If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

Companion Copping Boosts No-Till Profits, Soil Health

By Mark Parker posted on June 1, 2013 | Posted in No-Till Farmer USA

Growing double-crop sunflowers with multiple species has reduced inputs and enhanced primary crop health for Kansas no-tillers Robin and Kelly Griffeth. Double crop sunflowers planted with companion crops have a triple payoff for Jewell, Kan., no-tillers Robin and Kelly Griffeth.

With 2 years of companion cropping under their belts, the Griffeths are harvesting a more profitable sunflower crop, improving their soil and benefitting the subsequent crop in the rotation. The north-central Kansas farmers follow their hard red winter wheat crop with sunflowers intermixed with as many as nine different companion species, each selected for specific attributes. Continuous no-tillers since 1995, Robin and his son, Kelly, operate 3,700 acres as they raise corn, soybeans, wheat, grain sorghum and sunflowers. They were already believers in cover crops when an unplanned “experiment” revealed companion-crop potential.

“It was a fluke, really,” Robin says. “I was planting a field of buckwheat in July 2011. I had about 4 acres left and not enough seed to finish. I hate blank spots, so I mixed up some leftover sunflower seed, winter peas, five different clovers, canola, chickling vetch, safflower and a couple of different radishes — just to bulk up the volume enough to finish.” To their surprise, the sunflowers in the companion mix yielded well, without insecticide, herbicide or additional fertilizer. “We learned a lot by watching that 4-acre patch and decided this was something we needed to research a little further,” he says.

Designer Seed Mix

Kelly came up with a companion mix for the following year — common vetch, chickling vetch, spring forage peas, winter peas, cowpeas, crimson clover, oilseed radishes, purple-top turnips, buckwheat and sunflowers. At their normal rate of 21,600 seeds per acre, sunflowers made up only about 10% of the mix. Buckwheat had the largest number of seeds per acre at 64,800, with the other species ranging from 12,500 to 17,000 — for a total of 206,924 seeds per acre. The sunflower companion mix is planted as soon as possible after harvest, generally late June to early July.

The Griffeths had been planting double-crop sunflowers in 15-inch rows to achieve a quicker canopy. That meant planting at higher populations that depressed yield. What they wanted was a quicker canopy at normal seeding rates. Using their White 6531 31-row planter — which has Keeton seed firmers and Thompson closing wheels, and is set to 15-inch spacings — they planted sunflowers in 30-inch rows with the companion mix planted in the centers as a row filler, nitrogen producer and beneficial-insect attractant.

A Great Plains CTA-4000HD drill has also been used to plant the sunflowers and companion mix in 7½-inch rows, and the Griffeths continue to experiment. In the past 2 years, they’ve planted nearly 1,000 acres of double-crop sunflowers and companion species with the planter and, last year, drilled 54 acres. “You have more control with the planter, but we’re asking ourselves if we really need a picket-row stand,” Kelly says. “As long as we get the desired number of sunflower plants, and they’re fairly well dispersed, it seems to work fine — it’s more like mimicking Mother Nature.” Seeds are planted 1½ inches deep, the optimum depth for sunflowers. This year, Robin and Kelly are going to mix all of the seed together — including the sunflowers — in the planter boxes. They don’t expect a perfect stand, but believe using a soybean planter plate and optimum air pressure will produce good results.

Controlling Weeds

A burndown herbicide is applied after wheat harvest, and 4 to 5 weeks after emergence, the Griffeths spray Select to control volunteer wheat. “The companion crop does an excellent job of controlling weeds, and we may get to a point we don’t use any herbicide. But this is wheat country, so we have to control volunteer wheat,” Robin says. “We may add pearl millet because it will jump up quickly and out-compete weeds, then it’s killed by the Select, allowing other species to take over.” Regarding moisture competition in a 25-inch annual-rainfall environment, Robin points out that sunflower roots extend much deeper into the soil than roots of the companion species.

At harvest, the Griffeths use Lucke Manufacturing sunflower pans mounted on a rigid Case IH head, a system that has worked well. “Most of the taller plants are warm season and have been killed by frost by the time we harvest the sunflowers,” Robin says. “If a species is going to cause a harvest problem, it should be left out. The beauty of the flowers we plant is they get 6 or 7 feet tall. “I wouldn’t recommend this with a dwarf sunflower. You have to choose varieties and companion species wisely.”

Reduced Inputs

For the Griffeths, companion planting eliminates the need for an insecticide and a broadleaf herbicide — as well as an 80-pound-per-acre nitrogen application. Prior to companion cropping, a pesticide was used to control head moths. Now, the companion mix attracts beneficial insects — bees, predator wasps and lady beetles — that have successfully replaced the pesticide. At a cost of $15 to $20 per acre each for the insecticide and herbicide applications, Kelly says the companion-crop seed mix is basically paid for. The entire seed mix, including sunflower seed, costs $65 per acre — about the same cost as doublecrop soybean seed.

The primary profit impact of this comes at harvest time, Robin says. “Yields are comparable to sunflowers without a companion crop — they’re certainly not less,” he says. “The real profit advantage is grain quality. The sunflowers have better plant health, with far less insect damage and that gives us better oil content. “We’re paid a premium for high oil content, and with the companion crops, the oil premium has been the highest we’ve ever received.” Rental Income In addition to higher yields for grain sorghum and corn following sunflowers, the Griffeths may add to double-crop income by renting companion-cropped fields for winter grazing.

Kelly has taken the lead on identifying plants that contribute positively to the mix. “You have to do your homework to find out what companion species will work together,” he says. “If you look on the Internet, you’ll find most of the information comes from gardening Web sites. “You can find out which species grow together, and those that have a negative impact on each other. It’s important to avoid antagonistic combinations. You don’t just throw a random mix out there.” The Griffeths have grown doublecrop, food-grade buckwheat and believe it’s an important component. Kelly says buckwheat makes phosphorus more available for the following crop, establishes quickly and attracts beneficial insects.

Companion Criteria

There is a wide world of other species from which to choose, Kelly points out. “All species have to satisfy two criteria,” he says. “They have to be compatible with the primary crop, not detrimental. “And they have to help us accomplish something we’re after — quick weed suppression, soil building, nutrient cycling and attracting beneficial insects.” Although they continue to assess species and mixes, Kelly says one thing is clear. “I’m not sure you can get too much intensity,” he says. “If there’s been an issue, it’s because the mix is not intense enough. We had some marestail pop up here and there, for example, and we felt it was due to the companion stand not being intense enough.”

Crop Insurance

Robin and Kelly plan to extend their companion-crop concept to corn this year. It will have to be on double-crop corn, however, since crop insurance will not cover the practice. “Making a profit is our primary purpose,” Robin says. “We take care of cash crops first, and anything we try has to pencil out. We’d love to try companion crops on full-season crops but, from a risk management standpoint, you don’t want to make an insurable crop uninsurable.” The Griffeths will plant corn in 30-inch rows with a companion mix of lupins, cowpeas and sunn hemp.

Soil Benefits The Griffeths also plant cover crops ahead of soybeans — typically cereal rye, oats, safflower and mustard, or other mixes. Continuous no-till with cover crops makes a positive soil quality impact, says Kelly. In addition to decreased compaction, reduced erosion and increased water efficiency, the Griffeths have measured rising soil organic-matter content. “We soil sampled a CRP field we’ve farmed for 3 years,” Kelly says. “Organic matter was 3.1% when we took it over and, 3 years later, it was up to 3.5%. That’s all from using cover crops and notill, and I think the companion cropping can have an even bigger impact.

