbance will also adversely affect their populations, reducing numbers by as much as 80 per cent (Evershed, 2012). So, to boost methane oxidation, soils must be well aerated, and tillage and the use of inorganic nitrogen sources avoided. Also, research on alpine meadow soil found one group of methanotrophs to be strongly boosted by the grazing of cattle (Abell et al, 2015).

Livestock emissions

Ruminant emissions vary, even within species. Cattle, for example, produce between 164 and 345 mg of methane per day, with cattle on high-fibre feed producing more methane than those on a grain-based diet. But, as always, the whole picture has to be considered. Grain-fed beef animals may emit less methane, but overall, the energy required to finish these animals is twice that of pasture-fed, because of the use of fossil fuels in growing, harvesting and transporting grain, with additional greenhouse gas emissions from the manufacture and transport of nitrogen fertilisers etc. So, when looking at the lifecycle, it’s important to offset any methane production with sequestering gains; a well-managed, rotationally grazed permanent pasture will sequester carbon, so helping to offset methane production by the animals.

Plenty of lab-based studies have measured methane in a cow’s burp, but this takes no account of its lifestyle. When they are on pasture, head down and grazing, a burp of methane soon gets mopped up by methantrophs living in the soil. If you have a well-managed pasture with a soil rich in microorganisms, methane is not so much of a problem. But place them in unnatural situations, such as vast feedlot in the US or on a poorly managed pasture in the UK that is regularly fertilised, you disrupt the system and the soil will be less able to deal with methane.

Simply tweaking the diet can result in fewer methane emissions: for example, the feeding of sainfoin silage, adding more oil or seaweed. Biochar, too, may have potential. Research shows that biochar can increase the ratio of methanotrophs to methanogens in paddy fields and a similar process may occur in the rumen

Intensive systems

Many overlook the role of intensive livestock operations. Animal waste from intensively raised pigs and large dairy operations is typically stored in lagoons and slurry holding tanks, where the anaerobic decomposition of the organic material produces methane (as well as nitrous oxide which has almost 300 times the GWP of carbon dioxide). This can be avoided if the slurry is fed into an anaerobic digester and the methane captured, or the manure is spread on to heathy soil where dung beetles, earthworms and other soil life can pull it into the soil to be worked on by decomposers and the carbon locked up. Under these systems there will be no significant methane production (FAO, 2002).

There is no easy answer to the livestock question. I don’t think anybody wants a shift to highly intensive systems with all the welfare issues that would result, but without livestock, we’d need more plant crops and they require nitrogen. A lack of manures would mean more land under fertility-building leys or more inorganic nitrogen fertiliser which has a major role in the methane story. It’s a complex situation, whatever food type is producer, there are methane implications.

-

Drill Manufacturers In Focus…

COLLECTING AND MANAGING DATA

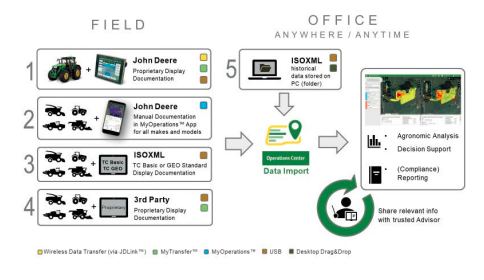

Farmers have to collect a large amount of data to manage their farm and for documentation requirements. With the ISOXML standard it’s possible to transfer field data from machine displays of the most popular manufacturers to the John Deere Operations Centre. In this way, John Deere is able to support customers that work with mixed equipment fleets.

Data commonly recorded by farm machinery includes field borders, application rates and crop yields, with the information helping farmers to operate more efficiently, cost-effectively and sustainably. However, customers with mixed fleets have often failed to successfully transfer and merge such data into as few software solutions as possible in the office.

