If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Farmer Focus – Clive Bailye

A Tale of Two Farms

It’s been an “interesting” autumn here! It was always going to happen following the “goldilocks” near perfect summer and autumn of 2018. Mother nature was bound to maintain her average and the rain was going to come sooner or later. For us, that time was harvest. We got all our OSR into store before things turned wet but then, sure enough, we were soon reminded how the grain dryer that didn’t run at all through 2018 worked. A brief dry spell saw beans and spring crops harvested dry again. Overall yields were decent but nothing exceptional or to brag in the pub about! The now forgotten dry spell through spring stopped us hitting any record yields. Our crops certainly flattered to deceive; I don’t think I have ever seen this farm look so good in July so the rather average numbers we saw over the weighbridge across all crops did feel like a disappointment at the time.

The big change for us in 2019 was the move away from the our 6m John Deere 750a drill to a 12m Horsch Avatar prompted by the loss of a full-time staff member. Our first use of the new drill in anger was establishing cover crops, despite being assured that our exiting 240hp (Fendt 724) would pull such a wide drill I can’t help admitting that actually seeing it do so up some of our steeper banks was quite a relief. The extra width on the same horsepower quickly proving value with fuel use now as low as 3l/ha (vs 4l for the 750a) and significant increases in work rates.

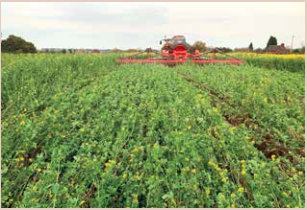

This extra establishment capacity made cover crop and OSR drilling a very quick event, 100ha plus a day being achievable without operators putting in silly hours. It had been my plan to establish OSR crops as early as possible but that wet weather mid harvest meant by early September we were already behind where we really needed to be with fieldwork. This latter establishment of both cover crops and OSR have resulted in much smaller rape plants and unimpressive cover crop biomass levels going into winter this year. But given the seemingly relentless pressure of CSFB and my aversion to using insecticides, I’m simply pleased to still have a crop on every acre we drilled.

The multiple drill hoppers in the Avatar created some interesting new opportunities. So, as well as my usual placement of nitrogen with OSR seed (this year with addition of phosphate in the form of DAP), we decided to experiment with placement of prilled lime in the form of Calcifert. As well as some neutralising value from the product I have long felt that Ca as a nutrient is often overlooked even on soils with good Ca content. Availability of this essential nutrient can often limit yield and for a few years now we have made routine tramline broadcast applications to crop in the spring and seen good response.

Various rates of Calcifert were placed with OSR seed, the idea being that the neutralising value of the product might help with acidic breakdown of residue “hair pinned” into the seeding zone at drilling.

However, what quickly became more interesting was the correlation between levels of CSFB attack which were in direct proportion to the Calcifert rate, which lasted through early establishment. Quite why this happened I have no idea. Could it be improved vigour of plants with better nutrition out growing or being less attractive to their attacker? Could there be some physical deterrent property from the calcium? Or could there be something completely different altogether going on? It is certainly something that is potentially very interesting and worthy of further investigation and proper trails. That’s for sure!

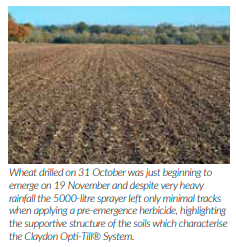

I think it takes a difficult season to remind us all why we do some of the things we do. Disappointing levels of biomass in later established cover crops remind why getting them in tight behind the combine is so critical. And keeping seed mixtures cheap is prudent. But more than anything else autumn 2019 have reminded me just how much my soil has changed over the last decade. Our ability to drill this autumn has been almost in direct relation to how long that field has been farmed without tillage and with a conservation agriculture mindset. By the beginning of November, we had already received nearly 300mm of rainfall but had 95% of our longer-term no-till soils drilled and up in rows. Things were not ideal and there is the occasional headland and poorly drained area that I doubt will come to much but, in a year, as difficult as this I feel it’s a great result so far.

Improved infiltration rates increased organic matter levels, far better soil structure and green covers have kept direct contact between soil and machinery minimal making our soils so much more resilient to these extremes of weather that seem to occur with increasing frequency. All is however far from rosy though. In complete contrast to our success on these longer-term no-till soils is a complete failure to establish any crops at all on land more recently bought under the care of our contract farming operation. In autumn 2018 we took on a new estate with a soil type similar to our home farm. Although it had been farmed very well its history was very conventional heavy tillage-based establishment, but the owner had clear ambition to transition to a conservation ag approach and asked us to take on the work.

We took our usual approach to new land and lightly surface cultivated a lot of it to level things in that first year, we established cover crops ahead of spring crops, setting up for the planned full no till transition this autumn. But as I write not a single acre there is established. The soil simply has not dealt with this autumn’s extreme rainfall well at all. Despite a good drainage system its ability to infiltrate and inferior structure has kept it far wetter and unworkable than land we have become more familiar with, it simply lacks the resilience which again was visible through the dry spring period where crops on that estate seemed to visibly suffer far greater through that dry period we encountered ……………. Conservation agriculture, the system that helped mitigate the losses of the dry spring is also helping me deal with such a wet autumn as well.

The last autumn I can compare 2019 to and certainly the only other very wet autumn I was no-tilling through was 2012. Looking back upon the experience from that year the key lessons were that patience paid, conditions matter more than dates on a calendar and a good spring crop is better than a poor autumn one. It can be very frustrating to be sat with a large workload ahead but limited by ability of machinery to get the job done, a lot of no-till drills are purposely heavily or have ability to transfer a lot of weight to coulters which is often required in uncultivated land yet when wet this is the last thing you need.

I have found the Avatar’s wet weather performance to be better than the 750a. Although there are clear similarities between the coulters, a lot of small changes all add up to keep the Avatar unit running both cleaners and seemingly better able to close the slot when soils are sticky. As well as work rate improvements, the 12m working width has also completed our 12/36m CTF jigsaw meaning any soil damage from the tractors weight is at least limited and easier to repair if required.

All drills however have a limit, and generally that limit is lower for a disc drill than a tine when it comes to wet conditions. So if conditions improve we plan to complete wheat drilling with our ULD converted CO6 (featured in issue 1). Modifications to drawbar have been made to allow the tool bar to be removed from seed cart and pulled directly behind the tractor fed by front hopper to distribute weight evenly. It feels like a great wet condition set up which might just make the difference in marginal establishment situations.

If conditions improve, we can have the CO6 working alongside the Avatar to give us 18m of drill coulters to make the most of any small weather windows we might get. Where you don’t have soil resilience maybe sledgehammer capacity is the answer! It’s also worth remembering that our best crop of winter wheat in that difficult 2012 season was established in early March. So, plenty of time yet!! Resilience is the word that I keep coming back to. It’s becoming so important in every aspect of our farm business today, financially, environmentally, mentally even. This is what 2019 has reminded me more than anything as the most important thing to build into any farming system. It’s a lesson learned and autumn 2019 is reminder from mother nature firmly taken on board!

-

Cover Crop Strategy 2 The Sequel

Written by James Warne of Soil First Farming

In my article in the last edition of this humble magazine I discussed basic cover cropping strategy, in this article I will

cover some of the frequent questions which have been posed to me since that article. I accept that to many this may

seem obvious but if you are new to Conservation Agriculture or thinking about zero-till then it may often seem like an

additional cost with little easily recognizable benefit.Cover crops seem to promote slugs, how do we deal them?

I would firstly argue that slug populations are cyclical, some years the environmental conditions are conducive to rising populations, other years lead to declining populations so it may not always be something you can easily control. Having brassicas too close in the rotation may cause problems as brassicas seem to increase slug numbers. Anecdotally mustard seems to provide beneficial habitat for slugs which seems to go against recent research which suggests that bare soil may actually increase slug numbers more so than mustard.

