If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

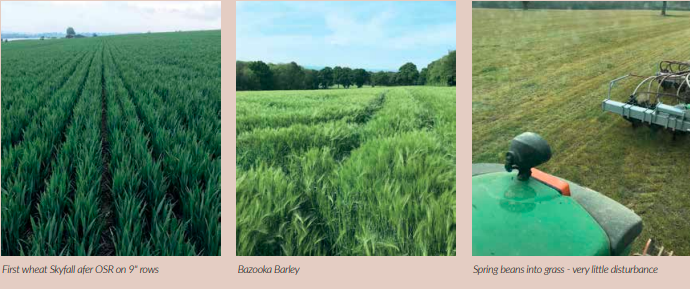

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Farmer Focus – Andy Howard

Farming in Transition

This year on our farm we have used no tillage, 40% less Nitrogen fertiliser than standard practice, over 50% less fungicides and only one insecticide on a 3ha field of Spring linseed. Has getting to this stage been easy? No. Has it all gone perfectly? Definitely not.

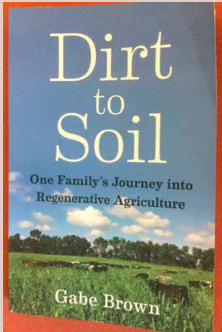

It has been a hard road we have taken to get to this stage over the last 18 years with many lessons learnt and many more lessons to come. Transition is difficult and you must be prepared to fail. When I visited Gabe Brown in North Dakota he said, “if he didn’t fail at least once a year he wasn’t trying hard enough!” When we started reducing tillage in 2001 there weren’t many people to advise us. The same was true when we grew our first cover crop a few years later and now we are reducing inputs there are very few people to advise us.

So, we had some glorious failures, this though now can be avoided as there is much more information out there now, as long as you speak to the right people. I think practising farmers are the best option. So why are we going through this transition? For me there are a few choices going forward into the future. We go for a high input/ high output system and probably fail on the high output part most years! We can go organic, I have had the pleasure of visiting many great organic farmers, but the system is currently not for me due to too much cultivation, potentially high weed burdens and large yield variation.

On my Farm I believe the best economic and environmental route is a hybrid system of the two.

Judicious use of pesticides and fertilisers with the aim of reducing their use year on year by using cultural and Agroecological methods. This will hopefully maintain yields but at the same time reduce cost per tonne produced, reducing the farms exposure to weather and market variations. There are a few other reasons why I am choosing the low input system over the high input system: firstly, I don’t believe we have a choice. Consumers, climate change activists, water companies, The Environment Agency and many others are demanding produce that is grown with less fertiliser and “cides”, these demands are getting louder.

The current drive to high input/high output cereal farming will I believe become uneconomical, possibly illegal, if the polluter pays principal is applied. Secondly the chemical tools in our armoury are quickly being removed and the ones left have increasing resistance to them, alternatives methods must be found. Finally farming this way is far more interesting. The conventional way of farming hides many issues with plant and soil health by covering them with fungicides and applying excess amounts of fertiliser. It is not until you reduce or remove their use that you start to see differences in terms of plant health between fields and within fields, then you need to try to work out the root cause of the differences.

An example of this, this year, our only areas of wheat affected by BYDV are on the sandy soil which became Manganese deficient in January, which then made the wheat attractive to aphids. So next year we will have to improve nutritional management on the lighter ground. Interestingly these same areas are the only place we have seen excessive disease in the wheat, no wheat had a fungicide until flag leaf. I personally think the deficiency of Manganese led to BYDV which then stressed the plant allowing disease to enter the crop.

I seem to spend a lot of my time being told by people that what I am doing is not possible. Most magazines you read will tell you of the impending disaster if you dare omit a pass with a chemical. If it wasn’t for my experiences on my Nuffield Scholarship, seeing amazing farmers around the world who have drastically reduce inputs while maintaining or increasing their yields, I may have had doubts and returned to the standard current practices. What did they all have in common? Diversity of cropping and a whole farm systems approach. There is no way I am going back now!

The major advantage of the standard practices is that it’s easy. Your agronomist gives a recommendation, you send out the sprayer to carry out the orders and you don’t even need to enter the field. This is not true of a low input regenerative system of farming. You need to be out there regularly checking your crops, observing differences, digging holes and sometimes have big balls to say no to your agronomist. Every year is different, standard “T” timings and products do not cut it. Achieving a successful low input system starts with the soil. A healthy soil grows a healthy plant which in turn needs less fertiliser and is more resilient to pest and diseases.

This whole farm systems approach is knowledge intensive not input intensive. You need diversity and need to be flexible, if you think you can just cut out inputs and all be fine you could get a shock. Adding diversity to our cropping for me is the most important strategy we need utilise more going forward. This year we have used oats as a companion crop for spring linseed, as I observed last year that the linseed growing in wild oat patches were less affected by Flax Flea Beetle. The Innovative Farmers trial here has shown that where linseed was planted with the oats, we have about 80-100 more plants per m2 survive the Flea Beetle onslaught compared to the monocrop Linseed. A great example of Diversity in action.

Unlike organic farming this reduced input approach doesn’t receive transitional payments or receive a premium for your produce and so for it to work costs need to be reduced and good advice needs to be taken, especially in the early years to avoid the big mistakes that we have made here on our farm. An issue with the whole farm systems approach is that it is complicated so their needs to be an understanding of the knock-on effects of each decision. During the last couple of years of travelling the country and talking at farming events I have noticed a real growing interest in reduced input farming. I was getting many questions on Notill, cover crops, intercropping and input reduction strategies so I thought there was an information gap that needed to be filled.

Like most farmers they prefer to listen from other farmers and learn from their successes and failures rather than experts with no skin in the game who can be driven by other vested interests and agendas. As a result, I have joined Abacus Agriculture as a consultant. Abacus are a group of independent consultants and farmers, who advise on transitioning to organic farming, agroforestry and soil management. Adding myself to the group seemed to make obvious sense, we are all advising on transitioning in farming and have much we can learn from each other. So if you think you want to start this transition take a look at our transition tool by scanning the QR Code.

Join the growing group of farmers leading the way to a sustainable farming future and making farming exciting again!

-

Earthworm Engineers

Written by Eliza Jenkins Community Development at Sectormentor for Soils. Eliza helps to nurture the community at

Sectormentor for Soils – a system that enables you to monitor and assess soil health on your farm.Earthworm Engineers #1: Ecosystem Services

Many fascinating papers on earthworms have recently been open access to online readers of the European Journal of Soil Science, so we chose four of our favourites to summarise into a series on the on-farm heroism of earthworms.

#1: A review of earthworm impact on soil function and ecosystem services

First, this comprehensive review reminds us of the many reasons why earthworms are farmers’ best friends. We can separate earthworm species into three categories: surfacedwelling worms (epigeic), deep-burrowing worms (anecic), and network-creating worms (endogeic). All three of these worm types play an important role. In their soils, earthworms are considered ‘ecosystem engineers’, and they earn this title for several reasons…

First, earthworms actually create soil! Worms feed on leaf litter on the soil surface then bury the organic matter into the soil, allowing it to be mixed and decomposed, and eventually incorporated as soil organic carbon within soil aggregates. This same process also allows for nutrient cycling in the soil, which is helped by the soils’ increased surface area due to the networks of earthworm channels. In eating soil and moving it around, worms have even been shown to heal soils that are polluted, by breaking down the contamination.

