If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Drill Manufacturers In Focus…

The last 12 months at Primewest have been interesting to say the least. We’ve seen Brexit come and go, new equipment, contracts and business partners and significant changes within the partnership with Cross Slot. We have a team of 3 permanent staff which is bolstered by additional support in engineering design and experienced farm labour as and when needed.

We have made the bold decision to buy a new Fendt 724 to replace a John Deere 6170 ensuring that we have the horsepower to continue to support our direct drill, the PW 4-19 using Cross Slot ® technology for the openers. Our Primewest direct drill continues to be a popular choice for contracting work having drilled around 1,500 acres as well as our own contract farming business, some of which has led to drill sales as well as the movement of second-hand machines. In the past 12 months, we have drilled a demonstration site for the Royal Agricultural College at Cirencester, hosted a visit from the Innovative Farmers Field Labs looking at cover crop destruction and living mulch and supporting Thames Water for soil sampling looking at how water flow and infiltration can be improved using a direct drilling system in the Glyme catchment area.

As well as new drill sales we have also helped several farms enter the no tillage world with second hand drills between 3m to 6m, all have been appraised and serviced by our experienced engineers, some have also been updated to use the latest Topcon technology after being in the country for 16 years and not needing any other work being done. We have worked closely with Cross Slot to bring down the prices in nearly every aspect of the drill and will continue to do so to provide a competitively priced product.

To go with the Cross Slot drill manufacturing and contract farming, we are also suppliers of CombeCut and Kvivk Finn. CombCuts unique technology you are able to fight weeds by combing in the lower part of the crop, selectively cutting the weed and letting the crop grow further Kvivk Finn the best cultivator in mechanical weed control, in an organic or minimal tillage situation. The cultivator is a combination of a cultivator and a pickup rotor. The special goose foot cuts off the roots, cultivates the soil and lifts he roots closer to the surface. The rotors specially des.igned spring pins grip the roots, shaking off the soil while the roots are thrown high into the air far behind the machine. The roots land on the field surface, far from the soil. On the field surface the weeds roots are exposed to the suns ultraviolet rays and wind, they dry up and lose their vitality. Come and see a demo machine working this spring.

The latest offering from our own design and engineering team are the PrimeFlo and the PrimeFill. PrimeFlo is a 1000 ltr liquid fertiliser system that can be either rear (sandwich tank) or front mounted and used on nearly every type of drill. Hydraulic pump and Topcon control system, variable speed and variable rate in the future. This can also be fitted with a granular tank and used on a drill or a cultivator to apply seed bed fertiliser or cover crop mix. PrimeFill. A 2000 ltr hopper that can be filled with a grain bucket and weigh the contents, using heavy duty 3000 kg load cells. With its 6 bag hooks underneath and easy slide door (hydraulic option) filling bags has never been so easy, or just carry it too the drill on the forklift and put it straight into your drill, knowing exactly how much you’ve put in and how much is left. Also optional static filling stand for filling bags in the yard and a close fitted cover to keep it all clean and dry.

As we are always looking at what’s new and different all over the world, and with this in mind, we are working to bring the Tractor Bumper from the Netherlands to the UK market. New tractors are getting bigger and can go faster. Speeds of 60-60 kph are not now unusual. Tractors are equipped with two headlights in the middle and there are 2 side lights linked to the width of the cab. The cab is smaller than the width of the tractor, so these lights don’t show the total width of the tractor or help with oncoming traffic. With TractorBumper it helps other road users to more easily see the maximum width of the tractor. In a frontal collision between a tractor and another road user, there is the risk that the vehicle goes underneath the tractor wheels because they are not shielded. The TractorBumper helps to protect this area, in front of the wheels and between them. When setting up the bumper 40cm from the ground it is the same bumper height as most cars.

We contract farm both conventionally and organically and have recently introduced sheep to the organic acreage in order to make better use of our clover leys and cover crops which is already allowing us to move away from the plough as the sheep can graze the fields to almost nothing. One of the challenges for this year is to try to reduce the amount of cultivations we undertake on the organic farm with our eye always on crop health and weed burden. We invite anyone interested to contact us to see our farming systems and the positive results that 16 years of no tillage can provide.

-

AHDB’S New Soil Management Guide Now In Print.

18 months ago, it came to our attention that a new revised soil management and cultivation guide was needed for the UK. The last comprehensive guide on soil structure was produced in 2001 by National Soil Resources Institute.

The remit was challenging.

• It had to work for all farmer and land managers, engaged in farming or not.

• It would independently cover all forms of soil management without bias towards one practice or another.

• It would include combinable and potato crop establishment

• It would feature a decision tree to highlight gaps in a management plan

• Would feature the best information available and be as up to date as possible

No mean feat. And in true AHDB style it could not favour any one approach and is designed to inform and enable the reader to make their own decisions; in short, we are not your mother! However, the guide does follow the theme of cost control, compaction avoidance and being open minded which inevitably lead towards more monitoring, reducing soil movement and a more systems-based approach. But also highlights the draw backs and potential pitfalls of your current system or the one you are thinking of moving towards. The decision guide rightly asks of your management capacity to change; if your family and/or staff are not behind you, buying a new drill isn’t going to help. And while we are taking drills, we have seen a new drill turn up that is so expensive that costs have not come down and yields have not gone up.

In the past the AHDB and HGCA have relied on agricultural science to produce Knowledge Exchange. The reason for this was that is was completely backed up by independent research and raw data was available for everyone to see. It countered any argument before it began. But this guide needed to be practical, readily digestible and based on farm scale experience. So, Philip Wright stepped up, along with Andy Newbold, Bill Basford and with Mark Stalham of NIAB-CUF casting his expert eye over the potatoes section. With these names in the bag it was a case of drawing the many information streams into one document of just 36 pages. Again, quite a challenge. But Philip set to work right away and soon and a working copy in circulation.

First things first, assess what you have, then what you can control. Unless you move you are stuck with your soil type, topography and rainfall, these three aspects will set the course. From there onwards is down to you. Your willingness to impose change on yourself, family and staff is an important next step. Change is interesting, exciting and necessary and the more open minded you can be the better.

Drainage systems in the UK are getting old, and maintenance often poor: a review of what’s needed is a good idea. The wet winter means it will be summer before work can begin, but autumn cover crops will provide a useful opportunity to repair or replace field drains. Search AHDB Drainage Guide to get more information.

The guide deals with crop residues and sets out the benefits of straw removal such as ease of entry for the next crop and generating some useful cash flow but also points out the risks of compaction caused by removal and in a catchy season the risk of late removal. If chopping, then attentions must turn to the combines capacity to spread residue to the full width of the cutter bar. Straw raking might be necessary, and the guide has some insights. Search AHDB Straw value for more information. Cover crops are in there. A short but honest assessment of what cover crops can do for you. Search AHDB Cover Crops for in-depth information.

In terms of your prime mover, notes include tyre or track choice, ballasting the tractor to pull an implement not pick it up, so consider trailed equipment over mounted. Taking advantage of modern tyre technology will pay dividends in improved fuel use and work rates while lowering soil pressure and could controlled traffic farming be incorporated? Combine/sprayer widths of 6/18, 8/24, 9/36 or 12/36 meters could be a no brainer soon if combine manufactures and cope with the loading auger/header width combinations.

While I know if you are reading this magazine you are already on-board with reduced soil movement or seriously thinking about it, throughout the guide, it suggests you probably don’t need to do as much to your soil as you are. In short, not as deep, not as intensive are paths to more costs saved and a reduction in horsepower requirements, weight and costs to the business. Is yield king? It does help, but not at any cost and from our understanding of benchmarking, there is a 20% chance of a profit from doing the same thing year in year out and relying on a good yield, or an 80% chance of a profit of being realistic about yield and managing costs effectively.

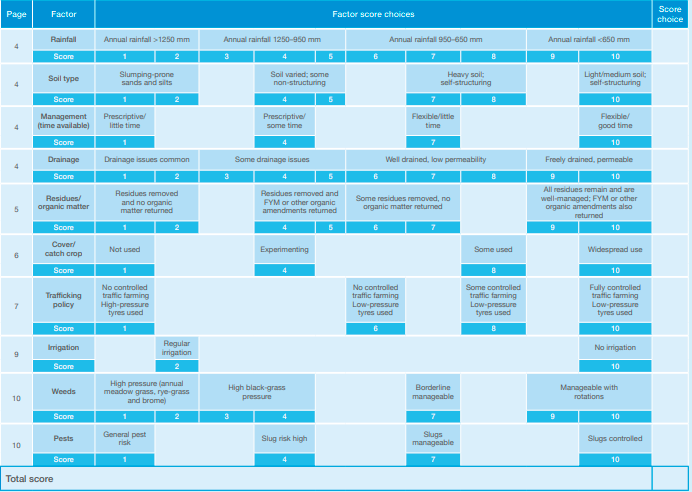

Back to the guide and one of the pages that took the most thought is the Establishment Approach assessment tool and I suggest giving it a try. The idea is you consider each of the 10 assessments with potential for 10 marks each and give yourselves marks out of 100. The top two you have little control over, but the rest are well within your control. The results should highlight where your strengths already lay and any gaps in your thinking. The follow on being to refer to the corresponding page number and review your options.

