If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

National Organic Combinable Crops (NOCC)

By Richard Harding

Organic’s potential for whole farm improvements came under focus at the UK’s largest organic on-farm eventThe 2018 National Organic Combinable Crops (NOCC) conference brought organic and non-organic growers together to hear the benefits organic systems bring to the farm business and the farmed environment. It is noticeable again this year the increasing number of farmers and agronomists practicing Conservation Agriculture who have become regular attendees. Held by Organic Farmers & Growers at Green Acres Farm in Shifnal near Telford, Shropshire. The day took place on another extremely hot July day, NOCC featured experts from across the production and supply chain. The day began with first speaker NIAB’s head of farm research Liz Stockdale, who discussed the organisation’s £1m, five-year project to improve understanding of soil health and biology as part of a whole eco system management. Liz is someone who has a natural gift to make a complex subject easily understood by all.

It is always welcomed by organic and conventional growers alike to reinforce the importance of soil biology as the driver of a sustainable farm business. Joel Williams an independent plant and soil educator followed Liz in echoing the importance of soil as a complex ecosystem and drilled down further into the integral relationship between the soil biology, chemistry and physics. Stating “they all have equal importance”. As with any farm system effective marketing is crucial. Lawrence Morden of seed merchant Walnes, joined the line-up to discuss the company’s project with farmer collective Organic Arable to develop plant varieties which will thrive equally in low-input regimes or an organic systems.

This year’s renowned NOCC lunch was provided by Kimberley Bell of the award-winning Small Food Bakery. As a conventional agronomist it is very noticeable the stark difference between the quality and care taken over food at organic events compared to conventional grower meetings. Kimberley and her team, who won Best Food Producer at the previous month’s BBC Food and Farming Awards, included many of the key crops grown on the farm in their menu to demonstrate the bakery’s approach to reconnecting food with the farmers who produce it.

The day was rounded-off with a farm walk, looking in detail at NOCC host Mark Lea’s business, which includes a green waste composting operation. It was a chance to look in detail at all the crops being trialed on the farm. These including wheat varieties Evolution and Spyder, KWS Basset, Crispin, Montana and Siskin, as well as the results of a bicropping trial of peas and triticale. The triticale being used to hold the peas up making harvest easier and improving the overall quality of the peas.

Mark explained “We’re always interested in trying different things on the farm, and hosting NOCC has given us even more motivation to experiment with what we trial here”. “Being organic has opened up a huge number of opportunities for us, not just in terms of what we grow and our production cycles, but also in how we manage the land to ensure that it is in the best possible state to produce food.” OF&G chief executive Roger Kerr explained that NOCC – which is now in its 11th year – has long been the highlight of the organic farming calendar.

With so much uncertainty on the horizon, all farmers could benefit from learning more about the developments and opportunities offered by this system. “A profitable and successful farm businesses need to be resilient in terms of economics, agronomy, and the environment,” he says. “Organic farming simultaneously offers all of these and in the face of major challenges, farmers need to build greater resilience into their businesses.” Whatever your views on Organic farming NOCC always provides an opportunity for farmers to come together and learn from each other whatever their system. It’s also a place to get new ideas and leave inspired by what is possible when you work more closely with nature. However, it is also a cautious reminder of why many farmers are addicted to a solution in a can. Here’s looking forward to next year and I hope to see you there

-

Base UK French Farm Tour Nov 18

By David White

A predicted slowish drive down the M11/25/20 turned out as predicted. Richard Harding my observer and I had left in plenty of time to catch our EuroTunnel train so a coffee and croissant in the terminal building we slipped under the channel on route Dieppe. Day one had been reserved for travelling down but rather than fill it with a long lunch stop at Le Touquet I had researched the resting places of some family members killed in the Great War so I could pay my respects. Blue sky and 17 degree temperatures made for a very pleasant drive across to Auby our first cemetery destination. November 1st was All Saints Day in France which meant the town cemetery was still brightly decorated with Chrysanthemums. After somewhat of a struggle we found a pair of simple graves that had been immaculately looked after by the Commonwealth War Graves Commission in the decades since the war, as they will be going forward.

Next stop Louvencourt, a CWGC cemetery, again immaculately tended on a quiet country lane which looked out over the peaceful French countryside, very different from what the scene would have been 100 years earlier. A plaque detailed the history of the battles on the Western Front and highlighted areas that had been fought over several times as each side gained a temporary advantage. I laid a poppy, left a note in the book of remembrance and we headed off for our overnight stay, covering miles in minutes that had been hard fought over for years ten decades earlier.

If you have family members who fought and fell in either of the wars a visit to their resting place is something you should try and do. My two relations, both young men were sadly killed in the last few months of the war. It was a special thing to be able to visit their resting places 100 years on in memory of their sacrifices.

Normandy

The French countryside in this area was punctuated by fields containing either just mustard that was being flailed and disced, through to a few with very varied cover crop mixes. Although spade-less we could not resist getting out to have look at what was growing in some of these fields. As some of the species growing we didn’t recognise Richard did he usual taste test to see if we were looking at turnips or radish, hot after taste so radish! Lots of questions for Victor about French farming regulations when we meet tomorrow. We dined very well in Dieppe, this was France, and after a comfortable night in a sea front hotel and a good continental breakfast we headed along the coast road through some lovely seaside villages to meet great friend of BASE UK Victor Leforestier at his first field.

This land, just in from the Normandy coast is very productive, capable of growing vegetables and roots and as evident from the operations being carried out, the plough and power-harrow drills clearly still favourite. These farms can produce 10t/ha of wheat quite easily, why change? The rules governing greening in France allow for destruction from Nov 1st so there were discs, ploughs and drills turning mustard cover into wheat everywhere. We have the impression that many farmers were “greening” because they had to, not because they could see the wider benefits.

We were greeted by a very different scene when we arrived at Victor’s field, no mistaking that we were in the right place (see pic 1). Victor is somewhat unusual in the world of Conservation Agriculture in that he is working with three root crops in his rotation, beetroot, potatoes and sugar beet, but still extensively using cover crops to build SOM and biology. He strip-tills for sugar beet but practices fuller cultivation for beetroot and potatoes. He rotation is built around flax, widely grown in Normandy, but also grows wheat and barley and we saw some impressive clover “understory” in some barley stubble. Initiatives like this and cover crops growing in potato ridges show what is possible in a non 100% combinable crop rotation. Victor had his tele-handler at the field to dig some soil profiles which demonstrated very well how he’d built up the organic matter near the surface and how roots had taken advantage of the impressive worm holes.

We enjoyed a very relaxed (this was France) lunch at Les Fregates Resturant in a little coastal village Veulettes-sur-Mer, then escorted by Victor who was acting translator for the afternoon visited Emmanuel Bellest who farms at Paluel. Emmanuel is also growing sugar beet in his rotation using strip-till with autumn sown cover crops, also like Victor he had the most amazing fields of multi species cover crops in flower and was using compost amendments and carrying white clover companion established in rape through several years of his rotation. You don’t get to visit some of the very best BASE France farmers without clocking up a few miles so on leaving Victor and Emmanuel we headed 150 kms west to Amiens for our second night.

Our town centre Ibis didn’t promise to much from the outside but the rooms were clean and comfortable (to comfortable for one who slept waaay to well….), it had a bar and secure underground parking, Result! So as to not dilute the memory of the exquisite dinner we’d had in Dieppe, and also to keep the trip on budget we went for a less upmarket resturant this time, we reasoned that as some locals were dining there it should be ok but the laminated menus should have been a clue to the fare we were about to have, if you value steak by how much chewing it takes to be able to swallow it we got great value!!!

Early to rise (for most of the team) resulted in a quick breakfast and check-out then 100 km drive south to the beautiful estate farm of Frederic Remy. We were greeted by Frederic and our host for the afternoon Julien Senez at a very impressive machinery shed and grain store. I had my usual attack of French trailer envy, gosh they do have fabulous trailers, and the Fendt on a new Horsch Avatar drill just off the do some contract work for a neighbour equally impressed. But as we know its not all about the machinery so over a coffee and croissant we enjoyed a very informative short presentation on Frederic’s farming history at the estate he manages and journey into Conservation Ag.

