If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Drill Manufacturers In Focus…

COVER CROPS DON’T NEED TO BE FANCY??

What is the function of a cover crop?

To cover the ground, reducing

1. Erosion

2. Weed growth

Retain moisture and nutrients for the following crop So, all hail the winter cereal cover crop, by accident admittedly (too many grass weeds) but effective none the less and not too expensive, certainly effective and as it turns out a good start for some spring oats. The Ma/Ag drill sows spring oats into winter barley sprayed off a few days earlier, simple and relatively cheap way to establish a crop and save the season with effective weed control thanks to low disturbance. If the intention to purely use the winter cereal as a cover crop then untreated farm saved seed would have given a cheaper and still effective option. Not the answer for everything but worth a thought and certainly focus the mind on what we are trying to achieve?

Last autumn, we drilled some winter Oats at 110kg/ha which we thought was a bit low, but were assured that drilled early they would tiller and fill out. This was the field after drilling into a mulched cover crop on the 30th August 18, and as a picture paints a 1000 words (and is much easier than writing !)

-

6 Years Of Robotics With NAÏO Technologies

As with most companies, there is always a bit of luck at the beginning. Naïo Technologies is the result of two robotics

engineers crossing paths, Gaëtan Séverac and Aymeric Barthes. They both believe robotics offer solutions to the problem’s agriculture is facing today.Their goal is to offer practical and durable solutions to agricultural issues while reducing workload with autonomous tools. Early robotic developments have focussed on providing solutions into high value crops such as vegetables and vinyards, but as the technology improves so should the entry price and therefore solutions to other crops will hopefully also become a reality. Over the past 6 years, Aymeric and Gaëtan have built a team of experts in agricultural robotics combined with practical advice from farmers and investors. They, like many of us have observed that farmland in the past, has been managed and yields increased using methods that negatively impact the environment and the soil structure we rely on to grow our crops.

Naïo Technologies is convinced that modern technology will help turn the tables around. Their agricultural robots and hi-tech tools aim to increase productivity while respecting the environment and making agriculture more human again!

They currently have 3 robots out there, Oz, Ted and Dino. We will cover Oz in this article, but you can read about the others on their website

Oz Weeding Robot

The Oz robot allows you to weed and hoe autonomously, this can increase your profitability while also respecting the environment. It is designed to improve working conditions and reduce your daily workload. Oz is entirely autonomous but you can also guide it to go wherever you need.

Oz is an environmentally friendly robot with an agricultural vocation. It weighs very little and consequently reduces compaction in your soil. Thanks to its surface hoeing technique, Oz protects soil structure. Oz uses up very little energy and its mechanical weeding technique allows you to save on other inputs.

Oz Operating Modes

Manual mode:

The robot is directly guided by the user with the help of a wireless remote control.

Tract and follow mode:

Oz can follow you around and transport loads. The robot is also able to tow a small farm trailer to help you during harvesting or assist you during heavy or strenuous work.

Autonomous mode:

In autonomous mode, Oz follows the crop rows of the plot and guides itself. Oz can weed all your crop rows without human supervision. To guide the robot automatically in autonomous mode :

• crops need to have leaves or be placed on mounds of at least 10 cm height.

• in between rows a strip between 55cm to 120cm wide is required.

• At both ends of the plot, Oz requires a strip of clean earth of mowed lawn that’s about 250 cm wide to be able to turn around and start on the next row autonomously.

The Oz robotic weeder comes with a configuration unit that allows you to pick the right operating mode for you. The unit will also ask you to enter specific information on the plot Oz is required to weed (number of rows, plot size, etc). When in autonomous mode, the robotic weeder will send a text message to inform its owner when it finishes weeding. It is also capable of detecting potential anomalies during work (obstacles, blocked tools, errors in row length…), in which case it will use text messages to send alerts.

The text message function is only available when network coverage is available.

Oz Technical Data

Size & Weight

• Size without tools: Width 40cm, Height 60cm, Length 100cm (130cm tool carrier included).

• Ground clearance: 7cm.

• Weight batteries included: 110kg without tools / 150kg with tools and weights.

Power & Autonomy

• 4 110W electric motors • 4WD

• Tires : o quad-style studded tires or o tractor-style tires depending on your type of soil.

• Maximum load on top of the robot: 90kg if Oz is not working the soil simultaneously.

• Maximum tow weight : 300kg if Oz is not working the soil simultaneously.

• Remote control : 7h autonomy, 10m reach without obstacles.

• 24V – 2 x 12V lead batteries, 80A/H or 2 x 12V Lithium batteries – up to 100 A/H

• Work autonomy: 3 hours on lead batteries and up to 10 hours on Lithium batteries.

• Charging: o manual charging by connecting the charger to the charging plug. o possibility to quickly change batteries in between sessions to have Oz rapidly continue its work in less than 5 minutes.

• Battery life : o 400 charging cycles (lead batteries) o 2000 charging cycles (Lithium batteries)

Use & Storage

• Required temperature during use : 5°C / 40°C.

• IP 64 Protection : resistant to dust and water projections (no high pressure cleaning).

• Maximum slope : 10%.

• Maximum speed : 1.3km/h (22m a minute). Therefore Oz weeds an acre in 6 hours 45 minutes based on 0.5m row spacing or 1.5 acres on a single charge (Lithium batteries).

• Communication with user via text message (coverage required).

Warranty & Maintenance

• 3 Year warranty, with the exception of consumables and wear and tear.

• Maintenance : replacement of the engines’ wearing parts : o Every 5 years or after 5 000 working hours : change the engines’ carbon brushes. o Every 10 years or after 15 000 working hours : change the motor reducers.

Oz Tools

• Plowshare : for weeding between rows, work width 40 to 60cm.

• Comb harrow : for in-row, interrow and mound weeding, work width 40 to 80cm.

• Weeding brush : for in-row weeding, 3 to 5 cm into the crop.

• Spring harrow : for the in-row weeding of crops with solid taproots.

• Spring tine harrow : width 20cm.

• Straight harrow : used to break slaking crusts.

-

Sustainable Food Trust: Farming And Climate Change

5th July 2019 – How to move towards net zero carbon emissions in Farming

Venue: Fir Farm, Lower Swell, Gloucestershire. Generously hosted by Sir Alan and Lady Parker.A new event has been organised by the Sustainable Food Trust with support from the NFU. The event will explore the unique ability of farming systems to address the threats of climate change. Showcasing the ability of farms to increase biodiversity, increase soil carbon levels, increase soil health and reduce inputs whilst producing high quality, healthy food. This conference was inspired by Minette Batters’ target of net zero carbon emissions from UK agriculture by 2040. It is the first NFU/SFT joint event, underlying the urgent need to work collaboratively as farmers to address the challenge of climate change.

They are inviting farmers, policy makers, investors and other stakeholders to join the event in exploring the practical, policy and economic changes that are needed to enable a transition to sustainable agriculture. We very much hope that direct drilling, regenerative and conservation agriculture will be the buzz words at this event and that this will lead to a greater light been shone on the good work many farmers have done to make their farms both physically and financially sustainable.

Speakers at the event include: Minette Batters – President, Jonathan Dimbleby, Professor Dieter Helm – Chair, Natural Capital Committee, Patrick Holden – CEO, Sustainable Food Trust, Tony Juniper – Chair, Natural England, Professor Michael Lee – Rothamsted Research, Charles Massy – Australian author and farmer, Henry Edmunds – Cholderton Estate, Gail Bradbrook – Co-Founder, Extinction Rebellion, Nicolette Hahn Niman – Author of ‘Defending Beef’.

