If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

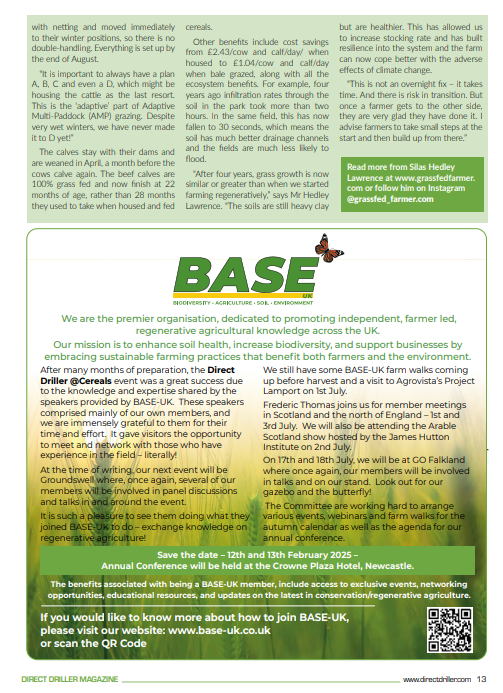

Fentech Agri – TS-600 AP

Find out the latest from Thom Graham from Fentech Agri / Simtech about their latest drill on the market, the TS-600 AP . Overall, the agricultural industry is feeling the pressure from uncertainty, particularly regarding government changes, growing issues with weeds—especially brome and blackgrass due to the mild weather—and adjustments to the SFI schemes, which paradoxically seem to discourage food production. However, rather than simply hunkering down and waiting for the storm to pass (whenever that may be), forward-thinking businesses are adapting to the changing environment—physically, environmentally, and financially. Fentech Agri is playing a pivotal role in facilitating this adaptation by offering a wide range of machinery tailored to customers’ needs.

Driven by FETF regulations, such as requirements for fertilizing in the slot and drilling into cover crops, our seeder range has significantly expanded and evolved over the past 12 months. What started as 8 basic models has grown to 20 baseline seeders, all of which can be customized with various applicators, add-ons, and control system options. While manufacturing such a broad range is something we typically aim to avoid, the current agricultural landscape makes it clear that a one-size-fits-all approach no longer works. Marginal gains can only be achieved through the use of highly specific equipment.

The recent adoption of Horizon metering systems on the folding drill and front hopper ranges has opened up new design possibilities due to the system’s compactness and simplicity. Dual product options are now available on all but the most basic box hopper seeders, without significantly increasing costs.

In addition, we’ve opted to integrate Farmscan Ag Ltd’s control system, which is by far the most intuitive and flexible system we’ve encountered. This system has the potential to elevate seeding operations, offering the ability to easily add or change inputs and outputs to suit specific needs. The tablet-based control system, with its large, rugged screen, provides superior monitoring and metering control. Clear graphical warnings and settings help reduce operator stress, while features such as wireless calibration make the process more efficient. Operators can now calibrate the machine using a mobile phone connected to the system, further enhancing convenience and efficiency.

For our more basic box hoppers, we’ve integrated the same control system with an electronic motor drive option, replacing the traditional ground-driven drive wheel. This “e-drive” system is retrofittable to all basic mechanical seeders in the Fentech Agri/Simtech range or can be specified for new builds. The benefits include more consistent seeding rates, more accurate calibration (within 2% of the set point), real-time monitoring and rate adjustments from the cab, and compatibility with variable rate maps.

While seeders remain our core business, centered around the Simtech drill brand, we’ve also been focusing on soil preparation prior to seeding. Establishing stale seedbeds is a crucial aspect of weed control. Our new 6m Phoenix mounted machine, featuring 16mm straw-type tines, disturbs as much soil as possible, while the rubber roller consolidates the seedbed and ensures seed-to-soil contact. Establishing a stale seedbed before seeding is essential for effective weed management. Alternatively, early-sown cover cropping can also help minimize weeds, even in the driest conditions, with the Simtech tine generating a tilth where it might otherwise seem impossible.

Alongside the Phoenix, we are also introducing our first in-house subsoiler, which utilizes the Metcalfe NG ultra-low disturbance system. This technology, proven over several years, provides flexibility to work at varying depths and widths. The system breaks up problem pans and fractures the soil vertically, allowing roots to grow more freely. You can see this in action at Tillage Live on September 18th, with a simple shear-bolt, 3m format.

Needless to say, it has been a costly year, with our R&D budgets significantly exceeded. However, the result is a far broader range of products, possibly offering the most bespoke seeder solutions available for various conditions on the market today. As always, our technical team is available to discuss how we can help improve your efficiency and capitalize on the changing agricultural landscape to make your business more profitable.

-

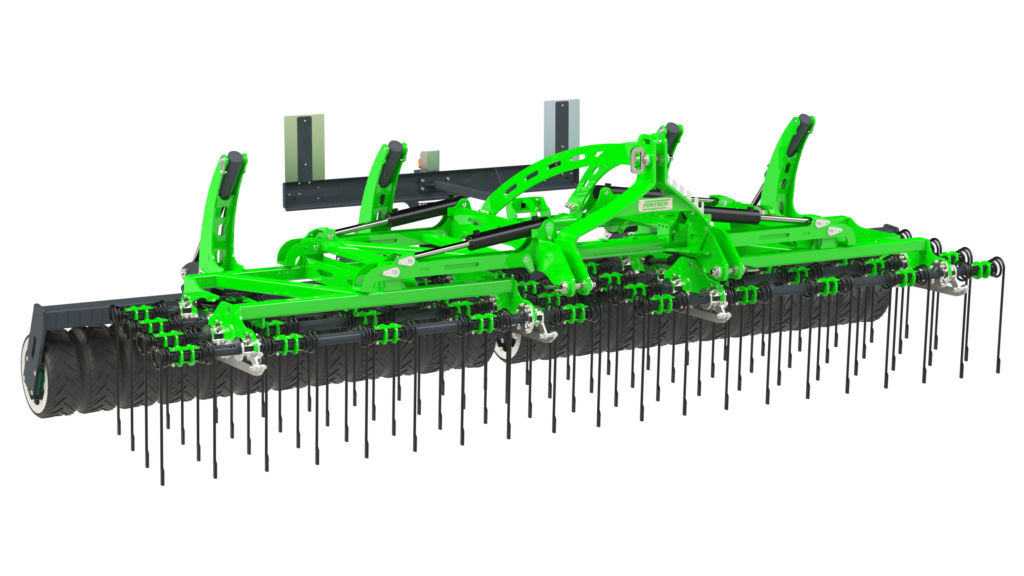

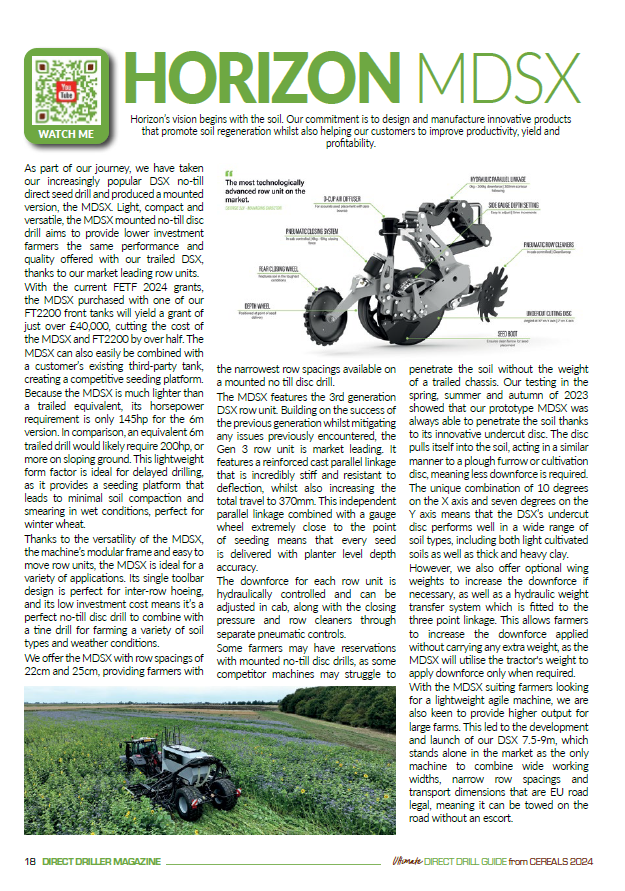

Horizon MDSX

Charlie Eaton gives a detailed insight of the latest MDSX mounted direct disc drill and FT2200 dual front hopper Horizon’s vision begins with the soil. Our commitment is to design and manufacture innovative products that promote soil regeneration whilst also helping our customers to improve productivity, yield and profitability.

As part of our journey, we have taken our increasingly popular DSX no-till direct seed drill and produced a mounted version, the MDSX. Light, compact and versatile, the MDSX mounted no-till disc drill aims to provide lower investment farmers the same performance and quality offered with our trailed DSX, thanks to our market leading row units.

With the current FETF 2024 grants, the MDSX purchased with one of our FT2200 front tanks will yield a grant of just over £40,000, cutting the cost of the MDSX and FT2200 by over half. The MDSX can also easily be combined with a customer’s existing third-party tank, creating a competitive seeding platform.

Because the MDSX is much lighter than a trailed equivalent, its horsepower requirement is only 145hp for the 6m version. In comparison, an equivalent 6m trailed drill would likely require 200hp, or more on sloping ground. This lightweight form factor is ideal for delayed drilling, as it provides a seeding platform that leads to minimal soil compaction and smearing in wet conditions, perfect for winter wheat.

Thanks to the versatility of the MDSX, the machine’s modular frame and easy to move row units, the MDSX is ideal for a variety of applications. Its single toolbar design is perfect for inter-row hoeing, and its low investment cost means it’s a perfect no-till disc drill to combine with a tine drill for farming a variety of soil types and weather conditions.

We offer the MDSX with row spacings of 22cm and 25cm, providing farmers with the narrowest row spacings available on a mounted no till disc drill.

The MDSX features the 3rd generation DSX row unit. Building on the success of the previous generation whilst mitigating any issues previously encountered, the Gen 3 row unit is market leading. It features a reinforced cast parallel linkage that is incredibly stiff and resistant to deflection, whilst also increasing the total travel to 370mm. This independent parallel linkage combined with a gauge wheel extremely close to the point of seeding means that every seed is delivered with planter level depth accuracy.

The downforce for each row unit is hydraulically controlled and can be adjusted in cab, along with the closing pressure and row cleaners through separate pneumatic controls.

Some farmers may have reservations with mounted no-till disc drills, as some competitor machines may struggle to penetrate the soil without the weight of a trailed chassis. Our testing in the spring, summer and autumn of 2023 showed that our prototype MDSX was always able to penetrate the soil thanks to its innovative undercut disc. The disc pulls itself into the soil, acting in a similar manner to a plough furrow or cultivation disc, meaning less downforce is required.

The unique combination of 10 degrees on the X axis and seven degrees on the Y axis means that the DSX’s undercut disc performs well in a wide range of soil types, including both light cultivated soils as well as thick and heavy clay.

However, we also offer optional wing weights to increase the downforce if necessary, as well as a hydraulic weight transfer system which is fitted to the three point linkage. This allows farmers to increase the downforce applied without carrying any extra weight, as the MDSX will utilise the tractor’s weight to apply downforce only when required.

