The Mzuri system delivers consistency and reliability in Herefordshire

Acres – 652 plus contract work

Type – Arable

Soils – Gravel loam, Bromyard series; Silt, Clay, Loam

Cropping – Wheat, OSR, Spring Oats, Winter Beans

Machinery- Mzuri Pro-Til 3T, John Deere 155 & 215, Cambridge roll with paddle boards, double press

In the picturesque countryside of Herefordshire, a farmer is singing the praises of a British drill manufacturer that has revolutionised his farming practices. Meet Adam Lewis, the forward-thinking farmer at the forefront of sustainable agricultural change. An AHDB monitor farm and an advocate for regenerative agriculture, Adam is also a Mzuri Ambassador supporting growers with their transition to single pass crop establishment through his own real-world experiences.

Adam’s journey with Mzuri began in 2017 when he purchased his first Mzuri Pro-Til after a knowledgeable demonstration the previous year. Since then, he has become an enthusiastic advocate for the company and its unparalleled commitment to customer service. “I am continually impressed by the outstanding customer service from the Mzuri team, an aspect that sets them apart from other companies I have dealt with. The sales and service team go above and beyond.” praises Adam.

A particular challenge Adam faced which prompted him to go down the Mzuri route was dealing with changeable soils that caused uneven crop establishment due to varying conditions and moisture levels across the field. With the Mzuri system however Adam is able to achieve consistent establishment across his fields and farm, thanks to several key innovative features at the heart of the Mzuri Pro-Til’s design.

