If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

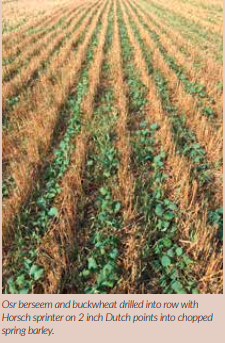

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Crop Protection Products The Modern Farmers’ Toolkit, Part 2

Contributed by Ralph Early, Independent Food Scientist and Food Ethicist

Ralph Early discusses the historical and current use of crop protection products in this second of a two-part article

(Page 61 Direct Driller Magazine Issue 6), and focuses on the use of herbicides and insecticidesThe first part of this two-part article explored something of the history and use of agricultural pesticides and focused on two important classes: herbicides and insecticides. Attention is given here to other pesticides of importance to farmers, as well as issues of significance associated with their use: principally environmental sustainability and human health.

We have seen that in the production of agricultural food materials herbicides are ubiquitous in the management and control of undesirable plant species that compete with crops and that insecticides are important to both crop and farmed animal protection. Other biotic threats of importance to agricultural food production are various fungal species which can be problematic in crop production, nematodes which threaten plants and animals, and common rodents.

In the production of food materials destined for use in primary processing and food manufacture, farmers seek to gain advantage over the variety of pests that threaten crops and animals. Failure to do so can result in product losses and reductions in yield, quality and profit as well as, in certain instances, food safety hazards. Yet though farmers must seek constantly to control the circumstances in which they produce agricultural foodstuffs through the management of pests, they must also remain cognizant of the possible negative impacts that measures may have on the environment broadly, and specifically local ecology and biodiversity, as well as the capacity to sustain food production resources for future use.

In many respects human survival has always represented a battle with nature, but as the agricultural pesticide industry developed through the 20th century and became an integral part of the mid-century Green Revolution, this notion came to emphasize and underpin modern farmers’ raison d’etre, particularly in Europe and North America. However, with the benefit of hindsight we are now beginning to understand that while synthetic pesticides offer immediate benefits for farmers and consumers they also bring longer-term concerns about negative effects on ecosystems and wild biodiversity. Enlightened farmers, like environmentalists, will therefore find wisdom in the words of Schumacher1 who stated,

“Modern man does not experience himself as a part of nature but as an outside force destined to dominate and conquer it. He even talks of a battle with nature, forgetting that, if he won the battle, he would find himself on the losing side.”

Consequently, as a result of growing concerns, agricultural pesticides are now squarely in the spotlight, from environmental, legal and moral perspectives, and approaches to agricultural food production in which pesticide use is reduced and even eliminated are gaining ground: some of which will be considered here in order to complete this snap-shot of the topic.

Fungicides

Fungi are ubiquitous in most ecosystems and are generally familiar as edible macro-fungi such as meadow mushrooms (Agaricus campestris) which produce large fruiting structures. They represent a kingdom of eukaryotic organisms which includes many species beneficial to human endeavour, for instance bakers’ yeast (Saccharomyces cerevisiae) used in the production of bread and Penicillium roqueforti, the mould used in the production of blue cheeses. Fungi are also represented by the numerous organisms responsible for creating the mycorrhizae essential to the production and maintenance of healthy soils and the growth of many plant species Indeed, fungi are nature’s biodegraders involved in the breakdown and recycling of organic matter including, significantly, the decomposition of lignin, the structural polymer of vascular plants.

The significance of fungi to agricultural crop production lies in their capacity to damage crops, causing reduced yields and crop failure as well as, in some cases, the production of mycotoxins harmful to both humans and animals3. Some fungi of the genus Fusarium are prolific cereal pathogens affecting e.g. wheat and maize. They are capable of producing hepatoxic and nephrotoxic fumonisins, and protein inhibiting trichothecenes.

Various Aspergillus and Penicillium species infect crops such as maize and peanuts producing carcinogenic and nephrotoxic ochratoxins, while organisms from the same genuses can produce the genotoxic mycotoxin, patulin, often associated with apples. The organism Claviceps purpurea infects rye, as well as wheat and barley, and is noted for its mycotoxin, ergot, an alkaloid and the cause of ergotism, consequences of which are convulsions and gangrene. Alongside fungi, and often mistaken as a fungal infection of crops, the organism Phytophthora infestans, an oomycete or water mould, is a disease of tomatoes and potatoes, and was the cause of the late blight that brought the Irish potato famine in 1845-49.

Matthews records the utility of fungicides in temperate and tropical crop production, describing their history and reviewing systemic fungicides. He explains that different fungicides have different modes of action, but all function to interfere with metabolic processes in target organisms, whether as multi-site inhibitors or a single-site inhibitors affecting e.g. the activity of specific enzymes.

Numerous proprietary fungicides are available to farmers and selection can be a minefield, which is why many farmers rely on specialist agronomists for advice. Some fungicides such as products containing fuberidazole (C11H8N2O) are used as seed treatments while others are applied to crops during growth, for instance products containing the active agent difenoconazole (C19H17Cl2N3O3) are used for disease control in fruits, vegetables, cereals and other field crops. Products containing the agents fenamidone (C17H17N3OS) and propamocarb (C9H20H2O2) are used to treat late blight in potatoes, with the former effective against foliar infection while the latter controls soil, root and leaf disease. Fenamidone-based fungicides are also used on e.g. grapes, tomatoes, tobacco and ornamental plants.

Nematicides

Nematodes – commonly termed roundworms – inhabit virtually all ecosystems. The exact number of species is unknown but estimates suggest around 40,000 with authors frequently describing and classifying new ones. Nematodes vary in size. Some are microscopic, typically 0.1 mm in length, with some species a few millimetres long and up to 1m in the case of several parasitic species. Nematodes vary between 5µm and 100µm in diameter. Of the numerous species, Caenorhabditis elegans, a soil organism, is the most extensively described and serves as a model in research.

From the perspective of agricultural food production, nematodes may be categorized as beneficial or harmful, i.e. as pests which require control. Beneficial predatory nematodes can be used as a form of biological control in the protection of crops from attack by cutworms, or caterpillars of the large yellow underwing moth (Noctua pronuba), the heart and dart moth (Agrotis exclamationis) and the turnip moth (Agrotis segetum), all of which can present problems for growers of potatoes and root vegetables, lettuce and cereals..

In Britain the potato cyst nematode (PCN) represents a particular problem for farmers. The twelve species of PCN belong to the genus Globodera and frequent the roots of the Solanaceae family, e.g. potatoes and tomatoes. As natives of the Andes, PCNs are not present in British fields until introduced, following which they can become a nuisance. AHDB5 states that PCNs are the most important potato pests in Britain capable of causing substantial yield losses, with two species, Globodera rostochiensis and Globodera pallida of concern. However, G. pallida is now more widespread due to a prolonged hatching period and selection pressure provided by the cultivation of potato varieties resistant to G. rostochiensis.

Control of nematodes by synthetic pesticides commonly employed the carbamate insecticide, aldicarb (C7H14N2O2S), which functions as a cholinesterase inhibitor. But it is extremely toxic and environmentally persistent, having been implicated in the collapse of ecosystems and the irreversible poisoning of farmland. It is also considered to be carcinogenic to humans. Consequently, biological methods of nematode control in crop production are of particular interest as an alternative to synthetics. Matthews4 describes use of the bacterium, Pasteuria nisizawae, a cyst nematode parasite, as a means of such control. He also reports the use of biopesticides derived from fungi such as Paecilomyces lilacinus, which is one of a number of nematophagous fungi producing toxins able to immobilize nematodes.

