Joe Stanley, Allerton Project and Graham Redman, The Andersons Centre

Joe Stanley

Since 2017, the Allerton Project has been conducting a nationally significant long-term rotational field trial in partnership with Syngenta across five fields of our heavy-land site. The initial five-year phase of the trial, as outlined in the June 2023 issue of Direct Driller, sought to assess the production, financial and environmental implications of three contrasting tillage and establishment regimes; plough (PL), min-till (MT) and light-till (LT). This is our ‘direct drill’ plot, and in some seasons a tine drill has been utilised which has created an amount of soil disturbance). Intensive assessment of soil health and other environmental metrics has also been undertaken to assess the balance between natural capital services and production.

The trial was replicated at a ‘sister’ light-land site at Lenham in Kent, undertaken in conjunction with NIAB and farmer Andy Barr. The results of this first phase of the project were highly encouraging, indicating improved economic and environmental outcomes from the LT system.

Representative plot plan – each plot is 1-1.5ha in size across five fields

Since 2023, the scope of the original ‘conservation agriculture’ trial has been broadened at both sites to encompass a greater range of sustainable and regenerative techniques such as the use of biostimulants and novel fertilisers (in conjunction with Yara), organic manures and fallow breaks. The results of this exciting second phase will be processed at the end of 2026, with the project hopefully continuing beyond.

In the meantime and in order to assist growers in making informed judgements on their future establishment strategies, Graham Redman of The Andersons Centre has been commissioned to analyse in greater detail the impact on profit per hectare and rotational profit and loss of the three systems to give a more representative analysis of the financial differences between PL, MT & LT across the span 2017-2023. As Graham recounts below, taking a more detailed dive into the fixed costs, efficiencies and farm depreciation does paint a more nuanced picture of the tens of thousands of datapoints collected, which remain however highly revealing.

Graham Redman

Detailed gross margins have been easy to calculate given that all inputs such as seed rates, fertiliser and agrochemicals and yield are recorded, as are all cultivations and fuel consumption. Inputs into each hectare do vary, but this level of financial assessment generally shows the highest yielding system tends to outperform the lower yielding cultivation practice at gross margin level. However, the costs of cultivations and farm management and occupation are not accounted for at this level, only considering direct costs per hectare. The labour and machinery costs and those of operating a farm business also need to be accounted for.

So, how do the profits compare over the long term for each system? Firstly, by making estimates of how many hectares of each crop is likely to be in a typical rotation, the weightings of each gross margin can be adjusted, thereby creating a viable weighted whole farm gross margin.

Making use of standard published costings figures, the costs of the field operations are applied. Standard machinery costs assume varying capacities (likely areas per year) for each machine. In fact, no farm has precisely the right hectarage each year to maximise the use of each machine. Machinery values do not only decline when they are being used, but by age as well. This inefficiency is therefore incorporated by reducing the capacity to fit within the 250-hectare model farm system. This adds to depreciation figures. Labour rates are doubled, on the basis, that tractor drivers probably only physically operate machinery in fields for 50% of their time. Fuel costs are elevated by 25% to account for travelling time, ticking over and other events such as visiting fields for crop walking which are not accounted for in the machinery costings.

Operating a farm inevitably requires management, so an appropriate figure was included, based loosely on an additional 25% on labour and machinery. Each system had the same management charge included. Other costs such as overheads, finance and rent were taken from the Nix Farm Management Pocketbook. Each figure could be argued, but to create a notional costing with realistic inefficiencies generates a model that reflects real farming systems. The calculations were interrogated by the farm managers of each location.