With the MDSX suiting farmers looking for a lightweight agile machine, we are also keen to provide higher output for large farms. This led to the development and launch of our DSX 7.5-9m, which stands alone in the market as the only machine to combine wide working widths, narrow row spacings and transport dimensions that are EU road legal, meaning it can be towed on the road without an escort.

-

John Deere drill work in all conditions

John Deere tell us about the John Deere 750A drill 6m width in the drill arena for Direct Driller at Cereals The 750A All-Till seed drill is available in 3, 4 and 6m versions. This versatile drill has a field proven Accord air seeding system, and is designed with large clearances for no-till drilling into stubble, working after minimum or conventional cultivations, and single pass operation for grassland and rough pasture renovation.

Single pass drilling offers several advantages over a conventional ploughing regime, including lower establishment costs, reduced nitrate leaching and increased conservation of moisture within the soil. In addition, the 750A’s no-soil disturbance at the point of drilling offers huge benefits for the control of blackgrass.

The 750A requires a minimum of 80 to 140hp and can work at up to 6ha/hr, depending on conditions, at seeding depths from 13 to 90mm. Seed is applied at a rate of 1 to over 400kg/ha via a central 1800-litre hopper and single metering system on the 3 and 4m units, or a 2300-litre hopper and twin metering units on the 6m model, which folds down to 3m for transport.

A single 46cm angled disc opens the furrow at 16.6cm row spacings, and has a depth gauge wheel mounted alongside to provide excellent seeding depth control. A semi-pneumatic press wheel pushes the seed to the bottom of the furrow for perfect seed to soil contact, and a cast iron closing wheel completes the job. There are 18 openers on the 3m model, 24 on the 4m and 36 on the 6m version.

There is also adjustable hydraulic down pressure of up to 250kg on each furrow opener, to handle the toughest soil and crop residue conditions – typically this would be below 50kg for most situations. This means the drill delivers consistent seed depth and excellent seed to soil contact for maximum germination. Fore-to-aft clearance is 1.2m, and under-frame clearance 60cm, to allow a virtually unobstructed flow of crop stubble and soil residues through the machine.

In operation, the 750A creates very little soil disturbance outside of the small slot opened by the single disc. This makes it ideal for drilling into stale seedbeds created for blackgrass control, where unnecessary soil movement could encourage further competitive weed seed germination and subsequent yield loss.

Other features include row marker and automatic tramline systems, micro metering for fine seeds, and an integral two-point hitch. All models incorporate hydraulically actuated brakes or an optional air braking system.

Drilling with new precision farming features

With the added benefits of John Deere precision farming technologies including DataSync, John Deere’s proven drill technologies ensure that drilling is more efficient and accurate than ever.

DataSync was introduced to the John Deere Operations Center last year to allow users to eradicate time taken to manually change records on each in-cab display, ensuring that stored field data is as accurate as possible, creating the most up-to-date and accurate field maps for drilling.

DataSync consistently provides the right setup information where it’s needed and at the right time. Field names, boundary changes, guidance tracks and flags can now be changed whenever and wherever at the press of a button and shared instantly across the fleet.

Real-time updates of where an operator’s drill has sown crops are accessible to the next machine to be used, such as a sprayer, which then can drive on the exact same path as the drill, increasing efficiency and accuracy.

Combining the enhanced efficiency thanks to DataSync and the precise seed placement of the 750A.

DataSync is free to activate and can be enabled or disabled for selected machines within the Operations Center, allowing team members differing levels of access. To us this feature, the machine must be equipped with a Gen4 display, JDLink modem, and an Operations Center account.

-

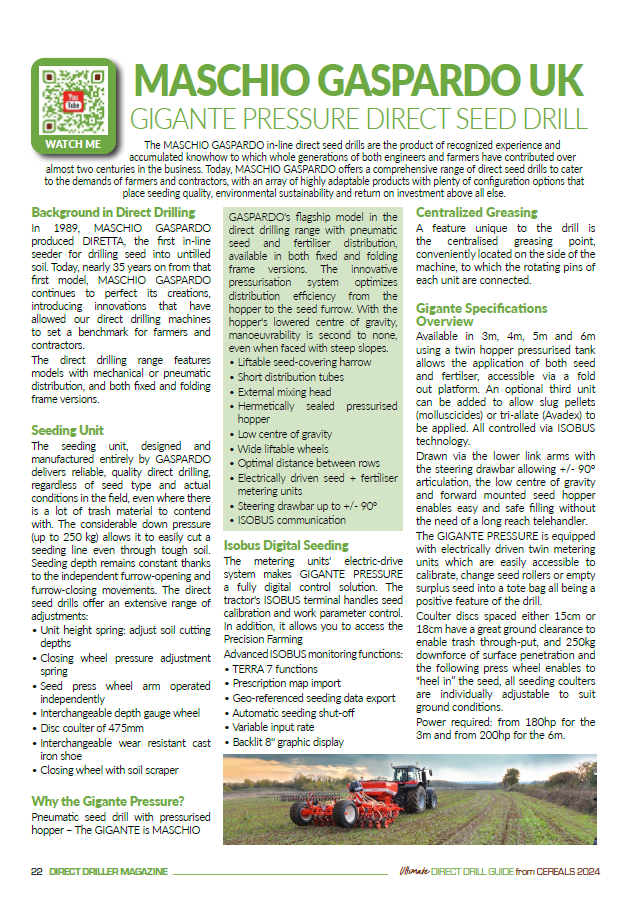

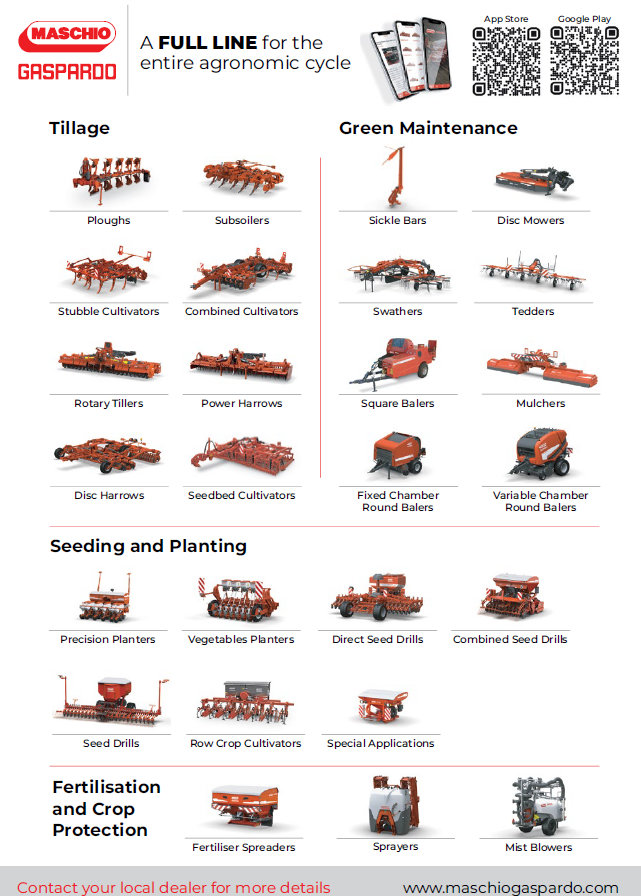

Maschio Gaspardo UK – GIGANTE PRESSURE DIRECT SEED DRILL

Mac Simpson from Maschio Gaspardo in the drill arena for Direct Driller at Cereals Event 2024 The MASCHIO GASPARDO in-line direct seed drills are the product of recognized experience and accumulated knowhow to which whole generations of both engineers and farmers have contributed over almost two centuries in the business. Today, MASCHIO GASPARDO offers a comprehensive range of direct seed drills to cater to the demands of farmers and contractors, with an array of highly adaptable products with plenty of configuration options that place seeding quality, environmental sustainability and return on investment above all else.

BACKGROUND IN DIRECT DRILLING

In 1989, MASCHIO GASPARDO produced DIRETTA, the first in-line seeder for drilling seed into untilled soil. Today, nearly 35 years on from that first model, MASCHIO GASPARDO continues to perfect its creations, introducing innovations that have allowed our direct drilling machines to set a benchmark for farmers and contractors.

The direct drilling range features models with mechanical or pneumatic distribution, and both fixed and folding frame versions.

SEEDING UNIT

The seeding unit, designed and manufactured entirely by GASPARDO delivers reliable, quality direct drilling, regardless of seed type and actual conditions in the field, even where there is a lot of trash material to contend with. The considerable down pressure (up to 250 kg) allows it to easily cut a seeding line even through tough soil. Seeding depth remains constant thanks to the independent furrow-opening and furrow-closing movements. The direct seed drills offer an extensive range of adjustments:

- Unit height spring: adjust soil cutting depths

- Closing wheel pressure adjustment spring

- Seed press wheel arm operated independently

- Interchangeable depth gauge wheel

- Disc coulter of 475mm

- Interchangeable wear resistant cast iron shoe

- Closing wheel with soil scraper

WHY THE GIGANTE PRESSURE?

Pneumatic seed drill with pressurised hopper – The GIGANTE is MASCHIO GASPARDO’s flagship model in the direct drilling range with pneumatic seed and fertiliser distribution, available in both fixed and folding frame versions. The innovative pressurisation system optimizes distribution efficiency from the hopper to the seed furrow. With the hopper’s lowered centre of gravity, manoeuvrability is second to none, even when faced with steep slopes.

- Liftable seed-covering harrow

- Short distribution tubes

- External mixing head

- Hermetically sealed pressurised hopper

- Low centre of gravity

- Wide liftable wheels

- Optimal distance between rows

- Electrically driven seed + fertiliser metering units

- Steering drawbar up to +/- 90°

- ISOBUS communication

ISOBUS DIGITAL SEEDING

The metering units’ electric-drive system makes GIGANTE PRESSURE a fully digital control solution. The tractor’s ISOBUS terminal handles seed calibration and work parameter control. In addition, it allows you to access the Precision Farming

Advanced ISOBUS monitoring functions:

- TERRA 7 functions

- Prescription map import

- Geo-referenced seeding data export

- Automatic seeding shut-off

- Variable input rate

- Backlit 8″ graphic display

CENTRALIZED GREASING

A feature unique to the drill is the centralised greasing point, conveniently located on the side of the machine, to which the rotating pins of each unit are connected.

GIGANTE SPECIFICATIONS OVERVIEW

Available in 3m, 4m, 5m and 6m using a twin hopper pressurised tank allows the application of both seed and fertilser, accessible via a fold out platform. An optional third unit can be added to allow slug pellets (molluscicides) or tri-allate (Avadex) to be applied. All controlled via ISOBUS technology.

Drawn via the lower link arms with the steering drawbar allowing +/- 90° articulation, the low centre of gravity and forward mounted seed hopper enables easy and safe filling without the need of a long reach telehandler.

The GIGANTE PRESSURE is equipped with electrically driven twin metering units which are easily accessible to calibrate, change seed rollers or empty surplus seed into a tote bag all being a positive feature of the drill.