The presence of earthworms improves the soil structure, as the pore network created allows for a higher ‘bulk density’ of stable aggregates. This pore network can also improve plant root penetration, and the water infiltration ability of the soil, by creating space for the water. The increased drainage and the creation of water-stable soil aggregates can also reduce runoff on farms, as well as soil erosion by up to 50%. As earthworms burrow into the soil and bury organic carbon, they also help the process of carbon sequestration – the locking up of of CO2 from the air into soil organic carbon (SOC) in the soil.

But this soil carbon can be re-released again as greenhouse gases, especially when the soil is disturbed during ploughing. The process of building up carbon in the soil is complex, and varies depending on how much organic matter is available to the worms on the soil surface. Considering all of these earthworm endeavours going on beneath our feet, it’s unsurprising that this paper finishes by reporting that the presence of earthworms has been widely shown to improve the growth of plants above ground. Now it’s clear why they’re considered the engineers of their ecosystem!

Earthworm Engineers #2: Arable Farming and Earthworm Populations

Many fascinating papers on earthworms have recently been open access to online readers of the European Journal of Soil Science, so we chose four of our favourites to summarise into a series on the on-farm heroism of earthworms.

#2: Effects on populations of earthworms of different methods of cultivation and direct drilling, and disposal of straw residues

Our second installment comes is a paper that makes some really interesting conclusions about the effects of cultivation on earthworms in topsoil. They tested the number of earthworms over four years on direct-drilled fields that were sprayed with herbicide before planting, and ploughed fields (of varying soil types). They found earthworm populations were consistently greater in the direct-drilled soils compared with ploughed soils, although deep-burrowing species were affected similarly in both treatments. They also test the effect of spreading mulch on the fields compared to burning straw residue, and find (unsurprisingly) that earthworm populations were greater in fields where straw residue was spread rather than burned, particularly in surface feeding species. This surface debris becomes an important food source for the worms, and makes their diet more stable.

It is also suggested that the extra earthworm channels created under no-till soils may help to reduce any compaction in the soil, as well as distributing organic matter and facilitating drainage. The reduction in compaction is also likely due to increased plant root penetration within earthworm channels.

The three key tenets of regenerative agriculture are maintaining soil cover, minimising soil disturbance, and diversifying crop rotations. This paper presents clear scientific evidence of the positive influence of minimal cultivation, and soil cover (as mulch) on the earthworm community, and as we learnt in the first edition of our series, earthworms have a significant influence on the health of soils. All the more reason to farm with a regenerative approach and encourage our earthworm friends.

Earthworm Engineers #3: Organic vs Conventional Symptoms

Many fascinating papers on earthworms have recently been open access to online readers of the European Journal of Soil Science, so we chose four of our favourites to summarise into a series on the on-farm heroism of earthworms.

#3: The impact of soil carbon management on soil macropore structure: a comparison of two apple orchard systems in New Zealand

When testing for earthworm populations, the researchers consistently found more earthworms in the organic soil compared with the conventional soil. They also reconstructed the 3D ‘macroporosity’ structure of both soils using X-rays, and again found greater macroporosity within the organic soil compared to the conventional soil. This isn’t a coincidence! Macroporosity is defined as the network of pores with a diameter of over 0.3 mm in the soil, and earthworms are known to create these kinds of channels. This increased macroporosity is important for several reasons. First, it is known to increase the rate that CO2 in the atmosphere is locked up as soil organic carbon (SOC), which both increases soil fertility and also has potential to reduce the rate of climate change.

As expected, this study then found that the organic orchard had a 32% greater SOC content than the conventional soils. Increased macroporosity also improves the soil structure, as the stability of soil aggregates is increased, which allows more microbes to live in the soil. Denitrification rates are known to increase in anoxic, water-logged soils, which leads to increased emissions of N20, a gas that contributes to climate change. As a result, increased macroporosity reduces denitrification in the soil, by allowing oxygen to penetrate into the topsoil, and reducing the chances of water logging. It’s amazing to see evidence of how organic techniques allow our earthworm friends to flourish, and how positive their presence is orchard soils.

Earthworm Engineers #4: Manure and Earthworm Populations

Many fascinating papers on earthworms have recently been open access to online readers of the European Journal of Soil Science, so we chose four of our favourites to summarise into a series on the on-farm heroism of earthworms.

#4: Quantifying dung carbon incorporation by earthworms in pasture soils

This study looks at the effect of different earthworm communities on the amount of soil carbon (within dung applications) shifted into the soil. They tracked this process by labelling the carbon with isotope tracing, which is a clever technique that gives a really specific picture of where exactly the carbon is moving to. The three main earthworm types were tested in different treatments: surface-dwelling worms (epigeic), deep-burrowing worms (anecic), and networkcreating worms (endogeic).

First, the researchers found that with increasing inputs of dung, the abundance of earthworms tested also increased, presumably because the worms had a more consistent food source in these pots and could flourish.

Most of the tracked carbon was found in the soils top layer (0-75mm), although when the earthworm population included deep burrowing (anecic) earthworms, carbon from dung was often found at depths of up to 300mm, which shows just how effective these worms are at burrowing materials from the soil surface into its lower levels. The most successful treatments (with the greatest flow of dung shifted into soil organic carbon (SOC)) were those with all three types of earthworms present (epigeic, anecic and endogeic). So, a diverse population of worms is necessary for optimal dung break down into soils. In pasture soils, dung left by livestock can therefore contribute to increased earthworm populations, as well as increasing SOC.

This is important for the soils nutrient supply, and also helps to reduce CO2 levels in the atmosphere, which has potential to reduce the effects of climate change. In conventionally grazed systems, the quantity of dung deposited per hectare are less than the amounts used in this study, but it’s interesting to think about how this research adds to the evidence supporting mob-grazing systems, where livestock graze fields more intensively, and more manure is deposited per hectare as the stock moves through. With more manure available, there is potential for enhanced earthworm populations, and increased SOC content as more organic matter can be pulled into the soil.

-

What Farmers Need To Know About Mycorrhizae

Written By Laura Barrera First Published on AGfuse.com

If someone asked you, “How do plants take up the water and nutrients they need?” you’d probably tell

them through the roots. But did you know that for many crops, those roots aren’t working alone?

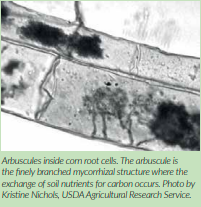

That’s because most plant species associate with mycorrhizal fungi.What are mycorrhizal fungi? University of Alberta biological scientist JC Cahill says that mycorrhizas are actually the interaction between a fungus and a plant. Although there are many different types of mycorrhizae, the only one crop farmers need to be concerned about is arbuscular mycorrhizal fungi (AMF), as 65% of plant species associate with it.

And barring anything extreme that’s happened to your fields — such as mining or a toxic spill — your soils should already have AMF in it, says Miranda Hart, a soil microbial ecologist at the University of British Columbia. The way AMF works, Cahill explains, is that they grow inside the plant’s roots, and in exchange for sugar from the plant, the hyphae — the threadlike filaments of the fungi — capture water and nutrients in the soil for the plant. While this symbiotic relationship is often seen and discussed as a benefit to crop production, Cahill and Hart warn that’s not always the case. But there are steps farmers can take to help AMF be more of an advantage than a disadvantage for their crops.

Benefits of Mycorrhizae

One of AMF’s benefits to crops, and perhaps the most significant, is phosphorus uptake.

A study at the University of Adelaide in Australia was conducted to quantify the contribution of AMF to phosphorus uptake in wheat. The researchers used phosphorus 32, a radioactive isotope of phosphorus, and grew the wheat in compartmented pots with highly calcareous and phosphorus-fixing soil from a major cereal-growing area in South Australia. Researchers found that over 50% of phosphorus uptake in plants was absorbed via AMF, and phosphorus 32 was only detected in the AMF plants. In fact, an influx of phosphorus in roots colonized by mycorrhizal fungi can be three to five times higher than in non-mycorrhizal roots, according to the article “Phosphorus Uptake by Plants: From Soil to Cell.” The reason for this is because mycorrhizae allows the plant to explore a greater volume of soil.

