If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

FARMER FOCUS – STEVE LEAR

A baptism of fire into Direct Drilling

They say if you want to see the sunshine you have to weather the storm. That couldn’t be truer of this year. From one of the wettest starts to spring followed by the hottest start to summer I can remember in my 34 years.

The first ever crop we direct drilled was a field of winter wheat last November. It was drilled into wet soils which got wetter as the winter progressed. The second crop that we have direct drilled was spring oats into wet heavy soils in April. Both crops then had to go from an extremely wet winter and early spring to drought conditions when they were supposed to be filling ears. Considering the conditions mother nature has thrown at us this year the crops have been very resilient.

The wheat tillered out well and looked very healthy the whole way through the spring with very little disease. It also held on throughout the late spring and seemed too be a lot more drought tolerant compared to the conventionally drilled crops. As for the spring oats, they launched up out of the ground and grew away extremely quickly with moisture under them and sun above. They yielded well but the bushel weight was down significantly as a fair few groats hadn’t filled out. Most of these will be fed to our herd of Limousins as they haven’t made milling spec.

We also tried some direct drilled maize this spring which isn’t looking so special. When we drilled it, I was sure the maize wouldn’t be able to get its roots down. This wasn’t however the problem with it. The root ball has grown down over a foot however the lack of moisture after establishment meant that the fertilizer sat on cracked out soil and was never taken up by the plants. This stunted the plants at the beginning of the summer when it should have been building biomass. I’ll try direct drilled maize again in the future but for now the cattle will have to enjoy some whole crop wheat and the field in question will be used as a cover crop and chopped back into the soil, at least the worms will enjoy it.

Crops aside I have progressed in building my knowledge about the soil and how plants interact with the biology within it. This in my eyes is a vital part to direct drilling. I was told that going along to Groundswell would be an eye opener and it didn’t disappoint. I would strongly advice anyone growing crops to take a day out and get them selves along to this event. I learnt more in a day at Groundswell then going along to the multitude of agricultural events over the years.

As well as listening to some great speakers and seeing some new technology I got to have a chat with farmers that have been running successful no till farms for decades.

A chat with a couple of renowned conservation agriculturalists at Groundswell has made me think differently about how we treat the farm yard manure that we produce from our cattle herd. Previously the muck would have been heaped up in fields before spreading on the arable land. This year I have decided to compost it aerobically. The idea behind this is to build a healthy population of aerobic biology including bacteria and fungi in the compost. I have also added some wood chip to the manure to help increase the fungal populations in it. A lot of what I have learnt has come from reading articles and science papers from Elaine Inghams from the Soil Food Web and her approach to producing high quality compost.

As well as compost we are using cover crops to help increase the health of our soil. Our cover crops were established after winter barley using our Cross-slot drill. They will grow on through until Christmas. We will spray them off to allow the ground enough time to dry out before spring cropping.

As far as cover crop species goes I have selected a complex mix that Kings have produced for me. The mixture contains: Quinoa, Blue lupins, Buckwheat, Phacelia, Berseem Clover, Oil radish, Vetch and Linseed. I’ve left the barley volunteers growing in the field as the cereal constituent of the mix. The covers will have digestate spread on them if they look like they are struggling, but I’m hoping they won’t need any. My first-year direct drilling has had some ups and downs but all together I’m happy with the results. On top of the economic side its been great fun learning a bit more about how natural processes and ecosystems in the soil work. This year, we will be establishing all our winter and spring crop with our Cross Slot, the heavy clay has cracked out over the summer to a depth of two feet which will help with a bit of drainage as we transition from tillage. I’ll let you all know how it goes.

-

GRAZING CROPPED LAND

The almost forgotten technique in the UK of grazing cereals is something being widely practiced across Australia in areas with widely varying rainfall levels. The Australian Grain Research and Development Council have produced a report titled Grain and Graze which sets out to evaluate the advantages and disadvantages of grazing a range of cash crops. We begin serializing this report over coming issues to explore what is currently an untapped resource.

Originally Published by Grain and Graze in Australia in 2016

The opportunities and potential downsides of grazing winter crops (why do it?)

Grazing winter crops is practiced across 19,000 mixed farms in Southern and Western Australia. In 2013 more than 2.7 million hectares of crop were grazed, representing 12% of the total area of crop grown. However the area grazed fluctuates from year to year, suggesting that grazing crops are often used as an opportunistic feed source rather than an annual feed supply. Suitable winter crops have commonly been referenced as ‘dual purpose’ because they can be used successfully for grazing and grain. Yet just because a crop variety may not have the tag ‘dual purpose’ does not mean it cannot be used for both purposes (refer to side story 1).

Balancing the benefits and the costs The decision to graze winter crops requires weighing up the potential benefits to the farming system against the potential losses. The most obvious opportunity in a mixed farming system is to graze the crop when it is tillering, eating the leaves at the time of year when other feed is often in short supply. The greatest potential downside is the reduction in grain yield as a result of this grazing.

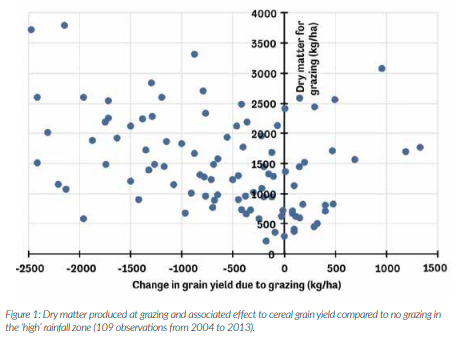

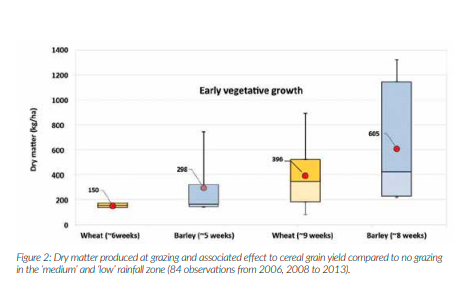

Examination of trial data from 193 comparisons in the high rainfall and medium to low rainfall environments shows a big range in dry matter production and impact on grain yield from grazing compared to no grazing (figures 1 & 2). These results are sourced from a range of years, cereal types, varieties, sowing dates and grazing approaches, so present both ‘good’ and ‘poor’ practice. Importantly it shows the opportunity for valuable dry matter production with minimal or no impact on grain yield if certain management choices and environmental conditions are met.

It also highlights the potential losses when circumstances are unfavourable.

However, the decision to grow and graze winter crops is more complex than just comparing dry matter against grain yield. Each individual farmer needs to evaluate the full range of potential benefits and costs associated with grazing winter crops to help decide if the opportunities outweigh the risks. The possible benefits and costs identified by farmers who have experience in grazing crops are summarised below. Greater discussion will be provided in further issues of Direct Driller.

Value to the livestock operation

• Provides high quality feed when fodder is often in short supply or replaces supplementary feeding

• Allows pastures to be rested to build a wedge of feed for use later in the year or for new pastures to establish

• Provides a worm free grazing environment

• Provides a place for animals to be ‘parked’ while pastures are treated with herbicides.

Costs to the livestock operation

• Grazing wheat crops for extended periods will require mineral supplementation

• May result in increased metabolic disorders, particularly with ewes in late pregnancy

• May require temporary fencing to ensure appropriate grazing

• Mobs may need to be ‘boxed’ to get adequate grazing pressure across a short time frame.

Value to the cropping operation

• Enables excessive crop canopies to be managed, reducing possible lodging, incidence of leaf diseases and future stubble loads

• Conserves soil moisture that can be used by the crop later in the year

• Delays maturity which may avoid late frosts

• Can improve the efficacy of some herbicide treatments e.g. broadleaf weed control and weed control e.g. selective grazing of grasses from oilseed or legume crops.

The possible benefits (the upside)

Extra feed for grazing The greatest upside with grazing crops is the additional high quality feed that is available in the winter period. The most common uses of this extra feed is to: • Fill a winter feed deficit, avoiding underfeeding, reducing the need for supplementation or the need to sell stock at low prices

• Provide the opportunity to ‘punt’ and trade stock, by purchasing at times of low prices

• To ‘spell’ pastures from grazing, enabling them to ‘get away’ and reach pasture benchmarks for lambing or calving.