A variety of parasitic nematode species affect farmed animals e.g. cattle, sheep and pigs, some of which are a threat to humans, such as the large roundworm, Ascaris suum, which causes ascariasis in pigs. Roundworm treatments include piperazine (C4H10N2), anthelmintics, such as benzimidazoles (C7H6N2) and ivermectin, a preparation derived from avermectins, naturally occurring compounds derived from fermentations produced by the soil actinomycete, Streptomyces avermitilis.

Rodents

Rodents as pests in agriculture are also familiar to those who work in the food industry. One of the key methods of control in agriculture is the pest-proofing of buildings and produce storage facilities in order to prevent structural damage and, importantly, the contamination of products with urine and faeces as well as cross-contamination with spoilage and pathogenic microorganisms. The common mouse (Mus musculus) and brown rat (Rattus norvegicus) are associated with farms and together carry a range of rodent-borne diseases, such as Salmonellosis, Trichinellosis, Leptospirosis and Weil’s disease (a more serious form of leptospirosis).

Anticoagulant, coumarin-based poisons have long been used to poison rodents in domestic and industrial situations, including farms. Warfarin, a first generation anti-coagulant, has commonly been used and disrupts vitamin-K metabolism involved in the synthesis of various proteins including some necessary to blood clotting6. A number of more toxic, second generation anticoagulants are now available, including difenacoum, brodifacoum and flocoumafen, all based on 4-hydroxycoumarin. The use of rodenticides on farms is tightly controlled under the UK Rodenticide Stewardship Regime.

Looking To The Future

As a tactical instrument of control, agricultural pesticides offer benefits to farmers and society in the management of pests in crop and animal production. However, increasing concerns about long-term strategic use and their negative effects on the environment, ecosystem stability and human health are causing environmentalists, public health authorities and policy makers to review rationales for continued use. It is clear that industrial agriculture, of which synthetic pesticides are an integral part, is not sustainable. The need to develop global food systems which are both Ecological by Design and Ethical by Design7 & 8 is now understood by many authorities and the part that pesticides might play in such systems will be rigorously scrutinized. Indeed, for many years approaches to reducing and eliminating pesticides have been explored, principally because of environmental concerns but now also because of concerns about human health.

Organic farming methods are well documented as an approach to food production that limits the use of pesticides, although some traditionally used compounds, such as copper sulphate, are extremely toxic. Agroecology, as detailed by Rosset and Altieri9, may gain ground world-wide as a form of agricultural food production that excludes synthetic pesticides and various governments are exploring its potential. Integrated pest management (IPM) as an approach to pest control in crop production has been under development since the 19th century10. It aims at reducing the use of pesticides through a combination of biological, cultural, mechanical and chemical pest control methods, thereby minimizing negative effects on wild biodiversity. However, concerns are raised that although pesticide use is permitted within IPM the prophylactic use of e.g. neonicotinoids challenges the spirit and practice of the technique11.

Precision agriculture using a range of technologies including satellite imaging and remote sensors feeding data to artificial intelligence (AI) systems controlling drones or UAVs (unmanned aerial vehicles) and robotic tractors are taking agricultural food production in new directions. Bongiovanni and Lowenberg-Deboer12 suggest that precision agriculture can contribute to long-term sustainability by enabling the targeted application of off-farm inputs such as pesticides, thereby reducing use. Interestingly, the rationale for precision agriculture appears to challenge agro-chemical industry assertions that agriculture based on the intensive use of chemical inputs can be sustainable.

This may explain why some corporations are investing in precision farming technologies as they may sense that for moral and environmental reasons the sun is setting on the market for synthetic agricultural pesticides. Precision agriculture then offers a strategic opportunity to maintain control over food systems. Indeed, environmental advocacy groups assert that genetically modified (GM) crops were originally developed with just such intentions: being a strategic means of sustaining the market for pesticides whose patents were expiring and, at the same time, exercising commercial control over food systems.

A quarter of a century ago GM crops were promoted as an ethically sound technology aimed at reducing pesticide use. A utilitarian ethical justification claimed that glyphosate tolerant crops would limit to one the number of pesticides applied to a crop as well as reducing quantities used. Environmental groups opposed GM crops on deontological ethical grounds expressing concerns, for example, about the eventual occurrence of glyphosate resistant weeds. In the event such weeds have become a problem in the USA where GM crops have been extensively grown.

To address the problem new GM crops have been developed which tolerate glyphosate and dicamba (3,6-dichloro2-methoxybenzoic acid), the latter being effective against resistant weeds. However, dicamba is controversial as it drifts onto non-target crops, trees and other plants causing severe environmental and economic damage. Lawsuits associated with dicamba are consequently being filed in the USA and linked to GM crop production, some American food companies are being sued over glyphosate found in food products, with claims made that residues may be harmful to human health.

Conclusion

We may think of food as simply a matter of energy replenishment, nutrition and hedonic pleasure. But it is inescapably also a political issue concerning not least the means by which farmers produce raw materials for transformation into saleable food products. Feeding a growing global population is frequently cited as the key challenge of the 21st century, with the prospect of world population reaching some 10 billion by 2050. This is not however the key challenge. Biodiversity loss and global climate change are rationally the priority issues for our time and both are impacted negatively by the world’s industrial food system which, significantly, is the food system commanded by global corporations to feed mainly urban populations. Indeed, if the problems of biodiversity loss and global climate change are not resolved quickly, the question of feeding an expanded world population remains purely academic.

Agricultural pesticide use is now intrinsic to the industrial food system and in many ways has become synonymous with it, as has the use of synthetic fertilizers. The work of organizations such as the Stockholm Resilience Centre (www. stockholmresilience.org) illustrates the need to reduce significantly synthetic pesticide use globally. In resonance with the Schumacher quote, it is becoming increasingly clear that we must learn to develop ways of farming with nature and not against it. So, in this respect, it is in the interests of pesticide manufacturers to transition from old-school 20th century pest control solutions and explore the development of products that are consistent with sustainable food production and, at the same time, the protection and proliferation of wild biodiversity.

Potential will likely be found in the development of biological pesticides, e.g. based on microorganisms and derivatives, possibly using GM technology, and macroorganisms such as arachnids, insects and nematodes, that allow pest control without being ecologically catastrophic. Indeed, we can be sure that the political dimensions associated with agriculture and food production will demand this as social and political concerns about mankind’s effects on the planet increase and take centre stage in national and international policy making.

This article was originally published as ‘Pesticides in Agriculture’ in Food Science and Technology, the journal of the Institute of Food Science and Technology.

-

Drill Manufacturers In Focus…

COST PER TONNE OF PRODUCTION MUST BE THE KEY DRIVER

The 2019 harvest yielded excellent results on the Claydon farm, resulting in a cost per tonne of production which provided a good margin, says direct strip seeding pioneer Jeff Claydon, who designed the Claydon Opti-Till® System.

In Issue 6 of Direct Driller magazine I discussed the importance of healthy soils and how to achieve them. This time, I want to reflect on the 2019 harvest and look ahead to autumn drilling, our goal now being to ensure that next year’s crops get off to the best possible start. Here in the East of England we have been very fortunate with the weather and at the time of writing this (20 August) we are over half-way through harvest, which has been relatively straight forward. However, I realise that has not been the case in many other areas of the country and sympathise with those affected.