The book, “Phosphorus in action – Biological processes in soil phosphorus cycling. Soil Biology Vol. 26,” explains that while root hairs can only extend a few millimeters, the hyphae of some AMF can extend many centimeters away. Alice Roy-Bolduc and Mohamed Hijri, authors of the article “The Use of Mycorrhizae to Enhance Phosphorus Uptake: A Way Out The Phosphorus Crisis,” say that in addition to the larger surface area, phosphorus is also highly immobile and phosphate ions become rapidly bound with cations, making it unavailable to plants. However, they say it is known that the presence of mycorrhizal fungi improves phosphate solubility..

Phosphorus uptake is not the only benefit of AMF. Roy-Bolduc and Hijri say that because they extends the root system, they help absorb more water and can access water in smaller pores, thereby increasing plant water uptake. They also improves soil structure, contribute to soil aggregation and decrease erosion. AMF can also help plants resist and overcome pathogen infections, as the authors note that it’s well-documented that mycorrhizal associations protect tomato plants from Phytophthora parasitica and potato plants from Fusarium sambucinum.

Cahill notes that part of the reason mycorrhizae may help with crop protection is because the AMF are already living in the plant. “They’re actually taking up space that other parasitic fungi can’t then take up themselves,” he explains. “So they may actually help protect crop plants from some soil pathogens by filling up the roots.” The combination of all these benefits ultimately can contribute to higher yields and healthier crops.

When Mycorrhizae Becomes Parasitic

While AMF can provide many benefits for plants, Cahill says that in some situations the relationship can be parasitic. An example of this would be if a plant doesn’t need phosphorus or water. The AMF is still present and taking carbon and sugar from the plant, but not giving anything in return. “So what we see in nature is this relationship between the fungus and the plant goes from beneficial to the crop to detrimental, depending on exact conditions at any point in time,” Cahill explains. It’s important to understand this because farmers can help avoid creating situations that would cause the mycorrhizae to become parasitic.

The best way to prevent a parasitic situation is by ensuring the soil isn’t too fertile, Cahill says. Unfortunately, there’s no measurement established that determines the fine line between when a soil is fertile enough for crops, but not so fertile mycorrhizae becomes parasitic. “One of the reasons there isn’t is because it’s so dependent on what species of fungi you have,” he explains. “There are different levels of parasitism, and different crops are going to be differently able to prevent or not prevent parasitism.” Because phosphorus uptake is the No.1 benefit AMF provide plants, Cahill says that if there’s no evidence of phosphorus limitation in your fields, then you might not need to be concerned about mycorrhizae. He adds that mycorrhizae can also change over time — whether it’s from applying an inoculant or introducing a different crop — the effects of which could be positive or negative.

Testing for Mycorrhizae

Unfortunately, at this time it’s difficult for growers to determine whether their AMF is benefitting their crops or not, Cahill says, because it’s not enough to know whether the plants are infected by mycorrhizae. Instead, it’s a question of whether the plant would do better on its own.

Because phosphorus uptake is the No.1 benefit AMF provide plants, Cahill says that if there’s no evidence of phosphorus limitation in your fields, then you might not need to be concerned about mycorrhizae.

“We want to be very skeptical of anybody pulling up a root system and showing you all of this infection because that’s no big deal,” he explains. “We know, typically, the amount of infection in the roots, the quantity of it, isn’t related to the yield of the plant. It’s more complicated than that. It’s the physiological functioning.”

One way to think about it, Cahill explains, is if a plant is infected with mycorrhizae in a positive way, then we can expect the plant to produce fewer roots because the fungi is doing more foraging for it. If you took the fungi away, then the plant would probably produce more roots. But having more or less roots doesn’t guarantee that the plant would produce more or less yield. “You might not actually see a shift in yield because the plants are outsourcing their foraging to the fungus or doing it themselves, but they’re spending a lot of their energy either way,” Cahill explains. If a grower is seeing unhealthy crops or lower yields than expected, then he can determine if it might be an issue with his mycorrhizae by replicating a test Cahill does in his lab. Growers simply take a little soil from their fields, put into a pot of sterile soil and see how the plants in that pot grow compared to plants grown in just sterile soil. “There’s no measure of fungal biomass that we care about,” he adds. “It simply is, put it on your plants and see what happens.”

Best Practices for Healthy Mycorrhizae

Increase Crop Diversity

The best way farmers can help AMF be beneficial for their crops is by increasing their plant diversity.

“The No. 1 way to increase the diversity of fungi, which will also increase the functioning of the fungi, is to increase plant diversity in agroecosystems,” says Hart. Keith Berns, a farmer, agricultural educator and co-owner of Green Cover Seed in Bladen, Neb., recommends having eight to 10 different species in a cover crop mix, with at least six of them being highly mycorrhizal. Aside from brassicas, which do not associate with AMF, Bern says most cover crops are beneficial for AMF. “It doesn’t mean you couldn’t have brassicas in your mix,” he adds. “You just wouldn’t want to have only those in your mix. Buckwheat is also not really highly mycorrhizal.” Almost all legumes, including peas, lentils, vetch, cowpeas, chickpeas and mung beans, are good for mycorrhizal fungi growth, he says. Grasses like sorghums, millets, rye, triticale, barleys — and oats in particular — are also excellent colonizers. He also likes to see flax and sunflowers in the mix, noting they both have excellent mycorrhizal hosting capabilities.

The reason Berns recommends growing so many different species is because it’ll provide a diversity of root exudates. “There may be different strains of mycorrhizae that will like something better than another one,” Berns says. He adds that it also helps ensure there will be something available to feed the mycorrhizae. “If we have weather conditions that are too hot, too cold, too dry, too wet, that may affect some of the species in the mix, but it’s likely not going to affect everything the same amount,” he explains. “It’s not so much the species as much as having the resiliency built into the system to make sure there’s something growing there, because the one thing that we do know is that having fallow ground is literally death to the mycorrhizae, because they have to have a living host.”

Rotate Brassicas and Maintain Weed Control

Because brassicas don’t associate with AMF, Hart recommends farmers who are growing them space them out in their rotation. “In Canada, because prices are good for canola right now, a lot of farmers are going back to mono-cropping,” she says. “But if you mono-crop brassicaceous crops, you’re going to destroy the fungal communities in a couple years completely, because they need carbon. And if they can’t form it with the crop plant, they’ll eventually become extinct in that site.” Hart says that having a brassica in rotation with at least two other crops would be ideal. But for growers who are in a two-crop rotation where one is a brassica, they need to look at ways of getting other plant species in their soil, such as through intercropping or cover crops.

The reason Berns recommends growing so many different species is because it’ll provide a diversity of root exudates.

Brassicas aren’t the only species that don’t associate with AMF. Some weeds, such as lambsquarters and pigweed, are also non-mycorrhizal — another reason why preventing and controlling weed infestations like palmer amaranth is so important. “Whatever plants become dominant in a field, be they crop or weed, we know that changes the composition of the organisms that live in the soil,” Cahill says. “So if you have a plant that doesn’t form mycorrhizae becoming very dominant, those fungi in the soil are likely to become a little bit starved and those populations are likely to go down.”