Coulter discs spaced either 15cm or 18cm have a great ground clearance to enable trash through-put, and 250kg downforce of surface penetration and the following press wheel enables to “heel in” the seed, all seeding coulters are individually adjustable to suit ground conditions.

Power required: from 180hp for the 3m and from 200hp for the 6m.

For product enquiries, please contact: Alastair Hall, Product Manager, Maschio Gaspardo UK:

ahall@maschiogaspardo.com

-

Moore Unidrill Celebrates 50 Years of Innovation

Moore Unidrill stands out among the many exhibitors at Cereals 2024, marking a significant milestone – it’s 50th anniversary. With a rich legacy of innovation and excellence, Moore Unidrill unveiled the new MDH-1700 Dual Hopper, reflecting its continued commitment to perfecting the art of direct drilling.

Brook Whyles shows us the latest MDH1700 Grain and Fertilser Drill with a Guttler Packer in the Direct Driller at Cereals arena A Legacy of Innovation: Moore Unidrill’s 50-Year Journey

Founded in 1974 by Sam Moore, Moore Unidrill has been a pioneering force in agricultural machinery for five decades. The company’s history is marked by a series of groundbreaking innovations that have reshaped farming practices and increased efficiency. From its early days, Moore Unidrill has focused on developing direct drills that meet the requirements that farmers are looking for. Simple, reliable and time saving all whilst promoting sustainable agriculture.

There is one part on all Moore Unidrill’s that has stood the test of time. System Moore, the unique Moore Coulter design. This system introduced a new method of seed placement, ensuring optimal soil contact and improving germination rates. The Disc and Moore coulter cuts through, removes and spreads existing root and plant matter. The three-degree angled disc and 40mm coulter creates a harrowing and levelling effect; spreading dung, removing ruts and winter hoof damage. The unique coulter design creates a mini furrow opening in the ground which the seed can thrive in. This mini furrow allows air, water and nutrients to enter the soil thus improving soil health and drainage. The mini furrow created helps to shelter the young seedlings. The serrated disc cultivates the slot creating an ideal seed bed for the seedling to get its roots into the ground as well easy access upwards to light and oxygen. Hence, the System Moore remains a cornerstone of the company’s product line.

Introducing the MDH-1700 Dual Hopper: The Future of Farming

At the heart of Moore Unidrill’s presence at the Cereals event was the debut of the MDH-1700 Dual Hopper, a cutting-edge grain and fertilizer seed drill that embodies the company’s legacy of innovation. This state-of-the-art machine represents a new era in agricultural direct drilling technology, designed to meet the evolving needs of modern farmers.

The MDH-1700 Dual Hopper features a unique dual hopper system, allowing for simultaneous planting of either different types of seeds and or the application of fertilizers. This innovation significantly increases efficiency, reducing the time and labour required for planting and fertilizing tasks. The drill’s advanced precision technology ensures accurate depth and spacing control, optimizing seed placement and maximizing yield potential.

Designed with sustainability in mind, the MDH-1700 minimizes fuel consumption and soil disturbance, aligning with Moore Unidrill’s commitment to environmentally friendly farming practices. By integrating the latest technological advancements, the MDH-1700 Dual Hopper provides farmers with the tools they need to improve productivity.

Celebrating 50 Years of Excellence

Moore Unidrill’s 50-year anniversary is not only a celebration of its past achievements but also a reaffirmation of its dedication to the future of agriculture. The introduction of the MDH-1700 Dual Hopper is a testament to the company’s innovative spirit and its ongoing mission to provide farmers with high-quality, simple and time saving solutions.

Over the past five decades, Moore Unidrill has remained committed to addressing the challenges faced by farmers and the agricultural industry. The company’s success is rooted in its ability to adapt to changing technologies and market demands while maintaining its core values of simplicity, reliability and quality all whilst promoting sustainable agriculture.

Looking Ahead: Moore Unidrill’s Vision for the Future

As Moore Unidrill looks to the future, the company is poised to continue its legacy of innovation and excellence. The Cereals event provided an ideal platform for Moore Unidrill to showcase its latest advancements and engage with the farming community.

Moore Unidrill’s participation in the Cereals event underscores its commitment to staying at the forefront of the industry, providing farmers with the tools they need to succeed in an increasingly complex and demanding agricultural industry.

In conclusion, Moore Unidrill’s attendance at the Cereals event in 2024 is not only a celebration of its rich history but also a bold statement about its vision for the future. With the introduction of the MDH-1700 Dual Hopper and its continued dedication to innovation, Moore Unidrill empowers farmers with the technology they need to thrive in the years ahead, ensuring that its legacy of excellence endures for generations to come.

-

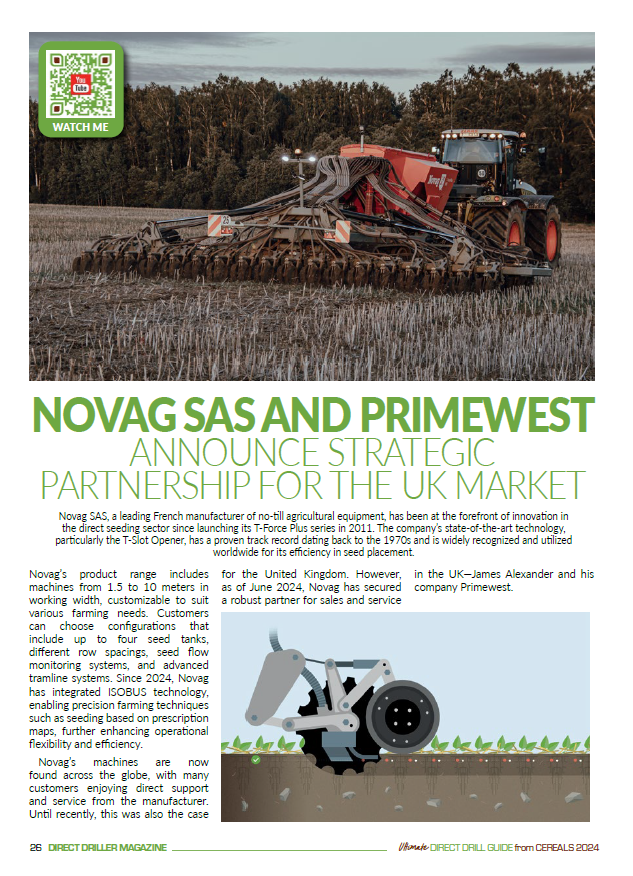

Novag SAS and Primewest Announce Strategic Partnership for the UK Market

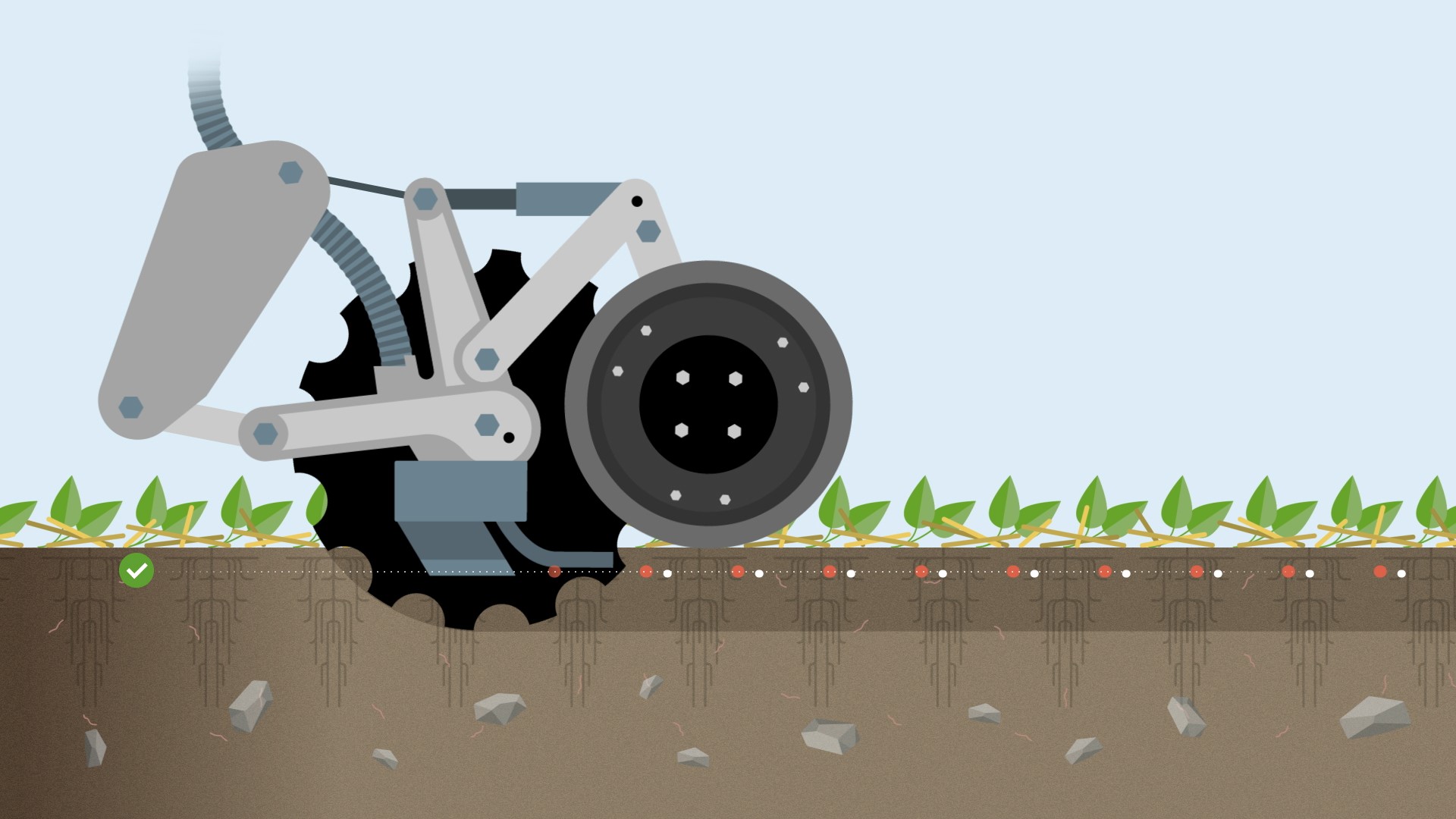

Novag SAS, a leading French manufacturer of no-till agricultural equipment, has been at the forefront of innovation in the direct seeding sector since launching its T-Force Plus series in 2011. The company’s state-of-the-art technology, particularly the T-Slot Opener, has a proven track record dating back to the 1970s and is widely recognized and utilized worldwide for its efficiency in seed placement.

Ramzi from Novag SAS and Philip talk about Novag SAS latest drill – the 4m width Novag T Force Plus 450 Novag’s product range includes machines from 1.5 to 10 meters in working width, customizable to suit various farming needs. Customers can choose configurations that include up to four seed tanks, different row spacings, seed flow monitoring systems, and advanced tramline systems. Since 2024, Novag has integrated ISOBUS technology, enabling precision farming techniques such as seeding based on prescription maps, further enhancing operational flexibility and efficiency.

Novag’s machines are now found across the globe, with many customers enjoying direct support and service from the manufacturer. Until recently, this was also the case for the United Kingdom. However, as of June 2024, Novag has secured a robust partner for sales and service in the UK—James Alexander and his company Primewest.