-

Farmer Focus Steve Lear

A Great Year to Start No-Till……

This autumn has been a good one for progressing into no till. The weather had done any subsoiling that was needed by cracking out the soil to a depth of two foot in places. In late September I was getting a little worried. I had been told that late drilling doesn’t work very well with no-till. The fields hadn’t greened up at all and I was loathed to drill anything until we had killed off a flush of blackgrass and volunteers. Luckily for us mother nature was on our side and we have been able to establish crops into unmoved soils into November after a good flush in mid-October.

We have a large acreage of hybrid barley in the ground which looks well but will need an early dose of nitrogen when the winter ends to get it going in the early spring. Our wheat all looks very well. Since going to no till, we have upped the seed rates in winter wheat. I may have put on a little too much in some fields as we have seen very good establishment this year, in fact its probably better establishment compared to our old conventional system. On all our cereals we have put a small amount of liquid phosphate down with the seed to help improve rooting. I would in the future like to find a biological product to do this job.

Instead of applying fresh nutrients into the soil, it may be better to apply a biological product that could help break the chemical bonds in the soil or help the plants take up the nutrients more effectively. I’m on the search for such a product and will carry a few trials out next year. We have only used a minimal amount of slug pellets on cold north facing slopes. I imagine that the dry summer has meant a huge reduction in the slug populations on our ground. On top of this I have kept with my plan to not use any insecticides on the farm. I hope I can continue to do this when we lose Deter seed dressing. Even though the weather has been ideal for them, we only had a minimal number of aphids arrive on our cereal crops, I’m beginning to think they don’t like landing in stubbles but I may still be proved wrong.

The wheat variety that we have chosen this year is Nelson. It is a highgrade German milling wheat. It also has shown to perform well in organic systems. I am hoping that we can reduce the number of fungicide passes we need in the crop to help protect soil microbes better. It will be interesting to find out if its high untreated yield is due to its symbiotic relationship with mycorrhizal fungi or the fact that it has a huge flag leaf.

We have also drilled winter beans this year, which is a first for me. We sprayed out a four-year grass and clover lay and direct drilled the beans at the beginning of November. The white clover has remained in the crop as its fairly resistant to Glyphosate and we will use it as a companion crop for the beans. I’m hoping the two species will fix a lot of Nitrogen for the following wheat crop and improve the structure of the field as well as suppressing any weeds that come in the spring.

We have reseeded some pasture land this autumn with great success. I have read up on how they do this in New Zealand. The pastures were grazed down very tight and no fertilizer was applied to the fields. This was to limit competition from the existing sward. We direct drilled the fields straight into the existing pasture using a mix of tetraploids and diploids at about a 2/3rds rate. The cattle were left on the pasture until the new grass had chitted and was at risk of being pulled out of the soil (about 2 weeks later, but I think we could extend that). The cattle are allowed to graze as soon as the roots of the new grass has established and it’s not possible to pull new plants out the ground. I’m interested in establishing more diverse pastures next spring and using some herbal plants. With a more varied root depth I think we will be able to pull nutrients up from deeper, increase soil biology and keep some growth in the fields throughout the drier months.

With no cultivation to do we have been able to spend more time on sampling soils in the autumn. I’m starting to carry out a sort of soil benchmarking of our soils. As a bench mark, I am testing soil that has been in a natural cycle for many years. This comes from either under hedges or in small wooded areas. I’m hoping this will give me some figures to aim for in terms of microbial activity and organic matter in the soil. My samples are tested by NRM laboratories who offer a package called the ‘Soil Health Suite’. It contains all the usual tests as well as a CO2 burst test for soil microbes, an organic matter test and a soil textural classification. As well as these I am also slowly getting around the farm and carrying out worm counts, infiltration tests and slake tests. This will help to see where we have improved soils and were we need to do more work.

As well as the farm, I am still expanding my knowledge of how the soil works. It seemed a sensible step to become a member of BASE. I’m looking forward to meeting members and finding out how they have improved their farms and if there is anything I can bring back home from the meetings, I am sure there will be. Since joining I have watched the presentation on the BASE UK website from Dr Kristine Nichols, it’s worth the membership fee alone.

-

Grazing Cropped Land

The almost forgotten technique in the UK of grazing cereals is something being widely practiced across Australia in areas with widely varying rainfall levels. The Australian Grain Research and Development Council have produced a report titled Grain and Graze which sets out to evaluate the advantages and disadvantages of grazing a range of cash crops. We begin serializing this report over forth coming issues to explore what is currently an untapped resource.

In Direct Driller Issue 3 we started looking at the potential opportunities of grazing winter crops. One of the greatest downsides is the risk of potential reduction in grain production and value due to grazing. This is where we pick up our content on grazing winter crops.

The Possible Costs (the downside)

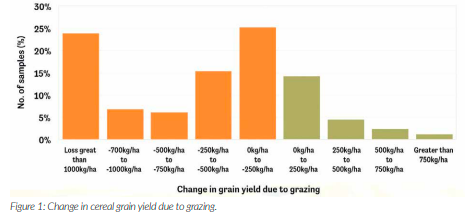

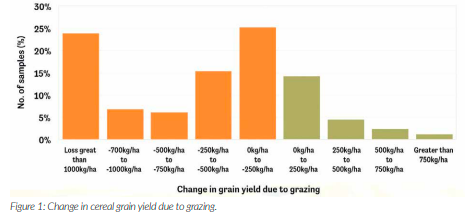

The greatest downside risk is the potential reduction in grain production and value due to grazing. Results from Grain and Graze and other experiments show a wide range of yield and quality responses to grazing, from large reductions in grain yield to no yield losses or even increases in yield. Reduction in grain yield Grain yield data from 2004 to 2013 was collected across 53 cereal trials and 246 measurements in Western Australia, South Australia and Victoria where a grazed and ungrazed comparison could be measured (figure 1). This included wheat, barley, triticale and oats. The results also include treatments where grazing was less than ideal, including grazing after stem elongation and when crops were under stress. These extreme treatments were imposed to appreciate the size of the yield and quality loss under adverse conditions.

Figure 1 highlights several key points:

• Cereal grain yield declined under grazing most of the time crops were grazed (78%), although the severity of the decline varied. The most common result was a yield decline of less than 250 kg/ha (25% of cases), with yield loss of between 250 kg/ha and 500 kg/ha occurring a further 15% of the time.

• Increases in grain yield were recorded in 22% of cases. The most common increase was up to 250 kg/ha although some larger gains were also recorded. The main reasons for the gains were attributed to reductions in lodging and less leaf disease, both a consequence of the removal of early growth by grazing.

• Large losses in grain yield were recorded (24% of cases). Four factors are believed to contribute to the large yield decline (table 2).

Canola

Grain data for grazed canola was limited. Most of the information was collected from Southern Victoria when the crop was sown at the conventional sowing time (late April to early May). Dry matter production was generally lower than cereals sown at the same time and the crop was slower to recover from grazing. This resulted in severe yield penalties. Best practice sowing guidelines for canola are to sow in Late March to early April, but this may be difficult to achieve in some areas because of stubble burning restrictions and weed control.

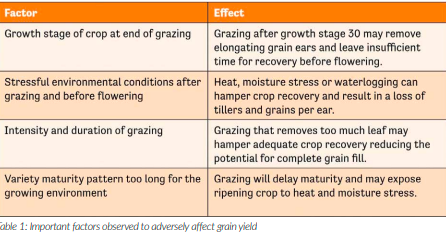

However, the availability of new canola varieties with strong winter habit provides the opportunity to sow by taking advantage of out of season rainfall (October through to February), where the crop is treated like a brassica fodder for grazing before being locked up and taken through for grain. Changes to grain quality Grazing resulted in a variable response to cereal grain quality. In some trials grazing improved grain quality characteristics, in other trials grain quality declined. The general conclusions from the spread in results are discussed. Protein Grazing did not affect the average grain protein in wheat but did with barley. Of the 64 wheat results examined, the average change in wheat protein from grazing was -0.1%, with a similar number of increases in protein recorded as decreases (figure 2).