Of course, there is a section on direct drilling and no till drilling, and we have gone to pains to describe both so there’s less confusion out there. If you are mindful of moving towards reduced on no-till cultivation, then this guide is the first step. Not buying or being sold a new drill. We discuss all the benefits and pit falls of adopting no till, not to put you off but to get you through that period in 2 -3 years in when the excitement has gone, and the management is needed at this time more than ever. I’m also aware that those reading this magazine may perhaps consider this cultivations guide to be already out of date. But remember, the vast majority of UK farmers are using techniques found in all the pages within. What the future holds will remain to be seen.

To download a copy go to ahdb. org.uk/greatsoils or Google AHDB C u l t i v a t i o n s Guide or to receive a hard copy posted to you, either phone our publications line on; 0247 799 0069 or email; publications@ ahdb.org.uk

-

Farmer Focus – Steve Lear

The Jet stream has kicked our arse, but we are still smiling….

With little winter crop in the ground and spring still feeling like a long way off our attention has turned to the cattle. I’m glad we baled every last bit of straw in the summer as we are going to need it going into next year. What seemed like a huge quantity of bedding is fast depleting. We may have to resort to baling bean straw this year to keep us going through next winter. I had planned to graze the cover crops off with sheep. Unfortunately, we had to change our plan as I didn’t think the tender arable soils would take to much trampling this winter. It has left us with some great covers that are just coming into flower now. The very few sunny days that we have had have brought the pollinators out from their winter homes and have given them some early feed, as well as providing some grazing for the three species of deer that now call our farm home. The cover crops have also shown up beautifully the soil that we are doing a good job on and the soils that need improving.

The ex-oat land was meant to get drilled with winter wheat but again the weather has stopped our plans dead. We have a good covering in these fields of volunteer oats after some heavy wind just before harvest shook a fair amount out to the floor. I’m debating whether to keep these growing and forage them for the cattle just before the black grass sheds. Let see what April brings. I have started doing some research into alternative forage mixes. We have already moved over to using whole crop cereals from maize for the fattening cattle. The plan is to develop a multi species forage crop that will give the pre calving cows everything they need without having to add any protein afterwards. I think using multi species mixes should also help improve soil health and reduce chemical inputs.

At present our pre calving cows are fed a mixture of grass silage, straw and field beans to up the protein levels in the ration. I’m hoping to find a forage that can mean we don’t need to mix anything up. I think we will try some oats companioned with either peas or beans to increase the protein in the forage to start us off. I have just got to work out the percentages of each species to get us the ideal mix of nutrition for the cows. Growing this forage mix will also give us a good early opportunity to stitch a multi species cover crop in before winter drilling.

After such a wet autumn and winter with little in the ground its easy to get a bit down about things. When I look around the county, I see many fields that have had a crop mauled into them and are sat very wet with serious soil structural issues, nutrient leaching and run off. I’m glad we stopped drilling when we did. Even though we have little cash crop in the ground most of our fields have a good green cover on them, which is keeping the nutrients where they belong, stopping the soil from slumping, keeping the microbial communities alive and increasing organic matter. So there is still something to smile about.

We also haven’t spent any money cultivating land, which has been a waste of money for many farms across the country this winter. I’m hoping going into April we will be able to get on and drill our spring crops. I’ve seen a number of farmers saying in the press that they are going to fallow land if its not drilled by mid-march. It’s rare to see much spring cropping done on our clay soils before mid-march in a normal year let alone a wet one, and in any case, I need the straw.

I have purchased a second drill for this spring to help us out a bit. I’ve gone for a Simtech to give us a bit more flexibility. The Cross-slot is a fantastic drill but when the soils are wet the last thing you want is a 12ton drill travelling over them. I’m hoping the Simtech will give us a wider drilling window at the end of autumn and the beginning of spring. It will also be used to establish beans a little earlier than we could do previously as the Cross-slot is always busy on cereals. We were helped out with the purchase of the SimTeth through the ‘Small Farm Productivity Grant’. Its well worth getting if you are looking at new equipment and is very easy to apply for, hopefully it will be funded going forward.

A trip up to York for the BASE UK agm gave me the opportunity to listen to some fantastic speakers once again, from the history of wheat breeding to a great talk on mob grazing there was plenty to inspire a hungry mind. I came away from the conference this year thinking about how farmers should be aiming to sell food to consumers rather than commodities to big cooperation’s. Maybe in the future we could see more flour mills, butchery shops and veg stalls owned by small groups of farmers selling their unique produce to the great British public, wouldn’t that be something.

Keep smiling and remember even a bad day on a farm is better than a good day in an office.

-

Drill Manufacturers In Focus…

Laurent Vaucher farms in the Lorraine region of eastern France, near the city of Metz. He also works as a contractor using a Novag 4m. He has bought since 2019 a wider Novag 6m to replace his first acquisition.

“I started my conservation farming approach because I was noticing a drop in the organic matter content of my soils. Intensive soil tillage had removed life out of my soils. I was getting big erosion problems in my hilly fields and too many stones. The level of expenses for my 140 hectares, with fields at multiple location, was simply too high. So, I went against the common belief, in our area where most farmer heavily criticize no tillage for not being suited to our heavy, cold land. The traditional crops we have been growing so far were winter wheat, winter barley, oil seed rape and spring barley. However, for 2 years I have started to diversify and I am adding spring peas, sunflower, grain corn and soybeans.

At our place, the farmer’s population is getting older and we do not find enough younger, motivated people to carry on their work. As a result of this trend, I think that custom farming will develop very fast in the next few years. But, contrary to the existing offer on the contracting marker, I wanted to emphasize the soil health benefits they would gain by not working their soils. However, to be successful in this job and keep the trust of my customers, I needed to be able to achieve the best quality for seed placement in a wide range of conditions.

I was looking at the Novag drill for a couple of years already. I visited other farmers who had a Novag for a few years and was quite impressed by the precision of their management. The new 4m I bought in 2018 was the biggest purchase of my carrier. But I don’t think any other technology could have worked in our conditions, since we farm on some hilly area, have a mixture of quite heavy soils but sometimes light sandy soils as well. We also have grain maize in our rotation, and that leave quite a lot of residue on the field. I thought that even if the Novag was more expensive, the quality of the job was more important than saving a few on the drill. In my opinion, many if not all leading brands offer implements that are too expensive for what they deliver!

I pulled the Novag 4m with my beloved Magnum pro 7210 (I must confess: I am an IH admirer). It’s such a great tractor, but you had to slow down going uphill. My normal drilling speed was around 7km/h on flat area and went down to 4km/h on hills. The first spring crops we planted, especially spring barley and peas, looked particularly promising and the difference with the cultivated fields of my neighbour was amplified by very dry spring conditions. These first “visual” results really triggered a demand for contracting service beyond my expectations. All of a sudden, my neighbours became interested in directly drilled spring crops. Winter Barley sown in 2018 emerging not less than 6 weeks after seeding. A real miracle: everything was there, waiting for the rain.

In 2018, I covered 700 ha drilled as a contracting service + 150ha for my own farm, and I realized that I already had to gear up and invest in a more powerful tractor, to pull a wider drill. It was the only way to meet the increasing requests I was receiving for 2019.

I sold the 4m to a farmer in the Champagne region in the spring of 2019, and had the opportunity to trade it with a used 6m Novag. Choosing the tractor was more difficult. I really would have wanted a Kirovets 400HP but it was too hard to find in France. In the end I found a good second hand Quadtrac 500. That would definitively solve any pulling problem on the hills! Laurent’s QuadTrac & Novag 6m marked with the Lorraine’s cross, the logo for his contracting business. Last year, 2019, the spring was no different than 2018: very dry, and summer was even dryer.

The soil was really tough and since I wanted to start planting cereals before the autumn rains, the full weight of the drill was needed to put the seeds quite deep. When you’re not expecting rain for a while, good slot closure is essential.