James Alexander brings extensive expertise to this collaboration, having previously built and sold no-till drills featuring the same T-Slot Opener system. As a contractor managing two arable farms, he has gained over 25 years of experience in Conservation Agriculture, making him an ideal partner for Novag’s operations in the UK. Novag is thrilled to work with someone who understands both the technology and the practical applications of their equipment.

For farmers interested in seeing Novag’s direct seeding technology firsthand, demonstrations can be arranged on their own farms by simply filling out a form on the Novag website (novagsas.com). Additionally, three field days are planned for the spring seeding season, where visitors can observe the machines in action and speak with the Novag and Primewest teams.

The partnership between Novag and Primewest signals an exciting development for UK farmers, offering advanced, sustainable farming solutions backed by decades of expertise.

-

Weaving drills power regen journey

Contract farming 3,500 acres around the parish of Upton Snodsbury, just east of Worcester, Colin Collins also runs 1,000 acres in his own right.

Having embarked on his ‘regen journey’ some six years ago, Colin grows a mix of arable crops, including oilseed rape, winter and spring wheat, winter beans, cover crops and maize. He also keeps 100 suckler cows and fattens store lambs on cover crops.

In the latest video from Weaving Machinery for Direct Driller at Cereals 2024, Simon tells us all about their GD6001T Disc Drill Colin was driven towards a regenerative system by the benefits it could supply in terms of improved soil organic matter and an increase in his soil’s carbon storage ability and as time has progressed, he has also seen improvements in yields.

Previously running two six-metre combination drills, Colin contacted Weaving when looking for a direct drill to fit into his new system, opting for the GD6401T G&F.

Colin says: “We moved over to a regen system because I believed it was just the ethical thing to do. We needed the appropriate kit to make the move and Weaving produced the best drill of its type.

“The drill itself was cost effective as a purchase as well as any future wearing parts. The factory is also local to me, which made it very convenient.”

With soil types ranging from sand to heavy clay, Colin also purchased a Weaving LD top-soiler to run in front of the drill to help tackle any compaction.

Colin says: “With use of the GD drill and the LD, we started to gradually wean ourselves on to the regen system, mindful that too much change too quickly could result in yield penalties.”

default As part of his system, every single acre of ground receives some sort of organic manure whether muck, sewage sludge or digestate and has several agreements with dairy farmers and digestor owners to ensure supply, while also being cautious not to over apply.

Colin says: “With the LD also in our armoury, we run a hybrid system of low disturbance subsoiling and direct drilled, or solely direct drilled. The LD helps to keep the soil structure right in the case of any compaction without disturbing dormant weed seeds. The LD also helps to limit erosion.”

Both the GD and LD are economical in terms of fuel and maintenance costs he explains, adding the power requirement upfront is less than his previous combination drills enabling him to downsize from Case IH Magnums to Case Pumas and Optum.

He adds: “They are easy to fold and unfold, simply calibrated and are also easy to load with seed and my drivers really like them.”

Two years ago, Colin added the purchase of a Weaving Sabre tine drill to his fleet for drilling crops such as winter beans and turnips in wetter autumn soils.

Colin says: “The purchase of the Sabre brings a new level of flexibility to our system. It is better in the wet than the GD. We compaction test the fields and will also use the LD with the Sabre if there is compaction or capping.”

Colin also comments the customer service from Weaving is extremely good.

He says: “We were having trouble with stones getting in the discs and the discs jamming, but we contacted Weaving who fitted stone guards, which now come as standard on all GD drills. They are extremely helpful and good to deal with. If there is a problem, they will sort it.”

About the GD6401T G&F – BOX

The GD drill is the outcome of continuous refinement and development, to create a simple yet precise seed drill. It features the patented and future proofed GD coulter, which provides remarkably low soil disturbance, has a very low draught requirement along with an excellent service life. The GD drill excels in its adaptability to satisfy all drilling systems, soil types and conditions.

- 6.4m working width

- 7ha hourly output

- 166mm row spacing

- 240kg minimum coulter pressure

- 38 coulters

- 180 minimum horsepower requirement

- Folding frame

- 8-12km working speed

- 2.99m road transport width

- 5,000 litre hopper capacity

- Hydraulic brakes

-

We are excited to deliver the Güttler Supermaxx Direct tined drill

Since the first exposure of the Supermaxx tined Cultivation system in 2013 at the LAMMA show Woxagriservices have promoted and generated sales of the machine with the conception of being able to be used as a very shallow cultivator for stubble processing or deeper cultivation for ground renovation.

The Guttler Supermax from Wox Agri Services The product is widely used throughout Europe and has found a place within the UK as a recognisable product for all levels of ground work along with acting as a stubble rake in the shallowest of settings.

The drilling side of this has come about after the request of a number of clients who started the design off during periods of prolonged wet weather ,forcing there hands down a route not really wanting to be sent down.

However the quality and standard of work became apparent that it was so good the machines have taken a front line position as a lightweight high performance machine for all growing seasons and conditions.

Key features of the machine are as follows,

Mounted Trailed 5 Row 7 Row 3m * * * 5m * * * 6m * * * 7m * * * 9m * * * * 10m * * 12m * * And it’s as simple as that, but what are the optional features which set this machine apart from the rest?

DCIM101MEDIADJI_0282.JPG Options

Rollers

1) The Güttler lightweight synthetic ultra roller for soil consolidation.

Well known throughout the market, the unique hard wearing but lightweight option of the synthetic ultra Güttler roller can be fitted to all of the 5 row versions of the Supermaxx machine. Depth control of the tines will be controlled by the roller – if no roller is fitted the depth of tines is accurately controlled by gauge wheels and the rear levelling tines.

Levelling options

2) Levelling boards and additional harrows.

Whilst standard machines are supplied with a single levelling harrow of 12mm sprung tines mounted behind the tines, options are available to fit an additional harrow or parallel levelling board behind the tines in any configuration to suit. This may be directly behind the existing harrow giving a ‘double row’ effect, between the tines and roller or directly behind the roller.

3) Hydraulic ripper boards and paddles

Hydraulically operated paddle boards are fitted in front of the tines on the trailed 9m, 10m and 12m versions of the Supermaxx as standard. These can be modified and fitted with 12mm ripper board plates if desired, and hydraulically operated ripper boards can be fitted to mounted machines.

Point options

4/ A choice of 2 tine points are available for the tines:

- 8mm thick reversible points are fitted as standard.

- Hard wearing, reinforced tungsten tipped points – approx. 5-6 times the longevity of standard points.

5) Patented lock washer

Patented Wox ‘lockwashers’ are available for the fitment of tungsten tipped points to ensure secure fitment of the point to prevent loss during cultivation operations as tine vibrations can easily loosen standard bolt and washer fitments.

Seeder Options

6) Fitment of Fine/small seeders

Convert this machine to a broadcast seeding machine by fitting a Guttler hydraulic seeder unit. The 410l seeder as supplied on the Greenmaster system is ideally suited to the Supermaxx system. Simple fitment of seeder and access platform will result in a system perfect for establishing cereal and cover crops without necessarily taking the “Direct option”

The seeder box can be

NEW patented direct seed coulter boots are now available to deliver seed directly into the tine slot,

This is now where the Guttler direct tined seed really does shine providing the full coverage in all-weather windows and scenarios.

The Coulter tip is bolted in place and then attached to the seeding tube is a removable pipe (without tools) allowing the quick examination/inspection of the seeding boot and also allowing the machine to be converted back to a cultivator in minutes without compromise.

The pipe work supplying the distribution heads can be from 102mm up-over depending on the brand of front tank being used, then there are 2 distribution heads allowing for ½ width shutoff and tramlines as required.

The advantage of this is that the row spacing can be kept at 125mm over the width of the machine yet because of the number of rows of tines trash clearance is exempelary.

The machines are able to carry the secondary seeder for all manner of small seeds and companion crops along with Avadex as an option either placing before or after the harrows or roller.

-

Covering Soils – Scotland

We ran our first Direct Driller Covering Soils event in Scotland in May 2024. The day was based around how Neil White (our Farmer Focus) writer runs his farm. The products and services Neil uses and the approaches he takes.

It was a great day, with great local food. We plan to continue these series of days, based around our farmer focus writers and the different rotations they use in different parts of the country.

For all those who weren’t able to attend this event, we have included write ups of each of the talks and you can watch content from the day.

Highlights

Valtra at Covering Soils

Thorburn Group at Covering Soils

Frontier and SOYL at Covering Soils

Mzuri at Covering Soils

-

Featured Farmer – Neil White

My name is Neil White and I hosted the first Covering Soils event for Direct Driller magazine in Scotland. Having written for the magazine for 4 years, it was a pleasure to be asked to be part of their events programme and representing Scotland!

I farm in Berwickshire, just over the border in SE Scotland. I believe it is the best place in the world to do what I do. We have farmed here since 1913 as tenants and owners. We are in the Merse valley, which has good soils varying from sandy loam to clay loam. The area and the soils played its part in me being lucky enough to win Farmers Weekly Arable farmer of 2023, but the biggest change was to my farming system.

2016 and 2017 were good harvests for me and I could have kept the farming system I had, it was working well, yields were good, but I wanted to keep things moving forward so I looked at making changes. I had some extra ground on a CFA and I was struggling in the autumn to cope with the workload on my own. I had used a contractor to plough but I was very keen to keep it all in my domain as timing is crucial.

I first looked on-line at some of the early adopters of direct drilling and strip tillage, the content was good, honest, and really helped me formulate a small list of drills I wanted to know more about. I think the decision was easier in those days as there was definitely less choice, but I believe I would have made the same call in the end. The Mzuri system kept coming up and looked like a good way to enter into reducing tillage for some of my crops. I take my hat off to those who sell the plough and combi drill the day the new drill arrives, that was never my plan and was a step too far for me. I was fortunate enough to have time chatting to some people who ran direct systems. They had mixed fortunes, but they were kind enough to talk to me and explain the pro’s and more importantly, the con’s of their systems. This honesty and generosity are found in the pages of the Direct Driller magazine, and it is another reason why I am proud to be part of it.

At cereals 2017, I asked Mzuri if they would do a demo up here in Scotland and they agreed. 3 months after the demo, I bought a second hand Protil 3T in mint condition. It was an easy decision as the wheat sown on demo straight into OSR stubble looked great all winter. The plan was to direct drill the OSR and wheat after OSR and beans. That was all I really envisaged doing with it. I then changed the plan and sowed spring beans, OSR, some wheat after beans and OSR that year but still ploughing for winter barley, some wheat, spring barley and spring oats. I ran the two systems together for many years slowly finding that the yields, while varied, were the same between direct sown and plough based. It went from 20%DD 80% ploughed in 2018 to 80%DD and 20% ploughed in 2021 to finally 100% DD. The time saving was the main driver at the start, but I soon noticed that my fuel bill and my tractor hours were also down by about 2/3rds. I was able to cover lots more ground on the optimum days, aiding establishment and reducing compaction. The thing I never considered was the improvement in soil health. OM and workability of my soils was always not bad, but I have seen measurable improvements since I changed my tillage. OM is up by over 1%-2% and the soil has that fresh smell again. I have a good rotation which helped, but the soils now, are more even and more resilient than they have ever been. This has allowed me to direct drill all my crops without any prior soil movement. The only pass beforeS sowing is with the straw rake to kill slugs and chit weeds.

