If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

“ConservES” project for research on biodiversity in intensive farmland

Three-year project to maximize ecosystem performance – eight project partners from four E.U. countries – DLG is professional partner and will communicate findings

A group of eight professional partners has just launched the international “ConservES” project for research on increasing bioversity in intensive wheat farmland, without reducing yields. The DLG (German Agricultural Society) will contribute with its biodiversity know-how and additionally lead the communication of project results to the agricultural community.

“The goal of the three-year project is to increase biodiversity in intensive agricultural areas without causing yield losses to farmers,” said Joan Van Baaren, professor at the University of Rennes. “We expect the project to deliver results that can help achieve the significant ecological benefits of floral enrichment for biodiversity as well as ecosystem services on conventionally farmed land,” added Van Baaren.

The benefits of hedgerows and flower strips as habitats for pollinators and natural enemies of pests and weeds will be the focus of the international research project, which is coordinated by the University of Rennes, France, with the professional partners Julius Maximilians University of Würzburg, Germany; Living Lab CLEF, France; Université catholique de Louvain, Belgium; DLG (German Agricultural Society); Crop Research Institute as well as the Association for Innovation and Sustainable Agriculture, both Czech Republic.

With the appropriate project description “Living-lab approach to floral enrichment as a tool to conserve biodiversity and maximising ecosystem services in European agricultural landscapes”, the ConservES project draws on resources from each member.

The project will explore the importance of habitats that exist naturally alongside farmed land, such as hedgerows, or habitats that have been established as “linear semi-natural elements” such as flower strips, serving to improve the abundance and diversity of organisms, pest and weed control, and pollination.

As wheat is the dominant crop produced.in the areas studied – western and northern France, Wallonia, Belgium, southern Germany and western Czech Republic the project will focus on conventional fields of wheat or other small-grain cereals.

The ConservES project is multidisciplinary and based on the combination of four approaches:

– The concept of the real laboratory

– Bioblitz field data collection in each of the five study regions

– Field trials to increase plant species diversity

– Simulations through spatial modelling within the five study regions.

Along a climatic gradient, it is expected that the climatic context will play a major role on the potential of ecosystem services in each area, as temperature is a key effect of climate change.

“Involving local farms is one of the most important activities and a key factor for the success of the project,” says Stephanie Timm, project manager at DLG. “The concept of the real lab is to work with farmers to develop scenarios for expanding diversity within, near and around fields to optimize agroecosystem diversity at the farm and in the countryside generally. The farmers will be involved in biodiversity conservation and ecosystem health,” she adds.

The project’s activities also aim to build an effective network of research and farming practices to communicate the value of ecosystem services and establish the application of the solutions developed beyond the project.

The activities of the project is also expected to build an effective network of research and agricultural practice to communicate the value of ecosystem services and establish the application of the solutions developed beyond the project.

The DLG is active in several biodiversity projects, including “BioMonitor4CAP” (Project number 101081964) funded by the European Union’s Horizon Europe research and innovation program, that aims to develop, evaluate and test affordable and reliable systems for monitoring biodiversity for application on agricultural land. This project focuses on specially protected areas for rare, endangered or vulnerable natural habitats and species of plants or animals.

We will report the finding of the studies in future issues.

-

What do you read – April 2023?

If you are like us, then you don’t know where to start when it comes to other reading apart from farming magazines. However, there is so much information out there that can help us understand our businesses, farm better and understand the position of non-farmers.

We have listed a few more books you might find interesting, challenge the way you currently think and help you farm better.

Agroecology and Regenerative Agriculture: Sustainable Solutions for Hunger, Poverty, and Climate Change

The book is an interdisciplinary synthesis of research and practice carried out over decades by leaders of the agroecology and regenerative organic agriculture movement. It provides detailed analysis of the multiple crises we face due to chemical and industrial agriculture, including land degradation, water depletion, biodiversity erosion, climate change, agrarian crises, and health crises. The book lays out biodiversity based organic farming and agroecology as the road map for the future of agriculture and sustainable food systems, both locally and globally. With detailed scientific evidence, Agroecology & Regenerative Agriculture shows how ecological agriculture based on working with nature rather than abasing ecological laws can regenerate the planet, the rural economy, and our health.

Who Really Feeds the World?

The world’s food supply is in the grip of a profound crisis. Humanity’s ability to feed itself is threatened by a wasteful, globalized agricultural industry, whose relentless pursuit of profit is stretching our planet’s ecosystems to breaking point. Rising food prices have fuelled instability across the world, while industrialized agriculture has contributed to a health crisis of massive proportions, with effects ranging from obesity and diabetes to cancers caused by pesticides. In Who Really Feeds the World?, leading environmentalist thinker Vandana Shiva rejects the dominant, greed-driven paradigm of industrial agriculture, arguing instead for a radical rethink of our relationship with food and with the environment. Industrial agriculture can never be truly sustainable, but it is within our power to create a food system that works for the health and well-being of the planet and all humanity, by developing ecologically friendly farming practices, nurturing biodiversity, and recognizing the invaluable role that small farmers can play in feeding a hungry world.

Reclaiming the Commons: Biodiversity, Traditional Knowledge, and the Rights of Mother Earth

Reclaiming the Commons: Biodiversity, Traditional Knowledge, and the Rights of Mother Earth lays out the scientific, legal, political, and cultural struggle to defend the sovereignty of biodiversity and indigenous knowledge. Corporate war on nature and people through patents and corporate Intellectual Property Rights has unleashed an epidemic of biopiracy resulting in important legal battles fighting efforts to patent the rights to many plants, including basmati, neem, and wheat. The author presents details of the specific attempts made by corporations to secure these patents and the legal actions taken to fight them. The book goes beyond the legal struggle to position the necessary solutions to corporate control including the exploring the Rights of Nature and proposing a framework for a Universal Declaration of the Rights of Mother Earth. It is the first detailed legal history of the international and national laws related to biodiversity and Intellectual Property Rights.

CLIMATE CHANGE and the road to NET-ZERO

CLIMATE CHANGE and the road to NET-ZERO is a story of how humanity has broken free from the shackles of poverty, suffering, and war and for the first time in human history grown both population and prosperity. It’s also a story of how a single species has reconfigured the natural world, repurposed the Earth’s resources, and begun to re-engineer the climate. The book uses these conflicting narratives to explore the science, economics, technology, and politics of climate change. NET-ZERO blows away the entrenched idea that solving global warming requires a trade-off between the economy and environment, present and future generations, or rich and poor, and reveals why a twenty-year transition to a zero carbon system is a win-win solution for all on planet Earth.

There Is No Planet B

Feeding the world, climate change, biodiversity, antibiotics, plastics, pandemics – the list of concerns seems endless. But what is most pressing, and what should we do first? Do we all need to become vegetarian? How can we fly in a low-carbon world? How can we take control of technology? And, given the global nature of the challenges we now face, what on Earth can any of us do, as individuals? Mike Berners-Lee has crunched the numbers and plotted a course of action that is full of hope, practical, and enjoyable. This is the big-picture perspective on the environmental and economic challenges of our day, laid out in one place, and traced through to the underlying roots – questions of how we live and think. This updated edition has new material on protests, pandemics, wildfires, investments, carbon targets and of course, on the key question: given all this, what can I do?

-

Farm Manager Seeking Regenerative Role

A practical and innovative farm manager wishing to go beyond sustainability seeks a hands-on position to focus on clean and resilient food, fibre and energy production; soil restoration and natural capital enhancement.

Please contact:

hello@vibrantsoil.co.uk -

Soil Farmer Of The Year Competition 2019

Written by Becky Willson, Farm Carbon Cutting Toolkit

The Soil Farmer of the Year competition aims to find, promote and champion farmers who are passionate about safeguarding their soils and building resilient businesses. The competition is now in its fourth year and attracts amazing farmers who are running a range of different enterprises and management systems, but are all connected by a focus on soil management and a drive to make the system more sustainable.

