If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Farminn From Rothamsted

Dr Ian Shield, Rothamsted Research, explains how this venerable farming research institution is now working directly

with farmers to increase knowledge transferWhilst you’ve probably heard of Rothamsted, the world’s oldest agricultural research centre, it’s possible you won’t have dealt with us directly, or maybe even been aware of what impact we’ve had on the way you farm. However, thanks to a new citizen science initiative, that could all be about to change. Traditionally, the evidence we’ve produced has made its way into the farming community through indirect routes – either by influencing policy; through the best practice advice given out by agronomists and consultants; or via its impact on the wider agricultural industry.

Our founder, Sir John Bennet Lawes, formulated superphosphate, which marked the beginnings of the global chemical fertiliser industry. His LongTerm Field Experiments continue to this day, and at 176 years old, are the oldest, continuous agronomic experiments in the world. This has given us unique insights into soil and crop nutrition and today this expertise continues to manifest itself when our scientists contribute to the fertiliser manual (RB209). Ronald Fisher, the founding father of field experimental design and statistical analysis was a member of staff here, and his legacy can still be seen to this day in how we design and analyse experiments.

Research in recent years

In the 1970s Michael Elliott’s team discovered synthetic pyrethroid insecticides at Rothamsted and these now account for a quarter of all pest control agents used worldwide, whilst our insect survey has been providing regular bulletins on the current state of aphid and moth populations in your area and right across the UK, for more than 50 years. And last year our scientists helped to decode the wheat genome, and our Designing Future Wheat research is developing and screening novel germplasm for the next generation of wheat traits.

All this means we’ve probably influenced at least one aspect of the way you farm – even if you never realised it. Having been around for over 175 years, we’ve witnessed all sorts of changes – to farming and beyond. From how, why, and when we communicate; through upheaval in our national and local institutions; to an increase in the general scientific literacy of the population, society has evolved, and the old barriers that once separated the likes of Rothamsted from farmers up and down the country, are breaking down. Until recently, less than one percent of money spent on agricultural research was farmer led, but such research schemes are now increasing in popularity across the country – take for instance the Innovative Farmers scheme, the Yield Enhancement Network, and other similar initiatives.

The rise of these schemes comes from a growing realisation of the positive impact farmer led research can have. Our recent farmland earthworm surveys are great examples of such collaborative working, which in that case involved co-developing a quick and economical method of using worm numbers to measure soil health. Thanks to the input of participating farmers, we’ve discovered that the pilot sampling method (which involving an hour’s effort across 10 soil pits) could be halved without detriment to the accuracy of worm population estimates. As times change, it makes sense that we also change. But we want to go further than just ask farmers what research they’d like to see done, or even to work with us – we want farmers to actually take the lead in conducting onfarm research.

Supporting Farmers with Smart Research Ideas – FarmInn

As a result, we recently launched FarmInn (in collaboration with AHDB Cereals and Oilseeds), a scheme that offers up to £3000 plus technical support to farmers with smart research ideas that they want to test out on their own farms. Whilst much of modern agricultural research is focused on the long-term improvement of crops, livestock or sustainability, there is a clear gap in the market for quick wins that boost efficiency, productivity, or sustainability at the level of individual farm businesses.

That’s why we decided to offer access to our world class facilities and perhaps even more valuably, the wealth of scientific expertise we have across the institute, to farmers who want to investigate their own theories. This allows us to rigorously test, farmer derived hypotheses by lending our scientific expertise to projects that produce farmer to farmer demonstration opportunities and case studies to inspire improvements on other farms across the UK. Rothamsted’s expertise covers both arable and livestock systems, and spans disciplines from agronomy and ecology to chemistry, genetics, and microbiology, whilst our statisticians will be consulted in the design of experiments and the analysis of data from FarmInn projects, so we have the best chance of getting meaningful results from your idea. Our hope is the FarmInn initiative will support innovative on-farm projects which aim to provide realworld, scientifically-robust solutions to the challenges faced by UK farmers.

Projects have the potential for Peer-Peer learning via on-farm demonstration days that can be held whilst the experiment is running. A recent AHDB report found using active demonstrations of new techniques were key factors in influencing behaviour, which will insure your idea will benefit the wider industry. Despite only being a few weeks in, we’ve been blown away with the quality of innovative ideas already coming in from farmers, and we’re excited to get projects started. As we’ve had a great deal of interest, we thought it would be a good idea to clarify what FarmInn is – and isn’t – about.

Firstly, ideas don’t have to be solely production based, they can be around boosting on-farm biodiversity and production techniques that have environmental benefits. On farm pilot studies aren’t necessarily a prerequisite– it’s the idea that’s important. We want ideas that farmers are passionate about and are in the forefront of farmers thinking. Many people might be reluctant to put time into filling a form to find their idea is not relevant, so we encourage you to get in touch if you’d like to discuss the initial idea before attempting an application.

You can even request a call back via the FarmInn email address (farminn@rothamsted.ac.uk). Sadly, we can’t support applications from non-farming businesses. Whilst we welcome the dialog, this is not in the remit of FarmInn, but we do welcome applications from all farming sectors. Many people still think of us as an arable institute only, but near Okehampton in Devon we have a 350ha livestock farm – and the experts and facilities to go with it. Hopefully that will have answered many of your questions about the scheme – but please do get in touch if you have any others. So far, we’ve had interest from farmers in England and Northern Ireland but welcome applications from all over the UK. The agricultural industry has a significant impact upon the country’s economy and natural environment, but it will need to be innovative going forward – even more so in the face of Brexit. We believe the FarmInn initiative and others like it will enable farmers to rigorously test new ideas whilst de-risking the process of being innovative.

More information on the FarmInn scheme, including how to

apply, can be found at: https://www.rothamsted.ac.uk/farminnDr Ian Shield has more than 25 years’ experience of agronomic research in temperate agriculture, largely in the UK. As Senior Scientific Manager – Agronomy, he supports the agronomic research conducted by Rothamsted Research and he is also responsible for the oversight of the use of the Rothamsted Farms as a platform for field experimentation.

-

Spring Into Action: Choose Adjuvants To Push Herbicide And Fungicide Performance This Year.

How can you keep weeds and disease at bay this spring? As warmer weather arrives and the season gets underway, we explore here the role of adjuvants in boosting the performance of herbicides and fungicides on farm to optimise weed and disease control.

Right time, right place

Bumper harvests are made in spring. Where every kilo counts, optimising a fit and healthy crop free from weed and disease competition is absolutely essential. Of course, this is easier said than done. As certain species become resistant to herbicides and fungicides, restrictions tighten and active ingredients disappear from the crop protection toolbox, the job certainly isn’t getting any easier for farmers. If conditions are challenging during application, as they so often are these days, things become even more stressful. Plants struggle, workloads rise and yields fall.

There isn’t much we can do about the weather. What we can do is make sure that crop protection products are delivered to the right place, at the right time – and that the tools we have are working as hard as possible. This is where adjuvants are worth their weight in gold. E m p l o y i n g a suitable a d j u v a n t e n s u r e s herbicides and fungicides are delivered exactly where needed, m a x i m i s i n g effectiveness and protecting yield. For those looking to get the most out of rotational weed control this spring, they are practically a secret weapon.

Kick-start your weed control programmes

We know that spring crops are limited in their post-emergence armoury. To give your plants the best start in life, it’s a matter of control. While the majority of black-grass germinates in autumn, the startling truth is it only takes 12 plants/ m² to reduce yield by as much as 5% and power seed return of an eye-watering 144m seeds per hectare. Pre-emergence residual herbicides need to be applied with precision in problem fields to protect yield, keep on top of populations and prevent issues in the next crop. Working in lighter soils, getting rid of spring germinators early – like knotgrass, black bindweed and redshank – defends sugar beet, potatoes and the like – crops where early establishment, free from weed competition is vital to protect yield. During the pre/peri-emergence spray timing your aim is to get maximum coverage with the spray and retain the herbicide in the top 5cm of the soil to control new flushes of germinating weeds that may appear over time.

