JOHN DEERE – FUTURE OF FARMING

Changes in weather patterns are just one of many challenges farming is facing. John Deere is investing huge resources into solving these challenges. Three core technologies are shaping the future: Electrification, Automation to Autonomy and Artificial Intelligence.

Electrification

Electrification isn’t just about using batteries as the power source. It’s about using electrical drives to replace engines and hydraulics. Electric motors have huge torque at low speeds, they’re more efficient, more reliable and lighter.

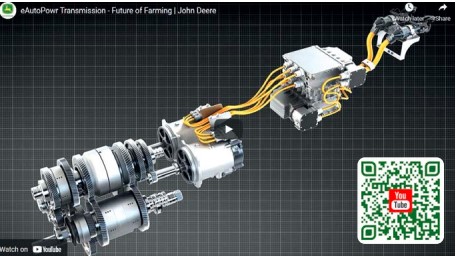

eAutoPowr transmission: eAutoPowr is the first continuously variable transmission with an electromechanical power split. Compared to conventional CVTs, the drive is more efficient and wear-free. Another special feature is the provision of up to 100kW of electrical power for external consumption. To demonstrate this, John Deere and Joskin have developed a slurry tanker with two electric drive axles. Thanks to this eight-wheel drive system, a much more efficient transmission of tractive power is possible. This can also reduce slurry incorporation costs by up to 25 per cent.

VoloDrone – The large drone developed jointly by John Deere and Volocopter has a diameter of 9.2 m and is powered by 18 rotors. It has a fully electric drive with replaceable lithium-ion batteries. One battery charge allows a flight time of up to 30 minutes, and the VoloDrone can be operated both remotely and automatically, on a preprogrammed route. The drone frame is equipped with a flexible standardised payload attachment system. This means that different devices can be mounted on the frame, depending on the application. For crop protection, the large drone is equipped with two liquid tanks, a pump and a spray bar. Thanks to the low flying height, very large area coverage of up to 6ha/hr can be achieved.

Autonomy through automation

The focus of automation is not to replace the operator. It’s about using technology to create the best operator possible. The journey began with hands-free AutoTrac satellite guidance to steer the machine. Now we have Integrated Combine Adjust on our S700 combines which makes real-time automatic adjustments to maintain the pre-set levels.

Autonomous electric tractor – John Deere’s new autonomous tractor concept is a very compact electric drive unit with integrated attachment. The tractor has a total output of 500 kW and can be equipped with either wheels or tracks. Flexible ballasting from 5 to 15 tonnes is possible, depending on the application, to help reduce soil compaction. Thanks to the electric drive, there are no operating emissions and noise levels are extremely low. Further advantages include low wear and maintenance costs.

Semi-autonomous tractor – This tractor drives semi-autonomously and is equipped with an integrated crop sprayer. Using a built-in camera, it is possible to work in row crops – for example, applying plant protection products to fruit tree orchards. Filling the sprayer tank is fully automatic at the filling station, so the user is not exposed to pesticides. This is designed to reduce costs and increase productivity by over 30 per cent.

Autonomous sprayer – This novel autonomous sprayer is lighter than a conventional self-propelled sprayer and has a 560 litre spray tank. It can enter fields after rain without causing any soil compaction. The high ground clearance of 1.9 m and four-wheel steering make it extremely versatile, while the tracks minimise ground pressure and greatly extend the operating window.

Artificial Intelligence

Artificial Intelligence is changing the way we spray.

See & Spray – With See & Spray technology, high-resolution cameras capture 20 images per second. Based on the images and artificial intelligence, the system recognises the difference between cultivated plants and weeds so that individual plants can be specifically treated.

With this new generation of weed control, the use of pesticides can be greatly reduced.

CommandCab – Whatever happens in the future, the farmer will always be in control. Our Command Cab shows how the journey from Automation to Autonomy is likely to evolve. The future vision of a driver’s cab reveals new possibilities for artificial intelligence. With its joystick control, touchscreen display and networking of all machine components, it´s a completely new operating concept. By integrating real-time weather data, individual pre-settings and job management procedures, the cab becomes the command centre for agricultural operations.