Direct Driller Magazine will be attending and writing up the event in the next issue

-

Farmer Focus – Steve Lear

There has been a bit of a backlash towards conservation agriculture methods in the media of late. Mostly from two camps of people. Those that are afraid of trying it and those that are afraid we might succeed….

When we first started our journey into no-till I was a little bit worried about row spacings on our drill. Most notill drills run at what I perceived to be wide spacings. We moved from a row spacing of 125mm too 250mm on our Primewest drill. It’s a fair increase in bare ground between rows and every man and his dog told me that blackgrass would be a problem between rows. To counter the spacing quandary we used varieties that produce more tillers. The winter barley is all a hybrid called Libra and the winter wheat is a high protein variety called Nelson which has shown good tiller numbers in trials. I’m very happy with the way both crops have filled in between the rows and due to the lower disturbance from using wider rows I believe the blackgrass is reduced rather than increased. I’m slowly working through the list of so-called problems with no-till that don’t actually exist.

The winter crops have come out of a very dry spring looking an absolute picture. Disease levels are very low in all crops and the plants look healthy. We put a little foliar feed and bio stimulant on with every fungicide pass on the winter crops which may have helped them in the dry periods. I haven’t done any areas without the foliar feed to judge the difference, which in hindsight I wish I had of done. The levels of blackgrass are visibly reduced on the no till land. The small areas of tillage that we carried out, stick out like a sore thumb. In one field we had to cultivate a corner of the field due to compaction.

You can see to the line where we ran the cultivator as that is where the black grass has taken a hold. I’m sure everyone will tell me that its because it was previously compacted that the blackgrass is there rather than the establishment technique. In the last edition of Direct Driller, I wrote about our winter beans that we had written off due too rook damage. I had given up on the crop with no visible plants three months after planting. We had another look at the field at the end of February and we discovered that the beans had started to poke through the surface again. After digging a few up, it was clear to see that the beans had put up two shoots that the birds had eaten, then they had waited through the winter and put up a third shoot in February which the birds haven’t touched. We decided to keep the beans rather than re-drill. The canopy is not as thick as I would like but we certainly have a crop to take to harvest and it will be very interesting to see how they perform.

We have around 150ha of land dedicated to spring crops this year which we have decided to sow with Spring Oats. Oats do well on our clays and if they don’t make the milling grade, we can always feed them to the cattle. We use all the straw from the oat crop for bedding which helps as I’ve heard oat residue can cause a few issues in no till fields. Half the oats were drilled into the previous volunteer cereal crops which was sprayed off at the beginning of winter, the other half had a multi species cover crop on them which was kept through till spring and terminated just prior to the drill going into the field. We have noticed that the fields with a cover crop on them over the winter have held the oat crop back somewhat. The only explanation that I can put together is that the cover crop had taken a lot of moisture out of the soil and being a dry year that had held the following cash crop behind. Next Year we may well terminate cover crops a lot earlier than we have this year or maybe have a few more winter killed species in the mix. After seeing some great results on twitter we may well roll the cover crops in a hard frost to kill them.

First cut of silage has been clamped in good time this year. The main block of silage had been rejuvenated with some diploid and tetraploid grasses last autumn which seems to have established really well between the existing thatch. The grass yields are down, but that is to be expected with the dry weather we have had. The quality looks very good though and it will be interesting to see how the feed analysis come back when we open the clamp up.

Silage machinery seems to get bigger and bigger and it can sometimes be a bit of a worry around forage season when keeping compaction to a minimum is high up the list of priorities. We use a local contractor for all our clamped forage who takes soil compaction very seriously within his business. Low ground pressure tyres, steering axles, good drivers and modern equipment all come together to help reduce the risk of damaged grass leys…. Its also great for some tractor porn as his fleet is something to behold!

I can’t wait to harvest our first full year of no-tilled crops, I don’t want to speak too soon but I don’t think we will be seeing the huge yield reduction that everyone has promised me, let’s hope the weather gods are with us come July.

-

Are We About To See Fendt Drills In Europe?

In 2017, AGCO Group bought the American company Precision Planting, a company that specialises in the agronomic

aspects of plant growth, in particular the establishment of crops. The product range includes technologies for optimising maize, sunflower, and sugar beet planting. Precision Planting solutions presented their drills for the first time in Europe at the Fendt Field Day in Wadenbrunn in 2018.With 25 years of production in the US, Precision Planting has been equipping North American farmers with innovative technologies which have a positive impact on the various growth cycles of plants. Now, for the first time, these systems are also being tested in northern and western Europe and more importantly, you will now see these drills in Fendt Colours. The Fendt Momentum was seen in Brazil at the end of April and we are hoping it will be at Agritechnica later this year. The Momentum as seen in Brazil has the vApply Granular system for fertilizer application and the new Fendt Smart Frame that ensures uniformity in the seed placement, as well as having the largest fertilizer capacity on the market and versatility for transport as it can fold and be ready to move in just 75 seconds.

The Fendt MOMENTUM will come in multiple configurations. 40 rows with and without fertilizer distribution, with a spacing of 45 cm. It can also be configured in spacing of 50 cm, with reduction of two rows in its nominal model. In this model of 40 lines, the capacity of fertilizers is 5,300 kg. It is the largest planting machine with distribution of fertilizer in the planting line of history for sale in Brazil.

Despite its size, when folded the planter is only 4.3 meters wide (meaning they will have some work to do to make this available in the UK) without the need to disassemble any component. The planter is easily transported on plank trucks simply by removing the fertilizer hopper and the outer wheels from the center chassis. The dual tires that works together in tandem allows the work together and helps in compacting the soil and in the operations along the transport between one crop and another. The working width is 18m, respectively. The sampling rate (seeds percentage and repeated failures) of the new plant can reach 99.6 per cent in corn, even at higher planting speeds.

Fendt MOMENTUM

The Fendt MOMENTUM features vApply Granular, a Precision Planting® technology that guarantees the most accurate application of fertilizer in every planting row. It is available in all planter versions. Like all other Precision Planting® technologies, vApply is controlled by the 20 | 20 Seedsense Generation 3 Display. In this display, all planter-related information is controlled in real time. And with the use of crop maps generated with software like Climate FieldView®, the display also makes it possible to work with variable seed and fertilizer rates; analyze seed application depth; monitor the soil, the pressure applied to the soil in each one of the rows, the contact of the row with the ground and the work map, among other information by the second.

Linked to the system that comes with vApply Granular, there is another device capable of bringing the traditional agriculture to a new level in the Brazilian market: the Fendt Smart Frame. It ensures that all rows are always in contact with the soil and controls seed depth for even planting. With it, the planting rows are not attached directly to the planter chassis, but to a bracket split into three sessions and driven by two hydraulic cylinders each to keep the rows always touching the ground.

In addition, by replacing the pressure spring of each planting row, there is the DeltaForce, also an exclusive release

from Fendt which, through sensors, guarantees the necessary pressure to cut the straw and apply the seeds at the same depth.

-

The Return Of The Natives: Grass-Clover Leys Boost Earthworm Recoveries

Written by Miranda Prendergast-Miller, as based on information found on Agricology (www.agricology.co.uk)

Above: Grass-clover ley (Photo credit: M. Prendergast-Miller, SoilBioHedge)

Earthworms have been in the news recently, with new data confirming that earthworm numbers are low in UK arable soils due to intensive ploughing, repeated soil disturbance and low soil organic matter. Earthworms are important soil organisms: their burrowing and feeding activities allow water to percolate through soil; they breakdown organic matter, releasing nutrients for plants and other soil organisms like bacteria and beneficial soil fungi, but also stabilising the residual organic matter. Earthworms form characteristic soil casts – these small mounds of earthworm-processed soil form little hotspots of activity on the soil surface and support a myriad of other soil organisms.