Both Frederic and Julien had a good enough command of English for us to have a good understanding of what they are striving for on their farms, Conservation Agriculture is of course an international language. Frederic does indeed have a very beautiful farm, just 14 kms from Paris he can see the Eiffel Tower from his tractor cab. The farm with its woods and glades, lake, beautiful old buildings, a small estate church and Castle make it the most amazing place to live and work. Frederic’s fields were immaculately farmed too, crops edge to edge even, save for a wheat headland grubbed up by wild boar, and his attention to detail and huge enthusiasm for how he is now farming and the success he’s had over the last five years was infectious.

Lunch time again and this time courteous of Julien in a gorgeous conservatory at a golf club near his farm at Vignemont. Julien has been zero-till for eight years and in that time has done around 60 trials on his farm to work out how to improve his soil to give increasing and reliable yields. Standing in a flowering cover crop that was around 5 feet tall made up of a 15 way mix looked to be cover crop perfection. But due to the high carbon to nitrogen ration of the crop residue in Julien’s wheat, barley and grain maize rotation he wanted to increase the nitrogen element so this cover was about to be terminated and then have a high % legume mix drilled into it to provide fresh new growth for the next 5 or so months before maize planting time.

The soil in this field had around 40% clay content but had the colour and structure of something you would find in a grow-bag at a garden centre. As France has already lost neonic seed dressings on cereals we saw many later planted crops which helped offset the need for early insecticide sprays as did planting into “the green” with the cover crop vegetation hosting some of the aphids instead of the cereal plants. Our final field stop was at the bottom of a sloping field which had a newly planted agri forestry scheme on it to help overcome drainage issues.

Some common themes on the very innovative farms we visited were; improving soil structures and nutrition, the use of cover crops in a rotation with roots, companions with rape, clover lasting through 2 or more crops in the rotation, strip tillage, very dense diverse cover crop mixes with investment in seed much higher than would be considered in the UK, the importance of on farm trials and time spent on research plus visiting other farms to build a personal knowledge base, the reduction in inputs, machinery labour and tractor hours that Conservation Ag brings to a farming business freeing up time for those farmers to spend doing other things, enriching their lives. On behalf of the group I’d like to thank Victor @VictorHolistic Julien @Senez8 Frederic @fredericremy95 and Emmanuel Bellest for their hospitality, generous time given and knowledge sharing that made the trip so worthwhile.

-

Discs Versus Tines At Petworth Monitor Farm

AHDB’s Petworth Monitor Farm group reignited two popular debates at their recent meeting (18 October 2018): discs versus tines and ‘to till or not to till’.

The Monitor Farm group is hosted by Mark Chandler at Moor Farm in West Sussex. Mark and the other farmers in the group wanted to see how different levels of cultivation and types of drilling affected his first wheat crop, following beans. In a normal year, Mark would cultivate behind the combine with a Simba SL600 cultivator running LD legs and points. He would usually use an LD subsoiler and carrier disks on compacted areas or tramlines, before drilling with a Horsch Sprinter Drill or Amazone Cayena lowdisturbance tined coulter drill. Paul Hill, AHDB Knowledge Exchange Manager, said: “Does Mark actually need all the machinery he has and can he get away with doing less tillage, so saving time and money? We looked at these questions and more during the Monitor Farm meeting.” The experiment at Moor Farm includes:

• Six plots, 2ha each, two tramlines wide

• Three plots undisturbed

• Three plots cultivated

• Simba SL cultivator straight after combine

• Vaderstadt Carrier Disk

• Weaving LD

• Half of each plot was drilled with Skyfall wheat to a depth of 2.5cm with a Horsch drill (tines) and half with a Sky Easy Drill (discs).

At this stage in the season, Mark and the group assessed the different plots by digging pits with soils guru Philip Wright. These pits were compared with un-moved ground in a neighbouring field which had generally very good soil structure. Paul said: “During the meeting, perhaps the most crucial topic we covered was how to dig a soil pit correctly. It sounds simple, but if not done right it could make it extremely difficult to analyse your soil structure properly.” Mark found that looks can be deceiving, early on in the season. He said: “The cultivated plot, although it looked good, was over-cultivated because actually the baseline soil structure was ok.

But by cultivating, we’d made the top four inches too fine which held the moisture up. It sat wetter and didn’t walk as well. “But the unmoved ground which we’d disc drilled was cosmetically poor but actually the soil structure under the surface was good, with good water penetration. Although it’s very early to judge the emergence, the rooting depth was looking good.” Throughout the growing year, Mark will be measuring seed germination, plant counts and, finally, yield. Paul Hill said: “This kind of measuring can be done with the AHDB Wheat Growth Guide. The Guide gives farmers a great baseline to compare different approaches against. It’s also a good idea to repeat the same on-farm tests over a number of years.”

Mark said: “The key so far, we’ve found, is to be versatile and make each decision according to the conditions in the field. Our soils are quite variable, so our management approach needs to be variable too, although this does take more time. We need to fine-tune our decisions and pay close attention to the soil.” What’s next? Over-wintered stubble before barley. Ordinarily Mark would cultivate the field and spring crop for black-grass control. The soil doesn’t need working, so he’s looking at keeping the surface cultivation as shallow as possible, but enough to get a black-grass germination. Find out more about the Petworth Monitor Farm at cereals.ahdb.org.uk/ petworth or contact Paul Hill on 07964 243699 or paul.hill@ahdb.org

-

Drill Manufacturers In Focus…

CAN’T AFFORD A CROSS SLOT, THINK AGAIN…

The Cross Slot from New Zealand has for many become the pinnacle of drills, with unique coulter, ADF technology and heavy build quality that was second to none. This unrivalled quality came at a price, built in and imported from New Zealand any Cross Slot Drill that arrived in the UK or Europe represented a significant investment for the buyer.

We are excited to announce that things are changing. Cross Slot drills will now be built in Europe bringing the unique NZ designed coulters together with a frame built in Europe and electronics from Germany. With this new process comes better efficiency and a new pricing structure for what has always been the “Rolls-Royce” of no-till drilling machinery.

The Cross Slot branded drill will be the only drill to feature Dr Bakers coulter design in the UK and Europe, branded and in the familiar red/ white colours of the original New Zealand built Cross Slot machines. In a world where other manufactures seem to constantly be raising prices Cross Slot prices are now set to drop significantly in both Europe and the UK. If you weren’t considering a Cross Slot before, now you should be. If you have always thought highly of the technology and quality build that comes with a Cross Slot drill but felt it was out of your price range – think again.

For more information about this exciting development contact us askus@CrossSlot.com

-

Primary Cultivation And Wheat Yields – Long-Term Work At NIAB, Lessons From STAR And NFS

By Nathan Morris, Elizabeth Stockdale, David Clarke – NIAB

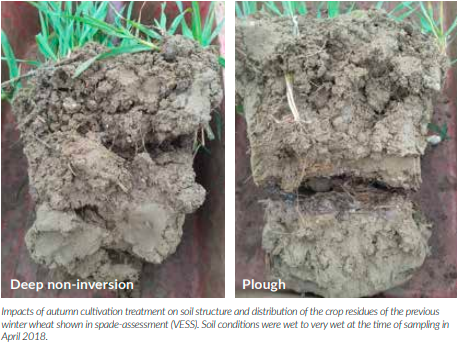

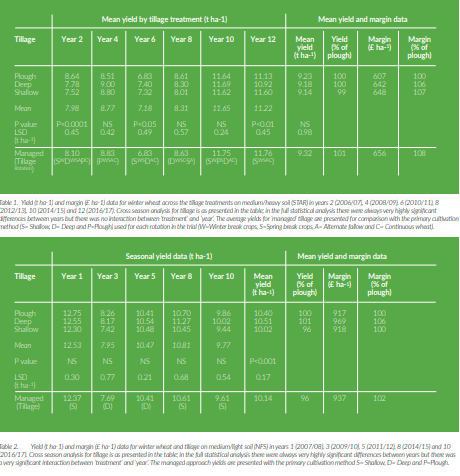

Long term findings from field-scale experiments (STAR and NFS) show that while yields with non-inversion tillage are similar in most years to yields with ploughing, when decreased costs of labour and fuel are factored in, gross margins under non-inversion tillage were better than under ploughed systems. Hence non-inversion tillage is advocated under ‘normal’ conditions.