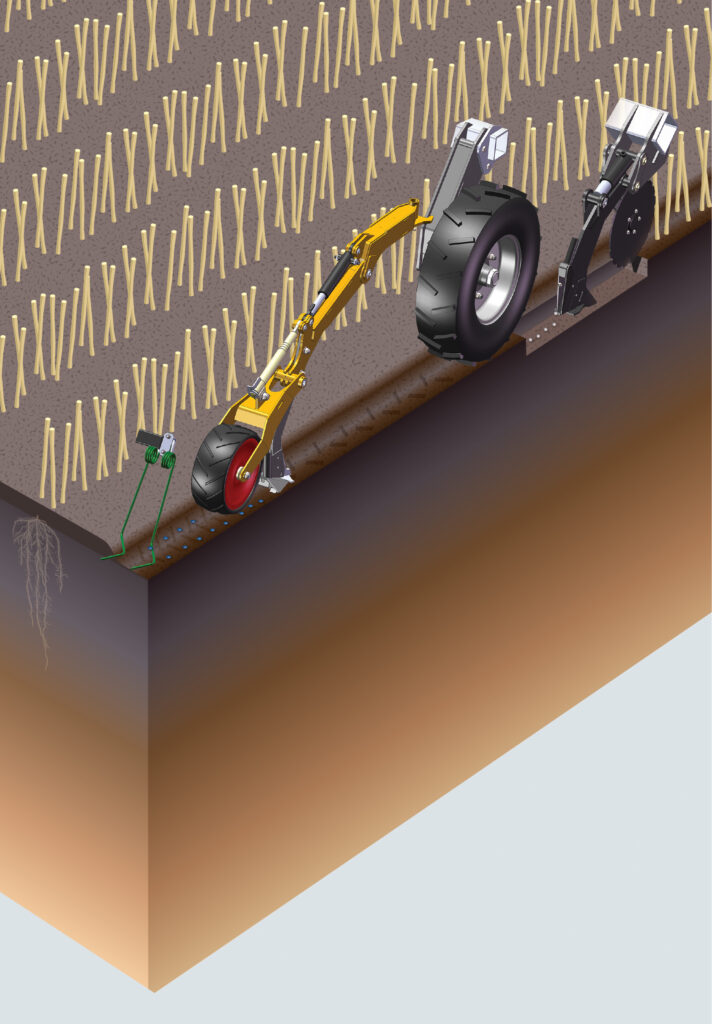

The Pro-Til features a leading tine which delivers fertiliser below the seed whilst also contributing to a clean, friable seeding zone. This ensures emerging crops have direct access to targeted nutrition required for even establishment and encouraging the quick get-away of crops in challenging seasons. Consistency of cropping is further strengthened by the Mzuri Pro-Til’s independent pivoting coulter arms, which individually guarantee accurate seeding depth thanks to hydraulic pressure exerted onto ground following depth wheels. Unlike simpler designs on the market, the inclusion of individual depth wheels ensure seeds are placed accurately across the width of the drill, irrespective of undulating terrain.

Between these seeded rows, previous crop residue is maintained on the field surface, acting as a natural shield protecting the soil from capping and erosion. The residue also contributes to improvements in soil organic matter, being utilised by worms and being allowed to break down naturally. As a direct result of leaving his previous crop residue on the surface, Adam has increased the soil organic matter content from 2.8% to an impressive 3.8%. Visiting guests have commended on the lift in soil colour, a visible testament to the positive changes.

The combination of these features, including operational and economic benefits, has resulted in a system that delivers for Adam year on year.

Minimising soil disturbance

Adam admits to being tempted by the call of a disc drill, however following a brief experiment on his own farm, it quickly became apparent that the disc drill could not deliverthe reliability and flexibility that Mzuri’s single-pass tine drill is renowned for.

Instead, still with an ambition to further reduce soil disturbance, Adam converted his Pro-Til to Mzuri’s 3-inch dual band coulters, which when drilled on 333mm row spacing delivers an impressive crop stand with minimal disturbance. “The coulter ensures minimal soil disturbance, even in adverse weather conditions there is no significant disruption to the soil” Commends Adam.

Another hallmark of a Mzuri sown field, is the wider row spacing over conventional establishment. Most commonly drilled on row centres of 333-363mm depending on model, the Pro-Til offers the ability to double this using it’s ‘Select’ mode which sees alternate legs raised to drill on 666-726mm centres, typically suited to Oilseed rape and Maize. Mzuri advocates drilling on wider row centres, which optimises light interception promoting healthier and well tillered crops. By widening space between crop rows, airflow is improved, which has contributed to a remarkable shift in folia and insect management practices for Adam.

Adam’s approach to working with nature has seen insecticides eliminated for an impressive decade at Hampton Wafre Farm, which in turn has reduced production and labour costs increasing the profit margin across the farm. In particular, a natural ally, the Devil’s Coachman Beetle has benefited from Adam’s stance on insecticides and has itself taken charge of slug control, offering a sustainable solution to a historically challenging issue.

Since adopting the Mzuri system, Adam has seen a significant reduction in diesel usage for crop establishment, saving an impressive 40 litres per hectare. Not only does this save on operational costs, but it also reduces the farm’s carbon footprint and contributes to a more sustainable agricultural operation.

FETF Grant Funded

Last year Adam upgraded to a 2023 Pro-Til 3T, which was part funded through the Farming Equipment and Technology Fund (FETF). Under the category code FETF206 (2024 code), the grant funded £25,000 towards the cost of the drill which has gone on to provide considerable cost savings over conventional establishment. The 2024 round of the FETF has recently been released and now offers growers up to £40,800 for direct drills with fertiliser placement (FETF206), which includes the Mzuri Pro-Til range.

Adam commented “The grant has been fantastic for updating our existing system and has allowed us to make the changes needed to secure a sustainable long-term future, both for our business but also the environment.”

Adam acknowledges that change can be daunting, especially when it comes to altering established farming systems. However, he firmly believes that the Mzuri system has been the driving force behind significant improvements within his soils, including greater consistency and resiliency and contributed to a noticeable reduction in chemical applications. With the Pro-Til, Adam now enjoys extended drilling windows and enhancing overall productivity, making it a long-term management plan with significant benefits.