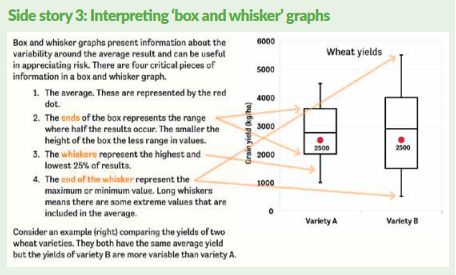

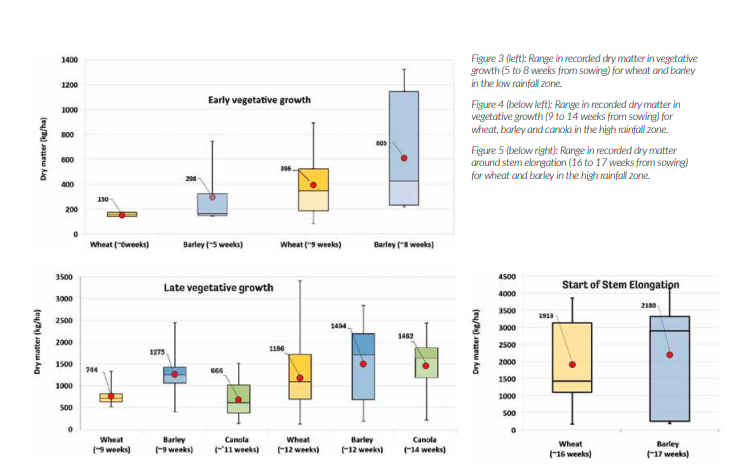

Examination of more than 500 measurements from 80 grazing crops trials conducted through Grain and Graze program over the past decade show a wide range in dry matter production. This variability is influenced by climatic conditions, type of crop, sowing rate, time from sowing to grazing and use of fertiliser, especially nitrogen. To convey the variability in dry matter production, ‘box and whisker’ graphs and percentiles are used to summarise the information (see side story 2 on interpreting box and whisker graphs). Results for wheat, barley and canola are grouped around vegetative growth in low and high rainfall zones and for the start of stem elongation (high rainfall zone only) (figures 3 to 5). The dry matter values are also presented in percentile tables (appendix 1).

Figures 3, 4 and 5 highlight a number of general, if not predictable, observations:

• Dry matter production is much greater in the high rainfall zone than the low rainfall zone for similar days from sowing. Rainfall, sowing rate and row spacing has a large influence on the measured difference.

• Barley provides more rapid early growth than spring or winter wheats or canola.

• Varieties within spring wheats, winter wheats or barley have much lesser influence on total dry matter when compared at the same sowing time, sowing rate and climatic conditions. This is not so canola, where hybrid varieties grow more rapidly under the same conditions.

• As the days from sowing increases so does the average dry matter production, however the range in dry matter production widens (seen by the taller boxes and longer whiskers).

High feed quality

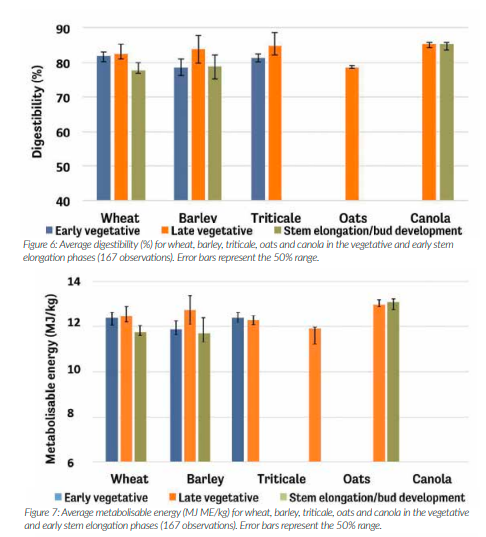

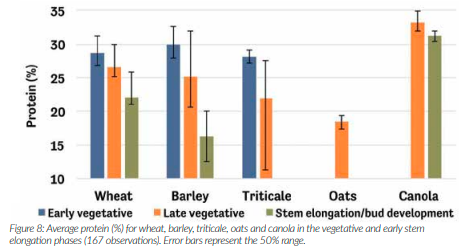

Winter crops offer high quality feed which is equivalent or higher than typical pastures at the same time of year. Canola is slightly higher than the cereals in digestibility and metabolisable energy (figures 6 & 7). Digestibility and energy in the cereals appear to peak in the late vegetative stage and declines once stem elongation commences. The protein content of all winter crops is very high in early vegetative growth, but declines as the crop matures, although the minimum protein levels remain well above the requirements of any class of livestock (figure 10). Maximum protein requirements for lactating or growing animal is around 14% to 16%. Animals are unable to store excess dietary protein, so any surplus protein is excreted by the animal in urine.

Potentially high animal growth rates

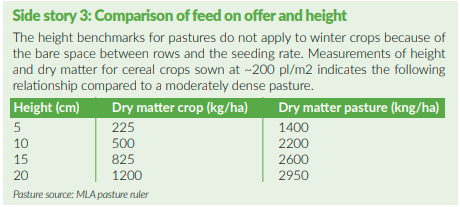

The performance of animals grazing winter crops (or pasture) is influenced by the quality of feed eaten and the amount available for grazing. Cereals and canola tend to be less dense and grow more upright than pasture. This means it is much easier for a grazing animal to consume a greater quantity of feed for each bite with a winter crop than with a pasture, even though the total feed on offer (if cut to ground level) is the same or less (see side story 3 on comparison of feed on offer and height). The difference in grazing height and the high quality of the winter crop has a considerable impact on intake and animal performance.

-

Drill Manufacturers In Focus…

MORE MECHANICAL WEED CONTROL OPTIONS FROM OPICO

OPICO has widened its mechanical weed control line-up to include a new range of inter- and intra-row hoes.

Joining Hatzenbichler comb harrows and hoes, German-built KULT machines add to the Bourne-based company’s offering with specialist cultivators designed for high-value vegetable and salad crops. In addition, the firm’s steerable headstocks provide a simpler, lighter, lower-cost option for implements with narrower working widths. KULT’s inter-row hoes can be equipped with a wide range of working tools from A-shares to L-blades with tines positioned to suit the narrowest 10cm spacings in wheat to row crops like pumpkins set up to 1m apart.

While dealing with weeds between the rows of crop is critical in maximising yield, in these high-value specialist crops it’s equally important to manage those in amongst the rows of plants. That’s where KULT’s innovative intrarow finger weeder comes in. A much simpler approach than other solutions on the market, pairs of plastic tined wheels either side of the row work in tandem to pluck weed seedlings out from between the crop plants. This intra-row weed control option is also available on Hatzenbichler’s line-up of inter-row hoes.

“With its success firmly rooted in the vegetable industry, KULT’s philosophy is very much about building bespoke machines to suit the customers’ requirements,” explains OPICO managing director James Woolway.

“Its weeders can be made to suit any bed size or working width and can be equipped with a wide range of tools to deal with different crops, soil types and weeds. That concept of configuring bespoke machines is exactly how we at OPICO are handling our mechanical weed control offering here in the UK. Our product specialists will work with growers to build exactly the right specification implement for the job.”

To that end, there is a range of options for the KULT’s steerable toolbars. At the most basic level customers can opt for manual guidance with an operator seated on the frame steering the unit either mechanically or hydraulically. This is often chosen where there is less of an emphasis on covering the ground at high speed. Moving to the next level of automation, growers can opt for camera guidance. Like Hatzenbichler machines, KULT weeders employ the British-made Tillett and Hague system. These camera-guided machines work closer to the crop and hence provide improved weed control at higher work rates. While Hatzenbichler comb harrows and inter-row hoes provide herbicidefree weed control options for broadacre crops, the KULT line-up is a much more bespoke offering to cater for a widerange of specialist crops.

“Although we’ve been selling Hatzenbichler comb harrows for weed control in organic arable crops for some 25 years, it was only last year that we introduced the Austrian firm’s inter-row hoes to the UK,” says James Woolway.

“Since then we’ve had enquiries coming from all sectors of both agriculture and horticulture. That demand prompted us to look at widening our offering. With a strong established following in vegetable and salad production, KULT was the natural solution. The company’s product line gives us a full armoury to deal with the increasing demand for chemical-free weed management.”

-

IS THE FUTURE BIOLOGICAL FERTILIZERS AND SOIL INOCULANTS?

While usage of biological fertilisers and soil inoculants in other parts of the world is growing rapidly, it is possibly not something you have even heard a lot about in the UK. Over the last 15 years, research and development of bacterial soil inoculation, combined with the invention of state-of-the-art microbiological and biotechnological methods have yielded ranges of soil specific inoculants. These bacterial soil inoculations offer a way to improve soil health and promote plant efficiency.

Biotechnological and microbiological methods can help cut back on the use of nitrogen and phosphorus fertilizers once the correct soil levels have been balanced. Microbiological soil enrichment methods have been trialled for the past 20-30 years in Europe and the USA. These microbiological products have since progressed from experimental plots and spread to commercial plant production, in both field and greenhouse cultivations. Today, in Europe hundreds of thousands of hectares are treated with soil inoculants. So why have they not been adopted in the UK?

