With catchy weather windows often forcing growers to put bigger, more complex mixes in the tank, careful preparation is key to avoid a disaster.

“If we look at weather we’ve seen this last year alone, it has been incredibly inclement and often left spray operators with just a day or two to get a lot done,” says Stuart Sutherland, technical manager at Interagro. “With such tight windows comes ‘larger-thanideal’ mixes – which heightens the risk of a problem. Mixing in cold water, at high pH and with hard water makes mixing troublesome.”

As well as ensuring products are compatible and best practice is followed, Stuart says a compatibility adjuvant can help overcome

some of the challenges. ‘If we take Kantor for example it contains a self-emulsifying agent that makes agricultural chemicals more compatible with each other, preventing undesirable interactions and ensuring that multiple products can be used effectively in a single application.”

“Adding micronutrients into the mix can be particularly tricky, but compatibility testing has shown Kantor helps them to dissolve, alleviating flocculation and sedimentation so they can be absorbed fully by target plants.”

Stuart’s top tips for avoiding a disaster in the tank-mix:

1 – Periodically inspect agitation system for wear and tear and ensure any worn parts are replaced

2 – Ensure the sprayer is scrupulously clean before starting

3 – Half fill the spray tank with water before adding any products

4 – Maintain good agitation throughout the filling process

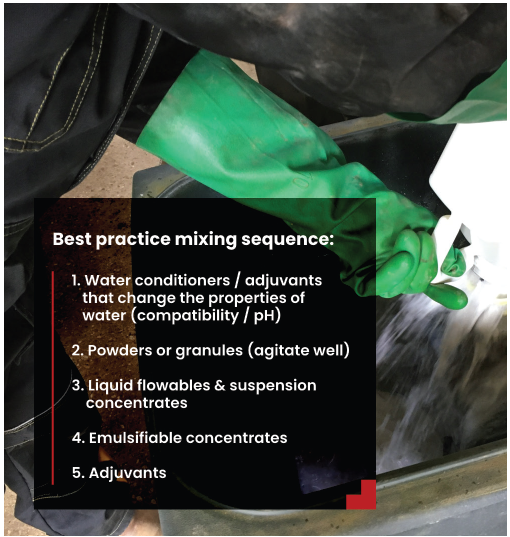

5 – Always mix products in the correct order – ensure product labels are referred to and always follow guidance. Carry out a jar test if you’re unsure of compatibility

6 – Add compatibility adjuvant Kantor (at rate of 0.15% v/v) if water is cold and/or adding more than three products into the tank, to help products dissolve. Kantor will buffer to optimal pH

7 – Add more water as products are added

8 – Make sure concentrates do not come in to contact with each other in the induction bowl and allow one product to completely clear the induction bowl before adding the next one

9 – Check slow to dissolve formulations like wettable powders and water dispersible granules are in solution before adding more

10 – Only mix up what you need – never leave a mixed solution in the spray tank overnight

11 – Clean the sprayer thoroughly between jobs