There has been increasing awareness about technologies that can be used to maximize soil protection against undesirable erosion, enhance soil biological activity, better manage water resources, or reduce the number of field passes, saving time and fuel consumption. Therefore, the technology of direct seeding, known as ‘no till,’ is gaining popularity. Along with the cultivation of catch crop, it is considered an important component of regenerative agriculture.

With rising input costs and a changing climate, there may be a gradual decline in the profitability of conventional farming. This is another argument in favour of the no-till method of managing agricultural land.

DIRECTO NO establishes crop in uncultivated soil, stubble fields or catch crop fields

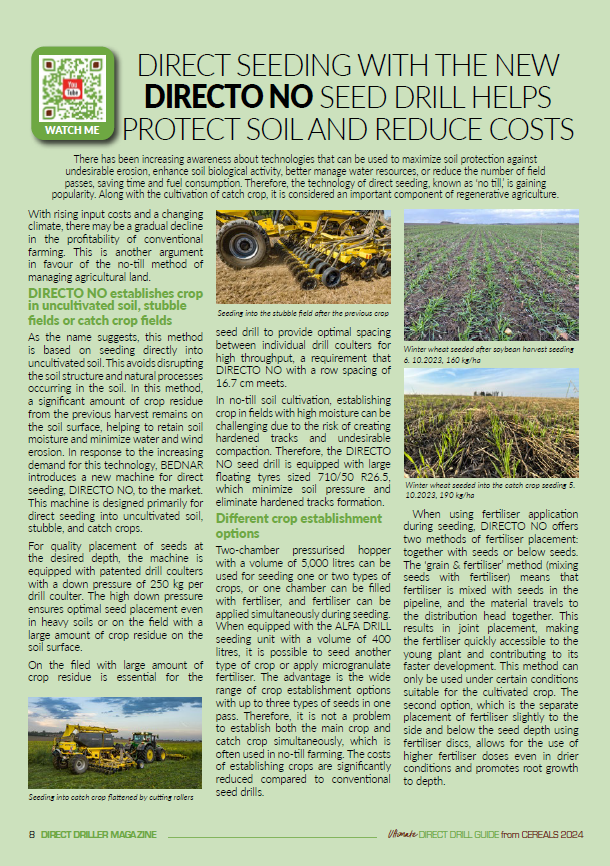

As the name suggests, this method is based on seeding directly into uncultivated soil. This avoids disrupting the soil structure and natural processes occurring in the soil. In this method, a significant amount of crop residue from the previous harvest remains on the soil surface, helping to retain soil moisture and minimize water and wind erosion. In response to the increasing demand for this technology, BEDNAR introduces a new machine for direct seeding, DIRECTO NO, to the market. This machine is designed primarily for direct seeding into uncultivated soil, stubble, and catch crops.

For quality placement of seeds at the desired depth, the machine is equipped with patented drill coulters with a down pressure of 250 kg per drill coulter. The high down pressure ensures optimal seed placement even in heavy soils or on the field with a large amount of crop residue on the soil surface.

On the filed with large amount of crop residue is essential for the seed drill to provide optimal spacing between individual drill coulters for high throughput, a requirement that DIRECTO NO with a row spacing of 16.7 cm meets.

In no-till soil cultivation, establishing crop in fields with high moisture can be challenging due to the risk of creating hardened tracks and undesirable compaction. Therefore, the DIRECTO NO seed drill is equipped with large floating tyres sized 710/50 R26.5, which minimize soil pressure and eliminate hardened tracks formation.

Different crop establishment options

Two-chamber pressurised hopper with a volume of 5,000 litres can be used for seeding one or two types of crops, or one chamber can be filled with fertiliser, and fertiliser can be applied simultaneously during seeding. When equipped with the ALFA DRILL seeding unit with a volume of 400 litres, it is possible to seed another type of crop or apply microgranulate fertiliser. The advantage is the wide range of crop establishment options with up to three types of seeds in one pass. Therefore, it is not a problem to establish both the main crop and catch crop simultaneously, which is often used in no-till farming. The costs of establishing crops are significantly reduced compared to conventional seed drills.

When using fertiliser application during seeding, DIRECTO NO offers two methods of fertiliser placement: together with seeds or below seeds. The ‘grain & fertiliser’ method (mixing seeds with fertiliser) means that fertiliser is mixed with seeds in the pipeline, and the material travels to the distribution head together. This results in joint placement, making the fertiliser quickly accessible to the young plant and contributing to its faster development. This method can only be used under certain conditions suitable for the cultivated crop. The second option, which is the separate placement of fertiliser slightly to the side and below the seed depth using fertiliser discs, allows for the use of higher fertiliser doses even in drier conditions and promotes root growth to depth.

Have a look at the equipment options for the DIRECTO NO seed drill in our open configurator.