If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Soil Resilience Strategy Launched To Answer Key Farming Sustainability Improvement Questions

How can I reduce tillage without adding to my risk? What are the best ways of cutting my vulnerability to the weather?

How much carbon can I realistically capture? What do I need to do to achieve the most rewarding SFI soil standards?

Where should I focus my improvement efforts for the greatest overall value?These are just a few of the practical questions the Green Horizons Soil Resilience Strategy launched this spring by national agronomy leader, Agrii is designed to answer. And, in so doing, help East Anglian growers improve the resilience of their soils and sustainability of their systems. Developed following studies with the UK Centre for Ecology & Hydrology (UKCEH) and others, the strategy pulls together the latest understanding of soil structure, chemistry and biology. It provides a carefully structured approach to improving soil resilience based on the best available science, a thorough understanding of soil management, and sound practical advice and action. Flexible packages of laboratory and field-based assessments are designed to suit every soil condition, farming system and farm need, with an expanding team of soil management advisers providing specialist support.

“Our strategy employs a range of modern lab tests and hands-on, infield appraisals to identify the current health of farmed soils,” explained Agrii s u s t a i n a b i l i t y manager, Amy Watkins at the Cambridgeshire launch.

“Together with a good understanding of each farm’s particular objectives, needs and resources and practical soil management intelligence, these enable us to work with growers to develop the most appropriate plans of progressive improvement action.

“As well as concentrating the attention on some of the best areas for and ways of improving both immediate farm productivity and long-term sustainability, our strategy provides an ideal foundation for making the most of the evolving SFI soil standards payments.”

Provided through both Agrii agronomists and Rhiza specialists, the Green Horizons Soil Resilience Strategy (SRS) starts with a thorough soil health assessment involving broad spectrum laboratory nutrient, pH and organic matter testing. To which can be added more detailed measurements of soil carbon at different depths. Alongside this, it offers a suite of infield soil biology, structure and water management assessments, employing standardised methodologies for worm activity monitoring, Visual Evaluation of Soil Structure (VESS), penetrometer, slake, aggregate stability and infiltration testing.

Carried out on a sample of fields representative of the farm as a whole or those posing particular management concerns – depending on individual preferences – the results of all these assessments are set out in easy-tounderstand reports. The Agrii team accepts that much remains to be fully understood about soil biology, the best ways of measuring it, and its complex interactions with soil structure and chemistry. So, their approach has been designed for the greatest flexibility in responding to future advances in the science as well as in meeting the individual needs of different growers and systems, not to mention changing legislation and agricultural support. Appreciating there is no ideal soil biological community, it sets out to assess the most practical indicators of all-round soil health and productivity available as benchmarks for planning and monitoring improvements over time.

“Capturing the detail of all our assessments in the standard field reports we have developed to present the results in the clearest and most practical way provides the best basis for benchmarking and improvement planning,” Amy Watkins said. “Our reports give an objective and scientifically-valid record of soil status, allowing individual farm teams to set realistic objectives for improvement; monitor their success in meeting them; and (increasingly importantly for the future) demonstrate their progress to others – be they customers, carbon offsetters, agricultural support providers or the general public.”

“To encourage the widest possible participation, we have kept SRS charges at standard consultancy and laboratory rates as reasonable as we can,” she stressed. “The individual cost will, of course, depend on the specific assessments selected, the number of fields included and the frequency of retesting.”

Scientific Understanding for

Practical Action

While its lab and field assessments produce a raft of b e n c h m a r k i n g data, the real value of the Green Horizons Soil Resilience Strategy is in the practical action plans it develops from them rather than what they actually show, stressed senior Agrii agronomist, Andrew Richards at the launch. Playing a leading role in developing the science behind the Strategy over the past five years, Mr Richards is adamant that only by combining a detailed understanding of each grower’s resources and objectives with the best intelligence on all aspects of soil health and its management can any findings be translated into the most appropriate improvement action.

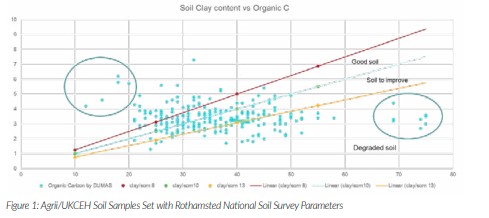

“More fundamental soil health constraints like pH, for instance, need to be addressed before it’s worth you doing much else,” he insisted. “Equally, moving to direct drilling without making sure your ground is ready for it could easily jeopardise performance. And it is essential to target levels of organic matter improvement that are realistic for both your soils and farming system. “While no single metric can capture the sheer complexity of soil health, the best science suggests soil carbon offers an essential, simple way to assess it. But this has to be done with an understanding of how soil structure affects its carbon-carrying content. “Our work with UKCEH has assessed the detailed organic content at DNA level of soils from almost 400 main southern England fields under a wide variety of management regimes. Amongst other things, this has shown that the clay:carbon ratio of soils is a much more useful measure of their resilience than organic matter alone. Because clay particles bind organic matter, the greater the clay content of a soil the more organic carbon it can store, but the higher the level it will require to be resilient and the slower it will be to build.

“So, we have made this metric central to our approach. Only by establishing exactly where soils sit on the clay:carbon resilience scale developed from Rothamsted work with the national soil survey, can we provide the most practical recommendations for both soil health and soil carbon storage improvements. (Figure 1).

Although the clay:carbon ratio is considered to provide one of the best available baseline measures of soil resilience status, soil organic matter changes only very slowly. So, Andrew Richards points out that merely monitoring changes in this parameter is not going to be enough to indicate progress – or lack of it – in improving soil functioning. “Which is why our drive to improve soil resilience also involves a range of other soil physical, chemical and biological assessments,” he said. “In our Visual Evaluations of Soil Structure (VESS) we record primary and extended root penetration depths and arbuscular mychorrhiza as well as soil plasticity, mottling and aggregation. We take penetrometer readings throughout the profile; carry out highly visual infiltration tests; and assess the type and activity as well as number of earthworms. Active carbon measurements are another useful tool alongside other laboratory tests.

“Taken together, these assessments enable us to establish exactly how resilient particular soils are and suggest the most profitable avenues for their improvement. This and a detailed understanding of each farm’s particular needs and constraints go into our action plans, the success of which we then monitored by careful re-assessment to the same protocols.

Key Soil Resilience

Assessment ConsiderationsExtensive Agrii trialling and onfarm testing over several years have identified a host of critical considerations in both assessing soil resilience and using these assessments to improve it. Most importantly:

• Selecting fields carefully on the basis of individual grower needs;

• Taking samples that are as representative as possible of field status;

• Making biological assessments at the best time, preferably in the spring;

• Recording the weather at the time of each assessment;

• Basing all organic matter testing on the same proven process (preferably DUMAS);

• Adjusting for bulk density, chalk and stone content for accurate carbon accounting;

• Following up in-depth initial assessments with seasonal snapshots;

• Re-testing every 3-5 years – ideally with active carbon monitoring in between;

• Making future assessments at the same time of the year and under similar conditions;

• Knowing the cultivation and cropping history of the fields assessed; and,

• Understanding the particular objectives and constraints of the farm.

