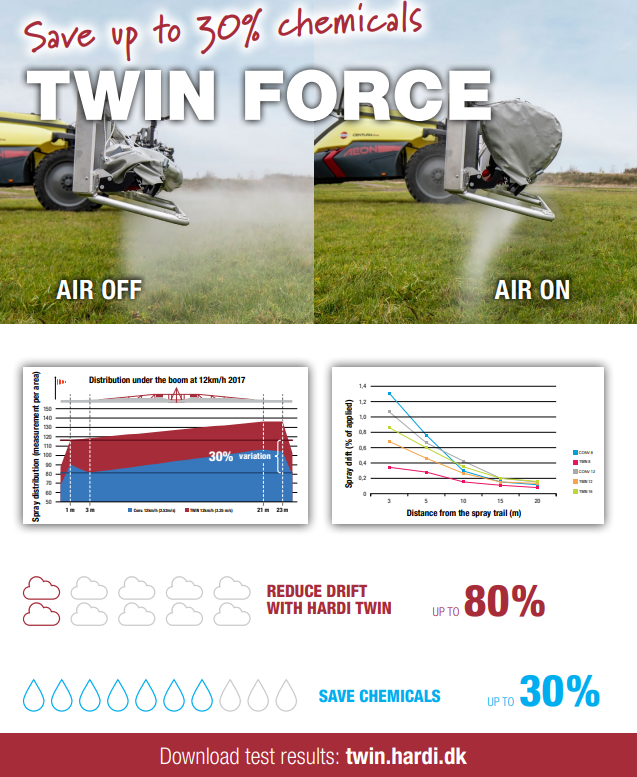

Want to save time, money and reduce your environmental impact during spraying operations? The TWIN FORCE boom from HARDI employs the world’s best system for spray control. Using an adjustable curtain of air to entrain and direct the spray, TWIN FORCE can reduce drift by an astounding 80% in comparison to standard boom configurations. The result is close to no loss of plant protection products or contamination of adjacent areas, saving the grower money and ensuring peace of mind that their crop is consistently and successfully targeted. Air-assisted spraying also guarantees more accurate spray penetration and coverage than conventional applications. All this translates into real savings for the farmer of at least 50% on water usage and up to 30% on plant protection products.

TWIN FORCE booms from HARDI gets the job done faster. Efficient drift control means more spraying days – studies prove an average increase from up from 31 to 76 spray days – as well as higher application speeds and fewer refilling stops. The result is higher sprayer productivity.

As well as an increase in efficiency, HARDI TWIN FORCE gives the operator more options for spray control than other air-assisted sprayers. By adjusting the air curtain’s speed and angle, from no air to full air, in effect producing two sprayers in one (hence the name – TWIN), the operator can guide all droplets, irrespective of size, to the target. Two powerful blower units provide air to the left and right side of the boom. Each blower can be automatically adjusted to a maximum output of 2,000 m³/h per metre of boom and a maximum air speed of 35 m/sec.

Weather dictates almost everything a farmer does, and spraying is no exception. Wind in particular can force a farmer to interrupt or postpone spraying due to the ultimate risk of drift. With efficient drift control, this is factor can become a thing of the past. Not only does air-assisted spraying prevent small droplets from drifting by blowing them downwards. It also opens the crops canopy to encourage better penetration. The air curtain parts and rustles the crop to expose all surfaces to the spray, and the droplets’ extra momentum created by the air propels them into the crop.

The outstanding performance of TWIN FORCE has been confirmed by numerous case studies from around the world along with field trials and studies. One independent, scientific study from the Research Centre Flakke-bjerg/Aarhus University, Denmark, demonstrated that the spray application quality of a HARDI TWIN sprayer with a 24-metre boom was unaffected by high wind at driving speeds of 8 to 12 km/h.

The researchers concluded that TWIN gives a more uniform deposition and significantly lower drift than conventional applications, especially in windy conditions. The study confirmed that TWIN can reduce spray drift by up to 80% – translating into a reduction in use of chemical products of up to 30%.

HARDI however are determined to further enhance growers’ savings with spraying technologies and in-house developed techniques, available from the original crop care specialists. Needless to say, the manufacturers can now prevent under and over-dosing with their PWM system, ‘HARDI PulseSystem’. The HARDI PulseSystem is the future of application technologies, currently available on the conventional DELTA FORCE boom on AEON and NAVIGATOR, plus the TWIN boom on AEON.

Together with the TWIN boom configuration on the HARDI AEON, which already has best-in-class drift reduction and penetration characteristics, the Danish in-house manufactured pulse-width modulation system, HARDI PulseSystem is an essential additional step forward in controlling where pesticides are applied directly from the driver’s seat. Combining two innovative drift-reducing technologies, HARDI has developed an application solution with the potential to deliver spray directly into the crop where the plant needs it, with minimal drift, thus improving efficiency and reducing costs for the grower.

By opening and closing the nozzles, the HARDI PulseSystem can keep the nozzles open from 30-100% at the same pressure flow while ensuring the droplet size is unaffected, regardless of working speeds. Drift is also minimised while the flow rate is optimised, as the desired droplet size can be maintained throughout spraying operations.

In addition, the PulseSystem works with a single nozzle on/off – at a width of 36m, control of all 72 nozzles at a single nozzle level. This can be done via a digital field map – and savings of up to 90% are possible by treating only the desired areas within the field.

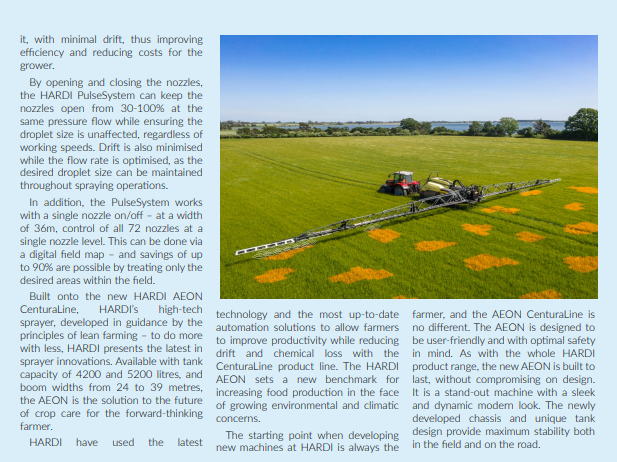

Built onto the new HARDI AEON CenturaLine, HARDI’s high-tech sprayer, developed in guidance by the principles of lean farming – to do more with less, HARDI presents the latest in sprayer innovations. Available with tank capacity of 4200 and 5200 litres, and boom widths from 24 to 39 metres, the AEON is the solution to the future of crop care for the forward-thinking farmer.

HARDI have used the latest technology and the most up-to-date automation solutions to allow farmers to improve productivity while reducing drift and chemical loss with the CenturaLine product line. The HARDI AEON sets a new benchmark for increasing food production in the face of growing environmental and climatic concerns.

The starting point when developing new machines at HARDI is always the farmer, and the AEON CenturaLine is no different. The AEON is designed to be user-friendly and with optimal safety in mind. As with the whole HARDI product range, the new AEON is built to last, without compromising on design. It is a stand-out machine with a sleek and dynamic modern look. The newly developed chassis and unique tank design provide maximum stability both in the field and on the road.