Following a Conservation Agriculture (CA) system will allow natural predators to build. Natural predators include carabid beetles, some song birds, hedgehogs, frogs and toads. Almost all farms we visit comment on how the wildlife returns to the farm gradually once in the system. Again it’s another indication that we all can benefit from not cultivating.

Consolidate the seeding zone well. Roll, roll and roll again after drilling to ensure good seedbed consolidation. I cannot stress enough the importance of rolling. Unless soil conditions are perfect at drilling it is most likely that the seed to soil contact will be reduced and the seed slot will not be well closed and consolidated. This allows slugs to travel with ease along the seed slot. Better soil consolidation will reduce this.

I seem to get reduced yields when drilling into cover crops in the spring, why is this? There are several contrasting theories on this but I believe most can be explained away by considering the carbon:nitrogen ratios within the soil and the cover crop. Whether the cover crop has been desiccated before or after drilling the cash crop, the soil microbes will have a nitrogen demand as try to digest the carbon contained within the cover crop residue. This will be in addition to any residue left from the previous crop. It must be stressed that the soil microbes will always have the first bite at the nitrogen cherry, taking what they require at the expense of the cash crop. This maybe seen as poor or delayed establishment, or most likely a disappointing yield. I cannot stress enough how important it is to consider the potential nitrogen lock-up that occurs when adding large amounts of carbon to the soil.

Here at Soil First Farming we are now confident we can predict these situations using a more robust soil test designed in the USA. This soil test attempts to predict the available nitrogen to the following crop by using a series of measurements such as (but not exclusively) soil respiration, active carbon and nitrogen levels. The soil test results then gives a recommendation for future cover crop in terms of legume/non-legume balance. It also gives a measure of ‘soil health’ which can be used to build a picture over a number of years of soil improvement.

I am direct drilling, are cover crops necessary?

Very simply, YES. You can direct drill and leave bare fallow but experience suggests that sooner or later you are probably going to have to cultivate. The cover crop provides a source of sugars to the soil microbiology, the roots provide stabilisation and drainage to the soil, the biomass above ground protects the soil from the effects of direct sunlight and heavy rainfall and they are capturing carbon. Without the effect described above the soil is open to the effects of rainfall which causes it to slump and compact. It is less able to withstand trafficking from machinery passes. Of course all of these effects are hard to quantify, but plenty of research has been undertaken to quantify the effects of nitrogen and phosphate lifting and storing for the following crop.

Another contentious benefit of cover crops is their ability to ‘dry’ soil. Cover crops tend to transpire more water and dry soils from early-April through to mid-October as a generalisation. But even outside of these dates the cover crop can still aid drainage. It is not exactly clear how this occurs but I suspect that living roots are still taking in moisture and allowing soil drainage to occur. For comparison see the two photos below, showing examples of the difference in soil moisture with and without a cover crop. In essence if you are following a CA system cover crops are an essential part of that system.

The seed costs are too high, what can I do?

We are very keen on keeping the costs down wherever possible, ideally we think you should be aiming to spend no more than £20- 25/ha on cover crop seed. The simplest way of doing this is to grow your own seed, but we appreciate this doesn’t suit everyone. Similarly many of the crops you have in store may also work very well such as OSR, barley and linseed. Buying straights and self-mixing is also cost effective.

What should I do with failed OSR?

Failed OSR could make a great overwinter cover crop which could be drilled into in the spring. Again normal caveats apply when deciding upon timing of destruction of the cover crop such as the amount of grass weed existing within the cover.

-

Landowner Focus – Sally Beard

Sally owns the Bradshaws Estate in Codsall Staffordshire and talks about why conservation agriculture is her preferred route going forward.

My father Peter Smith was a fruit and vegetable grower, farming 1500 acres on 6 farms in the Midlands and the Southeast. After the war, the revolution in farming when pesticides and manufactured fertilisers were widely used, enabled him to grow consistently good crops, made his farming business profitable and him into a pesticide junky. DDT, organophosphates, residual herbicide were all used in abundance. They enabled him to rid himself of much manual labour and expand his profitable farming empire.

Sadly he died suddenly in 1983 and I had to leave the comfort of my life in London and take on his farming businesses. I was 26, it was a steep learning curve. I continued his farming practices, his belief in operating in the unsubsidised marketplace of horticulture rather than relying on arable subsidies from Brussels, was a very much his ethic. He thought it would not last. How wrong he was.

By 1983, long-term use of pesticides had increasingly manifested itself in resistance to many of the chemical products. Thankfully many of the toxic chemicals had been banned. By then I continued to grow fruit for 20 years but finally switched my farming practices from horticulture to a fully subsidised arable farm; I equally still believe that subsidies should not and cannot continue. To farm without any subsidies is one of the reasons I chose to go down the no-till route.

Over 20 years looking at dull fields of wheat and oil seed rape on a four year rotation being drenched in nitrates and pesticides held little or no interest for me. The four-year rotation bothered me, particularly with club root in the OSR as did resistance to many of our chemical products. However, the income derived from the farm was and still is essential to my business.

I had the fortune to spend much of my youth with a wonderful Irishman call Dr David Robinson a plant physiologist and my father‘s best friend. They had met at a conference in Ireland in 1950s where David was the speaker about his work on residual herbicides, namely Simazine. His research revolutionised soil management and annual weed control.

It changed the way we farmed; we no longer needed to cultivate to rid ourselves of weeds in our perennial crops.

Most of our soft and top fruit crops were in the ground for 4-20 years. After the removal of each perennial crop and after years of Simazine application the soil was full of earthworms. Dr Robinson taught me the value of the soil we farmed. What went on underground was more important than what went on above. He preached grass leys and grazing sheep in our rotations (something we always resisted as we could not see any “profit” in that, although we understood his point). His pioneering work on residual herbicides has now all been overtaken and Simazine has been banned. His knowledge of plant physiology and the soil has stayed with me.

In my arable rotation I was growing potatoes, particularly as they were a good break crop. With the era of de-stoning and excessive cultivation of the ground in preparation for the potatoes, I had witnessed more and more destruction of my soil structure. My soil was washing down the drains and ditches. When I walked across a wheat field, following potatoes, I sank up to my knees. This was not good.

Many years ago, I had done a Nuffield scholarship. On one of their arable farm walks, I visited a notill farmer near Newbury, it really opened my eyes. He was trying to emulate the extensive grazing methods of the Prairies. (In 1800 there were 60 million buffalo grazing the land, they had been there for millennia and by 1900 there were only 500 left, wiped out by the settlers who had been encouraged to farm and cultivate there). The prairies had become a dust bowl; much of the land had become infertile, overcultivated with small rotation and no organic matter. Was this not what I had also done to my land? With the use of wide rotations, cover crops and grazing animals his earthworm population and organic matter was fantastic. On returning home I could not wait to dig a few holes in my soil. I found one earthworm in 8 digs and little or no organic matter.

The final straw came that May in 2018. I had been renting my land out for potato growing for 10 years. By the time I got home I called the tenant and said I did not want to rent the land to him anymore. Unfortunately, he was committed to crisping contracts so I had to honour our agreement. It came back to bite me. Within 2 days of him planting his potatoes we had 1 inch of rain in 30 minutes. My farm proceeded to make its way down the A41 main trunk road running along my farm boundary. Topsoil was covering both carriageways for a quarter of a mile. A couple of newly built houses down this road had my soil, carefully mixed with tons of seed potatoes filling their kitchen and sitting room up to 4 foot high. This topsoil which had taken thousands of years to produce. The home owners had to evacuate and live in caravans for a month whilst their houses were cleared of my precious soil. It was horrific.

That spring I fortunately had started to experiment with no -till farming. The fields where we had had a cover crop followed by spring oats, the storm water had run straight over the top. None of this soil had been washed away. If anything was going to make me change my farming techniques then this was it. I am now in my second year of no-till farming, I have adopted a 6 year rotation. We have used no insecticides for two years. My aim is to stop using fungicides. I do not currently have livestock in my rotation. Inputs are greatly reduced. Can we do this system profitability without subsidies? Not yet.

