Factors that could be reducing your crop protection efficacy through the season

Spraying delays / spray drift

Timely on-target application is crucial for crop protection efficacy, but spray drift is a risk to every application. It can stop you spraying all together, may damage off-targets and risks some spray targets being underdosed and others over-dosed.

Applications most susceptible to drift include:

Pre-emergence herbicides – Can be high risk due to bare soils that release stored heat causing air/spray to rise, and there being no crop to intercept the spray.

Post-emergence herbicides – Most herbicides are applied as a fine-medium quality. The smaller droplets provide better coverage, which is important when the target surface is small, but fine droplets are prone to drift.

Increased forward speed – Can impact boom height and stability. Spray drift doubles when the spray boom is raised from 40cm to 70cm, and again from 70cm to 80cm.

Poor coverage and retention in the soil

For residual herbicides, the target is the soil and making sure it is in position to be taken up by weeds that germinate in that critical top 5cm can be a challenge.

Rain after application – With heavy rainfall after application, a high percentage of residual herbicides can move out of the weed zone. Chemical leaching is particularly problematic with the stacking of residual herbicides late in the autumn, when soils become saturated with prolonged spells of heavy rain.

Lack of moisture after application – At the other end of the spectrum, a lack of moisture and dry conditions can also cause residual herbicides to fail as moisture plays a crucial role in herbicide activation and uptake.

Poor coverage and retention on the plant

Good coverage of plant surfaces is crucial for protectant fungicides and contact herbicides to work effectively. While coarse spray droplets can cause droplet bounce, high surface tension prevents the spreading of droplets on plant surfaces, limiting both coverage and effectiveness.

This is exacerbated when:

• target plants are very waxy e.g. oilseed rape, Fat-Hen.

• target plants have tricky surfaces eg. wheat ears, awns.

• plants have hairy/prickly surfaces e.g. bromes, nettles.

• low water volume spraying.

