Every farmer is always looking for a way to make their harvest season more efficient, effective and easier, and Mike Barr seems to have found the perfect solution with his complete Grain Handling System installed by Thorburn Group, based in the Scottish Borders.

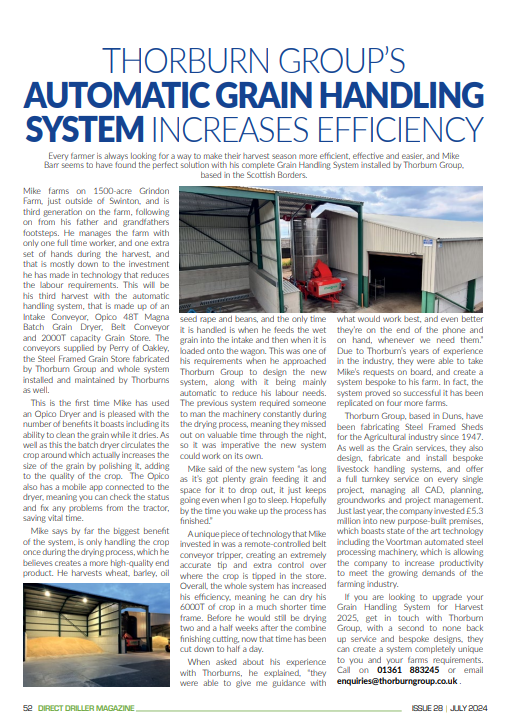

Mike farms on 1500-acre Grindon Farm, just outside of Swinton, and is third generation on the farm, following on from his father and grandfathers footsteps. He manages the farm with only one full time worker, and one extra set of hands during the harvest, and that is mostly down to the investment he has made in technology that reduces the labour requirements. This will be his third harvest with the automatic handling system, that is made up of an Intake Conveyor, Opico 48T Magna Batch Grain Dryer, Belt Conveyor and 2000T capacity Grain Store. The conveyors supplied by Perry of Oakley, the Steel Framed Grain Store fabricated by Thorburn Group and whole system installed and maintained by Thorburns as well.

This is the first time Mike has used an Opico Dryer and is pleased with the number of benefits it boasts including its ability to clean the grain while it dries. As well as this the batch dryer circulates the crop around which actually increases the size of the grain by polishing it, adding to the quality of the crop. The Opico also has a mobile app connected to the dryer, meaning you can check the status and fix any problems from the tractor, saving vital time.

Mike says by far the biggest benefit of the system, is only handling the crop once during the drying process, which he believes creates a more high-quality end product. He harvests wheat, barley, oil seed rape and beans, and the only time it is handled is when he feeds the wet grain into the intake and then when it is loaded onto the wagon. This was one of his requirements when he approached Thorburn Group to design the new system, along with it being mainly automatic to reduce his labour needs. The previous system required someone to man the machinery constantly during the drying process, meaning they missed out on valuable time through the night, so it was imperative the new system could work on its own.

Mike said of the new system “as long as it’s got plenty grain feeding it and space for it to drop out, it just keeps going even when I go to sleep. Hopefully by the time you wake up the process has finished.”

A unique piece of technology that Mike invested in was a remote-controlled belt conveyor tripper, creating an extremely accurate tip and extra control over where the crop is tipped in the store. Overall, the whole system has increased his efficiency, meaning he can dry his 6000T of crop in a much shorter time frame. Before he would still be drying two and a half weeks after the combine finishing cutting, now that time has been cut down to half a day.

When asked about his experience with Thorburns, he explained, “they were able to give me guidance with what would work best, and even better they’re on the end of the phone and on hand, whenever we need them.” Due to Thorburn’s years of experience in the industry, they were able to take Mike’s requests on board, and create a system bespoke to his farm. In fact, the system proved so successful it has been replicated on four more farms.

Thorburn Group, based in Duns, have been fabricating Steel Framed Sheds for the Agricultural industry since 1947. As well as the Grain services, they also design, fabricate and install bespoke livestock handling systems, and offer a full turnkey service on every single project, managing all CAD, planning, groundworks and project management. Just last year, the company invested £5.3 million into new purpose-built premises, which boasts state of the art technology including the Voortman automated steel processing machinery, which is allowing the company to increase productivity to meet the growing demands of the farming industry.

If you are looking to upgrade your Grain Handling System for Harvest 2025, get in touch with Thorburn Group, with a second to none back up service and bespoke designs, they can create a system completely unique to you and your farms requirements. Call on 01361 883245 or email enquiries@thorburngroup.co.uk .