HORSCH has updated its sprayers in each class to offer the highest performance. Close-nozzle spacing, pneumatic nozzle control and advanced cleaning systems are available across all HORSCH Leeb sprayers but at the heart of its sprayer innovation is its award-winning BoomControl system, an advanced boom design that keeps the boom rock steady and as close to the crop as possible.

In addition to BoomControl, AutoSelect and PrecisionSpray create an advanced suite of tools that ensure chemical application is very efficient and productivity is high.

Precision boom control up to 54m

The HORSCH Leeb BoomControl system is a renowned sprayer technology. All HORSCH Leeb mounted, trailed and self-propelled sprayers feature the unique system for exact sprayer boom positioning. Booms from 18m to 54m are held steady at less than 40cm above the crop at speeds up to 30kph, even on hilly terrain.

Three versions are available: BoomControl, BoomControl Pro and BoomControl ProPlus. BoomControl automatically maintains an exact, lowest possible working height even at high operational speeds. Boom is completely decoupled from the vehicle and held securely below a target area height of 40cm thanks to active adaption of the boom to the terrain via to two boom-tip sensors.

BoomControl Pro expands on this capability by adding active boom adaption via tilt and height control of the middle section. Using four sensors from boom tip to the middle section, greater terrain following is possible by the parallel angling of the boom arms in combination with the rotation of the middle section.

BoomControl ProPlus goes even further with active adaption of the boom middle section via the tilt and height control and double variable geometry of boom sections. This enables each of the boom section across the boom to lift and lower individually for the closest terrain following.

James Casswell farms at Horbling, Lincolnshire and runs a Leeb 7 GS with BoomControl Pro and remarks, “We expected it to be good, but the low levels of drift are unbelievable. The boom stability is amazing. The guys were spraying on a quite windy day and there was no movement under the boom.”

A powerful nozzle control system

AutoSelect is HORSCH’s own nozzle control system. In addition to the nozzle and the pressure range, the operator can also adjust the target area spacing. Multiple nozzle carriers and a 25 cm partition on the nozzle bar provide a wide range of possibilities.

Individual or even different nozzle places may be combined into nozzle profiles and up to 16 profiles can be controlled automatically. This allows the operator to ensure the optimum pressure range for the nozzle or the nozzle combination that is used, and that the optimum target area spacing is maintained if the operational speed changes. The boom height can be automatically adapted based on the nozzle spacings that are defined in the nozzle profiles. More nozzles give the operator a wider range of options.

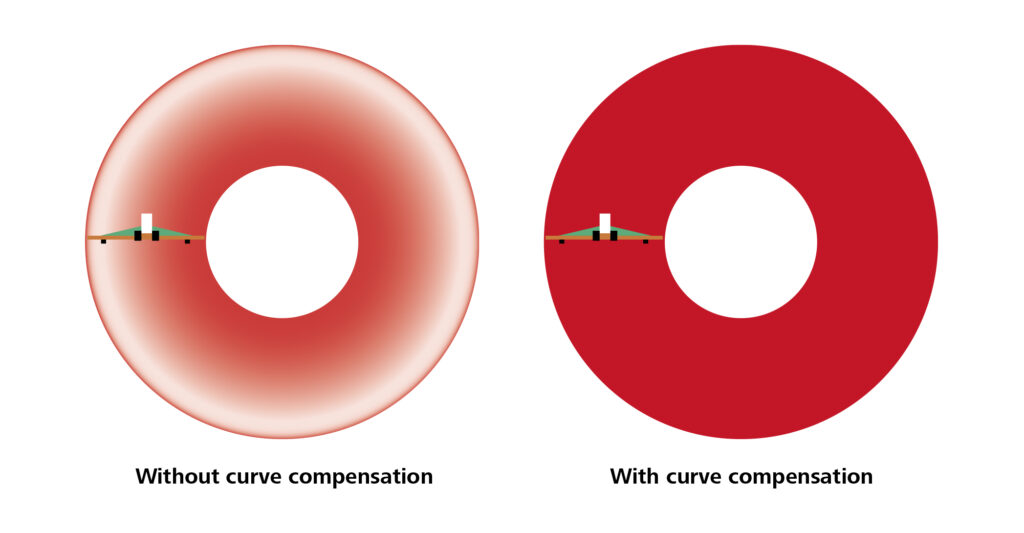

AutoSelect Pro adds curve compensation for operators not wishing to use pulse width modulation (PWM). By selecting differing nozzle types through the turn, AutoSelect Pro adjusts the spray volume across the boom length to allow for varying boom speed.

PrecisionSpray uses the latest generation pulse width modulation

HORSCH PrecisionSpray pulse nozzle system is available on all Leeb PT self-propelled and Leeb LT and GS trailed sprayers. “Although PWM has been available for some time from various manufacturers, PrecisionSpray is one of the first to integrate the technology completely into our own HORSCH sprayer software without requiring third-party controllers, making it easier to use.” explains Stephen Burcham, general manager at HORSCH UK.

PrecisionSpray uses the latest generation pulse width modulation nozzle controls to ensure spray volumes are consistent across the field despite variations in sprayer speed or changes in boom speed when turning. As a sprayer turns the speed of the boom across the ground is dramatically faster on the outside than the inside, and the effect is increased as the boom widths get greater. PrecisionSpray’s curve compensation alters the spray volume proportionally across the boom length to ensure the same volume of spray per square metre from the inside to the outside of the turn.

In addition to curve compensation, PrecisionSpray offers stepless adaption of the volume flow at constant pressure and drop size and can adapt the application rate without changing the spray characteristics.