We have seen big increases in the number of song birds and wildlife. Our local group of bird-ringers go out at night with a thermal imaging lens to study the birdlife. The increase in the numbers of Skylarks, Owls, Woodcock, Stock Doves, Golden Plover and even a Stone Curlew have been enormous. Locally there is a group of no-till farmers. The ringers only now visit the no-till farms in our area as the bird populations are so much higher. To a hedge line, you can see whether a farmer is cultivating or not. The wildlife is just not there in a cultivated field.

I still need my subsidies to make the farm profitable, but there is light at the end of the tunnel. If I can continue to reduce my inputs and my cultivation costs, increase the health of my soil, I am heading in the right direction. Soil is our most important asset.

-

Drill Manufacturers In Focus…

NOVAG SHINE AT AGRITECHNICA

For the second time in its history Novag had a stand at Agritechnica and put the spotlight on no-till and the importance of soil health. A visit to the stand at the show allowed you to meet the team and view the 3m drill, their 6m drill and their “fish tank” that lets you view how the drill interacts with the soil. When we arrived on the Novag stand, Alexander Klümper, the agent of Novag for Germany and Austria, was busy entertaining a crowd of German speaking farmers, seeking information about his experience with no-till. The French manufacturer brought 2 drills to the show. The 3m model was equipped with narrow row configuration, auxiliary hoppers, and very wide Michelin tyres. On the other side of the stand, the 6m drill offered a wider solution to bigger acreage farms with higher horsepower tractors. Its opener setup with larger diameter discs and wider press wheels is obviously designed to handle the softer black soils of the eastern markets.

Literally surrounded by ploughs and tillage equipment in Hall 11, the Novag team did not believe that the debate on glyphosate should be the reason to sell more soil cultivation equipment to farmers or to promote a more conservative approach on soil tillage. A continuing theme of no-till being possible without glyphosate is something we are all keen to explore. This was a big contrast to the soil working action videos broadcasted by Lemken on the next stand. Instead the Novag stand design included a tank of soil, promoting the importance of the different living organisms in any soil. The “fish tank” – included a Novag opener in action into a straw mulch and a specially planted cover crop, with real soil and plants. A cut of the T slot is represented at the back and visible through a window.

Long term Novag Users

We also spoke with Novag users on the stand, notably Jean Paul Rault, who purchased a machine back in 2012. Looking at the new machines he commented on the evolution that the range had gone through since he first bought a machine. A more practical layout, new options, a stronger sense of robustness, and plain press wheel rims overcoming trouble in grain corn residues. The control system including the monitor hasn’t changed much apart from the German language less to Jean Paul’s liking… Jean Paul has the privilege of being Novag’s first customer, farming near the Atlantic coast in very high clay content soils. He described Novag as “a determined and passionate team willing to change tomorrow’s farming, for the benefit of a living soil, less demanding in inputs”, as he told us.

Novag in the Southern Hemisphere

Novag’s recently concluded alliance with the Carrfields group, a dealership company originating from New Zealand, opens up the Australian and New Zealand markets to them. “Our exclusive distribution agreement with Carrfields will generate traction for our brand. Working with a different hemisphere – with opposed drilling seasons and delivery months – offers new opportunities for smarter manufacturing and stock management at the factory”, says Ramzi Frikha, one of the founders of Novag. Guy Fordham, heading the development of Novag in both countries will be assisted by Bill Ritchie. Bill joins the team with a lifetime of experience in no-tillage technologies. This dedication will enhance the value of the Novag brand in this significant part of the world.

“In these countries, especially Australia, where we think that farmers practice no-tillage in general more than in Europe, partnering with a renowned and well-established distributor could provide the backbone for our company development, while we continue to grow in our home markets : France, Germany, and eastern Europe.”

Innovations

According to Novag, the next innovations to be made in Europe will come from supporting leading farmers and helping them implement new practices such as relay cropping or permanent cover crops establishment. All of it potentially requiring new features and R&D on the drills. The UK market is another hot topic for Novag. The demo tour which was scheduled for October got cancelled due to our awful autumn weather, but the team had at least one opportunity to prove itself at TWB farms, in quite wet conditions. The 4m demo unit that was viewed at the event in the midlands has already been sold and will be delivered for spring drilling. Novag is in process of building a service network around the UK, is working on a new demo program for the spring with a replacement drill on the way and of course has already booked its stand and plot at Groundswell.

-

Moving Past Prevented Planting

Four Prevented Planting Acre Priorities Heading into 2020

Written By Emily Unglesbee , DTN Staff Reporter © Copyright 2019 DTN LLCIn a year like 2019 you realise in the UK we always expect get our winter crops planted. Our temperate climate means this is nearly always the case. There will be talk of exceptionally wet years like 2012, 2000 or back in the early 80s, but these events are rare. However, they seem to be becoming less unusual and maybe it’s time we except winter planting is not a guarantee in the UK? In the USA, it’s not such a uncommon occurrence. In fact, they have a name for it “Prevented Planting”.

Farmers can even insure against not being able to get a crop in the ground when they had planned to. I think a few farmers would have liked that insurance this year. Once you accept that you won’t always be able to get a crop in the ground, be it a winter or spring crop, then the next best thing you can do is prepare for the following season. Get your fields in the best shape they can be for when you can get crops in the ground. This article from DTN in the US talks about the steps one farmer took when he couldn’t get planted when he wanted to.

With 55% of his acres left unplanted in 2019, one might have expected Matt Foes to put up his feet and take a vacation. Instead, the Sheffield, Illinois, farmer rolled up his sleeves and spent a large part of this summer working a year ahead. “I went into the summer expecting that this fall would be no different than the spring — so really challenging,” said Foes. “So I spent the summer preparing those fields for 2020: I sprayed herbicides, tilled to smooth out seed beds and seeded cover crops.” In the weeks and months to come, he will tackle field repairs, cover crop termination, weed control and fertility management on those same acres, all before planting his actual crop — or so he hopes.

“If I learned anything from 2019, it’s that you aren’t guaranteed to get an opportunity to do anything you’ve planned,” he said. Farmers reported a record number of prevented planting acres this year after a historically wet, challenging planting season. By late August, USDA’s Farm Service Agency estimated that nearly 20 million acres were left unplanted. And of those acres, more than 4.7 million acres were seeded to cover crops — more than double the previous year. As these farmers head into 2020, much remains to be done. Fields that sat fallow could face nutrient and microbe deficiencies, as well as weed problems. Cover crops need termination and management plans, and many fields are in need of repairs from equipment and water damage. Here’s a look at the top priorities for prevented planting acres this fall and winter:

Have A Plan For Cover Crops

Foes counts himself among the unplanned cover crop experimenters of 2019. “I’m completely new to cover crops,” he said. “This is a learn-as-you-go situation — we’re calling an audible.” Moving quickly in late July, Foes broadcast and tilled wheat seed on all the acres destined for a soybean crop in 2020. On the acres destined for corn, he bought discounted leftover treated soybean seed from a seed company and planted the soybeans as a cover. Like many, he now must navigate how to manage them before planting season rolls around. Growers have a handful of options. First, they can let certain cold-sensitive covers (like soybeans) overwinter and die. That leaves a mat of residue in the spring to manage — and possible volunteer seed, if the cover went through reproductive stages in the fall. Foes was fortunate; by using a later maturity group (3.6) than he normally does, his soybeans made it to the podding stage but never produced seeds. He hopes to terminate them with tillage this fall, but so far Mother Nature has intervened with rain and snow events.

“I’m trying to avoid the ‘wet blanket’ effect on ground that is already typically wet, since 2020 will be starting with a full soil profile,” he explained. If he misses his fall window, Foes will aim to break up that blanket of dead covers with some vertical tillage in the spring. Other winter-hardy cover crops, such as wheat or rye, will continue growing in the spring, so growers will need a termination plan — will you aim to spray it out early in the spring or plant your spring crop into a “green” or living cover? Foes planted winter wheat that tillered out fully and grew a foot-tall canopy, but never entered reproductive stages. “It didn’t vernalize, so it won’t set seed,” he said. He expects some of it will winterkill and the rest will require a spring termination with herbicides.