What we have seen in other countries

Trials in Hungary have isolated beneficial soil microbes including nitrogen-fixing bacteria that are capable of fixing and transforming atmospheric nitrogen into a plant available. Phosphate and silicate mobilizing soil bacteria can provide available mineral available phosphates and potassium to plants by solubilizing them. Phytostimulating strains should also be mentioned, they produce plant hormones and hormonelike substances, directly enhancing plant growth and development and improving abiotic stress tolerance. Research companies have spent years isolating and selecting these bacterial strains to create complexes of plant growth promoting, nitrogen-fixing, phosphate and potassium mobilizing soil inoculants commercially available, but relatively unknown in the UK.

Taking into account not only the beneficial properties but the rate of growth and metabolic activity of the strains in acidic or alkaline pH and at low temperatures reaserchers have had to develop specific inoculant products for specific soils. Field studies in have shown that inoculation with the right products reduces nitrogen and phosphate fertilizer use and enhances crop yield in corn, wheat, barley, sunflower, soybean, rape, rice, sugar beet, cucumber, pea, sweet pepper and tomato cultivations.

Exact numbers, of course, depend on the variety and the quality of the soil. Regulated studies for some products have confirmed – an 18% increase in corn yields and 39% increase in soybean yields. Results and efficiency of field inoculation is greatly subject to weather conditions, like virtually all agricultural procedures, so expected yields can only roughly be estimated. According to the official studies, the success of inoculation is marked by an increase in root length, stem height, number and surface area of leaves, total protein content, shoot mass and crop yield. Besides the increase in profitability, improving yields and possible savings on fertilizer costs, the reduced environmental load is also significant.

What now?

In the UK, it is certainly possible that these products have the potential to increase yields and reduce the usage of traditional fertilisers. However, in developing countries, where overpopulation and a rapidly increasing need for arable land exists, having biologically sustainable soils is critical to feed the population.

In China and India, the increased requirement for food production has driven the use of chemical fertilisers up by 60%. In nitrogen and phosphate deficient African soils, the increasing but unsustainable agricultural production is promoted by subsidiary fertilizers and seeds. If the developing world continues to rely on chemicals and keeps increasing usage, they will soon face the severe issue of soil degradation that has been seen in parts or Europe and the USA. Transportation, storage and application of live biological products brings new challenges to farmers.

Products have a shelf life that can be extended through refrigeration, but how many farmers could currently store an 800-litre pallet of inoculants at refrigerated temperatures? While the wife may be happy for 10 litres to sit in your fridge, 800 litres just won’t fit. Therefore, these products would need to be supplied on a just-in-time basis where products arrive on farm and are used within days ideally Factors like exposure to UV light will degrade the products rapidly so they need to be incorporated to soils quickly after application or ideally placed in the slot with seed under a no-tillage regime. There is still a lot for us to learn about soil inoculants. As more scientific and farm trials take place in the UK we will understand how effective these products can be and whether the margin over input cost when using them is returned. It is yet another interesting technology for farmers to understand and investigate over the coming years.

Trials in the UK

Trials are already underway in the UK, we will report on them as they are completed in future issues. If you are able to conduct a trial with such a product and want to test it this Spring then please do get in contact.

-

BENCHMARKING COSTS IN RURAL BUSINESSES

Land Family Business were invited by Groundswell and Procam to benchmark a group of farmers who have been practicing no-till crop establishment for several years as part of conservation agriculture. Using our own client benchmarking process, it gives the opportunity to assess the financial performance of no-till conservation agriculture – against other no tillers and also against conventional crop establishment farming businesses. The results have large variations at every level – therefore, there is a great deal to discuss and analyse

Some Background

The 2017 Harvest Land Family Business Rural Business Client Survey shows some interesting results. The benchmarking was started in 1992 and until this year, all businesses had been ranked on the arable farming margin. This year we have included all other outside business income in the ranking, only excluding Rent and Finance – therefore the farms are ranked on Rural Business Profit.

Setting the Scene

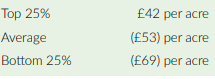

One of the most striking points is the margin from contract farming net of the power and machinery costs:

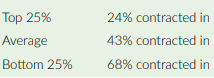

The relative contract area to the whole arable acreage is also significant:

Although the additional land generates a loss in margin, it does actually provide a contribution to overall costs because labour and machinery are fixed. If the additional land is given up the overall profitability will reduce

Therefore, many arable farming businesses are caught in a trap, or on a treadmill in having to expand acres to justify investment in machinery Adding acres in a competitive environment is not the answer The question is, are current contract farming arrangements really joint ventures or could machinery syndicates or share farming agreements be more effective in changing times?

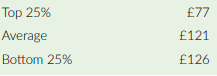

It is particularly important to review current agreements for the potential change in the Basic Payment Scheme support. Profit before BPS, environmental payments and nonarable income is a loss of £10 per acre in the top 25% which indicates that farming businesses are increasingly reliant on other activities other than arable production. This may need a change in skillset for many farming families. What is also a little daunting is the increase in investment in machinery over the past year or so, with capital sometimes exceeding £300 per acre. The depreciation and contracting and hire costs from the Survey results added together:

This is the annual cost of acquiring and having the use of machinery. This is not sustainable in an arable business. A management tool that many would benefit from is a machinery capital budget on a spreadsheet. This would show many key indicators such as capital employed in machinery per acre (including hired in), horse power per acre and an indication of future changeover costs per annum. Making business decisions based on correct financial information is vital however it is very difficult to obtain this information unless it is specifically produced and equally important – understood

As the industry faces one of the most radical changes in decades, many important business decisions will have to be made around farming kitchen tables over the next few months. Accurate management data is fundamental in making business decisions within farming families. These decisions could range from downsizing contract management agreements and selling land or property which could fund new enterprises to succession planning and retirement. It is quite common for example, for rental income to be subsidising arable losses. This is quite acceptable if it is a conscious business decision, however, all too often unless the accounts are prepared in management format these situations may continue undetected. Understanding the farm performance is crucial and we have a moral obligation to the next generation who are often asked to commit the rest of their lives to the business.

The fundamental problem with annual accounts on arable enterprises is that they will always cover an annual period which may not fit and conform to a production cycle. Typically, many farming businesses will have a 31 March year end which fits in with the annual tax period. But how does this relate to an arable farm with predominately autumn sown crops? In simple terms there are 3 types of accounts or budgets that can be prepared for an arable farming business:

• Financial statements following standard accounting practice, normally prepared by the farm accountant.

• Management accounts adjusted to financial statements often prepared by specialist farming accountants.

• Gross margins and associated fixed costs covering a production cycle, usually a budget prepared by farm consultants.

The profit shown in the first may bear no resemblance to the other two Once the homework has been carried out and a decision has been made to convert to a No Till Conservation Farming system – will it work on your farm?

Does No-Till Stack Up Financially?

The main points to be taken on board are:

• Yields of winter wheat average around 2.7 tonnes per acre – a reduction of around 20% from average conventional establishment yields

• Gross margin varies by around £100 per acre within the group – similar variation to conventional establishment. The average is lower than that from conventional establishment farms but the highest compares well with the Rural Business Survey average.

• Variable costs are £19 per acre lower in the no-till survey, this is significantly contributed to by a reduction in chemical costs.

• There is a substantial reduction in working capital requirement which will assist many businesses.

• Overall labour and machinery costs show a reduction of 43%

Drilling down further into the detail, the reduction in labour and machinery costs per acre from £213 in the average of the LFB Rural Business Survey to £120 in the no-till survey is significant. A major contribution to the reduction is the capital tied up per acre in machinery, resulting in a reduction in depreciation. Most arable businesses have been breaking even over the last 2 or 3 years because of high inflation in machinery costs, equating to £300 capital per acre in many arable businesses.

No-till provides a solution to this. In summary, there are lower yields and lower costs, therefore one of the key indicators is the cost of production per tonne. The cost of production per tonne for winter wheat in no-till is £101 and in conventional establishment businesses is £111. Inputs and paid labour costs in the no-till group are higher per tonne at £70 compared to £57 in the LFB Rural Business Survey. The big savings are because of machinery costs per tonne at £31 compared to £54.

