The Tyre & Compaction presentation hosted by Philip Wright & Stephen Lamb was an engaging and well-attended station during the event.

From a tyre perspective, the focus was very much on the Interface – the contact area between soil and tyre, and how by doing some homework, soil compaction could be dramatically reduced. Identifying the most suitable size of tyre for the application, with the aim of selecting the lowest operating pressure tyre within that size, which normally would be VF specification tyre, with many of the guests already benefiting from that fitment.

A demonstration was given to show, how in some cases, it can be more beneficial to go longer in the footprint, rather than just going wider, this is where VF technology can really play its part, by having a longer footprint, within the already committed trackway, as opposed to just going wider.

This followed nicely into an area, which is commonly over-looked, regarding tyre width vs implement width – which controls the – Tyre to Field Percentage Contact. Example a 3m drill with 710’s tractor tyres fitted has a Contact Percentage of 47%, that is nearly half your field in Contact with your tyre, and with whatever pressure you are operating at ! Whereas say a 6m Drill with 710’s would only have a 24% Contact in your field.

Three main aim areas were illustrated, if not already achieved :-

A – Aim to reduce your axle loads, where possible, to 5 Tonne.

B – Aim to reduce your operating pressure to sub – 12psi.

C – Aim to reduce your Field Contact Percentage – 20%

By being aware of these aims/goals, soil compaction would be greatly reduced.

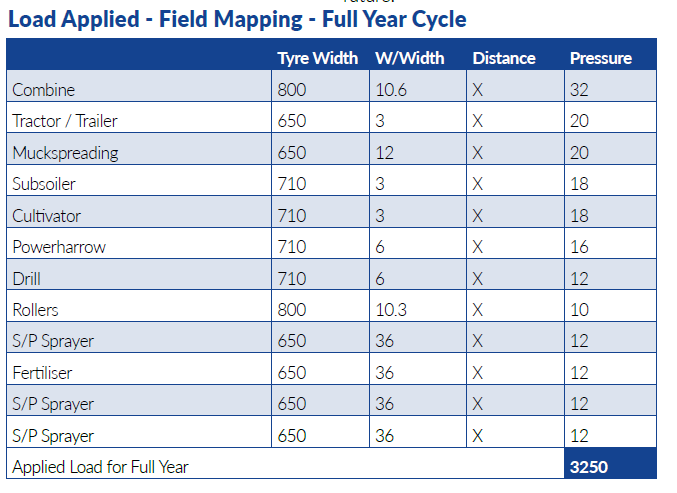

One additional area covered at the Station, was with all the hard data we have about the cost of establishment, inputs data, crop data, etc, etc. do we actually have a value as to what level of compaction we generate with each application within the field, especially during drilling – the last tyre before the seed goes to work, the answer coming back was very little hard factual data was known.

Yet we all know that compaction is a major player in poor soil health, yield loss and the business’s bottom line – yet we seemingly have no really reference point to it, in this data driven world – this got the guests thinking !

The station was however able to offer one value, which could be easily calculated, while not compaction itself, it is the element which develops compaction at the interface, subject to soil type, density, moisture, etc. that being the Load Applied.

From this calculation, Load Applied values could be mapped from each application within the field, and then with the whole farm on an annual basis. From this captured data, informed decisions can be made, on how to reduce the Load Applied values. Is it possible to achieve – by reduced applications, doubling up applications, Increasing the working width of an implement &/or reduce the width of tyre, looking for a lower operating pressure, specification of tyre, would all help to mitigate the effects of soil compaction to your business.

Load Applied Field Mapping could possibly be used as part of the Farm’s Management Soil Action Plan within SFI.

Load Applied data will be a value offered by OEMs within their field solutions – data capture – in the near future.