Managing the Soil

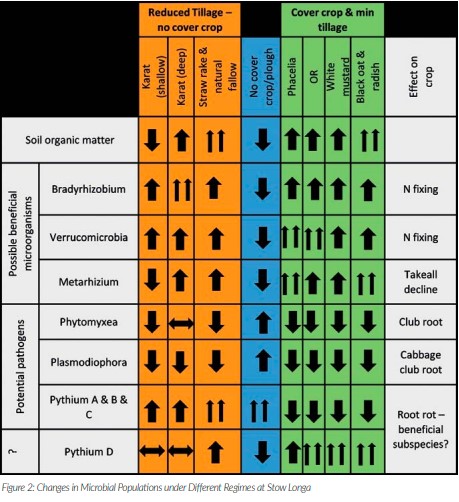

MicrobiomeDetailed UK Centre for Ecology & Hydrology UKCEH genetic barcoding work with the heavy land soil at Agrii’s Stow Longa technology centre has shown the encouraging extent to which its microbial communities have been influenced by different cultivation and cover cropping regimes run side-by-side under carefully controlled conditions over just three years. Altogether, the microbiologists identified an impressive 62,000 different bacteria, 2000 different fungi and 4000 different eukaryotes in the Stow Longa microbiome.

Irrespective of the marker genes they used, they recorded large differences in the communities of all three types of microbe between the cultivation and cover cropping treatments. These were clearly associated with changes in organic matter level. The degree of cultivation also appeared to be a factor, with the communities under a straw raking regime being similar to those under the various cover crops and distinctly different from those under either shallow or deep tillage.

The studies showed noticeable improvements in organic matter with both reduced cultivations and cover cropping. Even more interestingly, perhaps, increases in organic matter and decreases in soil disturbance were found to be associated with higher populations of potentially beneficial micro-organism indicators and lower populations of those considered to be harmful (Figure 2).

-

Farmer Focus – Clive Bailye

Risky business

The financial results are in, and they are good, in fact some of the best of my farming career to date. It would be wonderful now go on to describe how that is all down to the huge savings in fixed and variable costs made through our transition to a zero tillage, regenerative farming system, although that certainly contributes to the results it would only really be telling a part of a far simpler story. The truth is the financial performance was really because of just 2 key decisions, buying inputs (particularly nitrogen fertiliser) and selling outputs at the right time. So, did I make money farming or trading? And which is higher risk? Farming or trading? How we look at and deal with risk is something that is a key driver to many of the decisions we make within our farming business and something I think everyone should explore their attitude towards.

As farmers we grew the crops, we took the risk with weather, put in the hours and were rewarded with a decent harvest, no record breaker but certainly on par and budget for our soil type. As farmers I’m not sure we always realise it but there is great risk in what we do, my father has said in the past “there will always be a harvest” and this is certainly true in the UK but many who farm under climates more extreme than our own will understand this is not always the case. As a result, farmers in such countries seem much more aware of the risk of planting a seed with nothing more than hope of harvest and adjust their investment accordingly to mitigate this.

Weather related risk, be it drought or flood is something that British farmers have enjoyed lower exposure to, unlike many others. In the UK a drought is usually measured in weeks, maybe months, in places like Australia however it’s a question of years. The British are world renowned for obsessing and talking about our weather but in truth its nothing that extreme, making our exposure to weather risk some of the lowest in the world.

Yet most people I speak to seem to agree that our weather patterns do seem to be changing, climate change is becoming very real and whilst politicians and scientists talk about it, farmers are on the front line of that change. I’m not convinced the numbers tell the real story, looking at statistics for average rainfall and temperature in my area it seems little of significance has really changed, so why does it feel like windows to establish, harvest and spray are shorter than ever despite us having better technology and capacity than we did in the past?

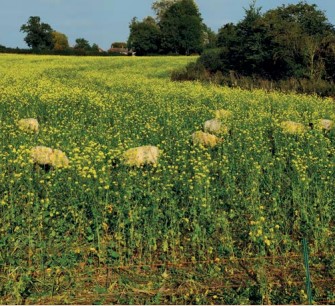

The numbers don’t reflect the patterns, the weather seems to get stuck in cycles of wet or dry. The autumn and winter of 2019 were the wettest I can recall farming through, establishing crops was extremely difficult and impossible for many the wet pattern lasted months and then as to add insult to injury was followed by a very dry spring / early summer during which we went 90 days without rainfall, a perfect storm of events which resulted in a lower yielding poor harvest 2020. We can’t control the weather, but I do believe we can mitigate the risk. Our move from a 6m drill to a 12m version for instance almost doubled our establishment capacity, reducing the length of window required for establishment, a move from 24m to 36m tramlines also had similar effect upon application timeliness and were both achieved whilst reducing costs and only really possible as a result of the lower horsepower requirements that no tillage bought to our farm. Regenerative farming systems typically are far more diverse in their cropping and rotation meaning all the eggs are never in one basket whilst spreading establishment, application and harvest timings.

Most importantly of all, however, is that building soil biology then changes soil structure and its ability to manage water. There is no doubt in my mind we suffer less from drought on our lighter soils that we used to, better structure and microbiological activity not only is more efficient and able to supply plants with the nutrition they need it is also important to the supply of water directly to where it’s needed. The image below shows 2 images taken the same day in July 2017 from a drone following several weeks without rain, the first is looking over our wheat, the second after turning the drone 180 degrees looks over neighbouring wheat, I think it is clear which crop is better supplied with water despite similar soil types, the only major difference being over a decade of no tillage vs a more conventional plough based system.

Lack of water isn’t always the problem, too much when you want to establish a crop can be equally disastrous. Again, no till certainly seems to reduce this risk and open larger windows for activity with cover crops providing a green bridge to drill upon isolating wheels and coulters from wet soil beneath and improved structure that builds over years on no cultivation rewards with huge networks of vertical worm galleries helping move excess water to drains and subsoils more efficiently.

Agronomically, I have no doubt that our no tillage, regenerative agriculture system has reduced our risk but that’s only really part of the story here.

Recent, tragic events in the Ukraine have caused chaos in commodities markets, the effect on oil and gas prices has seen red diesel rise to circa £1.25/L at time of writing. A big horsepower tractor working hard on cultivation can get though as much as 1600L of fuel a day, that’s enough fuel to establish about 1000ac without cultivation! Looking back at records from when we did cultivate every acre, we used 32L/ha of fuel to establish crops, today that number is closer to 4L/ha. The increase in fuel cost has increased the capital required to plant a crop, the stakes are higher no matter what your farming system is but the rise is far more significant if cultivating that if you are not, I honestly do not know how farmers stuck in the high horse power cultivation treadmill are going to justify burning through so much fuel this coming autumn, where will that extra margin required come from?

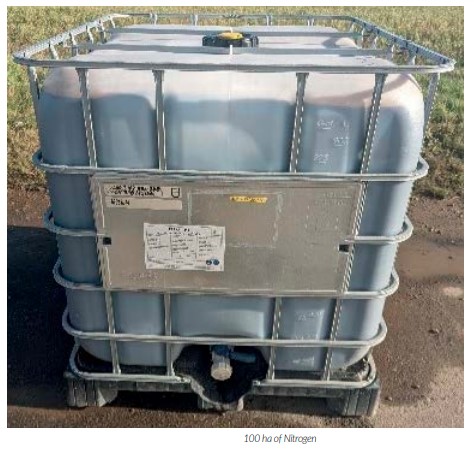

Fuel is just a sideshow however compared to the rises in synthetic fertiliser costs, nitrogen is now almost £1000/t, a 4-fold increase upon last year’s price yet with new crop wheat prices just 70% up. These are game changing numbers and although some are keen to point out that margin over input costs still makes application viable margins have been eroded, capital requirement increased and importantly risk yet again has grown. I have little doubt this will result in much lower planting of nitrogen using crops like wheat, barley and Oilseed rape this autumn. These are the high output crops that support high input farming system with high fixed cost burdens, take away the output and you are heading for financial trouble fast unless you can make rapid adjustments to your fixed cost structure.

