The 750A All-Till seed drill is available in 3, 4 and 6m versions. This versatile drill has a field proven Accord air seeding system, and is designed with large clearances for no-till drilling into stubble, working after minimum or conventional cultivations, and single pass operation for grassland and rough pasture renovation.

Single pass drilling offers several advantages over a conventional ploughing regime, including lower establishment costs, reduced nitrate leaching and increased conservation of moisture within the soil. In addition, the 750A’s no-soil disturbance at the point of drilling offers huge benefits for the control of blackgrass.

The 750A requires a minimum of 80 to 140hp and can work at up to 6ha/hr, depending on conditions, at seeding depths from 13 to 90mm. Seed is applied at a rate of 1 to over 400kg/ha via a central 1800-litre hopper and single metering system on the 3 and 4m units, or a 2300-litre hopper and twin metering units on the 6m model, which folds down to 3m for transport.

A single 46cm angled disc opens the furrow at 16.6cm row spacings, and has a depth gauge wheel mounted alongside to provide excellent seeding depth control. A semi-pneumatic press wheel pushes the seed to the bottom of the furrow for perfect seed to soil contact, and a cast iron closing wheel completes the job. There are 18 openers on the 3m model, 24 on the 4m and 36 on the 6m version.

There is also adjustable hydraulic down pressure of up to 250kg on each furrow opener, to handle the toughest soil and crop residue conditions – typically this would be below 50kg for most situations. This means the drill delivers consistent seed depth and excellent seed to soil contact for maximum germination. Fore-to-aft clearance is 1.2m, and under-frame clearance 60cm, to allow a virtually unobstructed flow of crop stubble and soil residues through the machine.

In operation, the 750A creates very little soil disturbance outside of the small slot opened by the single disc. This makes it ideal for drilling into stale seedbeds created for blackgrass control, where unnecessary soil movement could encourage further competitive weed seed germination and subsequent yield loss.

Other features include row marker and automatic tramline systems, micro metering for fine seeds, and an integral two-point hitch. All models incorporate hydraulically actuated brakes or an optional air braking system.

Drilling with new precision farming features

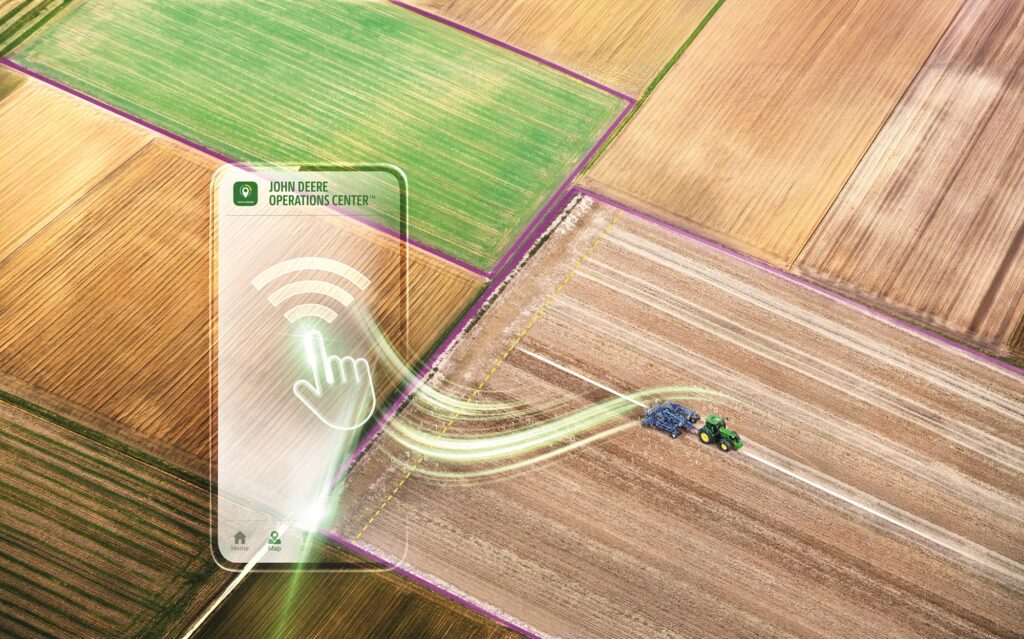

With the added benefits of John Deere precision farming technologies including DataSync, John Deere’s proven drill technologies ensure that drilling is more efficient and accurate than ever.

DataSync was introduced to the John Deere Operations Center last year to allow users to eradicate time taken to manually change records on each in-cab display, ensuring that stored field data is as accurate as possible, creating the most up-to-date and accurate field maps for drilling.

DataSync consistently provides the right setup information where it’s needed and at the right time. Field names, boundary changes, guidance tracks and flags can now be changed whenever and wherever at the press of a button and shared instantly across the fleet.

Real-time updates of where an operator’s drill has sown crops are accessible to the next machine to be used, such as a sprayer, which then can drive on the exact same path as the drill, increasing efficiency and accuracy.

Combining the enhanced efficiency thanks to DataSync and the precise seed placement of the 750A.

DataSync is free to activate and can be enabled or disabled for selected machines within the Operations Center, allowing team members differing levels of access. To us this feature, the machine must be equipped with a Gen4 display, JDLink modem, and an Operations Center account.