JOHN DEERE SEE & SPRAY™ ULTIMATE – TARGETED, IN-CROP SPRAYING

With See & Spray Ultimate, you can gain cost efficiency in your herbicide applications by reducing your spray volume, which in turn enables you to use more advanced tank mixes. We have added to the previously launched See & Spray, to allow in crop targeting of weeds (See & Spray was for fallow ground only). See & Spray Ultimate currently only detects weeds among corn, soybean, and cotton plants. It uses cameras, processors, a carbon-fiber truss-structure boom and a dual product tank. It enables targeted application of non-residual herbicides on weeds within corn, soybean and cotton fields. It can also be used for traditional broadcast application, as well as targeted and traditional spray combined. This strategy reduces crop stress by providing an effective weed-kill strategy, eliminating the chance weeds will rob plants of valuable nutrients and moisture, thus enabling crop roots to thrive. Plus, when using AutoTrac™ technologies, the sprayer will stay between rows and off the crop further reducing potential crop damage.

The dual-tank configuration lets you apply targeted spray and traditional broadcast at the same time, combining two passes in one to save you time and money. Target spray weeds and broadcast fungicide, or better manage weeds by applying a non-residual targeted spray and residual broadcast, all in one pass. Using Targeted Spraying to kill weeds, it can be done at a lower cost by applying only what you need – when and where you need it. Or, with the dual-tank capability of See & Spray Ultimate, use different chemical mixes independently of each other and at different target rates – all on the same pass. Plus, the amount of herbicide saved during Targeted Spraying can be used for a second and third pass during the growing season to address weed control all season long.

MEET SEE & SPRAY ULTIMATE

The cameras and processors are just the beginning. Discover how this See & Spray technology works.

Vision Processing Unit

Multiple processors across the boom use camera vision technology and machine learning to detect weeds from plants, and activate sprayer nozzles all within 200 milliseconds.

Cameras

36 cameras mounted across the boom scan more than 2,100 square feet (195 m2) at once.

Dual Product Solution system

The tank is split in two, with either 1,000 gallons (3,785L) or 1,200 gallons (4,542L) total capacity. Use two independent tank mixes simultaneously with targeted spray and traditional broadcast spray, or a single, combined tank mix for either targeted spray-only or broadcast spray-only.

ExactApply™ Nozzle Control System

Individual nozzle control with ExactApply offers precise droplet sizing for a consistent targeted spray that also reduces over-application and off-target drift.

Carbon-Fiber Truss-Style Boom

The new, 120 ft. (36.6 m) carbon-fiber truss-style boom is lighter than steel, providing the stability needed to enable targeted spray.

BoomTrac™ Ultimate Height Control

BoomTrac Ultimate ensures consistent height control when traveling across uneven fields for precise application, with 25% better spray accuracy* than the next best manufacturer. *Based on Iowa State University testing; scores represent composite data over a variety of terrains at factory-calibrated settings. Performance varies based on user-specified settings and adjustments. BoomTrac Ultimate tested on MY 2023 412R Sprayer with 36.6-m (120-ft) truss-style carbon fiber boom; NORAC installed on MY 2022 John Deere 4 Series Sprayer with 36.6-m (120-ft) steel boom; Raven AutoBoom XRT installed on MY 2022 John Deere 4 Series Sprayer with 36.6-m (120-ft) steel boom. Operated at 12mph and 30-in.

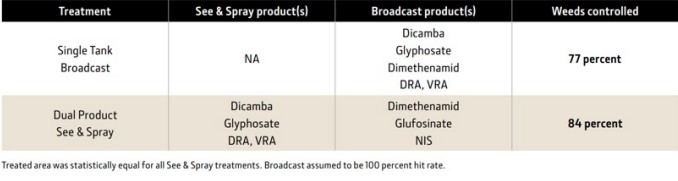

See & Spray™ Ultimate Agronomic Trial: Target Spraying with Dual Product Solution System for Waterhemp in Soybeans at V5 growth stage

Our study was conducted in an Illinois soybean field at the V5 growth stage to target spray for waterhemp in the summer of 2021. Using an enhanced herbicide program consisting of both targeted spray (non-residual) and broadcast (residual) tank mixes, and with higher sensitivity settings to study weed efficacy, See & Spray Ultimate delivered 7% better weed control with 47% less herbicide volume used. These results are made possible by the dual product system, which eliminates in-tank herbicide antagonism that reduces herbicide efficacy. Our agronomic and product experts have and will continue to partner with state universities on additional trials, plus we’ll continue to conduct our own strip trials to ensure our products and technologies help you gain improving yields, cost efficiency, and profitability in your operation.

Questions:

What’s the difference between See & Spray Ultimate and

See & Spray Select?

See & Spray Ultimate detects weeds among corn, soybean, and cotton plants. It uses cameras, processors, a carbon-fiber truss-structure boom and a dual product tank. It enables targeted application of non-residual herbicides on weeds. It can also be used for traditional broadcast application, as well as targeted and traditional spray combined. See & Spray Select is for use in fallow ground only. It uses a colour-detecting technology to identify and target spray green on brown soil. See & Spray Select can also spray both targeted spray and traditional spray in one pass, with a single tank mix. Reference chart above for features:

Can I add See & Spray Ultimate to my current Sprayer?

No. See & Spray Ultimate is factory installed on new Sprayers only. It is not available as a Performance Upgrade Kit. What model Sprayers is See & Spray Ultimate available on? See & Spray Ultimate is only available on the 410R, 412R and 612R Sprayers.

What boom sizes are available on See & Spray Ultimate?

The 120 ft (36.6 m) carbon-fiber truss-style boom is the only boom size available for See & Spray Ultimate. What are the dual tank split sizes available on See & Spray Ultimate? The 410R Sprayer has a 1,000 gallon (3,785.4 L) tank with a 650/350 gallon (2,460.5/1,324.9 L) split. The 412R and 612R Sprayer have a 1,200 gallon (4,543 L) tank with a 750/450 gallon (2,839.6/1,703.4 L) split.