Anything that can help reduce dependence upon synthetic fertilisers is now essential. Cover crops that can fix nitrogen are suddenly of greater value and interest to man. Diversity of rotation to include more pulses will look more attractive potentially causing oversupply in those markets, nutrient loss via offtake of crop residues and importing FYM and composts will become of greater focus. Of course there will be no shortage of products that claim to replace the need for synthetics, which some may well do but also many mostly probably will need time to provide proof via trials. For some on more marginal land fallow may become a better option than cropping, an option without output that really is only viable or something that a low fixed cost business can entertain. I don’t think the Ukraine situation is something that will see rapid resolution so just maybe the certainty of entering environmental schemes could suddenly look a lot safer bet.

The farmers that have already moved to lower fixed cost, lower inputs systems are by far the best placed to deal with these extremely uncertain times, they have already built more resilient farm businesses both agronomically and financially. I could make a good argument that now is the time to reap the rewards of change but in such a volatile market the truth is profit or loss is far more likely to being down to those 2 same thing that have yielded me such a good year, buying and selling at the right time. In summary, manage and minimise risk it’s what good business is all about, but more importantly be a trader, it’s likely to make more difference than pretty much anything else you do today.

-

Drill Manufacturers In Focus…

Triton seed drills are a British seed drill company that arrived on the market just 4 years ago and are now the fastest growing seed drill company in the UK with 120 seed drills now on the ground. Simon Chaplin who heads up Triton talks us through the background and development of the Triton Seed drill.

Farming in seven locations from Kelso to Cambridge over different soils in different climates gave us a broad idea of what most farmers in the UK require from a seed drill. To use a rugby analogy, i see the seed drill as the fly half of the farm yard..ie the make of harvester or sprayer that a farmer uses does not have much influence overall but a versatile seed drill dictates the game, ie the cropping options, the preparation and timing, and profitability of the business. Back in 2017 we were running several types of seed drills none of which were giving us satisfactory control of our farming system. We have an uncompromising cropping system based on highest potential profit with highest potential wildlife habitat.

These two goals are rarely seen to go hand in hand, but in my view they are natural partners. The highest quality habitats can run alongside a highly profitable crop, there is no need to turn a farm over to loss leading spring crops and scrappy expensive temporary cover crops to help nature, infact far from it. Temporary cover crops attract nature only to be destroyed. For example the roller crimper cover crop destruction technique does horrifying damage to nature.

Instead we have permanent cover strips round our fields made up of the Kings ‘Poacher Leave it’ perennial plants and the Bumble bee and bird mixes. These perennial plant wildlife strips are not cut back and they provide excellent dense nesting cover in the spring and winter cover for all types of nature. Our cropping is based on maximum financial output, minimum establishment costs, and minimal input costs and we don’t get taken-in by marketing.

For example if farmers used all yield the enhancement products advertised in a farming magazine then they would only need a few acres.. every seed treatment or fungicide or controlled release fertilizer will supposedly give a yield increase of 0.5t/ha, that could get up to 30t/ha if you used them all, so we don’t use any of them. We do use next generation biostimulants but only in recent years purely because our own weighbridge trials with AminoA flo gave good results.

We farm in a way which is kind to the soils and kind to nature, in a simple, straight forward fashion, the same could be said of our drills, designed to make crop establishment quick and easy, keeping cost of establishment low, the results speak for themselves, as does our customer feedback. Triton Drills have come a long way since 2017. We will shortly be delivering our 100th drill and we look forward to being part of the future of farming in an ever-changing landscape.

“My grandfather first tried direct drilling with a disc drill in the 1970’s with varying success. My father then tried in the early 1990’s with another disc drill, again with mixed results. Over the last 15 years I have tried a more tine approach but again results have been inconsistent. Closing the slot with either a disc or a tine direct drill of any make is the issue on clay soils with high magnesium levels. Open slots either fill with water drowning the seed, or dry out depending on weather after drilling. They also exacerbate slug issues. The Triton direct drill is the only drill I have used that closes the seeding tine slot. For me the closing blade on the Triton is the best on the market and has now given us the option of direct drilling high magnesium clay soils, when appropriate. It’s a true all rounder direct drill on both cultivated and none cultivated soils.” M G Sutton

-

Don’t We Live In A Crazy World

Written by Robert Plumb, Soil Fertility Services Ltd

Energy prices through the roof; inputs of fertilisers and chemicals at crazy prices; energy companies making seriously record making profits; Liz Truss – our own local MP, flying around the world with a big fat expense account and an expensive entourage to negotiate trade deals, at the expense of UK agriculture and now a War with Russia and consequences for Ukraine! Bear in mind when this was written – 1st week March 2022.

What is going to happen to your farming enterprises? The UK government would be happy for you to plant Trees or rewild – What a joke, maybe this European war will wake up our Government to back UK farmers to grow the food we need – as you are quite capable of doing.

For the past 70 years or so we have been hell bent on using chemicals and like any drug, we have become hooked on them. For a long time, 34% Ammonium Nitrate tracked the value of grain – roughly £20 tonne. In the last 10 years or so, it has drifted further apart due largely to increased demand from developing countries and increased application rates, as farmers chased yield. All good things come to an end. Apart from the damage to the environment, what about the damage to your soil and your pocket? Oh yes, we have seen increases in yield, but that is mostly due to plant breeding – the same with other crops. Yes, we are growing higher yields pretty much across the board, but not without cost and in many cases, nutritional content is lower.

With what is going on in Europe, there is not much hope for fertiliser and other chemicals to reduce in cost, rather you can expect to have problems getting product at any price. NOW then is the time to learn how to use the alternatives. So what is the alternative? Is organic not a valid choice? Not for everyone, but it is possible to grow good crops without using chemicals. Recently we have seen a move to another ‘alternative’ and that is the BIOLOGICAL OPTION. Soil Fertility Services have been promoting these concepts for 25 years and more; bear in mind we were the first people to have a soil profile pit at the Cereals Event as long ago as 1996.

SOIL is not DIRT. The difference is, there is LIFE in your soil – all sorts of life including a lot that you don’t want, but why don’t you want them? They are only a problem when they become dominant and then turn on your crops to live. Do bear in mind the years of poisons you have chucked on your soil and maybe, it is no wonder it is sick. Poisons can include N, P, K, and ALL other ‘fertilisers’ when they are applied in excess or out of balance with all other minerals. Even then they may be poisons to your ‘life in the soil’.

The first thing you need to do, is to learn how to talk to your soil; to read a comprehensive soil fertility audit and check compaction layer – what does it smell like, what is the earthworm count? Then you need to learn how to feed your soil and how your soil will feed your crop. For some 20 years we have been using Beneficial micro-organisms and we now have a stock of 25 different varieties that we can blend for specific purposes, including disease prevention and nutrition enhancement. These are Plant and Soil feeders and include specific products that can release so called “locked-up” minerals including Phosphate, Sulphate and Ammonium Nitrogen.

One of the keys to the success of this BIOLOGICAL PROGRAMME, is the food source that we produce to feed these micro-organisms. We call it V8; it is a mix produced from an organic equine Vermicompost that we use to extract all the minerals into a turbo charged biological stimulant. Because this is a natural product it is a complete food source with all essential trace elements with high levels of Humic and Fulvic compounds. On its own it is a low cost plant growth stimulant, when applied with a specific plant mineral required it can be highly effective. We do often get tarred with the label ‘snake oil’, well, it’s understandable, as we surely are ‘out of the box’ but science is always behind the innovators as many of you leading soil improvers and direct drillers will know. We work with specialist suppliers around the world and all our products are produced to the highest standards and used in human and animal health as probiotics; that is what they are – soil and plant probiotics.