One of the highlights of the competition is the opportunity to dig a little deeper into the finalist’s soil management strategies at farm walks which take place in early July on the top three farms. These events are always brilliant, not just because of the interesting things that are taking place on the farm, but also because of the honesty and openness of the farmers to answer questions and explain their management and how their system has evolved. The winners were announced in early June and we were incredibly lucky this year to be offered a space on the main stage at Groundswell to present the awards and allow our top three farmers to share their experiences with the delegates attending the show. This was a great opportunity for our winners to meet each other and discuss ideas, and the session was chaired by Joel Williams. All of the farmers gave a short presentation on their management system and some of the challenges that they had faced along the way.

Our winner this year was Julian Gold, an arable farmer from Oxfordshire, and on a sunny evening (when combining was in the forefront of people’s minds), we all gathered to hear more about Julian’s award winning management. Julian runs a predominantly arable farm, with a flock of sheep that graze cover crops and areas of permanent pasture. The fundamental management principle on this farm is managing carbon; by growing high yielding crops there is a lot of carbon pumped back into the soil and by reducing tillage, once that carbon is in the soil it doesn’t escape. Julian explained his key philosophy on the farm, “I am not a farmer, I am a facilitator of photosynthesis and everything flows from that.”

The key theme of the walk was focussed on the practicalities of residue management, specifically the management of barley straw and whether all of the issues that Julian has experienced was worth it. He is managing his system by returning all crop residues to the soil which is following his carbon principles, however practically it is causing some issues with crop establishment. By growing big photosynthetic crops, they are pumping carbon through the plant roots and into the soil which is great, and then by leaving the straw on the surface, it is acting as a soil biology primer. However dealing with the straw can present a challenge. The high carbon to nitrogen ratio of the straw will ensure that the biology have to work to breakdown the material, and Julian is convinced that the biology in his soil is now used to assimilating the straw. The nitrogen strategy on the farm currently is to apply it little and often however over the next few years, cutting back on nitrogen is a key management aim.

The farm occupies 800 ha and is mostly owner occupied. Julian runs a 6 year rotation, which is rape, wheat, spring barley, spring or winter beans, wheat and winter barley. There is flexibility between whether he grows winter or spring beans, and there is a guaranteed cover crop before spring barley after winter wheat, and if spring beans are grown after the spring barley. The farm runs a controlled traffic system which Julian started in 2012 which is based on 10m, which means that 20% of the field is ever driven on and 80% is not touched. No deep tillage is done and the carbon and root systems are protected. Julian was keen to recommend that everyone could try using a controlled traffic system at harvest, to minimise the potential damage by grain trailers and the combine.

Crops and residue management

The first field that we visited was a field of oil seed rape. This field had previously grown winter barley, and had a lot of chopped straw on the surface. The crop had established fine apart from an area where combining had carried on too long into the evening and straw chop quality was bad. A big issue with high volumes of straw residues is maintaining soil to seed contact as the soil surface layer is very fluffy and hard to consolidate. Another issue the farm struggles with is the battlement effect left behind when direct drilling with the tine drill. The undisturbed areas of soil support the rolls and make it difficult to consolidate the seed trench.

After the rape we went to look at a field of barley, which had had a cover crop before which had been grazed by sheep. The cover crop had a high biomass, as (similar to the cereals) Julian is keen to maximise photosynthesis even in the cover crop and provide a variety of rooting depths and species. Julian also explained how he creates the right mindset for soil friendly farming by imagining a fictional scenario “that way back in time as life was evolving on the planet, an intelligent soil ecosystem evolved first and needed a food source so created plants to grow and harvest sunshine and carbon dioxide to feed the soil community. The farmers function is to tend the food producing slaves and in return is allowed to take the seeds as payment!” Julian explained that “when you have this focus on farming for the soil it is a win-win scenario because the grain yields become better and more robust over time.”

Julian has been growing cover crops since 2014, starting off with vetches and black oats, and now including high biomass mixes. They are mob stocked with 50% of the cover trampled and the field is never turned brown with bare soil. The field is then sprayed off and drilled. Until the point that it is sprayed off, something is growing, providing soil cover. This year, on this field, however grazing with the sheep was challenging, as they couldn’t take advantage of the good weather early in the season to drill as the sheep were still grazing it, but Julian is still keen on the value of the sheep in the rotation, explaining “everything is an integrated holistic system, and you have to take some things on the chin to achieve the end goal.” The walk also took in a different field of oilseed rape which had been drilled with the Moore disc drill, and looked at some pollinator strips that are planted in the middle of a field of barley as part of a research project looking at management systems for sustainability. While the main benefits of the strips is crop protection and improvement of biodiversity, it will be interesting to see whether there is a soil health benefit from them being planted.

Future plans

Julian is trialling a few acres where he is undersowing clover and medic. Now that the soil organic matter levels have built up, the next plan is to start to reduce Nitrogen levels and improve nitrogen use efficiency which will reduce nitrous oxide emissions, with the ultimate aim of running a farming system which has lower inputs and positive economic and environmental benefits.

Cheshire Dairy man is runner-up

Our second place winner was Will Blackburn who farms in Cheshire. He runs a dairy enterprise with 300 milking cows and grows a range of arable crops. His light sandy soils make holding onto nutrients and water a challenge, and this has seen him adapt his management system to focus on building organic matter within the soil.

Will started drilling with a Moore drill 10 years ago for drilling grass into wheat stubbles. The farm was still growing potatoes, which prevented a complete switch over. He explains “when we were growing potatoes, it took 3 or 4 years of grass to get the soil back in good health. When potatoes were making good money that was ok, however when they weren’t making good returns, it didn’t make sense. You realise when you stop growing them how much they are damaging the system.” Since the move away from potatoes the focus is to develop a fantastic surface to the soil which will build a humus layer (and resilience).

Will is also grateful to the cows and grass being on the farm, which has made the switch that much easier as the soil biology was already good. The soil on the farm is changing, the stones are disappearing which he puts down to good levels of worm activity, the worms are constantly active and digesting the soil, taking soil up which pushes the stones further down the soil profile. As well as the light land that is surrounding the home farm, Will has some heavier land away which is being managed in a similar way. Traditionally after 3 years of ploughing these fields would need a lot of working back down to get a good seed bed for the next crop, however with this system, that isn’t the case.

The first field that we visited was a grass field. Here Will explained more about the soils on his farm and how he manages them. The soils on this farm are good at leaching potash, so the aim is to get carbon into the soil and keep in there to make best use of it (and not lose it). Although this is a simple message, by following it and looking after the soils by not cultivating it is possible to achieve. The light sandy soils are great for turning cows out early, but in periods of dry weather they can suffer. The system being developed here is predominantly looking to provide the resilience in drought conditions. The grass seed in this field was disc drilled in. Will explains, “By not disturbing the soil, when the conditions go dry you maintain the soil capillaries and old root channels which allow water to percolate, and the soil can perform its natural function.”

Although grass is fantastic for soil health and soil biology, Will is also keen on having a break from grass within the rotation and is seeing the benefits. It also provides an opportunity to get on top of the grass pests including leatherjackets. Grass management and efficient forage utilisation is something that Will has recently started to focus on in greater depth. Will maintains the grass in its vegetative state though grazing management. As well as providing high quality forage to the cows, he sees a soil benefit from this too as the grass is continuing to produce new roots until the seed head appears. By managing grass to keep it producing roots the soil biology is being fed and carbon is being cycled efficiently.

Lighter Machinery and Gradual Change

Will measures his grass once a week to calculate his available forage and complete a grass budget. Measuring grass covers and calculating his feed wedge has allowed him to improve his pasture utilisation and plan ahead. He explains, “the efficient use of grass means that we can use less concentrates, producing milk more efficiently.” The leys on the farm are predominantly high sugar grasses and clover. Will has had fantastic results from high sugar grasses and finds them great for milk production as well as being carbon efficient. Will isn’t a fan of intervening mechanically with machinery including the use of subsoiling or slitting as the aim is not to interfere unless there is a massive issue.

He explains, “if we can get roots, pore spaces and channels built up then the soil is more resistant to compaction, the soil starts to bounce and become resilient, however if you are tilling it, instead of bouncing back it goes down and stays down.” Will started off with a Moore disc drill but struggled on the heavy land as there were issues with drying out and the slots opening up which led to poor establishment. He moved over to a 750a and finds that it does what it needs to do and fits the system, although he admits its quite extravagant for the number of hours that it does! However Will is completely honest that not everything has worked

“if you look at the past with everything I’ve done conventionally versus no till, I’ve had failures with both but my failures in no till have cost me less. There can always be crop establishment risks whichever system you are running. Through not cultivating though I’ve really seen the impact, as on fields where I’ve previously ploughed and the fields have been uneven and full of clods, I now have a flat field.”