Reduce Tillage

One practice growers will want to reduce or avoid when trying to promote healthy mycorrhizal fungi and soil biology is tillage. “Tilling is terrible for fungal communities. It destroys the mycelium,” Hart says. “Some fungi can handle it, but some fungi really can’t and they’ll disappear. So you’re going to decrease diversity by tilling.” Cahill agrees, noting that tillage often contributes to soil compaction, which is also detrimental to soil life. “When you have really compacted soil, we know that impacts water penetration and can impose drought, but it also doesn’t give the air spaces and pockets that all these fungi, bacteria and even nematodes and other things need to live,” he explains. “So you need to keep that soil light, which is typically done through no-till.” However, Hart warns that no-tilling often increases a farmer’s herbicide use, which could also negatively impact fungi. But there are some no-tillers like Russell Hedrick andGabe Brown who are successfully no-tilling with fewer herbicide applications by implementing a holistic, systems’ approach.

Be Mindful of Fungicides, Fertilizers

Farmers also need to be mindful of the products they apply if they want to promote AMF growth. “Fungicides will kill fungi, and many of them will kill mycorrhizal fungi,” Cahill says, adding that if you’re concerned that a fungicide may have a negative effect on the soil life, you should test it. This can be done by putting some soil from your field into a couple pots, applying fungicide to one, then growing plants in both and seeing what happens. Growers should also be mindful of fertilizers, Cahill adds, as they often impose some acidity. And as soil pH decreases, it will kill off a lot of fungi and other soil organisms. “Fungi seem to be really sensitive to change in the acidity of soil and salt contents,” he says.

Should You Use Inoculants?

If you’re growing a perennial like alfalfa or a crop that’s going to be there for 10 years, then applying an inoculant may provide a jumpstart for AMF, says Berns. “With a perennial you have no fallow period breaks, so that’s where the mycorrhizae really shine because they never have to jump from one host to another,” he says, adding that it can be harder to justify the cost of an inoculant on an annual crop. But Berns has done some testing with these products on his farm, and has observed some differences between plots treated with inoculants vs. the control plots, particularly with aboveground growth and root mass. This year he put a lot on his corn and soybean acres and is waiting to see if they made any difference.

Cahill encourages all farmers to do as Berns has and become scientists on their own farms, “because they’ll be able to see with their own eyes whether it does or doesn’t have an effect.” He also recommends growers test these products before applying it to their whole fields by again testing them in pots. Farmers can do this by growing some plants in a pot of sterile soil with the inoculant and some in a pot without the inoculant, and seeing if there’s a yield difference.

Growers should also be mindful of fertilizers, Cahill adds, as they often impose some acidity. And as soil pH decreases, it will kill off a lot of fungi and other soil organisms.

The reason he wants growers to do some small trials first is because there’s no widespread evidence these products are beneficial all the time, and if a parasitic inoculant establishes in a field, there’s no easy way to remove it. In fact, he tells his students every year that the one thing he wants them to remember from his class is to not let their moms buy a bag of inoculum from the garden store and just apply it to their gardens. “She’s most likely paying to put parasites on her garden,” he says. “Until you can prove it works in that garden, it’s not worth the money.” He says to think of mycorrhizal inoculants like fertilizer. “We know that adding fertilizer doesn’t always increase crop yield because there are going to be some farms and conditions that have enough fertilizer, or you get toxicity,” he explains. “That’s going to happen with inoculum too.

There are going to be some situations where they’re not beneficial and they might be parasitic, but we don’t know if they are yet.” Hart agrees with Cahill that there’s no guarantee the effect of an inoculant will be beneficial. In fact, she says that the particular isolate being mass commercialized actually depresses phosphorus uptake. “A plant without that fungus is getting more phosphorus than the plant with the fungus,” she explains. “They’re not always mutualistic in every situation. Sometimes, depending on the soil nutrients, the plant and the growth stage, they will actually suppress plant growth and performance.”

But Hart says that in most cases, the inoculant is probably not even establishing. She recalls a 2-year field trial where the commercial inoculant only established in one out of 4 farms. “Where it established, it established quickly and it spread fast,” she says. “But in the other plots, it would’ve been a waste of money for the farmers to use it.” She’s also concerned about the effects these products may have on non-target species, pointing out that there have been studies where this particular fungus has occluded every other fungus in the community. The studies were short-term, Hart says, so it’s too early to make generalizations about it. But she says she can’t in good conscience tell farmers they should be using these products because we don’t know the dangers yet.

Grow Native Species

Instead, Hart recommends growers focus on promoting the mycorrhizal fungi populations already in their fields by trying to grow plants that are native to the land — whether it be through cash crops, intercropping or cover crops — so the mycorrhizal fungi and all of the soil microbes become more diverse, sustainable, and ultimately, more functional. “You want to make it as close as possible to what was original before the land was tilled,” she says. “Because native plants and fungi have evolved together, so they are more likely more beneficial for each other.”

-

Drill Manufacturers In Focus…

CROSSCUTTER MAKES LIGHT WORK OF STALE SEEDBEDS

Preparing the ideal stale seedbed ahead of a direct drill is an exacting task and like many farmers, Richard Budd has tried a number of approaches at Stevens Farm, near Hawkhurst, Kent. With 900ha of combinable crops on land varying from Weald clay to Tunbridge Wells sand, the focus is on winter cereals, but juggling the rotation can mean that volunteers are an issue as well as blackgrass. Volunteers have become a particular problem in winter barley after winter wheat where admix can lead to penalties knocking £15-20/tonne off net margins. “We need to create an effective stale seedbed post-harvest so that we can go in and spray off ahead of a Sumo DTS direct drill,” he explains. “We tried a Sumo Strake, but found it was not moving enough soil. We also looked at other disc systems but we don’t need to work at depth and risk pulling up weeds from below the surface, just to move soil evenly across the working width.” The solution came in the form of a 6.5m Vaderstad Carrier fitted with CrossCutter discs, chosen to work in the farm’s 30m CTF system.

“The CrossCutter disturbs the surface and chits weed seeds to encourage a green flush,” he explains. “It works to just 10mm deep but the two gangs of discs ensure that it moves soil and mixes across the whole surface.” Designed as a high-speed operation, Mr Budd reckons to travel at 16-18kph with the Carrier pulled by a Challenger tracklayer and can cover more than 60ha a day in the right conditions. “It’s a quick, easy operation that also produces a slight tilth to drill into; the packer roll crushes any clods effectively leaving a fine, level surface and we rarely need the levelling boards.” Described as simple to set up and operate, the Carrier is set at its highest working depth and does not dig in.

“We use the Challenger for convenience, but when it is tied up with drilling the Carrier can be pulled by our Fendt Vario 724 with no trouble,” says Mr Budd. He comments that the cleaner seedbeds give him more options with rotations, while retaining the benefits of direct drilling. “It might be considered a compromise but we’ve not had to resort to mintill to get the results we want. We had a shallow disc cultivator before but it tended to cultivate in bands, leaving 50% of the working width untilled. There was not enough of a flush with one pass, so we had to go in again, whereas with the Carrier and CrossCutter, it’s one operation and we can close the gate on it until we are ready to spray off for the drill.” He points out that the weed flush also acts as green cover ahead of drilling, avoiding the need to plant a catch crop. A first Vaderstad machine for Stevens Farm, Mr Budd comments that he has been impressed with the durability and build quality of the Carrier. “The discs have covered 1000ha, and would be good for 2000ha more,” he says.