Last year, despite the three-month drought, we enjoyed good yields, with milling wheats averaging over 8.5t/ha and £190/t. Yields are significantly higher this year, with oilseed rape averaging over 4.5t/ha despite coming under extreme pressure from Cabbage Stem Flea Beetle (CSFB) and milling wheats over 10t/ha. I am delighted that so that many of our customers have taken the time to call our office to report that they have done even better, equalling or improving on our performance, in some cases with average yields of over 12 t/ha. They deserve to be congratulated. The downside this year is oversupply and wheat is currently trading at around £130/t. At that level many farms which continue to use a traditional, high-cost establishment system will be making a significant loss on every tonne produced.

FOCUS ON COST PER TONNE

With added pressure caused by fears over possible tariffs and the uncertainties surrounding Brexit every farming business must aim to produce crops at the lowest cost per tonne. However, it would be disastrous simply to cut costs only for yields to fall, as that would negate any benefit.

For example, some might look to cut out a fungicide, or reduce the rate, but that would be a dangerous tactic as every single one that we used last season paid off, even when no signs of disease were evident. We also found substantial benefits to milling wheat proteins where higher rates of nitrogen were used. Assuming it is possible to accurately measure yields, I would certainly recommend that every farm has at least one tramline dedicated to experimenting with different rates of nitrogen and fungicides.

Going forward, the key must be to operate a system which is proven, enables crops to be produced with equal or better yields, and generates a healthy, sustainable profit margin. Those who purchase a direct drill solely to cut costs and expect instant results without investing time to understand how it works and how to get the best from it, will inevitably be disappointed. Before investing, it is vital to understand the fundamental differences between the various types and makes of direct drill, with harvest results providing the acid test of their capabilities.

On our own and contract farms we naturally use the Claydon OptiTill® System, a holistic approach to crop establishment which has been independently proven, over 16 years, to consistently produce high-yielding crops at very much lower cost than where either conventional plough-based or mintill systems are used, providing maximum profitability.

A good harvest represents the culmination of making the right choices throughout the season and we must address each field individually, understand any issues it might have and tailor our approach accordingly. Correct establishment is crucial to getting the best results from autumn and spring sown crops and is a subject that I have covered in previous issues of Direct Driller magazine.

A GOOD YEAR FOR STUBBLE MANAGEMENT

The damp weather during harvest has made compaction a major issue on many farms this year and in some cases the damage inevitably inflicted by combines, grain trailers, balers and other harvest machinery will be difficult to repair by cultivations alone. Trying to do so will over-work soils and exacerbate the situation, making them more prone to weather risk, erosion and slumping, resulting in poor crop performance.

Compaction can take years to repair and can adversely affect crops established using low-disturbance drills, which will be reflected in yields next harvest. Depending on the depth of the compaction, investigation should be done to ascertain the extent of the problem and appropriate remedial action taken. If compaction is found below the working depth of the leading tine on the Claydon Hybrid drill then subsoiling should be considered, particularly if you are new to the Claydon Opti-Till® System. Once it has been used then the drill’s leading tine usually works deep enough to eliminate any shallow compaction, providing excellent rooting for the new crop, which is key for plant development and to optimise yields.

Generally, this is not an issue with the Claydon Opti-Till® System because the patented leading tines on the Hybrid drill remove surface compaction as part of the drilling process, levelling the surface and ensuring that the seeding zone provides just the right growing conditions for the new crop to germinate quickly and grow away unhindered. In turn, this means less competition from volunteers and weeds, so inputs are used more efficiently and fully benefit the crop.

If your soils are in excellent condition and worm counts are at high levels, then the crops will also be right. As soils become healthier and more productive weeds and volunteers will naturally take advantage of the improved growing conditions. The reason that they sometimes appear to be less of a factor with low-disturbance or zero-disturbance establishment systems is simply that soils are in far from ideal condition because of compaction or because they can become anaerobic, with significant adverse effects on the crop. We all must play the cards that Mother Nature has dealt us, but the secret is to play those right cards at the right time and in the right order. Rather than following a prescriptive approach to farming, just because ‘that’s the way it has always been done’ we tailor our approach to the season, the key being to have a good rotation and avoid over-cultivating the soils.

The damp weather in August may have delayed combining on occasions, but it has provided ideal conditions for an effective stubble management programme. It is essential to encourage volunteers and weed seeds to germinate quickly so that they can be removed before the next crop is drilled, because it is much more efficient and cost-effective to deal with them at that stage rather than in the growing crop. Soil conditions this year are the opposite of those in 2018. Instead of containing zero moisture, soils are very moist, so we have adapted our approach accordingly. Slugs love wet conditions and wet trash, so a few can quickly become many if not dealt with effectively.

Immediately after oilseed rape had been combined, we used our 15m Straw Harrow to create a shallow surface tilth and followed that with the TerraStar light rotary cultivator to create a little more soil movement. This resulted in a carpet of OSR volunteers which were left in the hope that they would retain any remaining Cabbage Stem Flea Beetles and discourage them from migrating into next year’s crop, which was drilled on 9 August and five hours later received 15mm of rain, so it got away well.

When the new crop reaches the four-leaf stage and is better able to withstand CSFB attack, we will take out the OSR catch crop with the TerraStar and then clean up any volunteers with full-rate glyphosate before drilling winter cereals. It will be important not to let the volunteer OSR become too dense and give grassweeds the opportunity to flourish, but should that happen, or slugs begin to proliferate, we will hit them again with the Straw harrow or TerraStar.

The loss of neonicotinoid seed treatments and some products to control grassweeds creates a fear that the aphid vectors of Barley Yellow Dwarf Virus (BYDV) will increase significantly. This can be reduced considerably by using the Opti-Till® system to manage stubbles and take away the green bridge effect. You can also delay drilling, but to do that with any degree of certainty you must be able to get the crop in the ground quickly, which means not having too many operations before sowing. A key benefit of the Claydon System is that its high output potential provides much greater flexibility, so you can choose when to drill rather than having to press on regardless. That is very important because we don’t want the hassle and weather risk which ploughbased or min-till systems create due to the need to prepare seedbeds well in advance of drilling.

We do that by implementing OptiTill’s effective stubble management programme, followed by a robust application of glyphosate to tidy up any stragglers that might be left. The aim is to create a 3cm deep stale seedbed, certainly no more than 5cm, especially when working with clay soils which need to dry before following operations, so we only use the Straw harrow and TerraStar when conditions are right. When drilling with the Claydon Hybrid we recommend 50hp-60hp per metre of drill width, not to go deep but to comfortably maintain an operating speed of 10 – 12 km/h, giving very high outputs and ultimate flexibility. In my next article I will review the performance of our autumn-drilled crops and look ahead to what we have planned for the spring.

To learn more about the Claydon OptiTill® System and techniques to improve your farm’s performance contact your local Claydon dealer and arrange a visit to the Claydon farm. For further details go to www.claydondrill.com or call the Claydon office on 01440 820327.

-

Products In Focus…

COULD HYBRID RYE BE THE NEW CROP DIRECT DRILLERS HAVE BEEN LOOKING FOR?

From Scotland to East Anglia, growers are finding success with hybrid rye, what is it about the crop that captured their

interest?Frustrated by the performance of winter barley and no longer able to grow oilseed rape, Colin Mitchell, farm manager at Meikleour Estate in Perthshire, was searching for a new crop to extend the rotation. Although not the complete answer, hybrid rye is proving to be a rewarding discovery. “Farmers in Scotland need an alternative to wheat,” he says. “It is becoming harder to keep clean of foliar diseases that limit yield, and this is making it expensive to grow. The obvious choices aren’t that attractive.” The Meikleour Estate covers about 800 hectares and its fertile loam soils support a diverse range of crops including potatoes, energy beet and carrots. Cereals perform as a disease break for higher value crops but must still pay their way. Oilseed rape too is no longer a practical option due to severe clubroot problems and a desire to reduce disease risk from sclerotinia in high value root crops.