Future aspiration for Will include honing the grassland management system, and building organic matter levels even more. He is also interested in reducing fertiliser levels.

Lincs Farm gains Soil Farmer Award

Our final walk was with Paul Davey who farms 1100 acres in Lincolnshire. Spanning a mix of soil types including clay, chalk, medium and wold series, he grows a range of arable crops, runs a sheep flock of 200 ewes and a regional distribution business for local produce. The business has evolved to its current form through a range of different practices and growing of different crops including potatoes, vining peas, and onions. The broad rotation on the farm is 2 years of ryegrass, a legume break, wheat, an oilseed break, wheat, spring barley and then back to ryegrass. This longer rotation and cropping blocks of land has allowed him to reduce overheads.

The inclusion of livestock on this predominantly arable farm has been a key part of the strategy to be more resilient, sustainable and regenerative. The evening started with a presentation which explained the history of the farm and how they had decided to change the way they did things. He explains “What we’ve done hasn’t been a licence to print money, it’s been about trying to manage a ship in choppy seas. A key challenge has always been getting the equipment around the geography of the farm and get a margin at the end. So, we’ve always been on the lookout for changes to the system, but that involves finding a starting point.”

Within the logistical confines of the farmed area, Paul’s strategy is moving to lighter machinery and making gradual changes in terms of managing tillage and compaction. Having recently dug some soil pits and looked at rooting depths and soil structure, he has concluded that roots from the crop are capable of taking out compaction when you are travelling with lighter machinery. He has seen the impact of working with heavier machinery, as he remarks “two or three years later, you can see a wave across the field where the kit had been travelling.” He is comfortable with the use of extremely shallow cultivation to sort out any compaction that the roots can’t deal with. He is also keen on ensuring that tyre pressures are right for field conditions wherever possible (given the balance between travelling in the fields and between then on the roads).

Attentions were then drawn to the stripper header which is being used for the 6th season here on the farm. It is used for combining the ryegrass and allows the crop to be combined at the same rate as cereals, which allows for flexibility in tight weather windows, and it’s also perfect for linseed. Paul is experimenting with it to drill directly into standing stubble, maximising the soil armour. Paul comments “a key question for the future is how we manage crop residues and how to keep the carbon to nitrogen ratio high enough to deal with a large amount of residues.”

Grasses are the building blocks of the system that is run at Girsby Grange, and Paul is a passionate advocate of the benefits that grass brings. “Regardless of how you manage it, whether it is through growing grass for seed or grazed share farming agreements, it provides a massive benefit and up to 40 tonnes of organic matter per hectare over a threeyear period. It’s an extremely valuable crop, with a big mass of rooting which brings life back to the soil, nothing works like roots do.” After visiting a field of grass grown for seed, the walk finished up in a field of beans, where a soil pit was dug. The soil looked very well structured with good levels of soil aggregation. The previous week, this field had experienced 125ml of rain in 48 hours, but there was no evidence of any ill effects. This field will be zero tilled into wheat once the beans are harvested.

Paul is farming to improve the long term sustainability of his farm and a key part of that is farming for the rotation. He comments “it’s about taking a long term view, being flexible and brave and taking the risk. When you scratch the surface you can see the costs of our actions. Most farming practices seem to be fixing a problem by creating a different one, with this system of farming, there seems to be genuine solutions.” Three fantastic walks with three inspirational farmers that provided lots of ideas and knowledge for all who attended.

If you are interested in applying for the competition this year or nominating someone that you feel deserves to be recognised, the competition will open on World Soils Day (December 5th) and more information can be found at www. farmcarbontoolkit.org.uk.

-

What’s in a Name?

Welcome to the 5th Anniversary issue of Direct Driller / Normal Farming magazine. When we started the magazine, we really didn’t know what to call it. We knew it should focus on soil health, reduced cultivation, conservation agriculture (remember when it was called that), sustainability, efficiency and profitability. Lots of good words and I’d hope we have done well to sticking with those goals over the past 2000 pages of content. But that also gave us a lot of options for a title.

No-Till farmer already existed in the USA – so that was out, as was TCS from France. We put about 20 options up on a white board. It’s fair to say that none really grabbed us, but one was Direct Driller. It referenced more the machinery than the practice and that was our main reasons for not loving it. Because, while the right machinery is critical, we have always believed that to change anything requires a mindset change first. “Mindset Magazine” though didn’t sound a lot like farming and also now exists. Zero-till, Reduced tiller, Zero tiller, Conservation Farming, Regen Farmer were all considered too but nothing grabbed us.

When considering such creative questions, beer should be used to help come to a decision. It didn’t really help, in this instance, but as always made the process more enjoyable. After a couple of weeks, we settled on Direct Driller Magazine. We knew that most of the farmers who undertake this process will be using a direct drill of some sort, it seemed like common ground for all. The magazine was born.

You will see from the front cover we have changed to “Normal Farming Magazine” for this issue. We aren’t changing the name permanently,

mostly because this is an even worse title. However, we wanted to highlight just how much farming media and farming attitudes have changes over the past 5 years towards regenerative farming.We often say the reason we started the magazine was because we were told there was not room for a niche publication that only focused on

regenerative agriculture. We were in a unique position to be able to break new ground and launch something without a solid business plan behind it. This was at a time when companies were saying the print media didn’t have a future and smaller publications were going to digital. Yet now all the mainstream printed magazines are now full of regenerative content. They are all pivoting fast to this new normal. ESG,

sustainability, biodiversity and carbon credits are talked about everywhere.And this is our point behind the title. Regenerative farmers, like yourselves, have become trend setters, not followers. You are not outliers, those weird farmers who do things differently. You are now “normal”. I realise some of you are going to be quite disappointed by this new status, but I’m afraid it’s the truth. Those farmers who fight change are now seen as outliers, fighting for a past that clearly just doesn’t

work without governmental financial support.They are now realising they have to change, although that change could also be to move even further away from conservation practices. An odd consequence of what the government is trying to do. Regenerative farming is becoming the new normal – although with a long journey and a lot of learning still required. This new normal means this magazine will keep growing and growing. We never thought it would get to the size it has, but we see no reason why it won’t eventually have more farmer readers than anyone else.

Direct Driller magazine today, is the fastest growing agricultural magazine, created for and by farmers. Giving voices to those farmers who wanted to change and have not only changed their farms, but also influenced hundreds of other farmers to take steps that they would not have done without their support. This is something for regenerative farmers to be proud of. I wrote an article in Issue 14 about the 3.5% rule. We have seen this change in farming being driven by farmers themselves.

By reading this magazine, by going to Groundswell (and now Down to Earth as well), we have created a change in overall farming attitudes. Now everyone is reading about regen ag, even if they don’t read this magazine. For just one issue – here is to being “normal”. Embrace it, tell your nonfarmer friends about it and profit from it.

Thank you to everyone who has helped make this magazine what it is over the past 5 years. Raise your glass to the next 5 years over a Xmas drink with your family and friends.

Merry Christmas and a Happy New Year to all our readers.

-

Featured Farmer – Harry Heath

Arable & Pig Producer – Newport Shropshire

200ha Owned (Wheat / Barley / OSR / Sunflowers / Beans)

350ha Contracting

100 Sow Indoor/Outdoor Herd

Our arable business has always traditionally been a poor relation to the livestock enterprise. It has however dutifully had the important task of growing combinable crops to feed the hungry mouths of a 600 sow herd producing 17,000 pigs per year, at least this was the case till very recently. Market volatility and spiralling input prices ultimately were the start of us questioning the status quo in 2021 and it didn’t take too long to realise that our business needed to head down a different path.

Big changes have happened within the last few years, with the biggest being the exit from the indoor pig industry and the move to put agroecology at the centre of everything we do on the farm.

Before the pigs were the dominant enterprise on the farm, the arable land was farmed intensively with a three course rotation of potatoes / sugar beet and wheat. This, alongside a routine use of power harrowing and subsoiling took its toll in leaving our sandy soils prone to slumping and when tested scoring poorly in many other areas of soil health.