The contribution of these humble organisms to ecosystems is considerable, and low numbers in arable soils are a concern. What are the knock-on effects on other soil organisms; the release of nutrients for crop growth; for water retention and possible flood control?

However, all is not lost. Earthworms can make a comeback, and in a relatively short period of time!

I have been working with colleagues at the Universities of York, Leeds and Sheffield (scan the QR code at the end of the article to read more) to assess the recovery of earthworms in newly established grass-clover leys. We set up the leys in arable fields which had been used for arable farming for many years, resulting in low soil organic matter and poor soil structure. These soils also contained very few earthworms compared to nearby long-term pasture soils.

Using simple equipment, sturdy boots and a shovel, my team and I – all converted earthworm-enthusiasts – counted the earthworms we collected from soil pits before the leys were sown, and then every 3-4 months over 2 years, as the leys developed. The leys were managed following standard practice and were regularly mown. Within a year, the grass-clover leys looked good. Even from space, using Google Earth, I could see our experiment as green stripes in fields of ready-to-harvest golden wheat. But what was happening in the soil itself?

All that new plant growth was pumping valuable carbon into the soil, through the grass and clover roots, stimulating the soil biology.

So what did we find?

The best time to find lots of earthworms is in cool, wet periods, and the best chance of finding lots of adults is in springtime. (Perfect timing for this year’s http://www.wormscience.org/ !). Adults are easier to name to a species level, and I’m indebted to David Jones at the Natural History Museum for his identifications. This meant I could build a profile of earthworm diversity, not just of their numbers.

Earthworm numbers are low in warm, dry summer months. They are sensitive to moisture, and when soils begin to dry out, they go into protective mode, coiling up into balls inside their ‘aestivation chambers’ or, for those species which can, burrowing deeper into the soil profile – which makes them harder to find.

Earthworms have lots of offspring. Indeed, over 50% of our pit counts were juveniles. While finding only small similarly-looking earthworms may not be as exciting as finding a big one like Lumbricus terrestris, these juveniles are crucial to the next generation of earthworms. Earthworms loved the grass-clover leys. Within one year, average earthworm numbers were higher in the leys (9 worms per pit) than in the arable soil (4 worms per pit). Within 2 years, the average ley earthworm population (25 worms per pit) was nearing that of the long-term pastures (32 worms per pit) we were also monitoring.

Importantly, we found 2 species we had not recorded in the arable soils and a higher number of adult earthworms in the leys (5 worms per pit) than in the arable soils (1 worm per pit). This told us that the populations in the leys were healthy. We also surveyed earthworms under hedgerows and within grassy margins along field edges. These had higher earthworm numbers than did arable soils. On average, we found 12 worms (per pit) in hedges and 19 (per pit) in margin soils.

Depending on the species, earthworms were selective and preferred different habitats. Small ‘epigeic’ earthworms that typically live on the soil surface amongst rotting leaves and other plant material, preferred the relatively drier litter-rich soils found under hedges; whereas the grassy margins were home to a wider range of earthworm types, especially the deep-burrowing ‘anecic’ species. Endogeic earthworms, like the surprisingly green or pink Allolobophora chlorotica, were found everywhere. These species tend to live within the soil, forming horizontal burrows.

Not all soil pits are the same: the number of earthworms we found in pits varied considerably. Sampling strategy is important and we had to take an average of numerous pits to get a reliable estimate of earthworm numbers.

So what does this mean for soil health?

The key message from our data is that, although earthworm numbers were low in intensively managed arable soils, changing soil management by introducing a short-term grassclover ley can help boost earthworm numbers in a relatively short period of time. This is because the reduction in soil disturbance and the perennially green plant cover supplying nutrients increases the survival of juvenile earthworms, so more can grow and reproduce. And crucially, it’s not only the earthworms that benefit. The grassclover leys were a major boost to soil health all round by: improving soil structure; reducing bulk density; improving water retention; increasing resilience to flooding; increasing nutrient availability and plant growth; and increasing the number of beneficial soil fungi. Some of these improvements in soil quality are directly linked to recovery of earthworm populations.

Conventional inversion ploughing and power-harrowing does not support high earthworm populations. But shortterm changes in soil management can do a world of good to our soils – and help humble earthworms to thrive! So while you’re counting earthworms this week, think of ways to manage your soils to give you a beneficial effect in the future!

Miranda Prendergast-Miller says of herself:

“I am an environmental biologist, with a keen interest in soils, especially how soil-dwelling organisms, such as bacteria, fungi and earthworms interact, and how human activities impact them. In turn, I am interested in harnessing soil biology to reduce the impact of intensive agriculture and protect our precious soil resources. Currently, I am based at the University of York, working on a project with colleagues from the Universities of Sheffield and Leeds called ‘SoilBioHedge’. We are interested in understanding how farm management practices such as leys or reducing ploughing intensity affect soil organisms and the subsequent changes in soil productivity.”

SoilBioHedge:

This project was funded by the UK Natural Environment Research Council, under the Soil Security Program. The project is led by Prof. Jonathan Leake (University of Sheffield) and the earthworm study was led by Prof. Mark Hodson (University of York). Thank you to colleagues who joined in the earthworm sampling. Further project details can be found at:

-

Drill Manufacturers In Focus…

TALES FROM A BUSY SPRING

By James Dale

June will see Dale Drills showing at the Cereals and Groundswell shows, where we will be demonstrating our range of direct drills as well as showing our new low disturbance sub soiler; the Meir SC. This spring saw several new drill sales including our first machine in Norway. A 4m Eco-M was sent on a ferry from Immingham to Brevik then on to its new home in Kjeller, just North of Oslo. I was lucky enough to be sent to Norway to help the new owner set the drill up. Whilst there I realised this was the furthest North I had ever been, and yet the farming experience there seemed very similar to the UK.

Although the colder weather did highlight some different challenges, most of the 70cm of snow from Winter had melted by early April, but a milder winter had meant Snow Mold had been a major issue, with some fields of Wheat completely written off. Norway’s undulating terrain is another significant challenge, with plenty of arable fields on slopes of 20% or greater. Add to this the fact that most Norwegian Farmers consider a 150hp tractor to be huge, and you can begin to see why easy to pull drills are essential. Our customer used a John Deere 6125R tractor to pull the 4m drill. It managed it quite happily whilst I was there, and I was pleased to hear when my customer told me he had completed his spring drilling without struggling to pull the drill on even his steepest ground.

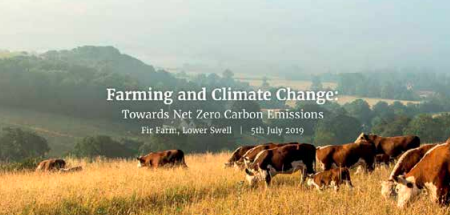

We also delivered a new 12m Eco-XL to a customer in Kent. The seed only drill was supplied with a pressurised tank split into 4 compartments. Each compartment supplies ¼ of the drill with seed via a metering unit driven by an electric motor. Using an Isobus connection to the customers John Deere 6215R tractor we were able to use a GPS controlled, automatic section control to dramatically reduce overlap and save on seed. After a trip through our workshop to have several modifications carried out, a used 3m Eco-M was also sent down to its new home in Kent. Our modular design allowed the drills working width to be increased to 5m via 2 x 1m hydraulically folding wings.

The seed and fertiliser option on the existing drill was bolstered with the addition of 2 new applicators; a Rotor Meter to feed product into the airstream to be drilled down the coulters and a Fan Jet Mini to spin product on behind the drill. Both applicators are controlled through the drills control screen, and automatically turn on/off with the drill as well as keeping rate consistent no matter what the forward speed. The drill was supplied with a deeper front tine kit allowing the owner to sow different seed types at different depths or to loosen to depth for ‘lazy’ rooting crops. Banded coulters allow the customer to spread seed in an approx. 100mm band whilst placing fertiliser 25mm deeper than the seed and in the middle of the band. A very versatile machine.