This can be challenging for three reasons:

1. Coverage can be compromised by drift, reducing the applied dose, missing parts of the soil altogether and allowing weeds to germinate and outstay their welcome.

2. The dry soils typically seen in spring have an impact on performance.

3. Levels of moisture in the soil can affect retention and therefore leach the potential of the herbicide.

Designed to reduce drift, a low-drift nozzle produces bigger droplets but reduces coverage –meaning we still have problems two and three to deal with. This is where a residual herbicide adjuvant like our Backrow product can help. Adding Backrow to spray water both reduces drift and improves coverage. The product helps soil retain herbicide and moisture in the top 5cm of soil for up to eight weeks and prevents herbicides leaching to groundwater or the roots of the crop itself. Used in this way, Backrow improves the efficacy and longevity of weed control and general crop safety, particularly in light soils. Field-scale research on onions has shown that where Backrow was applied pre-emergence, the leaching of all subsequent crop protection products was dramatically reduced. Follow-up work using lysimeters in a controlled environment revealed that the product upped water retention by 33% and diminished leaching by an incredible 62%.

Four ways Backrow can help increase overall weed control

Adding Backrow to your weed control has four central benefits:

• Increases contact between the herbicide and the weed

• Increases effectiveness of herbicide in dry conditions

•Increases longevity of weed control

• Improves crop safety

Over the past nine years, replicated trials have been carried out with a range of herbicides applied both pre and periemergence. The results of these trials have shown conclusively that Backrow advances the performance of herbicides by an average of 9%. Let’s crunch the numbers; for a black-grass population of 500 heads per m², 9% means a yield benefit of 0.45 t/ha, or to put it in financial terms, a margin of roughly £80/ ha. Importantly, it also means a reduction in black-grass seed return to the tune of 270,000 seeds per hectare (based on seed viability of 60%), protecting future crops from competition.

Broadleaf weed control in cereals: +13%

Broadleaf weed control in combining peas: +13%

Broadleaf weed control in spring beans: +10%

Broadleaf and grass-weed control in potatoes: +8%

Enhancing weed control post-emergence

Once weeds have surfaced, we are dealing with an entirely new target; aiming to get herbicide into a small established weed, rather than sufficient coverage of the bare soil. If the weed gets particularly big, hairy, or waxy in texture, things become even more tricky. What then if applications are delayed due to weather or workload? … If you find yourself with an out-ofcontrol weed situation, choose your solution wisely. A good adjuvant should reduce drift and improve retention on the leaf, rather than allowing the herbicide to simply bounce or run off the surface.

It will aid spreading across the leaf to optimise entry points, improve penetration and increase uptake. Sulfonylurea (SU) herbicides in particular benefit greatly from the addition of an adjuvant; on a molecular level, the very small nature of the active ingredient makes it hard to wet in formulations. Adjuvants like Arma and Kantor are ideal in this situation. Kantor would be the better choice to reduce drift and/or when using hefty tank mixtures. It has the ability to keep complex mixtures stable within the solution; a notable benefit with Basagran in spring beans which can be “hot” on the crop.

Pushing the performance of fungicides

While SDHI/azole mixtures have proven effective in controlling Septoria in cereals, monitoring data shows there has been another slide in sensitivity to SDHIs and azole chemistry. At present, we’re also experiencing disease control challenges in controlling Cercospera in sugar beet and Ramularia in barley, to name a few vicious examples. We’re not saying that adjuvants are the holy grail, but there’s no denying resistance poses a significant threat to the ongoing performance of fungicides. By optimising the application process, we can not only increase efficacy and yield, but importantly also reduce negative genetic effects and slow resistance.

During fungicide application the aim is to get as much of the active ingredient inside leaves as is possible. The surface area to hit is large and we need to protect it all. While multi-sites act as a protectant, they don’t move on the leaf. This means they can only protect the portion of the leaf they actually cover. If the base of the leaf doesn’t receive adequate coverage, the fungicide will be prevented from moving downwards, leaving that part of the leaf either completely unprotected or having received a sub-lethal dose of the active ingredient.

Although they work slightly differently, both the Arma and Kantor products will improve spreading and uptake to protect the whole crop. Prothioconazole-based mixtures will benefit in particular as it is a large molecule which needs to be converted to desthiocolnazole inside the leaf for it to be “activated” – so the quicker it gets inside, the faster it starts working. Extensive trials over the past seven years have also shown that where Kantor is added to prothioconazolebased sprays with chlorothalonil, antagnosism is reduced and yield is improved.

Over 6 years of trials, 44 comparisons, average yield benefit in winter wheat across all timings: +0.28 t/ha

+14% improvement in Cercospera control in sugar beet with epoxiconazole + thiphanate-methyl

Up to 18% improvement in Downey mildew control in onions with Invader

Our top tips

So how to get the best out of your herbicides and fungicides this spring?

• Choose your crop protection carefully and make sure it is applied in the right place, at the right time.

• Incorporate a suitable adjuvant to ensure your herbicides and fungicides are working as hard as possible.

• Aim for the highest levels of control when applying pre-emergence residual herbicides to give crops the best possible start in life.

• A good offence is the best defence. Use pre-emergence herbicides in problem fields in the spring to keep on top of weeds and safeguard against issues in the next crop.

• Rid lighter soils of spring germinators like knotgrass, black bindweed and redshank as early as possible. In crops like sugar beet and potatoes, doing so is crucial to protect yield.

• Employ crop rotation where necessary to crowd out weeds via competition.

• Pre/peri-emergence, choose a low-drift nozzle and aim for max coverage. Adding a residual herbicide adjuvant like Backrow can help optimise soil coverage and retain herbicide and moisture in the top 5cm of soil for up to 8 weeks.

• Post-emergence, aim to get as much of the active ingredient in the weed leaf as possible. Adjuvants Arma and Kantor improve coverage and uptake to control as many weeds as possible.

• To boost the performance of fungicides, apply an adjuvant like Arma or Kantor to boost spray coverage and uptake to protect the whole crop.

Adjuvants like Backrow, Arma and Kantor are a valuable tool, pushing performance of herbicides and fungicides and helping you get the most from your crop in health and yield. To discuss individual scenarios or to request product guides, please feel free to get in contact with us at info@interagro.co.uk.

-

Farmer Focus – David White

Writing on 28th Feb 2019, David White brings readers up to date on early spring work on this Cambridgeshire farm.

Farming 160ha of combinable crops on light “boys” land over chalk between Cambridge and Newmarket. I’m 100% combinable having been a sugar beet grower since the days of hand hoeing as well as offering a drilling and harvesting service with a 6 row tanker in the past, I have since stopped growing beet when I wanted to start direct drilling. All crops types are grown for premium markets and are stored in Camgrain central storage which makes having a rotation of 6 or 7 crops and different varieties very easy.

Spring drilling Spring Beans and Elyann Oats were in the ground by Feb 27th with only a little barley to go into a thick cover crop of Black Oats and Vetch on some land with blackgrass issues, so no hurry for that. There has been some deliberation as to whether its been too early to sow but conditions have been too perfect to ignore. What a difference from last year which wasn’t great for spring crops.

The oats were drilled into 18” high desiccated Linseed/Phacelia mix and I had some concerns about the linseed being picked up on my milled toothed 750a covering wheels and wrapping on the axles. This fear proved to be unfounded as certainly drilling into the cover when it was dry was 100% trouble free. Small oat seed of 36TGW required 136kg/ha to establish 350 plants. Half the N around 65kgs will go on following the drill to kick it off and N cores will help decide on the balance required. Three metre wide assist strips for pollen and nectar species have been left through a large field which will be sown later in March.

Rape companions Spring beans (inc some Berseem) have proved most successful again in reducing CSFB larvae numbers. Although the plants are carrying more burden than last year most fields are at early stem extension with visible flower buds and will require some PGR treatment I’m advised, some will be done. This is in stark contrast to many conventionally established fields in the area that are shrinking and slowing turning brown! Interestingly a later Sept 2nd sown high seed rate no companion area is suffering much more from larvae even though it emerged after the peak CSFB flight period.