Soil type and weather have a larger impact on no-till systems than conventional establishment. Therefore, they must be flexible to react to local conditions during a season. In conclusion, no-till establishment needs a completely different approach and way of thinking to the historic ‘Yield is King’ approach. This needs individuals who are prepared to question convention, take risks and be innovative. It must be remembered that no financial account has been taken for the increase in soil health and other environmental benefits. The rewards are achievable, but we need to be sharing knowledge to get there. To discuss further and get involved in benchmarking, please contact Gary Markham on 07970 794495 or email gary.markham@ landfamilybusiness.co.uk.

-

HOW TO BECOME A SOIL HEALTH EXPERT ON YOUR FARM

It’s clear that we need to build more resilient soils, both for the future of our farms and for the long-term health of the land. The satellite images of muddy waters spilling out of brown rivers around the UK after a heavy rainfall are hair-raising. We can visibly see the soil gliding off fields, into water streams and off into the sea. At the very least this is quite literally money going down the drain for anyone working from the land, at its worst this is hundreds of years of top-soil formation being lost forever and part of a global disaster. Soil health advisors are quite certain that this scenario is avoidable, it’s all down to how land is managed.

If this is the case then building soil health should be one of the top priorities on every farm. One major difficulty is how do we know if we are building soil health or not at a farm level? Science doesn’t seem to offer a simple answer to this at the moment, which could be considered quite worrying, but we see it another way: This is an opportunity for farmers and growers to lead the way, to become experts on monitoring and building soil health on their own farm.

September and October are the best time to do most of the soil health tests in the UK. So prepare to soak up all the tips and tricks from what we have learned so far, and then get out there learning and observing your own soils in the coming months! This is the first step to becoming an expert on monitoring and building soil health for your soils.

How can Farmers monitor their own soils?

We started working with the PastureFed Livestock Association (PFLA) and Soils Advisor, Niels Corfield, to investigate this very question. The PFLA ran a series of workshops where scientists and farmers came together and identified the most appropriate soil tests, based on all the resources and research available. We took the most popular in-field tests and went out on multiple farms to see how it worked in practice. We didn’t have an easy way of recording the results so we developed a version of our app, Sectormentor for Soils, that allowed us to record the observations and photos as we went for each field.

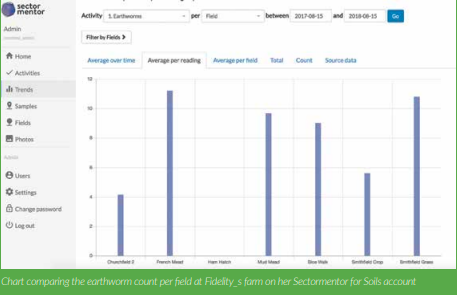

To understand the health of your soils it’s important to see how things are changing over time and examine trends of different indicators. In order to do this we encourage growers to set goals for each field they are monitoring and then choose four to five tests that monitor the results as they change management practices to meet those goals. For example, one PFLA farmer in Kent, Fidelity Weston wanted to see if grazing her animals differently would improve forage and carrying capacity on the land, without compromising diversity. As she changes her practice, she is monitoring the percentage of grasses/broadleaves and sward stick readings above-ground as well as Slake test, infiltration rate and a visual evaluation of the soil below to see how the change affects her goal.

We have found the most effective tests are very physical measures that are immediately understandable. There are lots of different protocols out there for how to do these tests, but we hope to provide a method with a good balance between being do-able for farmers and providing useful insights, as well as being based on sound science. You can find an equipment list, and clear guidelines for doing each test on our website soils.sectormentor. com. Here are three we have found particularly helpful:

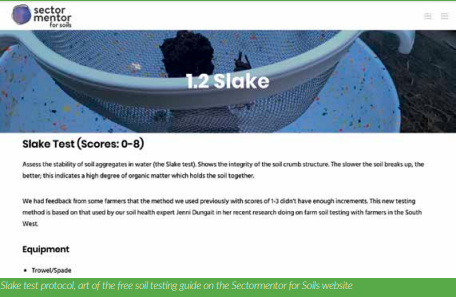

Slake Test (Wet Aggregate Stability)

The Slake test is a simple in field test that allows you to really see how well your soil structure holds up in water. It is also an indicator of biological activity. We have started to work with Soil Health Expert Jenni Dungait (previously soil health Professor at Rothamsted) and have adopted the in-field method she used in her research with farmers on multiple farms in Cornwall and Cotswolds regions.

Well-structured soil is composed of aggregates, so in this slake test you put a few small pieces of soil in a sieve, submerge them in water and then shake them around quite vigorously. Those small pieces that survive without breaking down at all are true aggregates, the water remains totally clear. For non-aggregates there is considerable break down of the pieces and the water can become murky. You score the breakdown on a scale of zero to eight, eight indicates a soil full of microbes and made up almost exclusively of aggregates. All details here An additional benefit of this test was highlighted by Jenni Dungait’s research (soon to be published) which shows that the slake test is an excellent proxy for Soil Organic Carbon.

Earthworms

All growers inherently understand the value of earthworms as we see them physically move nutrients around the soil profile. Earthworms are one of the larger organisms in the soil food web, so many earthworms is a good indicator of plenty of life in your soil.

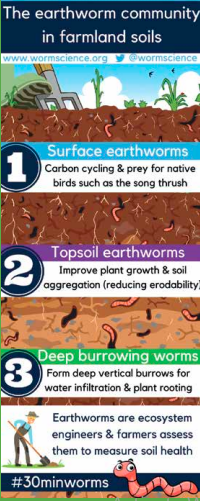

In the UK, an average of 15-20 worms in a 20x20cm soil pit is considered good. Earthworms counts are best done in late September to early October. This year we are preparing to do slightly more detailed earthworm counts based on the work of soil scientist Jackie Stroud at Rothamsted. There are three main types of earthworm: the litter-feeders which break down organic matter on the surface of the soil; the top-soil worms who work on soil aggregation and nutrient mobilisation; and then the deep-burrowers that keep water flowing from the soil surface to deep pools below, as well as increasing aeration and root development.

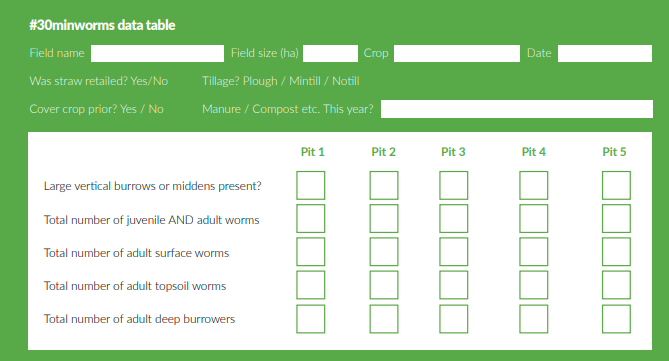

Jackie’s research shows that if you identify numbers of each type of worm, it can tell you what the worms are working on and uncover any changes you might need to make in your soil management to encourage all types – ideally you want to have all three types of worm working in harmony. Jackie Stroud is running a #30minworms citizen science project in September where she is asking farmers all around the country to dig 5 pits in a field and do earthworm counts and send her the results. You can find out more in the earthworm test protocol on our site, where you will also find a link to Jackie’s Worm ID Quiz, which is a brilliant way to learn how to identify types of worm for yourself.

Infiltration rate

The Infiltration rate test clearly shows how ready your soil is to soak up water when it comes. To do this test we use a 150mm diameter pipe (actually part of a chimney flue) and hammer the pipe 75mm into the ground. Then we pour in a set amount of water and time how long it takes the water to infiltrate. Originally we used a much smaller diameter baked bean tin to do the infiltration tests but we were finding it took over 20 minutes for the water to infiltrate which made it impractical to do in the field. One thought was forcing such a small diameter cylinder into the ground was causing artificial compaction in itself, which is why we have moved to a larger diameter cylinder.

Our aim is to find a method that takes a maximum of five minutes in most soils. This test is so relevant, imagine if every farmer and grower around the land had a clear idea of the average infiltration rate in each of their fields. We would definitely be better equipped to prevent those muddy rivers and top-soil losses.

The value of the app – soil health trends and patterns on your own farm. You can use all three of these tests, combined with above-ground observations to build up a picture of the health of your soil in each field, and see how it changes over time. This is how you start to become a soil health expert on your farm, go out and look for yourself, observe, document, ask questions and build up a picture over time.

The Sectormentor for Soils app makes it easy to record these observations in the field as you go, and then turn those observations into graphs and insights. Just a few taps and you have everything recorded, alongside photos showing what you saw both above and belowground. Essentially you can build up a visual diary for each field combined with numerical results from the tests. All those results are easily searchable (no more shuffling through piles of papers to try and find those scribbled notes) and quickly show how your soil health is changing over time.