This spring also saw the launch of Dale Drills in France with our new French distributor. A 6m Eco-M made the journey to Beaumont Village, in the Loire Valley to carry out the first demonstration. Sorgo was planted into a cover of beans on some challenging soil with a high percentage of sandstone. The drill was configured with our cover crop cutting disc followed by a narrow duet tine allowing DAP fertiliser to be placed alongside the seed. Visitors were impressed with the versatility of the Eco drilling assembly and many commented on how well the tine was able to penetrate and how consistent the depth was across the width of the drill. Following its launch at the LAMMA show, the Meir SC has been put through its paces this spring with several developments made.

The cutting disc positioned in front of each subsoil tine has been increased in diameter from 350mm to 450mm. This provides a more effective cut through residue, whilst also reducing the amount of soil movement at the surface. The subsoiler point has been refined to include a 15mm wide, tungsten carbide protected point, reducing wear and soil disturbance. Behind the point, the low angled wings have received a coating of tungsten to boost endurance and ensure effective soil loosening throughout the life of the wing. The rear roller has been re-engineered to include a smaller diameter central tube with deeper corrugated rings positioned either side of each leg. This improves the finish left after the subsoiler, most notably behind the tines where the soil is ‘pinched’ back into place.

Available in 3m and 4m working widths, the Meir SC will be shown working this autumn. A Dale Drills 6m Eco-M will also be available on a short term hire this autumn for those interested in trying it on their farms.

-

Herbicide Treadmill Is Ending

By Frank Lessiter of No-Till Farmer USA

Because of serious weed concerns with the area’s over 10 million acres of wheat and barley grown with extremely limited rainfall, Western Australia is the herbicide-resistance capital of the world.

Two of the biggest herbicide resistance concerns for Western Australian notillers are annual ryegrass and wild radish, which have developed resistance to several herbicides over the past 35 years. Studies indicate Western Australian growers are spending an extra 27% per acre to overcome extremely serious weed resistance concerns. And as Iowa State University weed scientist Bob Hartzler points out, U.S. farmers could be facing the same consequences within 5-10 years.

Worldwide Crisis

Globally, 255 different weeds have developed resistance to 163 herbicides. Most concerning for no-tillers is that 43 weeds around the world have developed resistance to glyphosate, including 17 species showing Roundup resistance in the U.S. For many years, weed control meant replacing one herbicide with another, what weed scientists refer to as “the treadmill of herbicide resistance.” That thinking is ending now that there’s little in the way of new herbicide chemistry coming soon.

University of Western Australia ag economist David Pannell says a variety of control measures are needed to deal with herbicide resistance, particularly with resilient plants such as ryegrass.

“Ryegrass will develop resistance to any control measure,” he says. “If we just rely on capturing weed seeds as our only measure, ryegrass will evolve to counter that, such as growing flat to the ground so the seeds can’t be captured.”

No-Till Obstacles

Pannell says one of the greatest threats is the continued emergence of weeds resistant to glyphosate, which is critical with no-till. Yet he’s convinced Western Australian farmers will find other ways to keep no-tilling if glyphosate is banned. For example, 70% of small grain growers in Western Australia are burning wheat and barley stubble as part of their weed control programs. They’re also looking seriously at mechanical methods, such as pulverizing weed seeds behind the combine. Even if new alternative weed control options are expensive, farmers won’t have much choice but to use them. With sufficient adaption and innovation, notillers can continue to farm profitably despite serious weed resistance concerns.

-

Farmer Focus – George Sly

Going into my second year as a farmer I feel a lot more confident than I did last year. I have learned what soils I have, what challenges I face, and the exciting times ahead for UK agriculture and decided on a long-term approach to improve my soil health. This year we are growing Sugar Beet, Maize, Triticale, OSR, Winter Wheat, Spring Barley and a trial of Strip till Pumpkins, Butternut Squash, Dwarf beans and veg (for which we will repeat the trials at Groundswell which will be on display). I have been extremely lucky starting my farming career with a very dry year, I farm at or below sea level on 30-50% clay, 30-50% silt soils, it holds water like you would not believe! Drainage will be an issue in the future but I have an affordable plan for that and don’t see it as a major risk to my crops, heavy tillage is not the solution! Localised pipes/trenches and the use of light/ low disturbance lifting/aeration when conditions are right.

I am very fortunate to be able to use our latest No-till and Strip till machines on our farm and I love pushing the boundaries of both technologies to see what is possible in the future. Having no prior farming experience what I have already learnt is diversity is key, with a high diversity and a rule to work with and not against nature makes everything more resilient. I am also working with a neighbour to share machinery, knowledge and resources, that is invaluable. Being able to use and push the limits of our machines puts me in a good position to advise our customers and hold farm walks. Our Winter Wheat and Triticale was all no-till drilled, some of it had some lifting/aeration and nearly all had a catch crop between harvest and drilling (last week October). We drilled around 60% our wheat with Nurture N (Molasses mix) and Bacillus microbes, this was placed very accurately into the furrow with our Exadose system. I don’t expect an annual benefit from this but I plan to monitor the fields that have regular applications. Can I quantify the benefits, we will see…

We fortunately decided to scale back OSR to 23 Ha from 65, we strip tilled into triticale stubble (something I wish I had not done, we should have no-tilled not strip tilled to retain moisture). I used the Stripcat to also sow an interrow companion of buckwheat, white clover and spring beans, beans drilled deeper and clover + buckwheat shallow. We then precision planted the OSR in between. We lost 12 hectares of the crop to CFSB. The remaining 11 Ha looks really good. The failed area we were left with a great cover crop! The companions all did well, in particular the white clover, which is now half way up the OSR crop. It may present a harvest issue, if I feel that it will we will swath it rather than direct cut. I hope to then keep the White Clover permanently, I am testing some new designs/equipment to manage it in the living crop and supress it. There is no doubt in the battle against black grass, that Beneficial’s help supress it, purely trying to farm bare ground, stale seedbeds and rely on Glyphosate is not in my opinion the long term solution.

Establishing clovers on heavy soils in a dry year has been tough, however I have learnt a little about what works and what doesn’t. We have Crimson + White clover growing on a 6 metre strip in one field that is now Forage Triticale. I established it ahead of spring oats in March 2018. We have managed to keep it alive through 2 crops now and although I have seen some minor negative impacts on the crop, if it is supressed either chemically or mechanically predrilling the cash crop I really think we could roll this out over a larger area for 2020-2022. Our Sugar Beet and Maize is all established using Strip till. We till the ground in the autumn and establish cover crops interrow to the cultivated strips. We can sow covers through 3 coulters in the interrow meaning we can establish a deep drill seed in the middle and shallower seeds either side. This system has real potential going forward with the loss of chemistry.

We have the benefit of being able to grow 2 crops usually associated with heavy soil degrading tillage but instead I believe we are improving our soils even with the big Carbon and K offtake associated especially with Maize. Last year we grew 65 Hectares of Maize and only 24 hectares of that required a selective herbicide after planting. We also went back in the maize at V3 growth stage and trialled under sowing IRG and Vetch, which given the dry year had limited success… Sugar beet is much trickier on such heavy soil, but my stubbornness means we will get there, its just requiring more R+D and though to get an even stand and hold 100,000 population. The planter we use for precision crops has control systems never seen in Europe until now, depth, spacing and fertilisation is all controlled very accurately.