Nitrogen All the OSR and winter wheat have now had some nitrogen although they didn’t look like there was any urgency. We’ve had a dry winter so little N will have been leached but the rape has got to a good growth stage with only 29 kgs/N applied and the wheat looked very well pre first application which suggests to me that the companions and enhanced soil biology achieved through not tilling is doing something for me. 900 mm deep N cores kindly taken by Niab show 22-29 kgs/N available over that profile.

These soil cores also showed the subsoil to be very dry! Cane molasses was added to the liquid N+S application at 5lts/ha without any problems. I cautiously pre mixed 50-50 with water in IBCs as I wasn’t sure how the molasses handled. This makes measuring into the sprayer easy through a suction probe using the scale on the container. A series of nitrogen variation tramline trials is being set up to compare to a soil biology only control.

Growing my own companion seed Winter peas are now about 75mm high and at sowing rate of 100 seeds/ sq mt look fine. After some head scratching for a way to keep my vetch off the ground enough to enable a chance of successful combining I’ve sown it into a companion of spring beans at 80 kgs/ha, watch his space. I have started taking tissue samples to check on plant nutrition status again with the first results in showing most main elements being find. As a BASE UK committee member I’m involved with the planning of events for the late spring/early summer including an interesting European trip which members can look forward to.

-

Practical Advice For Improving Soil Health

Soil health is one of the government’s main concerns relating to the future of agriculture, and with many farmers

now turning towards conservation and biological farming, it is important to get soil heath, the cornerstone of these

principles, right.George Hepburn, biological soils expert at QLF Agronomy, gives his six practical steps for improving soil health, no

matter what farming system.Analysis

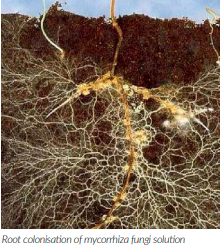

When looking to increase soil health, the first thing I look at is the soil itself. Go out with a spade, or in extreme cases a digger, and physically look at the soil. The presence of deep rooting systems, good soil aggregation and abundance of visible soil life are all key indicators of a healthy soil structure. To test this, look at how far rooting is going down and whether or not there are any fine hair roots. It’s also useful to smell the soil – healthy soil smells almost like dark chocolate, whereas anaerobic soils have an unpleasant smell.

Assess the aggregation of the soil to see if it’s crumbly or compacted, and check for soil life, such as millipedes, beetles and worms. You should see around 10 to 20 worms per spade in a healthy soil. It’s also useful to compare soil in the field with that from under the hedgerow, where soil health and structure won’t have been affected by cultivations or compaction.

Once you’ve assessed the look and feel of the soil, taking a soil test is the next step, because if you don’t measure it, you can’t manage it. However, it’s important to note that a standard UK test only provides N, P, K, Mg and pH measurements, which isn’t enough to accurately determine the level of soil health. I recommend a full spectrum test, which costs around £30 per sample. This will provide a more accurate picture of the soil make-up, by measuring calcium, boron and organic matter (OM) levels, pH, and the cation-exchange capacity (CEC) of your soil. It doesn’t really matter which lab you use, but once you have chosen one stick with it for consistency, as methods of analysis do vary. Once you’ve assessed the condition of your soil, you can then start to make changes.

Soil structure

Before you can affect the biology of the soil, the structure needs to be right. The soil micro flora and fauna need air to breathe, and food and water in the right proportions. The ideal soil structural makeup to provide this is 45% minerals, 5% OM, 25% air and 25% water. Calcium and magnesium are extremely important minerals as they help to define soil structure. Calcium deflocculates the soil, allowing air in and water out, and magnesium does the opposite, making the soil tight and sticky. Therefore, it’s essential to get this balance right. If there’s an imbalance you may need to apply gypsum (calcium sulphate) to help lower magnesium levels or apply calcium lime or magnesium lime. It may be the case that simple cultivation techniques such as subsoiling, ploughing or getting a tine in to aerate the soil, could be what you need to improve the structure.

Soil fertility plan

After creating the right conditions for the soil biology to thrive, you can now concentrate on providing the right inputs to make the soil more fertile. Traditional fertilisers, although necessary, generally do not improve the fertility of the soil itself. For example, as much as 40% of nitrogen can be lost to leaching, immobilisation by soil microbes, denitrification and volatilisation. This can leave you out of pocket due to wasted resources and can potentially reduce yields. Through experience, I would apply a new organically based input each year on each field to feed the soil. This could be FYM, compost, chopped straw, cover crops, lime, seaweed, gypsum, liquid carbon-based fertilisers or biologicals. These will all encourage the soil biology either by improving its habitat or directly feeding it.

Use quality inputs

When implementing a soil fertility plan, make sure you’re using the best fertiliser for your soil. This could simply mean switching from muriate of potash (MOP) to sulphate of potash (SOP), however there are also many other considerations when choosing inputs. We tend to focus on N, P and K but, although they are important, they’re a small part of the picture. Micro nutrients such as boron, zinc and manganese, are also important to soil fertility and include inputs that contain a range of nutrients can be much better for the soil, for example, Limex, P grow.

Ensure you’re using the right type of Nitrogen for your crop, establish if there is enough sulphur or phosphate, if the phosphate reserves are available to the plant and most importantly if you’re getting the most out of your applied fertiliser. There are a wide range of phosphate sources available, for example TSP is the most popular but the poorest efficiency of around 20%. Ironically some of the most efficient sources such as sewage sludge, fibrophos, FYM and digestate, are some of the cheapest. The added value of including organic sources of P, is that they also contain a mixture of other nutrients, such as sulphur and trace elements. Using a liquid carbon-based fertiliser, such as L-CBF BOOST™, can improve uptake efficiencies by stimulating the soil biology and providing an energy source which aids the breakdown of nutrients into a more readily available format for the plant.

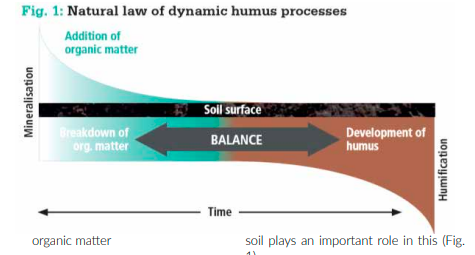

Carbon

Although nitrogen is essential for plant growth, don’t overlook carbon, and especially the carbon to nitrogen ratio. This is vital because when the carbon to nitrogen ratio isn’t balanced and high nitrogen inputs or amendments are used, microbes then feed on the soil organic matter for their carbon, respiring carbon dioxide back into the atmosphere, depleting carbon and causing long term soil fertility and environmental problems. Including a carbon source with any applied nutrient will help to stabilise and buffer the nutrient.

This is because the carbon binds to the nutrients, chelating and complexing them, which improves plant uptake. Applying a carbon source such as carbon-based liquid fertiliser, L-CBF BOOST™, seaweed extracts, organic acids, compost teas, compost or manure, can improve nutrient cycling and reduce losses, meaning you’re getting the most out of the input. Wherever you can, keep the soil covered with a carbon residue to protect the soil from the elements, and help reduce the risk of OM burning off into the atmosphere. This can be achieved with cover and companion crops.

Evaluate

Finally, evaluation is crucial. Testing the soil and the plant itself will help you to determine if your work has been successful. Tissue testing can give an indication of the uptake of nutrients by the plant and help to determine if any additional remedial work and fertiliser applications have been effective. This is even more important on land where you’ve cut back on nutrients. Take the first test when crops begin to grow in spring and repeat on a fieldby-field basis two to three times per growing season, as a deficiency in just one trace mineral could limit yields. If deficiencies are seen, consider foliar applications of micro and macro nutrients to address this. After six months, go out with a spade to check soil structure and compaction where you’ve made changes. Analyse the results of soil samples and tissue tests and continue to take them regularly. Yield is important, but what we should be aiming for is long-term soil fertility so that we can continue to use the land for generations to come. For more information on improving your soil health contact George at george@qlf.co.uk.