In autumn, we had rain like unseen before. This led to difficult conditions, and delayed seeding. In too wet fields, I faced a few compaction issues in headlands. However, I was able to make a generally satisfying work despite the conditions. Tilled field around greatly suffered from the heavy rainfalls and actually look worse. This wet climate is nevertheless showing that my soils have already started improving. My fields are not flooded, and my soils are only going to get better, and more resilient to compaction.

Novag in England.

New service agent in Wiltshire

Laurence Vaucher says “Congratulations to the Webb family for becoming the first UK service agents”. Their farming and contracting business is in Lyneham, Wilts Service Agents from which they can serve the whole of the country. The extensive configuration on their new T-ForcePlus 440 allows for a wide range of jobs, including the seeding of no tilled Maize which will be tested this spring in their region. In these areas, they will offer Novag demonstrations to any farmer seeking to try out this seeding system for himself, and they can count on full support from the factory. Novag drills and parts are fully available in the UK and sold on a direct sale basis.

Groundswell preparation

Following last, successful, edition, Novag is again taking part in Groundswell and will disclose its newest drill model, the T-Force 450ct at the occasion of the no-till show. Make sure to book your tickets in advance! The new machine will stay for a while in the UK and will travel after Groundswell to the fields of our partner TWB farms.

-

Key Factor In Improving Soil Water Infiltration Rates

Written By Laura Barrera and first published on Agfuse.com

Many farmers across the U.S. experienced wet weather last growing season. According to NOAA, the 12-month period between July 2018 and June 2019 set the precipitation record in the U.S. with an average 37.86 inches per month — 7.9 inches above average. The result of all that rain had a negative impact on growers. The USDA says that more than 19.6 million acres were reported as prevented plant, with the RMA paying out roughly $4.26 billion in claims related to flooding and excess moisture. One way to help manage these high rainfall events is to improve soil water infiltration — the faster it can enter the soil, the less likely it will pond or run off the farm, taking valuable soil and nutrients with it.

But what are the best practices for increasing water infiltration rates? University of Nebraska-Lincoln (UNL) assistant professor of agronomy and horticulture Andrea Basche set out to find just that. Along with Marcia DeLonge, Union of Concerned Scientists’ research director and senior scientist of food and environment, Basche conducted a meta-analysis that analyzed the effects of no-till, cover crops, crop rotations, perennial plantings and cropland grazing on infiltration rates.

A meta-analysis, Basche explains, is a research approach to carefully combine results from many experiments to look for broader patterns. Their metaanalysis included 89 studies from six continents.

Top Practices: Perennials & Cover Crops

Basche and DeLonge’s research discovered the practice that improved water infiltration rates the most was having perennial crops, such as grasses or trees, incorporated into the cropland. They found experiments where perennial treatments were compared to annual crops improved infiltration rates by an average 59%. The experiments included three types of perennial systems: agroforestry, perennial grasses and managed forestry.

“Despite differences among and between the practices,” Basche and DeLonge say in the paper, “the perennial practices showed a consistent pattern in that growing perennial rather than annual plants led to improved infiltration rates.”

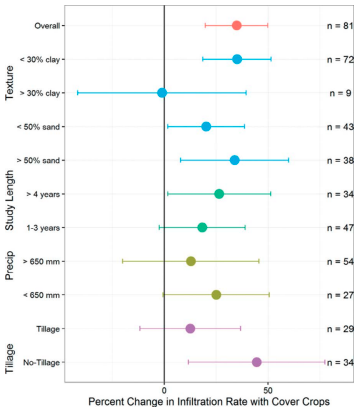

The second most influential practice was cover crops, which the meta-analysis found improved soil water infiltration by an average 35%. The longer the cover crops were used the better — studies where cover crop experiments were in place for more than 4 years had higher infiltration rates compared to experiments in place for 1-3 years (see chart below). Basche and DeLonge also noted there was evidence that cover crops had a greater impact on water infiltration rates in coarsely textured soils with higher sand content and less clay. And when combined with no-till, compared to no-till alone, cover crops significantly increased rates by an average 45%.

No-Till Not as Influential

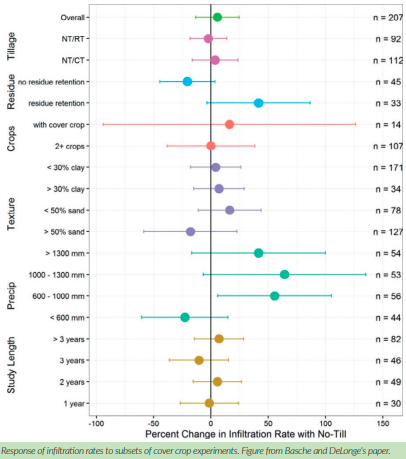

However, no-till on its own did not have as great an impact on water infiltration rates as might be expected. Data from 52 studies found no overall effect from no-till alone. There were only two situations where no-till improved water infiltration: in wetter environments and in studies where the data explicitly reported that residue was retained. Basche clarifies that this doesn’t mean the other studies were removing residues, just that only certain studies reported the data that way. Basche admits that no-till not improving water infiltration was the most surprising finding from the metaanalysis, considering other studies have shown a positive effect from no-till, as well as anecdotal evidence.

In fact, a meta-analysis study conducted by researchers from ICARIndian Agricultural Research Institute and the International Rice Research Institute found that no-till increased steady-state infiltration rates by 66%, and improved field capacity water content at surface and sub-surface layers by 6-16%.

So why did Basche and DeLonge’s meta-analysis find different results?

Basche believes part of it may be due to the way researchers reported their data, which she says is often a limitation in such studies. For example, some studies did not report different tillage treatments, while others may have reported infiltration rates for stacked practices (such as no-till plus cover crops), while their meta-analysis was looking to isolate practices. Another limitation may be in how researchers set up their studies, Basche says, noting that unlike farmers who will often make adjustments when they see something isn’t working, university researchers aim to keep everything the same so they can focus on a single factor.

The timing of the water infiltration measurements were taken may be another reason why no-till wasn’t as influential. Basche adds that it’s important to note that with an analysis like this, it can be hard to find general patterns about how much the environment, such as soil types, impacts the results. “You are limited by what studies are included in your database, which do not represent a full distribution of soils and environments,” she explains. “I think those types of results should be interpreted carefully.” Regardless of the meta-analysis results, Basche doesn’t want farmers to get hung up on the idea that no-till never increases infiltration.

“But when we looked at these different practices related to soil health, the most consistent and largest improvements came from those practices that had continuous roots in the soil,” she says. “It wasn’t just minimizing disturbance — it was the roots that had the biggest impact.”

Retain Residue

Since one of the instances where notill improved infiltration rates is where residue retention was reported, Basche says it’s fair to say that leaving residue may be what makes the difference in increasing water infiltration under no-till. Response of infiltration rates to subsets of no-till experiments. Figure from Basche and DeLonge’s paper. Results from other studies back up the importance of residue retention for water infiltration. A 6-year UNL study found that removing 60% of corn residue decreased water infiltration rates from 2.13 inches per hour to 1.43, and Sustainable Agriculture Research and Education (SARE) cites infiltration increasing up to 180% in field trials from soil surface coverage by residue alone.

Get More Roots Down More Often

Given the findings of the meta-analysis, Basche says that if growers want to improve water infiltration, their best bet is to consider ways they can increase the frequency and distribution of roots in the soil. While perennials proved to be the best option from the meta-analysis, Basche recognizes it may not be a suitable option for everyone. Which is why she says it’s more important to focus on the principle of increasing the frequency and distribution of living roots in the soil vs. the practice. “The two practices that offered continuous roots in the soil were the ones that led to the largest and most consistent improvements in infiltration,” she says. “Roots activate soil biology, improve soil structure, and potentially increase carbon. So it makes sense that they could be the start of the chemical, biological and physical changes in the soil that can increase water entering and being retained in the soil.

“If increasing water infiltration is a goal, then consider management strategies that can offer more roots in the soil more times of the year. How can you make it work on your farm?”

For many farmers, cover crops will likely be a suitable practice for achieving that goal. But deciding on the best species will depend on each farmer’s location and cropping system, Basche says, especially their annual precipitation. What works for a dryland farmer out west will probably not be the best fit for a farmer with a lot of rainfall in the Midwest.