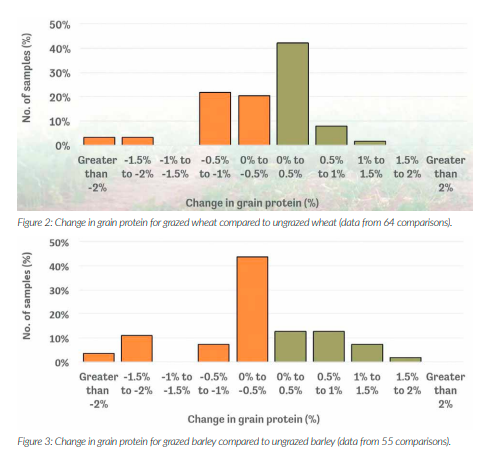

The grain protein response to grazing for barley was different, with grazing more commonly resulting in a decline in grain protein (65% of the time). The average decrease across all trials for barley was 0.3% (figure 3). The reasons for the decline in grain protein with grazed barley is not obvious. The results used in the analysis were collected across many years, using different varieties, nitrogen applications and time of grazing. This makes it difficult to identifying the possible reasons for changes in grain protein. The only loose association from the information is between grain yield and protein. It appears if grain yield is increased because of grazing, which happened in 40% of all the barley trials, then grain protein decreased (i.e. was diluted).

Grain size

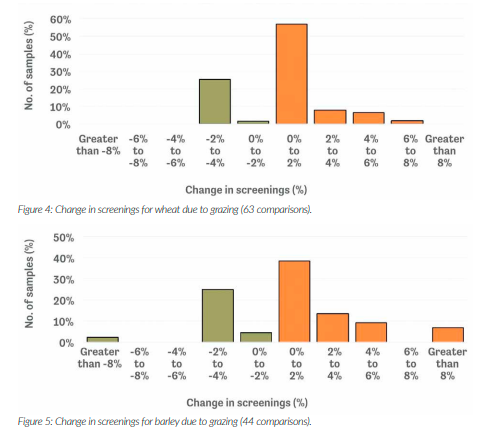

Grain size in wheat and barley was generally not affected by grazing. Of the 54 comparisons with wheat and 42 comparisons with barley, slightly more than half the observations showed a reduction in grain size due to grazing. The average reduction in wheat was 1% and 2% for barley. The limited (less than 10) observations of grain size for triticale and oats showed similar responses to grazing as wheat.

Screenings

Screenings increased slightly for both wheat and barley as a result of grazing. More than 73% of wheat and 68% of barley comparisons showed an increase in screening compared to no grazing (figures 4 & 5). The average increase in screenings for wheat was 0.9% and 1.4% for barley. There was a slight correlation between increasing screenings and a reduction in yield after grazing.

Calculating the value of grazing crops

Calculating the value from grazing winter crops can be challenging because while there are immediate benefits through feed for livestock, the flow on effects are often more difficult to quantify. These flow on effects may include potential grain yield loss from grazing, building a ‘feed wedge’ because pastures can be spelled and making different livestock management decisions. The gains are realised within the farming system and not simply by comparing the potential loss of grain yield with the livestock gain when the crop is grazed.

Modelling undertaken by the CSIRO2 would suggest the potential benefits to whole farm profitability are very significant, in the order of AUS$100/ ha to AUS$200/ha. Attention to variety selection, early sowing, adopting best grazing practice and increasing stocking rate are all required to achieve this potential. Individual farm considerations such as weed and disease issues, chances of favourable climatic conditions to enable early sowing, adequate farm infrastructure and cash flow to run more livestock and the manager’s position on risk may temper these potential benefits.

The Fowler family from East Esperance in Western Australia started grazing crops in 2008 as a trial before fully incorporating into their farming system in 2010. In 2011 they cropped 10,000 ha of wheat, barley and canola, of which more than half of that was grazed. Andrew Fowler said grazing crops had delivered a major lift in the profit of their operation and that it was one of the best innovations they had implemented on the farm. “We first tried it to make the pasture phase of our rotation more profitable and comparable with the cropping phase,” Andrew said. “Previously we were looking at about $200/ ha gross profit for livestock which wasn’t much when we compared it to cropping, which was about $500/ha.

“We needed to lift our stocking rate to increase our return per hectare to make grazing worthwhile, as well as to help recover some of the fixed c o s t s associated with livestock and m a i n t a i n i n g p a s t u r e paddocks.” By using grazing crops, the Fowlers have now managed to lift the pasture phase to $350/ ha gross profit and nearly double their stocking rate from 10 DSE (dry sheep equivalent) to 18 DSE. In 2010 they increased their net profit by $500,000 by growing an extra 1,000ha of crop and retaining their livestock numbers. “Grazing crops is a really important tool in matching the supply of feed to livestock demand, and it has helped the farming business to harness the synergies between livestock and crops” Andrew said. “As a result we have had some great benefits with liveweight gains, higher stocking rates, cost savings, crop management advantages and more: all with little impact on crop yields at harvest”.

Benefits of grazing crops

“Grazing crops significantly reduces the levels of disease in barley (especially powdery mildew) when compared with ungrazed crops, which eliminates the need for an early fungicide spray,” Andrew said “In our canola crops, the height of the crop is shortened which makes swathing and harvesting a lot easier. In 2010, the height of the crop dropped by a foot as a result of grazing.” Yield and quality are not compromised as a result of grazing. In 2010 the Fowlers’ highest yielding paddocks were grazed, a wheat heat paddock went 4.7 t/ha and a grazed canola paddock yielded 2.1t/ha. The quality was excellent with 45% oil and 0.6% admixture.

Andrew said an additional benefit is less grain is required for supplementary feeding. We wouldn’t be able to maintain our livestock numbers if we didn’t graze our crops. “We would have to feedlot the sheep and cattle, or decrease our numbers which would reduce the profitability of our pasture phase and this was the main reason for heading down this path in the first place”. The Fowlers have had excellent live weight gains from grazing crops. For sheep, they average about 300 grams/ head/day and 1.8 kilograms/head/day for cattle. In 2011, their drop of crossbred Merino White Suffolk lambs only spent five days grazing pasture before the first draft was sold on 8th August at 18.1 kg for $118 a head. (The rest of their lives were spent grazing crops.) The ewes lambed in stubble before grazing a barley crop at the three leaf stage. The lambs were weaned at six weeks, the ewes were sold, and the lambs continued to graze crops.

Challenges

Andrew said at the start, the hardest part was to open the gate and let the stock into a good looking crop, but he was amazed how quickly the crop recovered. Other challenges the Fowlers have faced and, that Andrew stressed, were very important for the system to work, include:

• the early seeding of crops

• good weed control

• a good rotation.

• providing ad-lib straw for livestock, and

• not over-grazing the crops, with the best results achieved if there is some biomass left after grazing.

Crop stages and management

Livestock are removed from crops at the first hollow stem (around Zadocks GS 30) in cereals, and with canola, stock are removed when the buds are about 10cm high and there are a few leaves left. “The best results are achieved when you don’t take all the biomass away – you can graze to the white line (when there is no green left) but we have found that the crop is a lot slower to recover if you do this,” Andrew said. They have found the early sown crops handle grazing well, but the flowering date of the later sown crops is pushed back a bit too far (and the yield affected) without careful grazing. The Fowlers finish grazing most paddocks by end-July and the latest date is early-August. After livestock are removed, the Fowlers immediately spray with a Nitrogen (N) application.