Our Veg plot trial was strip tilled in the autumn and White clover and rye was established, we then re-stripped and are planting pumpkins, squash, brussel sprouts, dwarf beans, sweetcorn and cauliflower, all while trying to keep the white clover as a beneficial and remove the need for selective herbicides. We are donating the produce to a local food charity this year, but we will see if there is commercial potential for this “low carbon”, “soil regen” fresh produce. We must as humans find ways to also grow fresh produce sustainably as well as Cereal crops. Farming to improve my soil is not something I feel is fashionable or trendy, it makes commercial sense. With a mortgage to 2051 and a son 14 weeks old, I feel deeply responsible to improve and regenerate my soils to hand over a profitable and sustainable business to the next generation. There are many farmers in the UK with similar thoughts and some fantastic groups to join and learn, we must think positively and embrace the future ahead.

-

BASE UK – Member Visit To Agrovista’s Lamport Project Trials On 8TH April 2019

Direct Driller Magazine’s Farmer Focus writer David White arranged this visit following an invitation from David Purdy. On behalf of the Base members who were able to attend, grateful thanks go to David Purdy for hosting us as well as Craig Morgan, Niall Atkinson and Philip Wright for taking the time to share their expertise. Thanks also goes to Agrovista for kindly sponsoring lunch for those who stayed to “network” further.

David White writes…

Quotes from the day:

“The value of my BASE-UK subscription returned in a single visit”.

“It’s criminal not to put a cover crop in the ground”.

Judging by the strength and temperature of the wind Agrovista’s Project Lamport site in Northamptonshire must have been an old airfield site, judging by the typography it certainly wasn’t! The day was cold but thankfully dry for the BASE group of over 20 members that had a very thought-provoking visit to the home of Agrovista’s black grass trial site in Northamptonshire. We saw a fascinating series of trial plots hosted by Craig Morgan and Niall Atkinson, demonstrating how after spending >£130/ha on chemical control in a traditional cultivation system you could still suffer over 500 heads of black grass a sq/m, but with a change of system and cropping that reduces down to ~1 a sq/m with minimal herbicide use. Soil disturbance, residue management, cover crop species and planting density, destruction timing and cash crop choice all play an important role It will be interesting to see how the soil on the various plots changes over the next few years and this body of work will I am sure help add to our understanding and influence how we manage our soil in the future.

David also highlighted his participation in Tea Bag Index, see www. teatime4science.org/about/the-project/

We were also very fortunate to have the expertise of Philip Wright on hand to talk through his trial of strategic tine intervention to improve soil structure, sometimes in combination with growing cover crops to increase the benefit from improved rooting increasing the value of the seed investment on certain soil types #roots&iron As one member commented after the visit; it was very much like an AA meeting, “there seem to be plenty of confessing to endless days cultivating, subsoiling, harrowing etc”, something many of us recognise and carry some guilt over, how much time and energy have we wasted over the years? It was a very timely visit to see the systems trial areas as the spring cereals were just emerging and, as we have been invited back to the site in early July, we will get to see the results of this year’s work. The invitation with more detail will go out to members nearer the time.

-

Are These The World’s First No-Till Crisps?

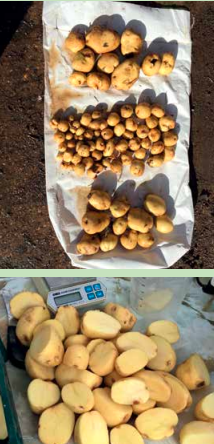

Just like growing cereals most people assume you need to do some form of cultivation to establish a cereal crop, or physically plant tubers into a loose soil to produce a viable potato crop? The Groundswell potato trial set out to showcase an alternative technique. The resulting crisps produced from the 2018 potato harvest are proof that cultivations are unnecessary.

However, for this technique to be successful it involves a “systems approach” to growing that begins the year prior to any potatoes being grown. It’s very important to remember permeant soil cover is a cornerstone of Conservation Agriculture and sustainable soil management. This cover can be achieved either with something physically growing in the soil or by utilising the previous cash crops residue. The trial began in autumn 2017 with a high biomass cover crop direct drilled into preceding cereal crop stubble. The aim being to capture any soluble nutrients left over from the previous cash crop and biologically cycle the inherent fertility of the trial site. An application (25tons ha) of cold composted FYM was then applied to the living cover in the Spring and prior to planting of the Endeavour seed potatoes. In this trial no further nutrition was applied or an application of glyphosate used to terminate the over wintered cover.

The seed potatoes are placed on not in the soil. Then a heavy mulch 25cm (10”) of loose wheat straw applied to cover the tubers. On this occasion no further herbicides or fungicides were then applied during the trial. There is the potential to use a mycorrhizal inoculate applied close to the tuber at planting which may improve nutrient availability to the establishing crop and this could be a particular advantage for a no-till establishment system. Work in conjunction with the Kent based company Plantworks is ongoing in this area. In order to harvest the tubers easily 6-meter beds were created and tramlines left to allow easy access for machinery. No irrigation was used on this crop apart from a light application of water to dampen the straw preventing it being blown away by wind. One reason not to irrigate was in order to demonstrate how the straw mulch will not only supresses weeds but retain the inherent moisture of the soil at planting some of which would normally be lost in a more conventional system.

By covering the soil it further prevents evaporation caused by the wind or sun. Hand harvesting of the crop was required in the autumn of 2018, however the next step in this trial is to investigate how to fully mechanise the technique as well as to evaluate the Be one of the first to try the first truly no-till crisps exclusively at this year’s Groundswell Conference in Hertfordshire being held on the 26th and 27th June.

-

The Importance Of Drill Selection

By James Warne of Soil First Farming

Drilling is the only operation you have to really influence the crop you harvest later, if the establishment is poor you are

constantly playing a game of catch-up. Get it right and suddenly the husbandry of the crop becomes ever so much easier.I appreciate that sounds obvious and simplistic, but so often we get it wrong and making an alternative decision would have made the difference for success. While this is also true for cultivation systems, the act of cultivating soil takes a lot of the risk out of crop establishment, in my opinion.

The autumn of 2018 was very dry, preceded by a very dry summer for most of the UK. Consequently, soil biological activity had all but ceased and became dormant. The biological dormancy delayed the onset of decay and digestion of crop residues. Consequently, at drilling there was still considerable chaff and straw residue on the surface. Now while this kind autumn and winter allowed the majority of crops to establish easily, by the time spring arrived things were looking a little different on some crops. Patchyness started to appear with an apparent lack of crop vigour. Once there was sufficient moisture the soil biology awoke and began the process of decay on the chaff and straw, enabled by the warmer winter soils we experienced.

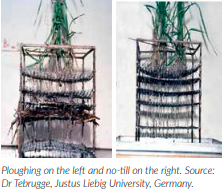

The patchiness and reduced vigour is, we believe, due to the release of toxins as the straw degrades. Many scientific studies have shown that decaying cereal straw releases a variety of phytotoxic compounds, such as acetic, propionic, butyric and phenolic acids. Research also shows that the decaying straw may also increase the effect of Pythium rootrot upon the establishing crop. The photo on the following page displays just how effective decaying straw can be on restricting the root growth. While some choose to ignore or disbelieve this actually is a problem, the scientific research above, coupled with the symptoms we see in the field encourages us to believe that there is clearly an affect, most commonly known as allelopathy.

Here at Soil First Farming we believe this is a bigger problem than most would believe. It is responsible for more disappointing crop yields than it is given credit for. Why? Well it’s much easier to attribute disappointing yield to lack of sunshine or rainfall or poor disease control etc. than to something that happened ten months ago and you could have directly contributed to. The usual early symptoms (in extreme circumstances) are stunted growth, lack of vigour and discoloured leaves. But by late spring seemingly unaffected crops may not have tillered, or drop tillers the root system cannot support, and ultimately the crop may produce smaller ears.