The good news is that several cover crop species have shown to increase water infiltration rates. SARE says that a range of studies found non-legume species increased infiltration anywhere from 8-462%, while legumes increased infiltration between 39% and 528%. The SARE book, “Managing Cover Crops Profitably,” also recommends specific cover crop species that can help water infiltration rates, including:

• Annual ryegrass. The book says its dense but shallow root system enhances soil tilth and improves water infiltration and is an “excellent choice for building soil structure to enhance water infiltration, waterholding capacity or irrigation efficiency.”

• Barley, as it improves soil structure.

• Brassicas like forage radish, rapeseed and turnip. These species produce large taproots that can penetrate up to 6 feet, the book says, and as they decompose will leave channels open to increase water infiltration.

Track Changes for Improvement

If improving water infiltration rates is a goal for your farm, be sure to measure your current rate before implementing new practices and changes, so you can determine what’s working and what’s not. Check out no. 4 in the article “7 Ways to Measure Soil Health Improvements” (Issue 7 of Direct Driller Magazine) for a simple way to measure your infiltration rate.

-

Pesticides: How The Pressure On Conventional Chemistry Presents An Opportunity For Sustainable Alternatives

Written by Felicity Lenyk from Eden Research plc

The situation

The Food and Agriculture Organisation (“FAO”) estimates that 40% of global food crops are lost to plant pests annually, equating to a yearly financial loss of over $220billion. This stark statistic highlights the importance of further research into new ways to tackle these pests if we are to feed the world’s growing population in the future. Agriculture has never lacked significant challenges, but continuous regulatory scrutiny is having a major impact on the conventional pesticides market around the world. Crop protection products and programmes are under constant review and increasing pressure from regulators and consumers is driving a global movement towards more sustainable alternatives.

The loss of numerous crop protection products and chemistries has recently been publicised in the media. Sentiment around the removal of these products has been positive from a consumer standpoint and slightly more critical from a grower perspective as they have voiced concerns about the fact that the industry is left without viable alternatives. The current situation is that farmers are facing challenges from pests and disease, but with no approved chemical solutions.

This rapid loss of chemistry is driving increased innovation throughout the crop protection market. The biopesticide industry is developing rapidly, currently growing at a CAGR of 15% and estimated to be worth $10 billion by 2025.

Biopesticides are derived from natural materials such as animals, plants, bacteria, and certain minerals and are generally considered reduced risk pesticides. However, despite the fact that they generally have a more favourable environmental profile, they are still subjected to a rigorous registration process as they must meet all regulatory standards and not compromise efficacy. Conventional pesticide product discovery and development takes 10- 12 years and costs in the region of $300million. The process is faster for biopesticides, but the costs can reach $25million.

So, where does Eden Research fit in?

Eden Research plc is the UK’s only quoted company focused on biopesticides for sustainable agriculture. Eden develops and supplies innovative biopesticide products and natural microencapsulation technologies to the global crop protection market. The products are based upon natural plant chemistries but deliver performance on par with conventional chemistry and complement integrated pest management (IPM) programmes.

Terpene active ingredients

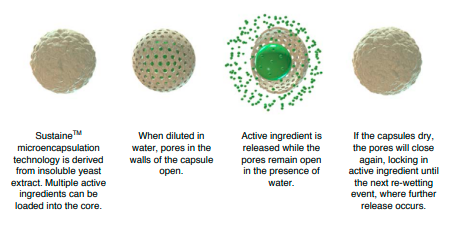

Plant terpenes are secondary metabolites and are one of evolution’s answers to natural plant defence mechanisms. Eden has registered three terpene active ingredients in the EU – geraniol, eugenol and thymol. This is no mean feat in a decade where it was more commonplace to see approvals being withdrawn. As volatile compounds found in essential oils, terpenes have been utilised as a means of crop protection for centuries. Until recently however, due to their volatility and hydrophobicity, there was no practical means of applying them successfully at scale in agriculture/ horticulture. Stable formulations rely on a means of encapsulation, and due to the use of Eden’s patented SustaineTM technology, high capacity loading of terpenes with a phased release mechanism is now achievable.

Terpenes are ubiquitous in the environment and are even found in many common foods. The terpene active ingredients in Eden’s formulations are Maximum Residue Limit (MRL) exempt and have no detectable residues, with pre-harvest intervals as low as 0-days for certain products. They have multisite modes of action against pests and therefore have no known risk of resistance, which is an increasing concern with many actives available on the market. Another key advantage of Eden’s formulated products is their lack of persistence in the environment which, combined with safety to beneficial insects, helps to protect the environment. A lack of accumulation of soil residues can help reduce the need for drilling, and products such as these works well with the development of field margins.

The innovative technology

Sustaine is a naturally-sourced, microplastic-free encapsulation system that is suitable for a wide range of active ingredients, including conventional chemical and biological actives. SustaineTM is the enabling core of Eden’s products and provides a biodegradable solution to microencapsulation that has been commercially proven. Stable capsule suspension formulations are possible with high loadings of active ingredients in aqueous, solvent-free formulations with excellent bio-activity and the potential to increase efficacy, protect against phytotoxicity and mix readily with a range of chemistries.

A key feature of these microcapsules is that the capsule wall is not eroded during the release process; the terpenes exit via pores, which open upon hydration and close again when the capsule experiences osmotic stress/ dehydration. In this way, the terpene active ingredients have a phased release pattern and prolong their activity across multiple rehydration/dehydration events. This controlled release can facilitate lower overall application rates of active ingredients as there is reduced risk of losses to the environment.

Solving the microplastics problem

The European Chemicals Agency (ECHA) has proposed an EU-wide restriction on the use of “intentionallyadded” microplastic particles. The proposed restriction includes the use of microplastics for agricultural and horticultural purposes, including polymers utilized for controlled-release fertilizers, encapsulated plant protection products (PPPs), seed coatings, and biocides.

By 2025 in the EU, pesticides containing synthetic polymer microplastics are likely to be banned and removed from the market to prevent their direct release into soil and water. The only acceptable alternative is the substitution with biodegradable formulations. Reformulated products will need to be evaluated and registered within the five-year transition period, and SustaineTM is a viable, proven and immediately registerable solution to the microplastics problem in formulations that benefit from encapsulation.

The ECHA Annex XV proposal for restrictions on intentionally added microplastics in agriculture/horticulture could mean up to:

• 200 reformulations of Plant Protection Products

• 50 reformulations of seed coatings

• 500 adaptations of seed coatings

The proposed microplastics restrictions for capsule suspension plant protection products (CSPs) and coated seeds could result in a total reduction of 15,000 tonnes microplastic pollution across the EU over the next 20 years. Eden is actively working with a growing number of partners to develop new, plastic-free formulations for their active ingredients including conventional chemistry as well as biologicals.

Eden’s current portfolio of biopesticides

To date, two commercial products using the terpene active ingredients and SustaineTM technology are approved – MevaloneTM is a bio-fungicide used primarily to tackle botrytis on grapes and CedrozTM is a bio-nematicide used across a wide range of vegetable crops. The main markets for these products are in southern Europe (approval is currently being sought in the UK). Both products benefit from being MRL exempt and having favourable environmental profiles compared to many conventional products. For example, drawbacks with a number of conventional nematicides include harm to the environment, difficulty of application, and long re-entry periods, which has led to various examples being withdrawn from the market over the years. CedrozTM is a water based alternative, applied with existing irrigation equipment and a proven solution to complement existing programmes.

Adding to the existing portfolio, Eden intends to launch new products in important new segments of the crop protection market, including insecticides and seed treatments. Mevalone has already received emergency use approval in France for post-harvest storage diseases in apples, which is another major new use and another step towards high quality, residue free food produce.

Reaching organic status

The organic market is growing considerably and between 2012 and 2017 the area under organic production in the EU increased by 25% to reach 12.6million hectares. Eden’s terpene active ingredients (thymol, eugenol and geraniol) have organic approval in the EU, providing growers with an alternative solution to use as part of IPM.

The current regulatory landscape

Government resources and regulatory bodies are under-resourced, which urgently needs addressing. The good news however, is that regulators are addressing the fact that biopesticides are distinct from conventional chemistry and must be assessed differently. Crop protection requirements are increasingly focussed on a need for sustainable chemistry, and going forward this trend is unlikely to change. Sustainable alternatives have the ability to impact the environment, as well as growers and manufacturers/distributors in the following ways:

• The environment: Products which are efficacious and provide reliable control of pests or pathogens to enable improved yields and crop quality must also have minimal impact on the environment. The challenge going forward is to maximise yields for a growing population, whilst reducing any negative impacts on wildlife or human health.