In 2019 I changed my original drill to a dual hopper Protil, plus stocks unit, this gave me the option of companion cropping, cover crops and placed fertiliser. I used the pelleter to put clover in with my OSR, and buckwheat and OSR in another field. This trial worked but didn’t seem to protect the OSR or increase the yield. I also now sow over wintered cover before spring oats and spring malting barley. The drill can do 3 different depths in one pass at 11kph, beans down the front leg, radish and phacelia out the coulter and clover from the pelleter. These crops cost money and need proper sowing methods to succeed. I had a beautiful clover underlay for 2 years which produced 2 very big wheat crops and the clover, but I didn’t know what to do with it back then, and I stupidly sprayed it off in year 3. The new drill also gave me the option to vary rates on each tank. I use VR seed now on all cereals and beans, I use VR pellets on my OSR with the same soil map applied to the pelleter motor. This, like the VR seed puts the correct amount in the correct place without using more product. The benefit of the VR seed is very noticeable in the yield mapping.

The final benefit really was by chance. Carbon and (eventually) our new payment scheme in Scotland are the hot topic and many meetings. I have had Mairi Gougeon, our cabinet minister down on my farm and she seemed very receptive to the idea of production and environmental measures running side by side. It now looks like my system could tick many of the boxes without changing things, meanwhile I am increasing my farm output. I believe we must try and maintain or improve output on the good ground in this country while using cover, companion crops, margins, crop rotation, and hedges to encourage biodiversity and wildlife conservation on our farms. Carbon is the market I haven’t entered ‘yet’ but it is something that I have had advice on. My carbon audit gives me very favourable figures to bring to the table, maybe for a 1-year deal at first. I haven’t jumped, but because of my system I know that I don’t have to change much to tick that box. Maybe Cereals will provide the nudge I need!

-

Gaining insights to make the best decisions for your farm

With long-term farming systems vital for sustainable supply chains, experts from Frontier Agriculture’s SOYL precision and Kings Crops are highlighting the solutions available to help growers build more resilient soils for the future.

Often considered a ‘farm’s greatest asset’, soil is fundamental to food and farming. Its condition can quite literally determine the success of a crop, while also having a direct influence on the wider environment and overall farm biodiversity. Often though it can be easy to overlook, taken for granted as something that’s there to be worked and prepared, but not necessarily measured and improved.

At the recent Covering Soils event kindly hosted by Neil White at Greenknowe Farm, Kings Crops technical advisor, Ed Jones, explained to visitors why it’s so important to go back to the basics to build an overall picture of soil health and, ultimately, farm performance.

“The physical, chemical and biological properties of soil are what define it as a healthy, functioning ecosystem. Each area is crucial on its own, but how they interact with one another is equally important.”

The physical components of soil can be defined by good structure that supports easy movement of water and air, supporting moisture levels and nutrient retention while reducing compaction. They help to create an ideal rooting environment too, which can contribute to better disease and drought resistance for crops.

When looking at chemical properties, this is about optimising a soil’s level of macro- and micro-nutrients, while in a biological sense, the microbial activity within soil is crucial for its health as it’s what drives nutrient and organic matter cycling. Being able to measure the microbial biomass in the soil and linking it to organic matter levels ultimately leads to better management and improvements overall.

Ed continues: “It starts and ends with soil. It is an essential natural resource, vital for the productivity, profitability and sustainability of every farm. So, how can you really find out what’s going on beneath your fields?”

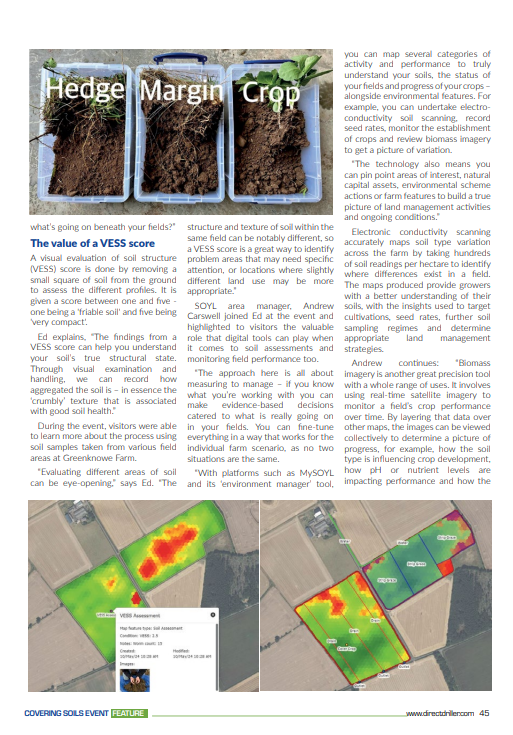

The value of a VESS score

A visual evaluation of soil structure (VESS) score is done by removing a small square of soil from the ground to assess the different profiles. It is given a score between one and five – one being a ‘friable soil’ and five being ‘very compact’.

Ed explains, “The findings from a VESS score can help you understand your soil’s true structural state. Through visual examination and handling, we can record how aggregated the soil is – in essence the ‘crumbly’ texture that is associated with good soil health.”

During the event, visitors were able to learn more about the process using soil samples taken from various field areas at Greenknowe Farm.

“Evaluating different areas of soil can be eye-opening,” says Ed. “The structure and texture of soil within the same field can be notably different, so a VESS score is a great way to identify problem areas that may need specific attention, or locations where slightly different land use may be more appropriate.”

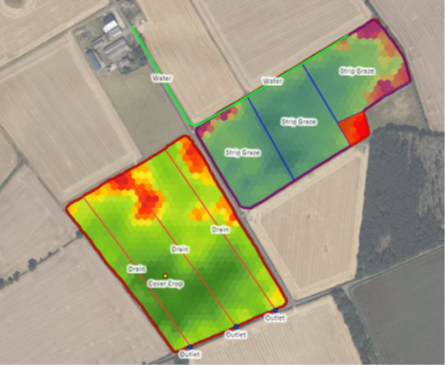

SOYL area manager, Andrew Carswell joined Ed at the event and highlighted to visitors the valuable role that digital tools can play when it comes to soil assessments and monitoring field performance too.

“The approach here is all about measuring to manage – if you know what you’re working with you can make evidence-based decisions catered to what is really going on in your fields. You can fine-tune everything in a way that works for the individual farm scenario, as no two situations are the same.

“With platforms such as MySOYL and its ‘environment manager’ tool, you can map several categories of activity and performance to truly understand your soils, the status of your fields and progress of your crops – alongside environmental features. For example, you can undertake electro-conductivity soil scanning, record seed rates, monitor the establishment of crops and review biomass imagery to get a picture of variation.

“The technology also means you can pin point areas of interest, natural capital assets, environmental scheme actions or farm features to build a true picture of land management activities and ongoing conditions.”

Electronic conductivity scanning accurately maps soil type variation across the farm by taking hundreds of soil readings per hectare to identify where differences exist in a field. The maps produced provide growers with a better understanding of their soils, with the insights used to target cultivations, seed rates, further soil sampling regimes and determine appropriate land management strategies.

Andrew continues: “Biomass imagery is another great precision tool with a whole range of uses. It involves using real-time satellite imagery to monitor a field’s crop performance over time. By layering that data over other maps, the images can be viewed collectively to determine a picture of progress, for example, how the soil type is influencing crop development, how pH or nutrient levels are impacting performance and how the current crop data compares to yield maps from previous years.

“All of this combined can help you to see the bigger picture. If a certain area is proving difficult when it comes to establishment or yield, you can use the insights to optimise management decisions for the future – for example, variably applying nutrients to meet the needs of the crop – an action now supported under the Sustainable Farming Incentive (SFI) in England.”

Reconditioning soils and the SFIThe soil actions within the Sustainable Farming Incentive (SFI) are designed to support improvements to ‘soil health, organic matter and biology’, with the aim of improving long-term productivity and soil resilience to benefit food production while simultaneously benefitting the environment.

Some of the actions available for soil health are:

- SAM1/CSAM1: Assess soil, produce a soil management plan and test soil organic matter

- SAM2/CSAM2: Multi-species winter cover crops

- SAM3/CSAM3: Herbal leys.

Soil assessments and effective record-keeping to evidence activity can help you meet the requirements of SAM1/CSAM1, whist other actions focus on keeping a constant cycle of living roots in the soil.

Ed explains: “These actions are about not leaving soil surfaces exposed for long periods of time, such as between commercial crops or at points of the year where they are vulnerable to risks such as erosion. Wherever possible, cropping should have a varied rotation to help maximise the benefits to soil.”

This is where cover crops come in, Ed continues: “They can deliver so many benefits – which can be monitored and measured too. They improve ground conditions, can reduce tillage costs, support soil to retain more nutrients, reduce the risk of erosion, increase beneficial microbes and encourage earthworm activity.”

Now is an opportune time to look at rotations and methods of production in tandem with environmental considerations. For example, a herbal ley could be a great choice as it builds soil organic matter over three to five years and reduces weed burdens.

Many species in a herbal ley are deep rooting, drawing up nutrients and minerals from depths that can’t be accessed by shallow rooting species.

Funding for cover, catch and companion crop options doesn’t need to necessarily come via schemes such as the SFI or Countryside Stewardship either, with the private sector now increasingly supporting farms to incorporate more sustainable farming actions to benefit supply chains.

Ed concludes: “Taking a holistic approach to crop production and broader land management is really important, as what works for one farm won’t necessarily work for another. It’s all about understanding your baseline – knowing what you’re working with means you can ultimately make the best decisions for your farm, the environment and continuity of food production.”

-

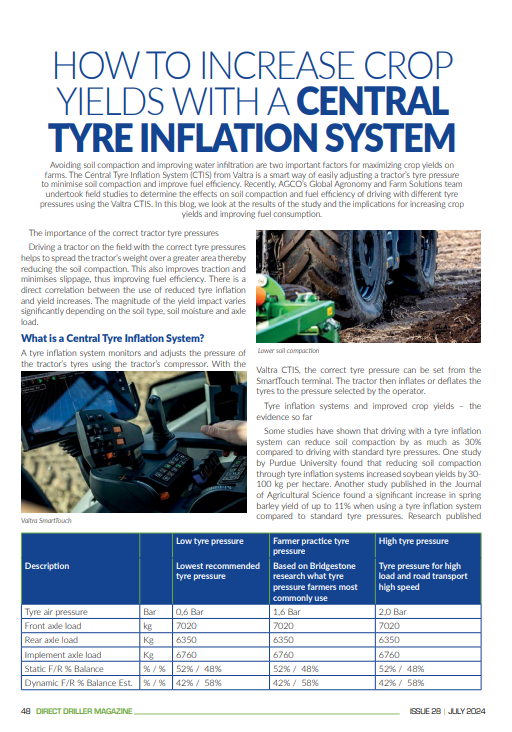

How to increase crop yields with a Central Tyre Inflation System

Avoiding soil compaction and improving water infiltration are two important factors for maximizing crop yields on farms. The Central Tyre Inflation System (CTIS) from Valtra is a smart way of easily adjusting a tractor’s tyre pressure to minimise soil compaction and improve fuel efficiency. Recently, AGCO’s Global Agronomy and Farm Solutions team undertook field studies to determine the effects on soil compaction and fuel efficiency of driving with different tyre pressures using the Valtra CTIS. In this blog, we look at the results of the study and the implications for increasing crop yields and improving fuel consumption.

