The National Museum of Rural Life in Scotland stands as a captivating testament to the country’s agricultural heritage, offering arable farmers a remarkable journey through time and a deep dive into the evolution of their craft. Nestled amidst the picturesque Scottish countryside, this museum serves as a vibrant tapestry of rural life, resonating with arable farmers who have played a pivotal role in shaping Scotland’s agrarian landscape.

For arable farmers, the museum provides a unique opportunity to trace the lineage of farming practices that have sustained the nation for generations. Exhibits featuring 12 meticulously restored vintage combine harvesters evoke a sense of nostalgia while highlighting the transformation of labour-intensive methods into the mechanised processes that drive modern agriculture.

As well as the combines, one of the museum’s prime attractions is its collection of historical crop varieties, which resonates deeply with arable farmers. From heirloom grains to ancient cereal crops, these exhibits showcase the genetic diversity that underpins the sector’s resilience. Farmers can immerse themselves in the stories of these crops, gaining insights into their adaptability and historical significance, thus fostering a renewed appreciation for the rich agricultural tapestry they contribute to.

The National Museum of Rural Life is well worth a visit for arable farmers. It celebrates heritage, showcases the evolution of farming, fosters connections among farming communities, and inspires sustainable practices for the future. We are going to briefly cover some of the combines there to see.