• Growers: Products are required that are easily incorporated into existing programmes, with current equipment. Easy to use and apply, with improved safety profiles for users, they also need to be based on active ingredients that have low risk of developing resistance.

• Ma n u fa c t u re rs /d i s t r i b u t o rs : Formulations suitable for commercial production and with broader storage conditions than many biologicals are required to enable efficient production and distribution at scale.

Outlook

The requirement for alternative solutions to challenges in crop protection will increase as regulatory pressure increases. Eden is confident that it is well placed in the market to deliver solutions going forward which are efficacious, residue exempt and polymer free, ultimately delivering products which instil confidence in regulators, growers and consumers alike.

-

Drill Manufacturers In Focus…

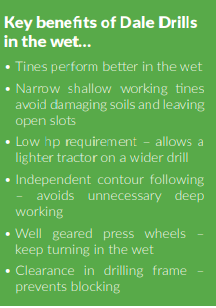

DALE DRILLS – VERSATILITY PROVIDES SUPERB SPRING ESTABLISHMENT

Established in 1999, Dale Drills have a wealth of experience when it comes to reduced and No Till establishment of spring crops. Directors Tom and James Dale use their range of drills and low disturbance cultivators on their own 3200ac arable enterprise which incorporates a variety of different soil types.

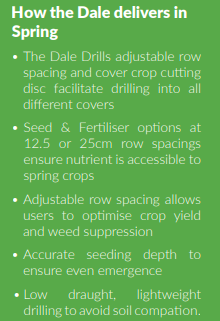

Spring drilling brings with it a number of different challenges, but Dale Drills believe their machine has the versatility to offer the solution.

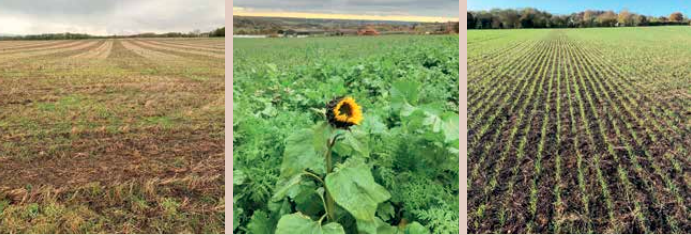

Configure for Covers

Biomass in the form of previous crop residues and cover crops, offer a wide range of benefits from acting as a mulch to increasing the soils organic matter content. The Dale Drills Eco range of No Till drills have been designed to cope with high levels of residue and is versatile enough to deal with both brown residues (such as chopped straw and stubble) and green residues (such as cover crops). The company advocates the use of tines – the Eco Drills standard setup, for drilling into brown residues as the straw will tend to ‘flow’ around the tines, whilst the tines work in clean soil under the residue. An added advantage is that the residue tends to be ‘combed’ into the areas between the drilled rows acting as a mulch against weeds.

When drilling into green covers size starts to matter. If covers are under 12” then chances are the drill will cope in the standard configuration with 2 tines fitted. If taller green covers are apparent the company offers a retrofit Cover Crop Cutting Disc Kit which bolts on to each drilling assembly. The disc cuts a path through the green residue, allowing the tine following to clean out any hair pinned material left by the disc and place the seed.

Focus Feeding Where it Counts

Dale Drills have offered drills capable of placing fertiliser alongside the seed since its inception. This technique is particularly effective with regards to Spring cropping as the reduced growing season and typically drier conditions will limit a spring crops ability to develop a rooting system capable of exploiting broadcast nutrient. The Eco range of drills can be specified to place fertiliser alongside seed at 25cm row spacing, and a recently developed option now allows customers to specify drills which can place seed and fertiliser at 12.5cm row spacings.

Match Row Spacing with Crop Type The Eco range of drills come with variable row spacing from 12.5 – 25cm as standard, and 50cm spacing as an optional extra. This versatility within the drill allows farmers to drill different crops at their optimum spacing maximising yield potential. For example spring barley can be sown at 12.5cm row spacing to ensure maximum coverage and if lodging occurs avoid excessive head losses, as can be the case where wider row spacings are used. Row spacing should also be matched to weed pressure. Crops drilled at narrower row spacings will be better able to compete against weeds.

Dale Drilling Depth Accuracy

With the shorter growing season, spring crops require the best get away possible. Dale Drills independent drilling assembly contour following, offers excellent depth control across the width of the drill. Placing every seed at an even and accurate depth, even on rough ground, ensures uniform emergence, improving management of the crop throughout its growth cycle.

Low Draught, Lightweight

The 12mm wide tungsten tipped tines used by Dale Drills reduce the horsepower required to pull the drills. Typically 25hp/m is sufficient to pull a Dale Eco-Drill. This is particularly useful in spring as a comparatively smaller and lighter tractor can be used to pull a drill avoiding creating compaction issues. Alternatively a wider working width of drill could be used on a typical drilling tractor reducing the overall trafficked area, preventing excessive soil compaction. As all Dale Drills use forward facing tine openers, they are more efficient at penetrating the ground than disc openers and so are typically up to 50% lighter than equivalent disc drills. This combined with smaller drilling tractors provide a lightweight footprint.

Meir SC – Low Disturbance Soil Conditioner

Dale Drills sister company, Meir Agriculture, has been established to provide a range of cultivators designed to fit within a Conversation Agriculture system. The Meir Soil Conditioner (SC) is designed to effectively relieve compaction down to approx. 12” without excessive soil disturbance at the surface. The Meir SC is now available with an optional small seed applicator. In this configuration the Meir can be used to establish OSR or cover crops. Initial trials have shown the use of low disturbance tillage combined with cover crops has given yield benefits to following spring crops.

-

Field Lab: Organic Wheat Varieties – Part 1

Authors: Dominic Amos [Researcher] Jerry Alford [Coordinator]

Introduction

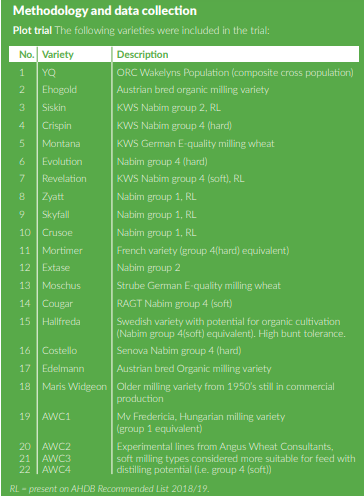

The field lab is focussed on investigating winter wheat variety performance using a single replicated plot trial on an organic farm and larger scale strips in farmers’ fields. The plot trial acts as a reference for comparison of a large number of varieties representing a broad range of genotypes from conventional and organic breeding and from modern and heritage lines. The key point has always been that varieties used in organic farming should be tested and evaluated under organic conditions, providing organic farmers with relevant performance data.

The group consists of organic farmers based in and around the Cotswolds who are interested in comparing varieties and assessing their performance under organic conditions to help make decisions about onfarm varietal choice. This field lab started in 2017/18 with a single plot trial, developing in the second year (2018/19) to a plot trial and farm trials, reported here. The field lab will continue into at third year (2019/20) with the plot trial and further farm trials in a more integrated network as a trial platform for organic variety testing.

Field lab aims

The aim of this field lab is to investigate and compare different wheat varieties and their suitability for organic farming by providing a platform for organic farmers to reasonably compare and evaluate a large number of varieties grown in an environment relevant to them. Specifically, the lab will assess various crop traits of different genotypes (varieties) to explore and understand crop performance and agronomic characteristics for organic farming. The trial will provide information on crop performance to help inform farmers’ decisions on varietal selection.

The lab also aims to contribute to the initiation of a coordinated variety testing platform for organic wheat (with potential extensions to other species) with testing at both plot scale and on-farm at field scale.

Background

Despite the increasing concern about the limited relevance of recommended lists (RL) originating from conventionally managed trials, there is no established central platform for variety trials under organic conditions. There is also concern that organic winter wheat does not consistently meet quantitative and qualitative expectations. Having been bred in, and for, conventional high input farming, non-adapted varieties are probably one of the main drivers of organic wheat under-performance (Murphy et al. 2007). It has also been demonstrated that breeding programs focusing on cultivar evaluation in highinput environments do not result in the selection of cultivars suited to low-input environments (Loyce et al. 2008).

The only recent publicly available varietal information is from conventional trials using full fertiliser and herbicide inputs with the untreated fungicide results the only indication of organic suitability. Organic farmers need better, more reliable information on varietal performance under organic husbandry and therefore need testing to take place under these conditions for the information to be of most relevance.

