Overall, the agricultural industry is feeling the pressure from uncertainty, particularly regarding government changes, growing issues with weeds—especially brome and blackgrass due to the mild weather—and adjustments to the SFI schemes, which paradoxically seem to discourage food production. However, rather than simply hunkering down and waiting for the storm to pass (whenever that may be), forward-thinking businesses are adapting to the changing environment—physically, environmentally, and financially. Fentech Agri is playing a pivotal role in facilitating this adaptation by offering a wide range of machinery tailored to customers’ needs.

Driven by FETF regulations, such as requirements for fertilizing in the slot and drilling into cover crops, our seeder range has significantly expanded and evolved over the past 12 months. What started as 8 basic models has grown to 20 baseline seeders, all of which can be customized with various applicators, add-ons, and control system options. While manufacturing such a broad range is something we typically aim to avoid, the current agricultural landscape makes it clear that a one-size-fits-all approach no longer works. Marginal gains can only be achieved through the use of highly specific equipment.

The recent adoption of Horizon metering systems on the folding drill and front hopper ranges has opened up new design possibilities due to the system’s compactness and simplicity. Dual product options are now available on all but the most basic box hopper seeders, without significantly increasing costs.

In addition, we’ve opted to integrate Farmscan Ag Ltd’s control system, which is by far the most intuitive and flexible system we’ve encountered. This system has the potential to elevate seeding operations, offering the ability to easily add or change inputs and outputs to suit specific needs. The tablet-based control system, with its large, rugged screen, provides superior monitoring and metering control. Clear graphical warnings and settings help reduce operator stress, while features such as wireless calibration make the process more efficient. Operators can now calibrate the machine using a mobile phone connected to the system, further enhancing convenience and efficiency.

For our more basic box hoppers, we’ve integrated the same control system with an electronic motor drive option, replacing the traditional ground-driven drive wheel. This “e-drive” system is retrofittable to all basic mechanical seeders in the Fentech Agri/Simtech range or can be specified for new builds. The benefits include more consistent seeding rates, more accurate calibration (within 2% of the set point), real-time monitoring and rate adjustments from the cab, and compatibility with variable rate maps.

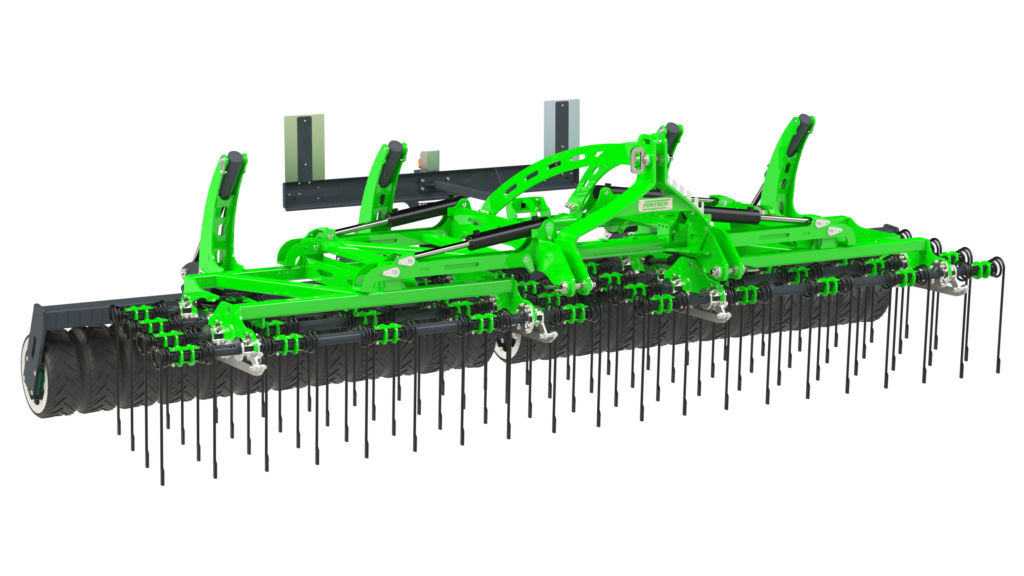

While seeders remain our core business, centered around the Simtech drill brand, we’ve also been focusing on soil preparation prior to seeding. Establishing stale seedbeds is a crucial aspect of weed control. Our new 6m Phoenix mounted machine, featuring 16mm straw-type tines, disturbs as much soil as possible, while the rubber roller consolidates the seedbed and ensures seed-to-soil contact. Establishing a stale seedbed before seeding is essential for effective weed management. Alternatively, early-sown cover cropping can also help minimize weeds, even in the driest conditions, with the Simtech tine generating a tilth where it might otherwise seem impossible.

Alongside the Phoenix, we are also introducing our first in-house subsoiler, which utilizes the Metcalfe NG ultra-low disturbance system. This technology, proven over several years, provides flexibility to work at varying depths and widths. The system breaks up problem pans and fractures the soil vertically, allowing roots to grow more freely. You can see this in action at Tillage Live on September 18th, with a simple shear-bolt, 3m format.

Needless to say, it has been a costly year, with our R&D budgets significantly exceeded. However, the result is a far broader range of products, possibly offering the most bespoke seeder solutions available for various conditions on the market today. As always, our technical team is available to discuss how we can help improve your efficiency and capitalize on the changing agricultural landscape to make your business more profitable.