Shared Perspectives and Added Learning

One other important piece of the puzzle for many farmers and growers is the power of discussion and other people’s perspectives. When you are out in the field taking these observations, in order to become an expert and understand better what’s happening we have found that it’s important to share your observations with others and get other perspectives. This is a big part of the learning.

Where possible it’s great if you can go out in a group, or with your agronomist. The digital diary on the app is perfect for this as it’s easy to share photos and results with other farmers, or to discuss things you have seen with an agronomist. That is a summary of our learnings for now. We are excited to support many more farmers and growers to get out there and become confident monitoring their own soils, head to our website soils.sectormentor.com where you will find more info about the app, our free online guide to the different soil tests and a blog filled with resources, case studies from different farmers and more. This is a brilliant opportunity for farmers and growers to move from here-say and anecdotes about what works on their farm into a more structured evidence base, not scientifically rigorous data, but just what is needed to build up the patterns and stories on your farm. This is about becoming a soil health expert for your farm.

-

FARMER FOCUS – CLIVE BAILYE

Farming mostly light soils is easy, isn’t it? I’m often told I farm “Boys’ land” and well, I guess in many ways it is. A bigger working window, low slug and blackgrass pressure all seem to make life that bit easier for me than colleagues on proper heavy clay “man’s land”. My gap year from agricultural college was spent in North Yorkshire, an absolutely stunning ring fenced farm with 100% “man’s land”. I spent most of my year ploughing up slabs of clay with the biggest, heaviest, high horsepower tractors I had ever driven. It was a dream job for a 21 year old horsepower-mad student and I promised myself that one day I would farm such land and grow the barn busting yields it was capable of.

Returning from college to my “easy” sandy loams and now with an unhealthy addiction to horsepower, it made perfect sense to set about them with similar huge tractors. Ploughing was far too slow though. The “tillage train” was very trendy, and I rapidly worked my way through the model ranges until the pinnacle of 600hp plus tractors was reached. Who needed heavy soils to justify these big and impressive monstrous machines? I wasn’t alone. The trend towards high horsepower quickly became something any self-respecting large farm must do. Marketed well by the likes of Simba and Monsanto as “eco-tillage” (although I’m not quite sure what exactly was “eco” about it all) many farms used this new method not only as a great excuse to fill their barns full of very sexy big kit but also as a way to spread existing labour over many more acres, FBT, contract farming etc… you were a nobody in farming terms if you were not shooting with Lord of the manor and his best pal land agent mates.

The FBTs got more expensive, the contracting margins slimmer as the land agents saw lower operating costs as a way to squeeze margins tighter and push up rent. It quickly became a rather pointless game to play if you wanted to actually make a living from farming and were not just in it for a couple of days shooting at the ‘big house’. However, there was a far more serious consequences to all this than lack of farmer profits. Tight rotations of wheat and rape combined with mintill and cultivator drills was the perfect breeding ground for grass weeds and pests, especially on that heavy land that I had so coveted as a student.

The more I saw others losing the battle against black grass and the plagues of slugs the more I started to see the advantage of my “boys’ land”. Trouble is, light land has one VERY big drawback ………… drought! Especially if it happened at grainfill when so often a couple of dry weeks at the wrong time will see an otherwise fantastic, clean, grass-weed-free crop go from hero to zero it less time than a pre-harvest family holiday in the Med will last. Even in a good year (read wet!) on lighter land my yield maps read like soil moisture maps, and it was this realisation a decade or so ago that set me out on my journey into no-till farming. In an epiphanous moment, whilst filling a CAT Challenger with 1000L of fuel for the second time that day, it occurred to me that a dry year in the UK was the normal in many other grain growing areas of the world. What we call a drought in the UK is a mere sunny spell in Australia. I wondered how they coped? How did they farm around this issue?

Manic research followed. The internet was a slow beast back then but eventually it became clear that the last thing any self-respecting cereal farmer in a dryland area would do is cultivate his soils. Evaporation was the enemy and cultivation and bare soil are the fastest way to lose any moisture that’s in the soil. Soil structure was the next thing I kept hearing others talk about, it made perfect sense to capture as muchof the rain that fell on the soil, reduce run off and hold the moisture in a rich sponge of organic matter for as long as possible. Apparently, worms were to become my new best friends: They along with a host of other soil organisms I had never even heard of before could apparently create this structure for me. All they asked in return was that I stopped destroying their world with cultivators and ploughs. Seemed like a fair enough deal to me and my journey as a no-till farmer began.

2018 – the year that could have been

So, a decade or so on and along comes 2018 – the year that could have been. Autumn establishment was pretty much ideal, and crops got away well. A long wet and cold winter followed, and social media started to paint a grim picture for some of the heavy land farmers. Blackgrass loves wet, heavy soil but our land was dealing with whatever mother nature threw at it just fine. The structure (well the soil life really) we have built was dealing with the rain well. Spring came and as applications went on, with the near perfect timing that lighter soils facilitate, crops got better and better.

Disease pressure was low in cool conditions, so we were able to pull back on inputs. Crop yield prediction models based on satellite radar images were forecasting yields the like of which we had never seen on this farm before and even my father (a notoriously hard man to impress) made the occasional comment that he had never seen the farm look so good. We all got terribly excited and I went away on my preharvest family summer holiday looking forward to returning to the harvest of a lifetime. I was happy with my boys’ land.

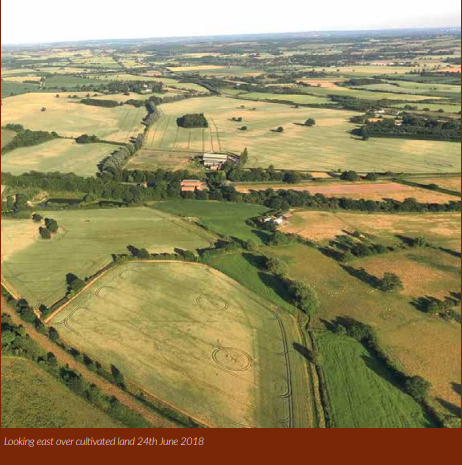

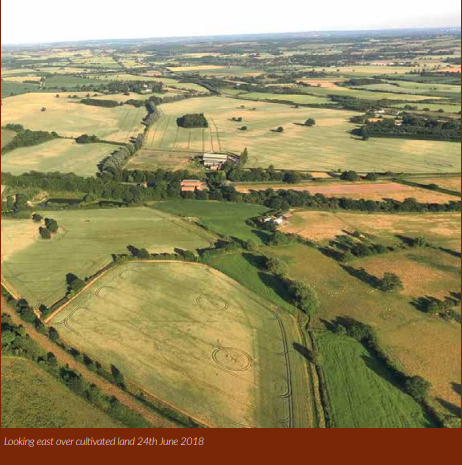

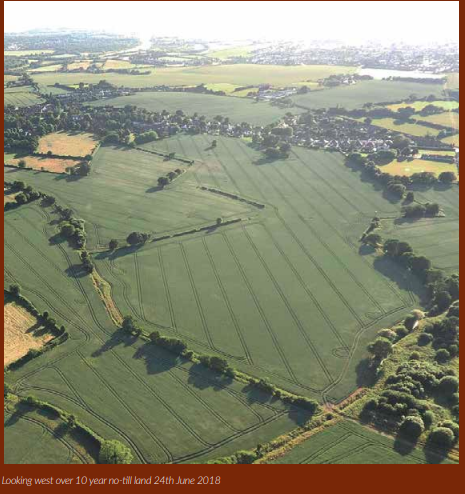

Then the inevitable happened, no rain through grainfill. The temperatures continued to rise, and the yield forecasts fell. It was visibly changing every day and the change wasn’t good. Crops were dying quickly and it’s a depressing thing for any farmer to see such potential just fade away in front of their eyes. Then whilst browsing Facebook one Sunday evening I came across a local drone photographer who had posted a few pictures taken while flying overhead that weekend.

He had been out and about taking various pictures around our area mostly to show up outlines of old building and roads in fields that the dry weather was showing up. A couple of his pictures caught my eye, they were taken from one of our boundaries and looked west over our land and then turned 180 deg east across land farmed by a couple of our neighbours. The contrast was stunning, our crops still looked pretty good, green and even however the view west over more conventionally cultivated land was very different, uneven and clearly much more affected by the drought at that point.

The deeper into no-till farming over the year I had got the more I had lost sight of why that journey had begun. Moisture was what it was all about for me and finally it seemed there was some tangible evidence that all those changes were making. Of course, there are many factors to consider here, my neighbours may have been growing different varieties, different drilling dates, different agronomy etc but the thing that was consistent is that we had all received the same amount of rain over the past month and for all of us that was nothing!