Plot trials remain the most reliable and simplest way of comparing a large number of varieties in a robust replicated design. However, there is also evidence that under organic conditions the increased e n v i r o n m e n t a l variation means that the most relevant information on yield and quality performance will come from field scale, commercial production on farm. Therefore, the plot trial must be used in conjunction with farm field scale trials (Kravchencko et al. 2016). Testing a restricted number of varieties at a field scale with a network of farmers, allowing for the effects of farm management, whilst maintaining a reference plot trial is a robust method from which to draw conclusions about varietal performance in organic systems.

Samplings and assessments

• Pre-trial soil texture, chemical analysis (N P K Mg pH) and Organic Matter A representative soil sample was collected from the trial area at drilling.

• Crop establishment – visual assessment to detect any differences in germination and early crop vigour. A simple visual assessment took place for each plot to determine crop establishment and make varietal comparisons if differences evident.

• Growth cycle length – crop phenological stage in correspondence of stem extension and late flowering/milk stage The growth stage of each variety was assessed using the BBCH scale at two site visits at stem extension (BBCH 31) and around milk stage (BBC75) to determine earlier or later varieties.

• Crop canopy height – on a plot basis, in correspondence of stem extension and flowering. The canopy height was measured using a ruler to give a representative canopy height across the plot.

• Crop and Weed cover – on a plot basis, at stem extension and flowering A simple visual assessment of crop and weed ground cover % was taken at these key times.

• Relative Crop Biomass – on a plot basis, at stem extension. A simple visual assessment of crop biomass relative to the highest biomass variety (Maris Widgeon) set to 100%. i.e. a variety with half the biomass of Maris W would score 50%, and variety with 3/4 the biomass would score 75%.

• Crop Growth Habit – on a plot basis at stem extension. A simple 1 to 5 scale from prostrate to erect to give an idea of crop morphology and canopy structure at this timing.

• Disease severity – on a plot basis. Identification of main foliar diseases and estimated average percentage cover of flag leaf and 2nd leaf in correspondence of BBCH GS 65

A simple percentage leaf area showing symptoms for the two leaves described was performed

• Ear density – count of fertile tillers on two randomly selected quadrats in each plot Counts of ears in a 0.25m2 quadrat to provide an estimate of ear numbers per meter squared.

• Farmer voting – Farmers vote on favourite variety according to observed crop traits in the field. Farmers voting for favourite varieties based on observed crop traits, beneficial for crop production on their farms. Voting to be held around stem extension and late flowering.

• Grain yield – plot combine harvest of each plot at maturity, with grain weight adjusted at 15% moisture and converted to t/ha. Each plot harvested to provide a t/ha grain yield and a moisture content to allow standardisation to 15% moisture.

• Grain quality – protein content and specific weight (hectolitre weight, HLW), and Hagberg Falling Number (HFN) measured in a lab by AWC Ltd.

Samples collected at harvest and analysed for each variety on a single bulked sample made up from all three plots.

3.2 Farm field scale trials

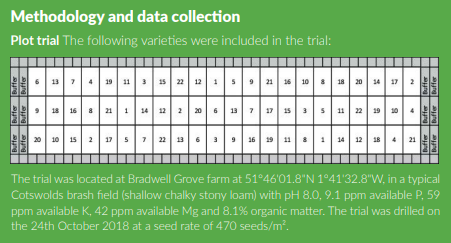

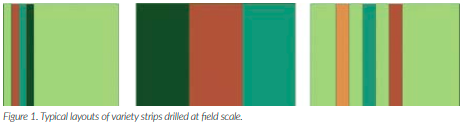

In addition to the plot trials three farmers selected three varieties (the farm variety that they commonly grow and two additional new varieties) to test at a field scale using commercial farm equipment. The varieties were drilled side by side in the same field as large strips of equal size. These strips were harvested and combine yield data provided by the farmers. Grain samples were sent for quality testing of protein, HLW and HFN. This testing provided each farmer with a direct and reliable comparison of varieties under their own farm conditions to compliment and compare with the plot trial results.

Examples of how the farmers laid out their variety strips in the field are illustrated below. The farmers drilled and harvested the strips and managed the varieties according to their own best farm practice:

3.3 Data analysis

The trial was designed as a randomised complete block, with 22 “treatments” and three replicates.. Data was analysed by a linear model to highlight effect of variety over any response variable. Validity of the model was checked graphically observing the diagnostic plot of residuals (quantilequantile plot). Pairwise comparisons between varieties was carried out through the Tukey’s HSD test. To visualise relationships between the tested variables, principal component analysis (PCA) was run in two steps. First, an interim PCA was run with all the variables included, and the quality of representation (Cos2) of each variable was checked. Second, a definitive PCA was run with those variables with a quality of representation higher than 0.5. The package ‘emmeans’ was used to calculate estimated marginal means. All analyses were done by R version 3.6.1.

Results to be reported in Issue 10 of Direct Driller Magazine

-

What Do You Read?

If you are like us, then you don’t know where to start when it comes to other reading apart from farming magazines. However, there is so much information out there that can help us understand our businesses, farm better and understand the position of nonfarmers. Below is a book you might find interesting, challenge the way you currently think and help you farm better.

The Future We Choose: Surviving the Climate Crisis

We can survive the climate crisis. This book shows us how. We have two choices for our future, which is still unwritten. It will be shaped by who we choose to be right now. So, how can we change the story of the world?

The Future We Choose is a passionate call to arms from former UN Executive Secretary for Climate Change, Christiana Figueres, and Tom Rivett-Carnac, senior political strategist for the Paris Agreement. We are still able to stave off the worst and manage the long-term effects of climate change, but we have to act now. We know what we need to do, and we have everything we need to do it.

Practical, optimistic and empowering, The Future We Choose is a book for every generation, for all of us who feel powerless in the face of the climate crisis.

This is the final hour: it can be our finest.

But we must act now.

-

Drill Manufacturers In Focus…

EVERYONE SHOULD HAVE THE OPPORTUNITY TO DIRECT DRILL

Despite the weather, direct drilled crops on the whole look well Certainly next doors conventionally worked and drilled field (inset) doesn’t look any different to Ma/Ag direct drilled the same day with double the horsepower per metre!!!

We just now need a bit of warmth to get things moving

In order to widen the appeal of the Ma/Ag drill and offer a much more price competitive units for smaller farmers and contactors wishing to start down the direct route, we have launched ready for Spring (when it arrives !!!) a 3 metre mounted version of the Ma/ Ag drill. Utilising the same fully floating coulter unit with its twin disc design, including scalloped straight disc and angled plain disc with a rear rubber press wheel.

If you want to carry tools, fuel or perhaps some cover crop seed, maybe you should treat yourselves to a WorkBox ideal for anyone who needs to have a workshop in the field?

The lid is waterproof and dust proof so every angle is covered, although dust seems a way off at the moment !

More details on drills or Workboxes contact Ryetec on 01944 728186

-

Featured Farmer John Pawsey

Farmer – Shimpling Park Farm

The Farm

Our crops are all grown for specific markets. We grow organic wheat, barley and beans for British Quality Pigs’s organic herd, which are sold in Waitrose under the Duchy Original brand. Organic oats are produced for White Oats, organic spelt for Sharpham Park and organic quinoa for the British Quinoa Company. We never put a crop in the ground without securing a market for it. We also have 500 New Zealand Romney sheep which graze our two year grass and clover leys which are either sold locally or through the Organic Livestock Marketing Co-Operative. We also mill some of our own flour which is sold to local bakers.

We are in a Countryside Stewardship Scheme which runs until 2023 with the main focus being on landscape restoration, farmland birds and education. So far we have restored various farm ponds as well as two medieval moated sites, replanted hedges which had been formerly removed, coppiced ancient woodland and restored some of the medieval wood pasture in Shimpling Park. We do in excess of 25 school visits very year and well as evening walks for various interest groups.

Every year we plant 40 hectares of pollen and nectar mixes for pollinators and 10 hectares of wild bird seed mixtures.

We conduct regular bird surveys with the last survey concluding, “The 17 year history of organic management at Shimpling Park appears to favour and encourage a stronger farmland bird community or at the very least may have prevented the declines experienced in areas dominated by intensive management”. The reversal of our declining arable bird species on the farm is something that we are particularly proud of.

We have a photovoltaic array on our grain store roof which offsets the electricity used by our electric grain drying fans. We also have two woodchip boilers which are fed entirely from the wood coppice from our ancient woodland which is in the middle of the farm. We also rent out a number of buildings to local businesses on a former USAF airfield at Lavenham.