-

27TH Annual US National No-Tillage Conference

Written by Ian Gould, Director of Oakbank Game and Conservation Ltd

In an attempt to take myself out of my own comfort zone and into a new learning arena, I decided to venture across the “Pond” and immerse myself in US Agriculture for a week. Arriving in Indianapolis in January 2019 I was intent on absorbing as much as I could at the US National No-Till Conference, an event that attracted almost 1000 farmers, advisors and suppliers. There was a definite bias towards Maize and Soybean growing at the event, but there was a great deal to take away that we could benefit from in the UK.

The first thing I took away was the level of interest in regenerative methods from outside agriculture. Much of this was driven by projects to protect waterways, such as the Chesapeake Bay, but also from large businesses that clearly think that there is commercial advantage to be gained by showing their environmental credentials. These include Wrangler Jeans, who are encouraging their cotton growers to use cover crops and General Mills who have started to set up strategic supply agreements with specific growers. I met a number of USDA and NRCS (Natural Resources Conservation Service) staff at the conference and they were liaising with the scientific / academic community and farmers to promote best practice.

The farmers that spoke during the event shared many of their successes and failures in some honest and informative presentations. They all spoke about how they started out in a small way without spending too much money, but wanted to see how things worked on their own farms. They all continue to trial new ideas and push the development of their own production systems.

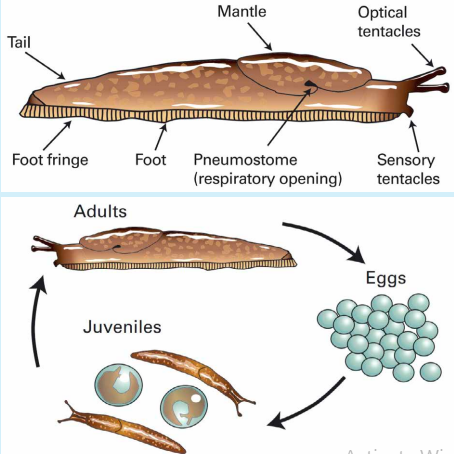

I enjoyed the talk by Trey Hill, who farms 13,000 acres in the Chesapeake Bay watershed. He was sceptical about cover crops initially but necessity drove him to “Plant Green” one year and he has never looked back. His key learning points were that consistency in the cover crop is crucial, so that after termination the conditions are even across the field. If not, establishment of the next crop could be highly variable. Trey also mentioned that he does struggle with slugs sometimes, but this has not diminished his efforts as he has experienced so many benefits from cover cropping the land. He said that he loves his soil so much now, he never wants to see it!

Rick Clark farms 7000 acres in Indiana and he stressed the importance of keeping good data and using this effectively to make better decisions. Don’t rely on your memory as this has a habit of filtering the data over time. Rick’s mantra was “good data leads to good decisions which lead you to a position of strength.” He believes that using cover crops to “Armour the soil” gives a good return on investment.

I had been looking forward to hearing David Brandt speak as he was someone that I had watched on YouTube before travelling to the USA. David farms 1100 acres in Ohio and has been No-Till Farming since 1971 and using cover crops since 1978, so there are few more experienced growers. His standard cover crop mix contains at least 10 species, including 4 different legumes. David has long term plans for his rotation, including where the cover crops will fit in. This then feeds into the planning for herbicides, etc so that they do not run into problems with residual chemicals. David is not an organic farmer, but he certainly learns from those principles, using very little in the way of fertiliser or pesticides. Brandt says he didn’t realize microbes were so important to farming a few years ago. “But I’ve read about how vital they are, and now I see as they increase, we see more good things happening in our soil— more nutrients being released, more water infiltrating into the soil. The more microbial activity we have, the better off we are,” he says.

“I’m really intrigued with the amount of water infiltration we’re seeing with our cover crops. As we go to cover crops with deeper roots, and bigger root masses, we’re seeing rainfall dissipate through the soil better. We don’t have water pockets in our tight clay soils any more.”

Cover crops also moderate soil temperatures. “On hot summer days, with air temperatures over a hundred degrees, our neighbours had soil temperatures of 118 degrees and ours was 86 degrees. Our corn really looked great at those times,” Brandt says.

Away from the main presentations there were so many learning moments, either in the smaller breakout sessions or over a drink at the bar. I was lucky to spend a few hours with Steve Groff who is known to many as the Cover Crop Coach. Steve has worked in this area for many years and has extensive knowledge of the subject. His research led to the development of the Tillage Radish but he is now focussed on developing best practice and educating farmers and advisors around the world. His advice to all cover crop users is “know what you are trying to accomplish!” Without a clear goal, how will you ever know if you are getting anywhere.

The other key piece of advice that Steve is always giving is that when it comes to planting “Every day counts!” Be organised in good time for planting season and get the drill into the field as soon as possible after harvest. We discussed intercropping and seeding into the previous cash crop, which with some of the new drills on the market could certainly become more achievable. Steve also emphasised that the most useful tool for a cover crop farmer is his spade, get out in the field and start to investigate what is going on as “showing beats telling!”

If you are particularly interested in drills and coulter technology I would recommend looking up Loran Steinlage (@ FLOLOfarms) who has a real in-depth knowledge of the subject. I don’t imagine any equipment in his barn is still exactly as it arrived as he builds a lot of it himself or redesigns old kit. His understanding of how metal and soil interact was fascinating and I look forward to seeing what his new role with Dawn Equipment will produce. By stepping away from our normal constraints of UK thinking I have confirmed some principles that I had and certainly challenged some others. The focus on profit per acre instead of simply yield was very strong, and the stacking of enterprises (Crops + Livestock) was diversifying the income streams and spreading risk for many.

I did enjoy the positivity and openness for sharing information, despite what has clearly been a tricky time for US farmers. The massive shift into GMO Maize and Soya has led to a number of problems but it has also created opportunities for individual businesses to diversify into nonGMO markets. They are finding consumer demand for their products increasing and the most successful businesses are very close to their end markets, keeping far more of what the consumer spends within the farm business.

It was a very interesting and enjoyable trip, one that has led to continuing conversations with new friends via Skype and Social Media.

Written by James Warne of Soil First Farming

The 28th annual National NoTillage Conference will be held in St Louis from 7th to 10th January 2020.

-

Brix, Magnesium, Manganese, And Plant Health?

Written by James Warne of Soil First Farming

Ever measured the brix levels of your crops? Been told that if you achieve the magic figure of ~15% brix then you won’t

have an issue with pest and disease?I have spent the last couple of years testing brix (during the spring) of most crops I visit and have never managed to get anywhere near to 15%. For a while I blamed my refractometer so got that tested against another one, no problem there. I then decided I must be measuring the sap from the wrong part of the plant. My understanding is that the sap should be taken from the newest ‘sink’, i.e. the newest emerging leaf. So I tried this as well with little success. However with another approaching growing season I intend to try again.

So what does brix measure? The general consensus is it measures the sucrose content of the plant sap, but this is only part of the story. It turns out that brix is actually a measure of all dissolved solids within the sap. So when measuring brix you are also measuring other solids contained within the plant sap although the largest proportion of these should be sucrose. These solids could be other sugars such as glucose and fructose although these are usually converted to sucrose for phloem transport; it could be amino acids, proteins and minerals also be found within the sap. Brix levels should be measured between 12pm and 4pm on bright days to get a meaningful result. The bris should then drop overnight as the sucrose has been delivered to the sink. If the brix does not fall by a considerable amount this may indicate a shortage of boron.

Why should you be worried at all about brix, after all its principally just a measure of the plant sugar? Well if your desire is to lower inputs and to get off the high input farming treadmill then creating an healthy plant community is essential to achieving a lower-input crop without reducing the output. Essentially it’s a simple measure of our abilities as crop managers at light capture and chlorophyll production.