The influence of primary cultivation method on crop yields will no doubt continue to cause debate, but long-term findings from the STAR (Sustainability Trial for Arable Rotations) and NFS (New Farming Systems) projects are giving some hard evidence of impacts across seasons and soil types. The long running STAR project in Suffolk (medium/heavy, clay loam soil) and NFS studies at Morley in Norfolk (medium/light, sandy loam soil) started in 2005 and 2007 respectively. Both studies therefore allow us to study impacts over the long-term and have allowed the impacts of the tillage systems to become established. NIAB co-ordinates and manages these trials but they are funded by a number of charities. The Morley Agricultural Foundation (TMAF) and the JC Mann Trust provide continued support for the NIAB New Farming Systems projects; the Felix Cobbold Trust and, historically, the Chadacre Agricultural Trust provide support for the STAR project.

The STAR and NFS projects are field-scale trials using farm scale equipment and techniques with fully replicated large plots. The experiments have the same primary cultivation treatments; however, the difference in soil type between the two sites provides an important contrast when considering tillage impacts. The proportion of particles of different sizes (soil texture) that make up the soil have a large impact on the soil structure and properties such as trafficability and workability. For example, clay soils usually have more small pores than sandy soils and these can hold on to more water for longer. Soil structure results from the interaction of the mineral particles (sand, silt and clay) with soil organic matter as they aggregate together to form the crumbs, blocks and other aggregates that we see when working the soil. In some ways, it is the gaps (pore space) between these aggregates that is the most important part of structure as the pores control the balance of oxygen and water available to plant roots and soil organisms.

Cultivation has a key role in shaping the soil structure. However, plant roots and some soil organisms (known as ‘ecosystem engineers’) also change the structure of soil by moving through the soil, moving soil particles around and extracting water. Along with a range of physical (drying-wetting) processes, these biological interactions have a central role in soil structure development and create micro-habitats for other soil organisms; in temperate agroecosystems, earthworms are very dominant within this group. In the STAR and NFS trials we are comparing 3 contrasting primary cultivation practices: inversion (c. 25 cm plough) and non-inversion tillage (using the subsoiler / disc-based combination, e.g. Sumo Trio) set either deep (c. 20-25 cm) or shallow (c. 10 cm).

These systems are used typically for primary cultivation each year to give the three main treatments. In addition, each study also has a treatment which allows a ‘managed approach’ where the cultivation system used changes with study, season and crop. The annual cultivation decision in these treatments is based on soil conditions, field assessments, previous cropping, weed burden and local best practice (see Table 1 and 2). Secondary cultivations (e.g. power-harrow, press) are used as needed on a treatment by treatment basis. The specific crop rotations used also differ between the sites, however, in both studies rotations employ only combinable crops and include regular winter wheat alternating with combinable break crops.

Winter wheat yield

In both STAR and NFS the regular cropping of winter wheat in the rotations provides a unique opportunity to examine the impact of primary tillage on long term performance of first wheat yields in large scale fully replicated studies. Statistical analysis has focussed on the ‘consistent systems’ (where treatments have remained the same over this time period). Winter wheat yield data for from harvest years 2, 4, 6, 8, 10 and 12 of STAR project are presented in Table 1. Analogous data from harvest years 1, 3, 5, 8 and 10 of the NFS Cultivations study are presented in Table 2. In both studies, winter wheat yields vary markedly with the season; i.e. year has a statistically significant impact on yield. In terms of the impacts of tillage systems, there is no clear pattern in all years.

Considered on average across seasons, in STAR there is no difference in the yield of the different primary tillage systems. In NFS taken across all years, there is a significant reduction in yield (-4%) in the shallow non-inversion systems compared to the other approaches; however, the difference is not significant in any individual year. This is possibly associated with the lighter soils being more prone to loss of structure where some rectification / management is not used. Overall these findings suggest only small percentage yield reductions with shallow tillage (cf. plough systems) indicating that wheat yields are relatively robust with respect to the tillage approaches assessed on these sites. More data analysis and crop modelling may help to explain the differences in the treatments year by year e.g. in terms of the direct impact on seedbed quality and consequent establishment.

At STAR the managed approach to cultivation gives a slightly higher average yield compared with the treatments where the primary cultivation techniques are applied consistently. At NFS yields are 4% lower under the managed approach compared to deep and plough tillage, possibly as a result of the high proportion of shallow tillage used (3 out of 5 years).

Winter wheat margins

When considering gross margins, both STAR and NFS non-inversion treatments (shallow and deep) resulted in greater margins in first wheat crops compared to the plough. For deep non-inversion treatments this benefit was 6–7% and for shallow non-inversion treatments gain was 1–4%. Margins were also increased in the managed approach compared with the ploughed treatments. However, in addition to margin it should also be noted that ploughing would have also resulted in slower speeds of working (cf. non-inversion tillage systems); this would potentially improve a farmer’s capacity and hence ensure timeliness of operations over the total farm area. This is potentially of greater importance than small differences in rotational margin.

Other impacts

In soils under non-inversion tillage, we found increasing tightness in soils in the upper subsoil; however we also sometimes found large improvements in soil physical conditions over a growing season driven by the growing crop. Where there were no changes in the organic matter inputs, there were no gains in carbon storage over the whole soil profile under noninversion tillage (compared with ploughed systems). However, with non-inversion tillage, organic matter becomes more stratified in the soil with higher amounts in the surface soil and lower amounts at 20-25 cm compared to ploughed plots. Currently herbicides are managing the weed burden on all treatments effectively – however, this year we are monitoring some un-treated areas to assess the role of the primary cultivation strategies on the weed seedbank.

Overall, the work in these studies and others is confirming that alongside decisions about primary cultivations, farming systems that support the biological processes of structure formation and increasing soil organic matter content have been shown to help create resilient soil structures that can both absorb heavy rainfall and hold water in drought; however, there is still a way to go before we have fully uncovered the mechanisms supporting structural resilience.

Acknowledgments and thanks are extended to The Morley Agricultural Foundation (TMAF) and The JC Mann Trust for their continued support of the NIAB New Farming Systems programme; also to The Felix Cobbold Trust and historically The Chadacre Agricultural Trust for their support of the STAR project.

-

Medicine’s Gone From Invasive To Keyhole, Farming From Keyhole To Invasive

Based on Interview with Dr John Baker, CrossSlot New Zealand.

Medicine has made quantum leaps in research, treatment and surgical procedures in recent years – now it’s time for arable farming to follow suit.Where medicine has moved from invasive to keyhole surgery, agriculture has gone from keyhole to invasive farming, resulting in the depletion of quality soil and contributing to global warming. International soil scientist, John Baker, says medical science, since last century, has learned to operate on people without disturbing anything more than the immediate part of the body being replaced or repaired. That meant the body wasn’t violated unnecessarily as surgeons identified the problem area. “This quantum leap resulted in significant improvements in survival rates, healing times and postoperative stress,” John Baker says. “Medical science is leading the way and continues to strive for improvement.

Why isn’t agriculture doing the same?” Dr Baker acknowledges that aspects of farming such as GPS guidance and precision farming have shown advances in accuracy, but the most fundamental task of all – seed sowing – is millenniums old. Arable farmers are still sowing seed with the same method that Jethro Tull invented in 1701. He explains our first farmers in Biblical days poked a hole in the ground and sowed a seed – an early form of keyhole surgery – but when someone shackled a primitive plough to a bullock, they started practising invasive farming. “The idea of the plough was to bury the weeds and loosen the soil to make it soft so they could create a trench and deposit the seeds more easily. Today farmers are still ruining the soil using the same system but with more sophisticated machinery,” he says.

Every time any form of tillage tool opens the soil, it releases carbon dioxide into the atmosphere which contributes to global warming. About 20 percent of atmospheric CO2 results from the world tilling its soil each year. It also loses humidity, essential for seeds to germinate and destroys microbes and earthworms which maintain the health of the soil. Dr Baker points out that this is not how nature intended it to be done. He explains that, in nature, most deciduous plants flower first, then form leaves. At the end of summer the flowers become seeds which drop to the ground followed by leaves. The end result is that seeds are covered by a mulch of dead leaves which maximises their opportunity to germinate and sprout new seedlings. “But farming hasn’t repeated nature’s lesson. Instead the leaves are buried or burnt – both of which cause more carbon discharge than the soil gains – and seeds are sown into bare soil without the benefit of the rich, decaying organic matter around them,” he says.

