Commodity price rollercoaster is making planning difficult

Global events and extremely wet weather mean that there’s a lot to think about on the Claydon family’s arable farm in Suffolk, says Jeff Claydon, inventor of the Opti-Till® direct seeding system.

February 2024

Since the start of 2024 it has become evident that farmers all over the world have been pushed to the point where rising costs, increasing legislation and governmental pressures have left them with little choice but to make their feelings known to politicians in no uncertain terms. As I write this, it seems as if farmers everywhere are protesting. In the UK, throughout Europe and as far afield as the USA, Canada and Australia, the slogan ‘No Farmers, No Food, No Future’ is being seen everywhere.

Something is obviously and seriously wrong in terms of how those who produce the world’s food are being treated and compensated, or rather inadequately compensated for the considerable risks involved. The decision to participate in such protests is not one that is taken lightly because inevitably it involves additional cost and time spent away from the farm, which most can ill afford.

It’s not difficult for those of us in the agricultural community to understand why things have reached a head. Farmers have always done everything that politicians have asked of them in terms of increasing production to ensure that sufficient food is available to the public at affordable prices. Yet, over the last two or three decades, our industry has come under increasing pressure and criticism. In some cases that has been from a public with little or no idea of what farmers do or what is involved in producing their food, in others from transient politicians who are often ill-informed and out of touch.

With geopolitical issues, international instability and global supply issues more pronounced than they have been for a very long time, one cannot help but wonder whether politicians from all nations have become complacent over food security and don’t recognise the long-term implications of this.

Supply chain demographics have also changed markedly over the last few decades. Having recently celebrated my 70th birthday I am old enough to remember when the UK was characterised by its small farms and local, independent shops. In the 1960s and 70s one could buy almost anything from the weekly market in my local town, Bury St Edmunds. All of it was locally produced or locally sourced, but now the market is much like any other, selling products which have been brought in from who knows where. That is sad to see.

Neither has the transition from having numerous local mixed farms and mills to a handful of large feed manufacturers, food groups and intermediaries who dominate the market been good for those of us who produce food, or indeed the consumers who ultimately buy it. One can only hope that common sense will ultimately prevail, bringing a return to more local suppliers with lower overheads and a greater personal stake in their local community.

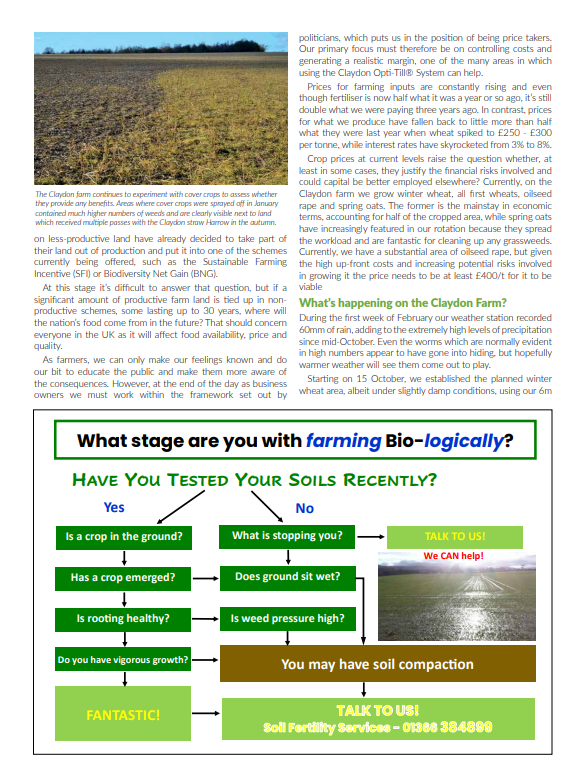

The big question for the farming industry going forward is whether we will see a major swing away from the globalists’ agenda favouring lower quality, factory-produced/artificial foods so that we can remain a nation of farmers, or will we be economically forced to become park keepers? Some farmers on less-productive land have already decided to take part of their land out of production and put it into one of the schemes currently being offered, such as the Sustainable Farming Incentive (SFI) or Biodiversity Net Gain (BNG).

At this stage it’s difficult to answer that question, but if a significant amount of productive farm land is tied up in non-productive schemes, some lasting up to 30 years, where will the nation’s food come from in the future? That should concern everyone in the UK as it will affect food availability, price and quality.

As farmers, we can only make our feelings known and do our bit to educate the public and make them more aware of the consequences. However, at the end of the day as business owners we must work within the framework set out by politicians, which puts us in the position of being price takers. Our primary focus must therefore be on controlling costs and generating a realistic margin, one of the many areas in which using the Claydon Opti-Till® System can help.

Prices for farming inputs are constantly rising and even though fertiliser is now half what it was a year or so ago, it’s still double what we were paying three years ago. In contrast, prices for what we produce have fallen back to little more than half what they were last year when wheat spiked to £250 – £300 per tonne, while interest rates have skyrocketed from 3% to 8%.