So what can affect brix levels? Brix can be negatively affected by most pesticide applications and some fertilizer applications such as ammonium nitrate as both place undue stress upon the crop. So how do we positively affect the concentration of sucose within the sap? As previously mentioned sucrose is the plants transport sugar and is made from the condensation of glucose and fructose, the primary products of photosynthesis. Plants produces glucose as the product of photosynthesis. Plants can also manufacture fructose, which is chemically very similar to glucose. It then combines these two monosaccharides into the disaccharide sucrose for transport from the source around the plant to the sink. The process of combining glucose and fructose into sucrose is known as condensation and is controlled by the enzyme sucrase-p-synthase. Potassium is well known to enable the sucrose to enter the phloem transport system. Once the sucrose has reached its sink the plant hydrolyses the sucrose into glucose and fructose to provide energy via the enzyme sucrase.

Photosynthesis is carried out in the chloroplasts by chlorophyll molecules. Magnesium and nitrogen are central to the chlorophyll molecule. We can assume that the crop is able to access sufficient nitrogen as most crops receive more than they can utilize and very rarely show any signs of deficiency, more likely than not most crops actually reveal an excess of nitrate. It is also worth noting that excess nitrate within the plant can actually depress brix as the crop uses more energy to assimilate nitrate than it does using ammonium. Can we ensure the crop receives all the magnesium it requires, especially in high pH soils or soils with excess potassium or low magnesium?

Of equal importance is manganese. Manganese is central to over 35 enzyme functions; it’s critical to chloroplast production, photosynthesis and the photosystem II process; nitrogen metabolism and nitrogen assimilation. Manganese is also believed to be essential to sucrose synthase. Manganese is also shown to be central to the plant ability to synthesis hydrogen peroxide which helps the plant defend against pathogens. Manganese is important for the process of lignification which give the plants strength to stand and resist pathogens within the roots.

Manganese deficiency is a common sight in cereals in the UK. The plant may be suffering from a shortage of manganese before we see physical symptoms. By the time we see the classic yellowing of the crop we are already two weeks too late, consequently yield will have been compromised. It takes around two weeks for the shortage of manganese to reveal itself with leaf symptoms so from that point on we are fire-fighting the deficiency. Over 95% of all the soil analysis we undertake shows very low levels of available soil manganese. While the obvious solution is to re-mineralise the soil using manganese sulphate or similar, in reality this proves expensive and doesn’t help with some of the underlying causes of deficiency such as soil pH.

Manganese deficiency is typical associated with high pH soils, loose well aerated (cultivated soils) and lighter textured soils. Soils high in iron can also reduce manganese availability. Manganese has low phloem mobility in the plant therefore regular foliar applications are necessary in situations where deficiency has been previously seen or maybe expected. Where the deficiency has already expressed itself in the form of visible symptoms a minimum of 750g of manganese as foliar manganese sulphate is required per application if you are using a straight un-chelated product. This can be reduced to 150g per application if using a quality chelated product. As with all foliar applications you always need to ask yourself the vital question; how does the positively charged metal pass through the negatively charged leaf surface? If your product or supplier cannot answer this question it probably means the product hasn’t addressed this fundamental question.

References.

Mineral nutrition of higher plants. Marschner. 2012

Principles of plant nutrition. Mengel & Kirkby. 2001

Applied soil trace elements. Davies. 1980.

-

Drill Manufacturers In Focus…

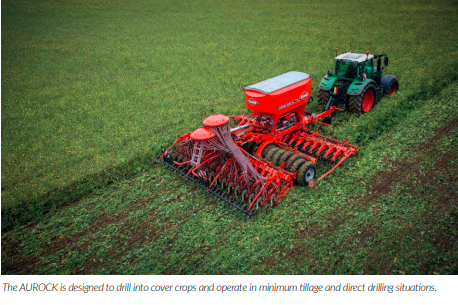

WHEN ADOPTING DIRECT DRILLING, VERSATILITY IS KEY

by Simon Clarke, Technical and Sales Manager for Simtech Aitchison

It is probably true to say that no other make of direct drill is working over such a wide range of agricultural environments as the Simtech T-Sem drill. Vineyards, walnut groves, upland and lowland pastures, the often arid and rocky conditions of places such as Corsica and the arable areas of most Western European countries, are just a few examples of the diverse range of uses encountered by T-Sem drills. They also have a heritage stretching back further than most. But with all this diversity, it is quite surprising to realise that, with the exception of some design tweaks, the same basic principal of operation has remained unchanged.

The unique T-Slot coulter creates a perfect environment for seed to germinate and develop. At only 10mm wide at its leading edge it is designed to cause as little surface disturbance as possible. Preceded by a vertical cutting disc, that creates a path through surface trash, the inverted T-slot coulter ensures that the seed is always placed on a firm, but importantly un-compacted base, with the vibrating tine creating the tilth to cover it. In soil held together with a large amount of root material the T-slot coulter creates a void in the soil, which is like a mini greenhouse, maintaining humidity to enhance the speed of germination, but at the same time allowing sunlight to penetrate through the partially open slot. This scientifically-proven feature allows small seeds to be placed deeper than would normally be viable into an environment which is much less likely to result in poor germination or seedlings drying out. Observers of the T-Sem say, “there is nothing to close the slot”, but in many conditions this is strength not a weakness, because to do so would be to place the seed too deeply to germinate.

Now with the current wide adoption of cover crops the T-Sem really comes into its own. Summer drilling, directly behind the combine is to say the least, challenging. Often quite hard ground conditions and large amounts of surface trash means that disc drills will struggle. If they can penetrate the soil, there is still the problem of “hair-pinning” the trash, which limits seed to soil contact and also rapidly dries out the slot. The power of the 30mm square double coil tine, means that you can place the seed deep enough to find moisture and give them the time needed to put their first roots down.

The other less obvious reason for investing in a T-Sem is that you are buying into the vast amount of experience that Simtech staff have accumulated through working with farmers across Europe for the past 2 decades. In the particular case of cover crops, the much earlier adoption of this practise in France has given us a head start in guiding our customers in the UK through this quite difficult, but in our view essential part of Conservation Agriculture.

So this is the strength of the Simtech brand. A product that works across such a wide range of conditions, which can cope with the extremes of climate and soil such as ours, must surely be a worthy of consideration.

-

Tips For Managing Cover Crop Mixes For More No-Till Benefits

Written byAngela Lovell, originally published in No-Till Farmer USA in November 2018

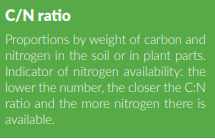

Choosing a cover crop cocktail is only a start, says Adam Daugherty, as managing carbon-to-nitrogen ratios and adapting planting strategies play a big role in success. There are many variables for growers to consider when they’re implementing cover-crop mixes into their no-till rotation — including mix design, carbonto-nitrogen (C:N) ratios, cash crop goals, termination strategies and biomass management. “The goals will be different for everyone and will change from field to field, with changing conditions and with time,” says NRCS district conservationist Adam Daugherty.

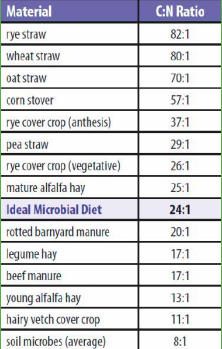

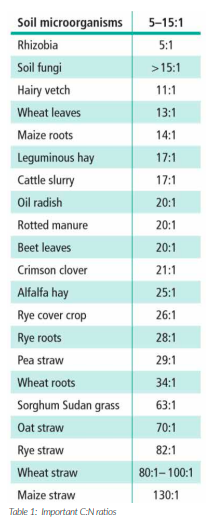

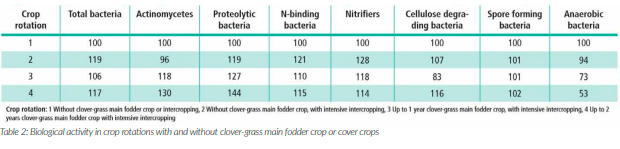

Here are strategies for thinking through some of these important decisions that were shared by Daugherty at the National No-Tillage Conference last January. Staying in Balance It’s vitally important for no-tillers to understand the C:N ratio of crop residue and how they play a role in the soil. C:N ratios are especially important when ascertaining how long it will take for soil microbes to break down residue. “The soil is a jungle ecosystem,” says Daugherty. “It has big and little critters. They all have to eat and they all play a role in cycling residue.” The ideal C:N ratio to feed microbiology in the soil, so it can efficiently consume biomass and cycle nutrients, is 24:1. Higher C:N ratios will slow down the decomposition of biomass and lower C:N ratios will speed it up, Daugherty says.

