If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Scrap The Pumps

It is becoming increasingly apparent that our approach to flood management needs a re-think. Expensive structures and barriers, pumps and sluices might look impressive but if all they do is push the water into someone else’s kitchen further down-stream then it’s a rather hollow victory. Likewise, dredging tonnes of lost topsoil from the riverbeds so the water can “get-away” more quickly does not address the question of how and why the soil got there in the first place.

So, what can we do? Well firstly a few centimetres of water across the top of a large catchment is much easier to manage than a fast-moving raging torrent concentrated into a narrow river valley further down. I have reached the conclusion that the solution lies in an integrated approach where a series of step-wise measures are employed, starting on the ground at the top of the catchment and employed systematically downwards through the system. The Allerton Project, based on an 800 acre mixed farm in Leicestershire, began to look at this idea 15 years ago.

In our catchment I observed farmers placing straw bales at the bottom of fields affected by soil erosion to keep the soil in the field – a sort of low tech flood barrier. The technique is about as effective as some of our more expensive defences! Yet if we were to make the soil more absorbent then we can reduce the volume of surface flow by enabling higher levels of infiltration, so the water doesn’t run across the surface and down the slope. For instance, our research has shown that moving away from ploughing to lighter surface cultivations prevents the socalled plough pan forming- a layer of compaction just below where the plough furrow passes through the soil- which increases infiltration. This then increases earthworm numbers. The soft body of an earthworm and cold steel of a plough are not the best of bed-fellows.

These earthworms create a myriad of tunnels in the soil which allow water to infiltrate more rapidly and in greater volume. Without the plough the crop residues remain on the surface because they are not buried, protecting the soil from erosion, and because we disturb the soil less, we need lower horse-power, lighter weight tractors which in-turn cause less compaction. We can also fit our tractors and other machines with low ground-pressure tyres which reduces compaction further- less compaction equals better infiltration.

We can grow cover crops on land which is not destined to be sown with a commercial crop until springtime, thereby protecting the soil. This adds organic matter, which in turn improves water holding capacity; tap rooted plants create deep channels that water can flow into; plants such as fodder radish push the soil open with their strong “tap” roots allowing water to infiltrate; we can manipulate our rotations and add organic matter by including grass leys and spreading in livestock manures and composts, which help the soil absorb water. All these measures are the first line of defence- to keep the water as close to where it lands when it first falls from the clouds.

Then comes the second line of defence; placing vegetative buffer strips in the field margins to slow the lateral movement of soil and water or grassing down shallow depressions in fields where water gathers, washing soil away. Beetle banks can be placed strategically across slopes- soil erosion is caused by the VOLUME of water and the VELOCITY it travels at- the beetle bank provides a barrier and puts the brakes on the flow. Studies by the soils team at the University of Sheffield have shown that a hedgerow running across a field can act like a drain, intercepting run-off water and allowing it to infiltrate; we suspect beetle banks do the same.

Semi-permeable dams can be used to hold water back higher up in the catchment. Recent research has shown that this can be surprisingly effective in preventing the surge of water from a sudden rainfall event all converging together lower in the catchment. Retention ponds can be dug; Allerton’s Head of Research Prof. Chris Stoate came up with the clever idea of damming field ditches on sloping land and feeding the water into settlement ponds dug in the field corners, an area of low agricultural productivity. These ponds are great for wildlife in summer, but they also allow sediment to settle out and hold water up higher in the catchment reducing the peak flow and consequently flooding downstream. Creating riparian strips with marshy absorbent ground and ponds and water retention channels can also help.

The third line of defence is to sacrifice areas, such as grassy fields in the flood-plane where water can accumulate. But what becomes of our friendly soil engineers then – do they drown in their burrows as water floods the land for often weeks at a time? Work at the University of York shows not. In fact in experimental trials it was found just how resilient these creatures are, capable of switching into a sort of hibernation for months on end, to re-emerge once the risk of drowning, or indeed drought, has passed.

So only when we have done all this should we move to the fourth line of defence where the barriers and pumps can be brought in. All well and good I hear you say- but who is going to pay for all this?

Actually, that’s not the problem it might appear. Many farmers have switched away from ploughing because the alternative is less costly; field margin strips and beetle banks are paid for options in Environmental Stewardship Schemes or can be counted as part of a farmer’s mandatory Ecological Focus Area requirements; field corner ponds are a new Stewardship option and if you look after your earthworms, well they come for free, indeed at a fraction of the cost of an expensive pump and immune to failure in a power cut!

The Environmental Land Management Scheme which will replace the existing stewardship scheme will pay farmers to deliver “public goods”, which will include enhanced payments for collaborative schemes within catchments where landowners employ a multiplicity of techniques to reduce flood pressures on dwellings down-stream. This is why agroecology is increasingly being seen as a way forward. Agroecology takes a holistic approach and seeks to work more closely with nature so that we can continue to keep our farms in business producing quality home-grown food, whilst enhancing our wildlife, our pollinators and protecting our soil, which belongs in our fields not on our river-beds or in other peoples’ houses.

-

The Potential Of CTF To Mitigate Greenhouse Gas Emissions And Enhance Carbon Sequestration In Arable Land: A Critical Review

Abstract from D. L. Antille, W. C. T. Chamen, J. N. Tullberg, R. Lal

The drive toward adoption of conservation agriculture to reduce costs and increase production sustainably causes concern due to the potentially negative effects of increased soil compaction. Soil compaction reduces aeration, water infiltration, and saturated hydraulic conductivity and increases the risk of waterlogging. Controlled traffic farming (CTF) is a system in which:

• all machinery has the same or modular working and track width so that field traffic can be confined to the least possible area of permanent traffic lanes,

• all machinery is capable of precise guidance along those permanent traffic lanes, and

• the layout of the permanent traffic lanes is designed to optimize surface drainage and logistics.

Without CTF, varying equipment operating and track widths translate into random traffic patterns, which can cover up to 85% of the cultivated field area each time a crop is produced. Nitrous oxide (N2O) is the greatest contributor to agriculture’s greenhouse gas (GHG) emissions from cropping, and research suggests that its production increases significantly under conditions of high (>60%) water-filled porosity when nitrate (mainly from fertilizer N) and carbon (usually from crop residues) are available.

Self-amelioration of soils affected by compaction occurs slowly from the surface downward; however, the rate of amelioration decreases with increase in depth. Consequently, all soils in non-CTF systems in mechanized agriculture are prone to some degree of compaction, which compromises water infiltration, increases the frequency and duration of waterlogged conditions, reduces gaseous exchange between soil and the atmosphere, inhibits root penetration and exploitation of nutrients and water in the subsoil, and enhances N2O emissions.

Adoption of CTF increases soil porosity in the range of 5% to 70%, water infiltration by a factor of 4, and saturated hydraulic conductivity by a factor of 2. The greater cropping opportunity and enhanced crop growth for given fertilizer and rainfall inputs offered by CTF, coupled with no-tillage, provide potential for enhanced soil carbon sequestration. Reduced need and intensity of tillage, where compaction is avoided, also helps protect soil organic matter in stable aggregates, which may otherwise be exposed and oxidized.

There is both circumstantial and direct evidence to suggest that improved soil structural conditions and aeration offered by CTF can reduce N2O emissions by 20% to 50% compared with non-CTF. It is not compaction per se that increases the risk of N2O emissions but rather the increased risk of waterlogging and increase in water-filled pore space. There may be an elevated risk of GHG emissions from the relatively small area of permanent traffic lanes (typically <20% of total cultivated area) if these are not managed appropriately. Quantification of the benefits of compaction avoidance in terms of GHG emissions may be possible through the use of well-developed models.