As with many other farmers in Scotland, Mr Mitchell’s interest in hybrid rye was aroused after he was approached by a neighbour in need of feed stock for an anaerobic digester, but it has since earned its place for other reasons. “We took a conservative approach; our 25 ha was modest in comparison with what some others were putting in. For many, it was the most profitable crop on their farms, and it can be, but you must properly account for the potash removed. This can be as much as 285kg/ha with a 50t/ha (AD) crop,” says Mr Mitchell. This brief experience was enough to capture his interest and he began to investigate other possible markets for the crop. “It grew well, and I was impressed with it, but because we want the straw to cover the carrots, we decided we’d rather grow it for grain. We use about 50t/ha of straw, which equates to about 4000 Hesston bales a year, to protect the carrots against frost. Hybrid rye produces about 25% more straw than winter wheat so there is obvious appeal.”

Variety choice is considerable but a call to Scottish Agronomy ensured he chose the right variety for his farm situation.

“Rye is susceptible to ergot, but the development of PollenPlus varieties, bred and marketed by KWS, has done much to remove this risk. Scottish Agronomy has long-term trials data on a range of varieties at two sites in Scotland so we knew straight away which variety to grow, what seed and nitrogen rates to use and how much growth regulator would be needed.” Growing rye for grain however, meant first finding a buyer for it. “A favourable amino acid profile means it is particularly well suited to pigs so that was our first thought, unfortunately it wasn’t to be. Eventually, we found a market for human consumption through a local merchant.”

As his confidence with the crop has grown, so has the sown area and in 2018-19 covered 110ha.

“In 2016 the crop yielded an average 7.7t/ha though this was on some of the farm’s least productive soils. The bestperforming field managed 8.3t/ha. This made us start to take it seriously as the best crop we’ve ever had in that field previously was spring oats which managed about 6t/ha. In 2017 it achieved the same average but then in 2018 it gave 8t/ha with the best field at 10.48t/ha.”

This compares with a three-year wheat average yield for the same period of 8.3t/ha. In the drought of 2018 wheat at Meikleour managed just 7.54t/ha and cost roughly £100/ha more in variable costs.

“It appears to be the one crop where real progress is being made year-on-year to improve agronomic characteristics, such as disease and lodging resistance. This year I’m growing KWS Edmondo and have entered a field in the ADAS YEN competition.”

“For us, it yields on a par with first wheats, but is cheaper to grow because it needs less nitrogen fertiliser and fungicide. It has already replaced some winter barley and I’m starting to think it could replace second wheat too.”

Eastern promise

Another grower frustrated by the poor performance of everyday cereals was Essex grower David Lord. After deciding to call time on winter malting barley and encouraged by a neighbour he decided to give hybrid rye a go. It’s now four years later and the crop area has expanded to 40 hectares as demand for the grain has increased. It was the low water requirement – at 300 litres per tonne of grain produced its moisture needs are typically 25% lower than that of wheat or barley – and early maturity that appealed in the first instance.

“I was looking for a crop to fit the light land rotation of potatoes, wheat, peas/onions, and wheat. Rye had good drought tolerance and the straw is useful for the cattle enterprise though we are careful to follow it with potatoes to replace the phosphate taken off (with the straw) and control the volunteers. “We budget for yields of about 8.5t/ha, but it often exceeds this. In good years it does 10t/ha or more and as our contract sees us paid the same as feed wheat it often produces a better gross margin because it is cheaper to grow,” he says.

It has since become an established crop and his 350-400 tonnes annual production is sold locally to a specialist food ingredients business. “It does better than wheat on the same ground and is earlier to mature, but later than oilseed rape, so helps ensure a smooth harvest,” he says. Ergot is the curse of rye, but since moving to a fully hybrid variety this has become less of a concern. “We moved to KWS Bono a few years ago partly for the higher yield potential, but also because the higher quantities of pollen these PollenPlus varieties produce means there is a far lower risk of ergot infection occurring,” he says.

“It’s not completely risk-free, but with milling wheat on the farm too we need to be proactive and PollenPlus varieties have helped greatly.” Sowing is much the same as any other cereal and Mr Lord will either drill it conventionally after cultivations or direct into stubble depending on the workload at the time, the field and weed burden to be considered. “It’s certainly easy to grow. We sow it in early October, normally apply two fungicides as mildew and brown rust are the main disease pressures, and a single application of Chlormequat to keep it from lodging. About 150kg N/ha is applied in two splits and that’s it,” he says.

New market opportunities

Just as the arable sector faces its own problems brought on by the loss of certain active ingredients and the need to find a more sustainable rotation, the pig sector has its own challenges. The need to reduce antibiotic use is common to all livestock enterprises, but the high health status of many pig herds makes it more achievable in the short term. Methods that promote gut health have been identified as central to improving overall herd health and thereby reducing the reliance on medication.

Rye has a role to play here as its coarse structure has been found to result in less ulceration in the hind gut compared with pigs fed with a conventional ration based principally on wheat and barley. A second issue is the need to promote general welfare across all production systems with the intention of eliminating tail biting among finishing pigs and reducing the incidence of aggressive behaviour among all pigs. Here rye too can contribute. Its denser structure promotes satiety – the sense of feeling fuller for longer – thereby leading to a feeding regime that sees pigs little and often. This leads to less boredom and less time to exert negative behaviour.

Environmental pressures are also forcing a change in production methods with the need to reduce ammonia emissions promoting interest in other feed sources and the viability of lower protein rations. Rye’s lower nitrogen and water requirement means a crop with a smaller carbon score which has not gone unnoticed by feed manufacturers. UK pig producers wondering how rye will perform in practice need only look to their continental counterparts for positive experience. In Denmark, Germany, Russia, Poland and Spain, rye is an established component of the ration.

-

Realising The Benefits Of Soil Health On Arable

Why is it that grass margins are usually in much better heart than the cropped land? Is there something

magical about grass? Field margins in many ways set the bar for soil health on your farm.

But is that as good as it can get? And do we need to go down to grass to achieve it?

“I believe the answer is no” writes Niels Corfield, crop advisor

We can go beyond the grass fallow and achieve good results in a short time frame. Because ultimately when cropping, we have more tools at our disposal. However, we have to employ those tools extensively, and thoroughly, if we’re going to actually see these results on our farms, in any reasonable period.

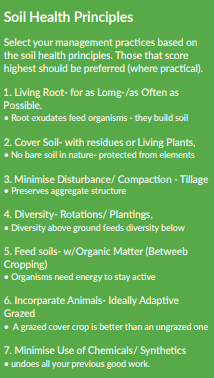

What are the tools that we have available to us? It’s just going no till, right? Well, basically, it’s the application of all the soil health principles. Mimicking the conditions we find under grass. That said, the acid test is in the soil condition. The good news is that you can actually see soil health. But what does healthy soil look like? Must it be lab tested? No, simply put, aggregation (crumb structure) is that measure. With that said what are the primary rationales for adopting soil health practices? Why should we, as farmers, advisors & land managers care? Are there any production benefits?

Improved soil health basically equates to better crumb structure that’s looser, easier to work and more absorbent. Certainly, the longer a ley is down for the better aggregated the soil becomes. So before we get into the detail, I want to put this in a global perspective. Ultimately, with 4 degrees of lockedin warming, coming down the line, business as usual is not an option. The warming we are dealing with now, as well as that coming means, for example, we can’t rely on rainfall to germinate spring crops, we need to do it with stored soil moisture (another reason not to till). Only improved soil health (crumb structure) can deliver this – so your disk drill can place the seed easily into a porous and moist seedbed.