Other questions remain, too. Cover crop supplies for certain species, such as rye, got pretty tight this summer, due to the high demand. Depending on the source and quality of your cover crop seed, growers should watch for weed seed invaders, surprise volunteers and even disease inoculum in those fields. Foes used bin-run winter wheat seed, but had it professionally cleaned to try to protect his fields. “I didn’t want to inherit someone else’s weed problems, so we didn’t do straight binrun seed,” he said

Finally, the heavy residue or growing cover of a fall-planted cover crop can be attractive to some spring insects, particularly those who need grassy covers to lay their eggs.

Watch Those Weeds

Absent a crop, weeds grew quickly on many prevented planting acres this summer. Some farmers managed to get across those fields with herbicide applications or tillage, but weather and time restraints stymied others. Summer annual weed escapes have spent the fall sowing seed in some prevented planting fields, and now winter annual weeds are emerging. Foes managed a pass of glyphosate and 2,4-D on most of his acres around the Fourth of July, but wet fall weather has blocked his attempts at additional weed control. He is worried about the waterhemp escapes he saw sprouting in some fields this summer.

Like many other farmers with prevented planting, Foes may have to grapple with dense weed seedbeds next season.

Know Your Nutrient Needs

Beware of Fallow Ground Syndrome on prevented planting acres planted to corn in 2020. Corn enjoys a symbiotic relationship with a type of soil-dwelling fungi called mycorrhizae that grow along its roots and help the plant absorb key nutrients such as phosphorus. When a field is fallowed or planted to a crop that doesn’t support these organisms, the next corn crop can struggle to take up nutrients, resulting in stunted, yellowed or purpling plants. Some cover crops, particularly grass species, can maintain populations of these fungi for a following corn crop; others, such as brassicas, will not. Some growers may need to consider starter fertilizer options to help a 2020 corn crop planted to fallow ground.

Do an accounting of your prevented planting acres’ applied fertility. Some nutrients such as nitrogen (converted to nitrates), boron and sulfur are very mobile in the soil and may no longer be present if you applied them in the fall of 2019 or the spring of 2020.

-

Why Do We Need To Sample?

Written by Steve Holloway from Soil Fertility Services Ltd

A soil test will give you numbers and guidelines of where your soil is and hopefully where it should aim for to consider it ‘balanced’ (note I didn’t say healthy); remember that it’s NOT an N-P-K world. Sensible soil nutrition is the first step toward higher crop quality and yields. Testing will measure levels of various elements within the soil such as Calcium (C) and Magnesium (Mg) which are two of the main building blocks of soil aggregation; high levels of either will have a negative effect of how well the soil functions. Mulders chart shows the interactions of soil nutrients (how one nutrient influence another), for example – too much nitrogen can reduce the plant’s ability to take up Potassium, Boron and Copper increase Potassium and reduce the availability of Magnesium.

This effect is known as antagonism. Calcium is a bit of a bully in the soil where antagonism is concerned; when levels are high Manganese (Mn), Magnesium (Mg), Potassium (K), Phosphate (P), Iron (I), Boron (B) and Zinc (Zn) are all affected. However, calcium is needed in plants as a building block and is vital as the ‘cement’ that holds cells together and produces stability for plant cell structure. Silica, although not readily plant available from within your soil, is also important for increasing the physical strength of plants and in turn the plant’s natural resilience to pest and disease pressures.

Having established a soil test shows the mineral makeup of your soil and a specific number of anions/cations relative to the elements measured, from there you can identify where your soil sits when compared to the ideal’ target range. But is that a healthy’ soil?

Many of the measured elements will not yet be available to your crop, if they were, the greedy plants would gorge on this deluge of goodies and make themselves sick while most unclaimed nutrients would volatilise or be washed away. It has to be a balancing act of what’s available and what can be ‘made available’. Within the soil, various elements hold onto each other, dictated by whether the element is positively charged (cation) or negatively charged (anion). This is how nutrients are ‘locked up.’ These bonds can be broken by the root microbes or by the environment. Humic and Fulvic acid are referred to as chelators; they improve the delivery and efficacy of foliar applied nutrients, forming strong bonds with trace elements and enabling the direct uptake of nutrients across the plant leaf with reduced risk of leaf burn.

When bonded with Humates, applied nutrients are kept plant available in the root zone, reducing nitrogen leaching and phosphorus lock-up.

Imagine how much healthier your soils could be with the addition of Humic acid. With a cation exchange capacity (CEC) of 300-500, an increased available water capacity up to 30-50% more, on top of that you get improved soil quality due in part to increased activity of the beneficial bacteria building better soil aggregates. Biological activity plays a key part in the soil/plant relationship and as such trades commodities with the plant, releasing tied up nutrients for plants to utilise. So, you could say the numbers in a soil test mean very little if you don’t have ‘the biological army’ around the root to support and maximise nutrient availability. A healthy soil will have balance; excesses and deficiencies – physical or biological can have a negative influence. Measuring and monitoring your soil and plant on a regular basis will highlight potential problem areas, for example: you test the soil and are low in (x) but when you test the plant you are not low in (x) is there an issue?

You get the lab to test for biological activity, and a result comes back with a high rating, so is everything ok? Are those organisms beneficial? What percentage? A decision made with blinkers on is not a decision it’s a leap of faith! Longer term assessment must be a part of your farming system; know your history to plan your future, be prepared to throw the rule book out the window. The soil test doesn’t tell you what’s in the plant, the plant analysis doesn’t tell you what is in the soil – you need both.

Soil Fertility Services was established in the 1990’s and has since been working hand in hand with farmers throughout the UK, constantly striving to find biological farming solutions that are efficient and more effective, in order to build soil fertility and provide crop nutrition.

-

George Sly Talks About The Future

We will be showcasing all the latest technology from Precision Planting at Lamma show 7th/8th January on Stand 19.412.

This will include the integration of downforce sensing, soil sensing and liquid control on our cereal disc openers as well as newretro fit options for all makes of drill + planter. We will also be revealing news about our new branding and brand new UK production Facility.

The Furrow – The Seed’s Lifeline

Digging seeds is a time consuming yet important task at planting time.

Getting your eyes on the furrow, where the seeds are placed, will allow you to understand if those seeds are in an environment to thrive. Does the seed have adequate temperature and moisture? Has it been surrounded by clean soil, free of residue? What is the power of the soil around each seed to feed the growing plant? Until now, you didn’t know these things for every seed, you were simply guessing. With SmartFirmer you can now have eyes in the furrow.

Smarter Every Season

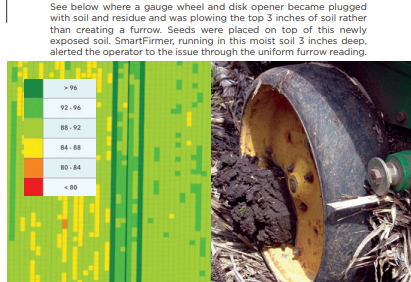

Soil warmth and moisture are the two most critical factors to consider at planting time for rapid, uniform germination to happen. SmartFirmer measures soil temperature in real time and displays it on the 20|20 allowing you to decide if the soil is warm enough for germination to happen quickly. Moisture can vary from heavy low ground to a sandy knob in the fi eld, and SmartFirmer will show this change to you, allowing you choose to plant a little deeper to maintain adequate moisture. Mechanical problems on the row unit, such as a loose gauge wheel can cause dry soil to shower into the furrow. SmartFirmer would alert you to this, allowing you to look for the issue on the row unit and fix it.

Residue Visibility

Old crop residue in the furrow hurts a seed’s ability to germinate quickly, but it can also carry disease into the new crop.