-

A Quiet Revolution In The Field

Farmers and agronomists in Canada began exploring the benefits of reduced tillage and direct drilling nearly 50 years

ago. The reasons were simple – the need to reduce soil erosion, retain soil moisture, save on fuel costs and reduce

the time taken to establish their crops. It hasn’t been the answer to everything, and in some years additional tillage is

required, but the technique has helped farmers achieve the goal of maximum yield while managing input costs.Here in the UK, direct drilling has become widely adopted lately. One of the drivers has been the emergence of a greater understanding of the need to look after the condition of our soil. The benefits of organic matter and its connection with increased water retention, the improvement in soil structure leading to stronger root growth, more earthworms to break down nutrients and less soil erosion are positive benefits ascribed to no-till. Originating from Canada, the Bourgault VOS system is imported into the UK by Martin Lishman. It is helping farmers to achieve the benefits we have already highlighted. Achieving such results with VOS is the product of many years of Research and Development and listening to farmers’ concerns. There are important considerations in coulter design that should be recognised. As Rick Schemenauer of Bourgault Tillage Tools in Canada says, “Not all openers (coulters) are created equal, so it’s very important that farmers educate themselves on the subject and choose an opener that makes a positive difference to the results.

This is especially true when it comes to ‘one pass seeding’ with high rates of nitrogen fertiliser placed at the same time as the seed. A dual or multi-shoot coulter must be capable of placing fertiliser far enough away from the seed so as not to negatively affect germination or impair the young plant. The VOS 4082 multi-shoot tip has integral outlets with precise horizontal and vertical separation of seed and fertiliser. The furrow is kept open until the fertiliser is delivered precisely and accurately and carbide sealer plates under the tip close the furrow and create a firm seed bed. The shallow angle of the 4” wide wings creates minimal disturbance, a gentle soil flow over the tip and a smooth field finish.

VOS stands for Versatile Opener System, and the range offered certainly delivers on versatility with various options of holders and compatible tips available. Tips come in single or double shoot versions to deliver seed only or seed plus fertiliser; pulses such as beans can be delivered with the same tips or there are specific versions for this purpose. The range also delivers on quality of design and durability. The low disturbance and low draft generated by the tips contributes to low wear rates as well as reduced fuel costs. This is complemented by the high chromium content of the tips and the carbide on the wings which self-sharpens as it wears and provides increased penetration with no soil smearing.

Andrew Harker of H.R.Bourn & Sons, Lincs has been one of the first farmers to adopt the Bourgault system. He shared his experience: “Bourgault VOS has improved the performance of our Horsch drills. Drilling late for blackgrass control, we are seeing less smearing of soil and much less soil disturbance. This is giving us less blackgrass to control in the crop, much improved and more even crop establishment with far better rooting plants.” James Porter of Porters Farms (Walpole) Ltd also gives the system the thumbs up: “The Bourgault VOS coulters have greatly enhanced the performance of our Horsch Sprinter drill. They are extremely versatile; we can use them on min-till land and when direct drilling. We have since benefited from even seed depth and less soil movement, which has greatly helped to reduce moisture loss and resulted in an improved crop establishment.” A quick look at @BourgaultVOS on Twitter will reveal pictures and videos of neatly and consistently drilled crops accompanied by claims of ‘improved drill performance’, ‘better germination’, ‘less blackgrass’ and ‘reduced moisture loss’

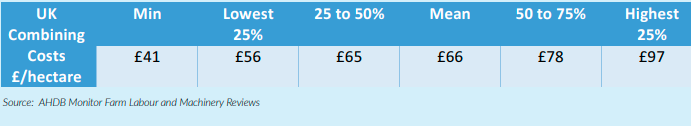

An automatic question on the tip of every tongue will be: how many acres or hectares will the tips last for? Of course, there is no simple answer since different soil types will create different wear rates that are difficult to compare. However, a farmer test in Alberta, Canada reached at least 7000 acres. Perhaps a more relevant question relates to min-till as a cost-saving concept. As observed by Adrian Joynt of Goulborn Farms and reported in Farmers Weekly, min-till enabled them to farm a bigger area with less labour and establishment costs reduced to £65/ha.

Growers will all have slightly differing views on what they believe is the right approach to cultivation and drilling, and the majority will get it right most of the time. There is no one answer or blanket statement that will suit all. However, Bourgault VOS has proved to be financially beneficial in saving time, fuel and wear; low soil disturbance has meant reduced weeds such as blackgrass and less chemical application; better moisture retention and improved soil structure has contributed to healthier crops, less soil erosion and reduced water quality concerns; and consistent sowing depth and precise fertiliser placement has helped to achieve increased crop yields and less waste. Users seem more than happy with the results, so it looks like a serious choice for not only Horsch drill users but also users of the tine drills from other manufacturers.

-

Balancing Your Soil

Written by Kristy Wesson of Secanim

KalFos is a slow-release calcium phosphate fertiliser produced from the combustion of animal by-products and

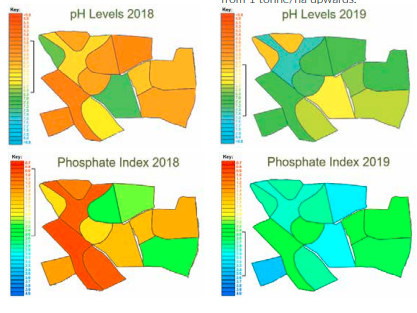

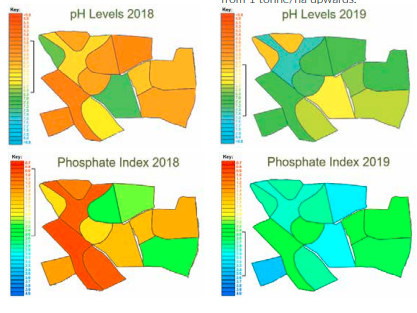

bioliquids. It is produced as part of the UK’s safe and responsible treatment of fallen stock and provides a valuable route for the recycling of nutrients.Replacing costly mineral-based phosphate fertilisers, the majority of which are produced from nonrenewable phosphate rock, the slow-release, acid soluble phosphate contained in KalFos can be beneficial to all cropping systems. Water soluble phosphates are at risk of lock-up or runoff depending on field conditions, and valuable resources can be lost to the aquatic environment, causing pollution of watercourses. The acid-soluble phosphate in KalFos will instead be broken down slowly in the soil, as it is absorbed through acid exudate from roots and their bacterial and fungal associations. This also means that applications can be made to supply multiple cropping year requirements, as the nutrients will be retained in the soil matrix.

In addition to supplying phosphate, KalFos also contains Calcium, Potash, Sulphur and a range of micro-nutrients. The nutrients are truly following a closed loop, as they are concentrated from livestock fed on crops and grass grown in the UK, and are then returned to be utilised for subsequent growing seasons. The product also has a neutralising value of circa 25%, which can be valuable in counteracting the inevitable soil acidification seen with the addition of nitrogen. KalFos is an incredibly cost-effective solution to build up and maintain soil P indices as part of a long-term integrated farming management system. Available in two grades, delivered prices can start from around £50/tonne, depending on tonnage, grade and location. The product is then easily applied using a conventional lime spreader at rates from 1 tonne/ha upwards.

For the best results, the receiving soil should be acidic, and there should be a healthy soil biota population which will maximise the potential uptake of nutrients. The product should ideally not be applied when the soil will be deep ploughed, as the product is best placed in the top 15cm of the soil matrix, in the rooting zone. If min- or zero-till methods are being followed, the product should be applied prior to any surface disturbance, as this will then aid incorporation. Recent trials have shown positive results when KalFos has been applied using variable rates, based on soil sampling results. Soil P indices have been raised across zones, with application rates tailored to zonal sampling results. In some areas, indices have been raised by 2, or up to 183% increase in Olsen-P measurable phosphate. These results show when KalFos is utilised correctly, taking into account soil indices and type, it is a valuable fertiliser for improving soil P supply and minimising potential damage to the surrounding environment.