Most annual cropping systems have a high C:N ratio: wheat straw is 80:1 and corn stover is 57:1, which means residue decomposes slowly and leaves more protective biomass on the soil surface. Plants with a lower C:N ratio (legume hay is 17:1) decompose residue faster and result in less cover being left on the soil surface. Daugherty generally advises no-tillers to stay on the high end of the C:N ratio because one of the first things that destroys soil function is leaving it naked. “I want to keep the soil covered the best I can so I shift a little to the high side on the C:N ratio, especially in fields that have had cover crops for a couple of years and I’m getting a good idea of what they’ve got going on,” he says.

Keep it Simple

Don’t over-complicate cover-crop mixes, advises Daugherty, but aim for one that has at least some diversity with grasses, legumes and brassicas. What generally works for Daugherty’s growers is 20 pounds an acre of legumes, 40 pounds an acre of grasses and 2 pounds of brassicas. To achieve this ratio, a fairly common mix would be 10 pounds per acre each Austrian winter peas and oats, 5 pounds of crimson clover, 5 pounds of hairy vetch, 15 pounds each of cereal rye and triticale, 1½ pounds of Daikon radish and ½-pound of another broadleaf. “That’s a common mix for us and we can manage that mix to achieve a lower or higher ratio,” says Daugherty. “That’s another thing that diversity will let you do — get more flexibility in managing your C:N ratios.” He recommends growers try out online cover-crop calculators to see how different species, maturities and percentages can alter the C:N ratio.

Management Comes First

Daugherty says it’s better to manage a less-ambitious mix properly than choose a “silver-bullet mix” and manage it poorly. “I design in the fall and manage in the spring for my desired results. This is going to hold true no matter where you’re at,” he says. “You can do the same thing with summer mixes. It all boils down to what my goals are for the field and the logistics that I’m going to manage to reach those goals in the spring.”

Happy Medium

The ideal carbon-to-nitrogen (C:N) ratio to feed soil microbiology — so it can efficiently consume biomass and cycle nutrients — is 24:1, says Adam Daugherty. Higher C:N ratios will slow down the decomposition of biomass and lower C:N ratios will speed it up, so it’s best for no-tillers to look for balance in their cover-crop mixes.

No-tillers should always be ready for something unexpected to happen and have a Plan B to deal with it. Daugherty showed growers a slide of two fields planted side by side with the same cover crop mix, on the same day and managed the same way, and while one field was an explosion of diversity the other was almost entirely heavy vetch. “I don’t know what went on, but I think that the soil gets the ability to dominate what species it needs growing,” he says. “We now have to manage this field differently and set up to plant differently. Even though we planned everything in the fall, sometimes crazy stuff happens, but it’s not the end of the world. We can manage anything.”

Art, Not Science

Growing cover crops is an art, not an exact science, says Daugherty. “You cannot write one recipe and just stick to it,” he says. “You’ve got to be very dynamic in your thought process. You have got to be able to switch on the go and do something different on Wednesday than you did Monday. It’s that variable.” Specifically, it’s important to do regular soil evaluations and analyse not just the nitrogen (N), phosphorus and potassium values but things such as microbial biomass, diversity index, organic matter, fungi and CO₂ content. That will help to determine the cover-crop mix and management that fits best.

“We can use this data up front to start making predictions, so we don’t plant something with too low a C:N ratio that we know is going to disintegrate,” Daugherty says.

Look and Listen

The final grade card is learning to read your field, Daugherty says. He cautions that there’s no soil test available that is more effective than growers who develop an ability to read the symptoms of what’s happening in their fields. Once a grower gets soil biology activated and working properly, they must keep feeding it to ensure there’s enough of what the system requires — especially carbon — to meet both soil and crop needs. “Carbon is our limiting nutrient, but liquid carbon is a different feed from other forms, like organic matter,” says Daugherty.

“Primarily we’ll be growing a monoculture cash crop and for at least half the year we’re going to be very nondiverse in a system that wants to be diverse. “In general, as soil biology functions increase, more carbon needs to be managed in the mix.” Growers must monitor stand establishment of their cash crops, assess the amount of residue left on the ground throughout the crop’s growth cycle and, in the end, determine if they have achieved their goals for the crop and the soil. “I don’t really worry about this when I’m starting with a degraded system,” Daugherty says. “I want to start priming it with a lower C:N ratio. But three or four years on, as the system begins to work, you’ve got to start watching this.”

Seed Depth Rules

What never changes with a cover crop is the planting depth for the following cash crop. “If you don’t want a yield drag, whether it’s clean dirt, no-till dirt or biomass dirt, you have to plant at the right depth,” Daugherty says. “Covers are forgiving of a lot of things but that doesn’t mean you can go out there and broadcast corn.” “In general, as the soil biology functions increase, more carbon needs to be managed in the mix…”— Adam Daugherty What typically works for planting in Daugherty’s area of south-eastern Tennessee is working in good-to-dry conditions using a smooth, solid closing wheel which can be changed to a spiked closing wheel in wetter conditions.

Wrapping isn’t usually a problem when planting into green crops that are crimped or rolled as long as growers plant in the same direction as the crops are laying, he says. Growers in Coffee County generally have a fair amount of moisture during the spring and fall, which in their heavy clay loam soils means they have to be careful to avoid compaction of the seed trench. Cover crops are a definite plus in these conditions, especially when growers plant into green crops pre-harvest, but Daugherty notes the firmness of the ground underneath the cover crops or post-harvest residue is still an important consideration. He advises no-tillers evaluate the seed trench by reading the sidewalls. “When you start seeing air pockets there, let it dry up a day,” he says. “Just because you’re planting into covers doesn’t mean you can muddle corn in.”

Low and High

Planting cash crops into low or medium biomass situations requires different techniques, Daugherty explains. With low-biomass cover crops — which he defines as 6,000 pounds of biomass per acre or less — the cash crop is easier to plant, even when it’s into a cover crop. There’s generally no need to roll or crimp it to the ground first. “With low-biomass planting, I highly recommend no-tillers leave it green because your planting window is going to be a lot wider,” he says. “Once you spray it, you’re at the mercy of the sunshine and the rainfall.

There is nothing else out there to manage with. There won’t be any wrapping when you’re planting into this stuff.” What growers need to watch in a lowbiomass cover crop is that the following cash crop — especially a heavy feeder like corn — can begin to run out of carbon as the residue begins to disappear by June or July. “You can still grow good corn. Infiltration and a lot of things are better, but it’s not bio mimicry,” he says. “You’re not rejuvenating the resources to the degree that you can, so you won’t have the results you could potentially get.” In a medium situation with 6,000- 10,000 pounds of biomass per acre, Daugherty says growers can make tremendous strides and achieve extreme resource

-

Drill Manufacturers In Focus…

CORRECT ESTABLISHMENT IS VITAL TO GET THE BEST FROM SPRING-SOWN CROPS

Spring crops have become an increasingly important component in many arable rotations, but to deliver best performance they must be established correctly, writes Jeff Claydon, who farms in Suffolk and designed the Claydon OptiTill® System

In the last issue of Direct Driller magazine, I highlighted the importance of effective stubble management in producing excellent crops and outlined how to achieve it. This time I want to look at how we deal with spring crops, of which we have 65ha this year, comprising 16ha of beans and 49ha of oats. According to the meteorological calendar, spring starts on 1 March while the astrological spring begins on 20 March but whichever measure you go by farming at a high level involves so much more than simply working to a date in the diary. Having an innate feel for everything that is happening around you and working in harmony with Mother Nature are much more important. The need for this has been illustrated quite graphically in recent years.