SmartFirmer senses residue in the furrow and displays a clean furrow metric on the 20|20. SmartFirmer residue sensing

compliments a fl oating row cleaner control system like CleanSweep® by allowing farmers to have confi dence that the

furrow is cleared and that row cleaner settings are correct.See The Difference

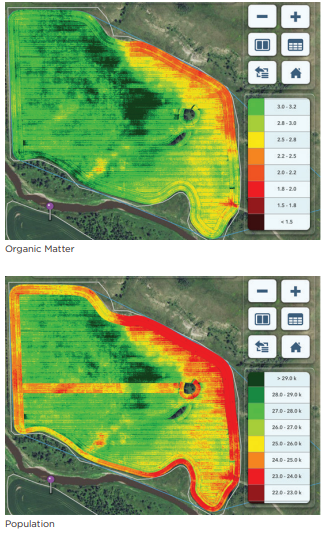

Organic matter is one of the most infl uential measurements for overall productivity of a soil. SmartFirmer provides a cost e ective way to measure organic matter in every inch of the furrow. SmartFirmer can also act on those organic matter measurements when paired with Precision Planting control technologies. Plant population, hybrid, and fertilizer rate can all be controlled on-the-go as SmartFirmer detects di erent organic matter zones in the fi eld. For farmers who have found variable rate technology too overwhelming, SmartFirmer provides a simple way to make the most out of every zone.

-

Drill Manufacturers In Focus…

VAXIO IS KEY MACHINE FOR SUMO

British farm machinery manufacturer, Sumo, first launched the Vaxio at LAMMA 2018, and after 18 months of testing prototypes on-farm, the longawaited shallow cultivator went into full production in 2019. Available in 4m, 5m and 6m working widths, the Vaxio is a high-speed and versatile implement that combines surface cultivation, loosening, levelling and consolidation – all encompassed in a minimal maintenance design. At the front of the machine there’s a twin-row of concave scalloped discs that cut trash and initiate the cultivation process. The discs are followed by two staggered rows of spring-loaded tines, 300mm apart and working at depths of 50mm to 250mm, allowing for either a full-width under-cut and mix or zonal work (depending on which points are fitted). At the back there’s a row of sprung levelling paddles designed to carry soil and even out the peaks and troughs, followed by your choice of packer rollers providing different qualities dependant on exact application. Excellent consolidation and moisture preservation are key across Sumo’s packer range.

Although an ideal tool for seedbed preparations, the Vaxio can also be run a little deeper if fitted with a SumoSeeder to give a one-pass oilseed rape establishment tool – a proven method for hundreds of farmers in the UK who have been harvesting impressive yields with Sumo’s flagship machine, the Sumo Trio. Filling a gap in Sumo’s product range, the Vaxio is a key machine for the British company, highlighting their commitment in helping farmers move towards minimum and zero-till farming methods and showing Sumo are a serious farm machinery manufacturer in the UK, Europe and the rest of the world.

Offering the versatility to work with or without its front levelling discs and the ability to go deeper with its tines if required are fundamental elements to the success of this fantastic, British built, machine.

The Vaxio will be showcased at LAMMA 2020, and there’s a fantastic retail offer for orders taken before 10th Jan 2020, the Friday just after the event.

-

Soil Sampling And Test Interpretation

Written by Keith Diedrick, Area Agronomist at Corteva USA

Summary

• Soil testing is a useful and relatively inexpensive management tool for growers to assess crop nutrient levels in their fields.

• Proper methods and timing of soil sampling help ensure reliability of test results for making informed decisions related to soil inputs such as fertilizer and lime.

• Standard soil tests typically evaluate pH, buffer pH, organic matter, cation exchange capacity, phosphorus, potassium, calcium, magnesium and base saturation.

• Micronutrient soil testing alone is generally not a reliable tool to predict potential micronutrient deficiencies. Tissue testing, soil properties, and growing conditions together are a more complete diagnostic approach.

• Critical levels of nutrients (the point below which crop yield may decrease quickly) and crop removal rates are useful for determining the rate and frequency of fertilizer application to a field.

Growers must efficiently manage field inputs while reducing the risk of yield losses to maximize profitability season after season. Fertilizers are significant variable costs in production, and tools are available to assess their need.

Soil Testing – Selecting a Laboratory

Competent analytical laboratories use strict standardized methods in controlled environments with quality standards; all of these are important to reliable and comparable data for informed decision making in the field. A number of commercial labs exist and some land-grant colleges have labs as well. Growers may benefit from a review of considerations and tips for selecting a soil testing laboratory (Diedrick, et al. 2010).

Soil test kits and strips found at garden centers are not a replacement for a professional testing laboratory analysis due to the risk of high variability and questionable precision. A good laboratory test report is a small investment compared to the magnitude of fertilizer and lime investments by an operation. Once a laboratory is selected, a quality sample must be collected and handled correctly for an accurate analysis.

Sample Collection

Regardless if the sampling plan is random or part of a precision management system, collecting and submitting a clean and representative sample is required for reliable results. Below are some best management practices for obtaining representative samples for analysis.

• Soil sample every 2 to 4 years for a given field; sampling every year rarely adds additional information.

• Sample when crops are not growing in the field (applies to standard soil sampling).

• Avoid fields where fertilizer, manure, or liming materials were recently applied.

• Sample fields at the same time

every year so that analyses are more comparable over time. Sampling 3 to 6 months prior to the next crop will allow enough time for any pH or nutrient adjustments. For many crops, this time is post-harvest in late autumn.

• Thoroughly clean the soil probe or instrument to remove all residual soil or debris. It does not take much of a foreign substance to significantly contaminate a sample.

• Be sure the sampling container is similarly clean to prevent any contamination. Plastic or stainless steel containers are preferable to other materials.

• Move residue, debris, and any vegetation from the soil surface at the sample site. Failing to do so will cause an incorrect (too high) organic matter measurement.

• Pull soil cores from a depth of 6 to 8 inches, or depth to plough layer where soil mixing occurs. Long-term no-till fields, perennial forages, ridge tillage, and similar systems may be sampled also at a shallower depth to note any shift in soil pH in the top 2 to 4 inches.

• Obtain 15 to 20 soil cores for an area of 20 acres or less. For larger areas, submit multiple samples for more accurate soil information, even if the field appears uniform.

• Mix cores together well for the sample. Usually, samples can be sent moist after mixing. For standard soil tests, air drying is permissible, but do not heat cores to speed drying.

• Follow the soil laboratory’s instructions for submission, using the containers recommended or supplied by the lab.

A Typical Standard Soil Test Report

Most laboratories offer a “standard soil test” which covers a set of soil chemical measurements that are important in agronomic decision making. Though some labs vary, typically this includes pH, buffer pH, cation exchange capacity (CEC), base saturation, organic matter (OM), and the macronutrients phosphorus (P), potassium (K+), calcium (Ca2+), and magnesium (Mg2+). In the Plains and western regions where salinity and sodicity are more common, conductivity, soluble salts, sodium (Na+) and chloride (Cl-) may also be reported in a local laboratory’s standard test. Nitrate (NO3-) and sulphur (S), are not usually part of standard tests, but are considered macronutrients. Nitrate tests are used in some regions for preplant nitrogen (N) management and in-season sidedress decisions, but recommendations vary from region to region.

Test Values Explained

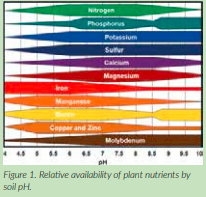

pH is the measure of acidity of a substance. pH is expressed as a number, not a percentage or other quantity. A value of 7.0 on the pH scale is considered neutral, that is, the substance is neither acidic nor basic. Lower numbers on the pH scale denote increasing H+ ions and acidity. The acidity of the soil solution affects many physical, chemical, and biological reactions necessary for plants to survive and thrive. The optimum pH value varies by crop and region, but is generally between 6.0 and 7.0 pH (slightly acidic), though alfalfa thrives between pH 6.8 to 7.0.