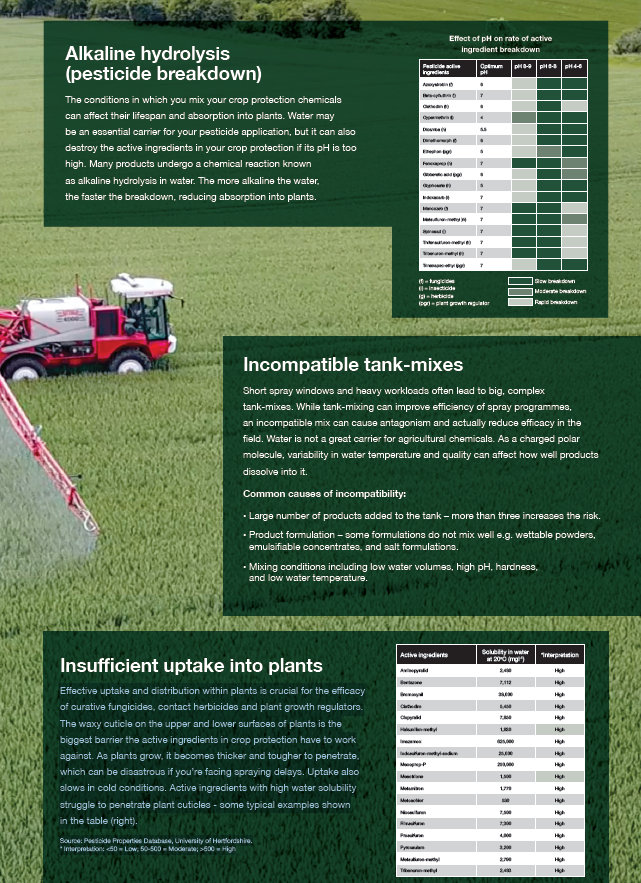

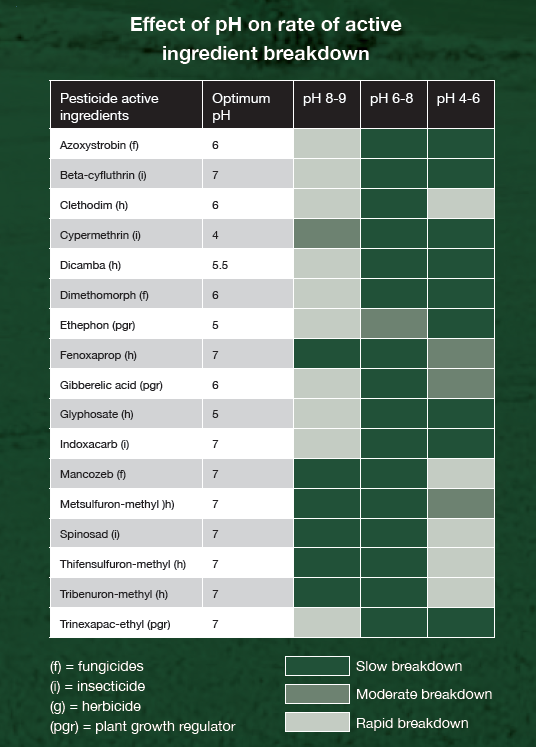

Alkaline hydrolysis (pesticide breakdown)

The conditions in which you mix your crop protection chemicals can affect their lifespan and absorption into plants. Water may be an essential carrier for your pesticide application, but it can also destroy the active ingredients in your crop protection if its pH is too high. Many products undergo a chemical reaction known as alkaline hydrolysis in water. The more alkaline the water, the faster the breakdown, reducing absorption into plants.

Incompatible tank-mixes

Short spray windows and heavy workloads often lead to big, complex tank-mixes. While tank-mixing can improve efficiency of spray programmes, an incompatible mix can cause antagonism and actually reduce efficacy in the field. Water is not a great carrier for agricultural chemicals. As a charged polar molecule, variability in water temperature and quality can affect how well products dissolve into it.

Common causes of incompatibility:

• Large number of products added to the tank – more than three increases the risk.

• Product formulation – some formulations do not mix well e.g. wettable powders, emulsifiable concentrates, and salt formulations.

• Mixing conditions including low water volumes, high pH, hardness, and low water temperature.

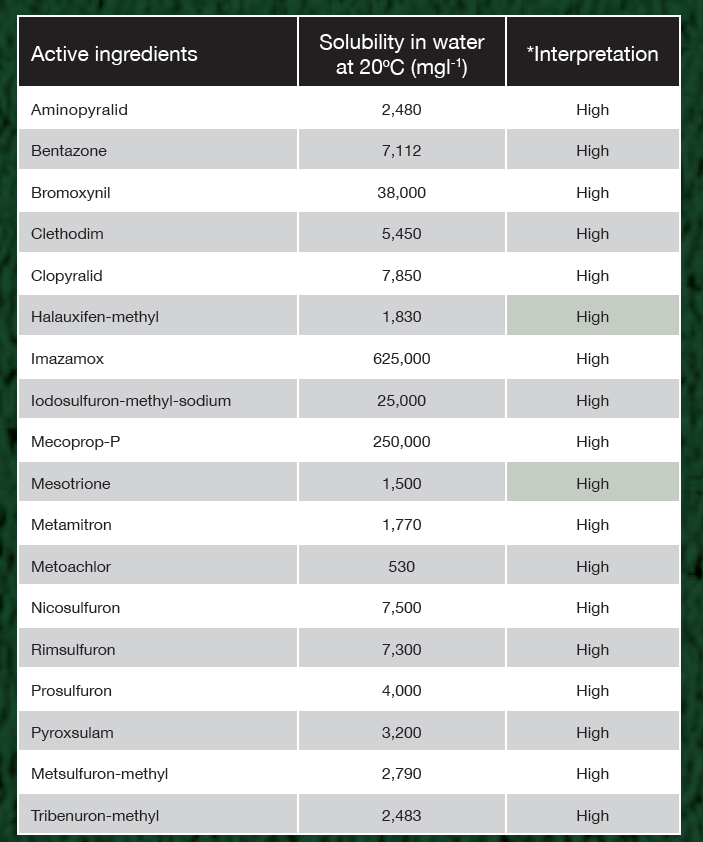

Insufficient uptake into plants

Effective uptake and distribution within plants is crucial for the efficacy of curative fungicides, contact herbicides and plant growth regulators. The waxy cuticle on the upper and lower surfaces of plants is the biggest barrier the active ingredients in crop protection have to work against. As plants grow, it becomes thicker and tougher to penetrate, which can be disastrous if you’re facing spraying delays. Uptake also slows in cold conditions. Active ingredients with high water solubility struggle to penetrate plant cuticles – some typical examples shown

in the table (right).

Source: Pesticide Properties Database, University of Hertfordshire. Interpretation: <50 = Low; 50-500 = Moderate; >500 = High