The winter of 2017-2018 was long, cold, wet and seemed to go on forever. The weather was anything but spring-like right through until the end of April, then we had four months of severe drought. Conditions this year, at least up to the time of writing on 21 February, have been the exact opposite, with winter almost non-existent and soil temperatures already at 7°C. The contrast could not be more marked. Drilling spring crops started very early on the Claydon farm, with spring beans sown directly into over-wintered tilth with no need for a prior application of glyphosate on 29 January following over-night frost when the temperature dropped to -5°C. Soil conditions were excellent, better in fact than when we drilled winter beans in October, which just goes to show that you must take an opportunity when it presents itself. One of the hallmarks of a good farmer is that they constantly watch for the many signals which nature provides and work accordingly. This is particularly important when the countryside wakes up in the spring.

Wide window of opportunity

The big advantage of the Claydon Opti-Till® System which we operate is that our soils become better every year and are in excellent condition, their very high resilience and carrying capacity providing a wide window of opportunity in which to carry out field work. Crops are established in just onefifth of the time of a traditional ploughbased system and in one-third of the time needed for min-till, which means that it is much more flexible and allows us to wait until conditions are exactly right for the soils and crops rather than having to muddle them in.

This way of working also greatly reduces the weather risk compared with a conventional system. The latter involves a sequence of cultivation operations that creates an unstructured soil profile with limited weight-bearing capability and an increased likelihood of sedimentation; this causes the soil to slump and become anaerobic. For example, had we ploughed the land destined for spring beans during the autumn and left it over winter, it would have laid wet at the end of January and no way could we have drilled the crop when we did. That would have had a substantial, adverse knock-on effect because we would have had to spend substantially more on ag-chems.

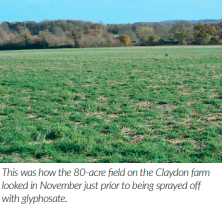

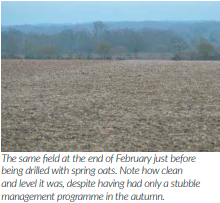

In the autumn we carried out a comprehensive stubble management programme which included several passes with the 15m straw harrow to encourage multiple flushes of volunteers and weeds, then killed off any remaining green material with a single application of glyphosate in November. This left the fields clean but with a shallow layer of surface tilth which provided ideal conditions over the winter and going into spring.

We were able to drill directly into this perfect growing environment because of the preparation work which had started back in the autumn using a combination of mechanical and chemical methods. With fewer herbicides now available, and remaining actives becoming more expensive and less reliable, it is vital to supplement them with mechanical methods, such as the straw harrow, to enhance the overall effectiveness of weed control. The other important advantage of this approach is that it creates 25mm to 30mm of tilth which retains moisture, allows the soil to breathe, makes it easier for worms to process the chopped straw and eventually covers the seed.

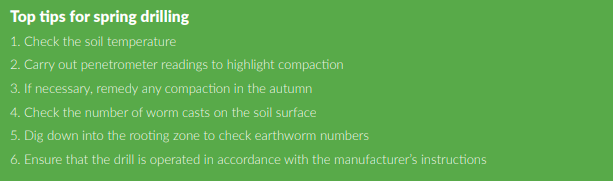

Pre-drilling routine

Before drilling, I always look at the weather forecast to check for three or four days of dry weather afterwards, because the last thing we want is heavy rain falling on freshly-drilled land. This would cause the surface of our heavy clay to cap, preventing air/water from penetrating and hindering the young seedlings’ emergence, at best stunting their development and perhaps even preventing them from doing so. Even if you get everything right in terms of preparing fields in the autumn there is no guarantee that when you leave them over winter they will still be ‘right’ in the spring so, before any crop goes in the ground, I carry out several checks to ensure that we are good to go with the drill.

I look to see how many earthworm casts are present on the surface, because this is one of the easiest, quickest and best indicators of good soil health. There’s nothing better than seeing clusters of worm casts and finding plenty of worms in the soil profile, because the entire process of farming depends on them. The passages they create in the soil promote air exchange and drainage, so without these essential little creatures you will never come even close to maximising the potential of your soils or crops. Before drilling any field, I always dig into the soil to check its condition. Healthy soil should be dry, but not too dry, friable so that it crumbles easily between your fingers and have a lovely ‘fresh’ smell which indicates that plenty of air is present.

In contrast, anaerobic soil will be lifeless, sticky, clump together and smell stale because it cannot breathe and therefore contains very little oxygen. If that is the case, you need to re-consider how you are farming. Part of this might be to change your system. When assessing soil condition prior to drilling I also carry out several penetrometer tests across the field to check that there are no soil pans. If there are you feel them immediately because the probe becomes much more difficult to push into the ground and the needle on the dial swings into the red zone. Pans are not caused solely by compaction from heavy machinery or working when conditions are unfavourable but can result from the sedimentation of soils that have been over-cultivated and ‘settled out’ over the winter.

Because we drilled spring beans so early this year, we deliberately sowed them quite deep, 70mm to 80mm, so that they would take time to emerge, allowing early-germinating weeds to be taken out cheaply and effectively with one application of glyphosate before the crop came through. Evidence of good soil structure could clearly be seen when drilling the crop, because the tyres on our 330hp John Deere 8345R ran clean in the frosthardened soil and left barely a mark on the surface, even when turning on the headlands with the 6m Claydon Hybrid mounted drill raised. Even in the tyre tracks the penetrometer reading remained well within acceptable limits. Last year, when the beans were at the ‘rosette’ stage we went over the field with a harrow to take out any emerging weeds, even though most were barely visible. This operation left the beans untouched, prevented weeds from developing, maintained a shallow tilth to retain moisture and helped the crop get off to a good start. It would also prevent the soil from capping in the event of heavy rain and baking hard when it dried out.

Since we started direct seeding 16 years ago, removing compaction is not something we have had to do because it has never been an issue. The soil has become so resilient that it has enormous carrying capacity and will easily support the weight of following operations. Our 5000-litre Knight selfpropelled sprayer weighs 18 tonnes, but it is used to apply nitrogen early in the season and that means crops get off to a flying start as soon as the weather turns warmer. The benefits of a resilient soil structure are evident throughout the farming year and, because it virtually eliminates machinery from sinking into the soil, the surface remains level, crops emerge unhindered, while field operations can be carried out faster, more accurately, more comfortably with less likelihood of damaging machinery. There is no downside and I will talk more about this in the next issue.

Fine-tuning production is essential

Whatever your views on Brexit, whether for or against, this prolonged process has demonstrated quite clearly that as farmers we must become even more efficient and self-sufficient. Farming is a very traditional industry and despite evidence to the contrary, many involved remain stuck in ‘The Cultivation Trap’, using traditional techniques and machinery which are time consuming, expensive, damage the soil, use large amounts of diesel and release large quantities of soil organic carbon. The key question we all must now ask is ‘how am I going to reduce my production costs to a base level which will enable me to compete in a global market, yet continue to operate a financially and agronomically viable farming business? With seed, ag-chems and fertilisers offering only limited scope for savings the focus must be on cutting establishment and machinery costs. There are many ways to do so, but critically it must be done without compromising yields and output, which means having a low-cost system which is reliable and repeatable.

Some farmers will continue as they have regardless, others will use some form of min-till to establish crops, but move a lot of soil and incur excessive costs in the process, while others will simply cut seed into the ground using a zero-till drill, but the UK’s maritime climate means that presents a huge risk and is like playing Russian Roulette with the future of your farm.