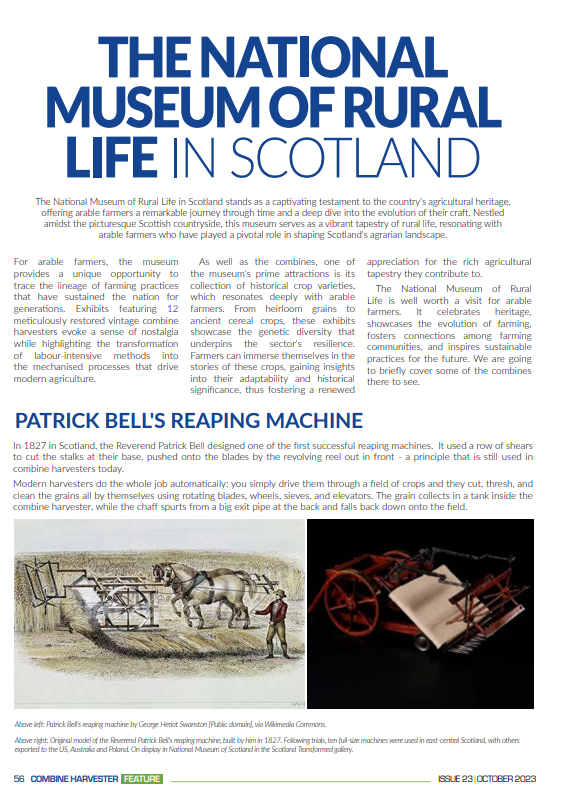

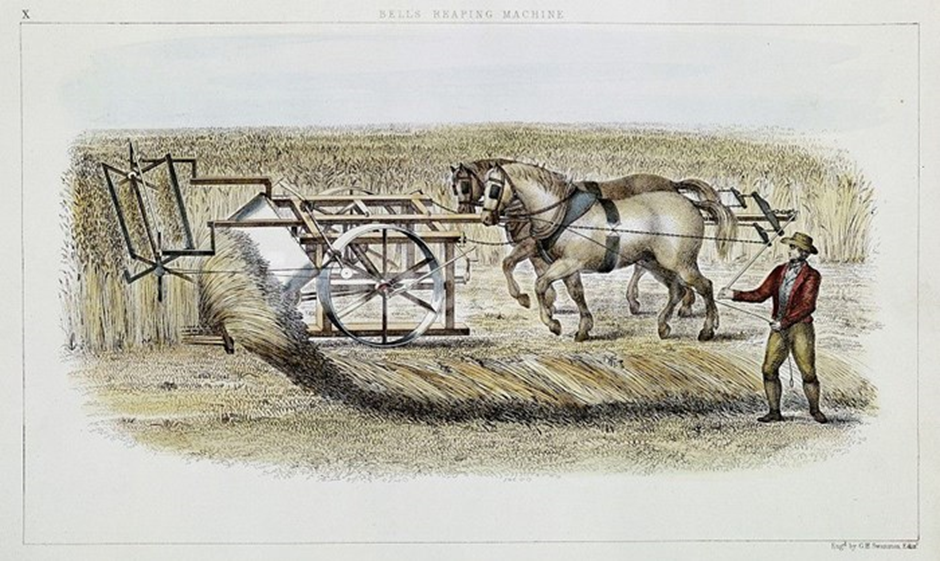

Patrick Bell’s reaping machine

In 1827 in Scotland, the Reverend Patrick Bell designed one of the first successful reaping machines. It used a row of shears to cut the stalks at their base, pushed onto the blades by the revolving reel out in front – a principle that is still used in combine harvesters today.

Modern harvesters do the whole job automatically: you simply drive them through a field of crops and they cut, thresh, and clean the grains all by themselves using rotating blades, wheels, sieves, and elevators. The grain collects in a tank inside the combine harvester, while the chaff spurts from a big exit pipe at the back and falls back down onto the field.

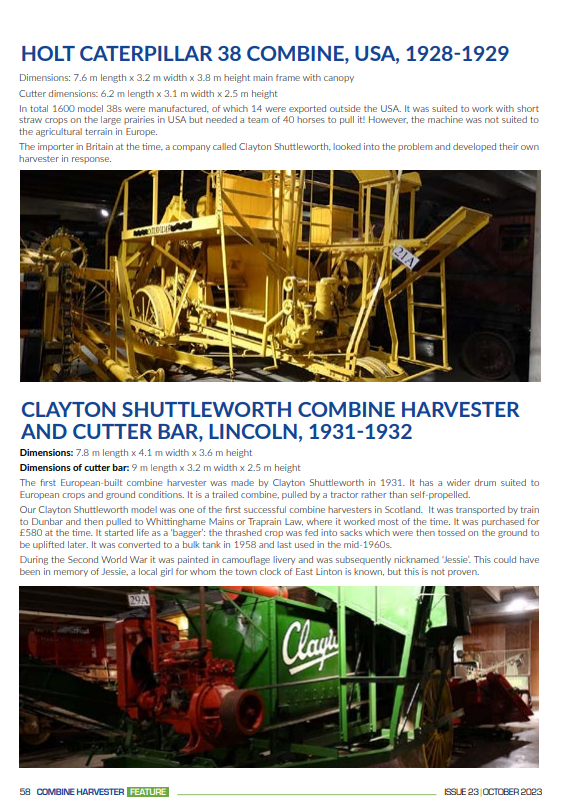

Holt Caterpillar 38 combine, USA, 1928-1929

Dimensions: 7.6 m length x 3.2 m width x 3.8 m height main frame with canopy

Cutter dimensions: 6.2 m length x 3.1 m width x 2.5 m height

In total 1600 model 38s were manufactured, of which 14 were exported outside the USA. It was suited to work with short straw crops on the large prairies in USA but needed a team of 40 horses to pull it! However, the machine was not suited to the agricultural terrain in Europe.

The importer in Britain at the time, a company called Clayton Shuttleworth, looked into the problem and developed their own harvester in response.

Clayton Shuttleworth Combine Harvester and Cutter Bar, Lincoln, 1931-1932

Dimensions: 7.8 m length x 4.1 m width x 3.6 m height

Dimensions of cutter bar: 9 m length x 3.2 m width x 2.5 m height

The first European-built combine harvester was made by Clayton Shuttleworth in 1931. It has a wider drum suited to European crops and ground conditions. It is a trailed combine, pulled by a tractor rather than self-propelled.

Our Clayton Shuttleworth model was one of the first successful combine harvesters in Scotland. It was transported by train to Dunbar and then pulled to Whittinghame Mains or Traprain Law, where it worked most of the time. It was purchased for £580 at the time. It started life as a ‘bagger’: the thrashed crop was fed into sacks which were then tossed on the ground to be uplifted later. It was converted to a bulk tank in 1958 and last used in the mid-1960s.

During the Second World War it was painted in camouflage livery and was subsequently nicknamed ‘Jessie’. This could have been in memory of Jessie, a local girl for whom the town clock of East Linton is known, but this is not proven.