Our move to focusing on soil health started in 2018 with a change agronomist. We are extremely lucky to have Ed Brown (Head of Agroecology for Hutchinsons) as our agronomist and I have no doubt in my mind that he has been pivotal to our business in challenging what and more importantly why we do things. We were also kindly asked to be the national agroecology site for Hutchinsons as part of their Helix Farm network. Undoubtedly this has assisted in us running trials to find out what works and more often than not what doesn’t work on our farm. Trials and testing are now the cornerstone for how we make change whilst not exposing ourselves to additional risk.

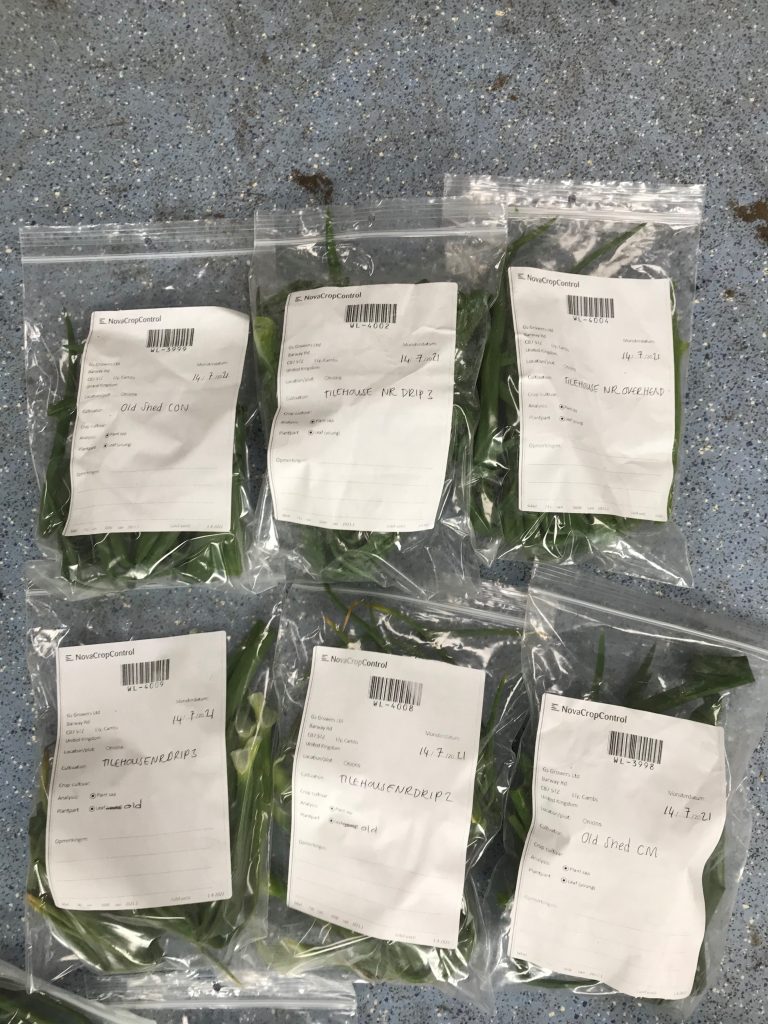

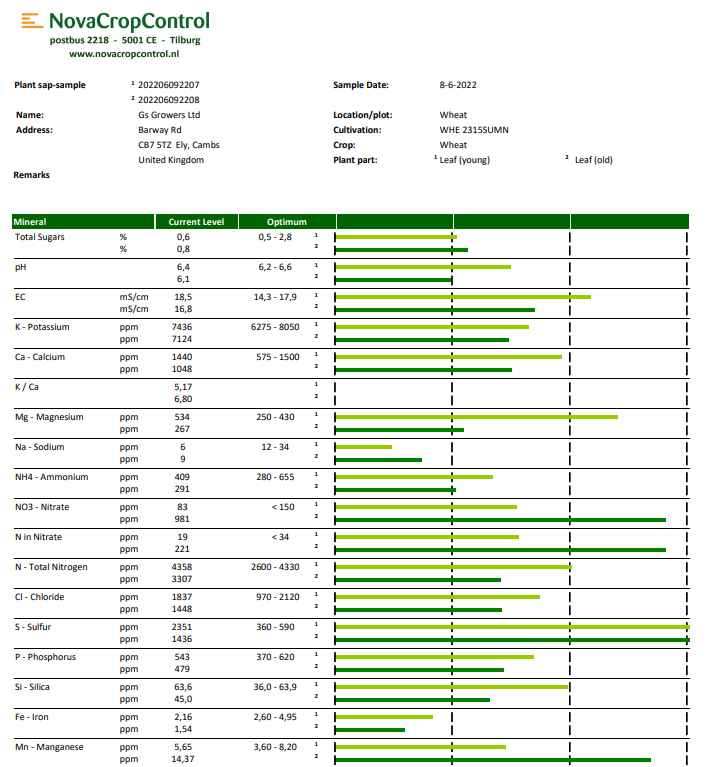

One of the first changes was doing the thing that everyone told us not to do, which was to buy a new drill. This was in my eyes a necessity, as we had no choice but step away from the combination drill if we ever hoped to start and build better soil structure. We bought a demonstrator 750a and swiftly signed up to an operators course hosted by Simon Chiles. Straight away this gave us confidence that was needed in such a radical change in how we established our crops. The autumns of 2019 and 2020 allowed us to cut out teeth in less than ideal conditions, but the disappointment of slightly lower yields were eased by lower costs which kept margins at parity. Nitrogen rates are starting to come back slowly (circa 20%) but it was only relatively recently that we brought legumes into the rotation and have now started to implement other tools such as foliar N and SAP Analysis to look at improving our efficiency further.

No one really can prepare you for the change in mindset required when going down the regenerative route. From ignoring how the field looks after direct drilling to ignoring the itch of recreational tillage, it’s been a learning curve every step of the way.

Getting living roots in the ground for as much of the year as we can, feels right in line with all the other changes we’ve made. We grazed our cover crops with sheep last year and we’ll look to repeat this again next spring. It’s been our first season this autumn drilling everything directly into catch crops. The biggest benefit to date is how well the ground walks even after the monstrous deluges of rain that we have had in previous weeks.

We are now three years into using untreated home saved wheat blends which seems to be assisting in lower fungicide usage as well as maximising genetic diversity within the crop. Companion crops of buckwheat and clover are grown with the OSR and a further drive to look at how best to use bi and poly cropping will begin again in the spring.

Our nemesis on the farm is undoubtedly herbicide resistant ryegrass. In a 5-6 year timeframe it has spread to a number of fields on the farm whilst we figured out transmission routes and resistance patterns. Now we are taking a much more robust approach to the weed. Firstly harvest hygiene is a number one priority with the combine being blown down with a compressor after every field. A chaff lining kit has been fitted to the combine in an effort to reduce weed seed return on either side of the swath. The one remaining change of the year will be to install a water treatment plant to clean up our borehole water and make it more suitable for spraying and biological amendments.

Our main investment this season has been the move away from the John Deere 750a to a Horsch Avatar. We saw clear benefits from last year’s demonstrator with a heavier closing wheel, more flexibility of drilling multiple products and easier calibration. The big move agronomically was to place liquid products down with the seed. We bought a second hand Opico Nitro Jet front tank and bought the rest of the kit from Simon at S&K Sprayers. With Johnson-Su bioreactors and vermicomposters in the shed, it has been great to make a start this year with placing these products down with the seed in furrow or as a seed drench. The OSR went in a little later than we had planned this year (Circa 21st August) but the addition of liquid fertiliser, seaweed and liquid fish seemed to improve crop vigour compared to control plots without any.

Change has definitely brought about new opportunities for our farm in a way that I could never have anticipated. The move to direct drilling has really helped us grow and expand our arable contracting by helping other local farmers focus on improving soil health.

From a previous life of out of hours breakdowns and alarms the initial prospect of being livestock free on the farm had an obvious appeal but the need for spreading risk and retaining a diversified income stream would always win out for us especially with modern livestock buildings with few options for alternative use. We made our decision to move from intensive to extensive production.