Read the full paper here: http://actfa. net/wp-content/uploads/2015/07/ antille2015.pdf or click the QR code here:

-

Farmer Focus – Tom Sewell

In the midst of difficulty lives opportunity!

Well, as I write this from my room at The Royal Agricultural University at Cirencester on the 25th February the rain is currently lashing against my window and its 3 degrees outside! Hardly the weather for spring drilling, applying fertiliser to backward crops and even clearing up grubbed orchards waiting to be burnt! Can you remember a 5 month period of almost constant wet weather? Fields have hardly had the opportunity to start drying out before the next deluge or storm arrives. It really is a very trying time for farmers and we are far from being in the worst situation. Many farmers up and down the country have seen huge swathes of land turn to lakes. Quite how and when these will have healthy crops growing in them is anyone’s guess!

At times like these its very easy to get disheartened and lose hope. My thoughts are with those who don’t have the option of leaving fields fallow or planting a cover crop in late spring to help the soil heal and restructure. Where rents have to be paid and a crop needs to be grown at a profit just too cover costs this is looking like a tough year. I’m currently on the first week of the Institute of Agricultural Management Leadership Programme. This takes place over 3 weeks with a week here at Cirencester, a week in Brussels in late March and a final week in London in late April. We are a group of 13 from across the agricultural sector and I’m looking forward to what happens over the coming months. Whilst on the subject of personal development I would like to bring your attention to a couple of things that I’ve done over the past ten years that have really helped shape me and given me confidence and ability to make changes within by business.

In 2008 I spent three weeks attending the Worshipful Company of Farmers Advanced Business Management Course. There were 20 on that course and many of us still meet regularly for a reunion and to catch up as friends. I can highly recommend the course which is run every year here at Cirencester RAU during November.

Then in 2013 I was successful in applying for a Nuffield Scholarship which saw me spend time in North and South America, Australia, New Zealand and UK.

If you fancy a challenge or some personal development these courses are definitely worth attending, not just for the course content, but for the experiences, travelling and the friends and relationships that develop.

Although the past 5 months have been largely a writeoff weather wise there have been opportunities that have come along which we’ve been able to take advantage of. The first of these is to take on extra land from this coming autumn. With a local farmer retiring at the completion of harvest 2020, we have been able to take on some extra acres locally. We are also expanding our contract drilling acreage with a few more farmers locally who are looking to use our low disturbance system on their farms. I can see this part of our business growing significantly over the coming years as smaller landowners and farmers look to those with experience of conservation agriculture, no-till systems and regenerative farming to give assistance by way of land management and contracting services.

Another exciting change is the addition to our team of a new staff member! With the increasing land area, contract drilling area and continued contracting services we have felt that we needed to add to the team which has essentially been Dad and myself on the farm for the past ten years. My wife and mother are also partners in the business with Sarah, my wife, taking care of most of the office work for ours and another business which we run. The new man starts next week and integrating him into the team, teaching him about regenerative agriculture and giving him responsibilities will be both exciting and challenging but I believe the right thing to do. For us it’s been the one missing part in our business that will allow us to progress and expand.

We have also been approached recently to host and demonstrate a Novag drill on our farm for the spring/summer period. This will be a 6m model of their T-force machine with the openers set at 10”/250mm spacing. The thinking behind this row width is that if/when we lose glyphosate inter row hoeing or weeding becomes a possibility with RTK steering. It will also give us the option of applying solid starter fertiliser and slug pellets in one pass and I’m confident our current 300hp tractor will pull the extra 4 openers over our current 4.8m 21 opener Primewest model. Just for the record we are very happy with our Primewest machine and the service we have received from them. But times change, machines improve and develop and workloads increase! As I said in my title, there are always opportunities to take advantage of and I’m hoping this gives us scope for more work, contracting and demonstrations. If you are interested in a demonstration in Kent and East Sussex of the Novag machine we will be available for demonstrations at a contracting rate. You are also welcome to come and see it working on our farm and some of the crops we have drilled using this system.

Our local discussion group have had some excellent speakers this season with Clive Bailye, James Thompson from Beeswax Dyson and John Pawsey speaking. There are always opportunities to learn and grow and that’s what we’ve endeavoured to do even if fieldwork progress has been zero! I can see the coming 12-18 months being a testing time for UK agriculture with the fall-out from Brexit, flooded and water-logged fields, and poor financial returns from harvest 2020 with which to invest and finance the coming years. Certainly, our long term no-till land is holding up better than most and where we did establish crops they look to have developed nicely over the wet and mild winter.

I mentioned in one of my articles that we don’t work on Sundays and often get a funny look or raised eyebrows when I mention this. For us 6 days on then one day off allows everyone to start back on Monday refreshed and ready to go again. We still get the harvest in and are just as forward with planting as anyone else locally. I also have a wife and 4 children and am on the leadership team of a large church locally. Spending time off farm is, for me, vitally important to put things into perspective and talk to non-farmers, family and friends. And with that I’d like to finish by encouraging you to look out for others around you particularly in the farming sector who might well be struggling over the coming months. Farmers who feel there is no hope or that would like to change but don’t have the opportunities, finance or abilities to do so may be those that you can befriend, help and get alongside.

As the tragic passing of Caroline Flack, at just 40 years of age, has reminded us, life can be cruel and heartless. Please think about the effect of what you write and what you say. “In a world where you can be anything, be kind” Thanks for reading this far! We all wish for a rapid resolution to the Covid virus which has upended so may lives and businesses, and best wishes to all.

-

Drill Manufacturers In Focus…

CHANGING WEATHER PATTERNS AND EXTREME CONDITIONS HIGHLIGHT THE IMPORTANCE OF SOIL HEALTH

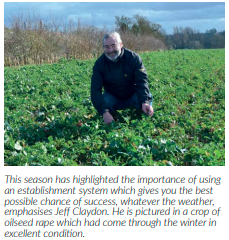

This season’s weather extremes highlight the importance of good soil health, says direct strip seeding pioneer and Suffolk farmer Jeff Claydon, who designed the Opti-Till® System.

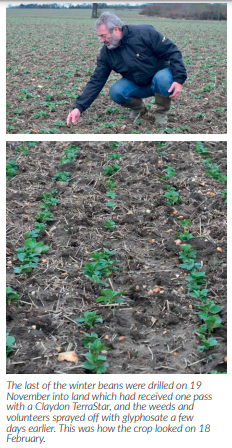

In the last issue I highlighted the importance of operating a crop establishment system which can cope with all conditions, the need to minimise weather risk and having machinery with sufficient capacity to exploit weather windows, allowing seed to be drilled at the right time and in the right conditions so that it produces high yielding, profitable crops. This time the focus is on soil health, a particularly relevant topic because as I write this on 18 February 2020 the extreme weather throughout the UK is headline news and a record number of flood warnings are in place. I sympathise with those who are affected and appreciate that, despite persistently wet conditions here in East Anglia, the region has got off lightly.