When it comes to carbon sequestration, soil health practices, of which conservation agriculture (CA) is one example, is the only framework that can deliver the numbers we need to be hitting, under commercial conditions. That said, if we are really going to be able to make the case for soil-based production, we have to be demonstrating significant soil carbon results. Recent data from Brown’s Ranch recorded 96 tons per acre of carbon in the upper 48″ of soil, as compared to 10-35 tons for farms in the region. While there is much controversy around carbon auditing, and it probably isn’t a tool for day-to-day decision-making, these results represent a pretty high bar, and also an indication of what is possible.

Cover Crops

Over-winter cover crops (OWCCs) are the bread-and-butter of CA, they perform a vital role: preserving soil structure, holding onto nutrients, protecting soils etc. And in warm autumns they may actually do some soil building but generally speaking with soil/air temperatures being low and day lengths short, microbial activity is low, and root exudation is minimal. Also when temperatures are low, little or no N-fixation occurs, calling into question the rationale for buying those expensive legume seeds. Beyond these shortcomings, there’s limited species choice and slow growth.

Does this mean we shouldn’t bother with them? No. They still play a vital role in protecting soil & preserving structure. Though that said, where planted too late, or too thinly, OWCCs may not actually give sufficient cover either. But is there a way we can go further with our cover crops and get more pronounced results? Certainly. Spring sown or full season cover crop mixes open up the floodgates for diversity. And with it being in season, there’s plenty of warmth in the soil for optimal microbial activity (soil building), including nitrogen fixation by free living nitrogen fixing organisms, eg azotobacter. The diversity of plants means more specialist organisms should be being well fed through exudates.

But what about the cost of fancy mixes like these? Well, source seed from the feed merchant. A good starting point is bird seed mix. These tend to have at least the 8 species that are suggested as a minimum – getting that diversity lever up to where it wants to be. Just to reiterate the ideal is to have eight or more species from three or more of the functional groups: warm season/ cool season, grasses/broadleaves. The warm season plants are also the C4 plants, eg sunflower, millet, meaning more solar energy capture. Add to this any farm saved seed available. As well as this, include a tall straw cereal, like rye or population wheat – these may well be on the pricier end, so why not grow a strip or two of these as straights for combining for future mixes.

Finally, all of these plants should be annuals as we then have more options for termination, including: rolling and trampling – so long as the planting is fully mature. It’s probably also worth leaving out any short-season inclusions, like: mustard, radish and even buckwheat, since they will shed viable seed long before this termination point, possibly volunteering in subsequent crops. At the end of the season obviously you will always have the option to spray off.

There’s certainly question marks around margin for in-season covers, probably the best return this would be to graze these covers, using low utilisation, ultra-high stock density (UHD) systems. By terminating in this fashion (along with rolling) and with having low utilisation there will be large pulses of root exudates produced during these grazing events. It’s exudates that contribute most directly to aggregation and soil organic matter. Ultimately the payback for root exudation is a steady supply of nutrients in a plant available form, that are free.

Diversity and Cash Crops

Are we limited to soil building under cover crops? No, techniques like: band sowing, strip cropping, inter row planting/undersowing, crop mixtures, intercropping and relay cropping, are all indicated. Simply shifting from a monocrop to a bicrop doubles the diversity. Of these probably the most straightforward is strip cropping. The narrower the strips the better, to ensure the greatest interaction between the crop’s roots. Furthermore, the wider the spacing for the main crop the more a second planting is indicated. It would possible to undersow with a winter wheat (potentially bicropped with a legume) – making this more of a relay crop than an undersowing, and removing at least one spray pass. Basically, do whatever it takes to get diversity into your cash cropping, and to maintain a living root in the ground through more of the year.

Advice for getting started

On small acreages or one field (potentially, close to home), modify your operation to incorporate some of the following (ideally with a commitment for three years minimum):

Cover Crops

Plant a cover crop, properly, with high seed rate, early sowed, and with starter fertiliser. Where cover cropping already, try a diverse mix, 8 species or more, cheap/ farm saved seed. If you’re on the diverse over winter thing, then try it in season, ideally UHD grazed. Drill a cash crop into cover crop residues.

Cash Crops

Diversify the rotation, try a novel crop – maybe a seed crop Strip cropping: could be a header width, or just a drill width (that you then stripper header). Plant an intercrop, a two way mix, with that are co combined.

Niels Corfield is an independent advisor and educator specialising in soil health and regenerative agriculture. Check out his events page at the back of the magazine for upcoming courses or follow the QR Code to book places..

-

Farmer Focus Neil White

I farm 155Ha owned at Greenknowe and around 100Ha contract farmed in Berwickshire, Scotland just 6 miles from the border at Coldstream. The land is clay and sandy loam, deep, very variable but the best of products to run an arable business on, any limiting factor is probably me! I do all the farm work myself except for the corn carting, high clearance spraying and baling. My son, Harry (age 13) and I have been flying DJI drones since 2014 and he posts the video’s on our Youtube channel ‘Everything is Greenknowe’ and pictures on Instagram under the same name.

The last of the livestock left in 2000 but 75% of all straw is still removed, as the local livestock farmers wouldn’t let me live with the guilt if I chopped it all. The organic matter tests carried out in the last 2 years show a 3 to 4.4% OM in my soils. I think this is helped by my long rotation, with grass being replaced with oilseed rape and beans and the addition of hen muck on stubble prior to rape drilling. The current rotation is WOSR, WW, SB, SO (Or Spring beans), WW, SB, WB.

All this added up to what I thought was a good place but I had always wanted to do more with less. In Scotland we usually have very short weather windows to combine and sow crops, an example this year when the phrases “your rape is at 14% that’s good” and “if it’s not raining I’ll be cutting”, were spoken loudly without an eyelid batted. This year I am not alone in cutting wheat at a lower moisture than my rape. Even in a “normal” year I was beginning to struggle to get all the winter crops in the ground with my plough based system and like many I questioned taking the great tilth presented after harvest and ploughing it down then try to recreate it with metal, diesel and man hours while risking it getting soaked or baked. I had even considered buying an old MF 30 or 40 just to sow the wheat directly after my beans but that felt like going back rather than forward. I had a contractor sow my rape with a subsoiler and broadcast method and this worked well most years but if I was to own the kit myself it had to do more than just sow rape.

I started in 2014 to look online for information on direct drilling and spent hours reading the farming forum comments and watching Youtube videos of people’s experiences, from that the Mzuri name came up. I had demoed other drills but most were a version of a combination drill rather than the options available now so I looked in more detail at the strip till concept. I think we all do our own version of min till, i.e. we all think we do the minimum amount of tillage necessary to achieve the desired results. I felt the Mzuri’s leading leg and consolidating wheel were necessary on my heavier soils to create the correct conditions rather than a slot or smear. After a visit from Mzuri’s Ben, who had a look round and a chat (he really was checking out the condition of my soil), we decided a demo was worthwhile and after wheel kicking at Cereals 2014 the autumn date was set.