Once a new leaf has fully emerged, barley crops are sprayed with a broadleaf and powdery mildew spray, and Roundup Ready Canola is sprayed (being careful to manage withholding periods if crops are to be grazed postspraying). The Fowlers admit the big advantage for them is the lack of frost occurrences in the region, which allows their crops to recover quickly.

Pasture tips

The Fowlers continue to strategically rest and graze their pasture paddocks while grazing crops. “We don’t lock up our pasture paddocks otherwise the cape weed gets away on us,” Andrew said. “If we continue to use our pastures, we find that it increases the quality and quantity of feed for August when we start full time grazing.

-

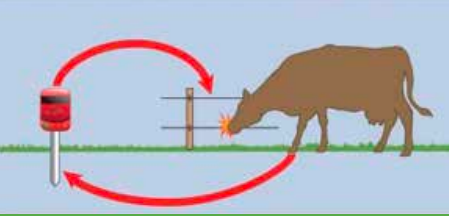

Using Temporary Electric Fencing To Graze Crops Or Cover Crops

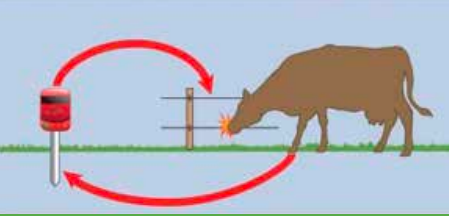

The main thing to understand is that an electric fence is a psychological barrier for animals. The initial electric shock they receive means they are deterred from approaching the fence again. Therefore, how a fence is erected and the speed with which it can be moved is critical when consider what is important in terms of using them to help graze crops. In this guide we will with the help of Rappa introduce the elements of a fence and what you would need to be able to graze your crops (so you just need to add the animals).

As you are already probably aware, an electric fence is made from three elements:

Energiser – generates a regular pulses of electrical current

Wire – conducts the current

Earth – returns the current back to the energiser.

Energisers

The energiser converts electricity from mains supply or batteries into high voltage pulses of electric current at one second intervals, that travels along the fence. The type of energiser you need depends on how close the fence is to a mains electricity supply, the fence length and the type of animals you want to control.

Wire

There are many variations of wire suitable for electric fencing.

• Steel wire, either single or multistranded, is strong, durable and highly effective at conducting electricity, so the animal receives a greater shock when touching the fence. Steel is heavier than other alternatives, and is best used in permanent or semipermanent fencing where you need good tension on the wire.

• Polywire is lighter than steel. It is made from UV-stabilised plastic twine with three or more strands of stainless steel wire woven into it. Polywire is designed for temporary fencing and stripgrazing, although the more substantial polyrope can be used for permanent fences.

• Polytape and polybraid consist of stainless steel wires and plastic strands woven into a ribbon, available in a range of widths and colours that can be used for permanent and temporary fencing. Both are highly visible, but can be vulnerable in high winds..

Wire Reels

A reel allows you to unroll the fence wire evenly without creating potentially damaging kinks, then roll it up again neatly for reuse. By locking firmly onto a reel post, the reel keeps the fence wire taut. We offer two kinds of reels:

• Rappa Reel – for use with our Rappa Fencing Machines

• Hand Reel – for manual fencing

Posts

Permanent fences use timber posts to support the wire, while temporary fences rely on metal or plastic posts, available in different heights and spacings, depending on the stock you want to fence. In addition, anchor posts are used for temporary fencing in the corners or at the beginning of a fence, and help keep tension on the fence wire. Temporary fences also require a reel post at the end to hold surplus wire and keep the line taut.

Insulators

Insulators keep the fence wire from touching the supporting post or stake, preventing electricity leaking back to the ground. Anchor or endstrain insulators also take the strain of the wire at the end of the fence line or at corners. Polyposts are made of non-conductive plastic therefore separate insulators are not required. Good quality insulators should be smooth and dry off easily to prevent moisture collecting in nooks or cracks causing current to leak, creating an ‘arc’. Arcing, which produces a regular clicking sound, reduces the effectiveness of the fence. Offset insulators give a longer life to permanent fencing by holding the electric wire a short distance away from a new or existing permanent fence, stopping animals causing damage by biting, leaning or rubbing.

Earth stakes

Earth stakes are inserted into the ground and attached to the energiser. They ensure the power returns through the ground and back to the energiser when an animal completes the circuit by touching the fence.

Fence Tester

All electric fences need regular maintenance. You should regularly measure the power on the fence lines using a fence tester – or voltmeter – that will help locate any problem areas where power is leaking away.

Electric fencing machines

While fences can be put up manually, there is certainly skill involved. Automating the process with a machine, will help keep the wire taught and visible and reduce the chance of accidental grounding. Electric fencing machines, also known as winders, are used to erect and dismantle up to four lines of fence wire quickly and efficiently, perfect for strip or cell grazing where fences are moved frequently – a typical 600m electric fence can be put up in 20 minutes and dismantled in 10. Rappa’s fence winders have been developed and built in the UK for the last 40 years, and now include a range of six machines, from manual-push barrow winders for small or inaccessible areas, to larger models that fit onto an ATV or RTV – from human to horse power! The RTV Winder is designed to pick-up on the left hand side so the fence can be dismantled without leaving the seat of the cab. The largest in the range, the Trailer Winder, can fence up to 5km in one hit, again this can be specified to pick-up the fence on either the left hand or right hand side. A complete range of fence packs have been developed to compliment the fencing machines.

Installing an earth

First, work out how many earth stakes you need. Larger fence energisers exerting more power, or longer fence lines with higher leakage, require substantially more earthing. As a rule aim for 1 metre of earth rod for every joule of energy, ie. a 5 joule energiser will require 5 metres of earthing. You need to link your earth stakes together with underground cable, which is then connected to the energiser’s earth terminal. Your earth stakes should be at least 4 metres apart, and kept well away from domestic earth systems, and at least 10 metres distance from any other earth installations, such as those used by telephone or electricity supply companies.

Never use steel water pipes or steel-framed buildings as an earth. You also need to place your earth system in a consistently damp site. In areas where the soil is very dry, or there is a lot of sand, peat, gravel, snow or frozen ground, you can boost the efficiency of the stake by watering the ground in dry weather or increasing the number of earth stakes. You can also run an earth return wire parallel to the fence line, and connect it to earth stakes at regular intervals. Bear in mind that an earth system installed in winter, which is adequate for winter conditions, may not be suitable for summer; this may explain any substantial loss in power on your electric fencing over the summer months.

Safety in electric fencing (the things you should and shouldn’t do)

Properly installed and maintained, electric fencing is safe for humans and animals. However, you must adhere to the following:

• Never electrify barbed wire or any other material that could entangle an animal or person.

• Never attach more than one energiser to a fence. Maintain a gap of at least 2 metres between separate electric fences.

• Put up warning signs at intervals of no more than 10 metres on any electric fence installed along a public path or highway, or at any other point where people may encounter the fence.

• Where your fence intersects a footpath or highway, you must incorporate a non-electrified gate or stile to cross the fence. • Never install connecting leads (underground cable) in the same conduit as mains supply wiring, communication cables, or data cables.

•Avoid running electric fences parallel with overhead power or communication lines, as it may induce a dangerously high voltage on the fence line. When crossing under power lines do so at right angles and make sure the fence height doesn’t exceed 2 metres.

• Install a mains fence energiser under cover, near a mains supply. Make sure it is out of reach of children, and away from flammable materials.

-

WATER FOCUS – AFFINITY WATER

Soil and Water

Our population is growing and so is the demand for food, highlighting the importance of farming to us all. This growing population will also need more water, especially in the south-east of England. The company I work for, Affinity Water, supplies water in an area already under ‘serious water-stress’ so it is vital that we manage our water resources, from source to tap, in the most sustainable way possible.