One thing that always struck me as odd with our previous pig enterprise was that meat eating quality was barely given a second thought. It was always increasing growth rates, reducing feed conversion or improving breeding performance but never actually the thing that ultimately mattered, what the consumer thought when eating what you produced. We were very lucky to meet a chef in London who also shared this same thinking and it didn’t take long to form a joint venture and make plans on how to take the pigs forward in the future. For now this venture is in its infancy but it will be great to see how we can best integrate the pigs with the arable so that both enterprises benefit from each other.

5-7-2022 ©Tim Scrivener Photographer – 07850 303986 ….Covering Agriculture In The UK…. July, 2022, Helix Agroecology Like so many readers of this magazine I’m always pleased to see it land on the doormat. This inevitably leads to me pouring over its pages for the following few weeks when chance allows. I’m continually inspired by how many other growers are reducing their reliance on inputs, focusing on profit over yield and showing how regenerative farming can be a sustainable lower risk model for farmers to adopt.

With some many other changes on the horizon such as ELMS, carbon and biodiversity trading and the full effects of Brexit and trade deals yet still to be felt I feel we are as aligned as well as we can be for challenges that lay ahead.

-

The curious case of disappearing nitrogen

Written by James Warne from Soil First Farming

It seems everyone is doing ‘regen’ these days. There is a lot of confusion and miscommunication around what it means. I was at a meeting recently where I heard someone proclaim that their arable business was carbon neutral even though they were still ploughing, combi-drilling and using an average of 230 kg/ha of nitrogen every year. I wondered which of the many carbon calculators threw out that spurious result, or the quality of the data fed into it?

Whilst on the subject of nitrogen, there is lot of talk amongst farmers and growers over simply reducing nitrogen rates. Every grower on social media is now growing record yields of wheat with zero inputs. It’s the latest form of alchemy, reduce inputs and conjure up something for nothing, it’s origins probably stem from Trussonomics.

But is it possible to reduce nitrogen by 80% and maintain output? Can you really grow 10 tonnes/ha wheat crop with only 40kg of applied nitrogen?

Research suggests the total nitrogen requirement for a wheat crop is somewhere between 280-360 kg/ha. That is for all the biomass of the crop, above and below ground. A 10 tonne crop of 11% protein wheat removes 190kg N alone. If we are reducing the total applied nitrogen, where is the balance going to come from?

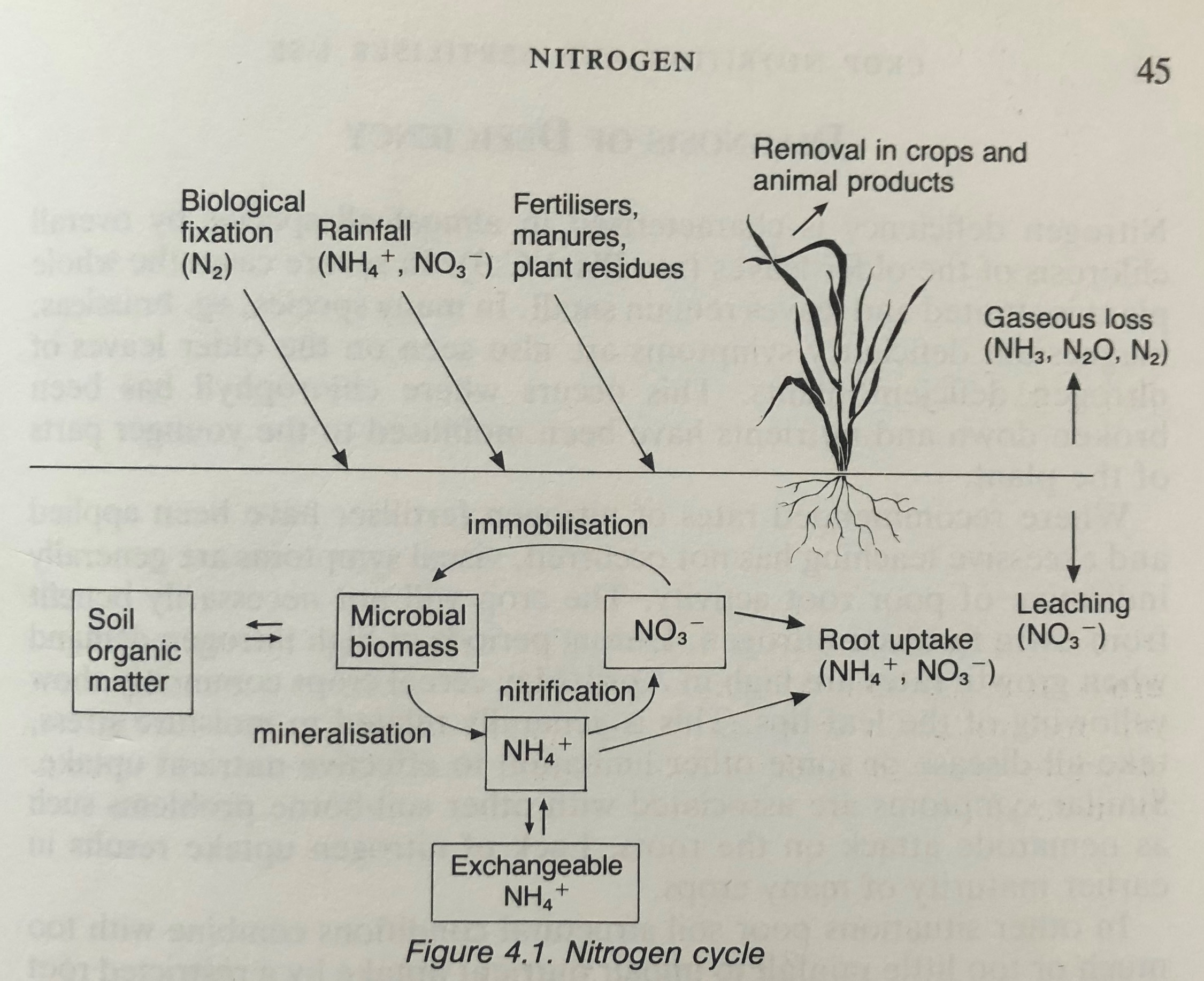

If we consider the nitrogen cycle (below) for a moment it is clear that aside from inputs there are only three other sources of nitrogen the plant can rely on;

1, Biological fixation

2, Deposition from the atmosphere, mainly rainfall

3, Mineralisation from Soil Organic Matter (SOM)

(reproduced from Crop Nutrition & Fertiliser Use, John Archer, 1985)

Biological fixation and atmospheric deposition combined may contribute anywhere between 0-40 kg nitrogen per hectare per year. Biological fixation is carried out by soil-dwelling, free-living, nitrogen fixing bacteria, such as species of Azotobacter & Bacillus. These free-living bacteria are not to be confused with the symbiotic species (Rhizobium) that associate with legumes.

As with all biological functions the bacteria need water, temperature, oxygen, carbon and a suitable pH in which to thrive. Remove, or reduce, any one of these requirements and they will stop reproducing and go dormant.

Mineralisation of SOM is also a biological function and as such has the same requirements given above. The potential nitrogen contribution from a typical arable mineral soil with low organic matter maybe as much as 50kg/ha in a good season, but it depends upon rainfall! Organic soils and those high in SOM maybe able to release more than 200kg per hectare of nitrogen.

However, having a good biologically active soil is only part of the story, the crop still needs to be able to access and utilise the nitrogen with high efficiency. This relies upon soil structure and crop rooting to explore the soil reserves. Good crop nutrition, especially access to magnesium to allow maximum solar radiation interception, and sulphur to fully express amino acid and protein synthesis.

Steve and I have been conducting our own trials, on-farm, and independently, over several years now and we have no doubts that it is possible to reduce the total nitrogen applied, increase nitrogen utilisation considerably and maintain yield. It is important to stress however that it can only be achieved in some very specific circumstances. If you are on a path of raising carbon levels in your soil it seems natural you may want to cut back on your nitrogen inputs, but this may not always be the most logical thing to do.

-

How Biodiversity Net Gain (BNG) is delivering alternative farm funding

With the farming landscape in the UK changing so dramatically in recent years, leaving many generational farmers facing reduced financial support as well as increased costs, the pressure is really on over how to make land generate a return.