Crop prices at current levels raise the question whether, at least in some cases, they justify the financial risks involved and could capital be better employed elsewhere? Currently, on the Claydon farm we grow winter wheat, all first wheats, oilseed rape and spring oats. The former is the mainstay in economic terms, accounting for half of the cropped area, while spring oats have increasingly featured in our rotation because they spread the workload and are fantastic for cleaning up any grassweeds. Currently, we have a substantial area of oilseed rape, but given the high up-front costs and increasing potential risks involved in growing it the price needs to be at least £400/t for it to be viable.

WHAT’S HAPPENING ON THE CLAYDON FARM?

During the first week of February our weather station recorded 60mm of rain, adding to the extremely high levels of precipitation since mid-October. Even the worms which are normally evident in high numbers appear to have gone into hiding, but hopefully warmer weather will see them come out to play.

Starting on 15 October, we established the planned winter wheat area, albeit under slightly damp conditions, using our 6m Claydon Evolution M6 drill. After that went in we recorded an average 1cm of rain per day for the next three weeks. To provide some context, that’s equivalent to a staggering 2100 tonnes of water per hectare.

That much rain falling on our very heavy Hanslope series soils made it more difficult to apply post-emergence herbicides, but the firm, supportive soil structure left behind the Claydon drill meant that our self-propelled sprayer had no issues travelling and barely left a mark. However, looking at the levels of weed control in the crops earlier today it appears that prolonged adverse conditions during the autumn and winter reduced the efficacy of the products which were applied.

The very wet soils have prevented crops from developing as quickly as they should, so plants are generally quite small relative to this time last year. Once the weather improves, they will need pushing to reach their full potential.

At the time of writing (26 February) some nitrogen has been applied. We took advantage of a short weather window last week to apply 150l/ha of N35 to our oilseed rape, but in the wheat fields where we were unable to achieve good control of grassweeds it was a question of do we apply nitrogen or sort out the grassweeds first?

The rain which fell just after harvest created ideal conditions for the Claydon Straw Harrow and we carried out multiple passes across the farm. That knocked out huge numbers of weeds, volunteers and any slugs which were present in the chopped straw. In October we applied glyphosate to kill any remaining green material, but almost immediately the heavens opened.

Given the wet conditions which have prevailed since then we are currently considering our weed control strategy. I recall that in 2012, another very wet season, the weeds that we thought had been well controlled in the autumn came back with gusto due to thinner crops and chemicals not working as well as they should have.

Given the lower levels of chemical control due to adverse weather I am feel much more secure knowing that we have our 6m TerraBlade inter-row hoe to call upon. This will be used to take out weeds growing between the rows, thereby protecting yields, increasing returns and preventing weed seeds from being carried over to the following crop. Independent research shows that using the TerraBlade reduces grassweed numbers by an average of 60%, which with wheat at £200/t has improved the yield and gross margin by £257/ha.

DRILLING OSR LATE WAS UNSUCCESSFUL

Painful experiences with cabbage stem flea beetle damage in recent years have made me nervous about sowing oilseed rape immediately after harvest, so as an experiment we drilled some in mid-September. A small amount of pest damage was evident in December, but by then the crop has fallen way behind that sown in August. Despite applying Centurion Max to take out any grassweeds it looked very vulnerable, and the weak plants ultimately fell victim to wet conditions and slugs. When conditions allow this area will be redrilled with spring oats, a crop we will be growing more of this year.

Normally, 50% of the farm is into first wheats and the remainder divided equally between oilseed rape and spring oats. The reason for majoring on first wheats is to keep on top of grassweeds, and with oilseed rape at significant risk from cabbage stem flea beetle we have drilled a higher percentage of spring oats this season as part of our block rotation system.

Land destined for spring oats was Straw Harrowed up to six times during the autumn to take out germinating volunteers and weeds at the cotyledon stage. Any green material remaining was planned to be sprayed off before Christmas. Windy weather meant only 30ha were sprayed and it was 9 January before we were able to spray off the remaining 120ha. This helps to reduce the toxic effect of over-wintering blackgrass and the land rested over the winter. Another dose of glyphosate will go on just before drilling.

As soon as the weather allows, we will drill the spring oats, any surface compaction caused by the extended wet weather being removed by the leading tines on our 6m Evolution drill. It will be interesting to see how those areas where we grew cover crops perform, and whether there is a sufficient increase in yield to justify the significant cost of growing them. The jury is still out on that one.

The exceptionally wet weather has also highlighted small areas of fields where drainage is sub-optimal. The leading tines on our drill are enormously beneficial in terms of allowing water to move from the surface down through the soil, but in some areas the laterals have been at capacity and unable to take any more water. We have identified areas where drains have reached the end of their working life, and others where more capacity is needed so, conditions allowing, we will install those new drains and mole other areas after harvest.