The obvious, but often overlooked, fact about drinking water in the UK is that every drop has been sourced from the natural environment in which we all live. We must abstract water from an environment that is also being used for food production, industry and human habitation. In the UK, agriculture is the dominant land use in many of the catchments used for public water supply. Whether you farm on the banks of the Thames or the tops of the Downs; every piece of land, every farm in this country sits within a water catchment. Therefore, what happens on farm and in the field is of interest to us in the water industry and we want to help farmers make positive choices for their farm business and the water environment.

As a reader of Direct Driller you are clearly interested in soil health and value your most important asset, the soil. Improving soil health, although difficult to measure in metric terms, is something you are working towards and see value in. What impresses me about no-till farmers is not only the desire to improve soil health but also the innovative ways many of you are farming. Innovation such as reducing inputs, trialling companion cropping and introducing novel crops into your rotations are a few examples. Many of these innovations will contribute towards a sustainable, resilient farm business but can also help the water environment by reducing soil run-off and losses of inputs to water such as pesticides and nutrients. More research is needed to quantify these benefits to the water environment at a farm and catchment scale, particularly in a UK context, but the perceived wisdom is that healthy soil will lead to healthy water.

Affinity Water, like many other water companies in the UK, have a catchment management team who are working with farmers and other land managers to solve water quality challenges at source. I am sure you have heard of (or are even part of) one of the many water company metaldehyde schemes across the country. Working on metaldehyde reduction in catchments has been an important learning curve for us and has helped us get to know many farmers across our patch and find workable solutions to this problem. Another important aspect of our work is investigating what methods can be used on farm to reduce nitrate leaching to water. We have been investigating the effectiveness of cover crops at reducing nitrate leaching in our drinking water catchments. Cover crops are well known for capturing excess nitrate in the soil but also have many other benefits to the soil and the wider environment. The trial, now into its third year, has tested different cover crop mixes to assess not only the benefits to the soil but also how much nitrate is captured by the cover Crop.

The results are promising and has confirmed to us that cover crops are effective at capturing nitrate. So convinced are we by the benefits of cover cropping that we are planning to incentivise farmers to grow cover crops in areas where we have a nitrate leaching problem.

The soil is the interface between the rain that falls from the sky and the rivers and groundwaters that rely on rainfall for their function. As an industry we are completely reliant on rainfall. We can’t affect how much water falls from the sky but the next best thing we can influence is the soil that covers our catchments. It is generally acknowledged that notill soils have better water infiltration than a tilled soil so one would assume that if a greater area of arable land in our catchments was under no-till then we have greater potential for water recharge into our aquifers. This hypothesis needs to be tested and we are planning to research this topic over the coming years. I hope to continue to contribute articles to Direct Driller and will keep you informed of any developments in our research into soil health and the water environment. If you have any questions or ideas for our catchment management work I’d be happy to hear from you. E-mail: shaun.dowman@ affinitywater.co.uk.

-

WATER FOCUS – THAMES WATER

Creating a Smarter Water Catchment in the Evenlode – Thames Water No Till & Cover Crop trial

Thames Water has recently started a No Till and Cover Crop trial in the Evenlode river catchment as part of its ‘Smarter Water Catchments’ initiative. The company’s work, alongside colleagues from Atkins and Natural England, is helping to encourage water sensitive farming across the Evenlode catchment and to reduce run-off of phosphorus from farms and fields into local watercourses. The project has a number of components in addition to the No Till trial, including an agri-environment grant scheme and advice service.

The River Evenlode catchment lies to the west of Oxford and is in the Thames river basin, partly within the Cotswolds AONB, with the river flowing from Moreton-in-Marsh to Eynsham over a distance of more than 75km. Thames Water is particularly interested in exploring whether a ‘no till’ approach reduces the loss of soil and, in particular, phosphorus, to watercourses, while improving soil health. The company is also interested in whether the approach can increase farm profitability and efficiency.

The trial started in September 2018 and is designed to run for five years, with research support from Innovative Farmers. The trial is farmer-led, allowing participants to test additional topics such as soil health, nutrient application and cost vs yield. Thames Water is supporting its trial farmers in exploring the challenges and benefits of the no till and cover crop approach by offering funding for machinery costs and cover crop seed provision for the no till fields. The aim of this is to remove some of the risk involved in trialling the approach. Field scale soil and water quality monitoring has commenced and will continue throughout the trial. The company looks forward to reporting on some of the initial results from this project in future publications. If the trial is successful, Thames Water will be looking to work with other farmers and land managers to promote this approach in other parts of the Thames River Basin.

For more information, please contact the Evenlode project team from Atkins and Natural England. Jay Neale, Atkins (jay.neale@atkinsglobal.com) or Sarah Olney, Natural England (sarah.olney@ naturalengland.org.uk)

-

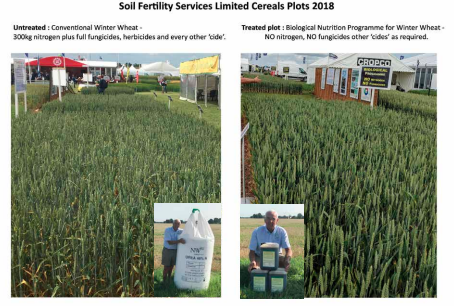

Soil Fertility Services

It was in 2002 that I first wrote an article outlining: ‘The need for’ and ‘Benefit of having’ a good population of mycorrhizal fungi in your soil. That is of course still true but it is not the most important of the life in your soil; so what is?

Of course there may not be any one type of life that is most important, but you will be well aware there are many that can be important but for the wrong reasons. For example soil microorganisms that are pathogenic to the crop you want to grow – you could argue these are the most important because of the damage they can do e.g. Take-all, Fusarium, Clubroot, Rhizoctonia, Scab, Cavity spot, Rust, Eye spot and others all determined to eat or damage your crop and that is without mentioning the insects that munch on the leaves.

What if we stay with the beneficials e.g. earthworms; there are three main species of these and they should be counted as V.I.M. (very important members), but it is none of these; in regular arable cropping it is the beneficial micro-organisms that will live in, on and around your plant; protecting it from the pathogens, feeding it from the soil reserves and from the atmosphere, providing such things as nitrogen, phosphate and trace elements. If you create the correct conditions, the mycorrhizae will inhabit your soil, creating a ‘cobweb effect’ across the whole area and provide some minerals to your crop. They will not protect it from the soil dwelling pathogens.

Beneficial micro-organisms are everywhere, and they are needed by all living organisms on earth. They live symbiotically with plants, animals, and us. If not for these little factories, we would not be able to digest our food and get the vast range of nutrients we require daily. They also defend their host by producing certain antibiotics or simply blocking pathogens away from infection. It is a cornerstone of a healthy immune system. The same goes for the plants; the topsoil is the digestive tract which will provide roots with nutrients that the plant requires, at the time it needs it.

Some of the micro-organisms will protect the host in exchange for sugary exudates from roots, so it acts as the immune system of the plant. To make sure soil is functioning properly, ensuring favourable soil conditions are a must. Additionally, it won’t be any good if we don’t have adequate numbers of these beneficial micro-organisms that will carry out these specific functions, so inoculating soil at key stages will ensure that the plant gets maximum benefit. The soil is a living breathing organism and as such, just like any other living creature, it needs air, water and food in that order. However, there are also plenty of anaerobic micro-organisms that are, for the most part, pathogenic and not what you want to encourage. The most important microbes in any living thing, including you and me, are the ones you can’t see but you can smell them. When your soil smells sweet, that is the geosmin wafting their aroma and is an indication of a healthy soil.