Sustainability In Practice:

Over the last 2 years we have developed a Controlled Traffic Farming (CTF) system on our fields with the aim of reducing tractor wheelings and therefore compaction on our soils. My inspiration came from Tim Chamen from CTF Europe Ltd. More can be found out about CTF on their website.

Essentially CTF means tractors run on the same track every time they enter a field treating the untracked part of the field like a bed never to be run on. This has obvious consequences of less compaction, better plant root development and optimum yield. For us it is early days, but already we are seeing the benefits of more even crop growth, consistent and deeper rooting structures, better water infiltration and more earth worms.

The main challenge was coming up with the track width which would be future proof. In the end we decided on an 8.8m system and at the time of writing all our field implements fit into that track width apart from our combine harvester but hopefully that will be concluded by harvest 2017.

Motivations:

My family have been farmers in Suffolk for four generations and before that in Ayrshire and so there was considerable pressure on me to take on the family business!

I came to the farm in 1985 and it was typical example of post-WW2 agriculture. Many of the hedgerows had been removed to make the fields easier to farm with larger machinery as well as making way for an American bomber base. Cropping revolved around wheat, oil seed rape and sugar beet and was stockless with the dairy herd going in the 1960’s and pigs going in the 1970’s. In the mid 1990’s I began to notice some of our better soils yielding less and some of them slumping. I also became increasingly concerned about the amount of chemicals we were using and I began to worry about their long term impact on my soils and wildlife.

A near neighbour of mine was farming organically and I spent some time with him working how a stockless organic rotation could run on our farm. In 1999 I converted 120 hectares and ran a six year rotation comprising of a 2 year ley followed by winter wheat, triticale, winter beans and then spring barley under sown with another ley. Not only did the rotation do slightly better financially than the rest of the farm I also found it to be a much more creative way to farm as well as a release from a high input system with costs I could increasingly not control. In 2007 we converted the rest of the farm to organic production as well as other local farms we were farming for neighbours under contract farming arrangements. Our organic contract farming operation has expanded by 30% over the last 18 months with us now farming a further 650 hectares for local farmers all within a 7 mile radius of our own farm.

Although farming a stockless arable rotation has been very successful my heart told me that we should reintroduce livestock to try and close the nutrient gap which we had been filling by importing manures and green waste. In 2014 we bought 250 New Zealand Romney ewe lambs with a further 250 following them in 2015. We have now closed the flock and intend to build it to 1,000 breeding ewes which will then be able to make best use of our 2 year leys. The flock all lamb outside and are pasture fed apart from the occasional winter supplement of haylage and oats all of which are grown on the farm.

My aims are to leave the farm’s soil in a better condition than I received it, increase biodiversity and make a profit!

When I converted the farm to organic production in 1999 I did a soil organic matter (SOM) test pre-conversion which gave us a 2.9% SOM result. This year we had tests averaging 5.5% SOM.

Visit www.agricology.co.uk to view other blogs, videos, podcasts, research projects and resources on growing and managing cover crops. Agricology is an independent collaboration of over 20 of the UKs leading farming organisations and provides a platform for farmers and researchers to share knowledge and experience on agroecological farming practices; online and in the field.

Subscribe to the newsletter or follow on social media @ agricology to share your questions and experiences with the Agricology community.

-

Can Mechanical Weeding Offer Reliable Weed Control Solutions?

Written by Dr Nicola Cannon, Associate Professor of Agriculture

Introduction

Herbicide resistance has become a major challenge to UK arable production and is forcing farms to rethink cropping choices and in some cases is even leading to fallowing instead of cropping to try and regain control of challenging weeds. The problem of herbicide resistance has been exasperated in recent years by narrow crop rotations, withdrawal of previously approved herbicides and a period of earlier drilling dates to try and maximise crop yield. A study by ADAS published in 2019 found that the majority of farmers view herbicides as the key method for weed control in cropping systems and that these products are often being applied in a reactive manner when weed germination is observed. There has been a shift to using herbicides in a more proactive manner but even when pre-emergence herbicides are applied there is often a requirement for some later weed control in the growing season.

Initial weed control options

The first step to regaining weed control without relying on herbicides is to develop a diverse crop rotation which allows for different sowing dates and the inclusion of crops which can be more competitive against weeds. The grower should have an understanding of the weed seed bank and therefore the weeds which are anticipated to grow in the selected crops. A detailed understanding needs to be gained of the germination periods, weed competitiveness, growth habit, flowering dates and periods of seed set and seed shedding. Varieties can selected which are known to be better at competing against weeds and then be planted to avoid the weed germination period of the key weed challenges.

The crop must be able to grow and thrive to outcompete weeds and therefore it is important to manage other obstacles to crop growth during the cropping season including the impact of soil compaction, crop diseases and pest damage. Once all of these factors have been evaluated and managed then other forms of weed control can be considered to help improve weed control.

Non-chemical weed control

Currently the main options for non-chemical weed control in a crop rely on mechanical weed control. However, improvements in precision applications may transform weed control techniques and allow improved weed species detection within the crop and enable plants to be removed by robots using techniques such as lasers, microwaves or air blasts. Currently in field scale agriculture there are three main choices of systems that can be adopted to mechanically control weeds.

General rules of mechanical weeding

The success of all mechanical weeding systems is determined by weather, with the best results being achieved in warm, windy and dry conditions which help the weed to die rapidly after the weeding pass. If these conditions are not met, the weeds can often simply become transplanted further along the row. However, if conditions are really dry, the weeding process can cause stress on the growing crop.

The action of passing a weeder through the soil results in some nitrogen mineralisation which has been estimated to generally be between 10-35kg/N/ha. This can be a useful nutrient boost to the growing crop in the spring, especially in organic management systems where nitrogen can be limiting at that time of year. But, the very process that leads to the nitrogen mineralisation also results in the death and disturbance of soil organisms and the oxidisation of soils results in loss of soil carbon.

Broad spectrum mechanical weed control

Tine weeders are available for agricultural use from 6m to 24m wide machines. Generally they are highly adjustable machines which allow for a range of tine widths and angles and this determines how aggressively the tines are pulled through the crop. Working speeds are relatively fast at about 10kph allowing for fast coverage of cropped area and potentially allow for several weeding passes in the same growing season.

The timing of weeding operations is really important and the final tine weeding must be completed before growth stage 31 in cereals or before stem extension in broadleaf crops to avoid unnecessary damage to the developing crop. It is important to get into a growing winter crop early in the New Year as weeds tend to grow very fast with lengthening days and increasing soil temperatures. There is always a compromise to be made between the weeding time and the risk of further weed emergence but big weeds are far harder to mechanically remove as there are far more resilient.

Tine weeders tend to be used in the same direction as the crop rows as running at an angle or across the rows would cause greater stress on the growing crop.

Inter-row weed control

This is an area where a great deal can be learnt from the horticultural sector which has a longer history of weeding between crop rows. Machines such as the Garford Robocrop have camera row guidance systems to enable more accurate and faster work rates thereby avoiding crop damage. Guidance systems on inter row hoes rely on being able to clearly recognise individual crop rows and therefore require row spaces of at least 20cm to define the rows. These systems also tend to work better when the drill width is matched to the inter row hoe width so any curves within the drilled rows is the same across the working width of the machine. It also helps to drill using GPS to keep rows straighter to aid the camera keep to the straight rows. Another really important factor is that there has to be more crop in rows than weed for these camera guidance systems to function successfully. Using camera guided inter row hoes in the weed scenario above would cause great challenges due to the narrow row spacing and the high weed population.

Other mechanical weed control options

Machines such as the CombCut or Weed Surfer work above the crop canopy and only cut weeds that are taller than the crop. Many weeds do not have a great enough height deferential to be effectively managed by this method. For those weeds which do grow taller than the crop, this height difference often does not occur until later in the growing seasons when weeds may have already caused some competition for light, water and nutrients with the crops. However, these machines can be a useful tool in preventing weed seed return and thereby help prevent greater weed challenges in subsequent crops.

These machines do not remove the weeds from the site and therefore they are most effective either prior to or during early flowering to prevent viable seed set. These systems do not uproot or fully remove the weed and are often used alongside other weeding techniques.

How many passes?

This is always a difficult question to answer as a mechanical weeding process can stimulate further weed germination and therefore increase weed burdens. Generally the important issue is to control the weeds before they become too big and this can involve making passes earlier in the growing season to avoid weeds becoming challengingly big. Early passes can be difficult to conduct in winter crops due to wet field conditions but can potentially be conducted when there has been a light frost to enable the field to travel.