The importance of the correct tractor tyre pressures

Driving a tractor on the field with the correct tyre pressures helps to spread the tractor’s weight over a greater area thereby reducing the soil compaction. This also improves traction and minimises slippage, thus improving fuel efficiency. There is a direct correlation between the use of reduced tyre inflation and yield increases. The magnitude of the yield impact varies significantly depending on the soil type[LI1] , soil moisture and axle load.

What is a Central Tyre Inflation System?

A tyre inflation system monitors and adjusts the pressure of the tractor’s tyres using the tractor’s compressor. With the Valtra CTIS, the correct tyre pressure can be set from the SmartTouch terminal. The tractor then inflates or deflates the tyres to the pressure selected by the operator.

Tyre inflation systems and improved crop yields – the evidence so far

Some studies have shown that driving with a tyre inflation system can reduce soil compaction by as much as 30% compared to driving with standard tyre pressures. One study by Purdue University found that reducing soil compaction through tyre inflation systems increased soybean yields by 30-100 kg per hectare. Another study published in the Journal of Agricultural Science found a significant increase in spring barley yield of up to 11% when using a tyre inflation system compared to standard tyre pressures. Research published in the Journal of Agricultural Engineering Research found that using a tyre inflation system on a tractor reduced soil compaction and increased winter wheat yield by up to 8% in test plots.

Studies by AGCO Global Agronomy and Farm Solutions team

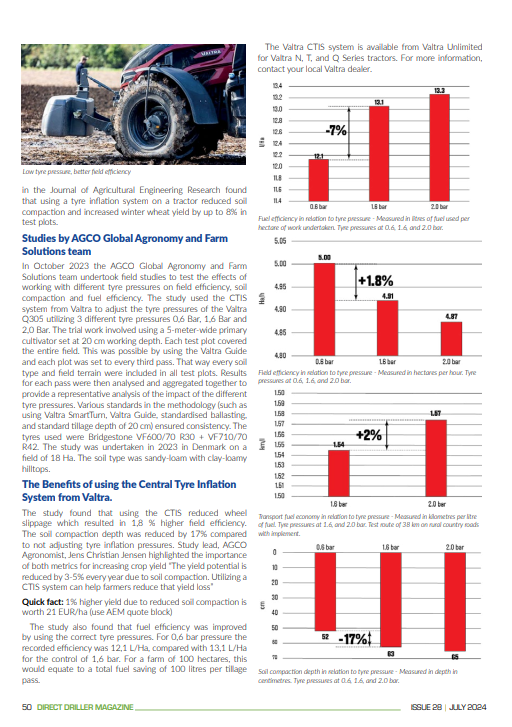

In October 2023 the AGCO Global Agronomy and Farm Solutions team undertook field studies to test the effects of working with different tyre pressures on field efficiency, soil compaction and fuel efficiency. The study used the CTIS system from Valtra to adjust the tyre pressures of the Valtra Q305 utilizing 3 different tyre pressures 0,6 Bar, 1,6 Bar and 2,0 Bar. The trial work involved using a 5-meter-wide primary cultivator set at 20 cm working depth. Each test plot covered the entire field. This was possible by using the Valtra Guide and each plot was set to every third pass. That way every soil type and field terrain were included in all test plots. Results for each pass were then analysed and aggregated together to provide a representative analysis of the impact of the different tyre pressures. Various standards in the methodology (such as using Valtra SmartTurn, Valtra Guide, standardised ballasting, and standard tillage depth of 20 cm) ensured consistency. The tyres used were Bridgestone VF600/70 R30 + VF710/70 R42. The study was undertaken in 2023 in Denmark on a field of 18 Ha. The soil type was sandy-loam with clay-loamy hilltops.

Low tyre pressure Farmer practice tyre pressure High tyre pressure Description Lowest recommended tyre pressure Based on Bridgestone research what tyre pressure farmers most commonly use Tyre pressure for high load and road transport high speed Data Tyre air pressure Bar 0,6 Bar 1,6 Bar 2,0 Bar Front axle load kg 7020 7020 7020 Rear axle load Kg 6350 6350 6350 Implement axle load Kg 6760 6760 6760 Static F/R % Balance % / % 52% / 48% 52% / 48% 52% / 48% Dynamic F/R % Balance Est. % / % 42% / 58% 42% / 58% 42% / 58% The Benefits of using the Central Tyre Inflation System from Valtra.

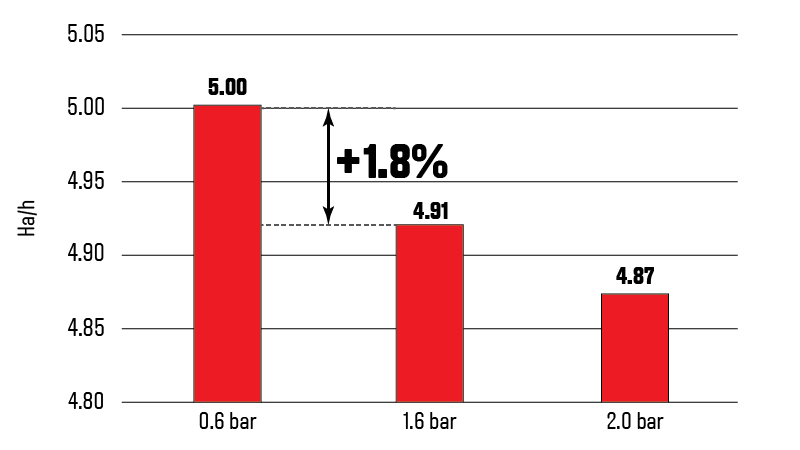

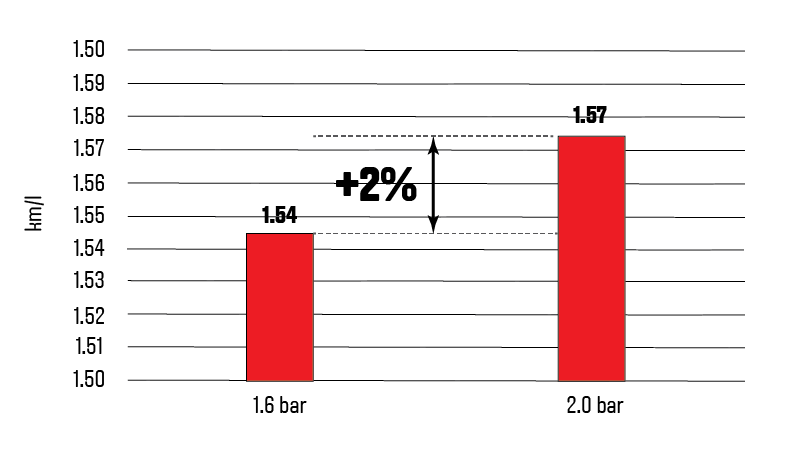

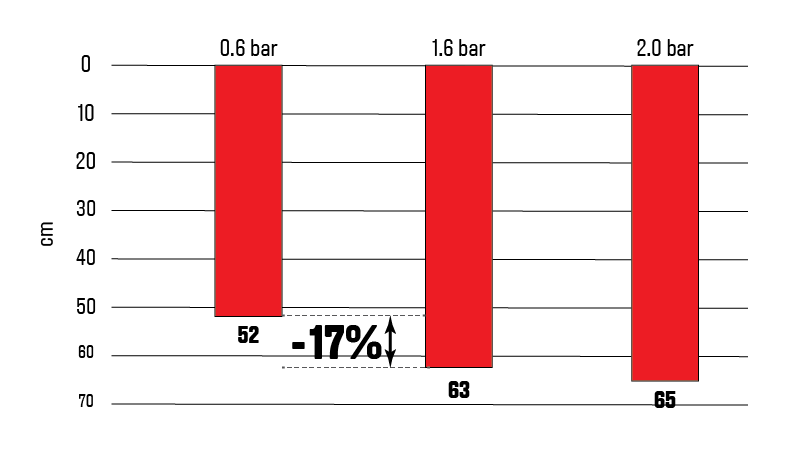

The study found that using the CTIS reduced wheel slippage which resulted in 1,8 % higher field efficiency. The soil compaction depth was reduced by 17% compared to not adjusting tyre inflation pressures. Study lead, AGCO Agronomist, Jens Christian Jensen highlighted the importance of both metrics for increasing crop yield “The yield potential is reduced by 3-5% every year due to soil compaction. Utilizing a CTIS system can help farmers reduce that yield loss”

Quick fact: 1% higher yield due to reduced soil compaction is worth 21 EUR/ha (use AEM quote block)

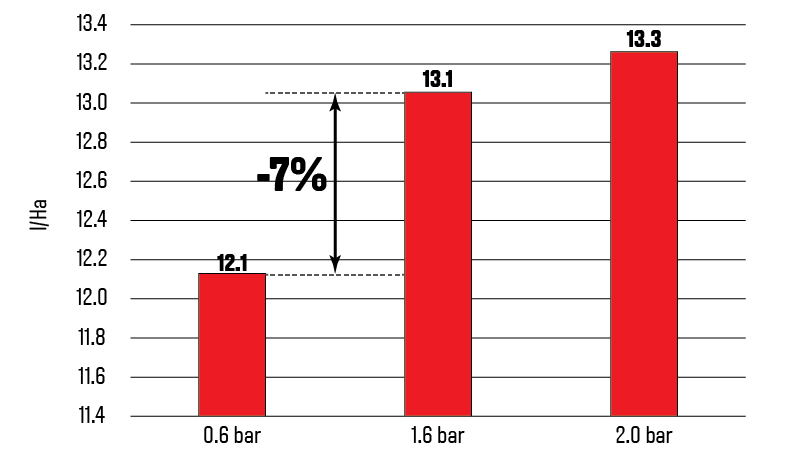

The study also found that fuel efficiency was improved by using the correct tyre pressures. For 0,6 bar pressure the recorded efficiency was 12,1 L/Ha, compared with 13,1 L/Ha for the control of 1,6 bar. For a farm of 100 hectares, this would equate to a total fuel saving of 100 litres per tillage pass.

The Valtra CTIS system is available from Valtra Unlimited for Valtra N, T, and Q Series tractors. For more information, contact your local Valtra dealer, below.

Figure 1 – Field efficiency in relation to tyre pressure Measured in hectares per hour. Tyre pressures at 0.6, 1.6, and 2.0 bar.

Figure 2 – Fuel efficiency in relation to tyre pressure measured in litres of fuel used per hectare of work undertaken. Tyre pressures at 0.6, 1.6, and 2.0 bar.

Figure 3 – Soil compaction depth in relation to tyre pressure measured in depth in centimetres. Tyre pressures at 0.6, 1.6, and 2.0 bar.

Figure 4 – Transport fuel economy in relation to tyre pressure measured in kilometres per litre of fuel. Tyre pressures at 1.6, and 2.0 bar. Test route of 38 km on rural country roads with implement.