The wheat went in perfectly as the Youtube video shows, and myself and a few neighbours dug and scraped the soil and decided, why wouldn’t it work? It did, and very well, the subsequent wheat crop more than matched any other wheat I had that year, so far so good. I would have liked to have said “just leave the drill here” but to justify a new drill to sow a small percentage of my crops was difficult. Mzuri told me of someone who had a drill and farmed locally, so myself and a friend visited Patrick Fraser who runs a mounted 3T version and his wheat and rape looked well established and his feedback both pros and cons were very helpful. I began to look for a second hand 3 meter Protil and I found a trailed one online, with Mzuri’s endorsement

I went ahead and bought a single hopper drill in immaculate condition and at a good price (even for a Scotsman) due to its single hopper. The 3 meter drill does come with an estimation of the horsepower required, at 180 it is steep, but even on my tougher soils it was realistic even at the start when the soils were tight and I would hope to require less as time goes by. Having said all that I did upgrade my tractor from a Valtra 183D to a Valtra 234D clad in Scottish rugby star Doddie Weir’s own MND tartan designed by my wife’s company no less. The tractor does feature on my Youtube channel ‘Everything is Greenknowe’ with the drill before anyone points out its more than a 180, but nobody buys a smaller tractor than they trade in, do they?

The first crop I put in with the drill was spring beans, again with Mzuri’s help in setting up, something they did FOC, above and beyond my expectation. The initial day was daunting as it was different to anything I had ever done before but the beans were through and rowed up very evenly a few weeks later, to my relief. Next I did spring oats, grown for Quaker, sown straight into over wintered stubble and again they came up and away very evenly but my first mistake was soon to come. Being a bit thrifty I had a dispute/discussion with my agronomist about the need to spray what looked like a clean stubble prior to sowing spring malting barley. After sowing, the cold wet Scottish spring stalled the barley long enough for every weed known to man to appear and confirm my agronomists concerns, first lesson learned, start with a clean slate.

Don’t worry he constantly reminds me! I now use a hired straw rake on my rape stubble mostly for slug and slug egg destruction as I find it halves numbers prior to wheat sowing and I try and glyphosate my stubbles as I don’t spray off crops prior to harvest. I do try to resist any other form of ‘recreational’ tillage as I strive to stop the part of my brain which is conditioned to think loose, brown, power harrowed soil and green rows are a sign of a successful crop. My strip tilling has now progressed to almost all of my crops with 30% of winter barley, 95% of wheat, all the rape, oats and beans put in with the Mzuri system with fantastic results. I have kept my 15 year old plough and the combi drill for the few barleys, but they won’t be replaced. I do still feel when I leave a field after sowing that it hasn’t really taken enough time and effort and it will never work, but it does.

This year’s harvest has produced some great crops, some of the best wheats I have ever grown, great OSR crops (sorry South of England) and the spring beans and oats are on Youtube and look excellent so far! I have sown 9 different crops with the drill to date with the standard equipment and I hope to try cover crops in the future if I get into the AECS scheme I have applied for. I have now traded in my single hopper 3T and have a new 3 meter dual hopper Mzuri with the new upgrades on the fan, disc and low disturbance single coulters which will all be useful, and I look forward to fertiliser placement which can only be a good thing. I would like to put beans down the front leg, cereals down the coulter and a clover out the pelleter as a cover crop but only with the help of a scheme payment.

I was recently lucky enough to be asked to take part in a Q & A at Cereals in the Conservation Tillage tent, hosted by Clive Bailye, a premier league of very experienced direct drillers and then me. I had so many of my own questions for the panel as they had many years of experience and each their own approach. I do a very simple version but we were all focused on improving soil health, margins and building a resilience in our soils and business in our own different ways. I was asked if I saw myself moving to direct drilling from striptill in the future but I stuck to my original thought, we are all doing the minimum tillage for our needs and strip tillage on my ground is, I feel, the minimum required. Of course like the British weather all that can change.

-

7 Ways To Measure Soil Health Improvements

Written By Laura Barrera and first published on Agfuse.com

While soil health may be harder to quantify than benefits like biomass production or input savings, there are ways of measuring how cover crops are making a difference in your soil.

While there are numerous reasons for using cover crops, a primary one is improving soil health. In fact, it’s the one benefit most farmers using cover crops have experienced: In the most recent US Cover Crop Survey Annual Report, of those who rated the statement, “Using cover crops has improved soil health on my farm,” 86% agreed or strongly agreed.

The report notes that it’s interesting and heartening that “soil health reflects an embrace of a long-term, hard-toquantify benefit of cover crops, and that for the past two surveys, it has achieved the top spot by garnering 86% of the responses.”

1 – Reduced erosion

Protecting soil from wind and water erosion is a common reason growers begin using cover crops. The easiest way to monitor this benefit is simply by looking for signs that less erosion is occuring. Diane Stott, National Soil Health Specialist for the USDA NRCS’s Soil Health Division, says you can visibly notice less erosion by seeing how little runoff there is from a field after a rain or strong wings. If you have tile drainage, it should be relatively clear after a rain.

But to quantify a reduction in erosion, Stott says you place use stakes with measurement marks at the edge of your fields, preferably with one stake in a nearby field that’s not in cover crops for comparison. Over time, you can check those measurements on the stakes to see how little soil you’re losing, if any, compared to the fields that are bare.

Stott notes that it doesn’t take much for a significant amount of soil to be lost. In fact, if a field loses as little as ¼ of an inch of soil per acre, that’s 10 tons of topsoil gone. “I have seen fields where people who have been in cover crops for a number of years, compared to their neighbours who have not, and it’s frightening the amount of difference there is in the level of soil between the two,” Stott says.

2 – Less compaction

Another soil health benefit you should see after using cover crops is less compaction and deeper root penetration, especially if you’re seeding species like daikon radishes, which are known for growing a deep taproot. To measure soil compaction, you’ll need either a penetrometer, a soil probe or a steel rod, Stott says. If you’re looking for more precise measurements of your soil compaction, you’ll want to use a penetrometer. Which measures the soil’s compaction in pounds per square inch (psi).

In a Penn State Extension article written by soil scientist Sjeord Duiker, he recommends using the penetrometer when the whole profile is at field capacity, which is approximately 24 hours after a soaking rain. Spring is the best time of year for this, he says, because the whole profile will have been thoroughly moistened during the winter. He notes that if the soil is too wet or too dry, compaction could be under- or overestimated, respectively.

Some other things to consider when using the penetrometer are the tip options. In a YouTube video by University of Wisconsin Integrated Pest and Crop Management, soil scientist Francisco Arriaga explains that there is a ½-inch tip and ¾-inch tip. The ½-inch tip is generally used on soils that are harder, while the larger tip would be used for soils that are looser and have better structure

To take a soil compaction reading, Arriaga recommends first taking a reading in a fencerow or somewhere with the same soil type hasn’t had any traffic on it, which would give you a good comparison of the soil’s natural compaction. Push it in the soil and watch the gauge to see how much pressure is required to get through. The easier it is to push, the better your soil structure is. You can return to the same spots in the field year after year to perform this test and see how the cover crops are alleviating soil compaction. Stott says that if you’re seeding a cover crop mix that contains 30-40% radishes, you should see a difference after just one year. She also notes that covers are best at alleviating plow pans and compaction that was formed by equipment, livestock or tillage. Cover crops may not be able to alleviate diagnostic compacted layers that are natural in the soil.

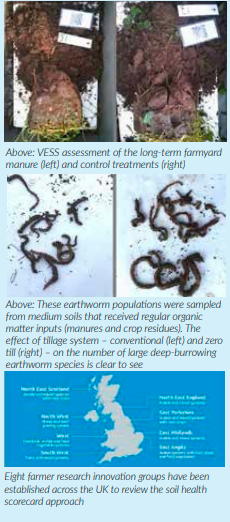

3 – More earthworms

Earthworms are another indication of good soil health that you can measure, as they “need moist soils that have sufficient residue or organic matter for food,” writes Christina Currell, a water quantity educator for Michigan State University Extension. You can do earthworm counts to see if your populations are increasing by digging out a square foot of soil one foot deep, and counting the number of worms found, Currell says. To count for deep-burrowing worms, you could also level out the bottom of the hole and slowly pour a solution of 2 tablespoons of mustard powder dissolved in 2 litres of water, which will cause them to come to the surface within 5 minutes.

