HIGH HOPES FOR HARVEST

With crops on the farm showing great promise, output prices at record levels and the family’s agricultural machinery business operating at capacity, Suffolk arable farmer and inventor of the Opti-Till® direct strip seeding system Jeff Claydon is optimistic for the months ahead. But it is tinged with caution, the watchword in today’s topsy turvy world.

25.05.2022

Whilst drafting my last article for Direct Driller, Russia had just invaded Ukraine, provoking military conflict and war in the country. Almost three months later, the catastrophe and humanitarian crisis continue with thousands killed, homes and cities destroyed along with millions displaced and seeking refuge. Global supply shortages have caused sky-rocketing prices with far-reaching and dramatic impacts. In the agricultural sector, global uncertainties and a tightening of exportable surpluses have pushed combinable crop prices to previously unheard-of levels, with wheat currently trading at north of £300/t and oilseed rape over £800/t. Whilst this will benefit the arable sector, those in the livestock and poultry sectors are struggling.

Higher prices are quickly being reflected in the cost of food in the shops and if there is any positive to come out of the current situation it will be to make consumers reassess the importance of farming and what they eat. Back in the 1970s food accounted for a substantial proportion of a typical family’s budget, but over the years governments of all persuasion have prioritised cheap food and it has fallen down the list of most people’s’ priorities. For decades, the public has given little thought to food security, where it comes from or how it is produced; perhaps this will provide a wake-up call and encourage them to focus on the things in life which really matter.

Global agricultural production is forecasted to need to increase 60 per cent by 2050 just to keep pace with population growth. But, even as governments around the world stress the need for farmers to produce more, the legislation which they and other bureaucrats devise and sanction is restricting our access to inputs and stifling yield growth. During the last decade production has plateaued and the current UK five-year average wheat yield is just 8.3t/ha, so something has to give.

A busy time

So much has happened here during the last three months that it is difficult to know where to start. Having just looked around the building site outside my office which will shortly form the new production and assembly area of the Claydon factory that is a good place to start.

With demand for Claydon products at record levels and our order books full for months ahead, I am delighted to see work on the new building progressing apace. Just this morning, for example, the four 3.2t gantry cranes which will move components and completed machines around the factory were delivered and installed. Measuring 36m x 36m, the clear-span building will add 1300m2 to our factory space and double production capacity. The plan is for it to come on stream in the summer, but we will announce that nearer the time. In the meantime, I would like to thank all our customers for their continued support and enthusiasm for the Claydon Opti-Till® System which has helped to generate additional customers and created the need for the new building.

Invest in the future

With production costs skyrocketing and inflation at its highest level for more than four decades, farmers are looking to reduce costs whilst maintaining or increasing production. Rather than squandering any windfall from higher prices by continuing to operate inefficiently, forward thinking businesses recognise the need to invest in equipment and techniques which produce lasting benefits to help secure their future, so interest in Opti-Till® is increasing.

The was confirmed at the start of the week when I and my team welcomed representatives from our distributors in Denmark and Germany who brought with them 25 existing and potential customers to see Claydon products being manufactured and tour our farm. This visit follows a series of visits by our importers and customers from Lithuania, Romania, and Poland. It was organised by Simon Revell, our Export Manager, and was at an ideal time of the year for visitors to see how well Claydon-drilled crops are looking.

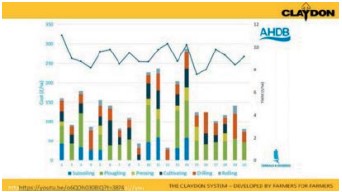

As part of my presentation, I showed our guests a slide based on information produced by Harry Henderson, AHDB’s Knowledge Exchange Manager – Cereals & Oilseeds, showing the cost of establishing winter wheat on 20 AHDB Monitor farms and the yields achieved by various approaches. Farm 12, with one of the highest yields of milling wheat but lowest establishment costs, was Rick Davies, a long-standing Claydon customer, who invested in a 3m Claydon Hybrid drill (upgrading to a 4.8m Hybrid in 2015) and a 7.5m Straw Harrow in 2010. Costs will have increased considerably since this data was produced but the proportional costs are really telling the story. When discussing his reasons for switching to the Claydon System in an article published in Crop Production Magazine during 2015 he summed up a number of points so well that I have quoted him in the paragraph below.

“It is no exaggeration to say that the Claydon System has transformed the way we think about farming and how we actually farm. Having used conventional cultivations and become used to seeing perfect-looking seedbeds for so many years, moving to the Claydon System was a huge leap of faith and it took time to get used to the idea that it would look different. But the results prove that you cannot judge a crop by its initial visual appearance and what really counts is how much goes into the combine tank. Now that we have experienced the benefits we continually ask ourselves why we did not consider the move earlier. But had we not done so when we did we would not be in such a strong position today. I am very pleased that we made the transition voluntarily rather than being forced into it by a lack of profitability, as I suspect some will,”

With some customers savings around £250/ha on their establishment costs and enjoying a yield benefit of up to 1.5t/ ha the advantages are obvious. On the Claydon farm our goal is to achieve the highest outputs at the lowest cost, but that does not mean skimping on inputs; far from it in fact. Rather than spending vast amounts on unnecessary tillage we invest in wisely in inputs which enhance and protect the potential value of our farm and crops.