Dr Baker says primitive man had a better solution when he poked a stick through the debris on top of the ground to plant a seed. Without realising it, he minimally disturbed the soil, preserved the humidity, retained the microbes and gave the seed the best chance to flourish. While conventional tillage or ploughing increased cropping, its constant rape of the soil has had a damaging global effect. Most of it has gone unnoticed until we woke up and realised that the projected 50 percent increase in the world’s population by 2050 will result in insufficient food to feed everyone and famines in some areas. Low-disturbance no-tillage, which, like rugby football, was invented in Great Britain but refined in New Zealand, uses a method of keyhole farming that primitive man perfected centuries ago.

Low-disturbance, no-tillage drills penetrate through the residue or vegetation on top of the soil to create seed slots beneath it. They can sow the seed and fertiliser in separate bands at the same time. As we have seen the process traps the humidity, preserves the microorganisms which enrich the soil, prevents carbon from escaping and increases crop and pasture yields. “Arable farmers now need to forget about how seeds were sown in the last few centuries and take the quantum leap to do it right from now on,” he says. “Fortunately leading farmers are already doing so.” “While a strong humanitarian reason is to preserve our planet, the most compelling reason for besieged farmers is that it’ll make more money for them.”

-

THE CHALLENGES OF NO-TILL

No-till remains the most exciting, and challenging, development in global farming today. My six years of continuous and enthusiastic journalism on the subject has come at a time of an ever-increasing flow of information. For notillers and those contemplating it, knowledge is essential. However there’s another challenge: getting information into the world of farm supplies and also farm education. Making the most of the new techniques; having knowledge and sharing the experience to predict and avoid pitfalls, all involve effective research and development. No-till has already had an impact on machinery, but crop rotation, fertiliser use, seed rates, timeliness are topics that present equal challenges to both the notill farmer and advisor, and all are comparatively new. Farm suppliers have an obvious need for genuine knowledge and experience which they can hand on to customers. Education is front-line and key to success. This third issue of Direct Driller shares a great deal of information that is of direct relevance to all those involved in the technique. Behind these pages is a huge wealth of knowledge, and the intention of this publication is to bring people together for the benefit of everyone involved.

SUPPORT FOR DIRECT DRILLER MAGAZINE FROM GEORGE EUSTICE MP

In February, just before the first Issue of Direct Driller was launched, we were invited to speak to Michaels Gove’s Defra

team about what constitutes systems of reduced cultivation and how they can be monitored in the future.After Issue two we again contacted the Defra team to see what they and the government in general thought about the focus of Direct Driller Magazine on improving our soils and reducing cost of establishment in the UK. In response, Farming Minister George Eustice said: “The work that farmers do to replenish our soils, cleanse our seas and rivers and cut greenhouse gas emissions is vitally important. “Leaving the European Union provides an opportunity to design a new system – public money for public goods – that delivers for British farmers and rewards them for the invaluable work they do to improve the environment. “In our 25-year Environment Plan, we have set how we will improve our soils, including investing in soil health metrics so that we can deliver the connected benefits for water quality and the wider environment.” Which reads to us like those farmers who are running a conservation agriculture based system, with high levels of focus on soil health are going to be those farmers who benefit most from public money in the future. What no one knows, is exactly how Defra will implement this, but we certainly have interesting times ahead!

-

SOIL ORGANIC MATTER AND ITS ROLE IN CLIMATE CHANGE MITIGATION

Written by Mark Measures BSc. (Hons.), IOTA (Accredited), ARAgS, Churchill Fellow 2017 of the Organic Research Centre,

first Published July 2018SOM is important and that poor rotations and lack of organic matter inputs might be something to do with their poor soil structure and static or declining yields. Organic farmers have always believed that SOM is important, not just for soil structure but also for mineralisation, which results in nitrogen release, needed for crop growth and they have in the back of their minds the idea that SOM has something to do with pest and disease control. More recently it has been realised that SOM plays an important part in overall soil biological activity and nutrient release.

The potential for carbon sequestration and for the soil to function as a carbon sink has led some to think that SOM can play an important and major role in reducing green house gases and addressing climate change. Many organic farming practices will contribute organic matter to the soil; grass clover leys, use of farmyard manure, compost, green waste, cover crops and green manures will all contribute to SOM.

The extent to which these inputs will result in a net sequestration of carbon is dependant on how they are processed in the soil, the level of nitrogen input and C:N ratio, on the initial SOM levels, on cultivations, soil type and climate. The evidence for long-term ongoing carbon sequestration from organic farming is not clear-cut and categorical statements that organic farming will have a significant impact on green house gasses and climate change should be treated with caution. The fate of organic matter, or carbon, added to the soil is particularly dependant on its form; fresh manure and slurry will contribute little to the build-up of SOM, but it will supply readily decomposable material that will provide nutrients to the plants.

Compost, on the other hand will provide a more stable form of organic matter, which will contribute to SOM build up. Mineralisation is the oxidation of the chemical compounds in organic matter by the soil microorganisms, in the process releasing nutrients, particularly nitrogen, phosphorus and sulphur in a form available for plant uptake, together with the release of carbon dioxide. This process of mineralisation is brought about by cultivations and aeration and is absolutely central and fundamental to providing the nutrients for organic crop production. Humus is an important component of SOM and of compost.

Humus is relatively stable and is primarily the result of fungal decomposition of lignin and has many roles in the soil including water holding, soil structure and nutrient retention. Farms that use well-made composted manure or green waste will tend to build SOM, while fresh or once turned FYM and green manures will not result in the same build up of SOM. They will of course be tremendously important for providing nutrients in a plant available form, either directly or indirectly as a result of biological breakdown.

Multiple cultivations, whether that is ploughing or repeated use of cultivators will tend to deplete organic matter as it encourages mineralisation. Soil type will have a major impact on SOM accumulation potential; dry, light sandy soils will tend to be difficult to build SOM and such soil in an arable rotation will often have naturally low levels of 1.5 – 2.5%, unless they have evolved under acidic conditions in which case levels of 6 – 10% may be found. Clay loam soils in the UK will typically have SOM in the range of 3 – 4.5%. Clay soils will tend to have higher SOM than other soil types. Finally we need to recognise that the SOM accumulation reaches some equilibrium. Depending on the soil type, management practices, organic inputs, rotation and the cultivations used the accumulation of SOM will tail off at some point; it is not realistic to expect to be able to increase SOM from say 4% to 10% under normal farming practices, an equilibrium will be reached before that.

Does organic farming increase SOM?

The evidence from farm experience in the UK is limited because there has been very little thorough and reliable monitoring; inconsistent sampling methods and field locations, changes in analytical methods and infrequent sampling are all a problem. Experience from the arable organic farms that I have worked with is that sometimes, but not always, SOM levels initially increase following conversion to organic farming from continuous non organic arable cropping;

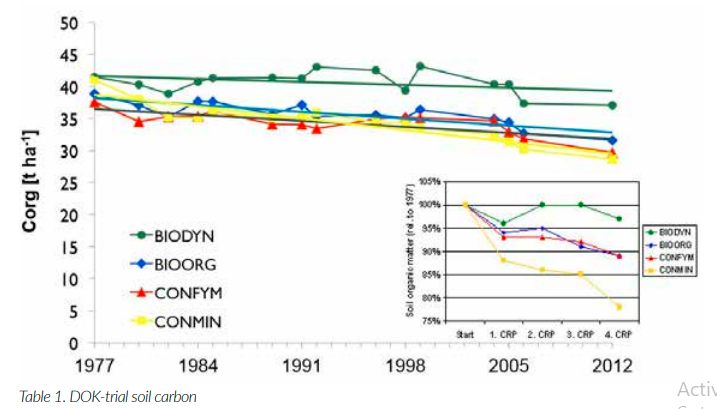

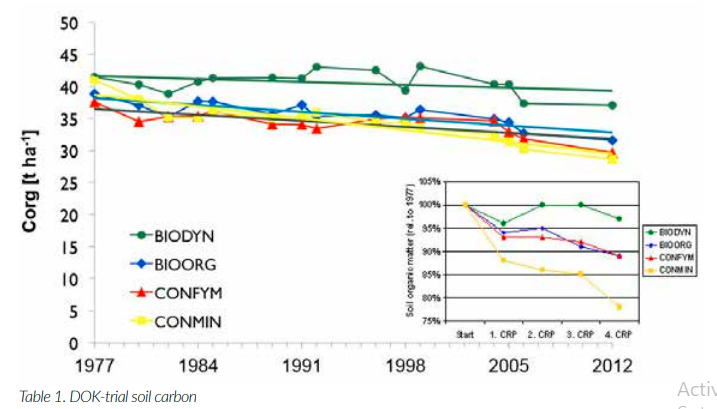

an example from Holme Lacy College shows an increase from 2.7 to 3.1% over 10 years, and average of 0.04% SOM per year. Experience elsewhere is that subsequently increases are small. Replicated research over long periods of time is a more reliable indication. The 40-year-old DOK trial at FiBL (Switzerland) compares conventional, organic and biodynamic systems. The results after 35 years, Table 1. show that SOM levels have declined slightly in all four treatments.