Many farmers today are facing the stark reality of dwindling subsidies, so it’s never been more urgent for farmers and landowners to explore securing long-term methods of creating diversified and sustainable income streams to safeguard their future.

Understanding what is involved in new schemes in practical terms can be challenging and there are many questions around how land used for natural capital projects will impact on a farmer’s core business. This is where Environment Bank can help.

What is Environment Bank?

Environment Bank was established in 2006 and was the first business of its kind in the world to launch Biodiversity Net Gain (BNG) Units. Founded by UK ecologist Professor David Hill CBE, Environment Bank developed a concept where biodiversity net gain (BNG) would ensure land used by developers for building and infrastructure projects would help leave the environment in a better state than before the development began, by providing net gains to biodiversity to meet their legal requirements.

BNG became a mandatory legal requirement in 2021 under The Environment Act, which David lobbied hard to secure in law over a 15-year period. Since then, Environment Bank was awarded £200m in private sustainable investment funding to begin establishing a nationwide network of Habitat Banks (parcels of land) totalling over 4,000 hectares across England that deliver BNG Units.

What is a Habitat Bank?

Environment Bank actively began establishing its Habitat Banks across England in 2021, which is essentially securing a parcel of land that creates a significant uplift in biodiversity. Typically they are created on low-yielding land upwards of 10 hectares in size and can be made up of species-rich grassland, woodland, wetland, mixed scrub or rewilding sites. They provide a secure and long-term income to landowners and a biologically diverse haven for nature, leasing land throughout England to the Environment Bank to create biodiverse habitats that help restore nature, selling the ‘BNG Units’, back to developers.

Ensuring the Habitat Banks don’t impact national farming requirements, Environment Bank looks to utilise the marginal or low yielding land with the Environment Bank only taking a lease interest in the land, so the landowner retains ownership.

Environment Bank can then raise BNG Units on biodiversity uplift which they can use to help organisations meet their biodiversity net gain requirements, removing all risk and long-term liability from the landowner.

Since launching its award-winning Habitat Bank scheme last year, Environment Bank has seen enquiries soar, with over 60 new sites expected to be established in 2023. It is partnering with farmers and landowners – including Tim Easby from Oak Stile Farm, North Yorkshire, and Toby Diggens, from Puddington Moor Farm, Devon – establishing Habitat Banks on their land through its privately funded management scheme that guarantees an income for 30 years.

What type of land is required for a Habitat Bank?

All types of land are considered for Habitat Banks including currently unproductive areas, old pasture and scrubland as well as under-performing arable land. This is across the acreage on parcels of land upwards of 10 hectares in size and doesn’t have to be in one block.

The ecologists work with landowners to establish habitats that work best for their land operations, and which creates the best outcomes for nature in their location. They won’t change the entire face of your farm, they will simply help support the replacement of your existing EU farm subsidies as an alternative use of small parcels of land.

How Habitat Banks benefit farmers

A crucial benefit is that farmers retain ownership of the land. A management plan, contracted to and delivered by the landholder, is tailored to suit the existing land management strategy and sources of funding, as well as ensuring the most tax-efficient solution. Environment Bank pays up to £27,000 per hectare over a 30 year period for the management and lease of the land, as well as a generous welcome bonus.

Being fully funded, Environment Bank typically arranges the lease and management payments within 20 weeks of registration, and covers all costs for establishing and managing the Habitat Banks, extending to legal and tax advice where appropriate. It has a ready-made solution, so unlike brokerage models, farmers do not have to manage the complex implementation process or take any of the risk of the scheme failing. All of that sits with Environment Bank.

Farmers receive an on-boarding fee, their first year’s rent upfront, and then annual payments which increase with inflation for the 30-year term.

The goal of Environment Bank is to establish a network of Habitat Banks in every area of England to restore biodiversity and help farmers achieve this all whilst protecting their assets, making it a win-win situation for hard-pressed farmers.

There are many benefits to the scheme. It is uniquely designed to fit within existing farm enterprises including the production of food, tourism enterprises and other business streams, as well as alongside the government’s new Sustainable Farming Initiatives (SFI).

The management schedule on a Habitat Bank

How the land is managed depends on the management plan agreed with the landowner and how the Habitat Bank will work alongside other farm enterprises. It will be monitored regularly by ecologists at Environment Bank, and the progress reported back annually to the local planning authority or responsible body as part of their BNG obligations.

For grassland, for example, each year, the fields will be closed off during flowering season and the land keeper can take a hay cut once wild flowers have bloomed. In the autumn, the ground can be used for grazing, before livestock come back off the land again in March to allow the flora and fauna to bloom again, attracting rare species including birds and insects.

Native shrubs are often planted around the perimeters of the grasslands and livestock fenced out from the area to allow new shrubs to grow. Once established, the fencing will come down and the livestock can graze in the open habitats. Ecologists may put in ponds and wet scrapes if required to attract bird species such as endangered curlew and lapwing to breed and encourage more rare species of wildlife.

The land is managed in this way by the landowner – or generations of landowner – over a minimum 30 year period to allow for a fully biodiverse habitat to be established.

What do landowners involved in the scheme think?

Speaking of the establishment of a Habitat Bank at Oak Stile Farm, North Yorkshire, Tim Easby said: “We are delighted that Oak Stile Farm is hosting a Habitat Bank so that we can do our bit to enhance local biodiversity.

“We took ownership of this former dairy farm over 20 years ago and have begun to enhance areas for wildlife with sections of woodland planting and new hedgerows. We have always wanted to do more and Environment Bank’s Habitat Bank scheme allows us to enhance large areas of our grasslands for wildlife at a scale we couldn’t do before in a financially sustainable way.”

Many landowners and farmers are signing up to the scheme, and there is none more passionate about the benefits of Habitat Bank creation than one of the first farmer’s to sign up to the programme, Toby Diggens from Puddington Moor Farm.

“Being involved in such a ground-breaking project was important to me, as it’s one of the ways we can contribute to restoring nature and help reverse the environmental crisis,” he said.

“There are so many benefits to protecting wildlife and nature fundamentally, but this partnership also allows us to guarantee an income for the next 30 years on land which we would have to conventionally farm very hard to see any profit.”

To find out more about biodiversity net gain and Habitat Bank creation options for your land, please call our team on 01904 202 990 or visit www.environmentbank.com.

-

From the Sea to the Soil

Inspired by history for the future of farming

Using fish in arable farming is not a new phenomenon. The practice can be traced back to the ancient Roman empire on this side of the Atlantic, and there are stories of Native Americans showing the Pilgrims how to grow corn by planting a fish with each seed. It may have all started as a happy coincidence when farmers observed that plants performed better when decomposing fish were left near them, but thanks to science and research, we now have a good understanding of how fish material positively affects crops and the soils that support them. Mindful of the Farm to Fork Strategy in Europe which is looking for a 20% decrease in the use of chemical fertilisers by 2030, Dr Geraldine Fox and the team at Pelagia has developed the UKs first liquid fish hydrolysate approved by Animal & Plant Health Agency (APHA) for use as an organic soil improver which is also approved as an input to organic farming systems by the Soil Association. Sea2Soil revives a traditional farming method that time has forgotten, one which aligns with the path of regenerative farming.

Pelagia has an over 100-year history of utilising fish and fish by-products from human consumption processing to produce valuable and highly nutritious feed materials. Long before circular economy waste management and waste valorisation became buzz words, Pelagia has been recycling 100% of fish waste to produce economically important products.

In 2019, our processing plant in Bressay on the Shetland Isles expanded its operations and obtained a licence to utilise the by-products from Scottish salmon farms with the aim of zero waste from this industry. Here in the UK, this type of product would ordinarily have gone into anaerobic digestion as a feedstock where the beneficial nutrients and characteristics of the hydrolysate are somewhat diluted by other stock materials. Our goal is to retain the integrity of the rich source of essential amino acids, fats, macro- and micronutrients contained in the hydrolysate and offer it in as pure a form as possible that can be easily incorporated into many formulations.