Secanim Ltd, part of the Saria Group, is pleased to support UK agriculture by producing and supplying KalFos to the farming community.

-

Farmer Focus – Clive Bailye

Staff changes and opting for a bigger drill

Someone once told me that one of the great skills of good management was not being afraid to change your mind. Over the last decade our move to conservation agriculture has created the need to change machinery and labour profiles to match the workload and give us the balanced and efficient fixed cost structure necessary for profitable, subsidy free, combinable crop production. This transition has been gradual. I know when some make fundamental changes to their farming system a farm sale is the first step, often followed by redundancies for staff no longer required. We chose to approach things differently, rapid changes can be expensive, machines sold before their previously budgeted lifespan can look expensive and no one ever wants to have to let good, loyal and skilled staff go. For us the initial transition was simple as our drilling had been done by a contractor for whom in return, we applied inputs and harvested his crops. Ending that agreement and buying a used 750a and a Dale drill to take this work back in house was all that was required. We were fortunate enough to take on an additional contract farm at that time, so no labour had to be let go, the same men were simply able to cope with a greater workload spreading their fixed costs more efficiently.

Over following years changes to the machinery we ran were made gradually, as tractors needed changing their replacements were much more suitable smaller models, that initial 4m second-hand 750a was replaced by a higher output 6m model and the Dale replaced by a much cheaper Horsch C06 conversion. Every change was very carefully considered and only done when a good reason was present. Rising new machinery prices and increasing demand for the equipment we were selling made things relatively painless, the business grew as more contract farming opportunities presented themselves, yet with the much-simplified farming system in place existing labour was able to cope comfortably.

The move away from a self-propelled sprayer to trailed that I wrote about in the last issue of Direct Driller was the final piece of a jigsaw that had taken just over 10 years to complete and I felt we had everything pretty much as efficient as I could get. The wallet was firmly closed, and I felt really rather smug that, come what may through Brexit or changes to farm subs, we were well set up to cope and had nothing but fine details to change over the coming years.

Then, as is so often the case in life, a curved ball gets thrown……. we run a small team of just 3 full time employees; I have always been extremely lucky to employ and work with some exceptional people. I have known two of them since we were in short trousers and was honoured to be best man at both of their weddings. They are not employees, they are some of my closest and best friends. I try to understand their needs, pay them as well as is affordable and involve them in every decision we take. I think as farm jobs go they do alright, we pay a salary well in excess of national farm wages, provide a very nice house for some and are flexible re time off, only really working weekends at harvest and drilling time. The equipment, buildings and facilities are all modem and well maintained and generally we let them manage their own time. It’s a team game, no one works for me, they all work WITH me.

So imagine the surprise when Mark, my friend and longest standing employee of 29 years, who stated working here at 16yrs old came to us one February morning and announced he was leaving. The reason was not pay, hours or unhappiness, he was in fact moving to much lower paid, shift work position in the elderly care industry. His reason was that of work / life balance, a need to know more certainly when he would be at home and ability to plan holidays and days out in the summer when children were off school. Naturally we all questioned his thinking, I honestly feel what we offer is a pretty good package and we are flexible to try and accommodate opportunity and time to do whatever they wish, but ultimately the decision was not mine to make and shortly after this bombshell announcement he left.

Instantly thoughts moved to replacing him, I advertised the position on The Farming Forum and across social media and had a lot of response very quickly. We often hear that there is a shortage of people wanting to work in agriculture, but this certainly didn’t seem to be the case judging by the response I had.

The filtering of CV’s began, most lacked the experience we needed but a few stood out as the kind of people we wanted to work with. Interviewing these applicants it soon became apparent that they were interviewing us, and all of them seemed to view a move to a “small” tractor and trailed sprayer as a backward step from their current positions where it seems a Quadtrac and a quarter million £ self-propelled sprayer is the badge of honour that singles you out amongst your peers as a “top dog” tractor driver. Quickly I realised that a negative attitude towards no-till farming that I had become all too familiar with amongst other farmers was ingrained much deeper within our industry. All that sexy marketing of big flagship kit that has drawn so many farmers into an unsustainable fixed cost Armageddon had clearly also reached deep into the very core of farming, the skilled men on the seats that make it all happen.

No one we spoke to impressed us, in a small team everyone has to “fit” and try as we might we just couldn’t find that person. Hindsight is a wonderful thing, but we should probably have been training up an apprentice, indeed we did try a couple of years ago, but the usual issues of mobile phone addiction and unreliability saw us give up on that idea quite quickly. We needed a plan ‘B’ and with spring work looming we needed that fast.

The question was could we manage without replacing that man? what would the saving be and what would the extra costs be? A week of burying myself deep in spreadsheets and costings began, it was easy to see the £40,000 a year salary saving that employing one less man would bring along with the capital and depreciation costs of a tractor for him to drive, but could we cope with the workload?

The answer was no, it would simply push remaining staff too far to be sustainable and fall apart in a difficult season. Doing less is a bit of an alien concept to us, our aim has always been to grow the business as viable opportunities presented themselves but a detailed analysis of fixed costs structure with one less full-time employee and frontline tractor consistently led me to better numbers with some of our less efficient contracting work dropped. As luck and life often seems to bring, this all coincided rather neatly with a change of business management for one of our contract farming customers, we were simply not comfortable with the changes and lack of commitment from the new management so gut feeling seemed to back-up the numbers on the spreadsheets and the decision was made. Maybe just like in the principles of our farming system less could be more?

The next consideration was the spread of the remaining workload, the labour gap was primarily for a sprayer driver and that created very little overlap to harvest capacity, it was drilling where the potential conflicts lay with still a very significant area to establish in autumn and spring. The existing 6m 750a and Horsch 6m CO with a ULD conversion had given us 12m of drilling capacity and flexibility between disc and tine but with one less highly skilled operator it would be a lot less likely that we could always be in a position to run both at the same time when required.

If any single machine I have ever owned represents the change to our farm over the years it has to be the John Deere 750a. From the first time we established a crop into tall cover it was clear to us all that it was the key component of a very different way of farming. Our first 750a was bought used from Simon Chiles following a visit to his heavy clay farm, I recall my father saying in the car on the way home from Kent that if he could make it work on his heavy clay soils then it should be a doddle for us on boys land …… and he was right, we never looked back, the 4m being replaced with a 6m in 2015. It’s always been the default choice of the low disturbance disc drills for me but being honest that choice was until quite recent years rather limited in the UK. They are not without limitation, our drill being heavily modified and adapted to make results more consistent, and they are also a drill that needs good and regular maintenance from a switched on and committed operator.

When moving from 4m to 6m I looked no further than the 750a, why change a recipe that we knew worked well? Despite there being a lot more choice in the market these days, I suspect that had a wider 750a been available in the UK, then it would certainly have been top of our list of replacements. But alas 6m is thw widest 750A available.

I wanted to move to at least 8m but ideally 12m to fit with our 12/36 controlled traffic farming system and give us more than enough capacity for even the most difficult of seasons, but I really didn’t want to abandon one of the basic principles of my system which was sticking to lighter lower horsepower tractors. Looking around again it became apparent that not many 12m no-till drills existed especially disc coulter versions which I wanted to stick with to compliment the tine option we have with the ULD CO conversion which we will continue to run. Choice narrowed to the Sly Boss drill and the Horsch Avatar.

The Avatar quickly became the stand out choice for me, at the time the 12m Sly was still not a tried and tested formula in the UK but there were already a couple of 12m Avatar users in the UK which I visited. All I spoke to seemed happy with performance and most impressive of all this drill seemed to have an unbelievably low power requirement for its width with just 230hp recommended by Horsch, meaning we could stick to using our existing Fendt 724 tractors that we use for all other arable operations. The coulter is also very similar to the 750a which gives me confidence as we know that it is a design that works for our soil, row width is however much wider at 25cm and is a big reason I guess for the lower power requirement.