The John Deere Operations Centre enables farmers and contractors to exchange different data formats, and there are several ways to transfer data from the machine to the Operations Centre:

• John Deere machines are connected directly and wirelessly with the Operations Centre via JDLink Connect, without any additional costs. Depending on the application, the data can be viewed in the Operations Centre in almost real time and work progress can be measured. Alternatively, the operator can use a USB stick.

• Field data from machine displays that use the ISOXML format can be transferred to the Operations Centre from the beginning of August, but a USB stick is needed for the exchange. Historical machine data can also be included if still present, for example when stored on a computer.

• Proprietary data from other machine displays can be sent to the Operations Centre via a USB stick. In addition, data can be exchanged via a smartphone using a dedicated memory stick. The data can be forwarded from the phone to the Operations Centre using the John Deere MyTransfer app.

• Manual documentation of field work is also possible. This helps for example when collecting information from machines without a documentation function, or if the driver has forgotten to start the documentation process. In this case, all data can be typed into the MyOperations app on the smartphone. Manual documentation via the app is currently available for soil preparation, drilling and crop care applications such as fertilising and spraying, with harvesting data to follow shortly.

In addition to seasonal machine documentation, the Operations Centre user receives a comprehensive digital field book. Customers can view and manage all data from any location using a computer browser or smartphone. The John Deere Operations Centre and MyOperations smartphone app are free of charge. In addition, the exchange of data from various sources does not involve any fees for farmers or contractors. John Deere dealers can provide further information on compatible displays plus the various data formats and transmission options available.

-

More Support Required For Agroforestry

Written by the Soil Association

A survey of 346 people interested in agroforestry reveals much greater support, information and payment certainty are needed for farmers and land managers to implement agroforestry in the UK. Planting trees on farms can boost farm productivity by 30%[i] and bring a range of benefits including improved soil health, carbon capture, biodiversity and animal welfare. It would also support Government tree planting targets.

Respondents were asked to complete the survey after downloading the free Agroforestry Handbook, produced in collaboration with the Soil Association and the Farm Woodland Forum to help farmers decide which trees and systems are best for their farms. The handbook gave most farmers more confidence to implement agroforestry, with over 75% of respondents more likely to implement agroforestry on their farms after reading the guide. Respondents’ most common motivations were increased biodiversity, landscape resilience, and farm resilience.

However, despite strong interest in the benefits of agroforestry for farms and the environment, the survey found significant barriers holding development back, including a lack of technical knowledge and uncertainty around support payments. Around 40% of respondents did not know where to go for further guidance on agroforestry, with many others finding that the information they need from government simply does not exist.

Ben Raskin, Head of Horticulture and Agroforestry at the Soil Association, said;

“The UK is amongst the least wooded countries in Europe – with only 13% of the UK under trees compared to 38% on average in Europe. Planting more trees on farms can be a win-win for climate, nature and health and would support the huge ambition of the Government’s National Tree Strategy. The UK is already well behind on our Government’s own targets and there’s been other issues, like the potential impacts on wildlife. It’s critical for nature and climate that the right trees are grown in the right places.

It seems a no brainer for UK government to provide a supportive policy framework and more clarity on payments in order to increase the uptake of agroforestry. Tree planting can and must play a vital role in a green recovery – tapping into the strong appetite for agroforestry could support more resilient farming, and help restore nature, health and a safe climate.”

Dr Tim Pagella, Lecturer in Forestry at Bangor University and co-author of the Agroforestry Handbook, said:

“Agroforestry is a new name for an ancient practice. Trees have potential to play a critical role as we move towards more sustainable and ‘climate smart’ food systems. Careful integration of the right trees onto our farms can improve soil and animal health, create diversification opportunities, enhance biodiversity, reduce inputs and deliver public goods in our rural landscapes.”

Survey respondent and Woodland Consultant, David Cracknell, said:

“One silver lining of Brexit should be that we can now shape our own domestic agricultural grants scheme so that we pay farmers to plant trees on their livestock farms – to improve soil, carbon storage, livestock well-being, productivity and the environment as a whole. With the right political will we could really lead on agroforestry in this country. We have the expertise.”