Sea2Soil acts by feeding your soil bacteria, in turn converting the macro and micro-nutrients contained into a form that is more readily available to the plants. We have evidence that Sea2Soil, which is naturally high in fat, promotes the growth of fungi, which are hugely important in soil root systems, performing important functions within the soil in relation to nutrient cycling, disease suppression and water dynamics. The improved microbial populations also feed secondary and higher-level consumers like protozoa, nematodes, and earthworms, which work to improve soil structure by aerating the soil leading to better root development and reduction in abiotic stress. These macro-organisms also contribute to improved nutrient availability within the soil through excretion providing additional bioavailable nutrients to the growing plant.

For the past 3 years we have been refining our process to produce an organic soil improver that is affordable, delivers on yield responses, reduces reliance on chemical inputs and is farmer friendly. We have resisted the temptation to call it a fertiliser, because it is so much more than that. We see it as a prebiotic for your soil leading to:

- A healthier soil environment;

- Increased crop health;

- Reduced reliance on chemical fertilisers; and

- Promotion of a regenerative ecosystem, where the environment and its living populations can renew and recover from damage and stress.

Farm trials began in 2020 across various locations within the UK and on various crop types such as wheat, barley, oilseed rape, oats and beans. The aim was to identify how and if yield performance was affected and to identify any areas of further product development. We found that yield was either maintained or showed an increase, but what the results highlighted was that return on investment was higher, due to the reduction of chemical inputs. We continue to develop this knowledge portfolio testing its effects in vineyards, orchards and Christmas tree farms as well collaborating with various research groups.

Paul Davey runs Girsby Farm Services, a progressive agricultural contractor with a commitment to providing high quality crop production services to customers with interests in conservation and regenerative agriculture, and has been using Sea2Soil on his land in Lincolnshire.

Paul has seen first hand the positive effects of our product: “The dry conditions this last spring and summer presented challenges in a number of different crops, especially maintaining plant nutrition and managing the associated stresses. There were visible benefits for maintaining growth in the herbal ley established in May which received a 10 lt/ha of Sea2Soil application through fertiliser streamer nozzles in June. This application stimulated a good deal of growth within three weeks in a very dry time. Two applications of 10 lt/ha of Sea2Soil on the spring beans during the same dry spell improved the canopy growth of the beans and removed the chlorotic symptoms of stress, significantly improving the verdancy of the plants.”

Looking back not even a hundred years, it’s easy to see how rapidly the industry has favoured chemical enhancement over natural counterparts – a change which we all know can be put down to countless societal and industry-specific pressures. None of us knew it at the time, but introducing chemicals was a case of solving one issue while causing many others, including topsoil erosion and the destruction of soil health which in turn has been detrimental to our crops. Sea2Soil can positively contribute to the recovery of soil health, by improving soil biology and soil microbial populations, hastening the restoration of our topsoil and improving overall plant health.

-

Pasture and Profit in Protected Landscapes Programme

Pasture and Profit in Protected Landscapes is a free, farmer-led programme of farm walks, events and webinars open to everyone farming in the Protected Landscapes of Surrey Hills, High Weald and Kent Downs. The programme is being run by Pasture for Life in partnership with the Protected Landscapes. We believe that farmers learn best from other farmers, so over the next 15 months farmers in Surrey, Sussex and Kent are opening up their farms to share how their low input approach to grazing sheep and cattle has helped protect their farm business from the crippling increases in fertiliser, feed and fuel costs, and mitigate the effects of the drought.

From mob grazing to conservation grazing, they demonstrate a range of approaches for managing their land and the challenges and the opportunities of farming in this way. The benefits include:

- Financial gain

- Improved pasture

- Increased biodiversity

- Improved soil health and landscape management

- Reduced (or removed) workload associated with indoor housing

- Reduced worm burden on stock

By joining the programme, you are NOT expected to become Pasture for Life Certified or transition to a 100% pasture-fed or 100% mobile grazing system. The programme is designed to meet your needs and support you, whatever your current system or goals.

Free Pasture for Life membership

When you register for the programme, if you are not already a PfL member, you will automatically receive free PfL membership until March 2024 which normally costs £100 a year. This will enable you to additionally benefit from being part of our engaged and supportive community, as well as the work we do across areas such as the supply chain, marketing and academic research, and access to our forum, which is full of advice and support from other farmers who will often be facing the same challenges as you. You do not have to provide any financial details when signing up, and you can choose whether to continue with PfL membership at the end of the programme.

Mentoring

By registering for the Pasture and Profit in Protected Landscapes Programme, you can also apply to be mentored for up to a year by a farmer with experience of rotational grazing.

We have trained 12 Pasture for Life farmers as mentors across Surrey, Sussex and Kent who have a range of approaches to grazing with sheep and cattle. For instance, some house their cattle over the winter while some leave their cattle out year-round. What they have in common is that they are all 100% pasture-fed with no grain or feed inputs, and all have adopted some form of rotational grazing. Without exception, they find that the way they now farm is more profitable than the system they inherited, that it has increased biodiversity and improved the health of their stock and pasture, and has made their farm business more resilient in times of extreme weather and spiralling costs. The experience has been transformative for them, and they are keen to share their learning with other farmers whether they are just curious to see other approaches or are wanting to change how they farm.

Signing up

For more information or to register for the programme, please email Sarah at Sarah@pastureforlife.org and she will email you a simple registration form, or call Deborah on 07543286709. Please note you must be farming in the Protected Landscapes of the Surrey Hills, High Weald or Kent to qualify.

Pasture and Profit in Protected Landscapes is funded by the Farming in Protected Landscapes Fund (FiPL) and supported by the Surrey Hills, High Weald and Kent Downs Protected Landscape Partnerships.

Meet a Mentor behind Pasture & Profit

Andrew Lingham, Court Farm Butchery, Rochester, Kent

Andrew runs a 320-hectare mixed farm, with 220 hectares of arable crops – including cereals, various beans, linseeds, millet and heritage wheat varieties – alongside his Pasture for Life Certified 30-40 strong herd of native breed store cattle and around 150 Romney store lambs.

For Andrew, this mixed, integrated system is key to his success. His animals offer a valuable additional revenue stream through his butcher’s shop, but perhaps more importantly, they play a crucial role in building soil organic matter and recycling nutrients. He has very little permanent pasture, and for the most part grazes his animals on cover crops, using a 60/40 rule. In his words, “you don’t let the animals graze down to the floorboards. Let them take 60%, and trample the remaining 40% back into the ground.” This approach, he says, is “far superior” compared to just using cover crops alone, and means the animals are “feeding themselves, feeding the soil, maintaining soil structure and increasing organic matter.” How long he leaves his animals on a crop depends on the conditions – in dry weather they will graze an area for around 3 days, but in wetter conditions it can be as little as 1-2 days to protect the ground from trampling.

“We actually see our animals gain more weight over winter by grazing on our cover crops than we do in the summer off the permanent pasture”, he remarks, demonstrating just how drastically different farming can look compared to conventional systems based on feeding costly inputs to grazing animals over winter. “This is a pretty low-cost system, and by low cost I don’t mean low output, it is truly working with nature. I know it’s an old cliche that’s fairly overused, but the further you get into this the more you can see that natural processes actually work if you don’t interfere with them too much.”

Andrew has always been drawn to doing things differently and questioning the status quo – for example, he started treating his animals homoeopathically in the mid-90s. He now thinks he can bring that questioning mindset to his role as a mentor, for those who are also open-minded to new approaches and wanting to make some changes. “I don’t have all the answers, but I’m happy to be a sounding board and guide people through the approach. And I don’t like lecturing people, but if you’re interested and want to learn, I’ve learnt a hell of a lot and I want to pass this on.”

His approach is certainly working. “My veterinary bills are pretty much zero, and it’s been years since I used antibiotics. Our worming treatment is pretty much just rotational grazing, and the use of some diatomaceous earth and seaweed kelp,” he says, when asked about other ways this approach has benefited his farm. Andrew has particular interest in building both the gut microbiomes of his animals and microbiome of his soil, and speaks to the interconnectedness of the two. One way he does this is by brewing his own microbial treatment, full of beneficial bacteria and fungi for his animals, which is put in their water. This keeps their gut microbiomes healthy and stable, and further inoculates the soil through their waste; another example of his holistic approach having multiple benefits across the farm.