This life in your soil is a constant battle ground, as one army becomes dominant this is then attacked by another and depending on the host plant, may be defeated. If the winner is a pathogen, then your crop will suffer, so now it becomes obvious we need to invest in the beneficials and that means feeding them and adding to their numbers to help them outcompete the pathogens. Bearing in mind it is a constantly changing environment, with plant growth stages affecting the food source for these microbes, which in turn affects the types of these mini bugs, that is why we have now introduced a complete biological programme.

It starts before you plant your next crop, feeding your soil with beneficial microbes in a unique food source. This will allow the beneficial microbes to inhabit the rhizosphere, providing nutrition to your plants with specialist root development enzymes. The inclusion of a range of ‘phosphobactors’ means your plants get their phosphate requirement from your own ‘locked up’ phosphate reserves. A pre-drilling application of Bio-Start is also preparing your soil for the nitrogen-fixing bacteria in the spring. It is all about priming your soil’s ‘microbial army’ for the spring growth surge. In spring we will once again feed your soil’s ‘army’ and will include a range of nitrogen-fixing organisms. Depending on the type of and the health of the crop being grown, further applications may be necessary; the important point is to maintain the advantage gained in this soil war. By now the plant is pretty much in charge of what is going on, unless you compromise your soil army with applications of ‘cides’. If you do need to apply pesticides, then help your soil army recover with a biological activator.

What is amazing is the speed this all happens; for example, if you apply these nitrogen-fixers to the leaf of your plant, within milliseconds these microbes will be translocated to your plant root system. R e m e m b e r the principle is ‘feed your soil and your soil will feed your plant, feed your plant and your plant will feed your soil’. There is a t e m p t a t i o n to apply a carbon source in the shape of molasses to feed the soil but this is not a selective food source and you can cause yourself a lot of problems if you end up feeding the wrong bugs. Better to supply the reinforcements in the shape of megabacters and feed them. Nitrogen fixers, phosphate fixers, plant protectants, root growth stimulants, this is your army. Look after it and it will help you to grow high yields of healthy crops; abuse it and there will be consequences to pay.

-

PLOWMAN’S FOLLY

By Edward H. Faulkner With a Foreword byS. Graham Brade-Birks M.Sc. (Manc.), D.Sc. (Lond.), of the SouthEastern Agricultural College (University of London), Wye, Kent

First published 1945Traditions of the Plough

Continued from Issue 1 of Direct Driller

Ploughing done when the furrow slice is plastic creates clods; every clod is so much soil mustered out of service for the season. The tremendous pressure necessary to separate the furrow slice from its base compresses effectively any soil that is moist enough to be plastic; and a moderate amount of clay in plastic soil serves to harden the mass upon drying so that adobe-like clods result. Smoothing implements may reduce the size of these lumps, but as clods they are likely to remain aloof from the rest of the soil throughout most of the growing season.

Such evidence of damage done by the mouldboard has passed unnoticed by farmers as well as by most other people. Several reasons may be given to account for the public’s blindness to obvious faults of the mouldboard plough.

To begin with, conditions such as modern farmers face were remote indeed when the plough was first used with a crude mouldboard attachment. The land that had been cleared of trees still was not very well subdued, for it was a hopeless task to try to keep the soil free from competing weeds and shrubs while a crop was growing. The forest was forever trying to recover the lost ground, and the only really effective tools farmers had against encroaching saplings, perennial weeds, and other unwanted growth were crude hoes, mattocks, and spades. Such ploughs as they had threw the soil both to the right and to the left.They did not cover rubbish very well, much less uproot permanently the wild growth which cumbered the ground. To-day the “bull tongue” plough of the South of the United States of America is of somewhat the same design as most of the ploughs which preceded the mouldboard.

Into such an environment the mouldboard was introduced. It was a godsend. Pulled by an ox, or even by men, this plough would actually lift and invert the soil. This made it possible, by careful work, to eliminate completely the perennial weeds and some of the smaller shrubs. And, what was more important, the farmer who previously could manage only a few square rods now could raise food on an acre or more. Such an invention at a time when England was never far from actual starvation captured the imagination of rural people everywhere.

It was electric in its effects upon contemporary thought. The population now could eat regularly and well, provided enough farmers could have mouldboard ploughs. Inventions did not occur often in those far-off days. New aids to living were rare indeed. The mouldboard plough, destined to revolutionize the living conditions of world populations, marked the beginning of a new era. So completely did it fill the greatest material need of a poorly nourished mankind that it was accorded a place in people’s thoughts such as is usually reserved only for saints and priests. The plough had saved humanity almost literally.

When we come to the eighteenth century we find that in England and America alike, the farmer had more trouble keeping unwanted things from growing than in getting his crops to grow. For him, then, the use of the plough was excellent strategy, because temporarily, at least, conditions were created which made it impossible for the weeds to grow. This gave the farmer time to get his root and grain crops started before the wild vegetation recovered from the setback caused by the ploughing. Once his crops were well started, the incomparable richness of the soil kept them well ahead of the weeds.

Now that the richness has completely disappeared from most land in the United States, our proper strategy may well be the exact opposite of what was advantageous then. His ploughing, even though it covered a lot of organic matter, could not create for him the sandwich, organic matter profile (OMP), for there was too much depth of blackness in the soil. The crude mouldboards of the eighteenth century could not be favourably compared with the burnished products of today’s factories. Hammered out by hand at forges erected at or near the ore mines, they could become smooth only through much use.

They were designed by guess after many trials and did not become stabilized to dependable shape until a century after farmers began to use them generally. Despite its shortcomings – much easier to appraise from our perspective than from that of the contemporary farmer — the plough was, even in its crude state, the greatest invention of the age. It dispelled hunger as the first oil lamp dispelled darkness. Aladdin’s lamp could not have been more wonderful. When in the middle of the nineteenth century the first experiment station was established at Rothamsted, England, no one seems to have raised a question whether the neat work done by the mouldboard plough might be responsible for the trouble farmers were beginning to have growing crops.

The men of science who manned that first station, as well as those in charge of the state experiment stations later established in the United States, inherited an unquestioning reverence for the plough. The doctrine of the Divine Right of Ploughs passed down from generation to generation, so that the possibility that the plough might account for the waning fertility of the soil never seriously occurred to anybody along the line.

For decades, to my own personal knowledge, men have sensed that the ploughing in of a layer of organic matter at the ploughsole must of necessity interfere with capillary movement; but the subconscious feeling that The Plough Can Do No Wrong apparently prevented anybody from doing anything about it. The result is that, although we have had experiment stations in America for more than three-quarters of a century, no one of them conducted tests, before 1937, designed to compare directly the effects of ploughing, on the one hand, with the surface incorporation of all organic matter on the other.

opening of the present century, it is difficult to avoid assessing blame, on the score of carelessness, against those who did not look beyond their immediate data to the established data gained from ploughing. This is almost implicit in the following:

The Yearbook of the United States Department of Agriculture for 1903 carries this statement on page 284: “Decayed organic matter, by itself or in combination with mineral soil, absorbs moisture much more rapidly than soil containing little or no organic matter; hence, the greater the amount of leaf mould and other litter, the more rapidly will the rain be absorbed. Rapidity of absorption is also influenced by the degree of looseness of the mineral soil. In the forest the mulch of leaves and litter keeps the mineral soil loose and in the best condition for rapid absorption.”