Currell points out that if earthworm counts are taken when the soil is dry, your number is likely to be lower, and populations are typically higher in areas with high organic matter. You should try to do your counts in a spot that’s a good representation of the field. She recommends doing the test several times during the growing season and to get an average count. Stott notes that if you’re located in a northern area, you shouldn’t be too worried if you don’t see too many earthworms.

“Understand that, especially in the northern states, earthworms are not indigenous,” she explains. “Most of them have been seeded. Anything that’s from a glaciated area, the earthworms are not native. So don’t worry if you don’t see any earthworms, it does not mean your soil is bad.” Instead, she suggests looking for other beneficial species and see if you notice an increase in populations as you continue cover cropping.

4 – Faster Water Infiltration

As cover crops help lower your erosion and compaction, while also increasing earthworm populations, your soil’s water infiltration rate should improve as well. To measure your infiltration rate, Stott recommends taking a No. 10 coffee can with both ends cut out and placing it in the soil. Pour two inches of water into the can and time how long it takes for the water to seep into the soil. The longer you use cover crops, the faster your water infiltration rate should be.

5 – Higher organic matter

Along with infiltrating water faster, cover crops should also help your soil’s waterholding capacity, as it increases the soil’s organic matter. According to the NRCS, organic matter holds 18-20 times its weight in water, which means 1% of organic matter in the top 6 inches of soil holds approximately 27,000 gallons of water per acre. Measuring organic matter just requires a soil test, but Stott warns that it’s going to take longer for growers to see a significant change in their organic matter percentages.

That doesn’t mean that soil organic matter isn’t increasing — just that it takes a while for the tests to detect those changes. Stott says you’re not going to see a significant change in your soil test values until there’s been at least a 0.3% change in the soil. If you’re in the Midwest, it’ll probably take 3-5 years to see your organic matter levels increase on your soil test results, she says, and if you’re in a drier region you may not see any significant changes for 5-10 years.

Because of how long it takes to see a change, Stott recommends taking a soil test before you start using cover crops to get a baseline number, but don’t test it again for another 5 years. In the meantime, look for qualitative changes to your soil for verification that your organic matter and soil health are improving.

6 – Better soil stability

One qualitative measure you can take to see how your soil health is improving is the Slake Test, also known as the Soil Stability Test.

The Slake Test, measures the stability of soil when exposed to rapid wetting, adding that soil stability serves as a “qualitative indicator of soil biological activity, energy flow and nutrient cycling.” To perform the Slake Test, you’ll need two glass jars, wire mesh that can be hooked onto the glass jars, and a chunk of soil from your fields, as well as some soil from another area that can serve as a comparison. The NRCS says this can be from a grassland, fencerow, or notilled field, if you’re not no-tilling.

The Slake Test: This compares how soils hold together when wetted. The soil samples are held in a wire cage which is in the top part of a vertical jar of water. The jar stands for some hours and the test is to see how quickly the soil disapates in the water. The faster this happens, the less stable the soil. Low stability soils get lost through field drains and erode from the surface run off. For a visual on how the Slake Test is done, scan the QR Code below with soil scientist Ray Archuleta using it.

Another simpler qualitative measurement similar to the Slake Test is to spray the soil aggregates found clinging to roots. Stott says to place the aggregates in a dish and spray water on them. You’ll see if the aggregates hold together or if they fall apart.

You can continue performing these m e a s u re m e n t s over time to see how much your soil structure improves from cover crops.

7 – Visual Changes

Finally, one of the easiest tools for observing how your soil health is improving is the shovel. Stott recommends digging 1-2 feet deep in your soil to examine the color of it, how deep roots go and how soil aggregates are clinging to the plant roots. The color of your soil should be getting darker, she says, and you should see more soil aggregates near the soil surface. “They’ll start seeing a marked increase in that nice crumbly feel in their soil,” she explains, noting that this can occur as soon as the first season after using cover crops for growers in more humid regions”

If possible, it’s a good idea to do this before you start cover cropping, she says. She also recommends digging in a fencerow that you can compare to your field, so you get an idea of the condition of your soils and how close or different they are from their natural state. “You can learn so much that way and it’s a lot cheaper than sending things to the laboratory,” Stott says. To better track how these changes progress, take videos and photos so you have a way to compare how much your soil health improves.

-

Drill Manufacturers In Focus…

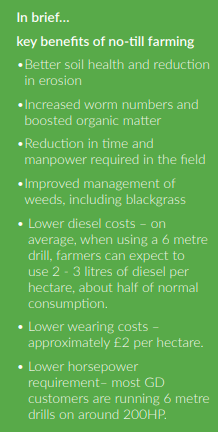

NO-TILL FARMING: BOOSTED SOIL HEALTH, CUT COSTS… IT’S THE FUTURE

Worcestershire-based Weaving Machinery – manufacturers and suppliers of farming equipment – have called on UK farmers to investigate and consider implementing no-till systems as part of a campaign for better soil health, highlighting not just the conservation benefits of low disturbance farming, but also the cost savings and greater control across the farm. No-till farming has seen a steady increase over recent years in the UK, despite historically slower rates of adoption compared to other parts of the world.

According to the UN Food and Agriculture Organisation (FAO), food production must increase by 70% by 2050, in order to meet the needs of the projected population of 9 billion. This will naturally require a rethink in terms of optimising productivity but also demands a greater need for sustainability. More and more farmers are already aware of this sea-change, and the industry is experiencing a shift towards no-till as a means to achieve better soil health and sustainable production… all while cutting costs and saving time.

“The shift has been massive,” says Simon Weaving, Sales Director at Weaving Machinery. “Five years ago, farming was all about completely mixing the soil profile. Today, it’s more about lifting the soil profile, rather than mixing. Farmers are beginning to understand the very real benefits they can see when incorporating a no-till system.”

The drive for better soil health

The UN recently stated that the world’s soil reserves has only an estimated 60 harvests left before complete degradation, with around a third of the world’s soil already at that point. Michael Gove, the former environment secretary, also warned that the UK is only a few decades away from “the fundamental eradication of soil fertility”, adding that “countries can withstand coups d’état, wars and conflict, even leaving the EU, but no country can withstand the loss of its soil and fertility.” The British government has also signalled possible incentives for farmers who promote better soil health following Brexit, though these are not set in stone.

While the importance of soil health is widely understood, why the slow rate of adoption? Part of this is the UK’s strong sense of tradition in farming, but a significant barrier to entry has been the cost. With many farms under increasing financial pressure, few are willing to invest and risk trialling a new method of farming, even if the benefits are clear.

For Weaving’s part, accessibility and affordability has always been one of their leading mission statements: “I completely understand that farmers may be wary of leaping straight into direct drilling or low disturbance farming,” says Simon. “Our drills are designed to work on conventional systems as well, for complete flexibility. Ultimately, no-till is the direction the industry is heading, and it’s a change that will directly benefit both this country’s soil health and, importantly, the financial security of UK farmers.”

The benefits of no-till farming

No-till requires more planning but advocates are quick to praise the huge benefits they’ve seen on farm. These include a cut in costs for machinery, labour, fertiliser, and chemicals. In turn, this leads to a marked increase in insects, birds and wildlife, as well as fewer floods and more resilient crops during droughts.

At face value, the cost savings might prove the biggest incentive for interested farmers. Savings include less money spent on diesel, parts that wear far slower, less manpower required in the field, and less horsepower (and therefore fuel consumption) during the crop cycle. These costs may be relatively small when taken individually, but quickly add up.