Harvest came early, in fact the earliest start ever for me here and that’s not something that bodes well as early combining means low yields as a rule. We started on the OSR and despite our lowest input spend ever on an OSR crop we were pleasantly surprised with yields slightly above our 5 year rolling average figure and interestingly very close to the numbers predicted by the satellite yield forecasting models. On to wheat and the news wasn’t so good. About half a tonne down on those rolling averages but at least milling quality was there and considering how dry it had been, the easy nature of harvest and the lack of need to dry anything it felt like a lucky escape and not too bad a result after all.

So, do I still want that “man’s land” I farmed as a student? Well “yes” is the answer. And indeed we do farm some stronger stuff for others as contract farmers. But I have come to learn that a nicely hedged position of light and heavy is probably the ideal place to be. Boys’ land and man’s land both have their pros and cons but with the correct management either can be farmed successfully under a no-till system.

-

STEPWISE MOVE TO NO-TILL DRILLING HAS PROVED A SENSIBLE APPROACH

A stressful time trying to establish autumn crops is what originally prompted Northamptonshire estate manager, Andrew Mahon, to move away from traditional cultivations. But it’s been a journey that’s paid off.

As manager of the 1,000 ha Bromborough Estate at Glebe Farm, Podington near Wellingborough – with 840 ha of owned land plus 165 ha under a farm business tenancy agreement – Andrew Mahon has overseen some significant changes during his 10 or so years in the post.

Farming on heavy clay soils brings with it problems of blackgrass. But this hasn’t stopped him making a success of moving from a traditional plough/ min-till based system to no-till. And in a fairly short space of time. “The rotation is driven by blackgrass,” Andrew explains. “In our low blackgrass situations, winter wheat is followed by a second wheat, which we then often follow with two years of spring crops. In a high blackgrass situation, winter wheat is followed by one of the spring crops. And in a moderate blackgrass situation, it’s followed by winter barley. “We dropped oilseed rape from the rotation three years ago because of problems with cabbage stem flea beetle, pigeons and slugs. But we are growing some this year after growing some again last year,” he adds.

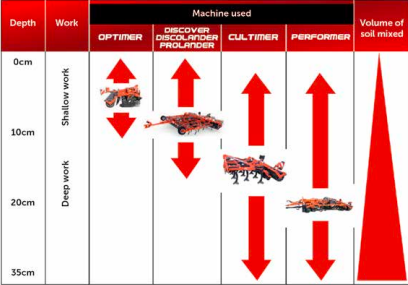

Initially, the idea of moving to reduced tillage was triggered back in 2012, when the wet harvest meant Andrew not only saw a 30% drop in yields, after struggling to get crops combined, but then also struggled to get crops drilled. “Back then we were using ploughing and min-till,” he continues, “ploughing about a third of the arable land every year. It was a really stressful autumn, so we looked at what we could change. We’re on heavy, predominantly Hanslope series, clay soils so therefore couldn’t really change our cropping. “At the same time, the BASE UK (Biodiversity, Agriculture, Soil and Environment) group was set up and I joined. After researching conservation agriculture and reduced tillage, I thought that was the way forward.”

The following year, 2013, Andrew took his first step by ordering a strip-till drill that only cultivated a four inch to nine-inch band of soil for drilling into. At the same time he sold the plough, a set of discs, a press, and two tractors, the latter being replaced with one tractor that was hired in. “We started using the strip-till drill in autumn 2013 and through 2014 and 2015. It became apparent in the first year that it was working. We saw no drop off in crop performance.

“However, I felt we were still moving quite a bit of soil and still having problems with blackgrass. So the next step was to look at no-till. In March 2016 we ordered a 5-metre Cross Slot No Tillage Systems drill. It’s been brilliant. We had good establishment and good crops again this last year.” Overall, Andrew sees three parts to conservation agriculture – cover cropping, diverse cropping, and no-till. With hindsight, he says moving to the strip-drill first before the no-till unit was the right thing to do. “It was a stepping stone – a gentle introduction. If we’d have gone straight to no-till we’d have struggled.

“Your whole mindset has to change because you’re drilling into trashy conditions and cover crops. Also, the soils need time to adapt. So you’ve got to be patient. And you’ve got to start slowly. “That said, even in our first year of notill the soils travelled better – with better trafficability. Also, our establishment costs are the lowest they’ve ever been – with reduced diesel and machinery expenses.

“We’ve also now got a wider drilling window. We can drill a bit earlier or a bit later. And there’s a lot less stress. “Using no-till, we also conserve soil moisture and reduce soil erosion, but you also get the natural drainage you need through worm channels by minimising soil disturbance. If you plough, the seagulls eat the worms straightaway. In one field we min-tilled and cross-slot drilled, there were about 17 worms per unit area of soil. Where we ploughed we found 5 worms. And where we no-tilled for two years we found 27. “There are still areas that we need to mole drain, but soil structure is definitely better.

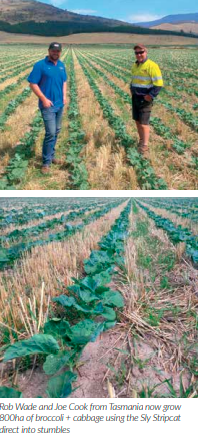

Anywhere that we need to subsoil we’ve done that,” he adds. In preparation for the no-till drill, straw is chopped and left on the surface and then drilled-into. Another benefit of the approach is that stubbles are left longer, which increases combine output, Andrew says. Organic matters are reasonable across the farm at 5-6%, he notes. “If you’re serious about conservation agriculture, you also have to encourage the soil mycorrhizae. I’d say the ability to minimise soil disturbance is key for mycorrhizae. They form fungal networks but are very fragile,” he adds. Allied to this, as well as changing tillage practices, 2013 was also the year that Andrew introduced cover crops as part of his move to conservation agriculture, planted directly behind the combine.

“We started with various mixes. I think they are an integral part. Keeping green cover or living roots in the soil for as long as possible in the calendar year is the name of the game. Cover crops also stop surface compaction as they decay. “We’re going increasingly to diverse cropping anyway because of blackgrass. We started with 60 ha of spring cropping, we’re now at 275 ha.

“In spring 2016, I also noticed that where we had cover crops and sprayed them off with glyphosate four weeks prior to drilling, the material on the surface helped retain soil temperature and moisture because the soil wasn’t exposed to drying winds.” Having transitioned through the experience, Andrew reckons the biggest issue with the move to no-till was the change in mindset that was needed, but he needs no convincing of its benefits. “I feel we are more sustainable for the long term. Brexit will have a huge effect on agriculture, and we are gearing our cost of production per tonne to be lower.

“We’re also starting to see if we can reduce inputs such as nitrogen as we increase soil health, and we’re looking at putting humates on and using seaweed extracts. No-till hasn’t been a magic bullet against blackgrass, but there have been some gains,” he says.

ProCam offers agronomy help and trials

Making the move to conservation farming can be very much a learning process. For a number of years, and during the conversion, Bromborough has been working with leading agronomy firm ProCam. As well as providing strategic agronomy advice and a range of chemical inputs, the company also carries out soil and tissue tests and has been heavily involved with the estate in conducting conservation agriculture-based trials. “I’m pleased to see them involved in conservation agriculture,” Andrew explains. “I’m there as a sounding board,” agrees ProCam agronomist Richard Rawlings, who has a strong, personal interest in the whole approach. “We are another head in the decision-making process when it comes to talking dose rates for various inputs and discussing things like whether to apply fungicides, and we provide a helping hand in crop nutrition. Plus, we’re working closely with the estate in at least three significant areas of trials.

“We’ve done a lot of trial work in a direct drilled situation with herbicides and blackgrass control. We found that we can control blackgrass in direct-drilled crops quite well, but have noticed some issues with brome. So we’re now looking at trials to control this without compromising the blackgrass control. “This season, we’re also about to start a medium-term, two year project looking at planting a companion crop of clover with wheat, spelt and spring wheat at different times – to gauge the response to the nitrogen fixed by the clover and the uptake of nitrogen, as well as the level of crop competition that the clover provides.

“In 2018, working with the company PlantWorks, we have also tried one of their soil-applied bacterial products to see if it would improve nutrient uptake. The theory is that bacteria in the soil interact with the roots to improve initial uptake of nutrients during the early stages of plant development. We’re awaiting the final analysis of the results.”