Buffer pH – Once a need for adjusting pH higher is identified, the buffer pH value indicates the amount of liming material necessary to make the adjustment. Low buffer pH values indicate that more lime materials are necessary to raise pH than higher buffer pH values. “Buffering” in this case refers to the ability of the soil to “recharge” acidity, and is a function of aluminium (Al3+) minerals and H+ in the soil (and is related to CEC). If a soil is poorly buffered (sandy), less liming material are needed to raise pH a certain level than a soil that is highly buffered (clayey soil). Some soil tests may report buffer pH as lime test index, or LTI, which is merely the buffer pH value multiplied by 10.

Organic Matter – Expressed as a percentage, OM is the non-mineral content of the soil sample and is usually determined by combustion. Organic matter has many functions, including water-holding capacity, nutrient cycling, and contributing to soil structure and CEC

CEC – Cation Exchange Capacity is measured in milliequivalents per 100 grams of soil. CEC is determined primarily by soil clay mineralogy and OM level in the soil. Cation exchange capacity represents a measure of electrostatic charge sites in the soil that can hold cations, or positively charged ions, like Ca2+, Mg2+, Mn2+, Zn2+, K+, H+, and Al3+.

For each “equivalent” charged site on the soil particles, a single positive charge can be held (denoted by the superscript number on these ions). In the case of K+, a K+ ion has a single positive charge, and is held by one CEC site. For a Ca2+ ion, two CEC sites are necessary to hold one Ca2+ ion, three CEC sites for Al3+, etc.

Higher CEC values in soil represent more capacity for nutrient cations to attach. For example, a high CEC soil can theoretically hold many K+ ions, but would require more K+ to be applied as fertilizer to fill the sites located on the soil particle surfaces before it is easily released to the soil solution and taken up by plants

P – Phosphorus is reported in parts per million (ppm) or pounds per acre (1 pound per acre = 2 parts per million). This is not a measurement of total P in the soil, however, it is an estimate of P that is available to plants. The testing procedure utilizes an extractant that is correlated with P uptake that might occur by plant roots. This value is reported on the soil test as “extractable P.” Not all labs use the same process; some may use the Bray-Kurtz P1, Mehlich III, Olsen, or other procedure. Reported P values will vary according to the test procedure and are not directly comparable to each other.

P is an important element in plants, as it is part of the DNA, RNA, the energy transfer molecule ATP, as well as amino acids and proteins.

K+ – Potassium is reported as ppm or lb/acre of “exchangeable K.” Like P, all of the K+ in a soil sample is not available to the plant. Most of the K is locked in mineral structures, some is available slowly from the clay edges, and other K+ ions may attach to the CEC (exchangeable) and flow easily to the soil solution. The K+ extraction solution measures K+ that can be readily moved from the CEC and into soil solution, simulating the processes that might exist with a root system in the soil

Potassium is vital in water regulation and enzyme activation in plants. Plant stomata, which are openings in the leaf used for gas exchange, open and close by movement of K+ in and out of the cells surrounding the opening. Potassium (and other nutrients) in plant stover or residue on the soil surface can cycle back to the soil with rainfall events and residue breakdown (this sometimes includes up to 80% of K in residue). If little to no rainfall occurs after harvest prior to soil sampling, the reported K+ value may be lower than expected because of this lack of cycling. Dry conditions also limit the movement of slowly available K+ to the CEC.

Ca2+ – Calcium content of the soil is reported in ppm or lb/acre, sometimes listed as “exchangeable calcium.” Calcium is a common element in a lot of mineral soils, and though they may occur in some regions, deficiencies are rare in most soil environments above pH 5.5. The easiest correction to a suspected Ca2+ deficiency is raising soil pH with a liming compound, and Ca2+ is considered sufficient at ≥200-300 ppm. Calcium is essential to plant cell wall structure, cell division, and many enzymatic processes.

Mg2+ – Magnesium levels are measured in ppm or lb/acre, sometimes listed as “exchangeable magnesium.” Magnesium is a key element in chlorophyll and many enzymes and enzyme activation. Deficiencies can occur in crops, and can be remedied with Mg-containing fertilizers or dolomitic limestone. Mg2+ is sufficient for most crops at ≥50-100 ppm.

Base Saturation – This is a description of the major cations held on the CEC on a percentage basis. Typically, Ca2+, Mg2+, K+, and H+ are listed (and sometimes Na+ and Al3+) as they are of the highest concentration. Other cations may attach, such as the metal micronutrients, but they are often measured in ppm, not a percentage (1 ppm = 0.0001%) The percentage of H+ is related to the buffer pH value discussed earlier. When H+ moves off of the CEC and into soil solution, the solution becomes more acidic. The portion of H+ on the CEC is sometimes referred to as “reserve acidity.

Base Saturation Ratios

There is a long-standing debate on the usefulness of base saturation for determining lime and fertilizer rates, particularly the Ca:Mg ratio. There is a lack of evidence that a certain ratio of bases is necessary for optimum crop performance. A large body of research shows that if nutrients are in the soil at high enough levels and pH is in the proper range, optimum yields in agronomic crops can be achieved across a wide range of Ca:Mg ratios.

There are a few ratios of note for specific crops and soils, however. The ratio of Mg:K is of importance to forage growers. If excessive K+ is taken up by the plants and Mg2+ is low, the forage may contain low Mg2+ content and cause a metabolic condition in livestock called grass tetany (hypomagnesemia). Dolomitic limestone and Mg-containing fertilizers are options, but supplying feed additives with Mg to livestock may be more economical.

When Mg2+ exceeds Ca2+, or when Na+ becomes high (>15%), this may be indicative of possible soil structural issues, such as clay dispersion or flocculation, surface sealing, and decreased water infiltration. This is most likely to occur in areas of naturally occurring Na+ and Mg2+, but these are not widespread in North America.

Soluble Salts – The soluble salt content (or conductivity) is expressed in dS/m or mmho/cm (which are equivalent). If soluble salts are too high in the soil, plants cannot take up sufficient water, wilt, and in severe cases, die. In most crops, performance and yield decline rapidly at 3 to 4 dS/m and higher, and may be affected as low as 2 dS/m.

Salt problems are a concern primarily in the Plains and western regions of North America where various salts are native to the soil in high levels. Some effluent irrigation waters and fertilizers have the potential to cause salt problems as well, most notably muriate of potash (KCl; 0-0-60) and urea (46-0-0). Use extreme caution when applying in-furrow or banding.

Micronutrient Soil Tests

Notice that standard soil tests typically do not include elements like manganese, boron, zinc, iron, and copper. At this time, it is difficult to correlate micronutrient levels in the soil with crop response. Plants require very little of these micronutrients to thrive and the exact required amount can be difficult to ascertain. The challenge for researchers is to reliably correlate a soil test level with plant uptake (like P and K). Even if this was known, the relationship to test level and crop response is similarly variable.

To further complicate micronutrient predictions, the availability of micronutrients can vary with soil physical characteristics which change during the year (moisture, aeration, microbe activity, etc.). If soil test levels of a micronutrient are high, crop responses to fertilization of that nutrient are unlikely. If a micronutrient level is marginal or low in the soil, the crop still may not respond to a micronutrient application. Additionally, not all crops have the same sensitivity to particular micronutrients. Knowing the soil, crop sensitivity, and environmental factors that may cause a nutrient deficiency is helpful to gauge risk and prepare appropriately (Butzen, 2010; Diedrick, 2010; Jeschke and Diedrick, 2010).

Choosing Fertilizer Rates

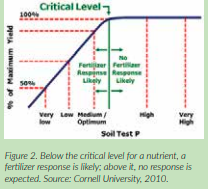

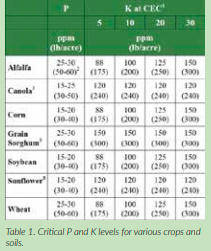

A starting point in nutrient management decisions is comparing soil test results to established critical levels for the particular crop. Critical levels are the point where yield loss potential increases quickly if soil test levels for a particular nutrient fall below that level (Figure 2).