If such a statement seems sufficiently old for its validity to be questioned, compare it with the following, taken from pages 609-10 of the Yearbook of the same department for the year 1938: “Forest litter — the carpet of dead leaves, twigs, limbs, and logs on the forest floor — serves in several ways. Water falling as rain on bare soil dislodges silt and clay particles by its impact. These are taken into suspension and carried into the tiny pores and channels between the soil particles as the water makes its way downward. Very shortly the filtering action of the soil causes the openings to be clogged by the particles; water can no longer move downward through the soil, so it flows over the surface carrying with it the dislodged silt and clay; and erosion is actively under way. A protective layer of litter prevents this chain of events by absorbing the impact of the falling drops of water. After the litter becomes soaked, excess water trickles gently into the soil surface, no soil particles are dislodged, the water remains clear, pores and channels remain open, and surface flow is eliminated except in periods of protracted heavy rains.”

I can detect no significant difference in the meaning of the two quotations. The latter gives a more intimate picture of the processes involved, but it fully confirms the less graphic description in the earlier statement. Moreover, every intelligently conducted experiment so far undertaken in this direction confirms the truth presented.

A paragraph from a letter dated February, 1940, should be interesting in this connection: “The Department of Agriculture has long been interested in developing new methods of soil treatment which will maintain and build up the organic matter content of the soil. Studies carried out by the Soil Conservation Service at a number of locations have already produced unusually outstanding results along this line. At Statesville, North Carolina, for example, it has been found that several inches of pine needles spread over the soil surface reduced the loss of soil by erosion to a point almost beyond measurement. There was also a considerable increase in the organic matter content of the soil and indications point to a worthwhile increase in crop yields. In Nebraska subsurface tillage, which leaves straw and other litter undisturbed on the soil surface, has proved remarkably effective in reducing soil and water losses and in preliminary experiments has led to a material increase in the yield of several crops tested.” This was signed by the Assistant to the Secretary of the United States Department of Agriculture. It may be said that my letter, to which this was the reply, had mentioned and asked for comment on the fact that the mouldboard plough had never been put to test for validation. No mention of the matter was made in the official reply.Failure to do this has definitely handicapped the development of basic soil information which might easily have prevented the debacle toward which American soils have been drifting.

The failure to harmonize the implications of ordinary observations with really scientific information may be the result of historical lag, or an attitude of mind, or mere carelessness, or, finally, a combination of all three. If we consider the published recognition given to the importance of organic material in the soil surface, especially since the The fact that no advance whatever is apparent, when the statement of 1903 is compared with those of 1938 and 1940, indicates that effort to implement the earlier findings into general farm practice has been neglected. The statements from the yearbooks refer to forest soils, of course; but that fact must not obscure the larger fact that the findings discussed concern principles of universal application. Principles which are valid in the forest are valid in the field, always; so it seems that researches into the importance of organic matter on the surface of crop land should have been started as soon as the earlier announcement had been made. If any such work was begun earlier than 1937, I have been unable to find any record of it. -

Drill Manufacturers In Focus…

A LIVING SOIL – THE KEY TO A SUSTAINABLE FUTUREMANAGEMENT

Simtech Aitchison has become a major player on the UK direct-drilling scene in recent years, producing a variety of machines all based on the Inverted T-Slot principle. They cover the broadest range of direct-drills on the market, encompassing arable, mixed, upland and lowland pasture and forage crops, to narrow drills for sowing cover crops in vineyards, walnut groves and orchards.

Simtech’s direct sales policy means that they are in constant contact with progressive and innovative farmers and producers, focussed on improving and experimenting with their cropestablishment and production methods. This gives the sales team a rich and varied insight into how sustainable agricultural systems are evolving into the future, which they in turn use to help customers get the best out of their purchase. “No-Till is not an adequate term for what we are looking to achieve” says Simtech’s Simon Clarke.

“Conservation Agriculture embraces the broader concept much better. Direct-drilling is a vital part of this equation, but needs to be allied with a diverse rotation, good residue management and optimum cover crop usage, to reach its full potential.” “It’s important to think of the soil as a living system and not a growing medium. Given the right tools, a living soil is capable of looking after itself and providing most, if not all, of the nutrients a crop needs. Cultivation disrupts the soil’s biology as well as its structure – tillage is detrimental to worm, mycorrhizal fungi and predator beetle activity, to name just three.”

“Cover crops do just what they say, along with the crop residue they cover the soil to protect it, feed worms and suppress weeds. A living soil can also hold onto much more water, therefore keeping crops growing for longer in times of drought. But of all the elements to building a healthier soil it is the Mycorrhizal Fungi that is the key. Hidden from view it is the web that drives all soil biology and responsible for making available nutrients that were previously unavailable to plants, producing proteins that are essential building healthy soil and protecting plants against pests and diseases.” Simon Clarke continues, “So the benefits are real and the savings on inputs can be massive. As we are presently moving into uncertain times and the near certain loss of main stream subsidies, adopting a more sustainable approach could mean the difference between profit and loss. Around the world, early adopters of Conservation Agriculture have seen their productivity and profitability soar, so this is a real thing and not a theory. It takes effort and commitment, but nothing is easy.”

Simtech continue to develop their machines to work in the environments seen in Conservation Agriculture, from drilling cover crops into often hard dry conditions directly after harvesting, late autumn drilling, when the soil can be quite wet, through to the spring drilling of cash crops into those same cover crops. With new trailed models planned for 2019 they are looking to offer the larger farmers the same capabilities that their core smaller and medium size customers have enjoyed for many years. Simtech have also been designing in extra versatility with a range of systems to allow one, two or even three extra products to be accurately applied at the same time as drilling.

Drills are available with one or two Stocks Rotor Meters for slug pellets and low dose fertiliser, which can both be metered into the airflow with the seed. A Stocks Turbo Jet can also be specified for slug pellets, fertiliser or seed for companion cropping in Oil Seed Rape. Simon Clarke says, “In 2018 we also developed a new model of our popular 300 and 300A Box Hopper drills. Called the T-Sem 300 Micro it has an additional 150 litre capacity “Micro Hopper”, which uses the same sponge feed metering as the main hopper and is capable of introducing slug pellets, seed or micro fertiliser into the seed slot. This makes for a very low cost, but incredibly versatile drill for smaller farmers or someone just starting out with direct drilling.” Liquid fertiliser is also now available across the range, with front mounted tanks up to 1800 litres and a choice of control systems including ISOBUS compatibility. To sum up Simon says, “Our whole philosophy is versatility combined with simplicity. We feel farmers need a crop establishment system that puts as few constraints on them as possible and many of our customers report that owning a T-Sem opens up new possibilities they had previously not thought possible.”

-

Farmer Focus Clive Bailye

18 years ago, we bought our first self-propelled sprayer and it revolutionized access to land, it was light and well balanced and made fertilizer and crop protection applications easy. Our timeliness and the ruts we used to leave in tramlines all but disappeared.

Back then If you had told me I would ever consider running a trailed sprayer on my farm again I would have thought you were mad. I was once told the difference between a good farmer and a bad one was “a week” so I have always placed ability to travel and make timely application of inputs highly on my list of farming priorities. So why today do I find myself the proud owner of a new trailed sprayer? Both bigger and heavier than any sprayer we have ever run before, and why am I more confident than ever of timely application with this heavy weight monster? What changed? Soil is what changed, and nothing is more demonstrative of that than this increased ability to carry traffic.

The improved structure that has resulted from zerotill can be seen through infiltration tests proving how its structure today can far better cope with rainfall events. Like many other UK farmers most of the land we farm has a now ageing drainage system under it, these systems were put in when grant money for such infrastructure investment was available. Tighter economics means many such systems are now getting tired and becoming less effective and in need of investment which for many is simply just not available. Drainage is essential to consistently successful zero till but doing so with a digger and pipes is a very long-term investment and certainly not something many tenant farmers would consider on a short-term contract.

