MORE STRINGS TO HIS BOW, MARTIN LOLE DISCUSSES HIS NEW IPASS DIRECT DRILL AND HOW IT COMPLIMENTS HIS EXISTING STRIP TILLAGE OFFERING.

Having a long history in designing and manufacturing agricultural equipment, from founding Spearhead when I was 30, going on to Mzuri Drills, and more recently the Razorback range, I am always striving to push the envelope in design and looking for innovative solutions for changing markets.

This passion is what led me to my latest development, the iPass direct drill which was launched earlier this year and demonstrated to the public for the first time at Groundswell and Cereals. I was pleased with the positive feedback we received, and whilst naturally the change in colour was questioned, it was important to me to send a clear message that this is a very different type of drill. When designing the iPass to complement the existing Mzuri range, I focused on producing a machine that could offer high output seeding, in a simple, accurate format whilst allowing operators the freedom to choose between strip tillage, direct drilling, and more conventional seeding as and when their drilling campaigns required.

Comprising of a leading spring-loaded disc, breaker leg and a clever parallel linkage assembly supporting the seeding coulter, adjustment of the drill couldn’t be more simple. The leading spring-loaded disc cuts through the previous crop residue and minimises surface disturbance followed by the auto-reset breaker leg that features replaceable point and wings to till the seeding zone and deliver fertiliser into the seedbed. This combination delivers a clean, residue free tilled zone and by simply adding or removing ram stops on the main lift ram, operators can easily adjust the extent and depth of cultivation.

The coulter assembly features a very simple adjustment lever to set the seeding depth in relation to the rear press wheel and once set, the seeding depth will remain consistent regardless of the depth setting for the breaker leg. This is a feature which is not commonly seen on drills in the current market, but it is one that I think is important when considering the accuracy needed for optimum establishment and when working with products such as preemergence herbicides.

Once seed is delivered into the zone created by the front leg, V-shaped press wheels ensure perfect soil to seed contact and reconsolidation. The whole assembly has been designed to offer minimal disturbance whilst still achieving an optimum seeding environment, something that I am very excited about. Following the seeding assemblies, a double harrow evens the field surface and if there is a lot of crop residue present, a second pass of our Mzuri Rezult harrow or a set of paddle rolls can work exceptionally well.

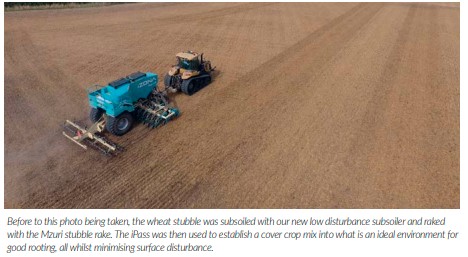

Typical examples of crop establishment trials during this past month includes establishing Oilseed Rape into Spring Barley, Winter Barley and Spring Wheat stubbles. We have established the OSR into multiple variations of pre-drilling field preparations, varying from direct drilling into untouched stubbles, drilling into stubbles that have been raked with the Mzuri Rezult, and finally into stubbles that have been subsoiled with our new low disturbance subsoiler and raked. From this we were able to see that the iPass was equally as happy drilling into all three scenarios and to conserve moisture, all fields were finished with a paddle roll.

Our trials involving pre-subsoiling stubbles followed by the iPass has been inspired from the growing popularity to couple low disturbance subsoiling with a one pass drill. It is a trend that we have seen developing, particularly where growers are looking for a quick, efficient and failproof system to establishment on a large scale and is why we have developed our new low disturbance subsoiler to compliment the range. With a leg spacing of 500mm and a generous stagger of 750mm, the new subsoiler will cope in high residue situations and glide through ground, lifting the soil profile while minimising surface disturbance. ‘Hammer-thru’ Shearbolts rather than a hydraulic reset system maintains the wing at the right angle to get the correct amount of disturbance, with the minimal amount of pulling power. It is a recognised problem with auto-reset that if the leg drags backwards, it dramatically increases the horsepower requirements, therefore reducing the efficiency of the machine. The rear packer puts the field back down level, with rings concentrated closely to either side of the legs, again to get maximum efficiency from the packer.

In situations where a lot of surface straw is present, or where the combine has not done a very good job of spreading it evenly, I have found that using our Rezult Rake to even it before drilling is a useful tool, particularly in the fight against weeds. By mixing a little surface tilth with the straw it not only aids breakdown, but also encourages a flush of weeds and volunteers. All that is left is to go straight in with the drill and it makes for a quite superb system. Going back to the iPass drill, on both my own farm and that of willing neighbouring land, I have found the system to work very well in both clay and sandy soils. The drill offers the flexibility to choose how much tilth to create and what depth to apply fertiliser. Everyone that has seen it comments on how easy it is to set up, by simply unfolding the wings and off you go. As I said before if you don’t like the cultivation depth just change the ram stops, it couldn’t be easier.

The coulter and breaker leg assemblies are mounted in front of the axle to allow for good visibility from the cab but to also ensure that the tines are being presented with an even field. Something that I also wanted to incorporate with a drill of this size was a means to adjust the draft when going up a steep hill or in hard going. The load transfer system incorporating weight transfer wheels to the front work in conjunction with the tractors lower link sensors and picks up on changes as you go along, lifting the drill up in tough going all while not changing seed depth.

It was also important to me to accommodate those operators who will be drilling anywhere from 12 – 15kph. To achieve accurate seed metering at high speeds, the 7000L tank is pressurised alongside four capable metering units (two for fertiliser and two for seed), to ensure accuracy isn’t compromised in exchange for higher working speeds. The output of this drill is truly phenomenal, and the simplicity and accuracy alongside even germination is what makes this a really special machine. The iPass is undoubtedly very happy as a one pass direct drill and is equally at home drilling into subsoiled ground – it ticks all the boxes. It also allows growers to achieve minimal disturbance to deliver on their soil health ambitions whilst avoiding problems commonly associated with disc drills, such as hair pinning, slotting and the requirement for ground to be in an almost perfect condition from the start.

Compared to our popular Mzuri ProTil, I absolutely believe that there is room for both drills depending on the customer’s needs. By moving less soil than the Mzuri Pro-Til, the iPass can be six and eight metres wide and requires less power per working metre. Whereas if someone wants to work with a lot of dense residue and cover crops, strip tillage remains a solid choice. The Pro-Til is very efficient at working in high residue situations and achieves excellent light interception between crop rows. The iPass can strip till if required, but with both 250mm or 330mm row spacings available we are seeing exciting progress with drilling crops with the iPass slightly closer together, to a create a more conventionally drilled look.

The iPass will continue to be extensively trialled throughout the UK and interest is already gaining momentum for the first production run starting at the end of this year. In the meantime, for those growers looking for a smaller drill, or a purely strip tillage machine, the Mzuri Pro-Til remains the best choice on the market.