The type of drill used can play a big part in this effect. Contrary to popular belief disc drills do not cut through chopped straw perfectly at all times. Discs tend to push the straw and chaff into the slot which results in hair-pinning and thus the seed is paced upon a layer of straw and chaff. In extreme circumstance the disc can actually ride -out of the ground and place the seed on the soil surface.

This hair-pinning can exacerbate the problem described above to the extent that the roots of the establishing crop can be severely pruned and restricted in their growth as shown in the laboratory photo above. This can also be seen in the field. Below are two examples of hair-pinned crops that we see on a regular basis.

What are the solutions?

Drill: Use the appropriate type of drill when drilling into dry residue situations, a tine drill should be the default choice unless you believe that the disc will make a better option, but this is unlikely.

Rotation: One of the tenets of Conservation Agriculture is diversity. Maybe trying to establish a second cereal is not the best choice?

Nutrition: The correct starter fertiliser choice coupled with correct timing and quantity can help to alleviate the effects.

Finally, for UK conditions a tine drill should be the default drill of choice, only swapping for a disc drill in situations where a tine drill won’t work e.g. drilling into large biomass cover crops, or when there is very little dry lignified residue. Both of these situations also require the soil moisture conditions to be perfect.

-

Drill Manufacturers In Focus…

Simplicity Is The Key When Starting Out

by Simon Clarke, Technical and Sales Manager for Simtech Aitchison

I’m sure few would disagree that converting to a no-till system of farming after years of moving soil around is a daunting task and finding your way through the increasing fog of advice is as difficult as the actual act of no-till farming itself. However through working with many of the early adopters of this practise over the past 12 years I have formed the opinion that keeping to a simple system is your best bet for success. You may say I am biased, as my job is working with one of the simpler tine drills on the market, but as I will layout, the facts speak for themselves.

Too much emphasis is often placed on zero soil movement, which is my view does not exist. Often a little soil disturbance is beneficial in mineralising some nutrients, eliminating the need for expensive starter fertiliser and the equipment to place it. Equally you are going to find yourself needing to drill in an extreme range of situations, from cover crops directly after harvesting, when the ground can be very hard, to potentially very wet conditions, as autumn drilling advise is now to drill quite late in the season, in the battle against blackgrass. Whilst talking about late autumn drilling it is also important to note that speed of emergence can vary according to the type of direct drill you are using. I have talked to many farmers that own both a tine and a disc type direct drill, who report that by comparison the speed of emergence can be reduced by as much as two thirds, when disc drills are used in cold wet soils.

At the other end of the spectrum, summer drilled cover crops need to go in as quickly as time and soil conditions allow, following the combine. Often drilling into large amounts of surface trash at a time when soil moisture content can be very low. Seed to soil contact is very important and “hair pinning” by disc drills is in my view unavoidable and very detrimental to germination, as the trash dries out the seed slot and prevents the seed being covered by tilth. Penetration is also an issue in these situations and getting the seed at a sensible depth needs a powerful coulter. For many years we have worked in France drilling complex cover crop mixtures of up to 13 different species, possibly containing beans and clover in the same mix. All these seeds go into the same slot at a depth determined by the largest seed in the mix, yet all the species emerge together, dispelling the theory that small seeds must be drilled very shallowly.

Another vital component to success is how good you can be at eliminating soil compaction. Investing in the right tyres is in my view as important as your drill choice, but tyres alone will not solve compaction if you are running around with several hundred horsepower on top of them. Combine harvesters vary considerably in weight between makes and ranges, so look very carefully at how light you can travel, as harvesting is the one thing you cannot delay in a wet period.

My final piece of advice is to understand what “living soil” means and study how to achieve it. We are very lucky that there is now a wealth of publications out there, from the highly academic to the down-right practical farmers who have “been there and done that” and are willing to share their knowledge with the rest of us and it does not really matter where in the world they are, because the principals of soil health are the same everywhere.

-

What Do You Read?

If you are like us, then you don’t know where to start when it comes to other reading apart from farming magazines. However, there is so much information out there that can help us understand our businesses, farm better and understand the position of non-farmers. Tom Sewell mentioned a great book earlier called “Dirt to Soil” and we have listed a few other books you might find interesting and challenge you way you currently think.

Growing a Revolution

For centuries, agricultural practices have eroded the soil that farming depends on, stripping it of the organic matter vital to its productivity. Now conventional agriculture is threatening disaster for the world’s growing population. In Growing a Revolution, geologist David R. Montgomery travels the world, meeting farmers at the forefront of an agricultural movement to restore soil health.

Whole Earth Discipline

An Ecopragmatist Manifesto – According to Stewart Brand, a lifelong environmentalist who sees everything in terms of solvable design problems, three profound transformations are under way on Earth right now. Climate change is real and is pushing us toward managing the planet as a whole. Urbanization – half the world’s population now lives in cities, and 80 percent will by midcentury – is altering humanity’s land impact and wealth. And biotechnology is becoming the world’s dominant engineering tool.In light of these changes, Brand suggests that environmentalists are going to have to reverse some long held opinions and embrace tools that they have traditionally distrusted. Only a radical rethinking of traditional green pieties will allow us to forestall the cataclysmic deterioration of the earth’s resources.

Drawdown

The Most Comprehensive Plan Ever Proposed To Reverse Global Warming – Drawdown maps, measures, models, and describes the 100 most substantive solutions to global warming. For each solution, we describe its history, the carbon impact it provides, the relative cost and savings, the path to adoption, and how it works. The goal of the research that informs Drawdown is to determine if we can reverse the buildup of atmospheric carbon within thirty years. All solutions modeled are already in place, well understood, analyzed based on peer-reviewed science, and are expanding around the world.

-

Introduction – Issue 5

It’s perhaps not so important whether Einstein said “ insanity is doing the same thing again and again and expecting different results” or not. The powerful phrase initiates progress and of course has considerable relevance in farming, where doing the same thing can be a bit of a habit. That is, of course, if you need change.

If the results of your efforts are already acceptable and worth repeating, change is the last thing to consider. But when things around you are about to change, as is the case of UK farming today, that’s the time to look hard at what you are doing and how you might do it better. This Direct Driller issue, the fifth to be published, presents a huge number of ideas and possibilities for cereal growers.

The breadth and depth of its articles is seriously considerable. It of course comes at a very critical time. The real consequences of current politics on farming will remain unknown for some time, yet the farming year progresses and forward decisions have to be taken. You’ll find a great deal of wisdom in these pages, from people who have been making and measuring change on their farms, companies which have forged ahead with new and better processes: mechanical; chemical and especially biological.

I still maintain that farming is on the cusp of a revolution in terms of production and its environmental impact. Farmers really are getting kinder to mother nature and are beginning to understand the powers which we can use to the good of all… and Direct Driller is a valuable resource for all involved. The fact it remains free of charge and produced without a government or quango handout is truly remarkable.