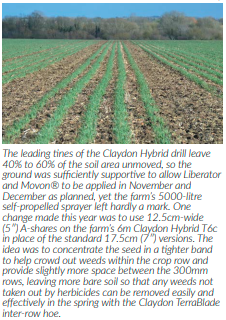

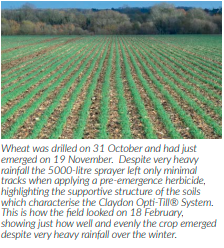

Crops never look their best in February, but I’m very pleased with those on the Claydon farm. After harvest we were able to carry out an effective stubble management programme using the 15m Straw Harrow and 6m TerraStar, get all our winter wheat in the ground by 31 October and completed the planned autumn establishment programme on 19 November when our 6m Hybrid T6c drilled the last of the winter beans. They established well and even the headlands look good. Checking the crops today reminded me that we would never have completed autumn drilling using a plough-based or min-till system; the plough-based taking four times as long and the mintill nearly twice the time.

When I walked our fields this morning the ground was so firm and supportive that my boots picked up very little mud – and this despite being a heavy clay farm. More remarkable was the fact that barely a mark, or any water, was visible in the tramlines where I had applied a pre-emergence herbicide to wheat in November and been through again in December with our 17-tonne, 5000-litre self-propelled sprayer.

After yet another night of heavy rain I did an infiltration test to check whether the soil could absorb any more water and whether any areas had drainage or compaction issues that may need to be remedied when conditions allow. The 20-litres of water in the infiltration tray is equivalent to 5″ of rain falling, but nevertheless it was absorbed fully in under five minutes, indicating that the soil is in excellent condition. I also checked for compaction, but even in the tramlines the indicator needle on the penetrometer never went beyond the green zone.

Travelling around the country on my way to visit customers I have seen countless examples of soils in poor condition, probably from being overworked, using inappropriate machinery, at the wrong time. Some fields were waterlogged, slumped and capped, worm activity was minimal, crops were stressed, and even weeds refused to grow in some areas. Elsewhere, vital topsoil which had taken millions of years to form had washed off fields into ditches, streams and rivers, causing pollution and crop loss.

In the 52 years that I have been involved on the Claydon farm I have tried every crop establishment system, under all conditions; it was their shortcomings that led me to develop OptiTill®. We’re now able to produce high yielding crops more efficiently, at much lower cost and with less agronomic and financial risk – all while improving our soil health. We have reduced our costs by £140/ ha – an excellent saving – but if our yields were to fall by 1t/ha, this saving would be wiped out. On the Claydon farm, we have never experienced any yield loss, just the opposite in fact. Independent tests by seed breeder Saaten-Union from 2006 to 2016 recorded an average 9% yield increase over a plough-based system, and up to 26% in an extremely dry year.

Soil Health is Critical

This season has been one the most challenging since 2012. It was too dry at the start and has been too wet ever since, although soil temperatures have averaged 1°C higher than last year. At a time when extremes of weather appear to be on the increase, good soil health has never been more important. Soil health comprises three elements:

• Physical health: Texture, soil structure, porosity/pore size distribution, water retention/ transmission and aeration

• Chemical health: Maintaining optimum pH, providing plant nutrients in the right amounts, in the right place, at the right time

• Biological health: Soil biodiversity, feed the soil regularly through plant and organic matter inputs, diversify plants in space and time

Dr Elizabeth Stockdale, Head of Farming Systems Research at NIAB, describes a healthy soil as one that can support crop and livestock productivity, whilst maintaining or enhancing environmental benefits, such as clean water, carbon sequestration and improved air quality. In healthy soils the interaction between soil chemistry (pH and nutrients), physics (soil structure and water balance) and biology (earthworms, microbes and plant roots) are optimised.

A well-structured topsoil has small, rounded, water-stable aggregates and a range of pore shapes and sizes that form a continuous network, allowing good aeration, root proliferation and better drainage. Plant roots and some organisms, such as earthworms, change the structure of the soil by moving through it, moving particles around and extracting water. Supporting the biological processes of structure formation and increasing soil matter content have been shown to help create resilient soil structures that can both absorb heavy rainfall and hold water in a drought.

A well-structured subsoil has vertically orientated, often continuous pores and fissures which are formed by physical shrink-swell processes and maintained by root and earthworm action. Between these pores the soil forms column-like structures, which in clay soils may be single prismatic aggregates. These give the overall soil profile strength to bear the weight of machinery. Such soils are resilient and better resist damage by compaction, but cultivations must be carried out with care to avoid weakening any natural column strength.

Recent data has shown that reducing the intensity of tillage operations benefits soil biology, with marked increases in larger invertebrate species, especially deep burrowing (anecic) earthworms, where inversion tillage is removed from the rotation. Examining soil physical structure should be done when it is in the moist to wet range, so early spring and late autumn are good times to get your spade out and have a systematic look.

How Opti-Till has worked this season

The OptiTill® System has been developed, refined and improved over 18 years, during which time numerous benefits have become apparent. They include huge time and fuel savings, much improved timeliness, faster emergence, larger and stronger rooting structures, improved soil health, greater resilience to extremes of weather and improved yields. Even headlands which we once accepted as not being particularly productive now yield just as well as the centre of the field.

A key reason is that the Claydon leading tine technology loosens soil only in the rooting and seeding zone, so the bands between the seeded rows (which make up 60-70% of the field area) are left intact. The leading tine aerates the soil, creating a friable tilth which provides the perfect environment for seedlings to germinate and develop strong, deep roots that tap into the moisture in the undisturbed areas. It also breaks up any shallow compaction and allows water to move away from the rooting zone, which eliminates ‘ponding’.

Because old rooting pathways remain in place the soil’s structure is not damaged, its density remains consistent and natural capillaries remain unbroken, allowing water infiltration and unimpeded rooting. This minimises stress on the crop throughout its life and means that soils managed using OptiTill® are much better able to support field traffic without the risk of compaction.

Earthworms thrive in unturned soil and their numbers have increased exponentially, vastly improving the soil to air ratio. The casts they leave on the surface are a tell-tale sign of good soil health and the channels they create, some over two metres deep, have been invaluable in draining water away from the surface this winter. Despite exceptional rainfall our soils have retained an excellent crumb structure and crumble between the fingers rather than clumping into a sticky, anaerobic mess.

The Hybrid drill has no press wheels touching moved soil so it runs when most other strip till, min till and nondisturbance drills can’t. A variety of options and adjustments are offered on the rear toolbars to suit different conditions to help get a fantastic finish. The Claydon drill can travel on firm stubble as opposed to the ‘porridge’ that is left in min-till systems when the moved soil gets wet and then can’t be worked until it dries out. Claydon Opti-Till® saves so much time it presents farmers with a wider window to get seed in the ground when the weather is good rather than having to cultivate it and then go out with a drill.

This is a huge benefit, for example, when drilling wheat behind maize late in the season. This is also a significant benefit for countries such as Scotland and the west coast of Denmark where harvests are late, and winters are early and cold, so farmers have a very short period to get crops in the ground and established. Particularly when drilling late after maize, the compaction created from post-harvest traffic with machinery including foragers, tractors and trailers is also alleviated by the Claydon leading tine.

The Claydon mounted Hybrid drill has been particularly effective this year at getting crop in the ground; comparatively, it doesn’t carry a lot of weight on the tractor, it has huge clearance and the leading tine has done its job at removing compaction, aiding drainage and creating tilth. Opti-Till® works in perfect conditions; it also works in far from perfect conditions, like this season, without damaging the soil.