The handbook also highlights opportunities for UK farmers to reduce farm inputs and replace imports with tree products such as fruit, nuts, fence post timber, animal bedding, fuel wood and mulches. Research by French think tank IDDRI has shown that in Europe a ten-year transition to agroecological farming practices – like agroforestry – would slash agricultural greenhouse gas emissions by 40%, help to restore biodiversity and protect natural resources – all while producing enough healthy food for Europe’s growing population.

-

Robots As Everyday Tools

Written by Chris Fellows based on information from AgroIntelli

After six years of intensive work, the new generation of Robotti, the autonomous implement carrier, celebrated its world premiere at Agritechnica last year amongst as lot of other robot technology. Built by Denmark’s AgroIntelli, it’s among the first autonomous implement carriers of its kind on the market and the way they have approached farming problems is certainly interesting.

The Robotti 150D is a versatile, autonomous implement carrier, with the power of a medium-sized tractor, but without a driver. Robotti is one of the first usable robots that can be used for harrowing, sowing, mechanical weeding, spraying and so on. Outputs of up to 3ha/hr are possible, depending on the task being carried out.

“With Robotti, we are at the start of a new agri-tech era in agriculture and horticulture where autonomous implement carriers become commercially sustainable and can be integrated into daily operations,” AgroIntelli sales director, Henrik Lynge Jacobsen, said.

“Timeliness, uniformity, time savings and sustainability are the major arguments for acquiring Robotti. For example, it is lighter and the soil can carry it as sooner, helping the farmer optimise sowing time.”

Robotti is equipped as standard with a laser scanner, camera and RTK/GPS, which provides precision of +/-2cm. AgroIntelli’s Robotti 150D is an evolution of the unique, autonomous concept that the company has tested during the past year with good results. These results have now been incorporated into the new model for 2020. It is larger and more capable, with bigger wheels and 150hp. A version with 75hp, called Robotti 75S, will also be available. Among others, Robotti has already been sold to Wageningen, Ghent and Aarhus universities, where it’s part of experimental work within robottechnology.

The new large version is equipped with two 75hp Kubota diesel engines that provide plenty of power and good operating speed of up to 10km/hr. In addition, the hydraulics come with three double-acting outlets and one return outlet. It offers ample power to handle a variety of implements via its standard three-point linkage. With a full height of 92cm, Robotti can also work during crops’ later growth stages. The centre mounting and the even distribution of weight on the four traction wheels helps balance the power and efficiency. Robotti is 35-50 per cent lighter than a similar conventional tractor, significantly reducing soil compaction.

Precision and safety are high priority

Precision and safety are based on digital technology and are a high priority for AgroIntelli. Robotti is equipped with a laser scanner, camera and RTK/ GPS as standard. The security systems have built-in redundancy and function independently of each other.

As an option, Robotti can be equipped with a number of powerful software packages, including plant counting and weed intensity measuring in the form of “weed maps”. Work plans for Robotti are managed online, where the user can use existing GPS field maps or create new ones. A computer calculates the most effective route plan to minimise fuel consumption, but also to minimise structural damage to the soil.

The log function also controls the machine history, with detailed maps stored and documented for each job. Likewise, images and recordings from mounted cameras and sensors on the autonomous robot can be stored via the logging function. During development, it was important for AgroIntelli to let Robotti operate under realistic conditions. Therefore, it’s equipped with standard Kubota engines and reliable hydraulics for low operating costs ,and easy servicing and maintenance.

Robotti is being used profitable

Henrik Lynge Jacobsen said the company’s calculations show that it pays to invest in a complete Robotti solution with tools for growing potatoes compared to a similar investment in a conventional tractor with implements.

“We have calculated the cultivation of 100ha of potatoes annually for a fiveyear period,” he added. “With Robotti, the return on investment is 181 per cent versus 138 per cent for the conventional tractor solution. This is partly due to lower labour costs and higher dividends because of less structural damage in the field.