This season all winter sown crops were drilled by midOctober, helped by the fact that Claydon Opti-Till® enables us to establish the crop in 20% of the time, at a fraction of the cost and using 10% of the fuel (<15 l/ha) compared with a plough-based system. High productivity counts for a lot when the weather is catchy, the window of opportunity is limited, and the number of drilling days are limited, while saving fuel has become essential at today’s prices.

A dry start to the year

2022 has brought with it a very mixed bag of weather. Between New Year’s day and today our farm weather station has recorded less than 170mm of rain, much lower than the farm’s long-term average, while April brought more days with overnight frosts than without, slowing the crops’ growth. Despite very little rain since 1 April, they have caught up well, highlighting the benefits of establishing good rooting structures to make best use of the moisture which is in the ground. Whilst driving around the farm this morning I called in at ‘80-acre’, a field which has been managed using the Claydon Opti-Till® System for 20 years and featured in Direct Driller throughout the season. All of it is into LG Skyscraper winter wheat, which despite the lack of rain continues to look very good. To date it has received just 180kgN/ha, plus the T0 and T1 fungicides, but holds great promise.

In the last issue of Direct Driller, I highlighted the importance of drainage and talked about an issue in the corner of that field where a decades-old tile drain had collapsed during the winter, resulting in a significant area becoming waterlogged. I had planned to sort it out after harvest, but the very dry weather allowed local drainage contractor W. R. Suckling & Sons to come in a couple of weeks ago and install new plastic pipes at a depth of 1m. They did an excellent job, and we will cross mole the area in the autumn if conditions allow or go through the following crop of spring oats early next year.

I also called in to check on the progress of our DK Excited hybrid oilseed rape which was drilled within three days of harvesting the previous crop of winter wheat on 15 August. We went directly into chopped straw and stubble using a preproduction version of our new Claydon Evolution drill and a seed rate of just 2.7kg/ha.. Experience has shown that the sooner we can drill oilseed rape behind the combine the better, as the plants are stronger and more able to fend off the Cabbage Stem Flea Beetle. The damp weather and slightly cooler temperatures after drilling, combined with the extra vigour of the hybrid seed, resulted in excellent establishment. Despite having received just 150kgN/ha the crop has developed exceptionally well and looks set to deliver a very high yield at harvest. With rapeseed prices currently around £800/t that would produce a very attractive margin.

This season’s spring oat area is taken up by Lion, a new variety which, according to its breeder Elsoms, combines excellent kernel content and hullability, together with stiff straw and good agronomic package. With seed in short supply, we drilled the crop on 15 March at just 100kg/ha and to date it has only received 50kgN/ha, although another 50kgN/ha will go on shortly taking the total to 100kgN/ha. ‘Lion’, a new variety of spring oats, looks good despite a sowing rate of just 100kg/ha and little rain when this photograph was taken on 18 May.

Even with very little rain since it was drilled the crop looks excellent and last week I went through with a Claydon TerraBlade inter-row hoe to take out grassweeds growing between the band-sown rows before they had a chance to develop and compete with the spring oats. Growing conditions have been much the same as last year when this low input crop achieved over 7t/ha with excellent margins, so I am optimistic that it will produce excellent results.

And finally!

After 44 years’ service the roof at Gaines Hall, our Grade II listed 16th Century farmhouse, is being rethatched, this time with wheat straw supplied by accredited master thatcher Harry Roberts of Harry Roberts Thatching Services. Harry is one of the very few who grows his own straw, enabling him to offer a comprehensive field to roof service and ensuring the quality of materials is as high as it can be. He uses straw from Maris Widgeon, now a heritage variety, which was originally developed in 1964 by the Plant Breeding Institute at Trumpington near Cambridge and has traditionally been used for thatching in the UK.

We chose Harry to do the job because he specifies that his straw crops are drilled with a Claydon drill. When I visited the farm which his brother-in-law Sam Clear owns to see it being produced Harry explained that sowing the crop in bands results in the wheat stems being much thicker, more resilient and of higher quality than those drilled at the conventional spacing. The crop is cut with a binder, stood in stooks for two weeks, then threshed in the traditional way to produce the best quality straw for thatching.

Harry is due to complete the work at Gaines Hall in June, so I am looking forward to seeing the final result. I will include a photograph of the finished product in the next issue of Direct Driller, as well as discussing the harvest and our plans for the season ahead.