-

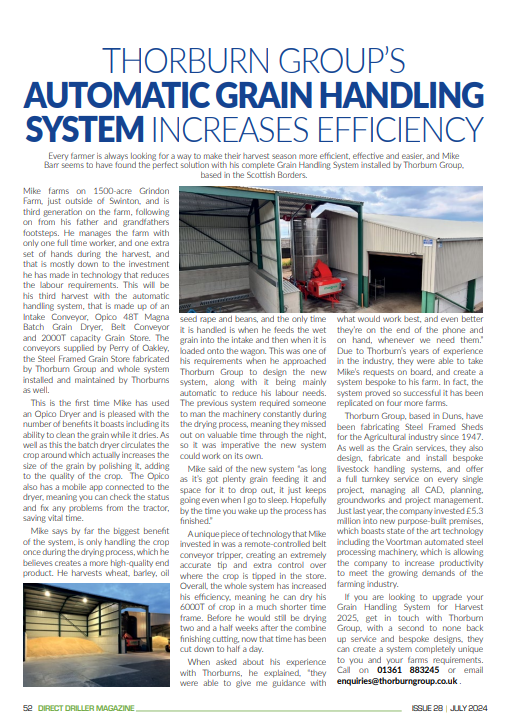

Thorburn Group’s Automatic Grain Handling System increases efficiency

Every farmer is always looking for a way to make their harvest season more efficient, effective and easier, and Mike Barr seems to have found the perfect solution with his complete Grain Handling System installed by Thorburn Group, based in the Scottish Borders.

Mike farms on 1500-acre Grindon Farm, just outside of Swinton, and is third generation on the farm, following on from his father and grandfathers footsteps. He manages the farm with only one full time worker, and one extra set of hands during the harvest, and that is mostly down to the investment he has made in technology that reduces the labour requirements. This will be his third harvest with the automatic handling system, that is made up of an Intake Conveyor, Opico 48T Magna Batch Grain Dryer, Belt Conveyor and 2000T capacity Grain Store. The conveyors supplied by Perry of Oakley, the Steel Framed Grain Store fabricated by Thorburn Group and whole system installed and maintained by Thorburns as well.

This is the first time Mike has used an Opico Dryer and is pleased with the number of benefits it boasts including its ability to clean the grain while it dries. As well as this the batch dryer circulates the crop around which actually increases the size of the grain by polishing it, adding to the quality of the crop. The Opico also has a mobile app connected to the dryer, meaning you can check the status and fix any problems from the tractor, saving vital time.

Mike says by far the biggest benefit of the system, is only handling the crop once during the drying process, which he believes creates a more high-quality end product. He harvests wheat, barley, oil seed rape and beans, and the only time it is handled is when he feeds the wet grain into the intake and then when it is loaded onto the wagon. This was one of his requirements when he approached Thorburn Group to design the new system, along with it being mainly automatic to reduce his labour needs. The previous system required someone to man the machinery constantly during the drying process, meaning they missed out on valuable time through the night, so it was imperative the new system could work on its own.

Mike said of the new system “as long as it’s got plenty grain feeding it and space for it to drop out, it just keeps going even when I go to sleep. Hopefully by the time you wake up the process has finished.”

A unique piece of technology that Mike invested in was a remote-controlled belt conveyor tripper, creating an extremely accurate tip and extra control over where the crop is tipped in the store. Overall, the whole system has increased his efficiency, meaning he can dry his 6000T of crop in a much shorter time frame. Before he would still be drying two and a half weeks after the combine finishing cutting, now that time has been cut down to half a day.

When asked about his experience with Thorburns, he explained, “they were able to give me guidance with what would work best, and even better they’re on the end of the phone and on hand, whenever we need them.” Due to Thorburn’s years of experience in the industry, they were able to take Mike’s requests on board, and create a system bespoke to his farm. In fact, the system proved so successful it has been replicated on four more farms.

Thorburn Group, based in Duns, have been fabricating Steel Framed Sheds for the Agricultural industry since 1947. As well as the Grain services, they also design, fabricate and install bespoke livestock handling systems, and offer a full turnkey service on every single project, managing all CAD, planning, groundworks and project management. Just last year, the company invested £5.3 million into new purpose-built premises, which boasts state of the art technology including the Voortman automated steel processing machinery, which is allowing the company to increase productivity to meet the growing demands of the farming industry.

If you are looking to upgrade your Grain Handling System for Harvest 2025, get in touch with Thorburn Group, with a second to none back up service and bespoke designs, they can create a system completely unique to you and your farms requirements. Call on 01361 883245 or email enquiries@thorburngroup.co.uk .

-

From Tradition to Innovation with the Mzuri System

From Tradition to Innovation with the Mzuri System

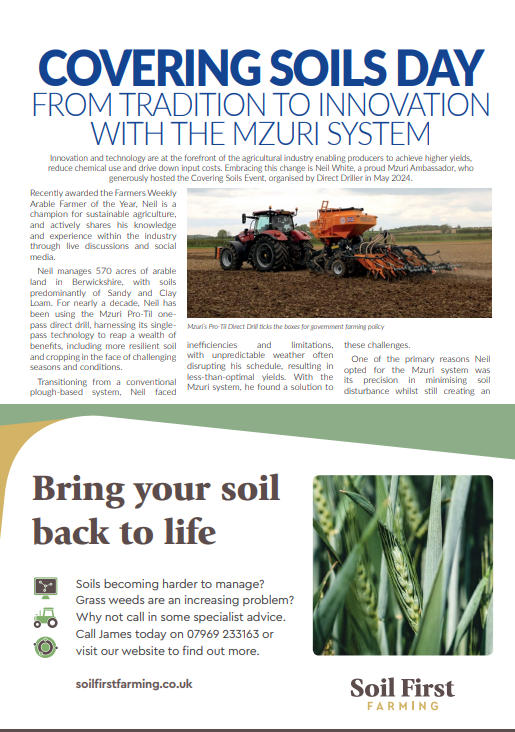

Innovation and technology are at the forefront of the agricultural industry enabling producers to achieve higher yields, reduce chemical use and drive down input costs. Embracing this change is Neil White, a proud Mzuri Ambassador, who generously hosted the Covering Soils Event, organised by Direct Driller in May 2024.

Recently awarded the Farmers Weekly Arable Farmer of the Year, Neil is a champion for sustainable agriculture, and actively shares his knowledge and experience within the industry through live discussions and social media.

Neil manages 570 acres of arable land in Berwickshire, with soils predominantly of Sandy and Clay Loam. For nearly a decade, Neil has been using the Mzuri Pro-Til one-pass direct drill, harnessing its single-pass technology to reap a wealth of benefits, including more resilient soil and cropping in the face of challenging seasons and conditions.

Transitioning from a conventional plough-based system, Neil faced inefficiencies and limitations, with unpredictable weather often disrupting his schedule, resulting in less-than-optimal yields. With the Mzuri system, he found a solution to these challenges.

Neil White – Mzuri ambassador and Farmers Weekly Arable Farmer of the Year One of the primary reasons Neil opted for the Mzuri system was its precision in minimising soil disturbance whilst still creating an optimal seedbed. Unlike traditional plough-based systems that often leave farmers at the mercy of weather conditions, the Mzuri system offered Neil the flexibility to work efficiently with minimal soil disturbance.

About the Mzuri Pro-Til

The Mzuri Pro-Til direct drill features leading tines which band place fertiliser below the seeding zone, to reduce fertiliser requirements and ensure early nutrient accessibility for quick, even establishment. In-line staggered wheels remove air pockets and reconsolidate ahead of the seeding coulters whilst excellent seed to soil contact is achieved by hydraulic pressure exerted to each individual seed depth wheel. By having independent, pivoting seeding coulters, with depth controlled via individual semi-pneumatic coulter depth wheels, accurate seed depth can be achieved across the full width even over undulating ground. Finally, a hydraulically operated adjustable pressure harrow ensures a level uniformed seed bed ideal for pre-emergence herbicide.

For Neil, the Mzuri drill significantly improved crop establishment, even across varying soil types. In direct-drilled Spring crops, where timing is critical, Neil observed substantial improvements. While farmers in the area, which were using conventional drills, faced uneven seed depths and stressed crops during the wet Springs, Neil’s crops remained unaffected, thanks to the adaptability of the Mzuri system.

Mzuri Pro-Til drilled Barley on Neil’s Berwickshire Farm Scotland’s wet climate poses specific challenges, but the Mzuri system’s soil conditioning capabilities proved beneficial for Neil’s farm by enhancing the soil’s nutrient content and promoting healthier plant growth. By promoting adequate soil aeration and reduced soil compaction, the system facilitated improved soil structure and better nutrient availability, minimising the need for chemical inputs. Neil’s commitment to reducing inputs was evident in his decision to no longer use insecticides on Spring Beans and reduce fungicide applications in Wheat crops, thanks to increased airflow through the crop as a result of the Mzuri’s wider row spacings.

Neil is acutely aware that new Government policies are requiring operational change for farmers, commenting “While Government policies are raising demands, the Mzuri Pro-Til ticks all the boxes, providing relief to farmers under pressure to meet Government standards.”

An incredibly wet Winter and Spring has presented huge challenges for growers intending to plant their Spring crops, with many unable to access the waterlogged land. In-between the down pours Neil successfully planted his Spring Barley, which is looking strong and healthy, despite the continued unpredictable weather.

Spring Beans looking strong this spring despite challenging conditions Mzuri, who are a British manufacturer based in Worcestershire, have an esteemed group of Ambassadors who are passionate about the Mzuri system and have tried and tested it over the years. If you wish for an honest, farmer to farmer review of the Mzuri system, please get in touch and we will put you in contact with your local Ambassador.

For growers in regions eligible for the Farming Equipment and Technology Fund and the Sustainable Farming Incentive, we are pleased to confirm the Mzuri Pro-Til is an approved machine under both schemes.

Call Mzuri for more information on 01905 841123 or visit www.mzuriuk.com

-

Pictures from Covering Soils Scotland

-

Direct Driller Issue 28 – Contents

Inside this issue:

- Welcome to the Groundswell 2024 Issue

- How will AI change farming?