Done correctly, direct seeding using the Opti-Till® System provides a thoroughly tried and tested method which will improve timeliness, reduce weather risk, produce more even and reliable establishment, increase yield potential, provide higher returns and much greater profitability. It also generates a raft of environmental and wildlife related benefits, including increased soil organic matter, reduced risk of erosion, increased carbon sequestration and more soil fauna. Where businesses are struggling to be profitable, they must review what they are doing currently, question whether and how they can do the job better, consider how to produce more for less and realistically assess the risks of carrying on as they are compared with the potential rewards of adopting a new approach. Some might argue that spending money on a new system is not the right thing to do at the current time, but I would argue that exactly the opposite is true. The key is to invest wisely, in a system which will save you money, generate increased returns and ensure that your business remains viable in the future.

To learn more about the Claydon Opti-Till® System and techniques to improve your farm’s performance contact your local Claydon dealer and arrange a visit to the Claydon farm.

-

Farmer Focus – Clive Bailye

The Gross Output hamster wheel

It’s not uncommon to hear no-till farmers talk about the ‘hamster wheel’ of tillage – i.e. that cultivation creates the need for more cultivation. This continues until you jump off the wheel and make changes, including those to your rotation and agronomy, breaking the bond that links tillage to growing successful, consistent crops. There is, however, another and often not so widely considered catch 22 that has become the normal in UK agriculture, and it is a massive barrier for any farmer considering changing their farming system. I’m talking about the need, or even the addiction, to farm for maximum output and gross margin at all costs.

It is something that has slowly but surely turned many UK farms into the financially unsustainable, subsidy dependant businesses that they are today. I don’t think its accidental either. A generation or more of farmers have been sold this gross output myth by those that supply them with inputs and machinery that promise bigger yield or greater efficiency. They fund trials, shows and advertising that always has the same message, “grow more” “do more” “increase output” and you will be better off. As farmers we need to ask ourselves who does this really benefit? The maximum gross output treadmill means management and cropping decisions must be based around generating as much cashflow as possible, rotation must be dominated by high gross margin crops like all autumn planted wheat and rape which also demand early input spend.

Fixed costs should be spread over the largest possible areas, biggest possible machines and lowest possible number of people. Often ridiculous levels of rent or cut-price contract farming deals become justified in such systems as it’s all about spreading costs further and increasing that gross output the business now needs because it has rent to pay and machinery loans to cover. Having as much to sell as possible becomes more important than the cost of achieving that output. Many farms seem to have lost sight of costs, and the profit they make before subsidy.

A business can be unprofitable for years and still survive, especially if like many farm businesses it has the ability to borrow money. However any business will only ever run out of cash once and that’s the day the farm sale signs get put up. This is the trap than many now find themselves in, where cashflow is more important than profit, yet surely long term ignoring profitability creates a somewhat fundamental problem and the hole being dug though increasing borrowings simply gets deeper. Gross output of a business and gross margin of crops shouldn’t be confused. “Yield is king” is an often-heard mantra and one that is to a great extent very true.

If you are committed to grow a crop you need to maximise its gross margin and any input that offers a margin over its cost is justifiable and surely the right thing to do. I have never thought of zerotill / conservation agriculture as a lower gross margin system, and I still farm fairly conventionally in terms of variety and crop protection product choice, and my aim is to get the best yield my soils are realistically capable of every year. Anything that can prove a MOIC is used here, it is not about low input producing low outputs of individual crops as is often assumed, but the aim in my system is always maximum margin.

So much focus is placed on variable costs and crop gross margins yet debating the pro’s and cons of one fungicide vs another as farmers often do is neither here nor there in the bigger picture and is really tinkering while Rome burns. Making a few inputs savings is unlikely to transform many farm business fortunes. But just maybe a radical restructure of the fixed costs might be the way to finally jump off that gross output hamster wheel? Many assume moving to zero tillage will bring significant inroads into the structure of fixed costs.

Yet it’s not as simple as dashing out and buying a shiny no-till drill. In fact in isolation that’s probably just going to make things worse! Farmers often don’t need much of an excuse to jump on the latest trend if it involves new machinery but in zero-till the drill is one of the last pieces of a complex jigsaw that needs consideration. Change starts with rotation, the cornerstone of any successful zero-till farming system. Less autumn cropping of high output crops like Rape and Wheat will usually mean a drop in farm output – but this shifting of work away from the bottle-neck of autumn to a more even spread of field work between harvest and spring will make a serious reduction in the amount of power, machinery and people required to get the work done. It can double the area you can cover with existing resources, or halve the size (and cost) of what you have. Either way the fixed costs per acre will fall dramatically as a result. Spring crops tend to be far less input hungry and use less nitrogen.

Their output is lower, but growing costs are also much smaller and the length of time your cash is out in the field vs in the bank is shorter as well. Agronomically they bring an opportunity to use different spectrum and timings of herbicides helping with potential resistance and grassweed issues. It also creates a chance for over winter cover crops to be grown, capturing sunlight, water and nutrition that might otherwise be wastefully disappearing down your drains whilst feeding essential soil biology and building soil organic matter levels. The value of these things is not only financial but also environmental, the habitat it creates for wildlife is obvious as are the bigger issues such as carbon capture and a reduction in soil erosion and water pollution etc. It seems that the government and environmental lobbies are increasingly aware that farmers are in the best position to improve this situation, so it could well form the foundation of future support schemes.

This return to a “proper” rotation is the big important first step to increasing soil health and dependency on bags and bottles which leads to better yields at lower costs. But more significantly it’s the key to the reduced power, labour and mechanisation that are involved in zero- till vs tillage systems.

Looking at my own farm and accounts when we ran a min-till system we were using 32L/ha of fuel at establishment, today that figure is 4L /ha – 32L is what we now use from stubble to stubble! Labour has halved from 1 man /1000ac to 1 man /2000ac, wearing metal costs are almost insignificant vs their historic levels and most importantly of all the capital tied up in machinery has more than halved as well. This has removed a huge amount of depreciation and finance from our accounts and freed up capital for other investment. My costs have fallen dramatically, my gross margins are improved as we grow better higher yielding crops these days. However the lower output spring crops have reduced gross output, but with far lower costs to finance I’m far less dependent on cash flow and far freer to focus on maximising profit.

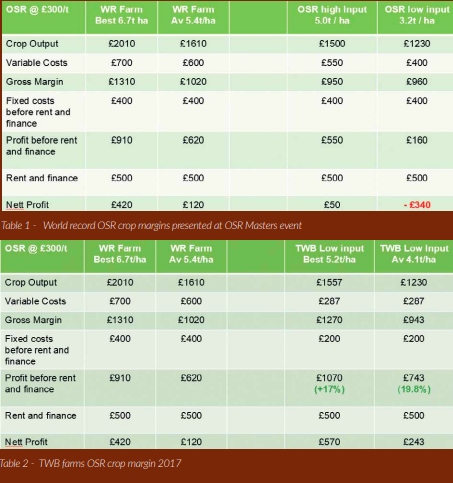

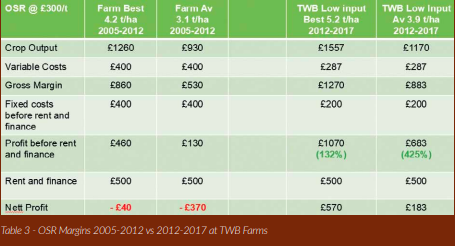

I am watching the ADAS YEN program with great interest and am in awe of the yields some achieve, they push boundaries to new levels and break world records along the way in some cases. To me its farming’s equivalent of watching a drag racing car, an impressive sight but not really something you want to be doing yourself unless you have very deep pockets ! I was recently shown the numbers behind the 2017 OSR world record presented at a “OSR Masters” event (Table 1). They demonstrate perfectly the maximum gross output approach – extraordinary yield yet despite the matching eye-watering variable cost spend, the proof is there of high gross margin. The message is clear, spending pays, and gross output is what successful and profitable farming is all about ………