If we supply your soil with the correct blend of beneficial micro-organisms, we can out-compete the pathogens. These microbes tend to be the aerobic varieties; hence we need soils with good earthworm numbers. When you think the air that we breathe is 75% Nitrogen, if you have aerobic soil, you could have 240kg/ ha of potentially available Nitrogen, right there in your plant rooting zone. But how to make it available to your crops? We have a consortium of specific bacterium and fungi that can do that; they convert the elemental Nitrogen into an ammonium form that the plant can then convert to Nitrate.

There are two issues we have to be aware of: Firstly these microbes do not like the cold, hence they will not work early in the Spring when you actually would like them to – the soil temperature is too cold; secondly, these microbes have to join up with your plant when they will ‘feed’ your plant, but only if it needs feeding then. This means you cannot get excess Nitrogen in your crop; however, because we are using a consortium of micro-organisms, there are many other plant health benefits such as improved root structure – hence more uptake of other nutrients including Sulphate and Potassium! ‘Snake oil? No, just ‘out of the box’, the best thing you can do is to give us a call and have a chat.

-

Nutritional Benefits Of Regeneratively Grown Crops

A new American study shows how regenerative farming practices — soil-building techniques that minimise ploughing, the use of cover crops, plant diverse rotations etc — affect the nutritional content of the food

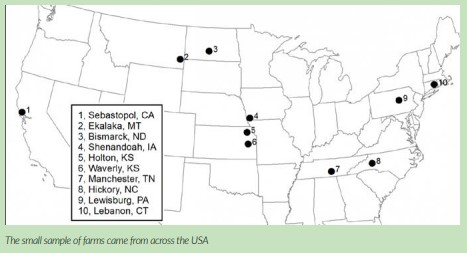

Everyone knows fruit and vegetable are good for your health says the University of Washington News, but which of the dizzying array of options – organic, conventional, CSAs, local agriculture – are best for your health? The university has done a preliminary study, under the leadership of David Montgomery, a UW Professor of Earth and Space Sciences, which shows that the crops from farms which have adopted soil-friendly practices for at least five years had a healthier nutritional profile than the same crops grown on neighbouring, conventional farms. Results showed a significant boost in certain minerals, vitamins and phytochemicals that benefit human health. The experiment is described as preliminary because it has only included 10 farms across the U.S. Given the remarkable results there will be further research work carried out.

Crops from regenerative agriculture farms had 34% more vitamin K, 15% more vitamin E, 14% more vitamin B1 and 17% more vitamin B2 compared to the conventionally grown ones. The regenerative agriculture crops also had 11% more calcium, 16% more phosphorus and 27% more copper. (Jan. 27 2022 in PeerJ) “We couldn’t find studies that related directly to how the health of the soil affects what gets into crops,” said David Montgomery, “So we did the experiment that we wished was out there.”

Montgomery designed the study during research for his upcoming book, “What Your Food Ate,” due out in June. His spouse, Anne Biklé, is a biologist and co-author of the study and the upcoming book. The authors collaborated with farmers using regenerative farming practices to conduct an experiment. All the participating farms, mostly in the Midwest and in the Eastern U.S., agreed to grow one acre of a test crop — peas, sorghum, corn or soybeans — for comparison with the same crop grown on a neighbouring farm using conventional agriculture. Co-author Ray Archuleta, a retired soil conservation scientist with the U.S. Department of Agriculture, visited all the farms and sampled their soil in summer 2019. Farmers then sent samples of their crops in for analysis.

The study looked at farms across the U.S. doing regenerative agriculture, which uses soil-boosting practices. In eight of the farms (farms 2-9) the farmers planted the same crop as their neighbour to allow a direct comparison of the soil and resulting food. “The goal was to try to get some direct comparisons, where you controlled for key variables: The crop is the same, the climate is the same, the weather is the same because they’re right next to each other, the soil is the same in terms of soil type, but it’s been farmed quite differently for at least five years,” Montgomery said.

The study sites included the farm and ranch of co-author Paul Brown. Brown had met the UW researcher during Montgomery’s work for the 2017 book, “Growing a Revolution,” which toured regenerative farms in the U.S. and overseas, including Brown’s Ranch in North Dakota. Results of the new study showed that the farms practicing regenerative agriculture had healthier soils, as measured by their organic matter, or carbon, content and by a standard test.

“What we’re seeing is that the regeneratively farmed soils had twice as much carbon in their topsoil and a threefold increase in their soil health score,” Montgomery said.

Crop samples were analysed at lab facilities at the UW, Oregon State University and Iowa State University. The food grown under regenerative practices contained, on average, more magnesium, calcium, potassium and zinc; more vitamins, including B1, B12, C, E and K; and more phytochemicals, compounds not typically tracked for food but that have been shown to reduce inflammation and boost human health. Crops grown in the regenerative farms were also lower in elements broadly detrimental to human health, including sodium, cadmium and nickel, compared with their conventionally grown neighbours.

“Across the board we found these regenerative practices imbue our crops with more anti-inflammatory compounds and antioxidants,” Montgomery said.

Organic farms avoid chemical pesticides but they can vary in their other farming practices, such as whether they have a diversity of crops or till the soil to control weeds. Results from a previous review study, published by Montgomery and Biklé in the fall, show organic crops also generally have higher levels of beneficial phytochemicals than crops grown on conventional farms. The researchers believe the key lies in the biology of the soil – the microbes and fungi that are part of the soil ecosystem – as these organisms directly and indirectly help boost beneficial compounds in crops.

“The biology of the soil was really the part that got overlooked in moving to chemistry-intensive farming,” Montgomery said. “It may be that one of our biggest levers for trying to combat the modern public health epidemic of chronic diseases is to rethink our diet, and not just what we eat, but how we grow it.”

The study also included cabbage grown on a no-till farm in California and a single wheat farm in northern Oregon that was comparing its own conventional and regenerative farming practices and provided both samples. The study included meat from a single producer, Brown’s Ranch; the beef and pork raised on regenerative agriculture feed was higher in omega-3 fatty acids than meat from a conventional feedlot.

“The biggest criticism I would have of this study is small sample size – that’s why the paper’s title includes the word ‘preliminary,’” Montgomery said. “I’d like to see a lot more studies start quantifying: How do differences in soil health affect the quality of crops that come from that land?” The other co-author is Jazmin Jordan of Brown’s Ranch. The study was funded by the Dillon Family Foundation.

For more information, contact Montgomery at bigdirt@uw.edu

-

Drill Manufacturers In Focus…

WEAVING TO EXPAND MANUFACTURING FACILITIES AND LOW DISTURBANCE PRODUCT OFFERING

At Weaving Machinery, we believe in offering effective and user-friendly low disturbance machinery at an

affordable price, all designed according to the real needs and requests of farmers.Yield is always a massive consideration on farms, and this is true now more than ever – as Clarkson’s Farm highlighted, profit margins are tight – therefore current high input prices require high output for the balance sheet to wash its face. To that end, the last couple of years have seen more and more businesses recognise the benefits low disturbance machinery can bring to production and sustainability. For example, all our machines are built to use as little fuel as possible, a strength more prudent than ever with fuel prices at an all-time high. So, the combination of efficient fuel consumption and less time on the land makes direct drilling an increasingly attractive opportunity. As a result, we’ve had a strong volume of orders and are now taking extra steps to not only meet that demand but also create new machinery that reflect the needs of our customers, immediately and for years to come.