With the dark, wet days of winter hopefully behind us, spring should be a period for optimism, so I’m looking forward to some warm, dry weather to get crops growing and ensure that they develop their full potential.

On a final note, I would like to thank the Suffolk Farming and Wildlife Advisory Group for presenting Claydon with their Peewit Award for Excellence in Ecological Farming. I was delighted to be presented with the award at their annual presentation event in January, an event made even more special because my sons Oliver (Claydon’s Operations Director) and Spencer (Commercial Director) were there with me to share the experience.

The Claydon website (claydondrill.com) galleries contain numerous videos on soil health and resilience, as well as showing the Claydon Opti-Till® System being used to establish all types of crops, in all situations, both in the UK and overseas. You can also keep up with the latest posts, photographs, and videos from Claydon and its customers through the Claydon Facebook page www.facebook.com/Claydondrill

Claydon wins prestigious ecological excellence award

The Suffolk Farming and Wildlife Advisory Group’s 2023 Peewit Award

for Excellence in Ecological Farming.

Claydon’s achievements in designing and manufacturing machinery which enables farming businesses to implement crop establishment solutions which are commercially and ecologically sustainable has been recognised by the Suffolk Farming and Wildlife Advisory Group (SFWAG).

Anna Beames, Chief Executive of SFWAG stated: “At a time when so much discussion is taking place about the environmental issues which are impacting the world it is very pleasing to note that where farming was once regarded as a major part of the problem it is now rightly recognised as a key part of the solution. This was confirmed at the recent COP28 summit in Dubai, where global leaders acknowledged the profound potential of agriculture and food systems to drive powerful, innovative responses to climate change.

“The Suffolk Farming and Wildlife Advisory Group was born from farmers with a deep understanding of integrated farming which considers both the environment and wildlife, so we are keen to recognise those who actively seek to reduce the industry’s environmental impact. Our annual awards highlight exceptional examples of ecologically sustainable agriculture which restore, protect and create high levels of Natural Capital to deliver ‘public goods’ whilst profitably producing healthy, nutritional food.

“Our theme for 2023 was ‘Sustainable Farm Solutions’ and Claydon is an extraordinary example of that. Because of that we were delighted to round off Suffolk FWAG’s series of farm walks last year with a visit to the Claydon’s arable farm at Wickhambrook in Suffolk. The farm has been in the Claydon family for nearly 100 years, with Jeff and his brother Frank farming there for more than 50 of those years; during which time the business has grown from 100ha to 250ha, plus 90ha which is contract farmed and some contracting.

“Soils are the farming industry’s greatest asset, yet many have been degraded to a point where now they merely provide a growing medium which depends on high levels of artificial inputs to maintain productivity. Jeff addressed this key issue more than two decades ago by developing the Claydon Opti-Till® System, a holistic approach to crop establishment which delivers consistent, high-yielding crops at low cost for maximum profitability. Crucially, it also enables farmers to become more ecologically sustainable.

“During our visit to the Claydon farm we were able to see the massive improvements which this approach has brought about over the last 22 years, including high numbers of worms and staggering levels of soil organic matter. Worms may not be sexy, but they are the unsung heroes of the farming world and instrumental in changing soils for the better, so as one of their greatest exponents Jeff is a deserving winner of the Suffolk FWAG 2023 Peewit Award.”

SECURING THE FUTURE

Jeff Claydon developed the Opti-Till® System in 2002 to reduce production costs without adversely impacting output, thereby securing the economic future of his family’s farm. Combining well-proven stubble management and direct seeding techniques, it enables farming businesses to operate much more efficiently, profitably, and sustainably.

Since launching its first drill in 2003, Claydon has relentlessly promoted the importance of excellent soil health and raised awareness of how to improve it. With more frequent extremes of weather, Opti-Till® is particularly relevant because it is effective in all conditions, minimises risk and provides sufficient capacity to exploit narrow weather windows. This allows all agricultural seeds which can be air-sown, from herbs and grasses to cereals and maize, to be drilled at the right time, in the right conditions and ultimately produce the high yields required to make farming businesses more weather and financially resilient.

Unlike many other companies in the UK farm machinery sector which import machinery made overseas, Claydon designs, tests and manufactures all its products from scratch, employs local staff and sources materials from UK suppliers.

Versatile, reliable, with a low power requirement and ownership costs, Claydon Evolution and Hybrid drills, Straw Harrows, TerraStar® light cultivators and TerraBlade inter-row hoes are manufactured to exceptionally high standards at the company’s factory in Wickhambrook, Suffolk, which employs over 70 staff.

European market leader in direct seeding technology, Claydon has seen demand for its products grow ten-fold since 2010. During 2023 the company experienced significant growth in sales as the business worked closely with its dealer and distributor partners in existing and new markets. With many markets still at an embryonic stage and its distribution network growing rapidly the company expects sales to continue increasing during 2024.