The same as the CO and less than a Vaderstad Seed Hawk demo we had many years ago, which to this day still holds the farm wheat yield record meaning I’m not really concerned that it is a negative, it may in fact prove to be a positive with ideas and plans already in place to trial interrow mowed organic spring milling wheat in the future……….. Watch this space! The final deal clinching detail was the price and standard specification, the 12m Avatar comes with 3 hoppers – ISO, seed, and fertiliser placement, guttler style closing wheels and row cleaners from the factory, all things we had to expensively engineer or add ourselves to the 750a’s and all at a price about 25% cheaper per metre as well.

Time will tell of course but it feels like the right decision, we have more capacity, a new drill, one less tractor to fund and one fewer full-time employee to pay. Of course, we also have a slightly lower gross output, but the spreadsheets tell a tale of the savings more than outweighing those losses. So it seems true what I was told years ago, good management is having the ability to change your mind sometimes, no matter how well you feel you might have things set up there is rarely no room for improvement and sometimes things that may initially feel like a step backwards are actually a step forwards.

-

Drill Manufacturers In Focus…

MAKE SOIL HEALTH YOUR NUMBER ONE PRIORITY

The importance of good soil health cannot be overstated, but the key is to achieve it. Strip seeding pioneer Jeff Claydon, who farms in Suffolk and designed the Claydon Opti-Till® System, explains how

In my last article for Direct Driller I mentioned briefly the importance of good soil health in producing highyielding, profitable crops and here I want to consider the subject in greater detail as it is critical to maximise the benefits of strip seeding. Soil health is a fascinating subject, as many of the 100-plus farmers who attended the Claydon open days at our factory and farm in Suffolk in May found out from leading experts. More from them later. Healthy, well-structured soils with excellent worm populations eliminate many of the risks involved in producing crops. Therefore, soil health must be the Number One priority for UK farming businesses if they are to survive and thrive in an increasingly uncertain global market environment.

The subject is particularly relevant now as many farmers who operate a conventional crop establishment system based on ploughing or deep tillage will be making a loss on every tonne of combinable crops produced at current prices because their costs are too high. These methods can also have an adverse impact on soil health, so to improve it whilst containing costs will require them to change radically how they establish crops. Conventional full cultivations and min-till systems can over-work the soil and destroy its structure, which adversely impacts worm populations and activity. The use of min-till systems and disc-type direct drills can also result in soils which drain poorly and flood easily, creating crops with poor rooting structures and low yield potential.

Degrading the soil in this way also reduces its ability to drain water away during periods of wet weather and increases moisture losses in dry conditions. If, after heavy rainfall, you see dirty water flowing from field drains that means it is full of sediment, so your valuable soils have been degraded by over-cultivation and are literally being flushed down the drain. This sediment will block worm holes and capillaries, starving the crop’s roots of essential air and nutrients, reducing yield potential and ultimately increasing the cost-pertonne of production, as well as creating greater risks from flooding and further soil erosion. With greater public awareness of the countryside and environmental issues such as soil erosion caused by poor agricultural practices farming businesses should review how they operate. A key part of that process is to reduce the agronomic and financial risks involved in producing crops, many of which result from traditional approaches to establishment. But that’s not to say you should go from one extreme to the other.

It is understandable that in the current economic environment farmers want to save costs, but you should not go into no- or reduced-tillage systems without fully understanding the concept and how to apply it successfully. There is no point in saving money on establishment if you don’t get a crop! In my view a completely notill approach cannot produce the consistent, reliable results and high yields which we have achieved with the Opti-Till System of strip seeding during the last 16 years, particularly on heavier soils. Using no-till alone also poses significant risk as you are much more at the mercy of wet seasons or dry seasons and may struggle to get seed in the ground or achieve sustainable yields, while corrective subsoiling may be required if the soil slumps. However, in some seasons a mix could work well, if you are able to justify the use of two drills.

A Holistic Approach

Claydon pioneered strip seeding and has perfected the Opti-Till® System, a holistic approach to crop establishment which delivers consistently high yields at low cost, thereby maximising profitability. Providing that the soil is drained, is reasonably sound, work is done when conditions are suitable, and you have a good rotation to help control weeds then this technique is suitable for every farm.

There are huge benefits from using Opti-Till® correctly. Soil health and structure are greatly improved, soil drains more freely in wet weather and retains moisture in dry conditions, while earthworm numbers are dramatically higher. This is critical, because healthy, well-structured soils with excellent worm populations eliminate many of the risks involved in producing crops. Rooting structures are much stronger, resulting in better crops that utilise inputs more effectively and more efficiently whilst being more resistant to drought, while yields increase and ‘per-tonne’ production costs are much lower.

The start of the process is to use the Claydon Straw Harrow to produce a shallow micro tilth up to 30mm deep, which destroys slugs and slug eggs and encourages volunteers and weeds to chit, enabling them to be controlled more effectively, at lower cost and with less reliance on chemicals. This micro tilth is usually more than adequate to cover the seed, create a warm, humid environment around it and promote rapid crop establishment. If slightly more tilth is required it can be created with a Claydon TerraStar light rotary cultivator.

The key to Opti-Till® is the Hybrid drill’s patented, leading tine, which has a breakout force of 600kg, more than twice that of many other direct drills, so it remains stable and works at an even depth. Adjustable from 0mm to up to 150mm deep for establishing deeprooting crops like oilseed rape, it lifts and aerates the soil, creating fissures, alleviating localised compaction, improving drainage and providing space for strong rooting structures to develop. The leading tine is followed by a separate seeding tine which places seed within a band in soil which has just been lifted and loosened. Using press wheels on the drill or rolling separately immediately after drilling, particularly on heavy soils which are wet, pushes the air out of the soil and can cause the particles to stick together. Therefore, we recommend letting the soil ‘haze over’ for 24-48 hours after drilling and then rolling or harrowing. This approach delivers perfect results.

The Opti-Till System does just enough to make direct drilling work without the need to subsoil, as with a lowdisturbance drill system, or having to correct damage from the sedimentation of over-worked soils where min-till or plough-based establishment is used. Doing just enough cultivation at the point of drilling retains the soil structure, provides the crop with the ideal growing environment and gives it the strongest possible start. This allows the soil to start improving and the sooner this process begins the more quickly it will do so. Targeting cultivations in this way ensures that soil density is retained over at least 50% of the field, which supports following field traffic throughout the season and keeps tramline depths to a minimum. Fields are left level due to the design of the Claydon Hybrid drill, soil structure and seedbeds are consistent over large areas, so crops develop and grow evenly. That makes it much easier to apply fertilisers and agrochemicals at the optimum time.

Drilling seed in bands provides an ideal environment for worms to thrive. This is essential because their action benefits soil health in so many ways. Because most worm burrows and capillaries are left undisturbed worm numbers are safeguarded, which aids drainage and water movement through the soil profile throughout the growing season. Plant roots are also left largely undisturbed which adds to the soil biota and improves soil structure, organic matter depletion is minimised due to nominal soil disturbance, while soil moisture and nitrogen are preserved.

The friable tilth created by the Claydon leading tine allows fast, strong rooting. Emergence is rapid and unhindered due to the excellent soil structure, while the soil can also absorb heavy rainfall without capping. Because the seed is sown in bands crops utilise more of the growing area, maximising moisture and nutrient takeup. The fact that seed is spread across the working area of the seeding share allows more air and light into the crop, which improves photosynthesis as the plant grows.