The cost of mechanical weed control

Contractor prices for mechanical weed control are not clearly determined and in many areas there is still a lack of availability. As with many contractors’ prices, the actual price is defined by the amount of opportunities available in the area for mechanical weeding but also on the amount of hectares to be weeded.

Mechanical weeding Approx. contractor technique costs (£/ha)

Tine weeder 22

Inter row camera guided weeding 45

Above canopy weed removal 30

Mechanical weeding results

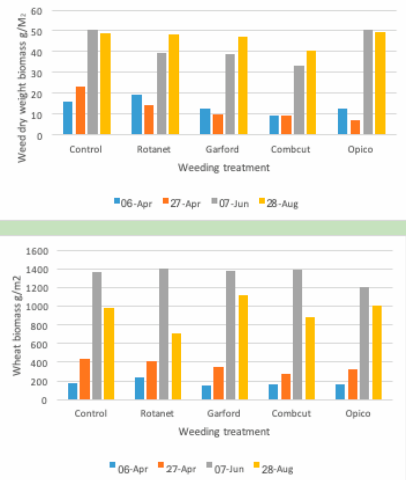

Trials conducted on the Royal Agricultural University’s farms in 2017 growing season showed relatively poor control of weeds through mechanical weeding. But, it has to be noted that this year suffered a very severe spring drought which really impacted crop growth over all the farm. Weed populations really developed when the rain eventually arrived in mid-May.

These trials were conducted under organic farming conditions, so no herbicides were used to assist in weed control and the crop was a second winter wheat which with a very high weed seed bank. Neither weed biomass or wheat yield were influenced by the weeding treatments due to the large variability in weed populations over the large plots sizes.

Conclusions

Mechanical weeding can reduce weed biomass but weeds can recover and mechanical weeding will only work if used in conjunction with other agronomy techniques to reduce weed populations.

-

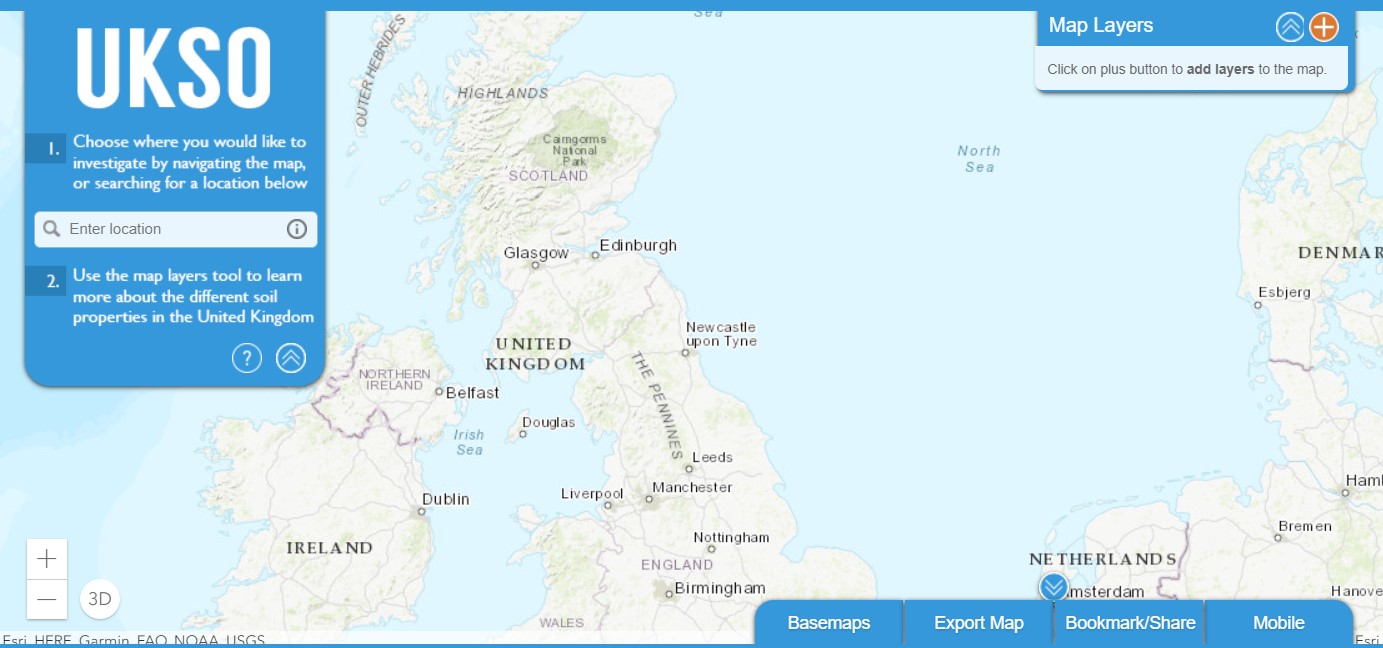

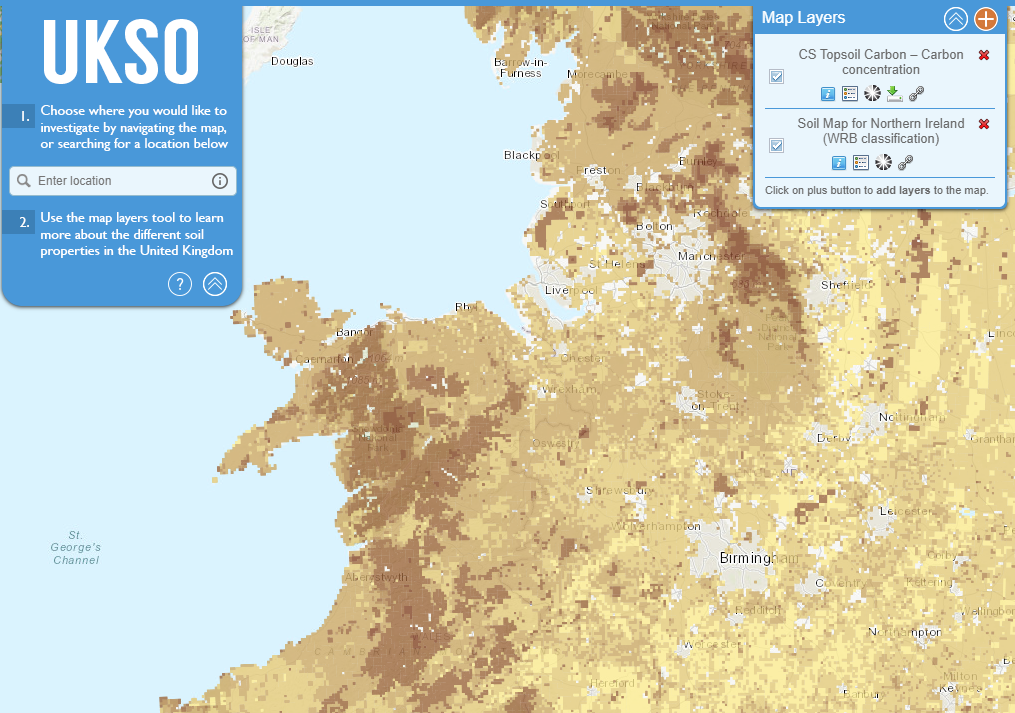

Free Data for farmers from the UK Soil Observatory

The UKSO is an online archive of UK soils data from nine research bodies. It provides easy access to fully described datasets allowing everyone to work with the latest UK soil research outputs. Knowledge of soil types and properties underpins good soil-management practices allowing us to develop vital strategies for sustainable agricultural production, UK’s carbon balance and a wide range of other services e.g. flood prevention.

What can Farmers do on the UKSO website?

The UKSO map viewer can be used by anyone to explore what we already know about UK soils. A large quantity of soil datasets (mostly as maps) are available, including soil type and a wide range of physical, chemical and biological properties. Each partner organisation has contributed data covering a mix of these topics. Users can also view the data within their own mapping software or apps. UKSO also acts an archive of soil-related resources and information such as soil apps, publications, events and research projects.

What are the main benefits of using the UKSO?

The benefits of the UKSO are significant and wide-ranging, and include:

- More transparency and accessibility of data in line with government data policy

- Less time being wasted by people either repeating or not being aware of the data already available and how to get hold of it

- New scientific understanding of the relationship both between different soil properties and those between soils and other natural resources such as water or biodiversity, using our easy to use map viewer and map export function

- Globally greater visibility of our rich soil data holdings, which will hopefully encourage new scientific collaborations and greater investment by businesses who rely on soils, including conservation, construction, utilities, agriculture and the insurance sector