“We’re finding by adopting even some small changes, we can make a clear difference,” he concludes. Growers wishing to find out more about how ProCam can help with conservation agriculture techniques can contact richardrawlings@procam.co.uk

-

AHDB NORTHAMPTON MONITOR FARM LAUNCH 4TH JULY

Report by Chris Fellows, Direct Driller Magazine

Recognising an interest in reducing soil movement, AHDB has picked a new Monitor Farm that predominately uses a system of reduced tillage. The 4th July was the first event held at Rick Davies’ Newton Lodge Farm. It was a great chance for us to get to know Rick and understand how he farms at the moment and how he wants to move forward and change to meet the challenges of the future. The evening started with a brief introduction by Harry Henderson from AHDB. Held in one of Rick’s barns, Harry talked about why they had chosen this new Monitor Farm and why AHDB felt a Monitor Farm with a keen focus on cost control provides an interesting platform for local discussion.

Giving the growing relevance of direct drilling and soil health in the UK and the fact that Defra and Michel Gove himself are keen to promote (and maybe even push) the benefits of no-till practices then it’s interesting that this Monitor Farm joins a long line of Monitor Farms that have abandoned the plough. Therefore, the level of direct drilling representation at a Monitor Farm level is growing all they time just as overall interest in the practice grows.

The important thing Harry stressed is that a Monitor Farm isn’t a demonstration farm, it is chosen as an example of a typical commercial farming business.

Harry also introduced AHDB’s Farmbench. Farmers can use Farmbench to better understand their cost of production. It allows them to compare their farm figures and performance against other growers in the local area and region. It is a confidential system that allows farmers to anonymously share information and by being able to talk to each other at meetings, learn from each other to find out where different systems can cut overheads. We will be discussing this topic of costings a lot in Direct Driller over the next few issues, as it is often so difficult to compare farms that are using conventional tillage to those using no-till and so often the benefits described have been anecdotal.

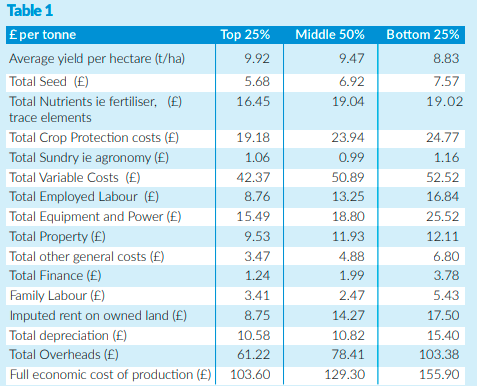

Harry presented a summary of Harvest 2017 Winter Wheat Group 4 figures, with a full economic cost of production per ton ranging from an average of £103.60 for the top 25% through to a average of £155.90 for the bottom 25%. The full breakdown of these figures is in Table 1.

Given the average sale price of Group 4 Wheats over the past 5 years, then some farms would be struggling to make a profit based on these figures. Harry then handed over to Rick, who talked about his farm. Rick is 4th generation and the family have been farming in Clifton Reynes since 1926. It’s predominantly an arable enterprise, with 404 ha farmed which is a mixture of owned and FBT. As with all farms, they have also diversified in several ways to help pay the bills. At Newton Farm they also have 14 office units, 4 industrial units, 52 Container Storage units and a Turf Sales and distribution business.

The big battle Rick is fighting is against black-grass. He even uses a plough (there we said it) as the “reset button”, should he think he has lost the battle in any given field. However even that doesn’t solve the problem, it just buries it and allows you to start afresh.

He’s using a different rotation in the fields that have a black-grass problem in conjunction with manual rogueing midseason. However, rogueing, comes a significant labour cost even though he does some of it himself. But it is one of the most effective ways to control black-grass. Rick told us that he is happy with the way he farms, but feels there are significant improvements that can be made to both the way he farms and to the profitability of his business. This was one of the main reasons he wanted to become a Monitor Farm. To open himself up to criticism and bring in ideas from other farmers. It’s a brave thing to do, when you know you aren’t perfect as there are always ways to improve and to put the way you farm on display for the world to see means everyone gets a “warts and all“ view. However, if you want to improve your business, then bringing in outside ideas is the best way to do it.

Rotations

In the fields that are black-grass free the rotation is: Winter Wheat, Winter Wheat, Spring Barley, OSR. In the fields with black-grass the rotation is: Wheat, Spring Barley, Spring Barley, OSR. These feel too tight for me and in the long term will struggle to be sustainable. I would expect that more beans and oats would need to be used in the future if Rick is to progress in his no-till development. He uses a Claydon 4.8 m drill for his drilling, rake and using a 12m Cambridge rolls to achieve a suitable seedbed.

For first winter wheat he will Dyna-drive, then drill with the Claydon, rake and roll. For second Winter wheat, he drills with the Claydon, rakes and then ring rolls. For the Spring Barley, Rick will Dyna Drive in the autumn, then drill with the Claydon, rake and roll. Oil Seed Rape he just uses the Claydon and then ring rolls. Rick will also Flat-lift where required at OSR and second Winter Wheats. The thing that did surprise me was that Rick wasn’t using cover crops at all and he admitted it was an area where he didn’t have a lot of expertise. It would certainly help with organic matter levels and given he uses the Dyna-drive in the autumn anyway prior to Spring Barley then he could seed at the same time and not involve an additional pass.

Machinery

In terms of the machinery Rick is currently using on the Farm. They are as follows: 4.8m Claydon (2011). Then in no particular order he has: John Deere 7530 – 4250 (2008), John Deere 6620 – 6950 hours (2006), John Deere 6430 – 2100 hours (2012), Massey 3085 – 6900 Hours (1995), Case 1494 – 5700 hours (1984), Massey 7380 25ft – 1100 Hours (2013), Manitou 9m Telehandler – 7100 hours (1998), Amazone 24m Mounter 2800lt (2012), 3m Dynadrive (2015), low-disturbance flat-lift 2.4m (2018), Claydon 7.5m Rake (2012), 12m Twose Rolls (2000), 6 Furrow KV (1998), 8m Spring Tines (1995), 4m SKH Crumbler (1990), Rabe 4m Powerharrow (1985), KV 24m Spinner (2013), JCB 3CX – 5500 Hours (2002), 2 x Baileys 14T and a Warwick 16T.

Direct drilling is known to have a lower horsepower requirement. The 2006 John Deere has depreciated well. The reality is that this is still a lot of machinery for a no-till farm to have, but given the machine ages you could also say there in no harm in keeping them as they have very low depreciation.

Soil Pit

The first stop on the farm tour was the soil pit with Dr Jackie Stroud or Rothamsted and Ian Robertson of Sustainable Soil Management. The pit had been dug on the edge of a field adjacent to the river on part of the flood plain. As you would expect, even in the dry summer we had, the moisture levels were still good. The crops looked excellent at this location and Rick estimated that this part of the field would yield 12t plus per hectare. However, you could see a line in the field where the crops became drought stressed as the land raised up from the flood plain. So the field average was not going to be this high and he hoped it would yield just under 10 for the whole field. Rick explained that over the wet winter we had, although the land had flooded, it had not done so for extensive periods of time. Jackie explained the importance of worm activity in the soil and found some example for us to see and how reduced levels of tillage encouraged worm activity.

Ian went on to explain about root structure in reduced tillage situations and how the crops were able to better access moisture in the soils. These crops had roots going down 4ft into the soil and they were still green and growing well. With 6 weeks to go until harvest it is possible that the crops in this location never became drought stressed at all and will have excellent yield potential. Just one of the benefits of farming on a flood plain.

Farm Tour

Rick took us around a number of fields, given some fields were on a flood plain, there were vast differences in the crops. Drought stress had meant that some were really struggling. We stopped at some of the better OSR with Rick saying why he felt this field had done better than the fields by the entrance that we all drove past on the way in. By Rick’s own admission, he certainly isn’t proud of some of his crops this year, but given the weather conditions, it looked like he was still going to get good yields overall, but nothing ground breaking on average.

It will be good to get an update from Rick in the future on what his yields were and how much they were down on 2017. It has been theorised that no-till farms wheat will yield closer to average figures than conventional tillage farms in a year that has had limited rainfall. Hopefully we will have more data on this in the coming issues. This year Rick explained that he was growing 242 Ha of Milling Wheat (Crusoe, Skyfall, Gallant and Zyatt), 55 Ha of Oil Seed Rape (V316, Campus and Elgar), 64 Ha of Spring Barley (Explorer), 17Ha grass and 26 Ha of margins, mid-tier and tracks.

Cost of Establishment

Looking specifically at the cost of establishment, which for many is the key driver to a move to a reduced tillage system, Rick was able to share a number of figures. The figures themselves had come from Labour and Machinery reviews being conducted by Strutt & Parker across the Monitor Farms. What can be seen from these figures is that there is clearly room for Rick to reduce his cost of establishment further. On a no-till farm you could see fuel usage as low as 3-4 litres per hectare. And with this reduced fuel cost, comes reduced repair and labour costs.