Significant Benefits

Our very heavy Hanslope Series chalky boulder clay soil is one of the most difficult to farm. When worked wet it can become impossibly sticky, unfriendly and slow to drain, then when dry it sets as hard as concrete. In both cases it is impossible to work, making it essential to carry out all field operations when conditions are right. When wetted, unhealthy soils ‘slake’, or run together, very quickly and they lack the natural glues that help bind the soil together. This blocks the natural pores and worm burrows in the soil, which can lead to ponding and waterlogging that can develop into erosion and loss of topsoil. Conversely, very dry conditions can lead to cracking, drying like concrete, inhibiting the crop from reaching its full potential.

Dick Neale from UK crop protection specialist Hutchinsons carried out a slake test at the Claydon farm last year and found our soils to be very healthy. He reported: “They have remarkable water infiltration rates, rooting depth and drainage due to the high porosity, low bulk density and abundant earthworm populations resulting from the tillage techniques employed. The natural aggregation, worms and invertebrate activity are all indicative of good biological health.”

See our slake test video at: www.claydondrill.com/video-gallery/ video/343 Next time I will discuss how our crops developed through the spring and how the Claydon TerraBlade inter-row hoe is used in conjunction with herbicides to help us minimise weeds and diseases.

To learn more about the Claydon Opti-Till® System and how to improve your farm’s p e r f o r m a n c e contact your local Claydon dealer, go to www.claydondrill. com or call the Claydon office on 01440 820327

-

Crop Nutrition In The Spotlight At Cereals 2020

Weeds and disease are an ever-present threat to crops, but nutrition plays a key role in tackling both and optimising it

should be a focus for farmers.From variety choice to the latest chemical developments, weed tackling strategies and nutritional advice, Cereals 2020 (10- 11 June) will deliver the knowledge to help farmers overcome many challenges. Nutrition is one of the key areas in the spotlight as growers consider where improvements can be made. Micronutrients in particular can easily fall under the radar, and yields can suffer as a result. This year especially, with the excessively wet conditions, leaching could be a serious problem for many. According to Natalie Wood, agronomist at Yara, boron deficiency is often an issue. “In 2019, 86% of our tissue samples were deficient in boron and this year we would expect it to be even worse if growers don’t apply it.” Boron deficiency affects the number of grains per ear, meaning crops lacking in it are unable to achieve their yield potential.

But boron isn’t the only micronutrient crops are often lacking; zinc and magnesium are also hidden culprits. “Macronutrients are often tailored for, but micronutrients aren’t always given as much attention and things like copper or boron are taken for granted as growers don’t always know the impact they have,” she explains. “Just because they are called micro, they are no less important, they are just needed in smaller quantities – and when crops are deficient in one, it can be a limiting factor to yield.

There’s still time for growers to act on this year’s crop though, adds Ms Wood. “If they can get leaf samples before the T0 spray, then they can apply the necessary nutrients then. Or T1 is another application option for nutrients – so there’s time to take tissue samples and get the right products ordered.” Growers do need to be cautious though, because rooting has been so severely compromised in some crops that they do not have the capacity to take up nutrients well, according to Chris Gamble at Olmix-Micromix.

Mr Gamble suggests that growers should look to use a multi-trace element mixture, as well as biostimulants and a non-scorch liquid nitrogen to aid ailing plants. “Use it at low doses to kick-start the crop to improve rooting, support tiller growth and boost yield.

“At this point some crops need a rescue remedy and anything we can do to make more root will support challenged crops,” he adds.

Improving root structure can also help plants compete with weeds, and blackgrass is still one of the biggest weed challenges for farmers. An endless amount of research goes into fighting this most stubborn and persistent of weeds, and John Cussans, weed biology specialist at NIAB will explore the most effective options for tackling it at the Cereals Event.

With a changing climate, keeping on top of pests and diseases can be particularly hard, so considerable research is also going into improving varieties to cope with emerging challenges. During a tailored session at Cereals, Rothamsted Research’s Kim Hammond-Kosack will reveal breeding research that will deliver resistance to aphids, take all, septoria, slugs and yellow rust to name but a few.

Further to this, the new world of biopesticides will be explored by Dr Roma Gwynn at BioRationale. Capable of playing a major role in tackling pests and diseases, these natural combatants could have serious potential on UK arable farms.

Using an all-round approach is continually hailed as the most effective way of tackling all arable challenges, which is why exploring the benefits of the latest technology at Cereals could revolutionise crop management. CHAP’s Fraser Black will explore how Crop Pro matches local growth stage to pest and disease risks and can provide spray window forecasts using bespoke weather monitoring. Or for those interested in utilising drone technology, DroneAg’s Jack Wrangham will be demonstrating how a smartphone-based app enables farmers to fly a drone to points in a field and get accurate green area index (GAI), emerging plant counts, and spot weeds and insect damage.

Farmers have faced a challenging year, but the progress of the industry has been no less exciting despite this, says event director, Alli McEntyre. “There is so much new and innovative technology available and agriculture is advancing continually; it’s important to keep abreast of it as it could revolutionise the way you run your business.”

• The Cereals Event will be held on 10- 11 June 2020. For more information or to book tickets visit www. cerealsevent. co.uk.

-

Farmer Focus – Tom Olivant

I am currently a final year student at Harper Adams University studying Agriculture with Farm Business Management. Although I am passionate about the Farm Management side of the industry, I am rapidly acquiring a vested interest into the Conservation and Regenerative Agriculture side too. I believe this has stemmed mainly through the placement year Harper Adams offer, where I was very fortunate to work for N E Salmon Ltd in Norfolk, a forward thinking business focusing on soil health and sustainability, implementing a ‘Harvest CTF’ system, alongside a diverse 9-crop rotation of which further included cover cropping. I managed to gain a huge range of new knowledge and experience through this placement in regard to regenerating and improving soil structure and health to provide sustainable yields.

The placement opportunity then led me to Western Australia for 8 months, which allowed me to see further alternative approaches to maintaining soil health when faced with different challenges in the dry climate and lack of structure within the soil. Harvest was spent at Dolany Farms, which was an 11,000ha unit cropping wheat and canola on a fully implemented 13.5m CTF system. This system allowed for high efficiency whilst only disturbing the soil once with the drill to conserve moisture. I was involved in the seeding (drilling) at the second farm, Stirling Ranges Beef, where we had the job to operate 2 new 21m Seed Master drills 24/7 over 12,000ha planting crops including lupins, beans, peas, grass, canola, wheat and barley.

To provide a background, we have a relatively small 300 acre farm at home, of which the entire area has been under a HLS scheme for the past 10 years. A flock of roughly 500 breeding ewes were reared for the first half, followed by a pedigree Hereford suckler herd for the remainder. Prior to this, the farm was run on an intensive cropping system, with a rotation including wheats, barleys, OSR and root crops with no real focus on soil health, just maximising output. As the HLS scheme expired in 2019, the decision was made not to renew, but to wait for the proposed ELMs scheme to become available. We believed the 10 year break and long grazing seasons would have left the soil in good condition with a relatively low weed burden.

Unfortunately, it has proven this year has not been the one to make a return to arable cropping after a large proportion of the farm has spent its time submerged in water following the Barlings Eau breach in early November. With focus away from the cropping, we were fortunate to establish a stubble turnip grazing mix, which saw the return of sheep to the farm again in February. Weather permitting, we aim to be successful in drilling some vining peas and spring barley, with the remainder of the permanent grassland being left for the year to cut for hay and hopefully some more be returned to arable cropping in Autumn 2020.