“The robots are ready, and now it’s up to the agricultural industry to adopt the new technology.”

How AgroIntelli are approaching solutions

Ole Green, CEO of Danish robotics company AgroIntelli, wants his solutions to be unique and not just replicate other ideas. Looking back at what has happened historically in farming helps his team do this, he even takes them to agricultural museums. He feels that modern day farmers have got detached from the soil itself, spending more time in tractor cabins, with air conditioning far away from the soil. Farmers of previous generations would have spent far more time walking their land.

Therefore they have taken the approach with Robotti to work with implements that already exist. Thus the robotic elements add valaue to the current equipment as opposed to simply replacing it. This is a similar concept to what Continental did and was written about in Direct Driller Issue 9. However Robotti is in a much bigger scale. You can see the machinery in action via the QR Code.

-

Field Robots Meet Farmers’ Mechanical Weeding Needs During The Corona Pandemic

Written by Malene Conlong from the German Agricultural Society (DLG)

The DLG Digital robot webinar explored mechanical weeding as alternative to herbicide: Field requirements, monitoring, wear parts, solar power and remote service.

As farmers around the world face challenges in the use of herbicides in crop production, autonomous robot, capable of mechanical weeding on the field, offers farmers an attractive alternative. At the online robot webinar “Robots for mechanical weeding” organized by The German Agricultural Society on 16th June 2020, international experts in field robots from academia, research and industry discussed what is practically possible for farmers today, including using field robots during the Covid-19 pandemic.

Mechanical weeding offers a solution to farmers in a number of ways. “Either the herbicide does not work as well or is not allowed anymore or, in some cases, societal pressure means some products, like glyphosate, cannot be used anymore. This is where autonomous mechanical weeding could provide a key solution,” said Klaus Erdle, DLG Competence Center Agriculture, introducing the DLG Digital webinar.

FarmDroid

Designed for fields of up to 20 hectares, commercial robots with the dual feature of seeding and weeding from the Danish company FarmDroid are already working on several European farms, having covered more than 1000 hectares in the Spring of 2020. Using high-precision geo coordinates to seed and weed, the robots are solar powered with a back-up battery and operate with 8 mm accuracy within and between rows, which means manual weeding is significantly reduced and in some cases not necessary at all”

“As a fast response to the Covid-19 pandemic one customer even ordered a second robot”, says René Jannick Jørgensen, CEO of FarmDroid, which shows that mechanical weeding robots are already considered to be reliable workers, also in a crisis.

The autonomous robot, which weighs some 700 kilos and has a working width of three metres, works both thoroughly and precisely at a steady pace of between 450 and 900 metres per hour.

The FarmDroid can be left in the field over the season and will carry out the work by itself through its connection with the RTK station.

Arno Ruckelshausen, Professor at the University of Applied Sciences Osnabrueck, Faculty of Engineering and Computer Science, Germany, noted that there are still legal and technical obstacles that need to be overcome before field robots will overtake the herbicide solutions.

With 30 years’ experience in mechanical weeding and field robot solutions for tractor-driven implements, including various sensor technologies, Germany company K.U.L.T. (Kress Umweltschonende Landtechnik GmbH) showed that autonomous mechanical weeding in the field is possible, but currently due to legal constraints still needs to be supervised by the driver.

In fact, farmers need to be actively involved when employing a field robot. “Farmers have to make a step towards the robot too, being open-minded for new developments, but also things like security systems to make them stop if there is a problem and, of course, they need to monitor the robot. A full control of the systems is important for the future set-up on farms,” explained Christian Kirchhoff, CEO, K.U.L.T., to the 450 viewers.

Practical farming expert, Dr. Beat Vinzent, Bavarian State Research Center for Agriculture, Germany, agreed. “It is a bit like when dairy farmers first discovered milk robots. They needed some time to adjust to the fact they were no longer just dairy farmers, but needed to learn to handle the system. But in the end this turned out to be just a transition period.