A further benefit of strip seeding is that drilling into stubbles helps to keep snow in place and settled on the seeded area, which acts like an insulating blanket for the crop in very cold weather. As the temperature rises, snow thaws and melt water drains through the soil profile. This area also warms more quickly due to the darker colour of the soil. The other advantage of strip seeding at 30cm centres is that the 14-15cmwide unseeded strip between the rows can be mechanically hoed. The Claydon TerraBlade inter-row hoe is a low-cost, mechanical method of controlling weeds in combinable, bandsown crops.

It provides an additional weapon in the agricultural industry’s weed control armoury at a time when the efficacy of some herbicides is decreasing whilst the cost of control is increasing. The TerraBlade eliminates weeds from that area reliably, safely and without using chemicals. This clears up any weeds that were missed by the ag-chems, or where such products cannot be used, greatly reducing the return of weed seeds, the overall weed burden, the potential for carry-over of weeds seeds and the risk of more resistant types developing. By keeping the unseeded rows clear of weeds during the early stages of crop growth, competition for nutrients, light, air and water is reduced and the young plants grow away strong and healthy.

When soil is biologically healthy and you have created a high worm population with a high level of worm activity, many soil-related issues, as well as many of the risks involved in producing crops, diminish greatly. In the 16 years of using the Opti-Till® System on the Claydon farms we have seen much lower levels of plant disease than on farms which still plough due to the much higher levels of soil biological activity. Instead of continuing the cycle of poor soil structure caused by conventional methods of crop establishment it makes sense to re-evaluate what is required going forward. Innovative equipment such as the Claydon Opti-Till® System greatly improves timeliness, reduces establishment costs by up to 80%, creates correctly structured, supportive soils, encourages high worm populations, promotes biodiversity and ensures excellent drainage. This results in sustainable, high yields, greater resilience to extreme weather, numerous environmental benefits and improved profitability.

But you should not expect simply to buy this type of equipment and expect instant results. It is important to understand how to get the best from this new approach, correct any deficiencies in soil nutrition and introduce an effective programme of stubble management between harvest and drilling. We invited Dick Neale, Technical Manager of Hutchinsons Crop Protection, to the Claydon open days to explain more about the importance of soils and how to achieve good structure. Visitors found what he had to say fascinating.

Transitioning To Strip Seeding

“Transitioning from conventional crop establishment methods to strip seeding is not difficult, but there is a process to go through to achieve optimum results,” Dick stated. “It’s very easy to get right, but also very, very easy to get wrong, so understand what needs to be done, appreciate that it takes time, be patient and do not expect instant results. “Many fields are over-cultivated and consequently farmers often say that their soil does not work like it used to, do what it used to or produce crops like it used to. Much of this is down to the fact that in a plough-based system there are 80 per cent less earthworms, so it will take two to three years to build their numbers sufficiently to completely break down surface residues and for the soil and ecology to adapt to a strip seeding system. When changing to the Claydon System you should therefore ensure that your stubble is very well managed or grow a catch/cover crop.”

Emphasising the critical importance of having a healthy earthworm population, Dick stressed the need to know the main types and how they operate:

• Epigeic: Spend most of their life above ground and survive by processing decaying/dead organic matter.

• Anecic: Tend to make vertical tunnels and their primary food source is decaying matter on the soil surface, such as stubbles. Can often be identified by characteristic soil ‘middens’ surrounding the tunnel entrance.

• Endogeic: Create sprawling burrows underground, only come to the surface when excess rain puts them at risk of drowning and live on organic matter beneath and mixed into the soil. They are key to optimising the soil’s structure, drainage capability and ability to store water and nutrients, but are very sensitive to cultivations.

“Worms burrow up to 2m deep, way beyond the scope of any mole drainer or subsoiler tine and are fundamental to efficiently draining and oxygenating the soil,” he added. “As they move throughout the profile they act as pumps, pushing oxygen around the network of borrows, but to do so must have access to surface straw to provide food. If we can achieve 30 deep-working earthworms per square metre things really start to happen in terms of benefits to the soil.”

Give Your Soils A Helping Hand

Another guest speaker at the Claydon open days, Dr Elizabeth Stockdale, Head of Farming Systems Research at NIAB, said that every farmer should ask themselves ‘How can I help the soil life help me?’ Soil is a very complex web of interactions, but if it is in the right condition, with the right structure and nutrition in place it will deliver the results you are looking for. The key is to appreciate that its natural biology is there waiting to help; you just need to create the conditions to allow it to kick in. She added:

“The physical, biological and chemical properties of the soil must all be right for it to deliver optimum performance. Address the soil’s physical component by knowing your textures, understand its limits in terms of workability and trafficability, optimise water balance through drainage if necessary, improve soil structure and minimise compaction to achieve effective, continuous pore space. Optimise the soil’s biology by feeding it regularly through plants and organic matter inputs, moving it only when necessary and diversifying plants in space and time. To address the chemical side, maintain optimum pH, provide the right amount of plant nutrients, in the right place, at the right time, and know your soil textures, as their buffering capacity provides a free supply of minerals.

“All land is unique and often one field can contain several different types of soil, which set the inherent limits to its physical properties, while management modifies those properties. Soil structure is broken, not made, by machinery: the plant roots, earthworms and glues/ gums created by the decomposition process are the keys to the soil’s structure and aggregating ability. Food diversity is essential for both human and soil health, so adding more food to the land will allow it to support more biodiversity. Therefore, move soil only when necessary, avoid leaving ground bare and ensure that crops are grown in optimum conditions so they can maximise photosynthesis. “Working effectively with the soil requires an integrated, flexible approach to soil husbandry. Changing one aspect of a system can change the entire outcome and so, for example, the same drill might work differently in different situations and soils. When changing to strip seeding you cannot simply buy a new drill and expect that everything will be fine: you must adapt your system and tailor your husbandry accordingly.”

FINAL THOUGHTS

The cost of the Claydon Opti-Till System is much lower even than with min-till and dramatically less than a plough-based system. Instead of using 150-180 litres of fuel/ha to establish a crop using a ploughbased system, with Opti-Till we use 10-15 litres/ha (average 12l/ha), which includes stubble management and drilling. The enormous savings that we make allow us to invest more in other inputs and areas of the farm that really make a difference. The cost of wearing metal is very low, at just £3-£4/ha. As the soil becomes healthier and in better condition the amount of power required to work it and cost of wearing metal continues to decline. Power requirement is just 50hp per metre for Claydon Hybrid drills, so output is much higher and fuel use is dramatically lower.

On the Claydon farms we use a 300hp tractor to pull our 6m Claydon Hybrid drill and because of the very high work-rate the tractor clocks up less than 100 hours per year to establish our 350ha of crops. With everything in the ground in good time we have time to do another 1250ha of contract drilling, creating additional revenue. It is not our experience to see a yield decrease where soil is in reasonable condition when you start with the Claydon System. We have seen an average 10% increase in yields on Claydon-drilled farms, as have customers who start with soils which are in reasonable condition, free of compaction, drainage or weed issues.

To learn more about the ClaydonOpti-Till® System

scan the code. -

What Is It Like To Do Sustainable Soil Management? The English Farmers’ Experience

Dr. Anna Krzywosznska is a social scientist, and a Research Fellow at the Department of Geography at the University of

Sheffield. Over the last few years she has been studying the uptake of sustainable soil management practices amongst

English farmers. She has found that the experience of adapting soil-friendly farming systems can be difficult for

farmers because it makes them ‘stand out’ from their peer community. As a result, these farmers create ‘communities

of practice’ in which they can both exchange learning and support one another. She has also found that these

communities are reaching out to scientists who become not only sources of information, but also sources validation for