The aim of the new system is to maintain and further improve the soil health following its years as grassland through a range of conservational methods including permanent soil cover through diverse cover crop mixes and rotations, and reduced tillage establishment techniques. I believe the best way forward in this situation will be to trial a range of alternative systems to see which will provide both the optimum financial and physical benefits together. I am a strong believer that all tools have a place on the farm if used correctly, and not one system will suit all due to variables such as climate, topography and soil type changing between farms.

In terms of University, within the course I am studying there is a relatively small amount of content on Sustainable Agriculture systems and soil health, which I guess isn’t surprising being a business management orientated course.

This has driven me to research more about the topic elsewhere, reading articles and attending a variety of events. This desire to learn more about the topic has also influenced me to base the topic of my dissertation on Conservation Agriculture, having recently carried out a survey investigating the factors that are influencing uptake within the UK. Farmers have been surprisingly willing and responsive to this piece of work, which has helped me gather some very interesting data from a range of different farming scenarios.

After carrying out preliminary research, I found although literature supported the global uptake Conservation Agriculture, there appeared to be a misunderstanding to why the uptake of the techniques had been relatively slow in the UK. Currently my research is showing that an overall lack of trustworthy information and knowledge, together with the uncertainty over future policies and key pesticides such as glyphosate is causing this stagnation. Interestingly the research has shown there is still a lot of people not willing to change as they are sticking with a system that has always been implemented and are not prepared to alter. Farmers on short term tenancies appear not to be as willing to adopt the techniques, which is understandable due to the low level of security resulting in them not wanting to adopt new techniques with benefits taking so long to materialise.

Although it’s hard to believe from the current press, I believe the future for UK Agriculture is positive as long as we are able to work together as an industry and show the public and policy makers that we are able to implement sustainable changes in an increasingly volatile environment, because at the end of the day, the demand for quality food is not going to disappear. This positivity about the future is emphasised to me at University with the current students as ‘the future of farming’, showing a very keen attitude to face the challenges that the industry is currently facing and will inevitably face in the future.

My plan now is to graduate this year, and further pursue my learning on a trainee management scheme on a larger scale farm. I would hope this will benefit my knowledge, as well as being able to implement some of the things I have learnt over the last few years in terms of management skills and sustainable agriculture practices

-

Drill Manufacturers In Focus…

SKY DRILL EVOLUTION

With Sky’s recent introduction of the latest generation EasyDrill, we chart the evolution of the minimal disturbance no-till seeder over the last four decades

The latest incarnation of the Sky EasyDrill gets individual row shut-off, blockage sensors, ISObus controls and four individual metering units. Placing the French-built notill drill at the tip of the spear for technological sophistication, these latest developments follow a 40-year evolution of the concept.

So how did it all start?

In the mid 1970s Sulky’s Jacques Burel returned from a visit to the Royal Show excited by the prospect of a multi-purpose minimal disturbance direct-drill he had seen at the event. Little known in Europe at the time, the Moore Unidrill had found success across the UK and Ireland particularly in use as a grassland reseeding tool but also as a mainstream cereal drill.

Inspired by what he had seen of the Northern Irish-built multi-purpose seeder, Jacques did a deal with inventor Sam Moore to start importing the drills to France and other French speaking countries, complementing Sulky’s existing range of fertiliser spreaders and conventional drills. In return the French firm started to supply the Northern Irish company with drill hoppers and metering units. Around this time Sulky moved from its trademark turbine metering units to peg-wheels better able to cope with larger seeds such as beans and peas. These could handle rates as low as 3kg/ha for OSR right up to 300kg for late-drilled winter cereals.

As sales grew, a bigger proportion of Unidrills were going to arable operations rather than the traditional grassland reseed market. This prompted the introduction of a different row spacing option with rows widened from 13.3cm to 16.6cm to better suit cereals. Over time working widths grew from 2.8m to 3m and 4m. A few 6m versions were even built – all boxdrills. In the 1990s tougher road regulations across Europe meant transport became an issue for boxdrills. Consequently both firms set about developing folding versions with pneumatic metering and distribution. Initially Moore used Accord hoppers but as demand grew the Northern Irish outfit switched over to the Sulky set-up with pairs of hoppers and metering units mounted in W-formation – these Unidrills were tagged as ‘W-series’ models.

From then on all R&D was done jointly – generally the bottom halves of the drills (frames and soil engaging metal) were designed in Northern Ireland while everything up top (hoppers and metering) was developed by Sulky. In the early 2000s Sulky shifted to rate controllers from Danish firm Linac. Employing electronic actuators on the metering units, these made variable seed rates possible. Operators could then alter rates from the cab as soil types varied. By now the Unidrill concept had proved itself as simple and effective in the way in which it worked but it wasn’t idiot-proof. Operators really needed to know what they were doing and be prepared to get out and adjust the machine as conditions and soil types altered.

This prompted both firms to look at ways in which the drill could be made more user-friendly – the ‘W1000’ series was born. With rubber gauge wheels up front and pairs of presswheels mounted at the rear of each unit in a bogie arrangement, this massively improved contour-following and adjustability. The key feature was a simple hydraulic adjuster that could alter the coulter carriage weight bias frontto-back to account for different ground conditions. Although a joint development, Sulky held the patent for this concept.

In 2007 the two firms parted company and the joint venture came to an end. Sulky developed the concept further with a number of tweaks and re-branded it as the EasyDrill. The disc bearings were switched from imperial to more readily available metric versions. Adjustment of coulter boot position against the disc was made easier – critical when working in damp, trashy conditions. The rear coulter press wheels were changed from ridgeprofile rings to a simple angled profile for more reliable slot closure. In 2013 the no-till Easy Drill and cultivator Maxi Drill 1000 series were rebranded under the Sky banner, a subsidiary of Sulky. A revamp followed this with bigger bearings throughout the drills to better cope with the requirements for travelling faster in tough conditions. Split twin hoppers were introduced with separate metering units, distribution heads and coulter outlets to allow different types of seed and fertiliser to be drilled at different rates in the same pass.

Shortly after this a separate ‘Pro Hopper’ applicator was launched to enable operators to add a further seed variety into the mix or apply micronutrient fertilizers or granular products such as slug pellets. At the same time Sky introduced a range of cover crop destruction rollers to aid growers wanting to plant directly into high biomass situations. By 2019 the EasyDrill has come a long way from its humble beginnings. Mid way through the year new easierto-adjust coulter carriages with heftier SKF disc and press-wheel bearings are launched.

In November at Agritechnica there was a big announcement with the introduction of the 20 series. Amongst other things this saw a change of control boxes – having stuck with RDS rate controllers for 20+ years, Sky switched to in-house developed electronics to easier facilitate GPScontrolled variable seed rates and ultimately ISObus. On top of this came blockage sensors and the ability to individually shut-off seed flow to each coulter, enabling operators to run with different row widths for different seeds. Alongside this came the facility for the drill controller to automatically shut off coulters for tramlining, without having to match drill width to sprayer booms. The new control boxes have the facility to support even more metering units so Sky now offers the option of a second Pro-Hopper, enabling operators to apply up to four different seed types/granular products in one pass.

Sky Drill’s UK product specialist, Joe Redman commented “The evolution from ‘just an old Moore drill’ to today’s state of the art lean, mean drilling machine has been no accident. Each stage of development and design has been carefully considered and rigorously tested by the Sky team. The EasyDrill really is a progressive drill for forward thinking farmers.