These established critical levels may vary from region to region, but recent research shows that critical values are close to the ranges in Table 1.

1 Critical level for ppm K = 75 + (2.5 x CEC) for all crops

2 Values in parentheses are lb/acre.

3 Several sources do not cite CEC specific K, and may vary. Consult your local Pioneer professional for additional local information.

One strategy that growers may adopt is to build soil test levels just above the critical levels and apply nutrients to annual or biennial crop removal rates. This accounts for variability in fertilizer spreading as well as assuring soil test levels over critical levels for anticipated crop removal. This practice may guide appropriate fertilizer rates for rented land or when fertilizer prices are high while still reducing the risk of yield loss. Approximate crop removal rates are below; these values may vary by year and growing environment.

Adapted from Warnecke, et al., 2004; IPNI, 2010.

1Based on Pioneer research. Fertilizer products will have an analysis printed on the bag or bin that identifies the amount of N, P, and K contained in the product. This is widely done with three numbers arranged as N-P-K. The N value on the tag is simply a percentage of N, however, P and K are listed as P2O5 and K2O.

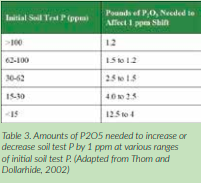

Crop removal and fertilization are activities that change soil test levels of nutrients. Depending on the buffering capacity (CEC) and soil mineral composition, the amount of P2O5 and K2O necessary to change soil test P and K will vary and in some cases, be difficult to predict. Research from Kentucky (Thom and Dollarhide, 2002) shows that for low levels of soil test P, more P2O5 fertilizer is required to change the levels than at high soil test P levels >100 ppm (Table 3).

To change K+ test levels by 1 ppm, K2O additions may range from 2 to 6 pounds per acre, again, depending on existing K+ levels, soil minerals, and CEC.

Conclusions

Soil testing is an inexpensive practice to learn about the ability of soils to support crop growth. With knowledge of what each soil test value means, growers can make more informed crop input decisions to minimize risk and maximize profitability.

References and Further Reading

Butzen, S. 2010. Micronutrients for crop production. Crop Insights. Pioneer Hi-Bred Int., Inc., Johnston, IA.

Cornell Univ., 2010. Northeast Region Certified Crop Advisor study resources. Competency area 3 – soil testing and plant tissue analysis.

Diedrick, K.A. 2010. Manganese fertility in soybean production. Crop Insights. Pioneer Hi-Bred Int., Inc., Johnston, IA.

Diedrick, K.A., G. Gao, R.W. Mullen, and M.E. Watson. 2010. Choosing a soil analytical laboratory. OSU Ext. Bull. HYG-1133. Ohio State Univ., Columbus, OH. [Online

Havlin, J.L., J.D. Beaton, S.L. Tisdale, and W.L. Nelson. 2005. Soil fertility and nutrient management: an introduction to nutrient management. 7th ed. Pearson/Prentice Hall. Upper Saddle River, NJ.

International Plant Nutrition Institute. 2010. Nutrients removed by harvested portions of crop. IPNI, Norcross, GA.

Jeschke, M. and K.A. Diedrick. 2010. Sulfur fertility for crop production. Crop Insights. Pioneer Hi-Bred Int., Inc., Johnston, IA.

Kansas State Univ. 1998. Grain sorghum production guide. K-State Res. and Ext., Manhattan, KS.

Kansas State Univ. 2009. High plains sunflower production handbook. K-State Res. and Ext., Manhattan, KS.

Seelig, B.D. 2000. Salinity and sodicity in North Dakota soils. NDSU Ext. pub. EB-57. North Dakota State Univ., Fargo, ND.

Thom, W. and J. Dollarhide. 2002. Phosphorus soil test change following the addition of phosphorus fertilizer to 16 Kentucky soils. Univ. of Kentucky Coop. Ext. Agronomy Notes, 34(2). Lexington, KY.

Vitosh, M.L., J.W. Johnson, and D.B. Mengel. 1995. Tri state fertilizer recommendations for corn, soybeans, wheat and alfalfa. Ext. Bull. E-2567. Michigan State Univ., Ohio State Univ., and Purdue Univ.

Warncke, D., J. Dahl, L. Jacobs, and C. Laboski. 2004. Nutrient recommendations for field crops in Michigan. MSUE Bulletin E2904. Michigan State Univ., East Lansing.

-

Future Tech: Soil Health Assessment

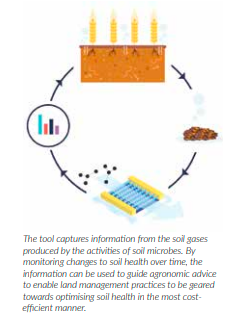

The future to understanding soil health lies in a tool that can sniff the gases produced by the soil’s microbial life.

You can’t optimise what you can’t measure, and the vital activities of microbial life in the soil are currently difficult to measure outside of a specialised academic laboratory. P.E.S. Technologies is therefore using cutting edge semiconductor technology to develop a sensor that can quickly assess soil health using a simple hand-held sensor out in the field. The sensor “sniffs” the soil to detect all the various gases produced by the soil’s microbes. By using artificial intelligence the soil health analysis system can learn what the different smells mean and give greater insight, on the spot, into soil health than current tests to asses soil biology.

The journey of getting your soil into a really good condition often starts with switching to no-till practices. But beyond that there are decisions upon decisions that need to be made to regenerate soil biology from choosing the best crop types to have in your rotations to which cover crops to plant. Additionally, there are a whole host of exciting new biostimulants to try out as well as reductions in nitrogen fertiliser applications that can be explored. Further, with nematicides disappearing from the market, optimising biofumigation processes that produce gluconsinolate gases in the soil to control PCN may become a priority in future.

But each farm is unique and what works best on one farm may not work best on another. So, the first step to managing soil health should be to measure it and then monitor changes over time as they occur depending on changes to management practices. However, currently the tools available to assess soil biology have limited capabilities and there are only a few to choose from.

To make the right agronomic decisions to optimise a farm’s soil health in the most cost-effective way for each farmer, a tool is needed that makes soil health assessments easy, affordable, quick, and comprehensive. On top of all that, data is needed that doesn’t become obsolete the minute soil scientists make new discoveries that change our understanding of what a healthy, functional soil is.

While huge strides are being made in the field of DNA analysis, the samples still need to be sent off to a laboratory and the costs per test are very high. Therefore, most currently used tests for monitoring soil biology rely on gas sensing—but they only sense one gas, namely CO2. P.E.S. Technologies have instead developed a sensor that can profile all the soil’s gases with a hand-held device that can be used in the field. In other words, we “smell the soil” on the spot. This allows us to assess soil health easily, quickly, and comprehensively.

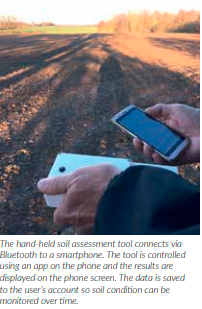

P.E.S. Technologies soil sniffer is hand-held, battery powered, and linked to a smart phone via Bluetooth. For each test, a soil sample should be taken from the top 20 cm of soil and placed into a small drawer in the device. Importantly, no other preparation of the soil sample is required. This means that each test can be completed in only 5 minutes. The agronomist or farmer never has to see the complicated smell patterns, all you get to see on the phone is the important information that is pulled out from that data: a soil health score and the various soil health indicators (for example, microbial biomass, nitrates, and pH amongst others) that are used to assess the health of the soil.

Soil gases are currently an underappreciated resource: they provide a wealth of information on soil conditions as specific microbial activities are associated with different gas patterns. As an example, microbes that are converting between the different forms of nitrates in the soil produce different gases that can then be linked to the concentration of nitrates in the soil. Additionally, bacteria and fungi give off distinct gas patterns, while different bacteria may flourish in well-aerated soils with good drainage compared with compacted soils.

