INDEPENDENT CROP ESTABLISHMENT TRIALS YIELD EXCITING RESULTS

Suffolk farmer Jeff Claydon highlights the results of independent crop establishment trials and discusses the

progress of harvest on the Claydon farm.

26 AUGUST 2021

In my last article for Direct Driller (Issue 14, July 2021) I promised to bring you some interesting information on the benefits of optimising crop establishment. Claydon have been assisting Agrii’s R&D Blackgrass Centre in Cambridgeshire with independent research into different establishment systems and some of you will have visited Rookery Farm, Stow Longa during the summer to see the work taking place. The trial site is on land owned by the Whitlock family, who have successfully used a Claydon drill to help them operate profitably for over a decade. Located on an old airfield near Huntingdon, it can be very wet and cold, providing ideal conditions for a range of grassweeds, from brome to blackgrass. Obtaining good, clean crops is a real challenge, but Martin Whitlock has proved that Claydon Opti-Till® is a major benefit in achieving that objective.

Agrii have carried out trials at Stow Longa since 2002, initially to investigate the effects of variables such as seedbed techniques, seed rates, drilling dates and varieties. However, in 2010 the researchers’ remit was expanded to include factors such as cultural control methods and the impact of establishment techniques. In May 2021, along with other members of the Claydon team, I went to see first-hand how establishment systems are evaluated. While we were there, Agrii Trials Manager Steve Corbett and Head of Agronomy Colin Lloyd emphasised the importance of operating a flexible farming system and a resilient method of establishment. They also stressed the critical role of soil health in achieving consistent crop performance and the need to make transitional changes between systems based on scientific evidence rather than ‘gut feel’. This, they stressed, is especially important when considering a low- or zerodisturbance system.

Even then, clear benefits in favour of the Claydon OptiTill® over conventional deep cultivation methods and a no-till approach were evident. These advantages continued through to harvest, so now we have the results of the Agrii team’s work to assess the performance of different systems in a high grassweed situation. Agrii evaluated a range of approaches, from no cultivations to the full Claydon Opti-Till® programme, including the use of the Claydon Straw Harrow, TerraStar light rotary cultivator and TerraBlade inter-row hoe in the spring to reduce blackgrass levels. The results are illuminating and with Agrii’s permission I am delighted to share them with you.

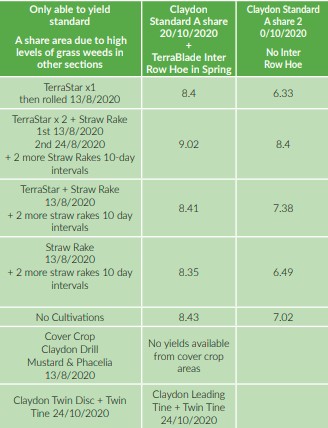

On the very heavy, sticky site the researchers found some surprising results, which are shown in Table 1. Even though a full chemical control programme was used across all trials it was very apparent that the lower the level of stubble management carried out, the higher the weed pressures were in the crop. Where no stubble management was done the yield was over 2t/ha less than where the full Claydon Opti-Till® System was used. At current wheat prices, around £210 per tonne, that represents potential lost income of over £420/ha.

Table 1: Agrii trial of Claydon Opti-Till® System at Stow

Longa, 2020-2021

The full benefit of the Claydon Opti-Till® System can be seen where the Straw Harrow and TerraStar were used. The increased tilth and better soil-to-seed contact which resulted also helped the Claydon TerraBlade to do an exceptional job in the spring, as can be seen clearly from the results. They also show that the TerraBlade is exceptionally effective in reducing the number and yield-sapping effect of weeds between the band-sown rows. It produced an additional 1.4t/ ha yield advantage (9.02 t/ha v 8.4 t/ha) through enhanced grassweed control, which underlines the value of this very effective, low-cost method of supporting existing ag-chem programmes.

Even where a full stubble management system was used, including two passes with the TerraStar, fuel use with the OptiTill® System was still under 20 litres/ha, less than 20 per cent of a conventional crop establishment system, which helps to minimise carbon emissions. We would like to thank Colin Lloyd, Steve Corbett and all the Agrii team for their input on this valuable work.