-

ST Louis 2020 No-Till Conference

Written by Andrew Jackson, Pink Pig Farm, Lincolnshire

I am a farmer from North Lincolnshire, amongst other things I have been described as butterfly and an evangelist, the former because I am always looking to land on something new which will improve my life and business, the latter because once I discovered regenerative farming, I felt compelled to learn more and to spread the word about its many benefits to friends and other farmers. I chose to attend the 2020 National No-Till Conference in St Louis USA because it is promoted by Lessiter media and I have read many of their publications and listen to their podcasts while field walking. After a 21-hour journey during which I was strongly advised by a kind lady on an internal flight “not to go downtown in St Louis”, due to the high homicide rate, I arrived at the Union Station Hotel only to find that the bar had just closed. It was 12.10am local time and 6.10 in the morning UK Time, my body was tired, and I retreated to bed.

I arrived a day early to avoid jet lag issues, I need not worried I woke up at the crack of dawn for a number of days. On my free day I explored St Louis and visited the National Blues Museum and the Gateway Arch, a 600 feet high stainless steel arch, completed in 1969, it is intended to promote the city’s position as the Gateway to the west for the settlers who passed through it, heading for the promised lands. St Louis was built on one of the major railroads which headed out West, it also sits at the confluence of the Mississippi and Missouri rivers, as such, it was and is, a major trading post and the hotel where the conference was hosted, displays the biggest hotel lobby that I have ever seen, due to the fact that it utilises the original train station ticket hall.

The average age of the farmer in the USA is slightly over sixty and like us they seem to have problems with the next generation coming into the farming business. There seemed to be plenty of farmers who had been practicing no-till for over thirty years, some of whom had received financial incentives from the state, however although some old timers claimed to have been using cover crops for many years, I got the impression that the wide spread introduction of cover crops was more recent.

Traditionally English farmers have worn flat caps and American farmers have worn baseball caps, I have made the observation that when inside a building it is very difficult to prise the baseball cap from some the American farmer’s heads, it is a fixture. They also like check shirts but with a slightly wider check spacing, a little something that I observed!

Most of the farmers at the conference were trapped into a twocourse rotation, not particularly out of choice, but because corn and soya were about the only crops which gave a financial return. They, like us were looking to break out and find a new financially rewarding crop. I did encounter one grower from Montana who was supplying Northern Pulse Growers with a variety of pulse crops, which were exported around the world. I mentioned that I knew a Canadian farmer who shut up shop in the winter and went to Florida, “Yes”, they said “that is known as a three-crop rotation, Soya, Corn and Florida!!!” On the Tuesday I attended a hemp growing seminar, this was mostly about growing hemp for CBD oils, which is currently illegal in the UK, the proceeds of the hemp harvest are distilled in a factory off the farm. Steve Groff highlighted the many hurdles that he had encountered growing, harvesting the hemp bushes and finding a secure outlet. This operation is not for the faint hearted, there is a lot of hard work and risk involved but the conclusion was that profit per acre generally fell between zero and $7000 per acre, although on a cautionary note, losses could be up to $20,000.

At supper that evening there was a discussion about banding cover crop seeds so that the following year’s maize seeds could be sewn into a less competitive band of radishes which are not winter hardy. Alongside the central row of radishes, crimson clover had been sown on both sides and furthest from the radish (where the maize seed is to be sown), are the hairy vetch and cereal rye which actually lie dead centre between the maize rows creating a firm base for all the tractor wheelings, and less competition for the cash crop.

Wednesday’s highlights included Jason Mauck, a farmer whom I have followed on Twitter, who explained his system of dual cropping winter wheat and soya beans, the idea being that the wheat is harvested earlier than the soya, and this then allows the soya greater access to sunlight. Another feature of this system is that the wheat provides shelter for the soya seedling, thus permitting the soya to be sown earlier than normal, providing an extended growing season. The consequences of which are, a small crop of wheat but a much bigger crop of soya, resulting in a greater net income. It’s all very scientific and I got the impression that it had worked in the trialling stage and he will roll out the system across his farm.

The other Wow was David Johnson who had been working on a Bioreactor, which is essentially an aerobic composter. The theory behind David’s work is that our soils have become dominated by bacteria and depleted in aerobic fungi. The composter is essentially a home-made tube, four feet diameter and about five feet high, it is filled with natural finely chopped material, (leaves, wood chip, hay). Air tunnels allow aerobic action and worms are introduced, the system is watered by one and a half gallons of rain water every day (ideally with an automated water system) and after one year, the end product should be seven hundred pounds of a black damp smooth compost which if his predictions are correct would in my opinion, have the equivalent value to gold. The beauty of this system is that it is low cost to set up and very low in labour requirements or fossil fuel usage.

The compost needs to be administered at one pound per acre, ideally by mixing into a slurry and placing next to the seed at drilling or mixing with the seed to form a seed dressing. David showed slides of how this product had brought desert land back to life and created exceptional maize plots with minimal use of fertilizer, all at the cost of twentyfive cents per acre. The idea was to re-introduce the aerobic fungi back into the soils, after which in a no-till situation they should multiply, as with human nature. I am tempted to build quite a few of these composters, in order to maybe increase the rate and apply the product every year. Another spin off, is that liquids, associated with this compost could be used as a fungicide, I guess that will come after more research, so we can look forward to another presentation from David. You can find David Johnson and his wife Hui Chun Su on YouTube at the sites shown below:

David Johnson Ecofarm Keynote (pretty much the same presentation that we received, although the sound quality is average)

Dr David Hui Chun Su Johnson (a small presentation on a farm, worth watching).

Johnson Su Composting Bioreactor (deals with the construction of the digester).

Smart Soil Ground Cover Ian and Dianne Haggerty (the Haggerty’s were mentioned in one of David Johnson’s presentations, so I found them on YouTube).

This bioreactor is being trialled on most continents and David Johnson and his wife welcome any feedback, which is most likely going to be in one and a half years, since the compost operation will take a whole year. Each day there were breakout groups when it was possible to choose a small discussion forum, for example I chose:

• Cover Crop Strategies in the North East, Mid Atlantic

• Winning ideas for no-tilling vegetables

• Solving the riddle of cover crops and fertilizer management

• Helpful hints for higher no-till wheat yields

• Using Mycorrhizae, humics, soil builders to unlock soil health.

The last one was hosted by James (Jim) Hoorman, Jim an retired government soil scientist had all the answers, the forum quickly moved from a group discussion, to a jaw dropping description from Jim on how the bacteria, microbes and fungi interact, to build fertility and access nutrition for the crop from the nutrients within the soil. There was so much knowledge coming out of his mind that is was difficult to keep up, I tried to make notes for future reference and understanding. Jim has set up his own consultancy company now and can be found at hoormansoilhealth.com

Jim also cautioned us, on how new high yielding varieties may not be so good at accessing nutrients from the fungi, he described modern varieties as being similar to a racehorse, when for what no-tillers want to achieve, utilising the soil biology and reducing manmade fertilisers, a work horse variety may be more appropriate. One way around this could be to keep your own seed back each year in the hope that that seed becomes familiar with finding the soil biology on your farm. On the final half day, once again I chose to listen to Jim Hoorman, this time about soil compaction, a powerful and entertaining speaker, he soon talked us out of getting into that tractor and cultivating the soil to alleviate compaction. He then once again broke down the functions of soil health into easy to understand comparables.