Having said this, the review showed that Rick had one of the two lowest wheat operational costs, with the other lowest cost producer also direct drilling. However, in general, they said there wasn’t a significant correlation between establishment strategy and labour/ machinery costs. Some of the cheapest producers were still using the plough in the rotation. The reviews recognized that this is because these producers had lower labour, depreciation and repair costs, and therefore the type of cultivation or increased fuel usage made less of a difference.

Taking into account all farms, when investigating a farm’s machinery costs. The labour and machinery reviews found that on average 26% was fuel, 35% was depreciation and 19% was repairs. Therefore, if a grower was adopting a mixed cultivation strategy and running well-maintained 2nd hand machines and implements it could still be as competitive as a direct drilling farm, despite the higher fuel costs. As always, it is so difficult to compare like for like in these situations, but it doesn’t seem that there was a lot of no-till farm data in the mix here.

The Evening BBQ

The evening ended enjoying the summer whilst having a BBQ and chatting to the other farmers who had turned up from the local area to find out more at the Monitor Farm event. The number of farmers attending is a testament to the Monitor Farm programme and the part it plays in helping farmers learn from each other. My lasting impression was of Rick’s eagerness to keep learning and keep improving the way he farmed. He recognised that he still had his fair share of problems and having made the big leap to massively reduce the amount of ploughing, he now could make further changes to improve his profitability.

Future meeting dates at the Northampton Monitor Farm:

27th November 2018, 18th December 2018, 22nd January 2019 and 13th February 2019. For further information, please visit: cereals.ahdb.org.uk/Northampton or contact Harry Henderson on harry.henderson@ahdb.org.uk.

-

TO TILL, OR NOT TO TILL, THAT IS THE QUESTION. FINLAND HAS THE ANSWER

Written by Harry Henderson of the AHDB, August 2018

Take a look at the European Conservation Agriculture Federation website and you’ll see Finland has the highest percentage of arable cropping in a no-till system in Europe – 13 per cent (the UK stands at 8 per cent). While you can understand dry-land countries, such as Brazil and Argentina, moving almost completely to a no-till system, why would a country where the southern tip is at the same latitude as the Shetland islands (and, presumably, a maritime climate similar to Scotland) have the greatest uptake of no-till cereal production in Europe?

It seemed the only way to find out was to stand in a field with a Finnish farmer and hear for ourselves. So in late May, bags packed, I flew to Helsinki with our strategic director Martin Grantley-Smith. First things first is day length. We landed at midnight. Although the sun had set, it was still reasonably light. By the time we got the hotel at 1am, it was already getting lighter. More on day length later… Some facts on Finland

• There were a total of 48,562 agricultural and horticultural enterprises in Finland in 2017. The number of farms dropped by approximately 1,000 on the year 2016.

• The average utilised agricultural area of the farms was 47 hectares.

• The average age of farmers on privately owned farms was 52 years.

• About 86 per cent of farms were family run farms and nine per cent were farming syndicates, less than three per cent were heirs, and less than two per cent were limited companies.

• Approximately 9 per cent of all farmers on privately owned farms are under the age of 35 and 27 per cent are over the age of 60

• Nearly 70 per cent of farms have plant production as their primary production line, and nearly 30 per cent of farms are classified as livestock farms. The rest of Finnish farms are mixed farms, with no clear primary production line

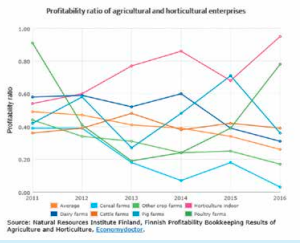

Look at the yield figures and profitability of Finnish farming and you soon get the sense that things are fairly tough. Yields, in particular, are poor.

The perception is that long summer days, 22 to 23 hours of sunlight at high summer, is good for plant growth and yield. But due to the cold, deep winters – where the sun rises at 9:30am and sets at just after 3pm, giving just under 6 hours daylight at the shortest day – the stress on the plant with the advancing spring is just too much to produce yield. For both winter and spring sown crops. This limits yield and with costs being similar or more than in the UK, income from growing cereals in Finland is hard to come by. Looking at the chart below, costs of growing a cereal crop have hovered around the 1350 to 1400 Euro per hectare mark. Divide this cost by an optimistic yield of 5.5 tons/ha of winter wheat brings a cost per ton of 255 Euros. With reducing EU support in recent years, this has made farming a financially tight business, if not a lossmaking activity.

With this, Finnish farmers have done two things. Cut costs to the bone and gone out and got a second job. A few farmers have taken on neighbouring land but an iron grip on costs still prevail, getting bigger does not mean bigger tractors for all, it means longer hours in the same tractor, double shifting with the wife in the peak time of spring.

After hearing this, it dawns on you that no-till is not a choice, it’s a necessity. Allowing compaction to creep into your soils and going out and correcting it mechanically is just not affordable. Finnish farmers had heard of the British love of recreational cultivations and smiled at us sweetly. Looking at no-till in Finland, they run a finely tuned system – all cost driven. The rotation is long, often containing winter wheat, faba beans, caraway seed, spring barley, oilseed rape and a small amount of set-a-side. Finland is, in fact, the world’s largest exporter of caraway seed, a semi-permanent crop that is combined for seed for several years and is a good addition to the gross margin.

The tractors are, for all field work, fitted with dual wheels all-round and are light high power-to-weight ratio 100hp to 140hp machines, nothing above 200hp at all. Unsurprisingly, the most common make is the home-built Valtra, built 190 miles North of Helsinki at Suolahti. The drills are also supplied domestically, either by Tume or Multiva. They are simple box drills, capable of handling seed and fertiliser and, importantly, able to work in a ploughbased seedbed or no-till. Both are discbased with attention paid to seed-depth control (essential for working in a range of conditions and soil types) supplied by rubber-tired depth wheels running close to the seeding disc. While a six-meter version is available, the vast majority are either three- or four-meter.

The thinking here is that if you limit the size of the drill, you don’t need a big tractor with a high traction requirement and so limit the chance of any compaction getting into you soils. Did I mention that compaction is absolutely avoided? Need more capacity? Have to be gettingon and not messing about with tiny drills? Get your neighbour in with their drill, set up a double shift and just get on with it! Finnish farmers were keen to get across that the hectares can be covered, if you keep the drill running. The drill was simply built to keep costs down, they doubted that air-seeders gave a justifiable improvement in seed placement and, while quite aware of precision farming, Finnish farmers just couldn’t see the cost benefit, preferring to focus on good farming practice. Having said all that, there’s a little twist. The Finnish government financially supports no-till farming.

Yup. I’ve said it now. You may well think; ‘well no wonder they are so keen’ but to be fair there is a good reason. I’ve mentioned the cold winters. After Christmas, temperatures regularly get to -20 Celsius and rarely get above freezing for two to three months. That can freeze the ground to a depth of 50cm. Permanent snow cover starts typically after Christmas in the Southwestern corner, but before mid-November in most of Lapland. The maximum snow depth is usually found around March.

Snowmelt contributes to spring floods. In the north, the peak flow of rivers always happens in spring; in the south 70 to 80 per cent of floods happen in spring. In the south, maximum flow happens in mid-April, in the north, in mid-May. And it’s this high risk in saturated fields with the huge potential of nutrient run-off, especially phosphate and topsoil loss, that leads the Finnish Government to pay farmers not to create a tilth that is more vulnerable to soil loss.

The Finnish farmer receives 30 to 40 euros per hectare each year for every field drilled, and/or left undisturbed. So. Key learnings to take home from Finland:

1. Compaction. Compaction. Learn to avoid it, rather than buy something to remove it. This is going to be tough for UK tractors adorned with ever-increasing sizes on weight boxes up front.

2. Rotation. Rotation. A long rotation and plenty of spring crops feature here. No time in the Finnish growing season for cover crops. All crop residue is left on the soil surface, as much as possible.

3. Farmer mind-set. If you expect no-till to fail, it will. The key component is the person in the tractor seat. If the attitude is not right, forget it – it’s not for you.

4. Be flexible. Finnish no-till farming is driven by economics, not fashion or religion. Most farms own a plough (they have a low resale value so it’s not worth selling) and will use it if needed. Also, if weather has delayed drilling, they are happy to use a light spring tine cultivator to open up the soil a little and drill.

5. Small machinery. Did I mention compaction? Less weight, more units, more hours in the seat (when the land demands it). So, 24-hour running is not unheard of at peak times. Time is short, summer is coming and while long days help, the season is short.

-

SOIL ASSESSMENT METHODS

AHDB

Soil Health