Oilseed rape returns

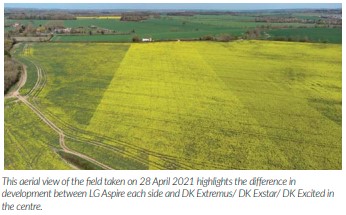

In the July issue of Direct Driller, I mentioned the excellent progress of oilseed rape being grown on the Claydon farm this season, a crop we had to stop growing for three years because of damage caused by cabbage stem flea beetle. For the 2021 harvest we drilled four varieties, LG Aspire, an exceptional conventional rape, together with three hybrids, DK Exstar, DK Excited and DK Extremus, the latter two having TuYV resistance, a major consideration given its increasing prevalence. All were sown at the same time and received the same inputs.

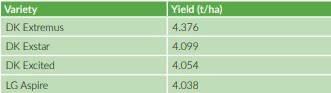

The photograph shows how much stronger the hybrids looked compared with the conventional variety in April and throughout the season they showed greater vigour. In contrast, the conventional variety was slow growing and suffered from frost damage, reducing yield in those areas. Surprisingly, however, at harvest when we compared weighbridge yields from adjoining strips in the field, all had achieved virtually the same yields (Table 2).

Table 2: Comparison of yields from different oilseed rape

varieties.

Evidently, the LG Aspire came back in the race and ultimately performed extremely well, although we still feel that hybrids are stronger and will deliver better performance in adverse areas or conditions. All varieties suffered some damage from cabbage stem flea beetle, but with oilseed rape prices at high levels they will provide very good returns.

A stop-start harvest

This has been a stop-start harvest, with measurable rain for eight consecutive days from 15th to 23rd August. Fortunately, the preceding hot, dry weather allowed us to work very long hours and combine until early in the morning. From 8pm on Friday 13 until 10pm on Sunday 15th August we harvested 1150 tonnes of wheat from 300 acres, including all 250 acres of winter wheat where we wanted to drill this season’s oilseed rape. We finished just as it started to rain on the Sunday evening.

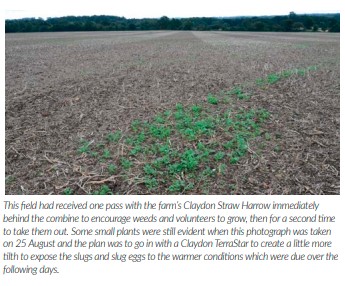

The following day, 16th August, we started drilling DK Excited oilseed rape at a very low seed rate, just 2.7kg/ha, into the chopped straw and stubble with our 6m Claydon Drill. Although 5mm of rain stopped play on the Tuesday, we completed the balance by the close of play on Wednesday. The first cotyledons poked through the surface five days later and we applied 4kg/ha of Ironmax® Pro (De Sangosse) slug pellets to deter any slugs that were undoubtedly there due to the moist soil conditions.

Dealing with slugs and slug eggs effectively is key to success with the following crop of winter wheat, so after harvest I regularly check fields when the soil is damp to see what is about. If you clear away residue that hasn’t been moved for several days both slugs and slug eggs will be evident. In the early days of the Claydon System we had big problems with slugs if we simply ignored them and didn’t do any stubble management, so that quickly became a cornerstone of postharvest operations on the Claydon farm. We can’t use slug pellets like we used to, and even though the new iron-type pellets are effective we don’t want to rely on chemicals, so the aim is to take out as many slugs and slug eggs as possible using cultural and mechanical methods.

The cold, dry April made for a tough start to spring and delayed growth, but all our crops looked very promising from then on. We could have done with warmer, sunnier weather in June to help fulfil that early promise, but that was not forthcoming and restricted yield potential, so this harvest is merely average rather than spectacular as we had hoped.

The weather is forecast fine for the next few days, so hopefully we will be able to crack on with combining and stubble management to get back on track. I’ll tell you how our wheat and spring oats performed in the next issue of Direct Driller, along with details of what impact, if any, cover crops had on spring oat yields.