In the long-term, no-till also increases worm numbers and boosts organic matter. Unlike conventional systems, no-till keeps everything underneath the surface, giving it a chance to build up. This also leads to another significant benefit for many farmers: a solid defence against blackgrass.

Fighting Blackgrass

Blackgrass is a grass weed that grows in any condition, particularly thriving in very wet weather, that grows in the crop and smothers it. A persistent threat, blackgrass has the potential to halve – or more – cereal yields. Simon Weaving identifies customers who saw their yields fall by as much as 4t/ha. Blackgrass seeds can lie dormant for years before activation, which can then be exacerbated by cultivating and mixing the soil profile. While by no means an all-purpose solution, notill means the seed hits the floor and stays there – making spraying much more cost-efficient, effective, and long-lasting.

“We made this decision because we just had to tackle blackgrass,” says one Weaving customer who adopted a no-till system. “This system was affordable and a viable route to go down. No-till has lots to recommend it in terms of preserving soil health, but to be honest ours was largely a practical decision. This is the right thing to do for our farm.”

The next step

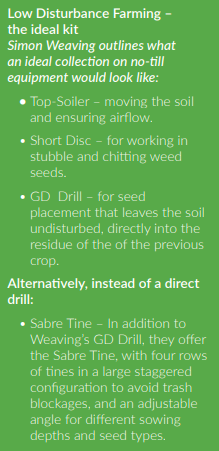

As more farmers begin to consider whether no-till can work for them, what are the next steps? Simon Weaving advises to take stock of your current situation. “First, look at your soil health,” he says. “Is it at the levels it should be? If the soil is in poor health, you might not want to jump straight into direct drilling. You can use a machine like our LD top spoiler to slice into and lift up the soil. This gets air underneath before putting it back down with minimal disturbance before drilling.”

“All farmers should be seriously looking at no-till as an option for their farm,” adds Simon. “Year on year, we’re seeing more farms trial whether no-till can work for them, to achieve better soil health, reduce costs, or implement better weed control. We’ve worked to deliver machinery that has the power and functionality for farms of all sizes and systems, to improve soil health – all while keeping yields strong.”

Find out if no-till could benefit your farm. Contact Weaving Machinery to learn more about their newest drills and other robust and reasonably priced farm machinery at https://www.weavingmachinery.net

About Weaving

Weaving is a family run company founded in 1983. Its aim from the very beginning was to offer farmers the best quality farm machinery at affordable prices. The company distributes farm machinery throughout the whole of the UK. The newest GD Drill, as with all Weaving products, is made totally on site. From design, fabrication, construction and spraying, everything is done in-house, all at the Evesham headquarters

-

Cover Crop Strategy Getting It Right For Success.

Written by James Warne of Soil First Farming

A cover crop can be anything that is not intended to be harvested. It is simply there to provide soil cover, light

interception, push roots in the soil and carbon sequestration.If you are following a true Conservation Agriculture (CA) system, cover cropping is an essential part of the system. The three principles of Conservation Agriculture are;

1, Minimum soil disturbance

2, Soil Cover

3, Diversity

The clue to cover crops is in the name, for them to work for you they need to firstly cover the soil, 100% of the soil, simple. While cover is the simplest measurement, they also intercept light and use photosynthesis to capture carbon and store it in the soil. Cover crops help us fulfil all three of the CA principles. Roots help to stabilise soil, and create structure by feeding biology, reducing the need for cultivation; providing soil cover when no cash crop is growing which protects the soil from the damaging compacting effects of rainfall and warming by the sun; and providing diversity in species and rotation.

Roots can help stabilise structureless soil and provide the ultimate cultivation.

A lot of CA promotion in the UK and abroad focuses on growing large biomass cover crops with multiple species, sometimes up to 15 different species in the cover crop. While this looks amazing and certainly does bring benefits, and is the eventual goal with cover crops there are downsides to this strategy particularly in the early years of CA adoption particularly with relation to cost.

It is easy to forget many of these amazing cover crops are being grown on soils that have been in CA system for many years and therefore have greater tilth and structure which provide better seed:soil contact to drill into and reliable establishment. There will certainly be better nutrient cycling, nutrient availability and greater water holding capacity and this is all due to the soil having more carbon stored within it. The Carbon to nitrogen ratio of the soil is also more likely to be in balance meaning the cover crop can access the nitrogen it requires. At Soil First Farming we believe in the early years it’s much better to stick to a simpler strategy and to build on this success year on year with increasing complexity of cover crop mix as you gain confidence in the system.

In the initial years stick to monocultures or mixtures with a maximum of three species. The soil is in ‘cultivation cold turkey’ at this point and it’s very easy for the soil to become compacted by trafficking at harvest, excessive precipitation and gravity. Therefore to stabilise the soil as quickly as possible you need roots, lots of roots. Focus on growing something cheap at a high seed rate to ensure not only soil cover but lots of roots per square metre. Preferably something with a reasonable taproot and some finer fibrous roots. Mustard is perfect for this. Crops in store can also provide a good starting point, such as OSR, Linseed, and be very cost effective.

It is very easy to lose confidence in the system in the early years especially when experience is low, the risk of cash or cover crop failure is high and there is little self-belief. To ward against this is it easy to think that if you spend a lot of money on a cover crop mix that you must be doing the right thing. Confidence then takes a crash as only two or three species of the expensive mix actually establish and the cover crop looks very thin and you realise it was an expensive mistake. In our experience it is much better to sow a simple crop and get it established in good time.

Many people get hung up on cover crop species and not wanting to grow brassicas or legumes because they have them as cash crops in the rotation already. We have been told not to grow these too close in rotation due to the potential build-up of soil borne pathogens such as club-root (a nutrition issue in reality) and rhizoctonia. But generally we don’t seem so concerned about growing cereals close in rotation. All of the in-field evidence suggests that using legumes and brassicas in cover crops does not increase the incidence of these pathogens providing they are not grown as a cover crop immediately prior to planting the same species as a cash crop. The only detrimental incidence I have seen is where BYDV incidence was high in crop of winter barley grown after spring barley volunteers were used as a cover and destroyed on the day of drilling the winter barley.

For over-wintered cover crops legumes are essential to balance out the large carbon input from straw and lignified cover crop residues. Too often we see situation where the following cash crop is struggling due to imbalanced soil carbon to nitrogen ratios, a big part of the feared yield dip. There is a desire to spend the budget on the seed and then forget nutrition. In order for cover crops to fulfil they part in the system we need them work hard, but to work hard they need nutrition. Chopped straw and other crop residues can quickly push the C:N too far in excess of carbon which then reduces the nitrogen available for the growing cover crop.

Most cover crops are destroyed before the crop has completed its full life cycle, we believe this is also detrimental for some pathogens which reduces the likelihood of pathogen build-up. As the soil biology begins to build we also see trash degrade quicker, large earthworm populations in particular can cover and digest chopped straw residues within a few months with ease. This reduces the chances of a green bridge effect of pathogen transfer. Some growers are also reporting that fusarium levels are much lower than the fusarium risk assessment would suggest. Again we believe this is attributable to increased straw digestion by greater soil biological activity. In our brave new world of Boris’s bold optimism it is important not to let the failures outweigh the successes. We must have a mindset of positive thinking and believe in the system for success.

-

Farmer Focus Adam Driver

“Driver Farms is a family run 1200ha contract farming business based in Suffolk farming hanslope series clay. They practice a regenerative agriculture system based on zero and min till. All agronomy is carried out in house. They are also five years into running a 12m CTF system’