Under our previous min-till system ponding was not uncommon and wet spots that could swallow a sprayer lay in wait to catch us out when pushing application windows after significant rainfall. Each year of zerotill these areas seemed to get smaller, the temptation to subsoil them was resisted in favor of a light late spring surface cultivation and cover crop mix established on any such bare patch or sticky headland, nothing repairs structure better than roots and the soil biology that surrounds them and it seems that if you can create a good natural structure it can go some way to making up for the failings of an ageing 1960’s drainage scheme.

Get enough wildlife working through your soils vertically and they create a massive network of small drainage channels that can quickly help move water from the surface down to storage in subsoils or out to existing drains very quickly. Worms do this very effectively and I have seen studies that show the combined area of the galleries they can create in a long term zero till soil can total the equivalent of a 4” drain every square meter of the land, if you try to visualize what that would look like it’s very difficult to imagine water ponding on any surface with a vertical drain every square metre.

Less is more when it comes to creating structure, if you plough 10” then then a heavy load will easily break through that 10” of structureless soil, if you min-till to 6” that will be the depth of your ruts when making applications in less than ideal condition, however if you don’t cultivate at all eventually your natural structure will improve to a point where it can carry much greater loads before failing. Cultivations simply destroy the essential channels and break down aggregated structures created by soil life making it a lot harder for water to flow away from the cultivated zone. This means in high rainfall events the soils soon reach capacity making it impossible to traffic and, in many cases, leads to run off, soil erosion and resulting pollution and sedimentation of our water courses.

Of course, soil doesn’t change overnight, it’s a gradual process so getting to a point where increased structure and infiltration can carry heavy loads needs thought and planning. I’m not a big fan of strict controlled traffic farming systems (CTF). Along with the often-high capital cost of adoption I have always felt it dictates too much, causing compromises with important residue management strategies. Although maybe a necessity in farming systems that depend greatly on very heavy high horse power tractors my view is that it’s surely better to just not use potentially damaging machines when you have viable lighter, lower ground pressure alternatives usually employed in zerotill systems.

A less prescriptive form of CTF has however played a vital part when it comes to the parts of our farming system where weight is unavoidable or ideal conditions not always possible. In our case this has been controlled traffic of application and harvest equipment. Fixing tramlines and boom / header width in multiples of 12m has helped us keep damage from such operations localized and allowed targeting of any remedial work. In the early years of system change such remedial work consisted of just leveling any rutted areas and resisting temptation to work deeply which would simply put any longer-term changes to structure right back to square one. Gradually the ruts got shallower and less frequent the heavily trafficked application tramlines became settled and compacted preventing deeper sinking. Our route onto the land had become more stable whilst the soil around it had become better able to infiltrate and cope with weather significantly increasing our windows of application.

Increased workload over the last decade means today we need more application capacity than ever, our self-propelled machine was ageing and replacement long overdue. The tractors we use today are much smaller than they were and with almost no cultivation to do are covering less hours than they ever did making them the perfect match for a modern self-propelled sprayer. The capital cost of a similar spec self-propelled machine was over double that of an equivalent trailed machine. From a financial point of view the savings from the change are significant and fit in well with the ethos behind our farming system of keeping things as simple, minimal and as few engines (which equals potential repair bills!) on the farm as possible.

It’s not all positive however, tractors don’t have the clearance of a self-propelled machine and changes between row crops and low ground pressure wheel equipment would take longer and be more frequent, trailed machines are not as “handy” in the smaller fields, backing into corners and working around obstacles. These are compromises we considered long and hard before making the decision to change. To mitigate this, we have moved from 24m to 36m tramlines. 36m still fits with the harvest operation where we control the unavoidably heavy machinery and 12m base organic fertilizer and lime applications yet even when running wide tractor tyres all year around the area lost to uncropped tramlines and reduced ground clearance is not much more in percentage terms than that lost to narrow wheels on a 24m system.

Farming systems are often compared primarily on agronomic merit. Often the first thing I am asked about our transition to zerotill is how do the crops yield? or what are gross margins like? Others are interested in the operational cost savings we have made like fuel and wearing metal. Although not insignificant none of these things are where the truly fundamental business changing difference are. Zerotill creates opportunity for complete business restructure, radically different rotations that include higher % of spring cropping may provide lower rotational average gross margins, but they also provide serious scope for cost cutting as well. UK agriculture has been obsessed with gross margin for too long and has lost sight of more fundamentally important profitability.

Chasing the maximum output rainbow has led many of us to unsustainable rotations and the current decline in soil health bringing symptoms like blackgrass, pest, disease or plateauing and even declining yields for some. As my recent change to a trailed sprayer demonstrates, smaller tractors add flexibility in their use and without cultivations to complete along with their drivers have more time available for more varied “allrounder” operations. The restructure here has been gradual, we never had a farm sale or made anyone redundant, we let things evolve and made machinery changes as and when they needed making and, in many cases, simply took on more work without needing to invest in additional infrastructure to complete it.

Today our capital employed per acre is less than half the level it was when we mintilled and a quarter of the level I believe would be required should we return to the plough, depending on circumstance that reduces debt and its cost or provides capital to expand or diversify. The increased diversity and spread of our rotation has reduced average gross margin, spring break crops will never compete with the output of a decent crop of winter OSR but with a lot less bills to pay does that really matter? These fixed costs savings are what makes the difference and will become essential in the potentially un subsidized trading environment we all face in the years ahead The big question is though as small becomes the new big here just how far will things go? Will I look back on this in years to come while my swarms (if that’s the correct collective noun) of robots work the land and laugh at what I once thought was “small”? Will my recent purchase be my last sprayer? There are some exciting times ahead of agriculture, nothing short of an agricultural revolution is on our doorstep and I really can’t wait for the many exciting challenges and changes that will bring.

-

Product In Focus…

BIOFIL – LIQUID ORGANIC SOIL INOCULANT IS NOW AVAILABLE IN THE UK

BioFil is a liquid organic bacterial soil inoculant which has been used by Hungarian farmers for more than 5 years with great results. The products are finally being launched in the UK and will be available from Farm Marketplace from January 2019. Research with pH-specific soil microbes commenced in Hungary more than 12 years ago, when scientists of BioFil Ltd. recognised that there was a need to find a way to grow crops in soils with extreme pH, either acidic or alkaline. They set out to find species of naturally occurring soil microbes that would support plant growth, help to improve soil structure and increase crop yields while at the same time re-duce the application rate of chemical fertilisers. Today BioFil Ltd. has a dedicated team of 25 researchers, three of whom hold PhDs in microbiology, who are continuously seeking to improve the performance of BioFil prod-ucts through careful selection of bacteria and to develop new products and services.

The current range of BioFil has six products: BioFil Acidic (pH 4-6), BioFil Normal (pH 5-7), BioFil Alkaline (pH 7-8), BioFil Pea/Bean, BioFil Soya and BioFil Post Harvest. Each of the products include up to 7 unique bacterial strains specifically developed with your soil pH in mind. BioFil Acidic contains bacterial strains which reproduce well in acid-ic soil pH. While BioFil Normal contains bacteria which prefer soils with neutral pH and have an excellent nitrogen-fixing ability. BioFil Alcaline was developed for alkaline soil and effectively suppresses the reproduction of plant pathogen fungi. BioFil Pea/Bean contains pea-symbiont bacterial strains which increases the formation of nodules and provides plants with nitrogen. Peas and beans become healthier and more developed, more resistant to various diseases. The bacterial inoculant BioFil Soya is re-sponsible for soya nodulation.

It contains a symbiont nitrogen-fixing bacterial strain. BioFil Post Harvest is used for intensive degradation of cellulose and can multiply even in low soil temperatures which makes it very effective in degradation of stems, leaves and roots so that the next plant culture gets access to valuable nutrients. There is no need to apply nitrogen for stalk degradation as this product contains nitrogen-fixing bacterial strain of high capacity.