The last speaker who left an impact on me was Rob Myers, I had already stumbled across an excellent presentation by Rob on YouTube. Rob puts across the many benefits of cover cropping in an excellent, easy to understand format. He tried to assess the pay back period for the investment in cover crops, the conclusion was that farmers will generally lose money in the first year, break even in the second and arrive at a profitable situation in the third or fourth year. The take home message for me was that No-Till is only forty percent of the story, the other sixty percent is the cover cropping which encourages the dominance of fungi in the soil.

It is the fungi that work with the microbes, bacteria and protozoa to access nutrients for the plant. Only when these systems start to work efficiently can the fertiliser which is locked up in the soil become fully accessible and available. However, it is a catch 22, because by applying fertiliser the soil biology becomes lazy, so my conclusion, I would pull the plug on applying P and K straight away, however I have already purchased this year’s fertiliser, so I may split the P and K over two years.

Humus the organic matter which is responsible for holding and supplying the soil nutrients can only be built from dead rotting plants and animals. If farmed well in a mature no-till system, which is keeping the soil covered with cash and cover crops, then possibly 0.1% growth in organic matter, might be achieved each year, some farmers had exceeded this. All in all, I considered The National No-Till Conference to be well run, informative and hopefully value for money. The American farmers were hospitable and eager to communicate with me. I will definitely consider going another year.

The book reading for the trip was “Cows save the Planet”. I thought that it would provide me with a wealth of information to fight off vegans. Actually, it was more subtle than that, many things that the book described I already knew, and the book acted as a form of confirmation about what I had learnt from other books. However, there were some thought provoking chapters for a wannabe regenerative farmer, so I would recommend reading it

-

Water Focus – Thames Water

It’s only 4ha, what difference will it make?

Written by Matthew Izod of Priory Farm

Priory Farm

Priory Farm is a 100ha arable family run farm in the Evenlode catchment of the Cotswolds, with 100ha also being rented. The farm is run by my Dad, Nathan, who has been farming here since he was old enough to reach the pedals! I joined the farm in 2015, not knowing much about farming! We have a mixture of soil types from clay to Cotswold brash, which seems to give us a lot of different approaches to farming.

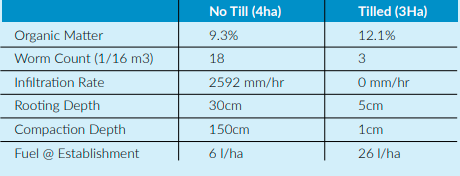

The Trial (as featured in Direct Driller issue 4)

Thames water are looking in to No Till drilling and cover crops to see if it can reduce sediment and phosphorus run off in to the water courses, whilst also looking at the wider soil benefits. The trial is part-funded by Thames Water to help remove some of the risk factors involved.

Following an initial taster event in February 2018, we expressed our interest, alongside two other farms, and were asked if we would like to take part in the trial. We decided on 4ha directly next to the river for No Till, with the remaining 3ha of the field being farmed in the same way we normally would. The cultivator was parked up from the spring of 2018 for that area of the farm and the trial began. A cover crop of oats was planted straight after harvest, which unfortunately never took off, not a great start to clear the doubt we already had in the system. 2018 was flood free so not much use for monitoring sediment run off, but a perfect start for us for the spring of 2019. Spring Barley was planted with a contractor’s Weaving Sabre Tine in to the 2018 spring barley volunteers. The other 3ha was cultivated twice with a pigtail cultivator a few weeks previous and drilled with the same drill on the same day. Both halves of the field emerged evenly and stayed very even up until harvest.

First Year – Soil Sampling & Harvest Results

We monitored the crop closely, wanting to see a difference in the two systems, but there was nothing in it until we started to sample the soil. The farm is periodically sampled for our P&K application, but we have never really paid much attention to any other results.

A Healthy Soils assessment was done to get some baseline figures for our first year. The results completely changed our way of thinking about the trial, I always thought the point of us cultivating was to minimise and get the crop off to a good start, which in this case it clearly hasn’t helped but created problems that we might not have had before we pulled a tine through the ground. It really showed how we need to do a bit more of an assessment of our soil before we start to try and alleviate problems that we think we have. When both sites were harvested, the tilled area 6.8t/ha & no tilled area 6.7 t/ha, the cultivations hadn’t effected the yield of the crop but equally the no till had performed just as well, but without a 20 l/ha cost of cultivation.

Second Year – Change of mind

A crop of Oil Seed Rape, companioned with buckwheat, crimson clover & vetch was planted on 5th September 2019 with the tilled side being no tilled OSR without companions, due to no time between combining and drilling. The crop grew well until, like the whole of the country, the rain came, and still hasn’t disappeared! We have experienced flooding at least six times this winter, so the crop hasn’t fared well and will be drilled with spring peas. This winter has really shown the resilience in some of the soils across the farm but also the area’s that need some improvement! Considering we have always cultivated to aid drainage, our no till site has coped very well and at times looked and walked much cleaner, often coming back with clean boots.

Soil movement has been minimal, only the last two floods have seen any noticeable erosion. We have also had some coppice bundles installed on the field’s edge by Earth Watch this summer to also see if this can help with catching sediment before it enters the river. We are always looking for new ways to help mitigate our effect on water courses; it often seems the simplest ideas are the most effective!

Future for Priory Farm

We have now started direct drilling some other parts of the farm now and are looking at reducing our cultivations, there is a lot to learn but joining the trial has really opened our eyes to different approaches to farming. Also taking part of the trial with Thames Water has opened many different opportunities to meet a lot of different people and have had some great conversations about new ways to approach conservation agriculture. I would recommend to any farmer to get involved in a trial or project with other farmers and likeminded individuals. It has really focused us to look to the future, across the whole farm, especially with the new agricultural bill and the bigger focus on the wider environment.

For more information about the Thames Water trial, please contact the Evenlode project team from Atkins and Natural England. Jay Neale, Atkins (jay.neale@atkinsglobal.com) or Andrew Russell, Natural England (andrew.russell@naturalengland.org. uk).

-

Farmer Focus – Tim Parton

Well, what a winter it has been, with the wettest February on record I can safely say it is the wettest season I have ever seen. My heart goes out to all the people who have been affected by the floods and those farmers who have had land under water for weeks on end.

On a positive note, it has been a pleasure here to see the soil infiltrate all this water and even after the heaviest of storms, the soil can still cope with more infiltration. In my mind, this goes to prove the more carbon sequestration we can achieve, the healthier the planet.

Carbon becomes a sponge within the soil holding more water for times of need, but also holding water back from our rivers. I firmly believe that our rivers are only in need of dredging due to the soil erosion from our fields. Low carbon and insubstantial soil structure, along with high bacterial soil levels mean there is little or no fungi to produce the glomalin glue which holds nutrients together. Thus, there is little in the soil to retain excess water in conventionally cultivated soils, resulting in soil erosion and nutrient loss from the soil into our rivers. This in turn culminates in dead zones from eutrophication across our oceans and seas. With conservation agriculture I am proving this doesn’t have to be the case.

Additionally, as a planet we need to clean up our act of polluting water because it is a finite resource, we cannot obtain any more and pollutant levels seem to be continually rising. There is even evidence to suggest that excreted pharmaceutical drugs (e.g., Prozac) entering the water course are having an adverse effect on plants’ growth, inhibiting their root production and inhibiting shoot development (“Plant Intelligence” by Stephen Harrod Buhner). This book has proved to be an interesting read revealing that plants produce serotonin (100 times more than any animal brain) which is essential for maintenance, physiological and morphogenic (form and structure) processes. These include light responses, root hair development, lateral root and shoot system development. When the plant is under stress, serotonin production in the plant tissues increase, resulting in alterations in root architecture – Aren’t plants amazing?

