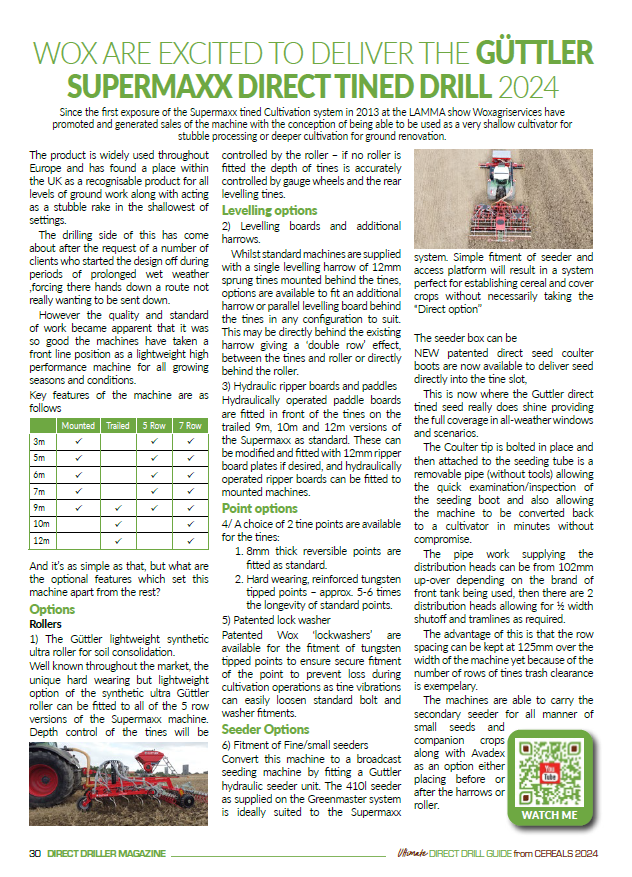

Since the first exposure of the Supermaxx tined Cultivation system in 2013 at the LAMMA show Woxagriservices have promoted and generated sales of the machine with the conception of being able to be used as a very shallow cultivator for stubble processing or deeper cultivation for ground renovation.

The product is widely used throughout Europe and has found a place within the UK as a recognisable product for all levels of ground work along with acting as a stubble rake in the shallowest of settings.

The drilling side of this has come about after the request of a number of clients who started the design off during periods of prolonged wet weather ,forcing there hands down a route not really wanting to be sent down.

However the quality and standard of work became apparent that it was so good the machines have taken a front line position as a lightweight high performance machine for all growing seasons and conditions.

Key features of the machine are as follows,

| Mounted | Trailed | 5 Row | 7 Row | |

| 3m | * | * | * | |

| 5m | * | * | * | |

| 6m | * | * | * | |

| 7m | * | * | * | |

| 9m | * | * | * | * |

| 10m | * | * | ||

| 12m | * | * |

And it’s as simple as that, but what are the optional features which set this machine apart from the rest?

Options

Rollers

1) The Güttler lightweight synthetic ultra roller for soil consolidation.

Well known throughout the market, the unique hard wearing but lightweight option of the synthetic ultra Güttler roller can be fitted to all of the 5 row versions of the Supermaxx machine. Depth control of the tines will be controlled by the roller – if no roller is fitted the depth of tines is accurately controlled by gauge wheels and the rear levelling tines.

Levelling options

2) Levelling boards and additional harrows.

Whilst standard machines are supplied with a single levelling harrow of 12mm sprung tines mounted behind the tines, options are available to fit an additional harrow or parallel levelling board behind the tines in any configuration to suit. This may be directly behind the existing harrow giving a ‘double row’ effect, between the tines and roller or directly behind the roller.

3) Hydraulic ripper boards and paddles

Hydraulically operated paddle boards are fitted in front of the tines on the trailed 9m, 10m and 12m versions of the Supermaxx as standard. These can be modified and fitted with 12mm ripper board plates if desired, and hydraulically operated ripper boards can be fitted to mounted machines.

Point options

4/ A choice of 2 tine points are available for the tines:

- 8mm thick reversible points are fitted as standard.

- Hard wearing, reinforced tungsten tipped points – approx. 5-6 times the longevity of standard points.

5) Patented lock washer

Patented Wox ‘lockwashers’ are available for the fitment of tungsten tipped points to ensure secure fitment of the point to prevent loss during cultivation operations as tine vibrations can easily loosen standard bolt and washer fitments.

Seeder Options

6) Fitment of Fine/small seeders

Convert this machine to a broadcast seeding machine by fitting a Guttler hydraulic seeder unit. The 410l seeder as supplied on the Greenmaster system is ideally suited to the Supermaxx system. Simple fitment of seeder and access platform will result in a system perfect for establishing cereal and cover crops without necessarily taking the “Direct option”

The seeder box can be

NEW patented direct seed coulter boots are now available to deliver seed directly into the tine slot,

This is now where the Guttler direct tined seed really does shine providing the full coverage in all-weather windows and scenarios.

The Coulter tip is bolted in place and then attached to the seeding tube is a removable pipe (without tools) allowing the quick examination/inspection of the seeding boot and also allowing the machine to be converted back to a cultivator in minutes without compromise.

The pipe work supplying the distribution heads can be from 102mm up-over depending on the brand of front tank being used, then there are 2 distribution heads allowing for ½ width shutoff and tramlines as required.

The advantage of this is that the row spacing can be kept at 125mm over the width of the machine yet because of the number of rows of tines trash clearance is exempelary.

The machines are able to carry the secondary seeder for all manner of small seeds and companion crops along with Avadex as an option either placing before or after the harrows or roller.