NO-TILL FARMING: BOOSTED SOIL HEALTH, CUT COSTS… IT’S THE FUTURE

Worcestershire-based Weaving Machinery – manufacturers and suppliers of farming equipment – have called on UK farmers to investigate and consider implementing no-till systems as part of a campaign for better soil health, highlighting not just the conservation benefits of low disturbance farming, but also the cost savings and greater control across the farm. No-till farming has seen a steady increase over recent years in the UK, despite historically slower rates of adoption compared to other parts of the world.

According to the UN Food and Agriculture Organisation (FAO), food production must increase by 70% by 2050, in order to meet the needs of the projected population of 9 billion. This will naturally require a rethink in terms of optimising productivity but also demands a greater need for sustainability. More and more farmers are already aware of this sea-change, and the industry is experiencing a shift towards no-till as a means to achieve better soil health and sustainable production… all while cutting costs and saving time.

“The shift has been massive,” says Simon Weaving, Sales Director at Weaving Machinery. “Five years ago, farming was all about completely mixing the soil profile. Today, it’s more about lifting the soil profile, rather than mixing. Farmers are beginning to understand the very real benefits they can see when incorporating a no-till system.”

The drive for better soil health

The UN recently stated that the world’s soil reserves has only an estimated 60 harvests left before complete degradation, with around a third of the world’s soil already at that point. Michael Gove, the former environment secretary, also warned that the UK is only a few decades away from “the fundamental eradication of soil fertility”, adding that “countries can withstand coups d’état, wars and conflict, even leaving the EU, but no country can withstand the loss of its soil and fertility.” The British government has also signalled possible incentives for farmers who promote better soil health following Brexit, though these are not set in stone.

While the importance of soil health is widely understood, why the slow rate of adoption? Part of this is the UK’s strong sense of tradition in farming, but a significant barrier to entry has been the cost. With many farms under increasing financial pressure, few are willing to invest and risk trialling a new method of farming, even if the benefits are clear.

For Weaving’s part, accessibility and affordability has always been one of their leading mission statements: “I completely understand that farmers may be wary of leaping straight into direct drilling or low disturbance farming,” says Simon. “Our drills are designed to work on conventional systems as well, for complete flexibility. Ultimately, no-till is the direction the industry is heading, and it’s a change that will directly benefit both this country’s soil health and, importantly, the financial security of UK farmers.”

The benefits of no-till farming

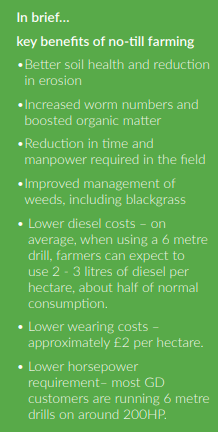

No-till requires more planning but advocates are quick to praise the huge benefits they’ve seen on farm. These include a cut in costs for machinery, labour, fertiliser, and chemicals. In turn, this leads to a marked increase in insects, birds and wildlife, as well as fewer floods and more resilient crops during droughts.

At face value, the cost savings might prove the biggest incentive for interested farmers. Savings include less money spent on diesel, parts that wear far slower, less manpower required in the field, and less horsepower (and therefore fuel consumption) during the crop cycle. These costs may be relatively small when taken individually, but quickly add up.

In the long-term, no-till also increases worm numbers and boosts organic matter. Unlike conventional systems, no-till keeps everything underneath the surface, giving it a chance to build up. This also leads to another significant benefit for many farmers: a solid defence against blackgrass.

Fighting Blackgrass

Blackgrass is a grass weed that grows in any condition, particularly thriving in very wet weather, that grows in the crop and smothers it. A persistent threat, blackgrass has the potential to halve – or more – cereal yields. Simon Weaving identifies customers who saw their yields fall by as much as 4t/ha. Blackgrass seeds can lie dormant for years before activation, which can then be exacerbated by cultivating and mixing the soil profile. While by no means an all-purpose solution, notill means the seed hits the floor and stays there – making spraying much more cost-efficient, effective, and long-lasting.

“We made this decision because we just had to tackle blackgrass,” says one Weaving customer who adopted a no-till system. “This system was affordable and a viable route to go down. No-till has lots to recommend it in terms of preserving soil health, but to be honest ours was largely a practical decision. This is the right thing to do for our farm.”

The next step

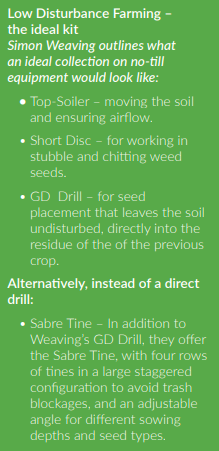

As more farmers begin to consider whether no-till can work for them, what are the next steps? Simon Weaving advises to take stock of your current situation. “First, look at your soil health,” he says. “Is it at the levels it should be? If the soil is in poor health, you might not want to jump straight into direct drilling. You can use a machine like our LD top spoiler to slice into and lift up the soil. This gets air underneath before putting it back down with minimal disturbance before drilling.”

“All farmers should be seriously looking at no-till as an option for their farm,” adds Simon. “Year on year, we’re seeing more farms trial whether no-till can work for them, to achieve better soil health, reduce costs, or implement better weed control. We’ve worked to deliver machinery that has the power and functionality for farms of all sizes and systems, to improve soil health – all while keeping yields strong.”

Find out if no-till could benefit your farm. Contact Weaving Machinery to learn more about their newest drills and other robust and reasonably priced farm machinery at https://www.weavingmachinery.net

About Weaving

Weaving is a family run company founded in 1983. Its aim from the very beginning was to offer farmers the best quality farm machinery at affordable prices. The company distributes farm machinery throughout the whole of the UK. The newest GD Drill, as with all Weaving products, is made totally on site. From design, fabrication, construction and spraying, everything is done in-house, all at the Evesham headquarters