This year, we launched our new Dual Disc, designed to run in front of seed drills to cut through cover crops and trash, even at high residue levels, in a low disturbance farming system. The Dual Disc works perfectly with both our GD and Sabre Tine drills which therefore benefits the two general routes we are seeing farmers opt for; many are looking to use a GD to drill into cover crops with a disc while others choose to transition into direct drilling at a more incremental pace with a Sabre Tine. We want to make each route viable and accessible for everyone.

Speaking of the Sabre Tine, we’re delighted to announce that a new model is coming this year. Our new 8 metre mounted Sabre Tine, ideal for larger farms, will launch in the autumn, following lots of demand over the last couple of years. As well as extending our main product offering, we have also taken on some bespoke product development over the last few months, which has included a few “mini” GDs for drilling cover crops in towns and cities as well as for drilling vineyards. Another way Weaving Machinery demonstrates its commitment to prioritising the needs of our customers even where the requirement is not an ‘off the shelf’ product. We’ve noticed more farmers opting for a low disturbance top-soiler to relieve surface compaction and get air in their soil. Our LD Top-Soiler effectively lifts the ground like a carpet and lets air in, before gently setting it down. This reduces compaction, improves drainage, and helps worm population levels all without mixing the soil profile. Demonstrations of our LD will be available by arrangement throughout the spring and summer drilling seasons.

Internally, we’ve also taken the step of investing in a new production hall at our home base in Evesham. The time was right to ramp up our capabilities and achieve a higher throughput, and we’re doing so without halting or delaying ongoing production. The revamped production hall will include new welders, holding bays, spray paint cupboards, and an automated shot blaster – one of the largest in the UK, in fact. Steel will come in one door and go out the other as premium low disturbance machinery.

In addition to the physical enhancements, we have also invested in human resource, with a new Production Supervisor, Purchaser and Warehouse Manager joining the team over the last six months, each bringing more knowledge and experience to the team as well as a new Service Technician dedicated exclusively to the eastern counties. Why does this matter? Because we aren’t just passionate about manufacturing best in class and affordable equipment, but also making our own internal processes slicker and smoother. Our intention is to double production, and the improved facilities and broader skill set will help us get there. As always, our actions are determined by our customers. We pride ourselves on listening to what our farmers need from us. That’s how we can keep delivering the exceptional service and personal support that our customers expect and deserve. The next year will see us taking that mission towards new and exciting developments in low disturbance machinery, including wider drills and more.

Despite the challenges and uncertainty, 2022 is an exciting time for British farming. We at Weaving Machinery are working hard to ensure we – and our customers – are always moving forward and achieving more in low disturbance farming.

To see our machines in action, be sure to join us at LAMMA in May and Groundswell in June. We hope to see you there.

-

Farmer Focus – Adam Driver

Last night we hopefully had the last frost of the year as the OSR is just starting to flower. I think we can finally relax with pigeon patrol. This has been relentless and my Father has spent a huge amount of time chasing them over the last few months. It seems to have paid off as the crop does look excellent whereas many have in the area have been eaten by pigeon. It is probably not a very “regen” thing to say but it does feel like the main way to getting some reasonably OSR is to drill it early, give it loads of early N, and keep the pigeons off. Last year where we didn’t do these three things well enough we had some poor crops. Lessons learnt. OSR is a real difficult one as to whether to keep growing it. It can be very profitable but is hit and miss. Brings early drilling and early harvest but I have to stay our slug pressure is concerning post OSR. I keep being told the beetles will eat the slugs but their obviously is not enough of them despite not using any insecticides for years. We will carry on growing it as I believe the benefits out weigh the weaknesses of the crop at the moment.

OSR has had its total spring N (140kgs)and a foliar of the usual magnesium and molasses etc. That may well be door closed until harvest unless conditions are good for a foliar flowering N and other goodies. Another question is how and if we desiccate it? It could cost over £40/ha just to spray the stuff off. We actually have more combining capacity these days so direct cutting is an option being discussed and could well be the way forward.

Malting barley, as usual went luminous for a week or two. It now looks normal again. It also has had its total N (100kg/ha)and a tonic of the usual stuff that appears to be needed on this soil. There is not much to report about winter barley apart from one failure on my part. One field had very poor straw chop due to a damp and brackled crop that needed shaving. It has resulted in some gappy areas where germination was poor and slugs attacked. That is a lesson learnt if it really is chopping badly. It will certainly knock yield a bit and is unsightly, MUST DO BETTER.

We do have some Blackgrass in wheat this year, mostly second wheat and some after OSR. These areas we will inter row hoe with the Claydon Terrablade and see how we get on. Maybe they will need doing twice. We are not in yield affecting levels of Blackgrass by any means, but I would like to take out as much as we can on these areas. I imagine we will run the hoe through about 15% of our wheat area and 5% barley (brome). We have had the hoe for a year now but did not really get the chance to do much with it last year. If it works well then perhaps a bigger, better penetrating camera guided hoe will be on the cards. Our aim is to keep Blackgrass at an economic level.

Spring drilling will be starting imminently. We have about 1500 acres to get through which will probably mostly be done with our tined sprinter. I really worry with the disc drill in the spring as we have seen time and time again the slot can just open up and dry out very quickly. This is regardless of whether it’s been drilled into dead cover, green cover, stubble, rolled, unrolled etc

-

Farmers-First: Gentle Farming With AGREENA

This is the most exciting time to be a farmer!

I am Thomas Gent, 24 years old, and I live on my family arable farm on the LincolnshireC a m b r i d g e s h i r e border. My grandad Tony Gent and my dad Edward Gent made the transition to using more regenerative farming techniques around 14 years ago.

During the first COVID lockdown, I started to look into the opportunities to differentiate and diversify my farm and the food we produce. After researching different opportunities and areas for innovation, I became aware of soil carbon and the amazing ability of the dirt under our feet to draw down carbon from the atmosphere. So I set myself an exciting challenge: to monetise the carbon impact of my farm. Little did I know, this challenge would lead me to speaking at FTSE 100 board meetings, working with academics, advising investors and featuring on prime time TV.

Combating climate change is the greatest challenge of our generation. As caretakers of the land, we as farmers have such a unique opportunity to become climate heroes, showcasing to the world the importance of healthy, local food sources. I founded a brand called Gentle Farming to explore these opportunities. After working for over six months on different ideas and solutions to monetise my farm’s carbon negative position, a number of factors became evident. I’d need to achieve high quality, internationally recognised verification and certification if I wanted to appeal to larger corporate buyers. At the same time, I’d need a system that was simple and easy to use in our day to day workings. Most importantly, it would have to put the farmer first. I wanted full control of my impact and the farming practices implemented.

There was no doubt that I’d set myself a difficult task, but after a significant amount of trialling, testing and researching multiple carbon certificate systems, things started to look up when I came across Agreena. I connected with Ida Boesen, one of the founders of Agreena, in February 2021. Ida and her team were developing and launching their carbon system and looking for farms across Europe to pilot the programme. From our first few conversations, it was clear that we had a shared ethos and joint mission; to drive financial and environmental sustainability in agriculture.

Fast forward a year, and together we’ve built AgreenaCarbon – a programme that mints, verifies and issues carbon certificates annually to farmers who transition to regenerative farming practices. The farmer, the owner of the certificates, can then decide whether to sell or keep the certificates.

Our home farm was the first UK farm to use the system. I used the brand name of Gentle Farming to facilitate other UK farmers joining the AgreenaCarbon program.