CLAAS MDB Combine Harvester, Germany c.1937

The MDB (Maedrescher-binder) was developed by August Claas and Walter Brenner. It was created to handle European crops, where straw was a valuable by-product of the cereal harvest. The CLAAS combine harvester, with the mower-thresher-binder (MDB), was specifically designed and built for European harvesting conditions.

The cross-flow combine harvester mower-thresher-binder MDB was a combination of a self-binder and threshing mechanism, with the threshing mechanism housed between the cutterbar and the binder. After chopping, the grain was delivered to the threshing drum via a feed belt, at which point the straw was re-routed by a chain conveyor and fed to the straw walker.

The crop then passed through two cleaning phases before the grain was put into sacks and the straw tied into bunches. The MDB entered production in 1937 and production ceased in 1943 due to the Second World War.

The combine on show was brought by Mr J Sword of Irvine, Ayrshire, and used on his farm until the early 1950s. In the 1980s it came into the ownership of Mr H Ritchie, who later donated it to the collection, where it was subsequently restored.

Massey Harris 726, Kilmarnock

Dimensions: 6.8 m length x 3.2 m height x 3.7 m width

The Massey Harris 726 was the first self-propelled combine to be produced in Europe. A number of trailed combines had been developed prior to this by European manufacturers, the Clayton Shuttleworth (built in 1928) and CLAAS MDB (built in 1937).

The 726 cutting head is narrow by modern standards, measuring only 2.6 metres. The machine was available with either an Austin or Morris engine. This example is powered by an Austin 6 cylinder, 4 litre petrol engine.

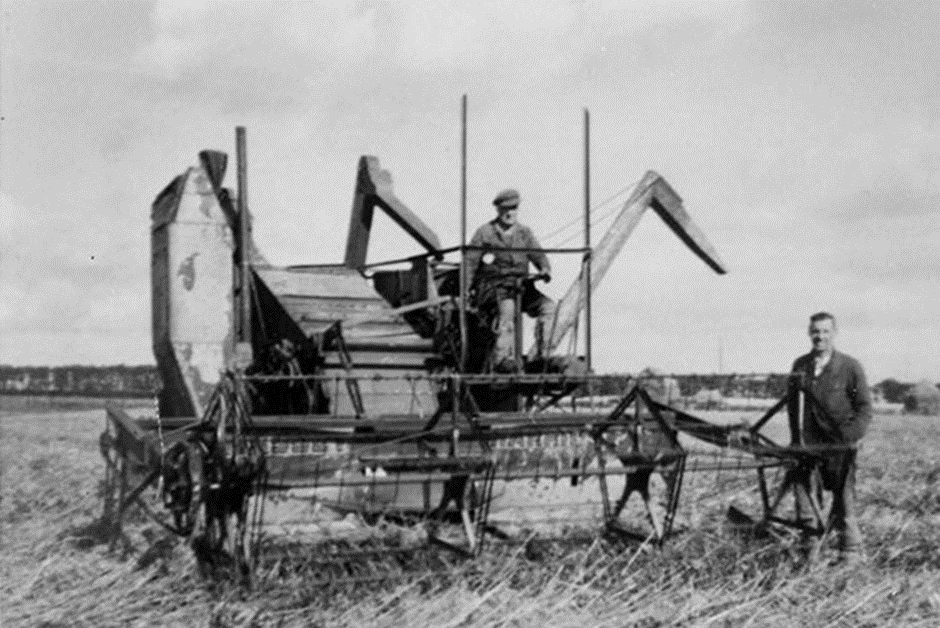

McCormick Deering International Harvester Co Travelling Threshing Mill, USA, c.1938-1939

Dimensions: 8.4 m length x 3m height x 2.1 m width

McCormick was of Scottish/Irish descendants. He emigrated to the USA and built up one of the world’s most famous agricultural engineering companies. The travelling threshing mill was the ultimate development of the mobile threshing mill.

It was operated by two people. The person on the stack threw the sheaves onto the elevator. The knives then cut the strings on the sheaves before it went into the drum. The second person took the grain off in sacks. The mill was last used in 1964 on Plains Farm in Perthshire.

You can visit National Museum of Rural Life on Philipshill Road, East Kilbride, G76 9HR. It’s open daily from 10am to 5pm – https://www.nms.ac.uk/national-museum-of-rural-life/