Each soil test requires a single-use sensor strip, which is what detects the gases. This unique test strip was invented by Dr Jim Bailey, founder of P.E.S. Technologies and previously a semiconductor physicist at Imperial College London. Another key aspect of the sensor system is that is that the system learns and provides better results over time. It does this by analysing the raw gas data in the cloud using artificial intelligence. The same way you can train a dog to understand the meaning of more and more smells, the artificial intelligence software can be taught to do the same. The test is therefore futureproof. A simple software update can expand its capabilities and data collected in previous years can simply be reanalysed.

This is future tech, but it is not that far off being on the market! Already, P.E.S. Technologies was able to demonstrate the feasibility of sniffing soil with its sensor technology for soil health monitoring purposes by working with experts in the field in a government funded project (Innovate UK project number 133537). A further three Innovate UK funded projects (project numbers 105534, 105664, and 105668) are currently under way to help fully train the soil sniffer software and get it into the hands of agronomists and farmers by 2021/22. This soil health data will allow better land management decisions that will help improve soil health faster and more efficiently: after all, you can’t optimise what you can’t measure!

While the technology is not currently scheduled to be released until around 2021/22, suitable test sites are currently being sought and an early-release version is currently being considered. Farmers and agronomists can register their interest at pestechnologies.com/ register.

-

Water Focus Affinity Water

Written by Shaun Downman from Afftinity Water

I’m sure you are all fully aware that this autumn has been wet! However, thinking back to September things were very different. Where I live on the Hertfordshire/Cambridgeshire border, I can pinpoint the day the dry weather ended. I had willingly brought my spade along to a field site to dig a few soil moisture probes into the ground as part of one of our research projects. I think a pick axe would have been more appropriate given how baked solid the ground was. As I left the site the heavens opened and, apart from a few days respite here and there, it hasn’t really stopped since.

I suppose its always been thus in the UK. We’re a maritime island on the edge of the Atlantic and our weather is a fickle beast at best. However, we’re all aware that the weather we get lately isn’t quite so ‘normal’ with new records broken each year. This year alone we saw the highest temperature ever recorded in the UK at 38.7oC and as I write Sheffield has recorded its wettest autumn with still a week remaining and no let-up in the rain on the horizon. A common phrase I hear (and repeat myself) is that this extreme weather is ‘the new normal’ and I tend to agree with its sentiment.

This ‘new normal’ weather is already having consequences for our lives, jobs and the environment and how we adapt to climate change in the coming years will be key. For us in the water industry we need to prepare for a future that will bring less predictable weather patterns with more intense rainfall and longer periods of drought alongside more people needing more water. Climate change will also affect the way we farm in this country and I believe that resilient soils will be key in helping farms stay profitable and adaptable.

In a wet autumn like the one we’re currently experiencing, soils that have had cover crops and reduced tillage have generally been easier to travel on and plant up than those deep tilled and without cover. This in my mind is what resilience is all about. Clearly, we are not going to get autumn weather like this every year, but we may get it more often. Cover crops and good soil health will give you that added resilience to get on the field in a difficult year. Also, in a dry year like the one we had last summer there was good anecdotal evidence of direct drilled fields holding onto the moisture for longer than those that were tilled.

The environment also benefits from resilient soils. Soils that capture more carbon could contribute towards offsetting rising emissions. In-turn raising your soil organic matter content will also hold more water which could help reduce flood risk and reduce sediment loss into rivers. Cover crops help capture excess nitrate which will readily leach if soils are left bare. These are all some of the ecosystem services that can be delivered by farmed land on top of the vital task of growing food and all signs are that future governments will have a greater focus on using public money to pay for these services.

Water companies too are interested in obtaining some of these ecosystem services with a number of companies, including Affinity Water, trialling schemes to buy the service that cover crops deliver to water quality which means the farmer doesn’t shoulder all the risk. We pay the farmer a fee to grow cover crops in areas that are high risk for nitrate leaching with a higher price given for those species that are known to scavenge nitrogen well, such as oil radish, and a higher price still the earlier the cover crop is drilled following harvest. Despite difficult (dry) drilling conditions and rife cabbage stem flea beetle, the scheme has worked well this year with some good covers being seen out there helping build resilient soils and protect water catchments.

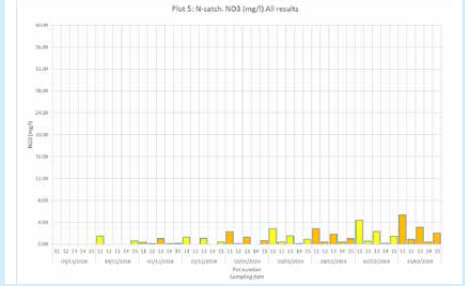

The graphs below show nitrate leaching in a stubble field (top chart) and a field planted with a cover crop (bottom chart). This clearly demonstrates how much nitrate is captured by the cover crop which will help reduce nitrate leaching and may reduce N rates in the following crop.

If you have any questions, comments or thoughts on our cover crop scheme or other work please don’t hesitate to drop me an e-mail:

shaun.dowman@affinitywater.co.uk

-

Drill Manufacturers In Focus…

At Agritechnica Väderstad presented an entirely new and unique technology in the form of the SeedEye seed counter for their seed drills. Farmers can now easily set the number of seeds per square metre without needing to perform calibration tests. SeedEye provides additional functionality for Väderstad’s established control system E-Control.

SeedEye:

1. The operator sets the seed volume per square metre from the control panel, eliminating normal calibration testing, saving time and effort.

2. The operator has full control of the sowing process via the iPad display at the control panel. If a seed coulter deviates from the preset permitted variation an acoustic alarm is sounded and the faulty seed coulter is marked in red on the display.

3. No resetting of the seed drill is necessary between different crops. SeedEye handles this automatically by the operator changing the value on the display, which increases efficiency.

4. Increased seeding reliability as well as increased operator comfort due to the operator having an overview and control as never before.

Sensors count total seeds

Sensors are located in the seed hoses. The seeds flow through the sensors, which are equipped with six optical transistors. These are illuminated with infrared light. When a seed passes a ray of light, the light is very briefly interrupted and the optical transistor registers a break in the flow of light.

The total number of breaks is registered and processed, enabling the seed volume to be specified with high accuracy. The sensors count rape with approximately 99 percent accuracy. The value for wheat and other grains is approximately 98–99 percent at 250 seeds per second. The system automatically sets accuracy and compensates for the dust and residue that can gather in the sensors. “Counting seeds is more exact than by calculating quantities based on seed weight,” says Crister Stark. “The system has been developed as a direct response to farmers’ needs to predict total plants per square metre.”

The operator sets the seed volume per square metre

The operator sets the desired seed volume per square metre on an iPad without needing to climb down from the tractor to perform a conventional calibration test. The seed drill’s radar measures seed drill speed and E-Control continuously calculates how well the “set point” for the desired volume of seeds per square metre agrees with the actual feed value as attained via SeedEye. The feed, which is electrically powered, is constantly regulated to produce the desired seed volume.

Easy to vary seed volume

If the operator wants to change the seed volume per square metre, the change is entered on an iPad where the volume is shown on the display. This is easily accomplished with preset steps of, for example, 10 percent. The seed drill immediately sets the desired seed volume per square metre regardless of tractor speed and displays the actual value. The system works equally well with or without ISOBUS.

Blockage Monitoring

SeedEye also works as a blockage monitoring system. The core of the system revolves around the SeedEye sensors, registering each individual seed as well as the flow of fertiliser passing through the tubes. SeedEye makes it possible to visualise and monitor the drilling operation in real time. If a deviation should occur, the SeedEye blockage monitoring system gives an immediate warning so that any impact on the crop result can be quickly remedied.

Videos of SeedEye working in action can be found on YouTube.

-

Farmer Focus – Andy Howard