It quickly became clear that Agreena wanted my help much more broadly than working in the UK. They offered me a full time role with the company to bring my “on the ground” regenerative farming knowledge to potential buyers of carbon certificates, who wanted to learn more about our form of farming. From the start of 2022, Agreena replaced Gentle Farming as the brand name for the carbon program in the UK. The AgreenaCarbon programme is now in its second year of operation, and consists of over 50 passionate people with expertise in agriculture, soil science, carbon markets, technology and finance.

I’m proud to say that working with Agreena, I feel we’ve been able to create a programme that meets the high-standards I set at the beginning of my journey. AgreenaCarbon is an internationally accredited soil carbon programme that works with leading technology and external verification partners. There is no doubt for corporate buyers and farmers that our programme delivers high quality carbon certificates. The programme is accessible for farms of all sizes and types and makes a transition to regenerative farming practices financially viable. Even farmers who are at the start of their regenerative journey can enter. If you meet our minimum requirements on the fields you enter (no conventional ploughing and no stubble burning) you have the potential to earn carbon certificates.

Just like a normal harvest, carbon certificates are issued annually, giving farmers an additional annual income. With rising fuel and fertiliser costs, additional financial support will only become more critical for farmers. What I’m most excited about is the amount of control we give to the farmer. Once the farmer has been issued their carbon certificates, they decide what to do with them. Agreena can support the farmer to sell their certificates to approved buyers, or alternatively, the farmer can sell certificates to their own buyers or alongside their grain. It’s also possible for the farmer to keep certificates to offset their own unavoidable emissions. Whatever the farmer decides is the best option for their farm, Agreena will support it.

If I could give one piece of advice to farmers looking to join a carbon certification programme, it would be to ensure you find a programme with flexibility to meet your needs – now and in the future. If you’d like to find out more about our AgreenaCarbon programme, visit www. agreena.com or scan the QR code at the top of this article. I see carbon farming as the first of many shifts in farming that we must be prepared for. UK agriculture is set for the largest change for over 50 years. We are losing government funding, being asked to deliver more environmental targets, produce food for a growing population, and somewhere amidst all of that, still run a business and make a profit.

To me, all of this is an extraordinary opportunity and an exciting challenge.

I believe as farmers we should be looking at something we have traditionally not been great at – marketing. The public now wants to know about

farming and food production, and they are willing to spend to get that value. Branding, marketing and storytelling about our farms is going to be a significant part of the future of UK agriculture going forward. I personally plan in the future to use Gentle Farming as a brand name to achieve this communication with my customer and capture more of the value that is traditionally lost through the supply chain.

Collaboration in this new age of agriculture is the way forward. Working with like-minded and entrepreneurial individuals is what makes these challenges exciting. I am always looking to connect with and learn from people who share my values and are passionate about the future of farming.

In conclusion, going forward Agreena will replace Gentle Farming as the brand name of the carbon program in the UK. But do not be surprised if you see Gentle Farming appear again in the near future with another solution to reward and recognise farmers who are using regenerative farming techniques to combat climate change and care for the soil that feeds the world.

-

Drill Manufacturers In Focus…

REDUCED TILLAGE DRILL CAN OVERCOME WET SOILS

KUHN Farm Machinery has developed a significant presence in the tillage sector over the last decade, introducing a range of cultivation equipment and drills with the versatility to work in varying conditions. Specifically, the Espro and the more recently launched Aurock drills have been designed to operate effectively in the unploughed seedbed, including an ability to cope with trashy conditions.

Originally launched in 2015, the Espro range has become a firm favourite with medium to large-scale arable farmers and contractors thanks to the low power requirement and high output capacity of the various models. The Espro is available with single metering in 3.0, 4.0, 6.0 and 8.0 metre formats and with dual metering in 4.0 and 6.0 metre formats.

The CROSSFLEX coulter bar is the key to the Espro range’s high working speeds, enabling seed to be placed accurately at up to 17kph. Each coulter is mounted on polyurethane blocks which allow the individual coulters to closely follow terrain contours. Ground pressure and seeding depth adjustment are controlled hydraulically. This ensures a consistent seeding depth across the machine’s full working width and enables accurate seeding to be carried out at high forward speeds.

The challenge of drilling in wet conditions is becoming ever more common and it is widely appreciated that this can have a significant effect on min till and direct drills. The Espro has large diameter, narrow, offset press wheels which help to allow trash flow through the machine by preventing a buildup in front of the wheels. The Espro is better suited to wetter conditions because the wheels are mounted on their own axle so they can turn independently of each other, which ensures they keep turning. For particularly sticky conditions wheel scrapers are also available.

This also has an impact on power output and fuel economy needed to operate the drill efficiently. This means the Espro can be operated by tractors with as little as 160 horsepower, even in wetter than average conditions. The 900mm diameter of the packer wheels reduces rolling resistance and therefore the power required to pull the machine compared to smaller wheels. The wheels are also narrower than some drills at just 210mm, leaving an 85mm gap to improve soil and residue flow. The narrow width means a larger infiltration zone inbetween the wheels which helps to reduce erosion. The packer wheels are offset 200mm front to rear, which prevents the sometimes-experienced bulldozing effect and makes the drill easier to pull. The reduced accumulation in front of the wheels also prevents the drill from bouncing, which improves the uniformity of seed delivery and placement.

This coupled with the larger 350mm diameter, bevelled edged seeding discs enables the Espro to cut through residue to ensure a consistent seeding depth. The offset discs also help to prevent hair pinning. To better deal with trash, further attention to detail has been given to the disc bearings which are moulded within the disc to create more space between the rows which allows trash to flow out more easily. The hydraulic adjustment of the working discs also helps in trashy conditions by allowing the operator to adjust the position on the move. RC models of the Espro feature a double hopper to further increase efficiencies by choosing to apply fertiliser or a second crop in conjunction with the primary crop. The seeds pass through both metering units and are brought together in the main distribution head and subsequently sent to the coulter bar.

By choosing to apply fertiliser at the same time as the crop, the Espro is able to place fertiliser under the roots between two seed rows. This configuration is of real value for applying elements such as phosphorus. The adjustable fertiliser depth also prevents seedlings from burning. However, should the farming system benefit from cover crops, these can be doubled up and seeded together. The entire hopper can also be used for two varieties of the same seed species. This allows for separate metering but joint seeding for precision drilling of a main crop.

With windows for drilling decreasing in many areas, and the desire to move to a reduced tillage method increasing, the Espro is a valuable machine. The combination of speed, accuracy, and the ability to deal with tricky soil, even in the wet, will make it more attractive should climate change continue to disrupt conventional drilling periods..

-

Hutchinsons Direct Drill Demonstration

Written by Mark Hatton

East Yorkshire is a part of the world I’ve always enjoyed spending time in, I wasn’t expecting a North sea breeze to be

quite as cold as it was when I visited the Hutchinsons Direct Drill demonstration at the beginning of March.

The event was put on by Hutchinsons North team with the kind permission of M.Meadley and Sons, Grange Farm, Driffield. To be honest, I wasn’t really sure what to expect from the day, with a lineup of speakers discussing everything from soil health to the transition from BPS to environmental schemes and everything in between.

With well over 100 visitors throughout the day, the group was split into two for the opening presentation. Dick Neale (Hutchinsons Technical Manager) took the audience through a very interesting discussion on Healthy Soils, soil structure and the benefits of cover crops.

The switch from conventional plough based or minimum till systems over to Direct Drill is not overnight, the most successful transitions seem to be 3-5 years, with current input costs now becoming a much bigger consideration the temptation to go ‘cold turkey’ and put the whole farm under direct drill, would need some very careful consideration.

Cover crop selection is also a topic that also requires careful consideration, farmers that have tried cover cropping with little success and dismissed it as not worthwhile, have possibly chosen the wrong mix for their soil type. Oats for example, often used as being a cheap cover, lock in moisture near the surface, as seen on site at the demo.