The conventional and the organic treatments are not significantly different, however it would be expected that if the conventional had followed a continuous cropping rotation that this would have resulted in a greater decline and that the difference between the organic and the conventional would be expected to be greater. The biodynamic treatment resulted in a small but significantly higher level of SOM than the conventional or the organic; this may be a result of the use of wellcomposted manure rather than the fresh manure in the organic.

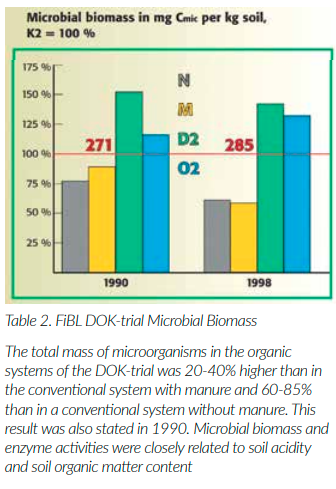

Interestingly there is a significant difference in the soil microbial biomass between some treatments, Table 2., Showing that Organic (O2) and Biodynamic (D2) has greater biomass than Conventional both with manure (M) and without manure (N). The Aarhus University (Denmark) farming systems trial was set up in 1997 on 3 sites, the one at Foulum continues to run. A replicated trial compares organic using both green manure and manure with a continuous cropping non-organic rotation.

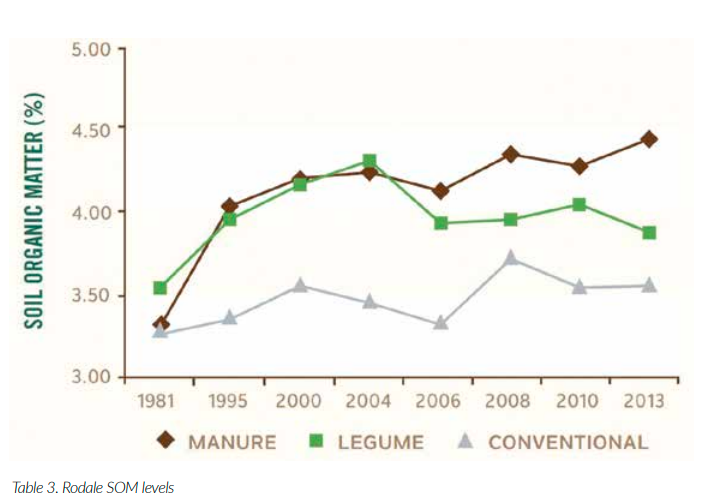

While there are significantly higher levels of carbon inputs to the soil under organic management and there is indication that a one-year green manure with residues returned does increase SOM, overall the conclusion is “not able to detect consistent differences in measured Soil Organic Carbon between systems”. The Rodale Farming Systems Trial (USA) has been running since 1981, it is a replicated trial comparing an organic manure system with an organic legume system with a conventional continuous arable cropping system. Table 3. The SOM levels in both the organic systems increased from 3.5% to approximately 4.25% in the first 20 years (0.37%/year) thereafter stabilising or in the case of the organic legume system subsequently declining to approximately 3.9%.

The conventional has shown some recent decline to approximately 3.3%. In the absence of trial data and peerreviewed papers it is not possible to know the statistical significance of these results. The Scotland Rural College (SRUC) organic systems trial was set up in 1991 following a period of conventional ley arable farming. The results, Table 4. show over a period of 20 years that organic ley-arable under a rotation of 50% ley, 50% arable maintains SOM, but that under the prevailing conditions SOM did not increase, even during the conversion period.

This reflects the previous cropping regime and the fact that these are inherently high SOM soils, in the order of 8%. The stockless organic rotation introduced 8 years ago indicates a slight decline in SOM, but which may not be significant. The conclusion of the review of available evidence undertaken by Organic Research Centre in 2011 is that: Organic cropping systems have considerable potential for increasing soil carbon, through the incorporation of fertility building grass-clover leys and use of livestock manures within diverse crop rotations, when compared with specialist (e.g.: monoculture) cropping systems;

The exact amount of carbon that can be sequestered through organic management of cropping systems is still uncertain, due to the disparity in assessment methods, and farming/ land-use systems; The difference between the wide range of organic and conventional farm types is not yet clear, partly because of the current difficulty in defining these systems and their individual characteristics; Organic management of grassland is unlikely to increase soil carbon levels over those from conventional management, but the reliance on legumes and biological instead of industrial nitrogen fixation will still have a positive impact on climate change mitigation through reduced fossil energy use and related carbon dioxide and nitrous oxide emissions

The ratio of Clay to SOM is considered important by some of authorities (Agroscope and Aarhus University) and it may be a more important measure of the need and potential to increase SOM levels than SOM% per se. Claims that the practice of Mob Grazing results in substantial increase in organic in the order of a change from 3 to 5% over 3 or 4 years have not been substantiated under UK conditions.

The use of very high levels e.g. 50 tonnes/ha/year of imported manure, compost or green waste will undoubtedly result in SOM increase over time, up to a point, but that is not typical of organic farming. The studies that I have seen have focused on arable systems, the situation with permanent pastures is very different, and soils under permanent pasture generally have higher SOM and will have developed an equilibrium. This higher level may be due to both the lack of cultivations and the use of manures and fertilisers as well as forage residues. In my experience there is very little difference in SOM levels between conventional and organic management of permanent pastures.

Conclusions

Based on the evidence of the three farming systems trials that I visited under the Winston Churchill Fellowship in 2017/18, the results of the SRUC trials, my personal experience and the review of research by Organic Research Centre I draw the following conclusions. SOM is important for soil physical, biological and nutrient reasons and mineralisation of SOM is particularly important in organic farming.

The following practises will all tend to increase SOM: Grass clover leys, farmyard manure, compost rather than fresh manure, green waste, over-winter cover crops and annual green manures. The following will tend to decrease SOM: cultivations, continuous cropping, nitrogen supply. Given that organic arable farming involves many of the beneficial practises identified above, there is likely to be some advantage to organic farming during conversion from conventional, continuous cropping conventional farming, particularly where longer leys are involved.

There is no evidence that organic arable farming offers potential for on-going, long term sequestration of carbon in the soil. The indications are that increased SOM levels of between 0 and 0.4% per year may be possible during the first 10 – 20 years of organic conversion, but that this depends on the initial SOM levels, soil type and management practices. Thereafter increases are unlikely. SOM is likely to be higher under some established organic arable rotations than under conventional rotations, but this is not necessarily so and will depend on various management practices, particularly the length of the ley and use of compost. 65% of organic farms in the UK are permanent pasture, not in an arable rotation.

These farms are unlikely to show a significant difference between conventional farms. Organic arable farming has higher levels of soil microbial biomass compared to conventional. Organic farmers wanting to improve crop productivity should focus on improving the quality and biological activity of their soils rather than merely focusing on total SOM. Given the wide range of results from arable system comparisons and the fact that the majority of organic farming in the UK is permanent grassland claims that organic farming will contribute significantly to climate change mitigation through carbon sinks should be avoided.

Climate change mitigation is one the principle challenges of our time and needs to be addressed by a radical change in the food and farming system as a whole, including food distribution and with a particular focus on drastic reduction in use of fossil fuels. Organic food and farming systems offer the best agricultural system to do that. Soil carbon sinks play a supporting role.

-

FEATURED FARMER

DAVID WHITE – HAWK MILL FARMS

Farming 160ha of combinable crops on light “boys” land over chalk between Cambridge and Newmarket, I’ve just had my third direct drilled harvest. I’m 100% combinable having been a sugar beet grower since the days of hand hoeing as well as offering a drilling and harvesting service with a 6 row tanker in the past, I have since stopped growing beet when I wanted to start direct drilling. All crops types are grown for premium markets and are stored in Camgrain central storage which makes having a rotation of 6 or 7 crops and different varieties very easy.