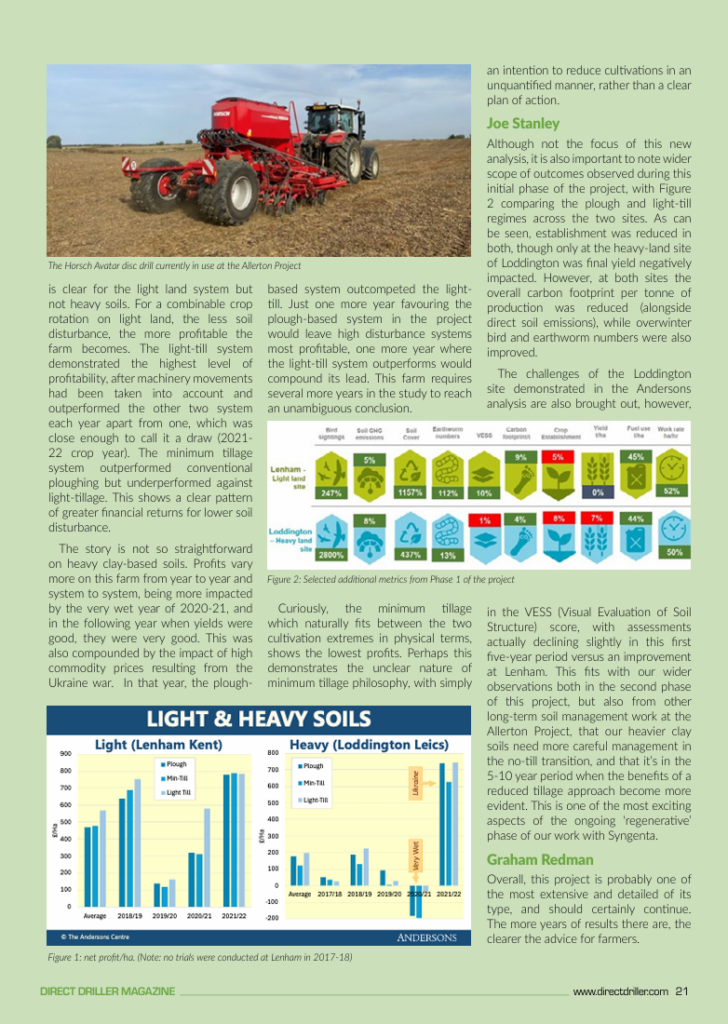

The Horsch Avatar disc drill currently in use at the Allerton Project

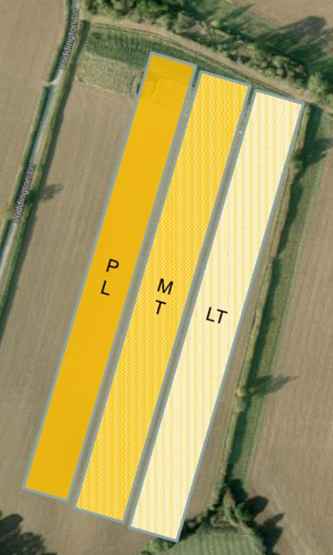

The financial results, as shown in the graphs, are enlightening. The outcome is clear for the light land system but not heavy soils. For a combinable crop rotation on light land, the less soil disturbance, the more profitable the farm becomes. The light-till system demonstrated the highest level of profitability, after machinery movements had been taken into account and outperformed the other two system each year apart from one, which was close enough to call it a draw (2021-22 crop year). The minimum tillage system outperformed conventional ploughing but underperformed against light-tillage. This shows a clear pattern of greater financial returns for lower soil disturbance.

Figure 1: net profit/ha. (Note: no trials were conducted at Lenham in 2017-18)

The story is not so straightforward on heavy clay-based soils. Profits vary more on this farm from year to year and system to system, being more impacted by the very wet year of 2020-21, and in the following year when yields were good, they were very good. This was also compounded by the impact of high commodity prices resulting from the Ukraine war. In that year, the plough-based system outcompeted the light-till. Just one more year favouring the plough-based system in the project would leave high disturbance systems most profitable, one more year where the light-till system outperforms would compound its lead. This farm requires several more years in the study to reach an unambiguous conclusion.

Curiously, the minimum tillage which naturally fits between the two cultivation extremes in physical terms, shows the lowest profits. Perhaps this demonstrates the unclear nature of minimum tillage philosophy, with simply an intention to reduce cultivations in an unquantified manner, rather than a clear plan of action.

Joe Stanley

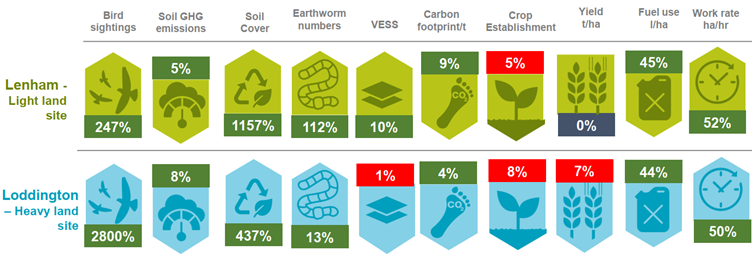

Although not the focus of this new analysis, it is also important to note wider scope of outcomes observed during this initial phase of the project, with Figure 2 comparing the plough and light-till regimes across the two sites. As can be seen, establishment was reduced in both, though only at the heavy-land site of Loddington was final yield negatively impacted. However, at both sites the overall carbon footprint per tonne of production was reduced (alongside direct soil emissions), while overwinter bird and earthworm numbers were also improved.

The challenges of the Loddington site demonstrated in the Andersons analysis are also brought out, however, in the VESS (Visual Evaluation of Soil Structure) score, with assessments actually declining slightly in this first five-year period versus an improvement at Lenham. This fits with our wider observations both in the second phase of this project, but also from other long-term soil management work at the Allerton Project, that our heavier clay soils need more careful management in the no-till transition, and that it’s in the 5-10 year period when the benefits of a reduced tillage approach become more evident. This is one of the most exciting aspects of the ongoing ‘regenerative’ phase of our work with Syngenta.

Figure 2: Selected additional metrics from Phase 1 of the project

Graham Redman

Overall, this project is probably one of the most extensive and detailed of its type, and should certainly continue. The more years of results there are, the clearer the advice for farmers.