Brassica and Legume choices should be matched with soil types to help improve soil structure. A soil structure assessment pit had been dug along with trial boxes of the same soil with different seed mixes to demonstrate the effects of correct mix choice. As well we know, worms are critical to soil health and soil structure, trials have shown that worms take material from the surface, even distribution of chopped straw is critical, with straw rakes becoming much more widely used to ensure much better coverage.

One of the biggest questions was the choice of drill. With a selection of machines in the field, spanning both tine and disc, there is no simple answer. The die hard direct drillers will advocate discs, purely down to less disturbance, however many would argue the case for tines, both have their benefits, both will depend on soil types. Before we got to see the drills in action, the Hutchinson team presented the benefits of the Omnia Precision mapping services and Terramap. Omnia Precision is an unrivalled precision agronomy system that analyses information from a variety of sources, to enable intelligent and informed decision making for the full range of variable applications. It enables grower and agronomist to work at sub-field level.

It highlighted the savings on farm inputs in today’s uncharted world of costs at an all time high. Directly linking the ability of many of todays drills to place both seed, fertiliser and companion crops accurately. TerraMap produces the highest resolution soil mapping layers in the world at over 800 data reference points per hectare.

The in-field process of collecting the data is carried out in two very simple steps; scanning and collecting reference soil samples. The raw scan, soil data and soil samples are then combined and processed to produce up to 28 high-definition soil property layers. With representation from eight drill manufacturers, a mixture of tine and disc systems, there was plenty of variation of drill designs to compare. Given the amount of rain prior to the event, the conditions were surprisingly good. Drilling into a variety of sprayed off cover crops, both types of drill worked surprisingly well. In my opinion the disc drills had the advantage over the tine based machines, the amount of moisture seemed to ball the soil up leaving more seed visible than the disc drills.

The disc drills appeared to leave a much more even, consistent seed placement, less smearing of the surface and better seed coverage as the pictures below show. After what seemed like a long winter it was good to be back out seeing live demonstrations. The biggest take away from the event for me, was the amount of interest in changing how we farm, not just today but in a constantly changing world of ever increasing costs.

-

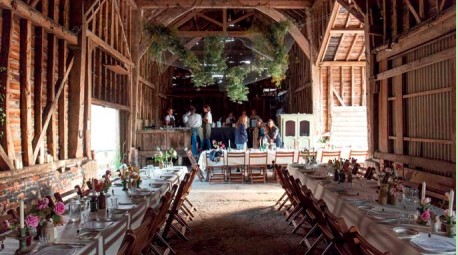

Groundswell 2022

There are probably as many different ways of farming as there are farmers. This certainly applies to farmers who are

trying to work out how to farm in a regenerative manner. I’m sure that you are all familiar with the five principles of

regenerative agriculture which give us a direction to work with nature rather than against her. Our cousins in America have added a sixth principle, context, to these five which helps us focus on the particular factors that affect our own farm whatever they may be, like family set-up, local markets for produce, soil types, local weather patterns and the myriad peculiarities that affect our decision making.This year’s Groundswell Show, which we are currently organising, will, we hope, feed delegates with ideas to implement techniques that enable us all to find ways of growing abundant crops with minimal inputs, within our contexts. We have been overwhelmed with suggestions for talks from a large array of different quarters, most of which sound fascinating. Unfortunately we haven’t got space or time to fit them all in, but we hope that the ones that we let through will resonate and stimulate. More details on these will become available nearer the time.

Meanwhile we have some keynote speakers flying in from abroad, after a couple of years of no-one flying anywhere. I’m particularly excited to welcome Dwayne Beck back to the UK. I’ve been asking him to come every year that we’ve put a show on, but he’s always been too busy with his own annual event at Dakota Lakes Research Farm in South Dakota. Dakota Lakes is a farmer owned operation which studies ways of making farming more resilient economically and ecologically and, in the many years with Dwayne at the helm, both he and the farm have become leading lights in the no-till world. You might think that there is not much we can learn from someone and somewhere so different to the UK, but if you thought that: you’d be wrong! Jill Clapperton came to the first Groundswell Show we put on and we’re thrilled to have her back this year. Like Dwayne, she’s a titan of the world of soil and she explains what’s going on under our feet beautifully clearly. We have also lined up various speakers who can explode the myths that suggest grazing animals are inevitably disastrous for global warming, like Diana Rodgers and Seth Itzkhan.

Greg Judy is back to tell us how he manages his grazing animals, he will also be joining us for the traditional moving the mob event and providing us with on hand advice. I’m afraid, yet again, it is going to be really hard to choose which talks to go to and which to watch on the computer later, but just tell yourself it’s character building. Meanwhile we have the direct drilling demos in a slightly rejigged demo field, with machines from thirteen drill-makers all drilling into an established cover crop/weed mixture. There is also going to be an inter-row hoe or two demoing in a crop of wheat. We have lined up various different composting techniques in the compost zone, which could easily engross me all day. There’ll also be another dung-beetle safari, as last year’s one was ridiculously popular.

There are lots of interesting exhibitors taking stands, many of them will be giving their own talks and demos, there won’t be any dull moments. The main attraction is, of course, all you lot, some of the country’s most innovative and delightful farmers all gathered in one place for a couple of days…it’s incredibly reassuring being surrounded by such a peer group, old and new friends chatting away and egging each other on. There’s nothing quite like hearing other people’s stories to convince yourself that the future need not be quite as dark as the present seems to be.

-

Products In Focus…

ONE APPLICATOR FOUR USES… SO FAR

Microcast 200 applicator reduces crop passes, saves fuel and

helps a Northamptonshire farm reduce its carbon footprintReplacing a troublesome liquid fertiliser spreader on his John Deere 750A drill with a Microcast 200, an applicator designed for precision placement of seeds and granular products, has enabled arable farmer Andrew Pitts to improve the accuracy of previous broadcasting systems and widen the use of the new applicator via different metering cartridges available through Microcast manufacturer, Techneat Engineering. Andrew, who farms 800ha of combinable crops alongside brother William on primarily heavy chalky boulder clay soils near Mears Ashby in Northants, originally changed his method of establishment from minimum tillage to direct drilling in 2016. After trialing six direct drills between 2016 and 2018, he eventually settled on the JD 750A as he found it moved the least amount of surface soil, critical to the ongoing success of the farm’s blackgrass strategy built around minimal soil disturbance.

Eighteen months on from the investment in the Microcast 200 and, amidst the farms move towards a new 6-year crop rotation, the change to a new applicator has also revealed some additional agronomic and economic benefits. “As a business we have always been very market driven. Everything we grow is based on a forward contract, and this enables us to track our fixed costs against predicted returns with a reasonably good degree of accuracy. With machines our policy is performance, accuracy and reliability so, when the liquid fertiliser spreader’s distribution heads started to continually block up, we made a quick decision to switch to a granular application system using the Microcast 200 from Techneat. “We’ve known Techneat for 30 years, since purchasing their Autocast V2 for rape establishment back in 1992. They build simple, well-engineered, reliable machines and, when required, can also innovate with a hands-on engineering approach if we’re looking to achieve something that may fall outside the standard specifications. The Microcast has a quick set up, is easy to calibrate and delivers granular fertiliser, or seed, into the furrows accurately via a flexible number of individual outlets spaced evenly across the full width of the drill.