Rumours of my retirement are very much exaggerated

There comes a time in life where the pressure of being either at work or on duty (ie on stand-by in case the wind should drop to allow some spraying to be completed or it being dry enough to drill or harvest a crop) most days of the week for most of the year becomes tiresome.

An opportunity arose to reduce my contracting workload, the distance I travelled and the area I farm. The need to be “on duty” so often came along, so I took it thinking this would be staged or semi-retirement, something farmers are very bad at! This coincided with an interest in a different type of farming being stimulated through discussion on Twitter and The Farming Forum, (I won’t name the culprits as where there is blame there is a claim!) which also requires less “intensity” in many forms. I also have other business interests which bring diversity to my business life through selling Trimble GPS correction signals for precision farming www. rtkfarming.co.uk and the other being Vice Chairman of Camgrain Stores, both of which make farming a less solitary profession and life very much more interesting. So, back to this different type of farming.

Some of the local walkers that use the footpaths through Hawk Mill clearly had heard mention, probably down the pub, of “retirement” and noticing that my fields appear to be growing what are in their eyes weeds thought I had thrown in the towel as the farm looked as if it had gone to pot. “Farming Ugly” as the Americans call it is something that takes some adjusting to as traditionally the best farms have been the smart tidy farms, but I quickly realised that beauty is in fact soil deep.

The journey to a new way of farming.

Conservation Farming, it’s like going back to school and questioning and unlearning most of what I thought essential to be a successful arable farmer, but am now largely not bothered about.

• Inversion of “trash” to stop disease carryover; trash is good

• Deep loosening, especially tramlines so crops can root well; none done

• Annual dressings of P and K to maintain fertility; very little now purchased

• Short stubble for easier management; long is better

• Fine seed beds achieved through intensive mechanical soil manipulation; none done

• Multiple seed dressings to stop disease or early insect attack; not used

• No green bridge to prevent disease and insect carryover

• Wide tramlines so no green grains at harvest; no coulters blocked off as green living tramlines stay drier

• Pre-em herbicides and active stacking essential; use now reduced

• Autumn insecticides essential; reduced through later drilling and companion cropping

A farming career born of ploughing, subsoiling one year in four to 18” deep, discing, harrowing, rolling, harrowing again, rolling again all went out of the window the minute I got my head around the fact that roots and worms do all that for you 24 hrs/day for very little effort and expense. Instead of increasing the size of tractors purchased each change in the traditional way of the agri rat-race I find the smallest on the farm is more than enough for most jobs.

Instead of a tine and disc machine, a plough, a press, another press, a disc-roller and a harrow for every soil condition I now have two drills and some infrequently used rolls doing all the establishment. Homework consisted of reading catalogues of seeds of plants that I’d mostly not heard of, never mind grown before such as Phacelia, Vetch, Black Oats, Buckwheat, Crimson Clover, Forage Rye, Tillage and Oil Radish, White Mustard and Sunflower. What type of root system do they have, how do they influence soil biology? So the result of the changes has been to reduce the fixed costs of running a farm through requiring smaller tractors, less machinery, lower labour and tractor hours, reduced consumption of fuel and wearing parts but with the requirement of increased level of management skills and understanding of how nature works. Trying to work with it not work against or change what naturally happens is a new mindset you have to want to buy into to make Conservation Farming work.

Machinery inventory, listed by importance

• Polaris Ranger (used daily)

• Spade x 2 Fork x 1 (kinder on worms)

• Fendt 716 and 415 with Trimble RTK Auto-Steer

• S/H Horsch CO4 with Dutch openers and Bullock Tillage small seed hopper (soon to be 2)

• John Deere 3mt 750a bought new with Techneat small seed hopper

• Bateman RB25 24mt with full Trimble control

• JCB Loadall 530-70

• 6 of 1.25t Tote bins (extremely useful)

• KRM Bogballe spreader

• Grain and seed trailers

• 9mt Cousins rolls

• Note, Combining done on contract by a neighbour

Three years in how’s it been?

Fascinating, the farm is now a more interesting place, it supports more wildlife and with a more diverse rotation relies less on artificial inputs and feels much more sustainable. Whilst yields of spring beans and oats can’t be compared BCF (before Conservation Farming) as they weren’t grown. The yields of winter wheat and spring barley have been maintained but are still influenced by occasional partial flooding in a wet spring or over 30-degree temperatures in June. Not much we can do about that, and oil seed rape now grown again has increased.

Reduced cultivation and direct drilling have quickly changed the look, feel and structure of my soils which I’m hoping will make this light land yield potential be more resilient in a dry year with a more reliable margin through reduced costs. There is no question that the soil is now better able to resist compaction from machine trafficking due to higher organic matter levels, like driving on a spring mattress. Tramlines despite being perinatally placed with RTK are level not rutted and the ground carries harvest equipment very well. Fertilizer indices have remained stable at 2/2+ despite not having an annual dressing of P and K. The top 3” of soil have changed colour a are more friable leading to easier slot closure with a disc drill if using it in the right conditions, something we all get excited about in the early years of direct drilling.

Eureka moments

Visiting Agrii Stow Longa site and seeing a difference in soil comparing a cultivation plot and a cover crop plot 50 yards away that was like moving to a different county! Seeing pictures on Twitter and The Farming Forum of the variety of cover and companion crops in flower being grown in the UK! A social media contributor saying that if this field has just grown a 10t/ha wheat crop and I don’t do anything to change it (mechanical interference) why won’t it do it again! Attending a BASE UK arraigned talk arranged by Frederic Thomas @ FthomasTcs and subsequent visit to his and other farms in France which highlighted the value of a flexible rotation and companion cropping with rape. An Irish direct drilling farmer in America describing how the “fines” get washed down in cultivated soil upsetting the natural structure. Buying a spade and starting to open my eyes to what goes on underground.

Farm trials past and Ongoing

My future aims are to keep trying new things and on-farm trials, as I thought when I started out drilling wheat with the JD 750a for the first time in four foot high mustard, if this doesn’t work I can always plough it in and stick in some spring barley, truth is I’d now spray it off not plough but pushing the boundaries and making mistakes is the only way to learn. I also want to reduce reliance on Glyphosate, reduce nitrogen rates and maintain yields and ultimately to become an insecticide free farm, only trying on one field at present that is my target.

-

CHOOSING BETWEEN DIRECT DRILLING OPENERS

Dr C John Baker, Feilding, NZ

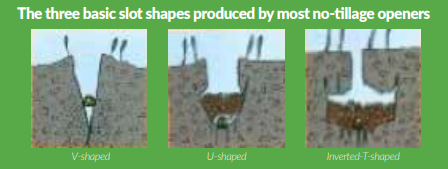

If you want to start a pub debate amongst farmers, try telling them which direct drilling (no-tillage) opener is the best. Everyone has an opinion. Here are some of the problems that direct drilling openers have to cope with, plus summaries of what published science and field practice tells us about how close each generic opener type comes to fulfilling those functions. This is an opportunity to sort fact from fiction. Please note, this author uses the terms direct drilling and no-tillage synonymously. It is helpful to firstly understand that the functions we have asked drill openers to do have changed over the approximately 60 years since the first attempts at direct drilling were reported in the 1950s.

• In the 1950s, the main purpose was to introduce new and improved pasture species into cloverdominant pastures in New Zealand’s Central Plateau without tilling the soil.

• In the 1960s and 1970s, the main aim changed to reducing wind and water erosion in North America and reducing on-farm costs and historical soil compaction in arable soils in the UK.

• By the 1990s and early 2000s, although the original soil erosion and cost objectives remained, emphasis shifted to making food production sustainable.

• Now the objectives have morphed further into reducing Green House Gas (GHG) emissions and regenerating soil health, plus all of the above.

Early direct drilling demanded disc openers because of their ability to handle residues. But most disc openers at that time produced patchy establishment and were expensive and difficult to use. So farmers gravitated to tined or shank-type openers over time. In the UK, the chemical company ICI Ltd (now part of Syngenta) sparked a lot of the early

developments.

ICI had developed the herbicide paraquat but no European machinery company was prepared to design a special drill for untilled soils. ICI therefore designed its own triple disc openers. But these turned out to be so limited in their functions that everyone in Europe eventually gave up direct drilling altogether and reverted to minimum tillage, because it did not require a special drill – just shallower tillage tools.