-

Conserving Water With Cover Crops

Large parts of Germany have struggled for years with very erratic rainfall patterns. Some farmers are now tending to

question the usefulness of cover cropping in dry and even semiarid regions largely on the basis of their experience in

the dry summer and autumn of 2015. Does cover cropping conserve water or squander it?Written by Markus Scheller ∙ Dettelbach-Euerfeld

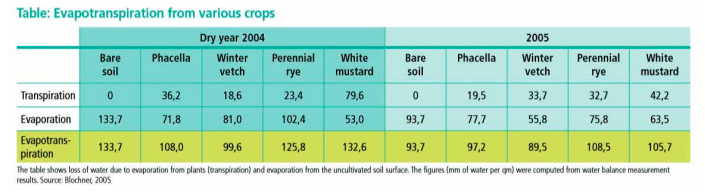

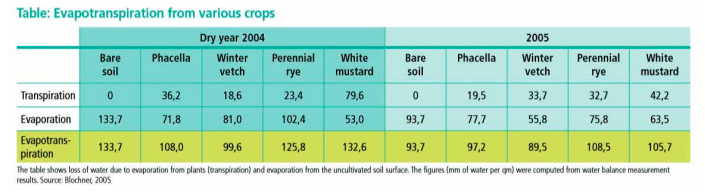

The benefits of cover crops are undisputed: They help to increase biological activity in the soil and improve the soil structure. Cover crops also prevent soil erosion caused by wind or heavy rainfall and reduce nutrient leaching. Some species even have the ability to unlock nutrients bound in the soil, making them available to the crops. Despite this, cover crops are frequently accused of consuming water that is badly needed for the follow-on crop. Long term practical experience and scientific studies, especially in dry regions such as Austria‘s Burgenland, have clearly shown that this is not the case. Cover crops do not consume any more water than fallow land.

Water evaporation on uncultivated land is significant

The table below shows that water loss is large due to evaporation from the uncultivated soil surface. By contrast, the sum of transpiration for cover crop growth and evaporation from the cover crop canopy – evapotranspiration – in dry years is lower than that of evaporation from the bare soil. In winter in particular, the canopy cover reduces non-productive water evaporation from the soil.

Winter rainfall is normally sufficient to make up for the increased water consumption of cover crops in the autumn. Cover crops have not been shown to have any negative effects on the subsequent crop either. Quite the reverse, in fact; carefully chosen cover crop mixtures can prepare the soil specifically to meet the requirements of the follow-on crop. This has been demonstrated by comparison trials at Kraichgau in Baden-Württemberg (South-West of Germany) in which cover crop mixes were found to be superior to the standard single crop mustard both in terms of nutrient fixation and the productivity of the follow-on crop grain maize.

Moreover, the productivity of the follow-on crop depends far more on the rainfall pattern in the crop year than rainfall events during the cover crop growing season. Experiences on my own farm in Lower Franconia, Bavaria (Central-South Germany) with wheat/sugar beet rotations demonstrate the importance of establishing the cover crop. It is not always easy to use the residual moisture in the soil to germinate the cover crop seed, especially in the dry conditions typically found in Lower Franconia.

Strategies for preserving soil moisture are the key

This begins right from the point of harvesting the previous crop. It is important to pay careful attention to your combining operation. For example, check the settings on the combine harvester (low losses), make sure the knives on the straw chopper are sharp, select a short chop length and uniform straw distribution. The timely use of a mulcher to shred the straw may even be worthwhile to reduce the ‘chimney effect’ of the stubble, i.e. loss of water via the hollow stalk, especially with large quantities of straw. Control of volunteer cereals is also critical for the successful establishment of the cover crop.

If the straw is harvested, pay particular attention to the area underneath the swath as the proportion of shed seed, chaff and weed seeds will be particularly high here. The main thing is to prevent the volunteer cereals swelling or germinating ahead of the cover crops seeds. If volunteers from cereals that are harvested early in the season, such as winter barley, are encouraged to germinate, it is very important to shallow till immediately after the cereal harvest to break the capillary action. In later crops such as winter wheat, farmers are often left with no choice but to till at the same time as sowing the cover crop, as sowing ought to take place by the end of August at the atest to ensure reliable establishment of the cover crop. Plan to sow as early as possible to prevent non-productive evaporation from bare soil during summer when temperatures are high.

The aim is to make productive use of the residual moisture to form biomass and absorb nutrients. By cultivating a mixture of crops it is possible to exploit the benefits of cover crops even under unfavourable climate conditions and to minimise risks. Cover crop mixes containing a variety of components promote diversity and provide herbage growth even when individual species fail – often ensuring that adequate soil functioning can still be achieved.

Sowing methods that conserve water

Direct seeding and shallow mulch seeding are effective means of conserving moisture. Since good reconsolidation is important with these techniques, it can be helpful to make an additional pass with a roller.

The right tillage for the followon crop

The way in which soil is prepared for the follow-on crop and therefore how the cover crop is managed also has an important impact on the soil water balance. Leaving the cover crop in situ until just before the following crop is sown maximises water conservation. A rolling pass in autumn or winter when the soil is trafficable can encourage the cover crop to die off over winter, if this is the intention. This has proved particularly helpful in the mild winters of recent years. For early sown summer crops, e.g. oats, spring barley and sugar beet, a shallow cultivation pass in winter when there is a ground frost is a good idea, depending on the location, to speed up the drying of the soil prior to sowing.

If the cover crop is followed by maize, the cultivation pass may either be carried out to incorporate manure or immediately before drilling. Even cover crop plantings that are not needed to satisfy greening requirements should under no circumstances be ploughed up in autumn or early spring. Such action would have a negative impact on the water balance and reduce the performance potential of the cover crop.

Conclusion

Cover crops are an important part of the crop rotation system, even under difficult conditions. They benefit the soil in many ways, often giving more back to it than they took from it in the first place in the form of water or nutrients. The positive effects of growing cover crop mixes are numerous; they support soil organisms, increase aggregate stability, reduce the risk of nitrate leaching and erosion etc. The key to success, however, is to pay as much attention to the cover crop as to the main crop. The farmer‘s job is to find the right timing, prepare the seedbed optimally, and select a cover crop mix that is appropriate for the region and the crop rotation system.

Cover crops for nitrogen fixation

After the cereal harvest there is an opportunity to produce and fix nitrogen for follow-on crops. Special cover crop mixes with good nitrogen fixing capabilities are available for this purpose. N-Fixx is a good choice for winter cereal crop rotations. It comprises nine different components, including 80 % legumes. According to Deutsche Saatveredelung AG (DSV), this mix is not only good at fixing nitrogen, it also enriches the soil humus and promotes soil health to boost the performance of subsequent food and forage crops.

-

Featured Farmer – David Miller

Wheatsheaf Farming Company (WFC) farms around 700 Hectares of grade 3 land in Hampshire for 3 landowners. 2 of the landowners also own WFC as a method of farming their land more cost effectively. David Miller, their farm manager, describes details of their move from conventional to no-till farming.

I have worked in farming full time since 1975 and have progressed through the farming fashions that have presented themselves through the next 35 years. As such this branded me as a “conventional” farmer. We moved from a low input, low output system to the new-fangled German Schleswig-Holstein method of wheat production. This involved increased nitrogen applications matched by increased fungicide applications to produce higher yields. ICI promoted a system of direct drilling which used liberal doses of Paraquat and a Bettinson 3D direct drill with disc openers. We tried deep ploughing, shallow ploughing, square ploughing, deep cultivating, shallow cultivating and scratch tillage.

We changed the crops we grew to match the latest fashion. Oilseed Rape came into the rotation with fields of Jet Neuf and Bienvenue. Eight feet tall and not a CSFB in sight. We didn’t own a quad bike or use slug pellets. Sugar beet were dropped to help us concentrate on our goal of becoming paid up members of the illustrious wheat 10 tonne club.

Straw was a nuisance to all noninversion cultivation so a straw spreader was fitted to the back of the New Holland 1540 combine to spread the straw the full 13 feet width of the header so that a comprehensive all over burn would be achieved. When burning was banned we started dealing with the swaths of straw with a tractor mounted chopper, hours sat in a Ford 5000 with no rear window and a crash helmet for safety against flying stones. The combine was eventually traded in for one with the chopper already fitted. The chopped straw was sprayed with a “Stubble Digester” to help break it down before it was ploughed with the hope that it would not be ploughed back out again the next year.

