Written by Mark Hatton

I was recently, lucky enough, to be invited to attend the UK leg of the Michelin Tracks and Tyres European Tour in Cambridgeshire. The event was to showcase the features and benefits of their VF AXIOBIB 2 tyres, the latest track technology and the benefits of using the PTG Central Tyre inflation systems to vary tyre pressures to improve efficiencies, which we will focus on in this article, it turns out there’s much more to tyres than just being black and round!

With tractors supplied by New Holland, a pair of identical T7.270, one fitted with Michelin’s Very high Flexion VF 710/60 R42 and VF 600/60 R30 Axiobib 2 tyres and the PTG Central Tyre inflation system, the other tractor fitted with 650/65 R42 and 540/65 R30 Multibib tyres. The event began with a demonstration to highlight the difference in tractive effort between different tyre pressures. To create the load a New Holland T8 SmartTrax was deployed to create resistance: lets call it the brake tractor method. This keeps the tractor at a constant speed, as it accelerates the wheels increase the tractive effort.

This is the most reliable method for comparing traction efficiency, in the form of weight and resistance. This is done to measure the tractive effort at the drawbar. A sensor integrated into the drawbar linking the tractor to the convoy will measure this effort, which is a value in decanewtons (or kg). Linked to this sensor, a live display screen, allow us to see this value. The higher the value, the higher the tractive effort. In other words, the higher the tractor’s traction. Two runs were made with the T7.270, fitted with, Michelin’s Very high Flexion VF 710/60 R42 and VF 600/60 R30 Axiobib 2 tyres at different pressures, altered via the PTG Central Tyre inflation system. At a constant speed of 4.6 km/h, we can see an average of 6800 decanewtons or kg

The higher the value, the higher the tractive effort. In other words, the higher the tractor’s traction. By reducing the tyre pressures from 16 Psi to 10 Psi, we saw an increase of 17% tractive effort from of 6800 decanewtons to 8000 daN. This increase provides benefits in the way of reduced wheel slippage, less soil structure damage, increased fuel efficiency and overall improved machine productivity. The second test was a demonstration comparing tyre sizes, type of type (ULTRAFLEX and MULTIBIB) and tyre pressures. To achieve this, the New Holland T8.SmartTrax was again deployed to act as the resistance, by connecting both of the T7.270’s with a cable, which passes through a pulley attached to the T8.Smarttracx , Like for the previous tests, the tractors are set to travel at an identical speed. We will see over a given distance how many meters are gained with the more efficient configuration. The tyres pressure were again set on both machines, for the AXIOBIB 2 with CTIS is set as the previous test: rear 0.7b (10 Psi) and 0.6 b (9Psi)

The tractor fitted with the Multibib, a pressure of 23 Psi, was selected as the most used pressure by farmers in UK. As the tractors set off down the field, it was easy to see the difference between the two. The T7.270 fitted with the VF AXIOBIB tyres, set at a lower pressure quickly pulled ahead of the tractor fitted with the Multibib tyre. As with the previous test, the benefits of the different tyre technology between the AXIOBIB ULTRAFLEX and the Multibib, in combination with the lower tyre pressures, resulted in better traction and increased productivity.

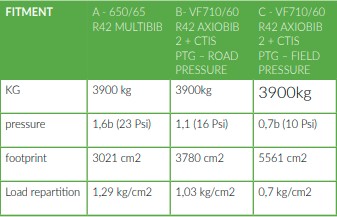

The impact of reduced tyre pressures on soil structure can be seen easily with the following experiments. The soil footprint sandboxes show the difference in tyre type and pressures, as shown in the table below:

• A: MULTIBIB 650/60 R42 MULTIBIB – Most used pressure by farmers in UK: 1,6b (23 PSI)

• B: VF710/60 R42 AXIOBIB 2 & CTIS PTG – ROAD PRESSURE → 1.1 bar (16 Psi)

• C: VF710/60 R42 AXIOBIB 2 & CTIS PTG FIELD PRESSURE → 0.7b (10 Psi)

The bigger the footprint, thanks to the reduced pressure, the higher the traction. In term of soil protection, bigger footprint reduced the kg by cm2 and spread the load on more surface. This ties in with the final test which calculates the weight transfer through the soil structure, compaction. By using probes inserted horizontally into the soil at around 20cm, When the vehicles go over the sensor, the probe is compressed, and the compression is measured every time a vehicle goes over the top. Even at tyre pressures of 23psi, there is less than 1 bar of pressure at 20cm depth (tested with the T7.270 on the MULTIBIB 650/60 R42

Around 10 years ago, Harper Adams University conducted a study on the effect of pressure on yield. This study, which was carried out using a wheat crop, involved growing plots side-by-side.

The same soil composition, the same seeds, the same crop protection products, the same tools, vehicles, crop growing techniques. Only one factor was different: for one plot, the vehicles were fitted with UltraFlex tyres (so low pressure), and in the other, standard technology tyres (higher pressure), like today. And this was throughout the growing cycle. As we offer ULTRAFLEX VF tyres for all farming vehicles: tractors: small, medium and high power, harvesters, sprayers, self-propelled spreaders, dump trucks and trailers, etc.

After harvesting, the university recorded an average 4% improvement in yield.

• 1 – Every year is different: the weather in particular, or the effect of previous crops, the choice of seeds, vehicles, etc.

• 2 – We need to have a complete vehicle fleet management approach. As we need to optimize tyres all year round for each task in the field and for all vehicles. It is not logical to have a tractor at 0.9 bar with tyre trailer at 4 bar.

The more the soil is protected, the more productive it is. The 4% average, also reported in US and Brazilian studies on soy and maize crops, represents a real return on investment.

Overall, Tyre choice and tyre pressures can directly affect not only soil structure and health, but play a huge part in increased productivity, machine efficiencies, primarily by increased traction, allowing larger implements to be operated and less wheel slippage damaging soil structure, overall not only better for the soil but better for your business as well.