Fermentation of “hairpinned” straw, slot wall compaction, difficulty in closing the slot, stimulation of unwanted grass seed germination and an inability to band fertilizer separately from the seed, were just some of the shortcomings of triple disc openers. Most USA drill designers simplified the design of triple disc openers to double disc openers and also introduced single angled disc designs. But these only partly overcame the shortcomings of the original triple disc design. On the other hand, Argentina and Brazil managed to live with triple (and double) disc openers, mainly because their soils and climates are so kind that it is difficult to fail with any opener design. Australia and North America were the first arable countries to abandon disc openers in favour of simple shanks or tines.

While these designs allowed fertilizer banding to be added to the list of desirable functions, tines disturb a lot more soil than most discs and block with long residues. This, in turn, severely limited the opportunity to use crop residues as a mulch to smother weeds, reduce evaporation, control the slot microenvironment and re-stock the soil with photosynthesised carbon.

Tined openers made crop residues into a partial enemy of no-tillage systems rather than their greatest asset. Their limitations in this regard forced farmers to change their notillage cropping practises to minimise the amount of residues that tined openers had to cope with. Burning made a comeback and other practices included pushing the residues aside, chopping them into shorter lengths and even burying them in vertical trenches. Most of these actions either required an additions pass over the field with a separate machine or demanded additional power from combine harvesters when they were asked to chop the residues during harvesting.

Over time, tined no-tillage openers have become synonymous with strip tillage because many farmers take comfort from seeing the seeds embedded in tilled strips of soil as they used to in fully tilled seedbeds. But the science shows clearly that re-positioning residues (chopped or un-chopped) over the sown slots in otherwise undisturbed slots (in order that the mulch of residues forms the top layer of the slot-covering medium with little soil visible) is one of the best things a no-tillage opener can do. It traps soil water vapour (humidity) in the seed slot itself, creates a barrier against the soil-discharge of CO2 into the atmosphere, and sequesters new carbon into the soil for the first time since mankind began arable farming on a large scale.

These are scientifically proven facts that are very significant for several reasons:

a) The world’s arable soils have already lost approximately 75% of their organic matter from oxidation caused by repeat tillage and other soil disturbance.

b) The residues left after harvesting arable crops are rich in carbon that has been re-captured from the atmosphere by photosynthesis. If left to decompose on the surface of undisturbed soils, this carbon is taken back into the soil by earthworms and other soil fauna.

c) All undisturbed soils contain 100% relative humidity in the pore spaces between individual soil particles, even when very dry.

d) Most seeds can germinate in 90- 100% relative humidity, even in the absence of liquid water.

e) All soil disturbance (including strip tillage) allows this pore space humidity to escape.

f) Because we have tilled soil for centuries (and thereby eliminating the role of pore space humidity) we have come to believe that seeds only germinate in contact with soil.

g) But it is no accident that the world’s network of seed testing stations germinate their seeds on blotting paper where there is no soil present at all.

h) In the field, untilled soils therefore have two moisture resources for germinating seeds, vapour and liquid water. Tilled soils have only one, liquid.

i) Strip and minimum tillage simply eliminate one of those germination resources altogether and therefore defeat one of the main objectives of no-tillage in the first place.

j) Not only does strip tillage allow water vapour to escape it introduces excessive oxygen to the soil, which re-oxidises soil carbon into CO2, that escapes at the same time.

Mankind has therefore inadvertently moved backwards in its otherwise understandable preference for highdisturbance no-tillage openers. We must now move back towards lowdisturbance no-tillage Against this background of conflicting problems and solutions, this author spent 30 years identifying and mitigating the issues that had been hampering direct drillers from the outset. Some 30 graduate students and numerous fellow scientists at New Zealand’s Massey Universities published a multitude of research reports in the international scientific literature that explain the many hitherto unstudied interactions between machines, soils, seeds, seedlings, fertilizer, growing plants, weeds, and pests. For those practicing no-tillage, the following list of issues might be familiar:

1. My drill or planter only works well if some prior surface tillage has taken place.

2. I only get reliable establishment if I cause maximum slot disturbance with the openers.

3. Most of the time I get lower crop yields that when I practiced tillage.

4. Although I get reasonable germination when the soil is crumbly, I get only patchy results when the soil is wet or even sometimes just damp.

5. I find that although crumbly soil is preferable, it is also drier and this sometimes creates germination problems if I don’t get rain or can’t irrigate immediately after seeding.

6. Where irrigation is available, I nearly always irrigate after notillage seeding.

7. In damp soils, although I can usually get adequate seed cover, I am often left with poor establishment when the soil dries after drilling causing slot shrinkage that exposes seeds. 8. I find that the timing of no-tillage drilling or planting is critical.

9. I find that my machine will direct drill some crop types well, but is limited with other.

10. I find I often have to make significant adjustments to the openers when going from one field to another, or even sometimes in the same field when conditions change.

11. I have had to modify the drill or planter openers significantly since purchasing the machine in order to make the machine work best in my soils.

12. I find that my machine works fine on flat land but is not very effective on hillsides.

13. I frequently have difficulty drilling into sod or dense pasture.

14. Stony soils cause numerous breakages and other problems with my machine.

15. My machine can cope with stones but in doing so brings many of them up onto the surface.

16. The soils on my farm have become more difficult to drill since I changed to no-tillage.

17. I seldom see 70% or greater residue-cover over the slots after drilling or planting.

18. I often find I have retained less than 50% of the residues that were there before drilling.

19. Getting good seed-to-soil contact is often an issue for one reason or another.

20. I try to avoid spring drilling if at all possible because establishment is problematical.

21. I restrict my no-tillage to lowvalue crops, cover-crops or pasture and seldom risk it with high-value crops.

22. My machine has difficulty handling heavy residues without blocking.

23. In addition to spraying, I nearly always need to pre-treat the residues or soil in some way before drilling or planting.

24. My machine handles chopped straw, sod or standing stubble OK but has difficulty with long un-chopped residue or straw, especially if it is damp.

25. I never attempt to direct drill through long rank grass or weeds without at least a 6-month spray-fallow beforehand so the residues can decay somewhat.

26. I frequently get residue blockages that are sufficiently severe to require stopping.

27. My machine physically handles residues OK but has difficulty avoiding hairpinning (tucking) of uncut straw into the slot, which in turn affects germination.

28. The way that my openers handle residues is to push them to one or both sides of the row.

29. My machine cannot position seed and fertilizer in separate bands at seeding.

30. I would like to drill in narrow rows but my machine can’t band seed and fertilizer separately in narrow rows so I am forced to drill in wider rows than desirable or broadcast fertilizer.

31. My machine can position seed and fertilizer in separate bands in some soils and at certain drilling speeds, but not in other soils or at other drilling speeds.

32. My machine can position seed and fertilizer in separate bands but uses two openers per row to achieve this, which increases soil disturbance.

33. My machine could not be described as a low-disturbance no-tillage drill or planter.

34. Seeding depth varies noticeably across the field, especially where the surface is not smooth.

35. My machine cannot seed consistently shallower than 1” (25 mm) without risk of the openers riding out of the ground altogether in some places.

36. I have difficulty getting enough downforce on the openers when the soil is hard or dry.

37. I cannot vary the downforce on my openers without leaving the tractor cab.

38. My machine is not capable of constantly and automatically increasing and decreasing the downforce applied to the openers on-the-move to match soil hardness.

39. I find I need to seed deeper than desirable in order to be sure of getting adequate covering.

40. The maximum speed I can seed at is seldom greater than 5 mph (8 km/hr).

41. My openers stimulate too much weed seed germination. 42. There are a large number of greasing points on each opener that need frequent attention.