Drill fashions were also followed, from a Massey 30 in the early days to Vaderstad Rapide more recently but including Amazone and Kuhn combinations and a couple of Accord air drills also.

The advances in yields in the first 20 years saw the rise from 2T/acre to 4T/ acre. Over the next 15 years it has not been so good with only a very marginal increase. This is despite advances in the varieties we grow as well as better plant protection products, better fertilizers, GPS and sensor application techniques and basically anything big business could convince farmers to buy with the promise of improved yield/ income. Journals, Conferences, Field days and any other method of knowledge transfer afforded us with a greater understanding of every aspect of crop production EXCEPT the resource we totally rely on, SOIL.

In 2010 our emphasis changed to looking at how we could help the soil function better. Cover crops were trialled and gave visible if not scientific results. The first was a crop of Crimson clover sown on half a field which gave a visible line in the next 2 crops. Next was beans and vetch over 2 fields which gave similar visible results quantified with an N-tester which showed a greater amount of N in the leaf of the following crop. By 2014 all spring cropped ground was cover cropped with a diverse 6 way mix.

A lesson learned early on was that this is a long-term project and not a yearly spend for a positive financial return in the same year. The next step was to consider direct drilling as the logic of not disturbing the soil structure, root channels, worms and worm burrows as well as weed seeds was confirmed in many articles written about boosting soil organisms. We had now also stopped straw removal.

We stumbled through the next few years adjusting our system from theoretical knowledge gained from principles, ideas, guidelines and gut feelings. This has now given us experience, results, successes and failures with which we are better armed to base future decisions as to how we evolve the system. We have gone from conventional farmers to now practicing Conservation Agriculture (CA). According to a UN FAO definition in 2007 that states,

CA is a concept for resource saving agricultural crop production that strives to achieve acceptable profits together with high and sustained production levels while concurrently conserving the environment. Based FEATURE Wheatsheaf Farming Company (WFC) farms around 700 Hectares of grade 3 land in Hampshire for 3 landowners. 2 of the landowners also own WFC as a method of farming their land more cost effectively. David Miller, their farm manager, describes details of their move from conventional to no-till farming. FEATURED FARMER DAVID MILLER DIRECT DRILLER MAGAZINE www.directdriller.co.uk 9 on the 3 principals of minimal soil disturbance, permanent organic soil cover and diverse crop rotations and interactions These are to give the benefits of increased organic matter, increased water conservation and improved soil structure.

Our present rotation is based around nearly 50% spring cropping and includes Winter Wheat (milling and feed), Winter Barley (feed), Winter Oilseed rape (with a companion crop), Winter Beans, Spring Barley (seed crops), Spring Linseed (yellow for human consumption). We are also trying some Spelt wheat and also growing Lupins and buckwheat for our own cover crop seed.

Cover crop mixes have continued to evolve and 2 principals are adhered to, no cereals in the pre spring barley mix and no brassicas in any mix. In the very wet first years the oil radish and tillage radish caused massive and costly slug problems as well as not having any Mychorrhizal association. I am confident these principals will change as we progress further into CA. Huge quantities of above ground biomass are less important, at the moment, than the amount of diverse root architecture. Current species used in covers are Lupins, Vetch, Beans, Phacelia, Buckwheat, Berseem Clover, Linseed and Camelina. Average cost per hectare is now around the £20 mark. All seed is bought as straights and mixed on farm. Companion cropping for oilseed rape this year is a mix of Crimson and berseem clover and one field has inter row Beans. Cost of both scenarios is about £15/ha. A wheat field with a companion crop of volunteer Beans will have several different trials on it based on fewer inputs of fertiliser and fungicides.

Potash has historically been spread variable rate according to soil analysis maps but this stopped 5 years ago and no bagged potash has been applied since. Last year’s analysis maps have shown no great deficiencies and, in some cases, increases especially where more cover crops have been grown. Phosphate is applied under an EA derogation as DAP to all winter cereals at a yearly decreasing rate and we are currently placing 50kg of product per hectare. Nitrogen mineralisation through cultivation is said to release about 30 kg of N and in the early years of transition to No-till this lack of available N at drilling shows up as backward and sickly looking emerging crops. As the soils improve this application is actually detrimental to soil organisms so it is a commercial balance between growing a viable crop and improving the soil. Spring crops receive a DAP and enhanced Urea blend which supplies some available N as well as some slow release N.

The new system has had an effect on fixed costs with reductions in machinery as well as labour. Diesel has been calculated as the total diesel used over 12 months divided by the total hectares cropped. 10 years ago this figure was around 85 lts/ha and calculated for 2018 it has fallen to 58 lts/ha. A 30% drop in fuel usage. CO2 release has been cut by 60% through cutting out cultivation, using less diesel and less nitrogen fertiliser.

Our system for establishment is to stubble rake after the combine and maybe again before drilling. This is mostly as cultural slug control by disrupting slug nests and eggs. This should become less necessary as the soil biology becomes more in balance. Drilling is done with the Cross-Slot drill which applies the fertiliser beside the seed and also a couple of kgs of Ferric Phosphate slug pellets. Fields are rolled post drilling, not really for consolidation but more for the flints that which may be sticking up.

We are now 5 years fully into a longterm system that has been embarked upon with the vision of being able to farm more in tune with the environment, with less inorganic inputs, producing healthier food from healthier crops and ultimately having a more resilient business and regenerated soil.

This is a personal account with thoughts based on my journey through over 44 years in arable farming both in Essex and Hampshire. The whole experience has now increased my thirst for knowledge about soil health and its direct impact on plant health. Books by such experts as Gabe Brown, Jon Stika, David Montgomery and the visionary from the 1940’s , Edward Faulkner with his books, Ploughmans Folly and Ploughing in Prejudices have all been read. This has managed to either, confuse me further or helped make sense of some of the practices we have embarked upon. Conferences with speakers such as Gary Zimmer, Dr Christine Jones and Joel Williams have been eagerly attended with multiple pages of notes taken. This then led to many hours of trying to understand how the principals contained in their presentations could be put into practice within our transition from a 40 year chemical based farming system to the brave new world of Conservation Agriculture.

-

Hitting The Sainfoin Trail

As based on information found on Agricology (www.agricology.co.uk)

Richard Smith, farm manager of Daylesford Organic in Gloucestershire, is a regular contributor to a series of video

blogs produced by Agricology. One topic that he favours for the organic system is growing sainfoin as a forage crop.

In this article he reveals some of his experiences of growing and managing sainfoin on the farm:

At Daylesford, we’ve grown a variety of crops over the years but the one that has consistently come out on top is sainfoin, due to it being a highly nutritious (palatable silage) hay crop or grazing crop for livestock. It was grown widely throughout the Cotswolds a hundred years ago; mainly to feed the heavy horses that worked the land (25% of crops grown 100 years ago were to feed working animals such as horses). Sainfoin is favoured because of its high yielding and drought resilient qualities compared to other crops. We have found the crop to easily yield 15 tonnes per acre, with a potential protein content of around 22% and a metabolizable energy (ME) of 12. Other crops, such as rye grass would only yield 8 – 10 tonners per acre, with about 14- 15% protein content and an ME of 10.

We operate a rotational grazing system, moving the cattle morning and night to make the most of the available forage. Cows are ruminants and therefore require high fibre diets, the vast majority of which, on our farm, is made up of grass; either fresh or conserved. Thirteen years ago we started a breeding programme to take our herd from a high yielding, high input Holstein herd to a much more sustainable low-input British Friesian cow.