Andrew talks with enthusiasm about how for him, every day is a learning day, grappling with new questions and challenges and thinking through how to approach them. This often sees him tapping into a global network of farmers who are also turning to nature-led, low-input systems. ‘It’s so easy for the current generation to learn if they’re interested. There is so much information available online. In mentoring I see myself as a bit of a guide towards people and resources who have been mentors for me, people across the world who you can tap into and who do actually respond. When they come back and answer some pertinent questions you have, you really feel that you are part of a global movement.”

If you’re interested in being mentored by someone like Andrew, please email Sarah at Sarah@pastureforlife.org and she will email you a simple form, or call Deborah on 07543286709 to register for the programme, and state your interest in getting a mentor. Please note you must be farming in the Protected Landscapes of the Surrey Hills, High Weald or Kent to qualify.

-

Farmer Focus – John Pawsey

I can’t be certain when you will be reading this contribution to the UK’s formative regenerative publication, but what I do know is that most of you will be about to, or will just have, sat around the Christmas table with your family.

It can be tricky territory. Especially if you are all working together in a family farm situation where life expectations have never been discussed and/or familiarity has bred contempt. It does happen.

I’m not a fan of mirrors because whenever I pass one, a weird old bald man stares back at me. At fifty eight years old and with three young adults between the ages of nineteen and twenty four, I am reconciled to the fact that some kind of succession will have to be discussed as it’s becoming increasingly obvious that the weird old bald man in the mirror is me. Knowing my lot, after a few late festive nights, lashings of wine from the West of France and endless cold turkey sandwiches, my offspring’s future involvement in the family business will be discussed. I need to be prepared.

Unfortunately the days are gone when the reins of any business can be passed onto one’s children just because they have sprung from your loins, or more accurately in my own situation, from Alice’s loins, (I played a small part a few months earlier in the pregnancy, apparently) as we need the best people for the job. But what are the opportunities if your successors don’t necessarily fit the traditional farming bill?

For many of us, having diversified our businesses over the last twenty years, it’s not just about farming, which is a bit of a relief as my one of my daughters whilst hermetically sealed inside a luxury tractor cab, blasted with banging tunes, is quite capable of entering a field with an implement that she has assumed has been liberally greased and adorned with fresh wearing parts by the previous occupant. On exiting the field she has been known to turn around for the first time to discover that she has three punctured tyres and the right hand wing of said implement is imbedded in the field’s sole telegraph pole, or as we call them in the barren wastelands of East Anglia, a Suffolk tree.

When I joined our family company in the mid eighties when all we did was farm, persuading a son or daughter to join a family farming business was considered to be a form of child abuse, but possessing no qualifications due to being terribly naughty at school, I was grateful for any opportunity laid at my door. Also, there was a certain agricultural establishment in Gloucestershire that laughed in the face of scholastic achievements as long as your cheque didn’t bounce. No longer the case these days I’m afraid.

The modern rural business is now able to offer a multitude of opportunities which weren’t available to me in my early twenties, and anticipating a Christmas questioning, I have been considering how to engage my young adults and their various aptitudes, and have drawn up a list of new job titles to tempt them.

The roles are as follows.

An Enlightened Agronomist: a few do exist but the majority of agronomic advisors are still happy to reach for the plastic bottle to cover their backs just in case. We have knocked the confidence out of our farmers with the complexity of chemically based agriculture making us feel unqualified to make even the most basic decisions. It’s like raising the bonnet of a car and on seeing an expanse of plastic you close the lid, leaving the job to someone else because you can’t see any recognisable components. You assume that it no longer contains the internal combustion engine that you have worked on for years. Enlightened agronomists can see though the plastic.

Trial Designer and Data Analyser: we are constantly trialling various agronomic scenarios but often don’t complete the work with any rigour to get meaningful answers, or we just do it for a year and think that the results are good enough. We have been collecting data in terms of yield, crop quality, work rates, soil health and biodiversity but we haven’t layered that information to really understand where the real opportunities are for efficient profitable food production with room for nature. It’s not a full time job but when combined with the enlightened agronomist role, it could be.

Administrator, Book Keeper and Inbox Curator: to free us up to do all the creative things (see above). We need to get out of the office. Although mobile devices have allowed us to de-shackle ourselves from the swivel chair, my life is still plagued by administration. I remember being lectured by someone from our levy body about not being as productive as other European farmers. It’s because I’m spending too much time dealing with nonsense when I should be making better decisions for my business. The only inbox I had when I arrived on the farm was a physical paper one but now I have that and an ever expanding array of digital ones too. No, I don’t want to join your f***ing WhatsApp group!

Contract Farming Massager: although I like to feel that we give our undivided attention to our farmers we contract for, there is always more love to impart. Where agents are involved, our farmers get lots of juicy figures but we need to spend more time keeping them up to date with all the things that we are inventing and trialling on our own farm so they know that we are future proofing their businesses as well as our own. We have also missed opportunities to take on new contract farming arrangements mainly due to the lack of time to pursue them. It has to change.

Crop Polisher and Value Adder: part of the reason for converting to organic farming was to go more niche and make the market rather than take it. But we need to go nicher (is that a word?). The easy wins are to take back some of the processing and added value we give away. De-hulling our spelt, cleaning our home saved seed and mixing seed blends on the farm. Separating our own bi-crops and other multi-species crops. Putting in a bagging unit to direct sell some of our exotics. You are probably all doing it already.

A Roboticist: a role that gets me thinking of the term motorist. Motorists were invented over a hundred years ago and were “a thing” because you couldn’t just jump in a car and roar off. You had to check a multitude of lubricants, learn copious amounts of hand signals and something called double-de-clutching. Nowadays we just drive a car, possibly own more than one and never check the oil. In a hundred years time I suspect that we will just instruct robots, possibly more than one and never check their (vegetable) oil. In the meantime, we need the skills of a roboticist.

And then there are all the jobs that we hand over to the man (it usually is) in the coloured corduroys: an Environmental Designer, a Net Zero Minder, a Carbon Creditor and a Green Washer. All new roles and crucial to capitalise on the opportunities that will be available to us in the coming years. Some expert help will be needed but we should be able to do a lot of the work ourselves. Biodiversity net gain needs to be our net gain and not somebody else’s.

There is an opportunity for a Website Wizard, Social Media Schmoozer and a Brand Manager. Our website is horribly old and clunky and needs immediate attention. You maybe aware that I love a bit of social media, and although @Hanslope on Twitter gets my full attention, @ShimplingPark does not. And then there is all the other platforms that we are blissfully ignoring like TicTac and SnipChit to name but two. Everyone needs a brand manager, don’t they? The above is not a full time role, but an important one if we are to fully engage with our customers.

Although most of our redundant farm buildings have been re-purposed as offices, commercial lets and dwellings, there is always room for improving our offering and so two new roles could be created as a Property Tickler and an Asset Sweater.

The list goes on, and I suspect that reading this you have come up with several more positions of your own. Please do email me your inspired wisdom to john@shimplingparkfarms.com as soon as you can and they will be presented to my progeny.

You may be asking yourself at this point what any of this has to do with direct drilling? Absolutely nothing. But succession is something that we all have to grasp and if you are not doing so, then please make a New Year’s resolution to do so. For the sake of you and your family.

Wishing you an extremely Merry Christmas, the best New Year and an amazing Harvest 2023

-

Drill Manufacturers in Focus – Dale Drills

Top Features for Farmers

James Dale reviews the key features and benefits of the Dale Drills range which tick the boxes for his customers.

Like 2021, 2022 has been another very busy year for Dale Drills, with sales of seed drills up on previous years. A growing interest in no-till and regenerative agriculture along with funding in the form of the FETF grants have certainly helped, whilst our continuous drive to improve, and build versatility into our machines has also been well received.

A busy build schedule throughout spring and summer was made slightly more challenging with the global supply chain crisis. As a British manufacturer, we’ve always endeavoured to use UK products and suppliers where possible and our close working relationship has helped to reduce the impact of any supply issues, ensuring all our delivery deadlines were kept.

Autumn brought the opportunity to get out onto farms to commission the new machines. It is always interesting to meet with new customers and discuss their plans to incorporate a new machine into their farming strategy. Our focus on producing versatile seed drills mean they will suit almost all strategies from inversion tillage to no tillage and all things in between.