43. I expect that the useful life of my current drill or planter will be less than 5 years.

44. I experienced a reduction in crop yield during the first few years of direct drilling.

45. Even after several years of direct drilling, my crop yields seldom beater tillage yields.

46. I do not believe that no-tillage opener design can influence crop yield.

47. Purchase price is more important to me than the machine’s potential to influence crop yield.

48. My dealer does not seem to know a lot about no-tillage as a farming practice.

49. I find no-tillage to be altogether more risky than tillage.

50. If it wasn’t for the environmental issues, I would prefer to go back to conventional tillage.

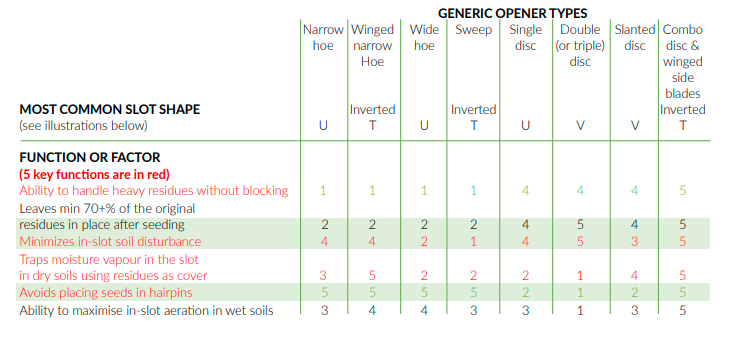

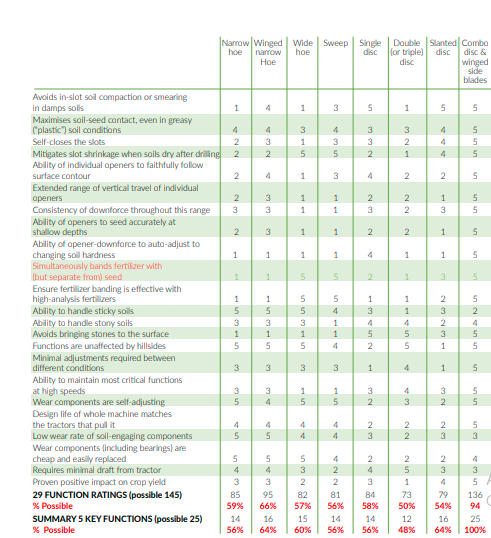

Our research sought to mitigate as many of these issues as possible and the results can be seen in the Table below, which quantifies how well (or badly) 8 generic no-tillage opener types perform 29 identified functions. Five of these functions (shown in red) are considered to be vital to all no-tillage cropping.

COMPARISONS OF 8 GENERIC NO-TILLAGE OPENERS BY FUNCTION

CONCLUSION:

• 5 of the 8 generic no-tillage opener types (63%) performed little more than 50% of the 29 desirable functions listed.

• 3 of the 8 (38%) performed about 2/3 of the 5 vital functions listed.

• Only 1 of the 8 (12%) performed all of the vital functions and 90% of the desirable functions.

OVERALL CONCLUSION:

Most people are little more than half way towards mastering true notillage or direct drilling – but at least they are that far. And half way means progress in the right direction. Keep learning!

-

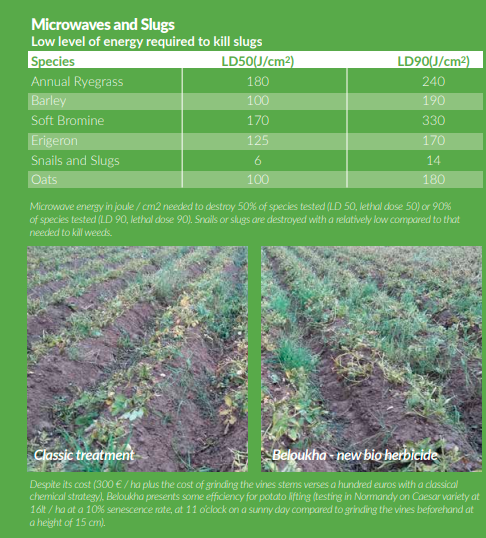

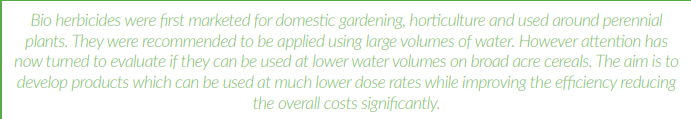

ALTERNATIVE WEED CONTROL – A WORLD WITHOUT GLYPHOSATE BUT WHAT ARE THE ALTERNATIVES?

Written by Maxime Barbier. First Published in TCS Magazine N°97 in March 2018

With the list of agrochemicals that is available to agriculture constantly shrinking and a threat hanging over the use of glyphosate, there is a growing interest more and more in alternative weeding solutions. All over the world many alternatives are being investigated; electricity, microwaves, thermal foam, water jet and bio herbicides. However a cheap and reliable alternative systemic weed killer at the same unbeatable price as glyphosate is not available currently. But who knows, from the emergence of all these innovations there will perhaps come new tools to help control the most challenging weeds growers and farmers face.

Will these alternatives consolidate or even improve our systems in both Conventional and Conservation Agriculture systems? The first problems appeared with the beginning of agriculture. Without the domestication of animals and crop raising we would probably have had to stay as hunter- gatherers, feeding on berries, acorns and wild meat. So busy finding food we wouldn’t be able to write this article! We evolved from largely a dense forest canopy of oak and beech to a succession of annual plants which has led to an incessant energy expenditure against Mother Nature who only wishes one thing; to return to a balance of perennials.

A struggle, helped in recent decades through the development of synthetic herbicides, has allowed us to maintain a perpetual crop of annuals. Now the list of usable agrochemical products as well as their efficiencies is decreasing, the situation is more and more urgent to find replacement techniques. Encouragingly, solutions exist already and interest is much revived and accelerated with the regulatory and consumer pressure on the use of glyphosate.

A complete herbicide through using an electrical current

The use of electricity as weed control technology was invented in the early 20th century but little interest was shown in the technique and had been largely forgotten due to the growth of synthetic herbicides after the Second World War. The first patents were issued in 1913, however it wasn’t until 1990 that the researcher NippoBresilien Satoru Narita, restarted the research on this method of weeding, with the help of private funds from a large owner of a forest that wanted to manage his weed problems which including herbicide resistance in some areas of the plantations he owned.

A project 10-year research was set up with the University of Brazil and in partnership with a Brazilian private sector company Sayyou, the first prototypes were launched in 2012. Large-scale trials of electrical current have been conducted in forestry and horticulture and also on wheat, soya, and citrus plantations. One major benefit is that the systemic action killing the whole plant. The current destroys both parts of the plant. The foliage and its root, preventing the plant from being able to regenerate.

“In the tests, the level of weed regrowth after 3 or 6 months is comparable to treated plots using glyphosate” says Benjamin Ergas, director of the company Zasso Group AG, from which Sayyou (now Zasso Brazil) is now part. Indeed, the machine, called the Electroherb, is distinguished by a destructive effect that kills foliage of the target plant to the root system. This mode of action is possible because the machine runs on a closed circuit. The PTO generator transfers the electricity to a row of “plant” applicators located on the front linkage made up of metal spatulas spaced every (10- 20 cm). Working widths are available from 1 to 10 meters. These applicators are interchangeable with a cultivator. As the spatulas touch the plants, the current flows through the tissues returning through a second row of spatulas which act as an earth closing the circuit. By getting into the vegetative parts of the plant, electricity has the action of breaking the vessels and damaging cells.

The machine delivers a high alternating current frequency (3-30 kHz), with a voltage (5,000-15,000 V), the charges usually don’t exceed 6000V. The dose of voltage is determined by field conditions and type of plants encountered. “The system self regulates according to many parameters: height and density of foliage and weed roots, soil moisture and density, topography, tractor speed and lastly width of Applicators. There are several patents that revolve around this problem, the main challenge being to provide a continuous and stable feed of current” explains the director. The energy needed varies from 100 to a 1,000 joules, enough to dry out foliage without burning or cooking it.

The destructive effect is better in full sun, although the manufacturer indicates that the machine can operate under most conditions, except heavy rain. There are less favorable conditions at dawn, because of the dew, and also when the plants to be destroyed are very close to the ground. In this case, the current may tend to dissipate more easily, the loss of effectiveness can then be order of 10% “ comments the specialist. The machine seems to have a useful action on dicotyledons, identified as having non-parallel leaf veins, tap roots and seedlings with two cotyledons. “The lower the dry matter of the plants, the more they are sensitive to the electrical current. This is equally the case for their root structure also.

Weeds with rhizomes like wild buckwheat are harder to destroy than grasses, which have a network of roots more which are more concentrated.” explains Matthias Eberius, technician at Zasso. New evaluations in 2018 were carried out in France. “We tried the prototype on organic plots of soybeans sown direct in the stubble of the previous crop. The technology is very interesting in organic systems as it may be possible to evolve towards a direct seeding approach. The operation was used just after sowing because we have a window of 5 days before crop emergence. The tool has controlled annual weeds, which measured between 5 and 25 cm above ground.