“How successful the adoption of robots by farmers continues to be in the end will certainly depend on the reliability of the systems and on whether farmers own the robots or if they just buy the robot work as a service from a contractor,” added Dr. Vinzent.

Field requirements, wear parts, remote service and security

“From our experience we know that farmers are ready to adopt the technology, even many small farmers,” commented René Jørgensen, CEO of FarmDroid. “They recognize it still requires some effort. The wear parts need to be considered since minimal tillage can be hard on tools, so the farmer of course has to ensure that the parts are in good condition. Simply speaking, the same attention you give a tractor, you need to give a robot. We can track the robot any time, if required for security reasons, and we are also currently setting up a remote support centre that can identify any issue and deal with it before it become a problem in the field,” added Jørgensen.

The requirements for some robots, like the one from FarmDroid, state that the field should not exceed 10 degrees slope which is determined by the power-to-weight ratio of the robot.

Return on investment within two years

Questions from online attendees covered investments and costs

“How much do I have to invest?” “What is the return on investment?” “How high are the costs of maintenance?”

“Seven hectares and above gives a feasible business case, dependent of the crop type” explained Jørgensen. “Return on investment is less than two years in a typical scenario in which a farmer uses the robot for organic sugar beets for the spring season and then again for rapeseed, or any other similar crops, in the autumn. We have had creative farmers who have utilized it for many different crops and herbs, thus they themselves have managed to improve the business case beyond our calculations,” added Jørgensen.

“The FarmDroid robot can be easily transported to another field using a tractor to get an even better business case by covering more hectares,“ he added.

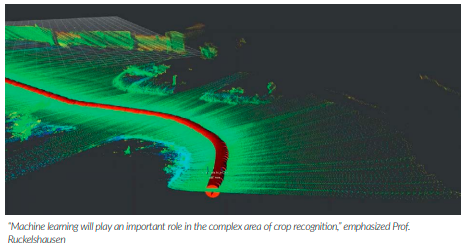

The prices of robots reflect their functions. The field robots from K.U.L.T., which uses a combination of GPS, lidar and camera sensing technologies, range from 25,000 Euros for small ones and 125,000 Euros for larger ones with in-row equipment. K.U.L.T. supplies robot systems to Naio robots, an Agritechnica innovation awardwinner from France. The autonomous seeding and in-row weeding robot from FarmDroid is priced at 65,000 Euros. Future trends – Machine learning to distinguish between weed and crop; Swarms of robots will work as teams “Over time, field robots will learn how to distinguish more accurately between weed and crop.

This is achieved through analysis of literally thousands of images recorded by field robots that enables the distinction between weeds and crop in the field. In other words, the field robot will be able to tell what kind of crop it sees and distinguish between harmless and critical weed. With this knowledge accumulated over time, the robots will be able to compare previous experiences, which will result not just in smarter robots, but also in smarter weeding,” commented Prof. Ruckelshausen.

Other future trends noted by Prof Ruckelshausen include quality checks of the soil and plants. This could mean that field robots could specialize in tasks. One could be measuring the moisture of a plant and if it needed water, it could send a signal to another field robot, which would react and provide the required moisture. This is what has been termed ‘swarming’. The field would be equipped with several small autonomous robots that would work as a team,” concluded Prof. Ruckelshausen.

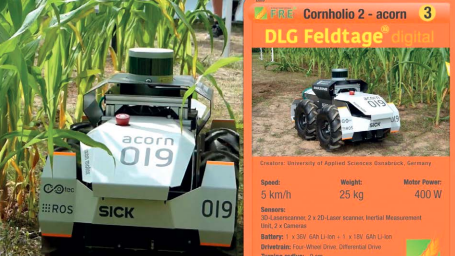

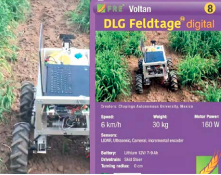

Crop residue and stone detection