Now, I haven’t got all the answers of how to clean up our planet, but what I do believe is that healthy soils produce healthy nutritious food, which contributes to healthy people. Investment in soil health may be a wiser long-term investment for a healthier population and improved planetary environment. “Food Matters TV” (“FMTV”) is an informative site where food is used to prevent and cure all ills, without intervention from the medical world of pharmaceuticals. I believe that in the future, the consumer will be able to monitor nutrient dense food and will pay a premium for it. Dan Kitteridge is such a person already working on spectrometers to measure food nutrient densities. For nutrient dense food to be produced, soil needs to be healthy with welladjusted bacteria to fungi ratio and high carbon content.

As is also the case with plant production, I can stop most disease and pest problems by working with nature, with the use of nutrition and biology. From the coming year I am hoping to carry some wheat through to harvest with no herbicides apart from post drilling glyphosate. This will be a first for me. My soils keep improving, with less and less unwanted plant growth (“weeds”), since they are not needed because the soil is always covered with a cover crop. Farming with nature and not against it, as life is always easier when you work with nature.

With the help of my biological agronomist, Nick Woodyatt (Edaphos) we have come up with the programme this year which will eliminate the use of fungicides. As we proved last year it can be done. This gives me the confidence to rely on it more for the coming season. This will be alongside the correct nutrition as done correctly we have eliminated PGRS and strengthened the cell wall of the plant to protect against fungal attack. We found last year on the T3 spray on the untreated fusarium was 36% on the treated with Bacillus it was 2%. This is a double whammy: higher levels of control than we would have had with fungicides, but more importantly we are not carrying spores over into the following crop.

Without the use of fungicides straw is cycled far quicker in soil as fungi can do its job and break the lignin down within the straw. It becomes a far better product for soil health. Fungicides are very similar to insecticides; I am finding that once you use one you are then on the hamster wheel that you have to continue because you have stripped the leaf of its natural resistance, which then makes it more vulnerable to fertiliser scorch. Whereas using biology (bacillus) we are again working with nature and its own natural defences. Nature has all the answers; it’s just we thought we could do better. We are now learning that we cannot, and I firmly believe that this will be the century in farming known as the biological farming century. There is so much to learn and we are just on the tip in my opinion.

Oilseed rape companions of berseem clover and white are looking healthy, with the clover nodulating well. All winter crops will start off with a trace element blend in order to get the plant ready for its nitrogen application so that it can utilise it correctly. There has been a lot of talk in the press to get nitrogen on early. I cannot see the point if the plant has not got the tool kit within itself to utilise the nitrogen which then results in more pollution and carbon burning. Putting nitrogen on will result in a green looking crop, but in my experience, it will have poor rooting which will be devastating when we hit a dry period which is inevitable after all this rain (in my opinion). Also, with all that top growth a PGR will be a must, as the cell walls will be weak and open to fungal attack.

Birdlife on the farm continues to expand with the conservation agriculture policies implemented. Monitoring skills from the local bird ringing group (Belvide Bird Ringers) help to identify the variety in birdlife. Over 50 different bird species have been spotted or heard on the farm; 27 different bird species ringed; 4 of these species are on the British Trust of Ornithology amber endangered list and over 12 of these species are on the endangered red list. There were 85 breeding pairs of skylarks on the farm. Nest boxes around the farm had 90% occupancy of great tits and blue tits rearing clutches of between 8 – 10 chicks, which goes to prove the abundance of food found on the farm in order to sustain such large numbers. The bird group was aired on Radio 4’s Farming Today on Monday 9th March, if you get a chance to listed back to it.

I wish us all a favourable and productive Spring.

-

Drill Manufacturers In Focus…

MZURI, MAIZE AND MANAGING SOILS

Mzuri’s trial farm manager and knowledge exchange officer, Ben Knight highlights the benefits of the Mzuri system for establishing profitable Maize crops this Spring.

Through regular contact with Mzuri users around the country and conducting our own trials, I have seen first-hand how the Mzuri system can reap benefits for Maize establishment.

Under sowing and drilling into cover

By far the most relevant and up and coming aspect of successful Maize production that the Mzuri system is well placed to deliver surrounds under sowing or planting into cover. Many of our growers are achieving excellent results either through seeding Maize and grass down alternating legs of the Pro-Til or by drilling directly into already established grass leys or stubbles.

I wholeheartedly believe that growing Maize with some sort of continuous groundcover will become a mandatory regulation in the near future in a bid to protect our soils from the huge amounts of run off and erosion we so commonly associate with Maize. Not only that but a growing crop underfoot can mean the difference between a harvested crop in the clamp or not being able to get in the field with the harvester in the first place (let alone getting it out again) – a sight that was all too common last year. A grass based Maize system can provide businesses with additional grazing or another cut of silage from the grass crop, pre or post Maize. In a time where bottom lines are increasingly under pressure, this could provide a helpful alternative income for land that would previously be nothing more than a post-harvest mud bath, requiring extensive remedial action. The green cover will also mop up residual Nitrogen, making the most out of the applied products and returning it to the soil in a stable state.

I have no problem in advocating the use of dual cropping in a Maize situation and have seen first-hand how the network of roots stabilise the soil long after the Maize crop has senesced. When we’re being faced with huge amounts of rainfall, a growing cover can give us the protection we need to keep our soils in the field where they belong.

Band placed fertiliser for better phosphate uptake

With the popular dual tank Pro-Til models, growers can apply DAP or another product of their choice below the seed via the front leg at the time of drilling. It’s commonly known that Phosphate is very immobile in the soil, so by placing the fertiliser under the seed for the seminal root to access, the young crop benefits from guaranteed nutrient availability which is important for good plant development. I have seen this replicated numerous times across trials where Maize has been established with and without band placed fertiliser. It was clear throughout the life of the crop what positive effects early nutrition (or the lack of) had on factors such as cob maturity. By placing this fertiliser in a targeted band, it limits the availability of nutrients for weeds which helps to reduce competition and gives Maize the best possible start. It also has the added advantage of reducing the need for an additional pass which saves both time and money.

Accurate spacing, even around corners

There’s no doubt I’m a proponent for the Mzuri strip tillage system, but it’s when planting Maize that the Pro-Til’s independent pivoting coulters really come in to their own. By following the direction of travel of the drill, even around tight headland corners, seed is placed accurately into the centre of the tilled nursery zone. The level of uniformity across the field ensures row spacings and seed depth are consistent and coupled with the Xzact seed singulation units, plants are evenly spaced apart, maximising the light interception to be converted into yield.

As the founding fathers of strip tillage, North America have conducted many trials which highlighted the importance of seeding in the centre of the tilled zone. It’s been well noted that seeds placed outside or on the peripherals of the tilled strip don’t perform as well as those that are accurately drilled and go on to have a negative effect on the overall performance of the field.

Lock up carbon and protect our soil structure

I’m delighted that soil health and carbon sequestration are finally getting the mainstream ‘airtime’ that they deserve. It’s been long overdue but with discussion around the future of red diesel prices and the need for more sustainable farming there has never been a better time to look at the best way to utilise soil as our most precious asset.