- Farmer Focus – John Cherry

- Revolutionise Your Farm: How Trinity AgTech’s Sandy Empowers Farmers to Master Natural Capital

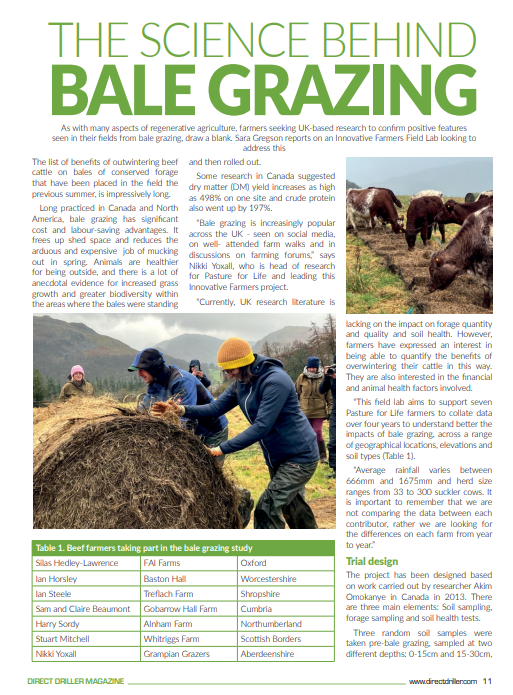

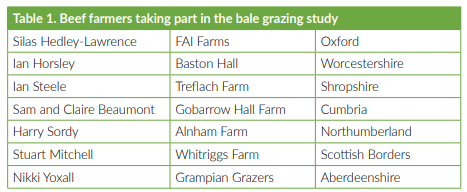

- The science behind bale grazing

- BASE UK at Cereals 2024

- Farmer Focus – Elle Seville

- Water Focus – Affinity Water

- Embracing Agroforestry for Climate Resilience and Sustainabity

- Nitrogen and agriculture

- The good, the bad and the ugly

- Agronomist in Focus: Ron Granger

- The Future of Soil Health Measurement

- The role of nitrogen and innovative biological solutions

- Agronomist in Focus: Lisa Hambly

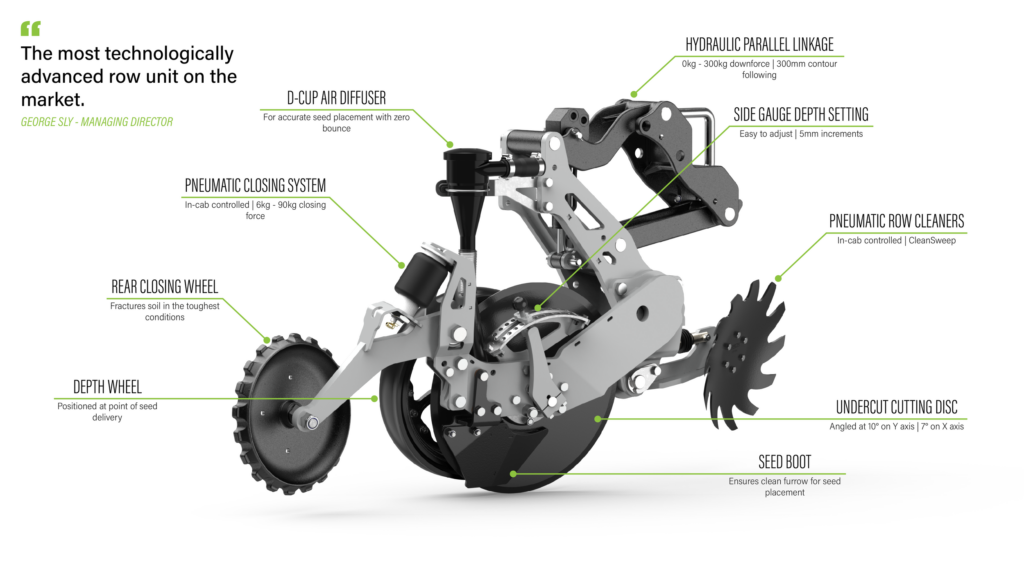

- Farmer Focus – George Sly

- New Partnership Between Bourgault Tillage Tools and Grange Machinery

- Decisions, decisions, decisions…

- AHDB outlines biostimulants basics

- A special relationship

- Can you farm carbon?

- Farmer Focus – David Aglen

- Horizon – Our first Agritechnica

- A brief history of the Recommended Lists (RL)

- BYDV threat under the spotlight at TWB Farms open day

- Farmer Focus – Ben Martin

- Why liming should be on every direct driller’s agenda

- Spring 2024 Challenges in Grassland & Forage Crops

- Going for gold

- Soil Carbon Measurement: A Practical Guide for Farmers

-

Welcome to the Groundswell 2024 Issue

We are thrilled it’s that time of year again, Groundswell 2024 issue. A special event dedicated to the transformative world of regenerative

agriculture. Groundswell, has become known as a beacon of innovation, knowledge sharing, and community building for farmers, the supply

chain and practitioners dedicated to sustainable and resilient farming practices.This year’s event promises to be a landmark gathering, featuring an array of workshops, talks, demonstrations, and exhibitions that highlight the latest advancements in regenerative agriculture. As we navigate the challenges of SFI, climate change, soil degradation, and biodiversity loss, the insights and technologies showcased at Groundswell are more crucial than ever.

Following that lead, this edition covers those same themes. We all know healthy soil is the foundation of productive and sustainable agriculture. Through cover cropping, reduced tillage, and a better understanding of organic processes, farmers can enhance soil structure, increase water retention, and foster a thriving microbial ecosystem. This edition continues to delve deep into these practices, offering practical advice and real-world farmer experiences (the real experts).

We have also set out our plans to highlight technology and innovation as driving forces behind the large-scale adoption of regenerative farming. We hope you all have enjoyed the first two technology issues. From advanced soil sensors and data analytics to cuttingedge

machinery, the tools available to today’s farmers are changing how we approach agriculture.But as we all know, Groundswell is not just about techniques and tools; it’s about community. The event fosters a spirit of collaboration and

mutual support, offering numerous networking opportunities. Farmers, researchers, policymakers, and industry leaders come together to

share experiences, forge partnerships, and inspire one another. We also tend to enjoy a drink together and share the amazing food that will be on offer.We look forward to seeing you all at Groundswell 2024.

-

How will AI change farming?

It’s not a matter of if, but more how Artificial Intelligence (AI) will change the farming sector. But I’m not sure that robots will be the way it manifests itself in our live. For sure, it will introduce innovations that significantly enhance efficiency, productivity, and sustainability. But one of the primary ways AI is transforming agriculture is through better data processing that can be used by our current machinery.

By leveraging data and sophisticated algorithms, farming can improve how they use inputs. AI-powered sensors, can collect a greater number of data points and process that data to monitor soil health, moisture levels, and crop conditions (even in real-time), enabling precise application of water, better use of foliar fertilisers, and crop protection products. However, wouldn’t it just be nice to get a better weather forecast!

AI automated machinery has received massive funding from Innovate UK, over £11m in the last 5 years with just 3 companies (two of which have already gone into administration). I don’t see automated machinery changing our lives in the next 10 years. While, these machines can handle planting, weeding, and harvesting autonomously, I always struggle to see how they fit into a smaller farming system.

If you only have one tractor, you need a robot as well as the tractor, so the capital savings just don’t exist. If you have 10 tractors, it’s a different matter. The real areas where I think we will see change, is in countries with marginal farming land. Land that could previously not be farmed, could become farmable.

Did you know they are now growing large scale wheat in the UAE? A country known for oil, vast deserts and 40 degree temperature. Smart irrigation systems are benefiting from AI advancements. These systems use AI to optimise water usage, reducing waste and ensuring crops receive the right amount of water at the right time. IoT sensors collect data on soil moisture, weather conditions, and crop needs, which AI algorithms then use to automate irrigation schedules.

Additionally, AI models predict drought conditions, allowing pre-emptive measures to conserve water. But is more food production abroad good news for the UK? That probably depends on population growth abroad as well.

-

Farmer Focus – John Cherry

I don’t want to bang on about the weather, but the farm here doesn’t look brilliant as a result of all the wet we’ve had these last few months. That and some poor management decisions in the autumn, leaving some undrilled land bare over winter and various late drilled fields succumbing to slugs and rooks and drowning. The spring crops look ok, we drilled everything with the Horsch CO4 as we have struggled to get good results with the disc drill sowing in the spring – especially when it rains incessantly on the new sown land.

We’ve got a crop of heritage Maslin (a blend of wheats and ryes) growing in the field next to the Groundswell demo area. It went in very nicely, we cross-harrowed it with an Einbock a couple of times after emergence as the deal is it is not to have any chemicals on it at all. We added some Rivendel clover on the second pass, which has made a surprisingly good effort at getting going considering the canopy that’s growing above it. There is quite a population of grass weeds lurking in the ground; we took some out but probably encouraged more and it’ll be interesting to see if the tall crop and no fertiliser makes life too hard for the weeds. We can but hope.

Meanwhile there’s a bit of preparation going on next door for Groundswell (26/27th June), and it looks like being the best yet. Some of the speakers are jetting in, including, John Kempf talking on agronomy, Derek and Tannis Axten from Canada on companion cropping, Anna K from Finland on the soil and Josef Holzer from the foothills of the Alps on permaculture. They’ll be joining the 260 odd other speakers looking at everything regenerative, from the tiniest creatures in the soil to the dysfunctional food systems that aren’t helping anyone beyond a handful of multinational companies. As always though, it’ll mainly be about what we as farmers can do to make our businesses more resilient. There are also more safaris, heading off to look at anything from beetles to ponds and agroforestry, through truffles to hedge life.

We have started a demonstration seven year rotation on site to show how, for instance, no-till potatoes can be incorporated into an arable system, the key question being how do you cope with all that straw that is left after the potatoes are harvested. As this is in its first year, we don’t have last year’s potato-covering straw on site, but we have planted sweetcorn, beans and pumpkins with George Sly’s marvellous purpose-built Horizon drill, even if the row-cleaners weren’t actually necessary this time. The plan is to clear a strip every 50cm or so and grow the crops in there and leave the straw in between as mulch and a mat to keep pumpkins/ gourds etc off the ground. By the end of year two, the straw should be rotted to a lovely surface compost dressing.

It’s been an extraordinary journey, hosting Groundswell that is, these last eight years. It feels as if we’ve been constantly surfing the groundswell of ideas that have risen up from this wonderful, farmer-led revolution. We didn’t expect regenerative agriculture to become so fertile and to spread into the realms of food and community; Jill Clapperton advised us after the first show in 2016 that we might be best off only attempting to put an event on every other year, as there wouldn’t be enough speakers to fill an annual schedule!

There is a growing understanding about how the quality of the food we produce affects the health and wellbeing of those that consume it. As farmers, we can be quite isolated on our own piece of ground and so it is a real pleasure and a tonic to focus on the wider issues and to come together with a bunch of like-minded enthusiasts.

It seems a shame to restrict all this to two days a year, so we’ve been working on Groundswell Outreach, to look at other ways of keeping the message expanding. One way is helping get other events up and running, like the fabulous GO Falkland in Fife, Scotland https://falklandestate.co.uk/go-falkland/ (17th/18th July 2024). They’ve got a brilliant line-up of talks aimed squarely at a Scottish audience this year and I recommend everyone North of the border to make a bee-line there.

Another project is Groundschool, on which we are collaborating with Writtle University to offer hands-on experience and teaching. This will be available not only to students, but also farmers, gardeners, cooks, business people, policy makers and anyone else who might be interested, like Uncle Tom Cobley.

This is all very much a work in progress and we have no idea quite how it will turn out, but we’d be delighted to talk to anyone who fancies getting involved. The first project which is underway is a small market garden which should soon be providing vegetables for the local community. This is all happening at the other side of the village to the Groundswell site.

-

Revolutionise Your Farm: How Trinity AgTech’s Sandy Empowers Farmers to Master Natural Capital

Introduction

Last September, near Windsor Castle, where the Magna Carta was signed in 1215 heralding a new ‘Just Era for All’, Trinity and the Trinity Natural Capital Pro Council declared this “the Natural Capital Century.” This declaration recognises the value and the vital role of natural capital – the resources that sustain not only food and farming but also humanity itself, and underpin 53% of global economic output – and our pursuit of a just, profitable, and sustainable future.