“Although the primary reason for investing in the Microcast was to replace the liquid fertiliser system with a granular fertiliser applicator we were also aware that the machine can double as a seeder unit with minimal modifications. Fast forward eighteen months and we have now successfully widened the use of the Microcast 200 to include applying cover crops, companion crop planting and slug pellets through use of different metering cartridges that can be changed quickly and easily. “The economic savings from reduced fuel use and agronomic benefits of protecting our soil through reduced passes are important, enabling us to reduce the farms carbon footprint. However, when further examining savings on fertiliser inputs in greater detail, the overall benefits of the Microcast investment look even more impressive.

“In early August 2020 we used the new applicator to apply a mix of starter fertiliser and stubble turnips. Soil mineral nitrogen tests conducted in March 2021 indicated that, before being grazed by sheep, that mix had captured 85-90kg of nitrogen/ha, equating to 100% of available nitrogen. So, on the Spring barley crop that followed, we were able to reduce the applied nitrogen by 150kg/ha because we already had that amount of nitrogen being used in the soil operating at 60-70% efficiency. Given the current high cost of fertiliser, that equates to a considerable cost saving made by planting a companion crop, not to mention the creation of an extra use for the field itself in that we’re effectively growing 3 crops over 2 years at minimal cost.

“The adaptability of the Microcast 200 applicator helped facilitate the addition of the companion crop so it must take a fair amount of the overall credit for the cost savings” concludes Andrew.

-

Are We Closer To Seeing Robots On Farms?

Progression as a company over the last year.

In the last few years there has been a clear focus on deploying and demonstrating ROBOTTI around Europe. This is the best way to prove the robustness, reliability and the commercial value. In the last two years Covid-19 had a big impact on the company and its activities, limiting the possibilities of moving around. The reliability of ROBOTTI is already getting proven by the number of approaches from the third parties – there are many companies and people believing in the technology that we have developed. AGROINTELLI has been progressing significantly over the last year. Our capital structure has been strengthened. The “capital equity injections” from our two main investors – Nordic Alpha Partners and Vækstfonden have enabled us to scale up, both commercially and in terms of operations and production.

We have aligned our organization so we have been focusing our sales activities towards distributors to establish a very tight distributors network all over Europe. We have started onboarding quite a lot of distributors, e.g. UK, Germany, Hungary, Poland, Italy, but we also saw an interest in Australia and overseas. We have been also focusing much on end-customer and not so much on universities and research institutes. We have focused on quality insurance on our production and procurement and we are continuously working on our risk assessment on ROBOTTI to ensure that we have one of the safest robots in the world. We have technologies to support the safety of ROBOTTI with 10 different systems related to safety.

We have established a relationship to a number of implement manufactures both traditional and intelligent implements. They were interested to change the design to fit even better to ROBOTTI. Examples of traditional implements: Schmotzer weeder, Danfoil sprayer and other are in progress. We are also working with manufacturers of intelligent implements, where we combine different types of autonomous technologies with our robot, e.g. in harvesting. Last summer we expanded our activities in Germany with establishment of an office and demonstration field in southwest part of the country, in Baden-Württemberg state. It is placed in a strategic position, making it much easier to support ROBOTTI’s distributors and activities around Europe.

In December we have won Agritechnica’s Silver Innovation Award for RoboVeg ROBOTTI, fully autonomous broccoli harvester. The same month we have introduced the new model – ROBOTTI LR, which is built upon the experiences of ROBOTTI 150D. The main difference is that ROBOTTI LR is designed for nonPTO operations, has one motor, and is able to drive up to 60 hours before the next refueling.

How do you see the market going forward and future

plans?There is a clear trend in the market towards more and more automation. We expect the market to increase continuously. There is a need of automatization of operations as it is considerably difficult to get labor. “AGROINTELLI will keep developing its technology to be able to offer autonomous solutions to the market, so the existing workforce can do other tasks, that are creating more value.” – says Jakob Bebe, AGROINTELLI’s CCO. Agriculture is a special industry and it is a task to convince such conservative customers as farmers to robots. They have to believe in it so we have to change their mindset to embrace this technology. Since ROBOTTI can take over the repetitive work, the farmers can save the lacking workforce and this is one of most convincing arguments. On our side it is a matter of showing that ROBOTTI can handle capacity and it is reliable. We are going to do that this year by operating on fields from 20 to 200 ha.

Where farmers can see the robots.

An option available at all times is our “ROBOTTI” YouTube channel. Another source is our website, there is an option “book a demo”. You are always welcome to call us to hear more. In there you can also see where the nearest distributors are located. All AGROINTELLI’s distributors, without an exception, have a demo robot, which is meant to be shown to the potential customers and those that are interested in this technology. Customers can also see it in Denmark at our production facilities and the headquarter. We are planning to make various demonstrations in the countries in which we don’t have currently distributors.

We, or our distributors, are going to present the robot at the agricultural fairs. DLG Feldtage, SIMA, FIRA – are only some of them. A new activity that we have already started are field trips to the existing customers so farmers can talk to farmers about the experiences with ROBOTTI.

-

Drill Manufacturers In Focus…

HORSCH PUSHES DIFFERENT ASPECTS OF AUTONOMOUS DRIVING SYSTEMS

In five short statements Michael and Philipp Horsch describe what they understand by autonomous driving systems, which technical requirements are necessary, how the topic developed in the HORSCH company and what will be required in the future.

1 Michael Horsch: Our first steps towards an autonomous driving system must have taken place in the early 2000s when we bought the first AutoFarm GPS steering system for HNG. At that time, it was the first RTK system from the US which allowed for driving within the range of a centimetre. When it worked, we thought: If something like this works, we should be able to drive autonomously. But at that time the project came to nothing. When we bought our test farm AgroVation in the Czech Republic, we had the chance to focus on CTF and track planning. We originally started with an agronomic point of view, but we soon realised that CTF first and foremost is about planning. This was another step towards autonomous driving systems.

2 Philipp Horsch: I would rather call many things which today are associated with the term autonomous automation. Let’s take the example of a tractor that drives with GPS and can reverse on its own – for a start this only is an automation step, there is still somebody sitting on the machine who controls it. Autonomous means that there really is no driver. And we are talking about different vehicles, i. e. without a cabin on it. And what is extremely important: Automation comes before autonomous driving. It definitely is the first step. As automation has been an important topic for years, we have been making good progress. However, there still are quite some hurdles to clear until we reach complete autonomy.

3 Philipp Horsch: To be able to work in a partially autonomous way today, three things are required: First of all, the track planning system. Then you need geofencing, i.e. a digital fence. And the third point is the safety topic. Today we solve it by placing a “driver“ with a remote control in the field whose task it is to monitor everything and to intervene in case of emergency. The remote control is authorised for a range of 500 m. These three aspects are important to make sure that we soon can work in the field in a partially autonomous way and be safe. The next step logically is the sensor system so that the machine can be monitored, e.g. a clogging detection etc. From a technical point of view, we are working on different concepts, for at the moment we still do not know what will stand the test and in which conditions. What we know is that we have to take the different concepts into the field, exercise respectively, learn and develop further. In any case, our approach is free from any bias.

4 Michael Horsch: The current legal situation is another important issue. At the moment, from a legal point of view, the legislator does not separate between road and field, but treats them as equal. But on the road, you drive significantly faster and there is opposing traffic. The need for a re-definition and the public pressure to finally create appropriate framework conditions is enormous. If we separated road and field, we could get started in the field much faster. Another point is the possibility of the homologation of the safety concept, i.e. camera systems, radar and lidar systems. We hope that in the next few years the safety systems will have developed in such a way that they can be homologised, for from a technical point of view we are ready. All this is perfectly sufficient for a test farm, for this is where we want to gather experiences, test machines and integrate them into the farm processes.